Patents

Literature

646results about How to "Adjustable pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

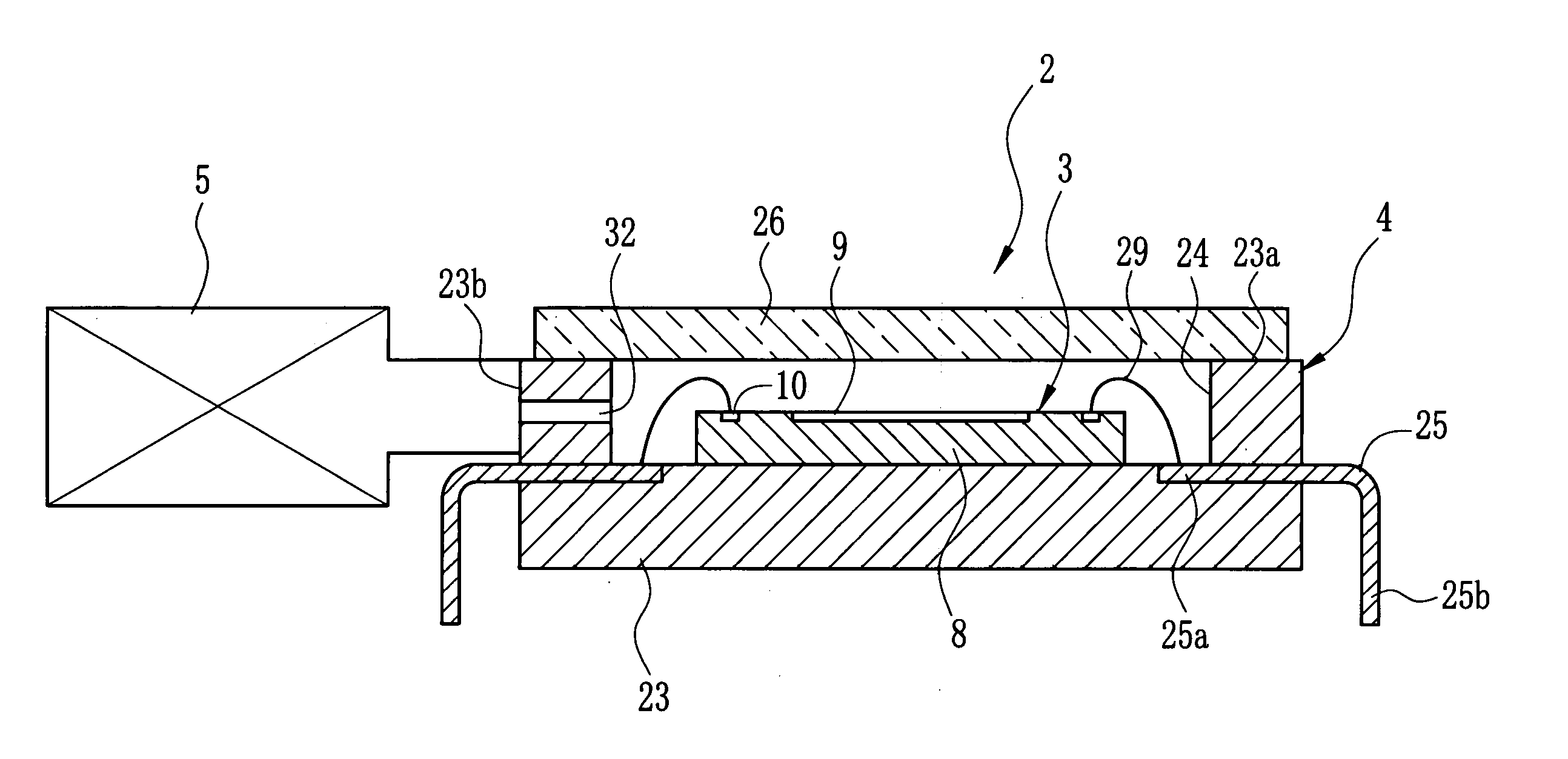

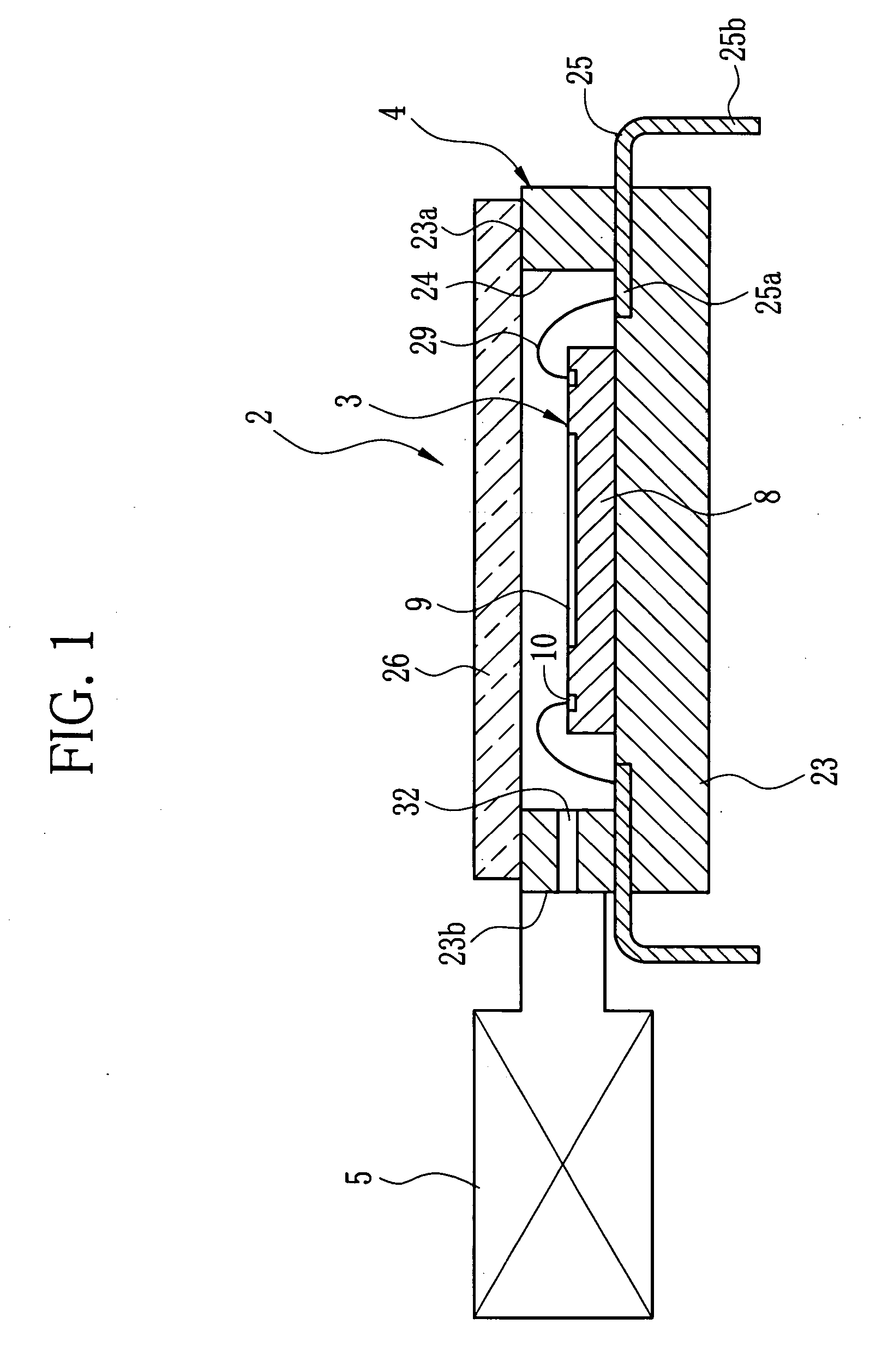

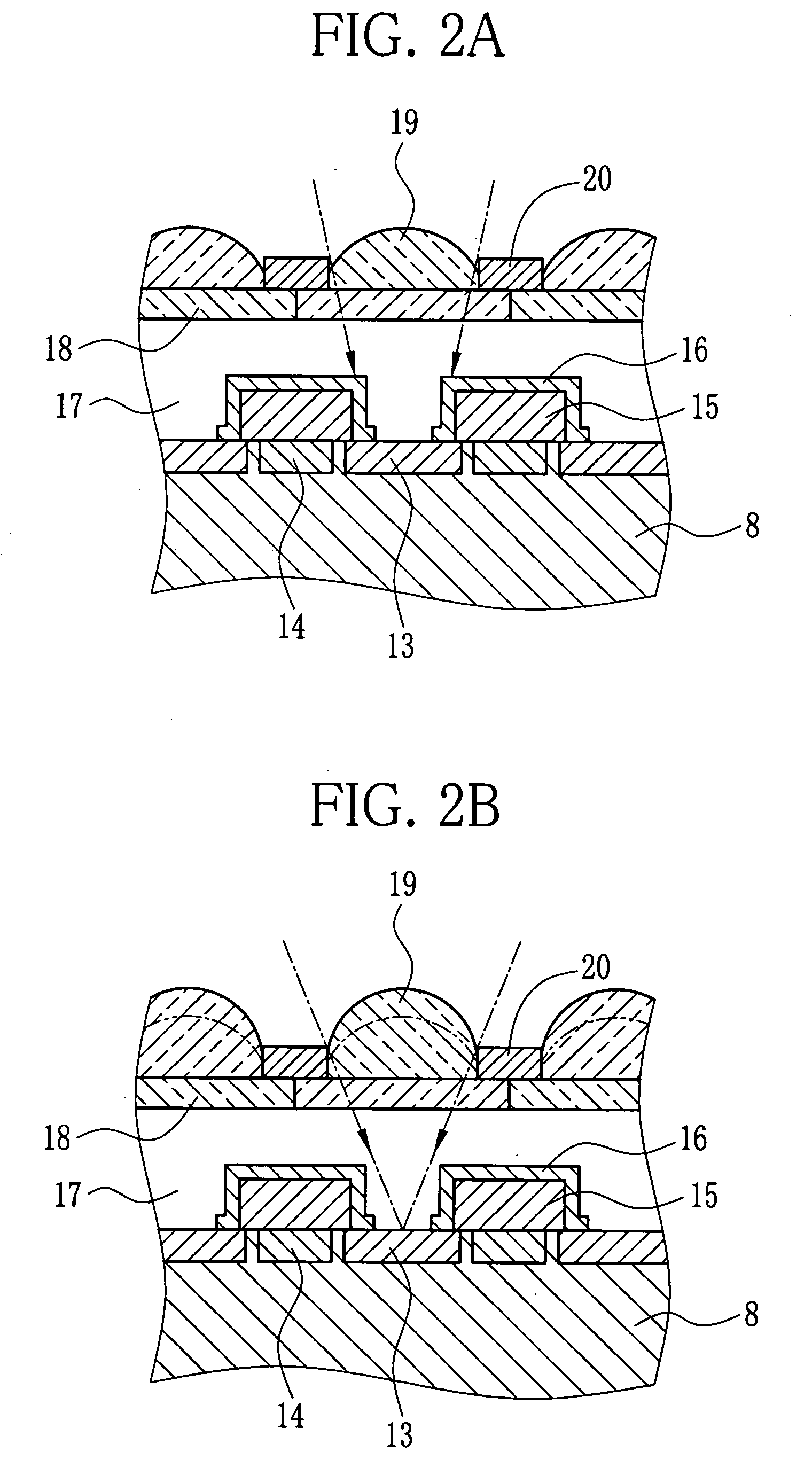

Imaging device and digital camera

InactiveUS20060279648A1Quantum efficiencyHigh imaging sensitivityTelevision system detailsTelevision system scanning detailsEngineeringAtmospheric pressure

