Matrine microcapsule suspension agent and preparation method thereof

A technology of microcapsule suspending agent and matrine, applied in botany equipment and methods, insecticides, acaricides, etc., can solve the problems of environmental pollution and pest control effects and deficiencies, and achieve increased insecticidal effects and safety Good sex and long lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] Embodiment: Below in conjunction with embodiment and experimental method, the present invention will be further described:

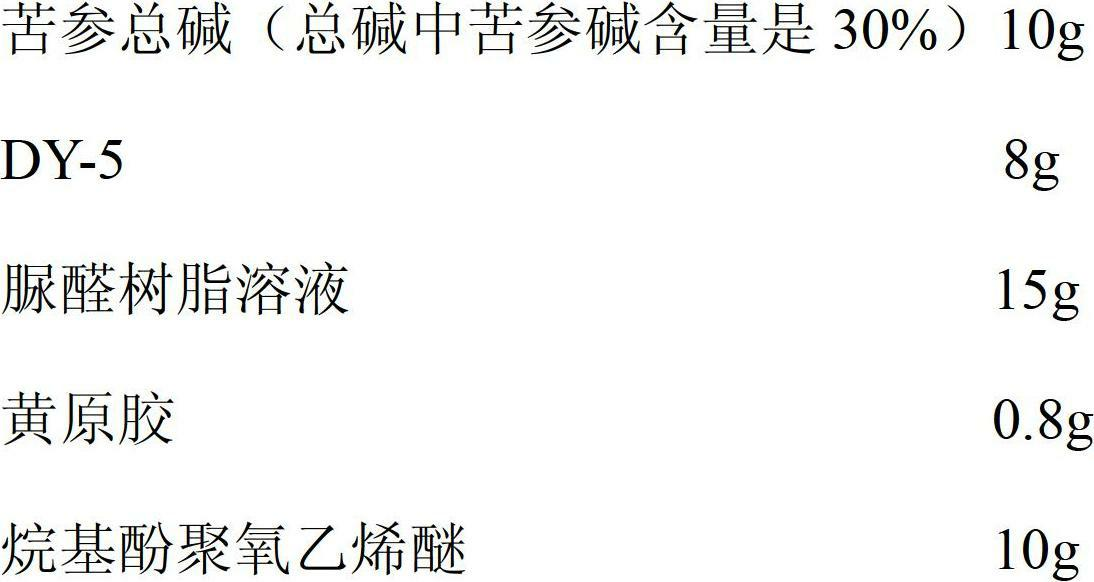

[0031] A matrine microcapsule suspending agent, the suspending agent is mainly composed of: 1-25 parts of matrine total alkaloids, 5-20 parts of organic solvent, 1-25 parts of capsule wall material, 0.1-25 parts of colloid 3 parts, emulsifier 1~20 parts, deionized water to make up to 100 parts. The suspending agent can also include antifreeze and preservative; the distribution relationship is 1 to 6 parts by weight of antifreeze, 0.01 to 1 part of preservative, and 100 parts of deionized water;

[0032] The total alkaloids of flavescens are extracted from roots of flavescens and purified repeatedly, and the content of flavescens is more than 30%. The organic solvent is one or more combinations of xylene, cyclohexanone, DY-5 and castor oil. The capsule wall material is an aqueous solution of urea-formaldehyde resin. The colloid is composed of on...

