Synchronizing circuit applicable to double suspension hoist

A hoist and double lifting point technology, applied in mechanical equipment, water conservancy projects, marine engineering and other directions, can solve the problems of large pressure drop, narrow flow range and low synchronization accuracy of the diverter and collector valve.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

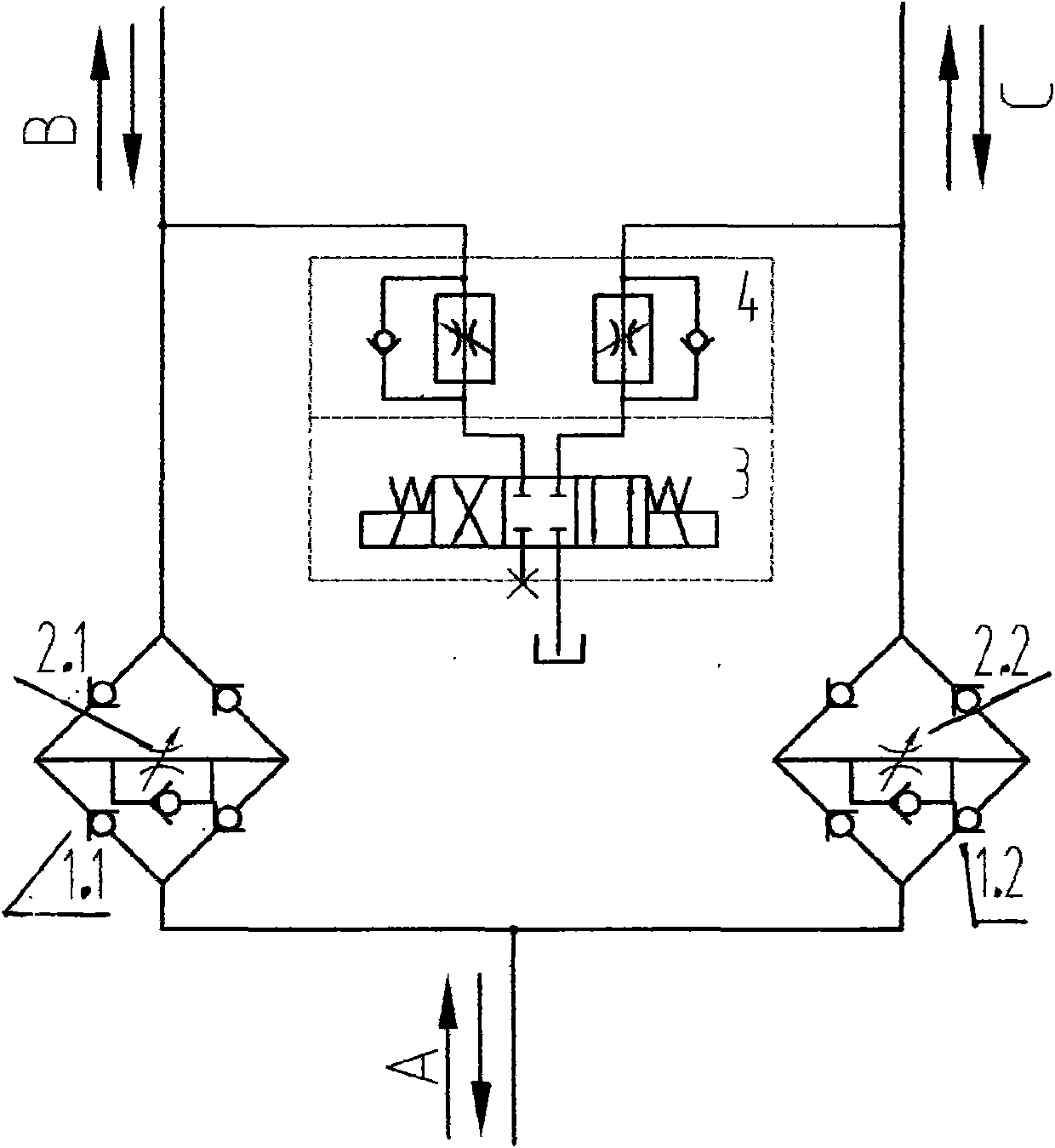

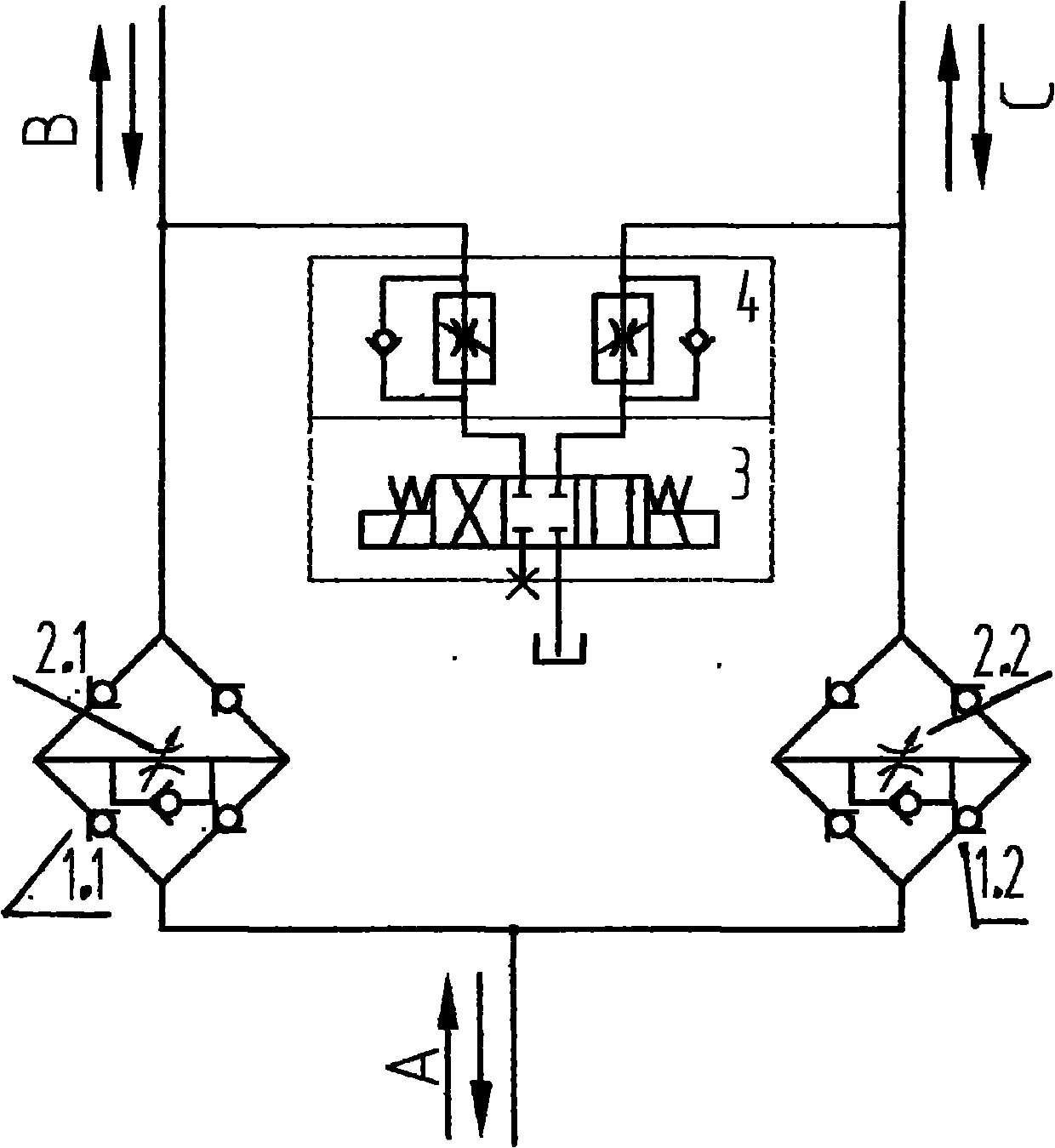

[0010] Embodiment 1: as figure 1 As shown, the pressure oil from the oil pump passes through two rectifying plates (2.1, 2.2) and two speed regulating valves (1.1, 1.2) and then enters the left cylinder and the right cylinder respectively, so that the oil cylinder moves, and the oil cylinder drives the gate to open and close. When the position error between the left cylinder and the right cylinder exceeds the specified value, the position sensor or the gate opening detector sends a signal, and the electromagnetic reversing valve (3) is powered on and off, and the oil in the fast-moving cylinder is passed through double one-way throttling. The valve (4) and the electromagnetic reversing valve (3) bypass back to the oil tank, slow down (when the gate is opened) or speed up (when the gate is closed and opened), until the synchronization error of the two cylinders is less than the specified value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com