An imaging device includes an image sensor chip and a package for containing the image sensor chip. Formed in the package is a vent hole that is connected to an air pump. In a light receiving area of the image sensor chip, there are photodiodes and microlenses above them. The microlenses are made of a gel-like transparent material. When the internal air pressure of the package is changed by the air pump, each microlens transforms in response to the change of the internal air pressure, and thereby changes the surface curvature thereof.

Owner:FUJIFILM CORP

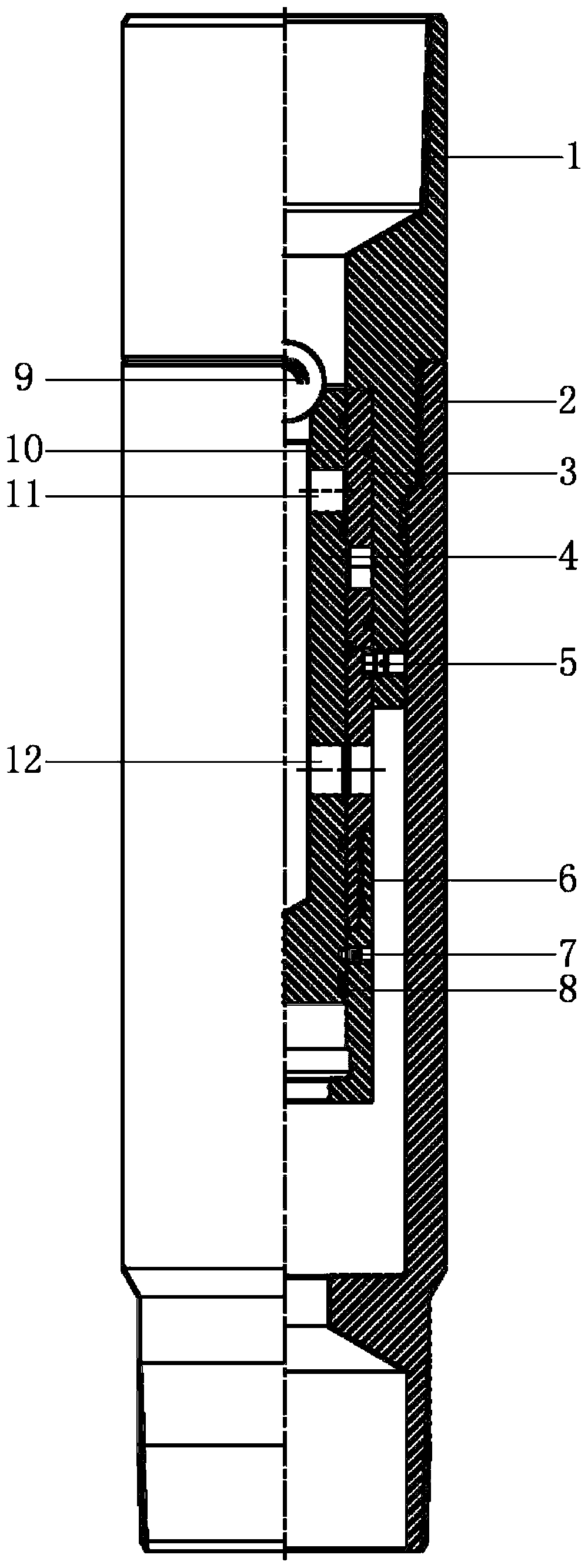

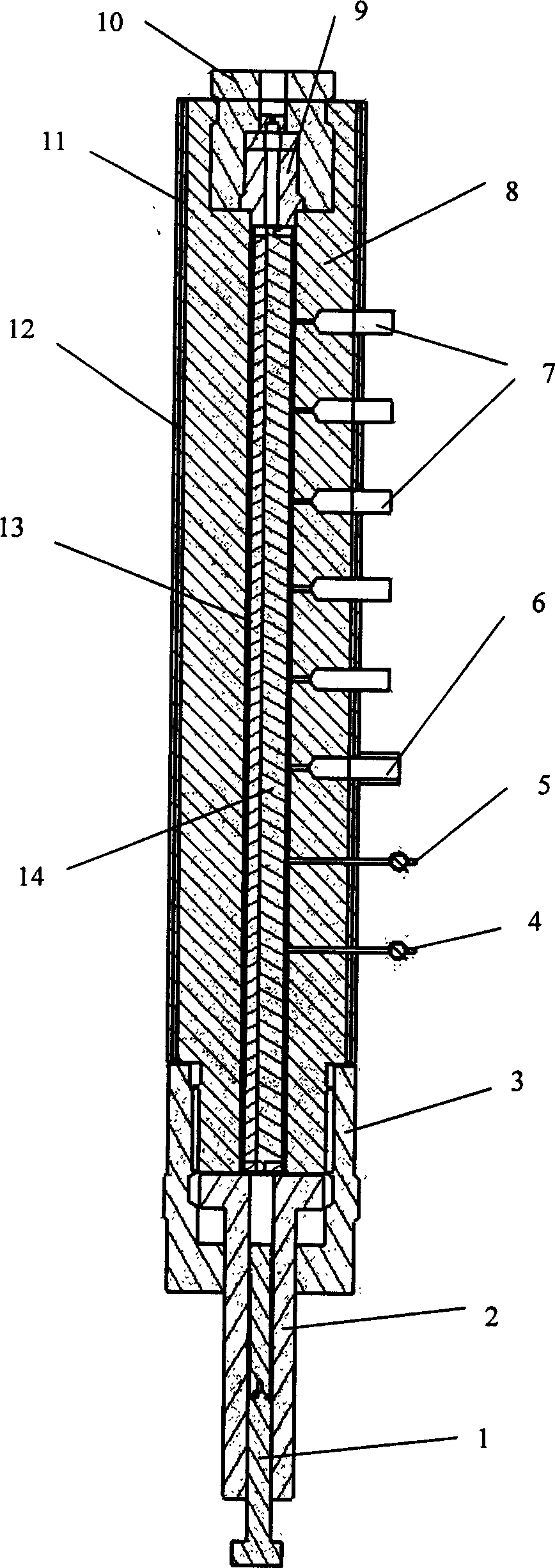

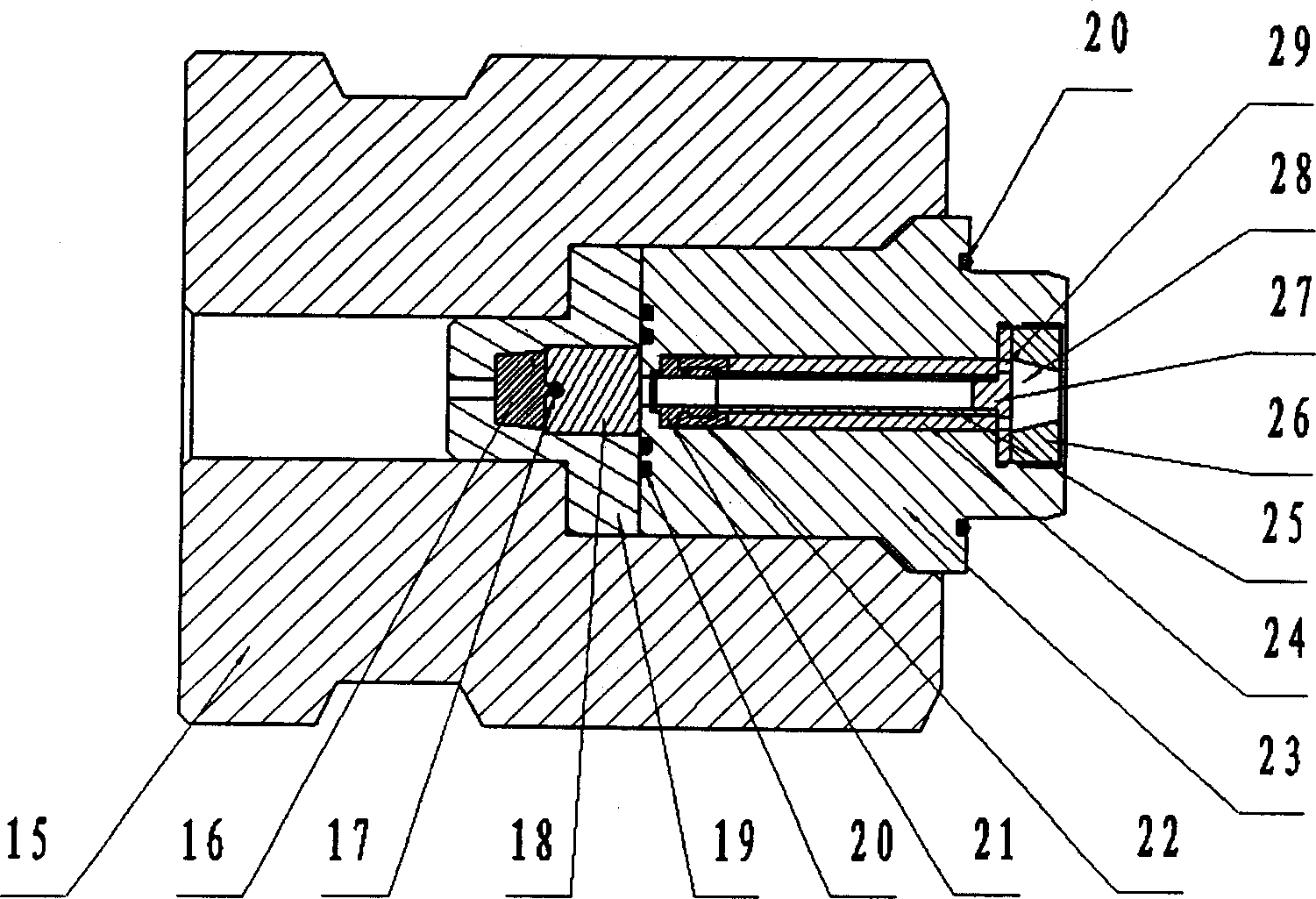

Starting pup joint with second-time opening function

PendingCN110080707AWith secondary opening functionAvoid resetFluid removalUpper jointDifferential pressure

