Compressor of turbo machine and its compressor wheel

a compressor wheel and turbo machine technology, which is applied in the direction of liquid fuel engines, vessel construction, marine propulsion, etc., can solve the problems of high stress amplitude applied to the compressor wheel b>16/b>, and less stress on the compressor wheel. , the effect of reducing the weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

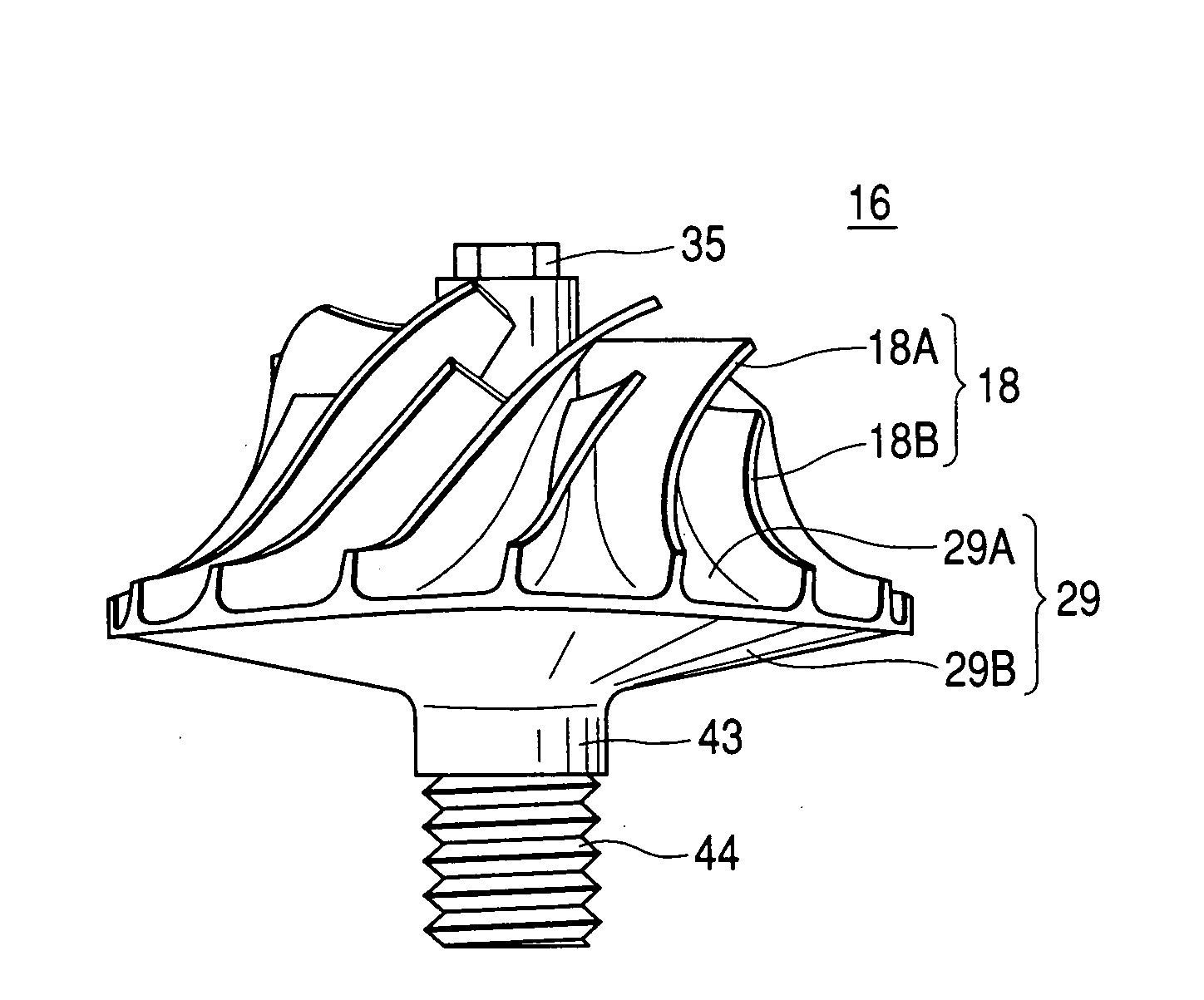

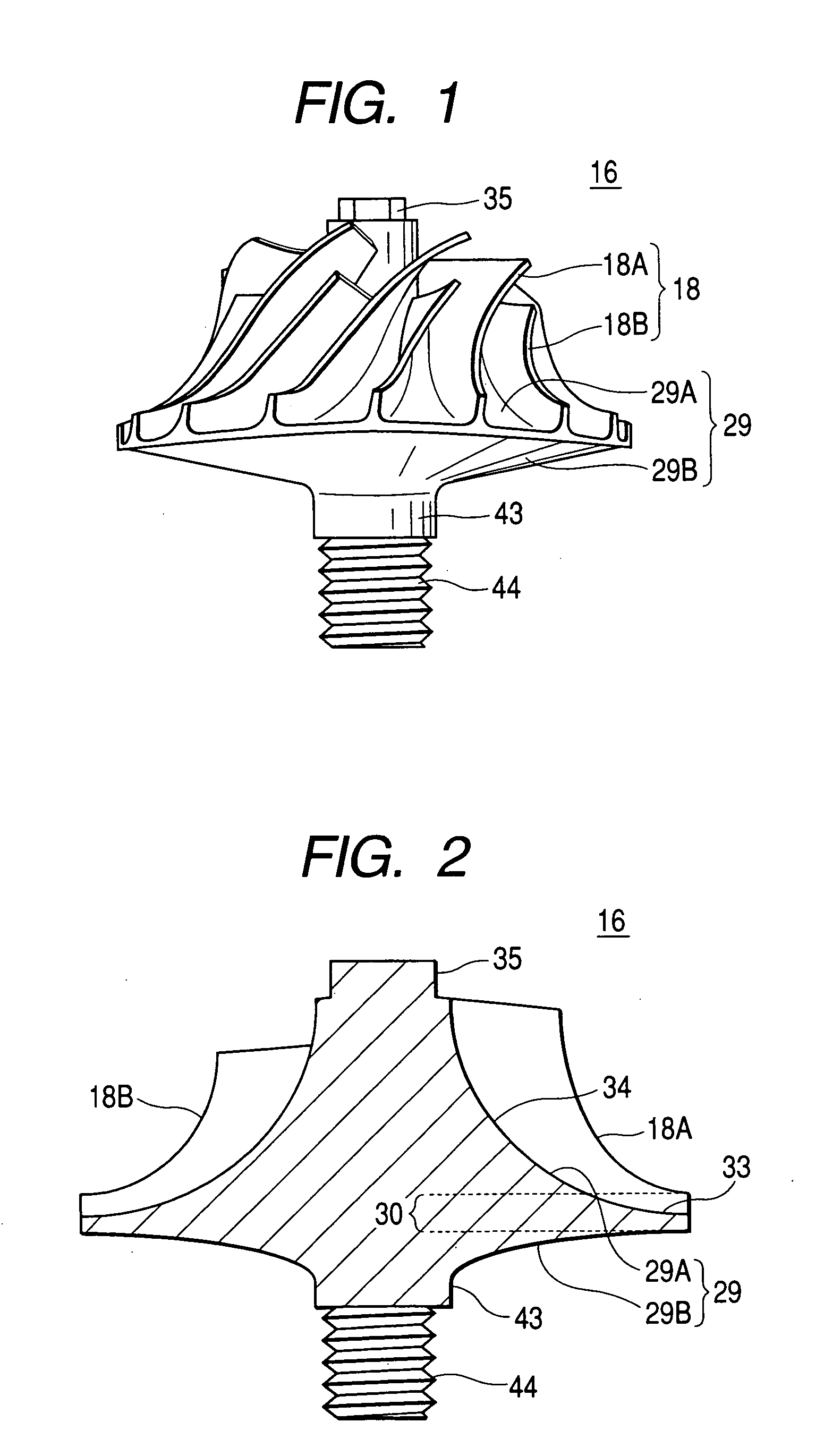

[0038] A preferred embodiment of the invention will be hereinafter explained in detail with reference to the accompanying drawings.