Embodiment 1

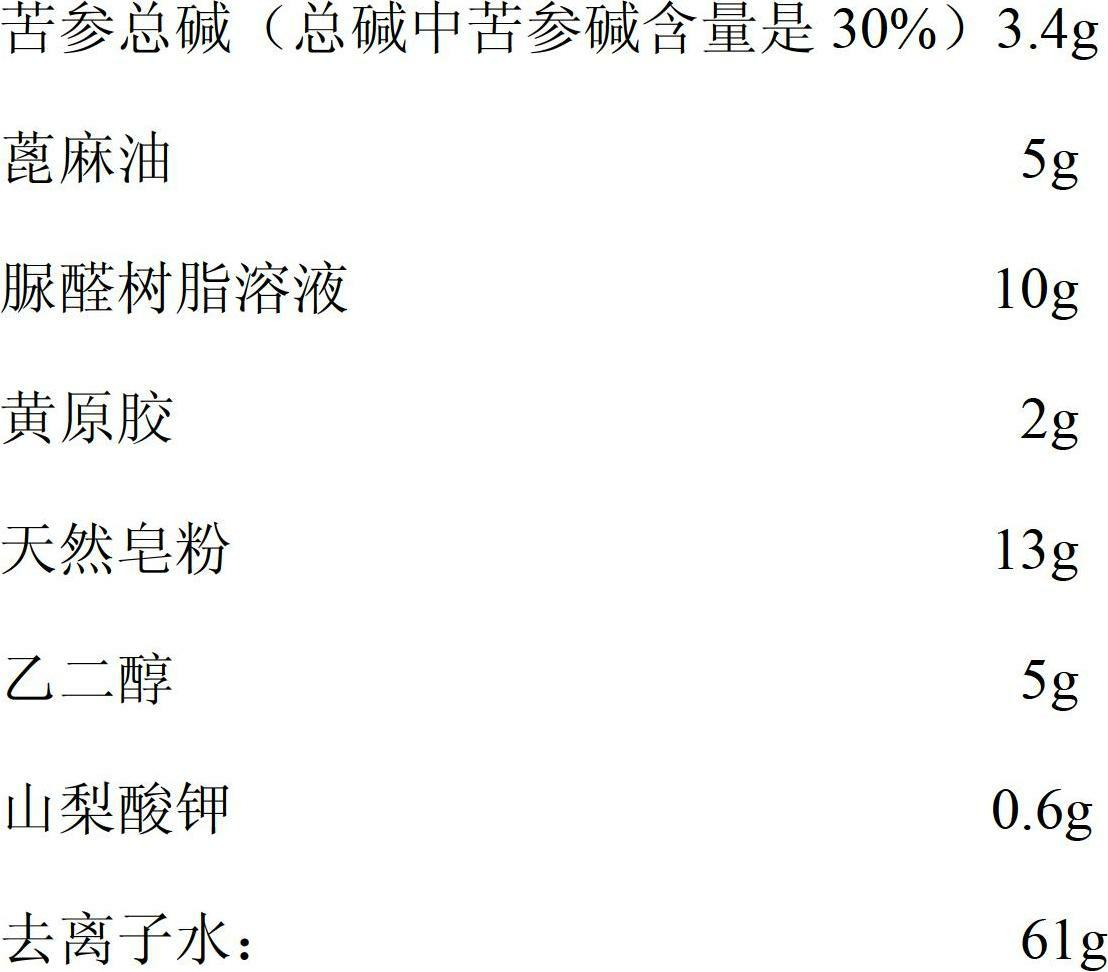

[0040] Embodiment 1 prepares 1% matrine microcapsule suspension, by weight:

[0041]

[0042]Mix and stir 3.4 g of matrine ointment and 5 g of castor oil solvent to dissolve them all, and then add a certain amount of urea-formaldehyde resin solution 10 g under stirring. Then add 2 g of xanthan gum and stir at 1500 rpm to form an oil-in-water emulsion. Reduce the number of rotations, stir for 10 minutes, then add dilute hydrochloric acid to adjust the pH value to 2.0, stir for another hour and then reduce the rotation speed to 800 rpm, raise the temperature to about 50 degrees, continue stirring to form stable microcapsules, and add hydroxide after 2 hours Sodium adjusts the pH to 7.0. Add natural soap powder 13g, ethylene glycol 5g, potassium sorbate 0.6g under stirring state, after stirring for 2 hours, add 61g deionized water to make up 100% and continue stirring for 2 hours to obtain matrine microcapsule suspension.