The invention discloses a starting pup joint with a second-time starting function. The starting pup joint comprises a core shaft and a setting ball. The core shaft is connected with a sliding sleeve,the setting ball is connected with the core shaft, the sliding sleeve is connected with an outer sleeve, the outer sleeve is connected with the core shaft through a first-stage shear pin, a groove isformed in the core shaft, a baffle ring can be embedded into the groove, the baffle ring is in contact with the outer sleeve, the sliding sleeve is connected with an upper joint, the upper joint is connected with a lower joint, the upper joint, the sliding sleeve and the core shaft are sequentially connected in a step mode, the core shaft is provided with a fluid channel and a fracturing channel,and the sliding sleeve is provided with a fluid channel and a fracturing channel. Setting of a packer can be achieved when the packer is opened for the first time, and when the differential pressure sliding sleeve cannot be opened normally, the starting pup joint is started for the second time, and the fracturing channel is opened.

Owner:JEREH ENERGY SERVICES

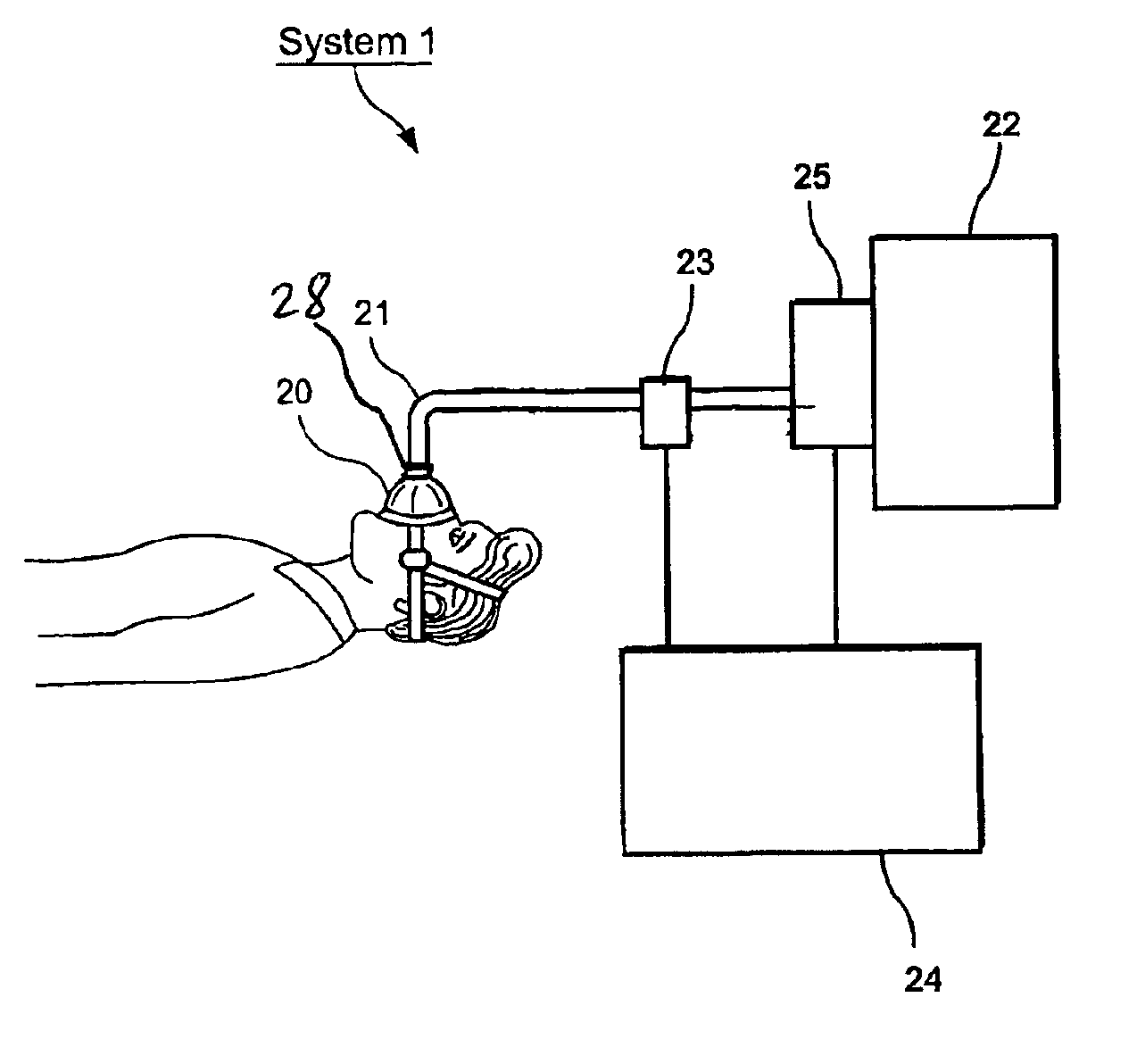