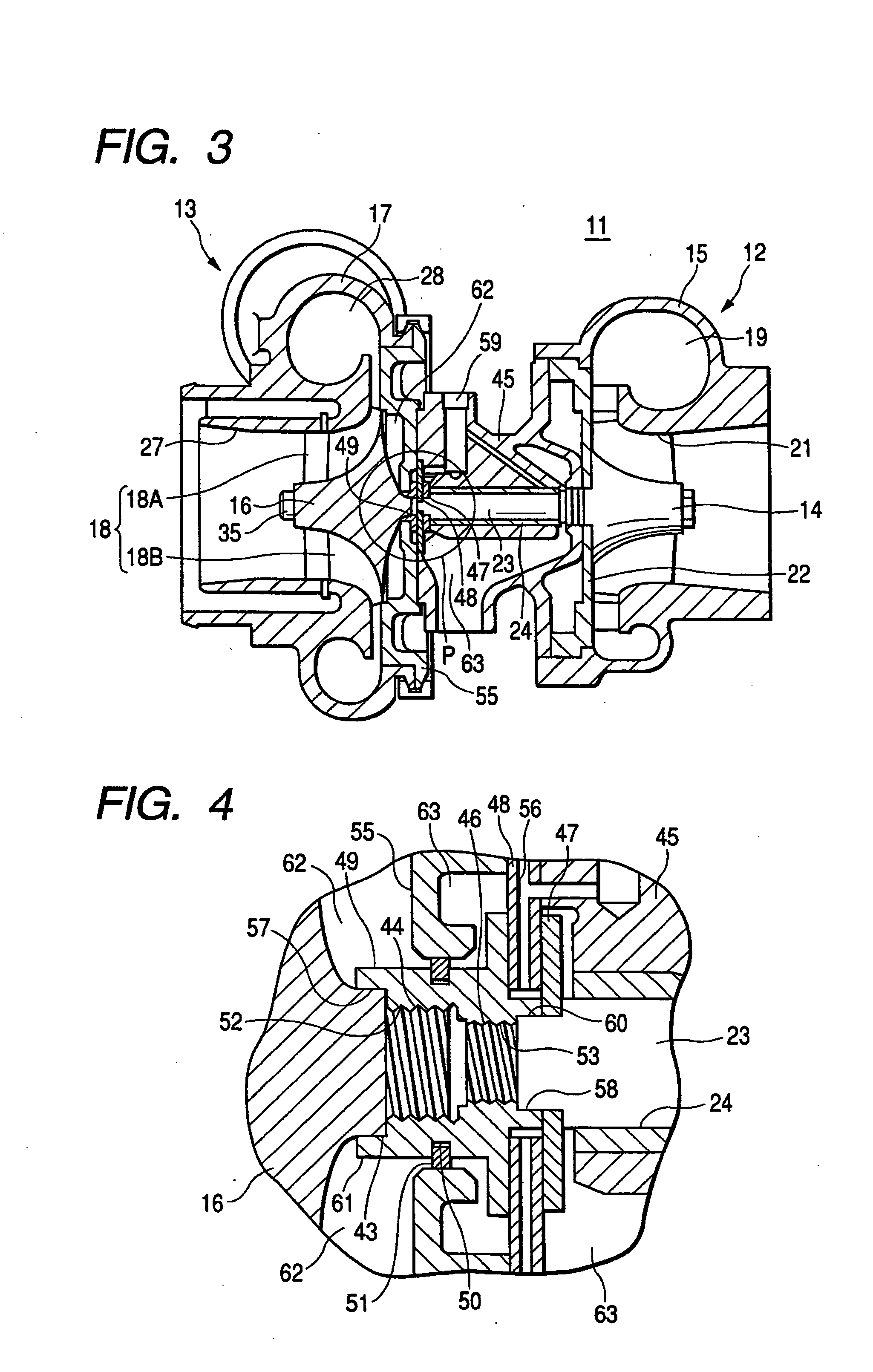

[0039] Referring to FIG. 3, an exhaust-side unit 12 includes an exhaust-side housing 15 and a turbine wheel 14 having a plurality of vanes and supported by a shaft 23.

[0040] The exhaust-side housing 15 has an exhaust inflow passage 19 for supplying an exhaust gas to the turbine wheel 14. The exhaust inflow passage 19 is formed into an annular shape in such a manner as to encompass the outer periphery of the turbine wheel 14 and is connected to an engine exhaust flow passage through which the exhaust gas emitted from an engine, not shown, flows. The exhaust-side housing 15 has also an exhaust outflow port 21 for emitting the exhaust gas after imparting energy to the turbine wheel 14. The exhaust outflow port 21 is formed substantially into a cylindrical shape that is concentric with the center of revolution of the turbine wheel 14. An opening on the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com