Embodiment 2

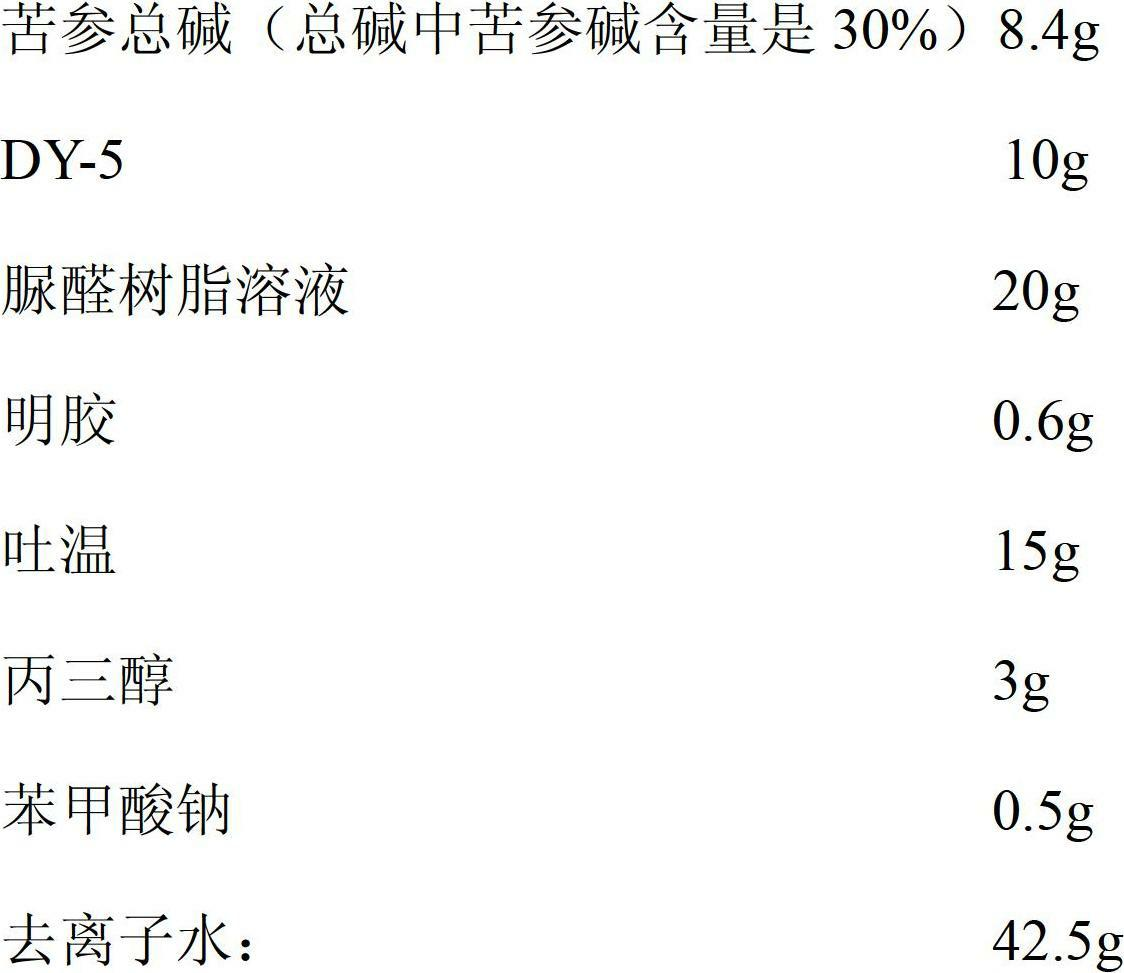

[0043] Embodiment 2 prepares 2.5% matrine microcapsule suspension, by weight:

[0044]

[0045] Mix and stir 8.4g of matrine ointment and 10g of DY-5 solvent to dissolve them completely, and then add a certain amount of urea-formaldehyde resin solution 20g under stirring. Then add 0.6 g of gelatin and stir at 1500 rpm to form an oil-in-water emulsion. Reduce the number of rotations, stir for 10 minutes, then add dilute hydrochloric acid to adjust the pH value to 2.0, stir for another hour and then reduce the rotation speed to 800 rpm, raise the temperature to about 50 degrees, continue stirring to form stable microcapsules, and add hydroxide after 2 hours Sodium adjusts the pH to 7.0. Add Tween 15g, glycerol 3g, sodium benzoate 0.5g under stirring state, after stirring for 2 hours, add 42.5g deionized water to make up 100%, continue stirring for 2 hours to obtain matrine microcapsule suspension.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com