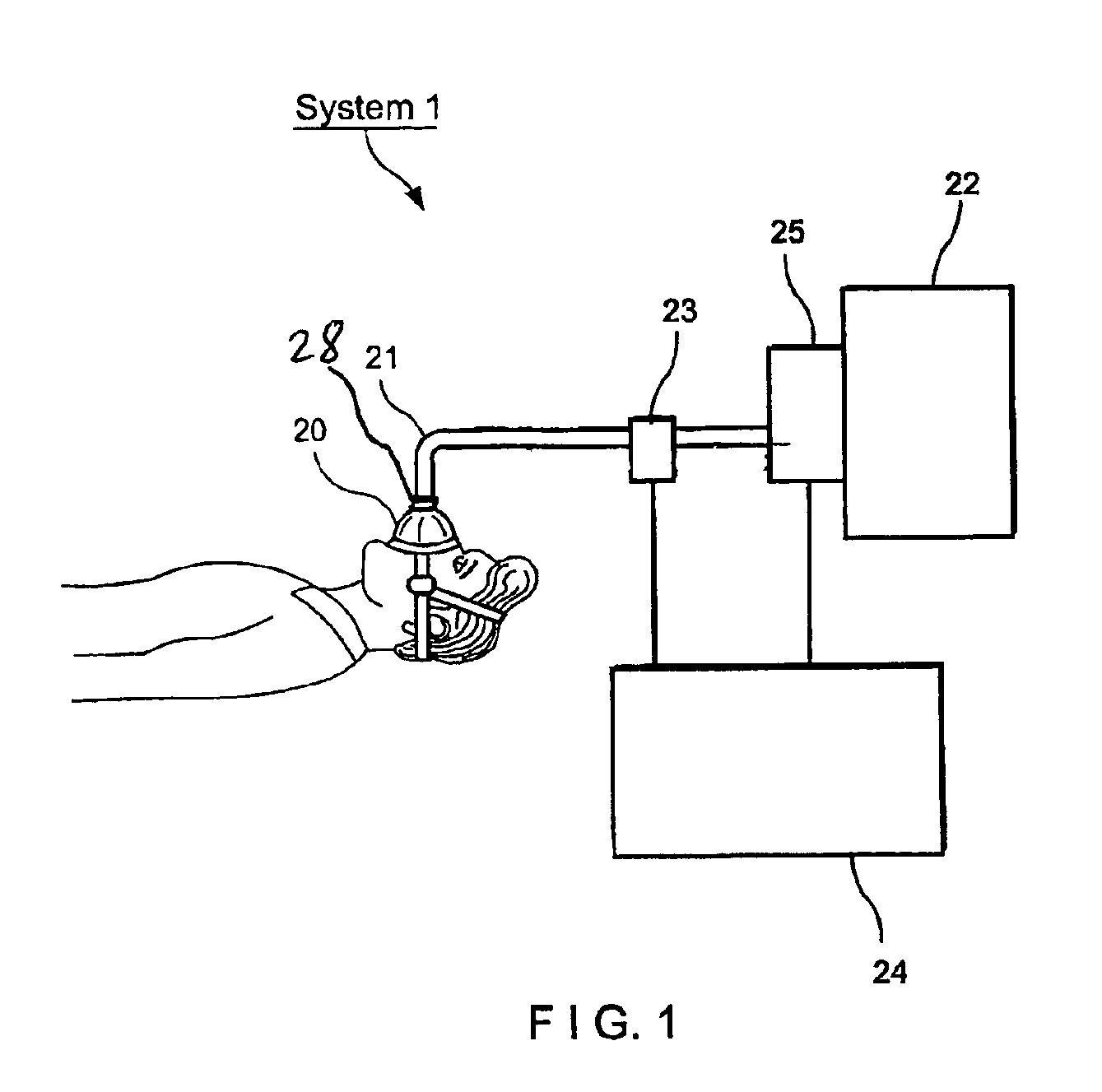

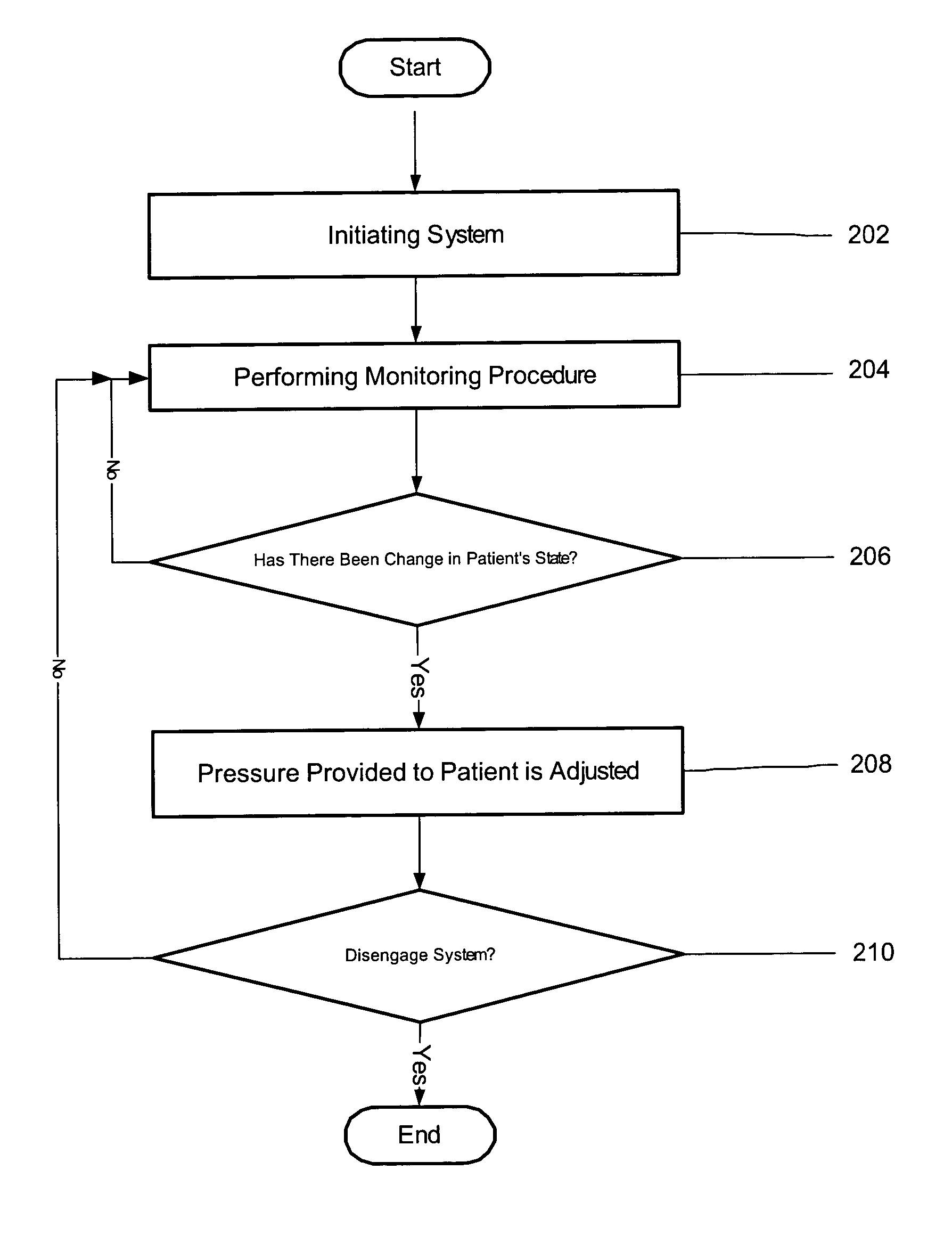

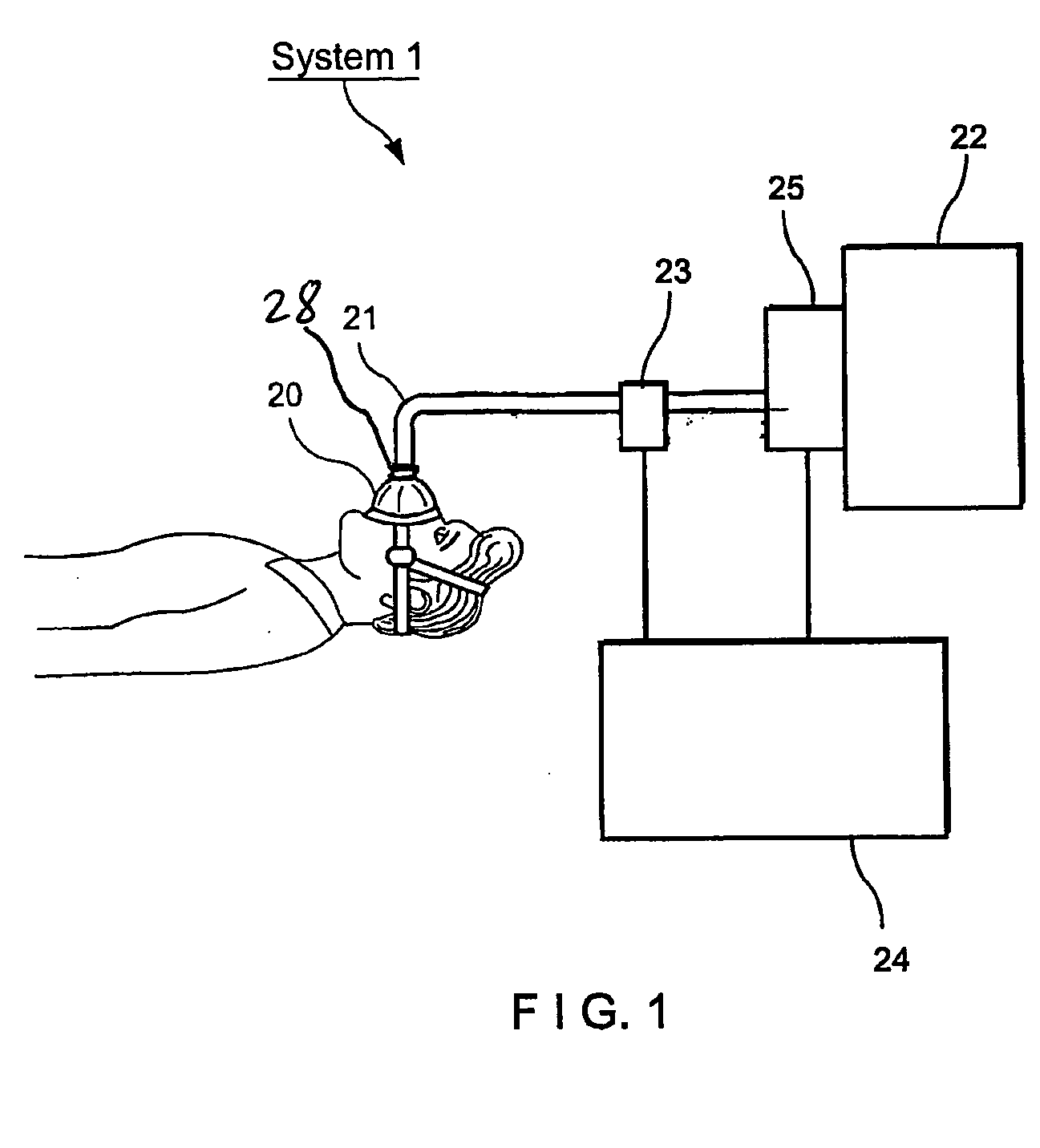

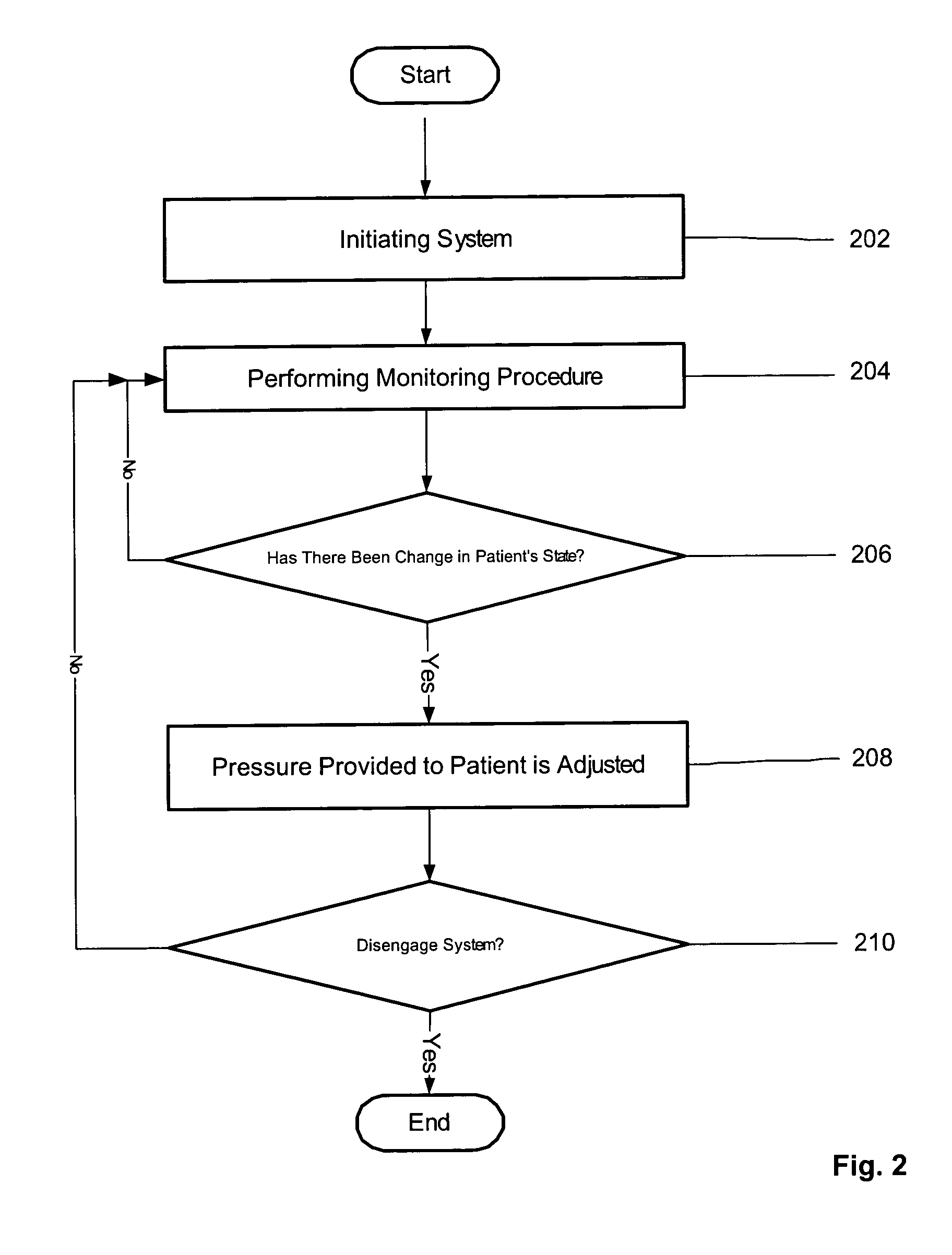

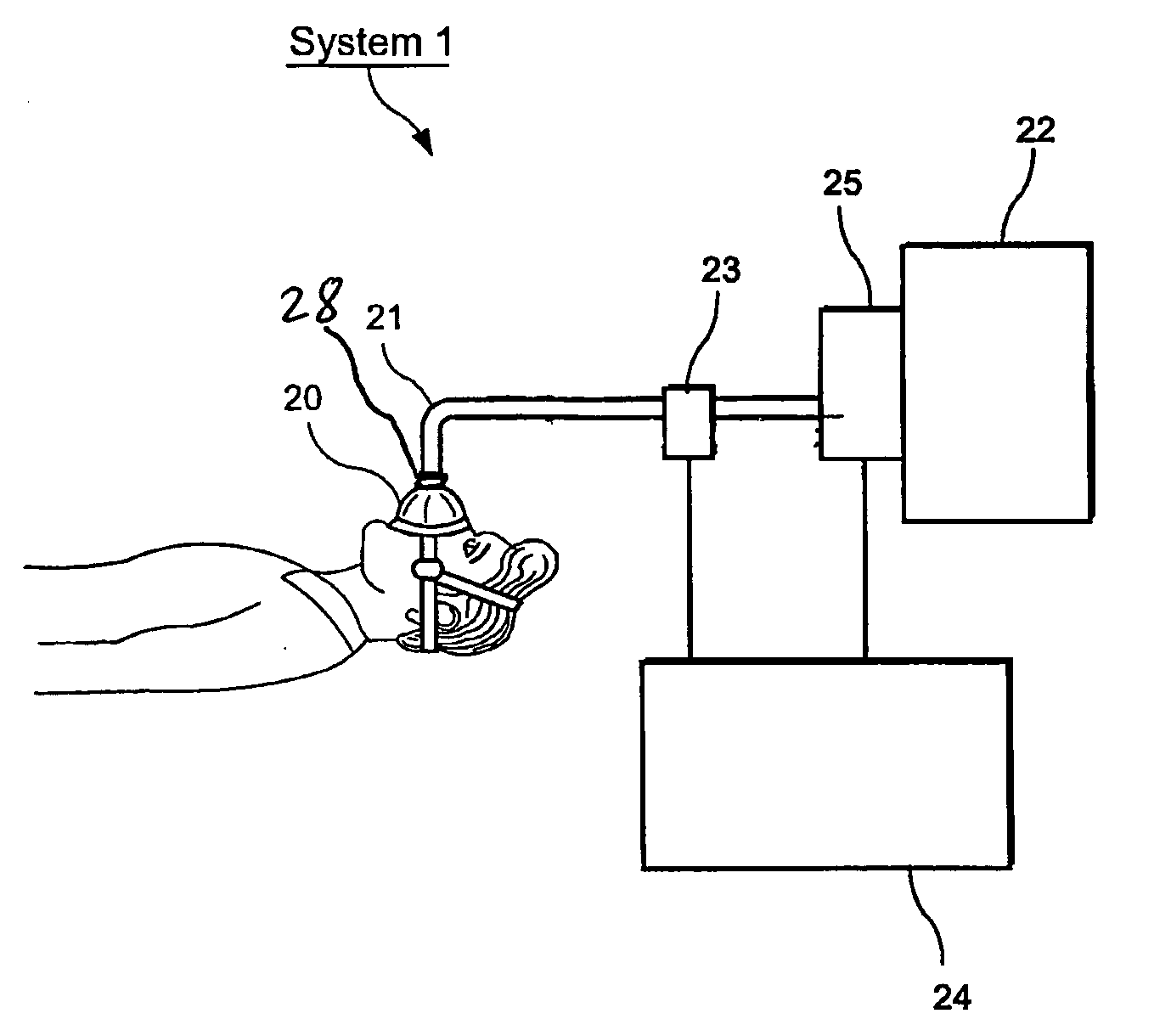

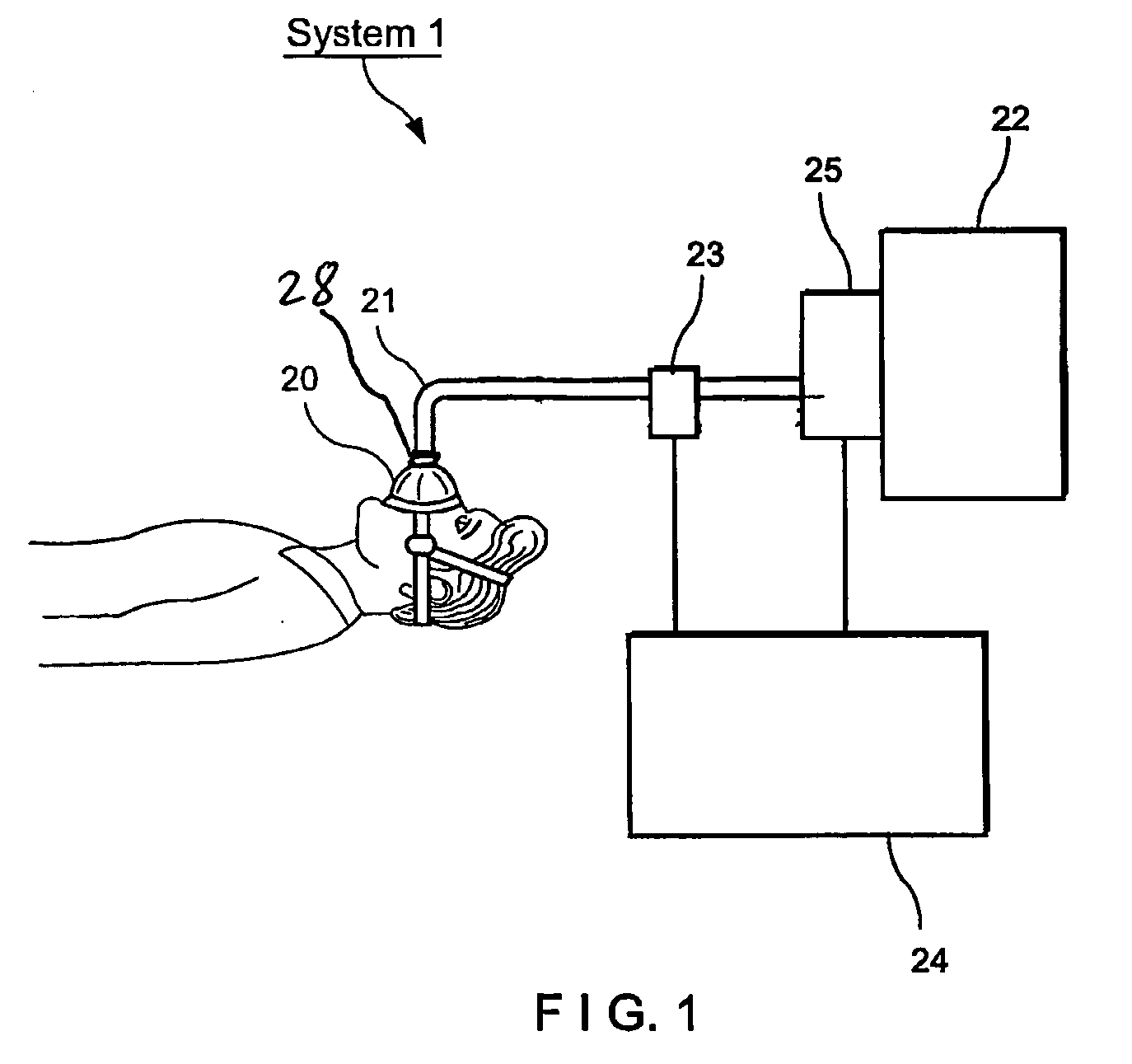

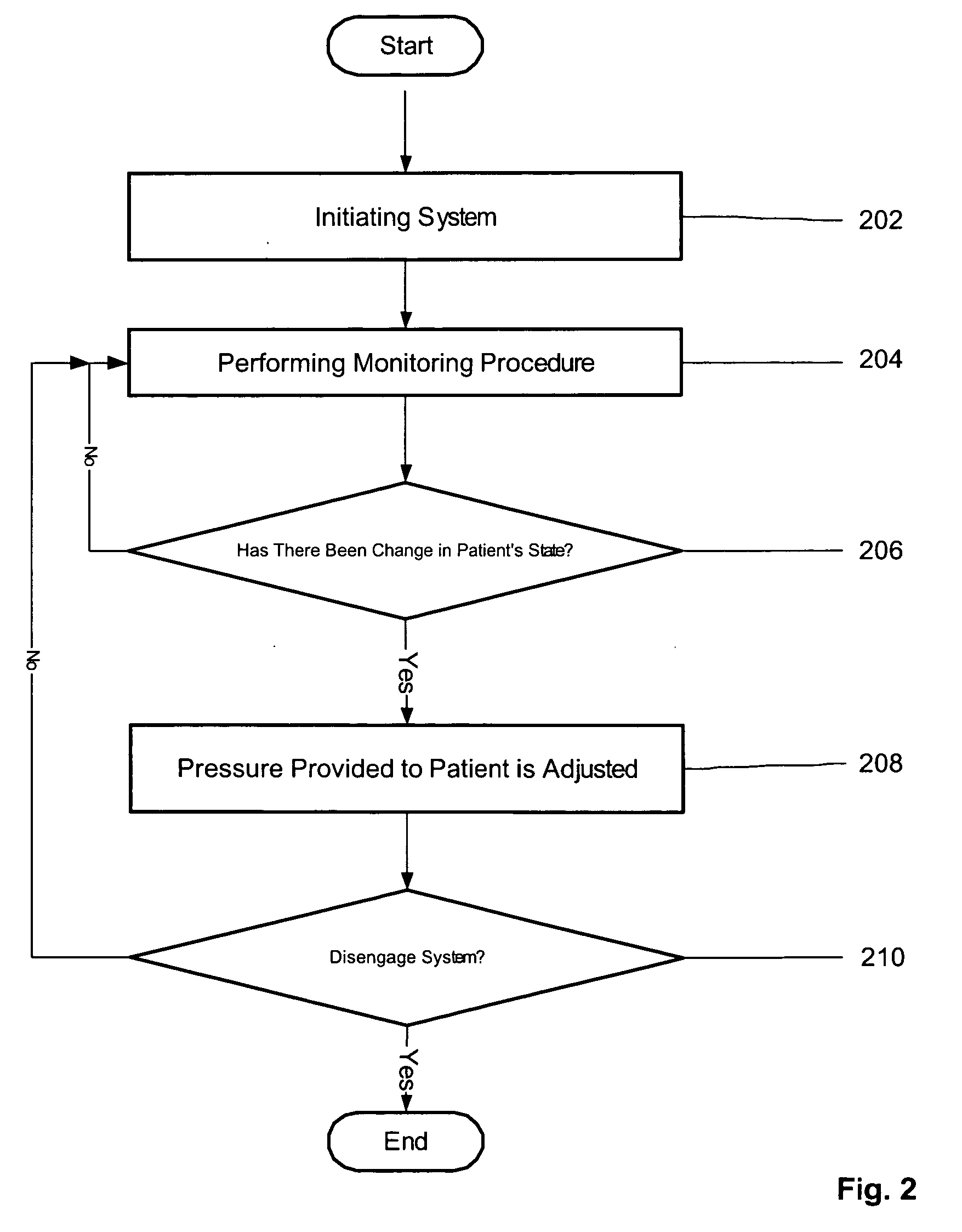

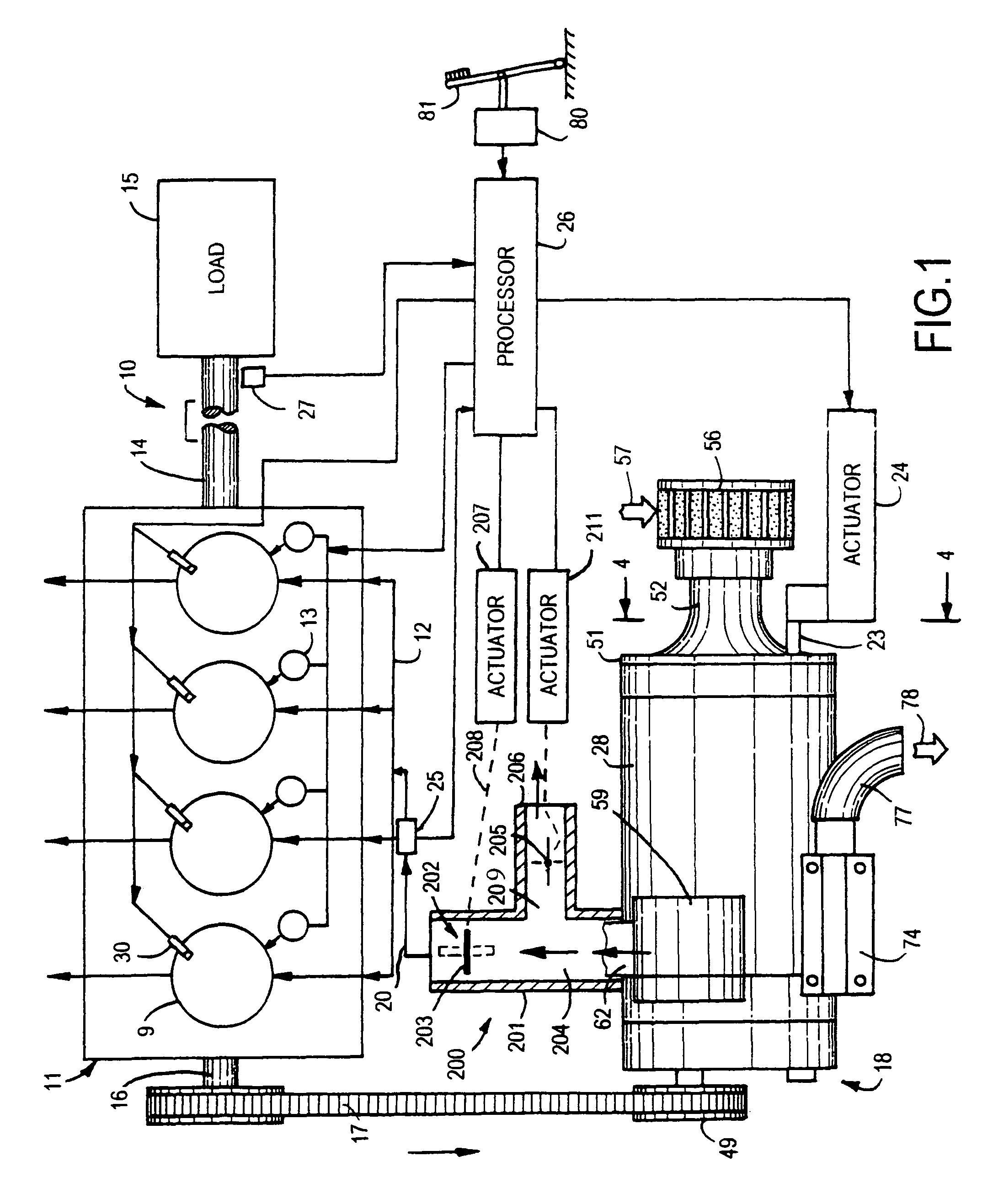

Positive airway pressure system and method for treatment of sleeping disorder in patient

InactiveUS6988994B2Increase pressureAdjustable pressureElectroencephalographyOperating means/releasing devices for valvesSleep disordered breathingSommeil paradoxal

Owner:NEW YORK UNIV

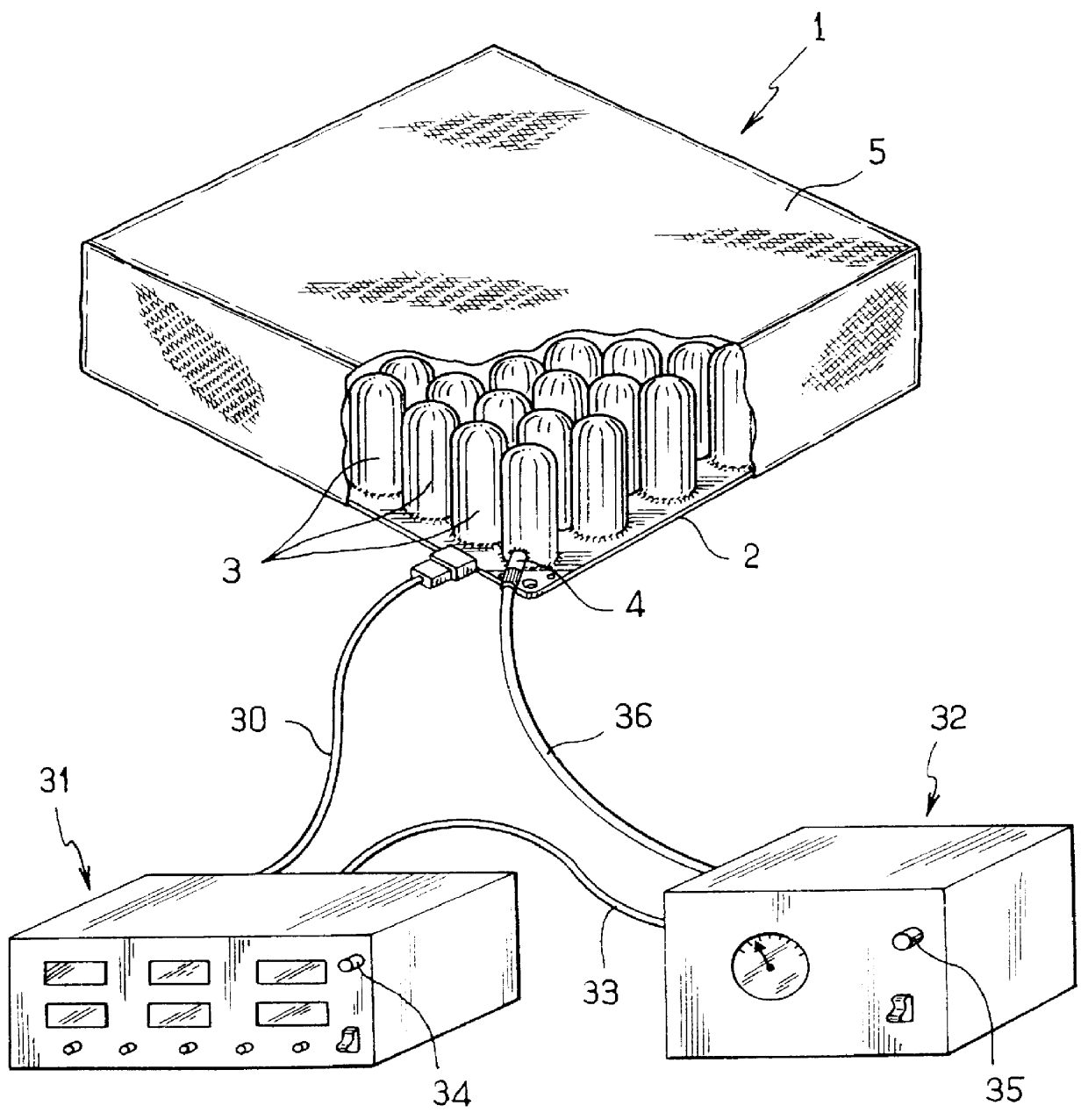

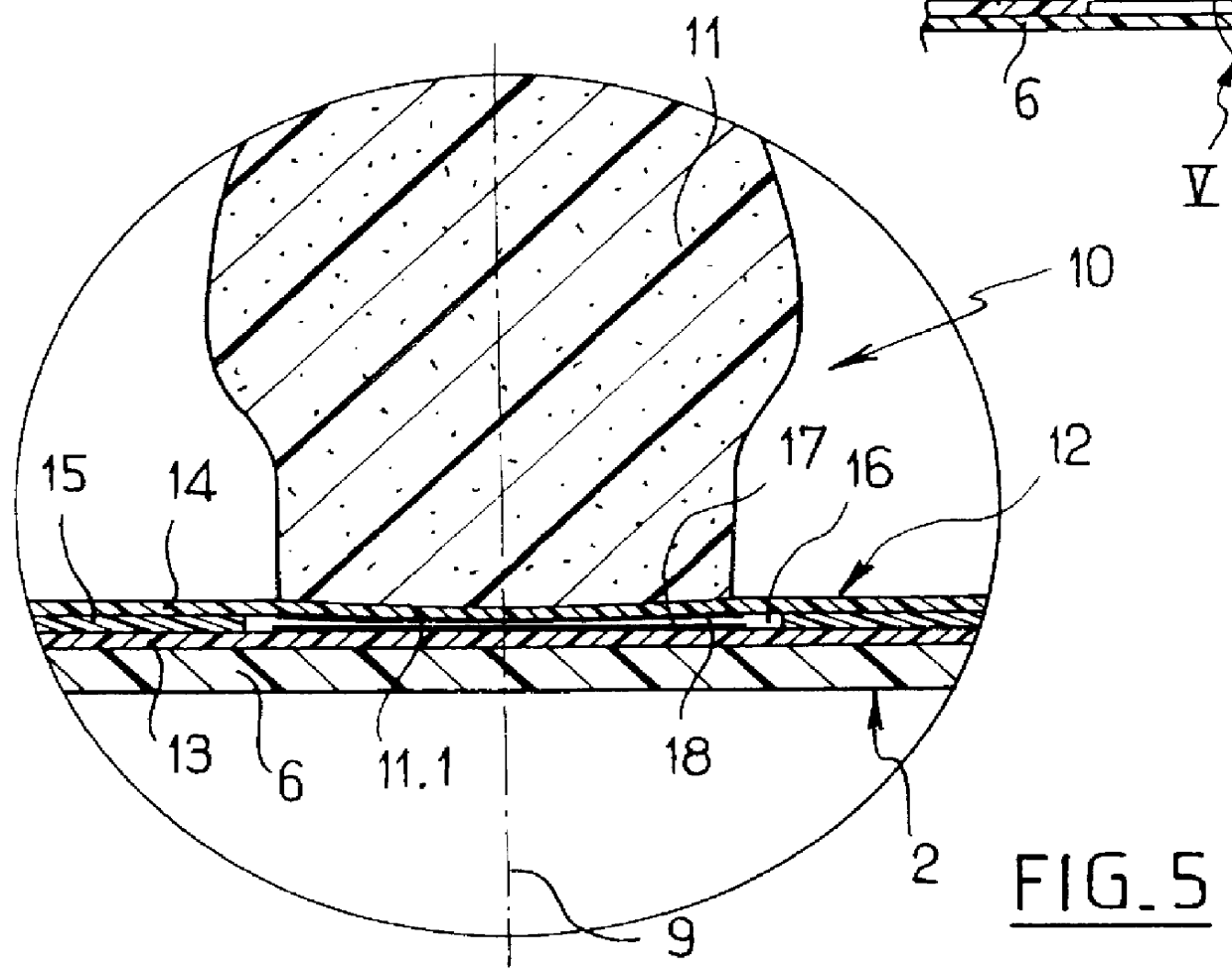

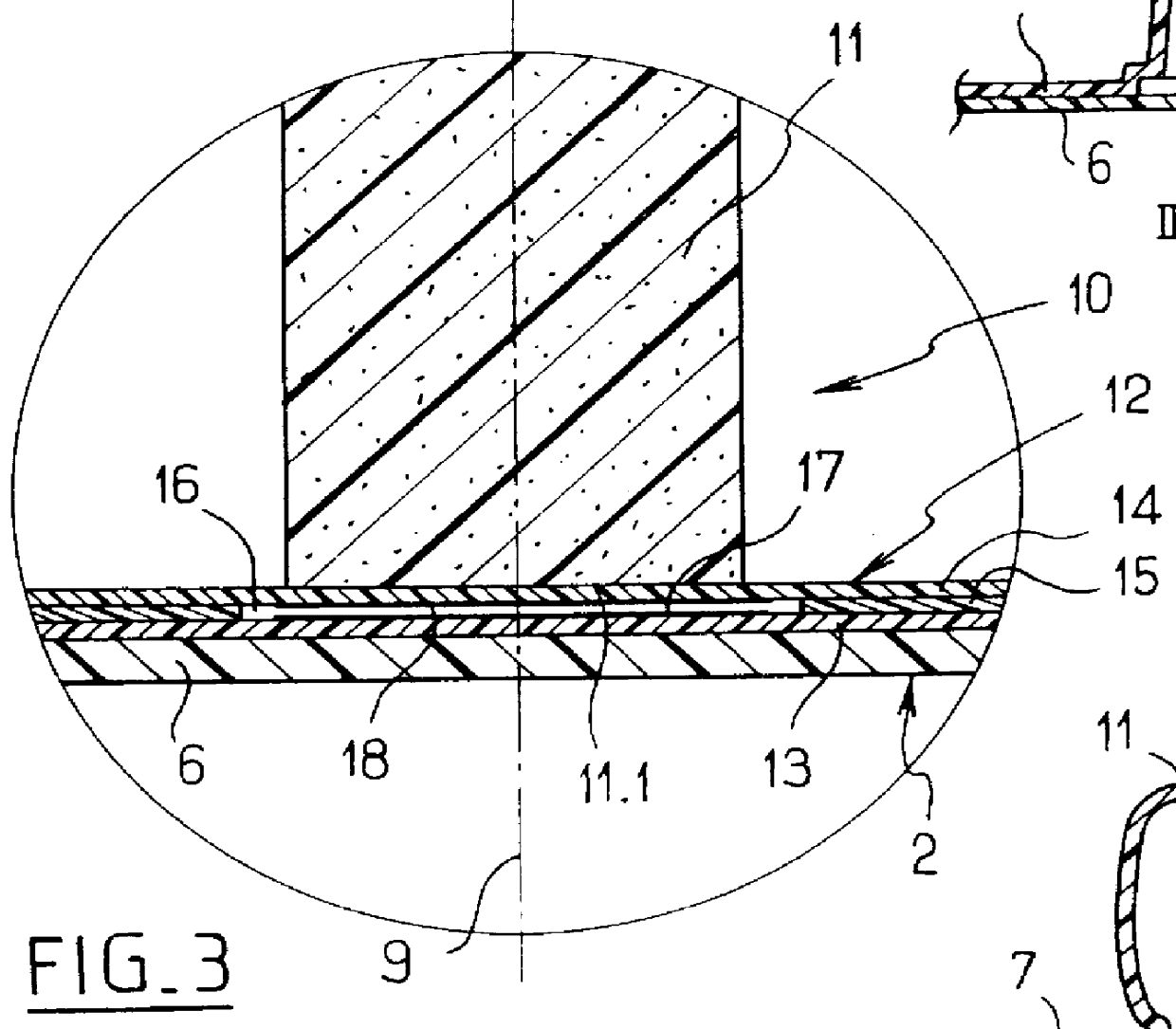

Pneumatic cushion having individually deformable cells

InactiveUS6154907AAdjustable pressureReduce pressureStuffed mattressesSpring mattressesBiomedical engineeringCushion

PCT No. PCT / FR98 / 01582 Sec. 371 Date Mar. 8, 1999 Sec. 102(e) Date Mar. 8, 1999 PCT Filed Jul. 20, 1998 PCT Pub. No. WO99 / 04673 PCT Pub. Date Feb. 4, 1999The invention relates to a pneumatic cushion (1) having a base sheet (2) from which there project a plurality of adjacent inflatable cells (3) that are individually deformable in height. At least some of the cells (3) are internally fitted with respective individual sensors of cell deformation that deliver electrical signals indicating that a determined threshold of deformation of a cell (3) has been crossed.

Owner:POLY SYST INJECTION

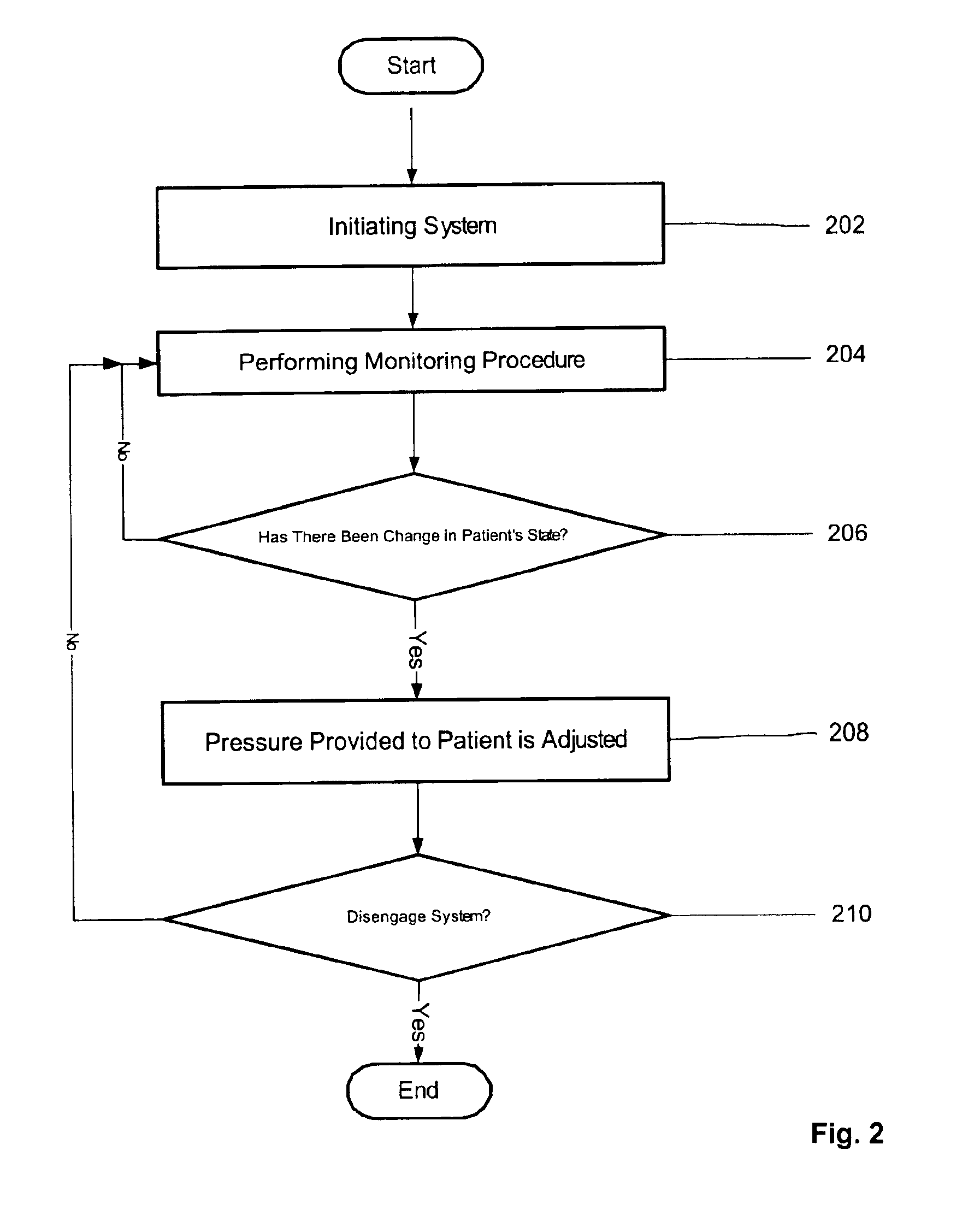

Positive airway pressure system and method for treatment of sleeping disorder in patient

ActiveUS20050038353A1Increase pressureAdjustable pressureElectroencephalographyOperating means/releasing devices for valvesPositive airway pressureSleep disorder

Described are a positive airway pressure system and method for treatment of a sleeping disorder in a patient. The system includes a generator, a sensor and a processing arrangement. The generator supplies airflow and applies a pressure at to an airway of a patient. The sensor measures data corresponding to patient's breathing patterns. The processing arrangement analyzes the breathing patterns to determine whether the breathing patterns are indicative of at least one of the following patient's states: (i) a regular breathing state, (ii) a sleep disorder breathing state, (iii) a REM sleep state and (iv) a troubled wakefulness state. The processing arrangement adjusts the applied pressure as a function of the patient's state.

Owner:NEW YORK UNIVERSITY

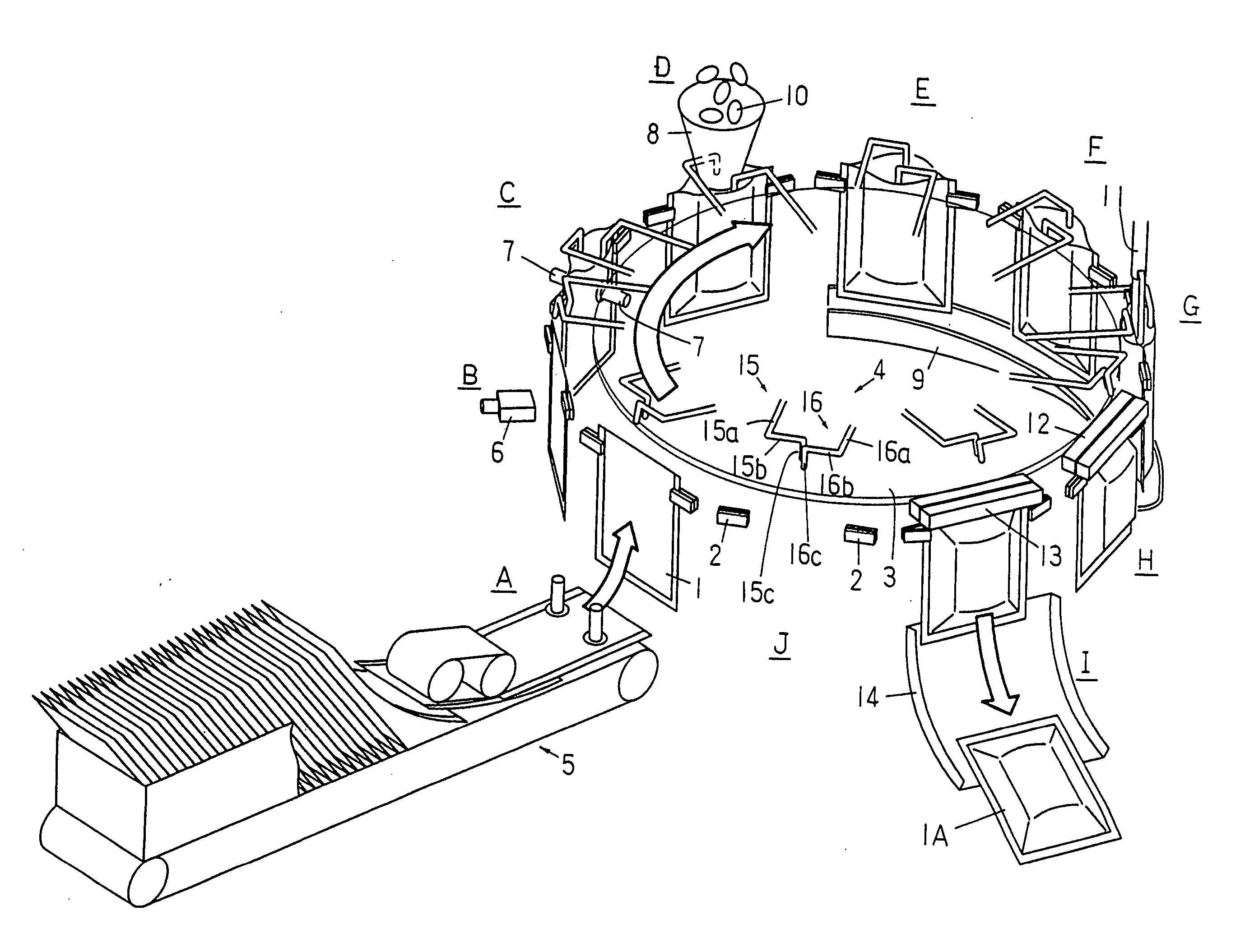

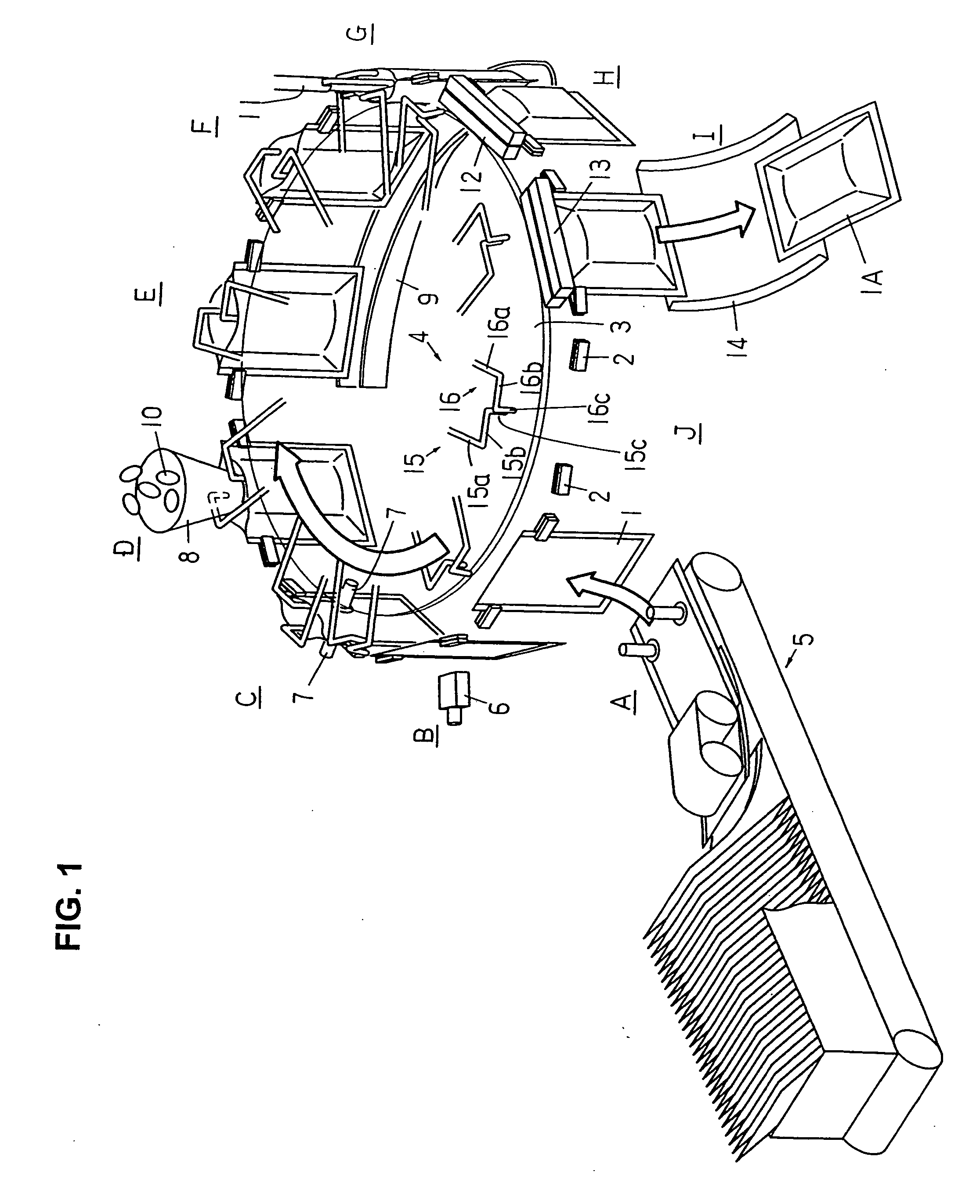

Bag-filling packaging machine

InactiveUS20070074492A1Stable fashionWithout compromising production efficiencySolid materialPackaging under special atmospheric conditionsRound tableEngineering

A bag-filling packaging machine in which supplied bags 1 are gripped by pairs of grippers 2 disposed on the periphery of an intermittently turning round table 3, and the bags, at stopping positions, are successively subjected to prescribed packaging operations with the gas inside the bags being replaced during that process, wherein a pair of guide members 15 and 16 for keeping the bag mouth opened is provided on the table 3 in correspondence with each of the gripper pair, and guide members 15 and 16 are connected to an inactive gas supply source and have gas blow-out ports at the tip ends that are inserted inside the bags, thus allowing the guide members 15 and 16 to not only keep the bag mouth opened but also function as gas blow-in nozzles.

Owner:TOYO JIDOKI CO LTD

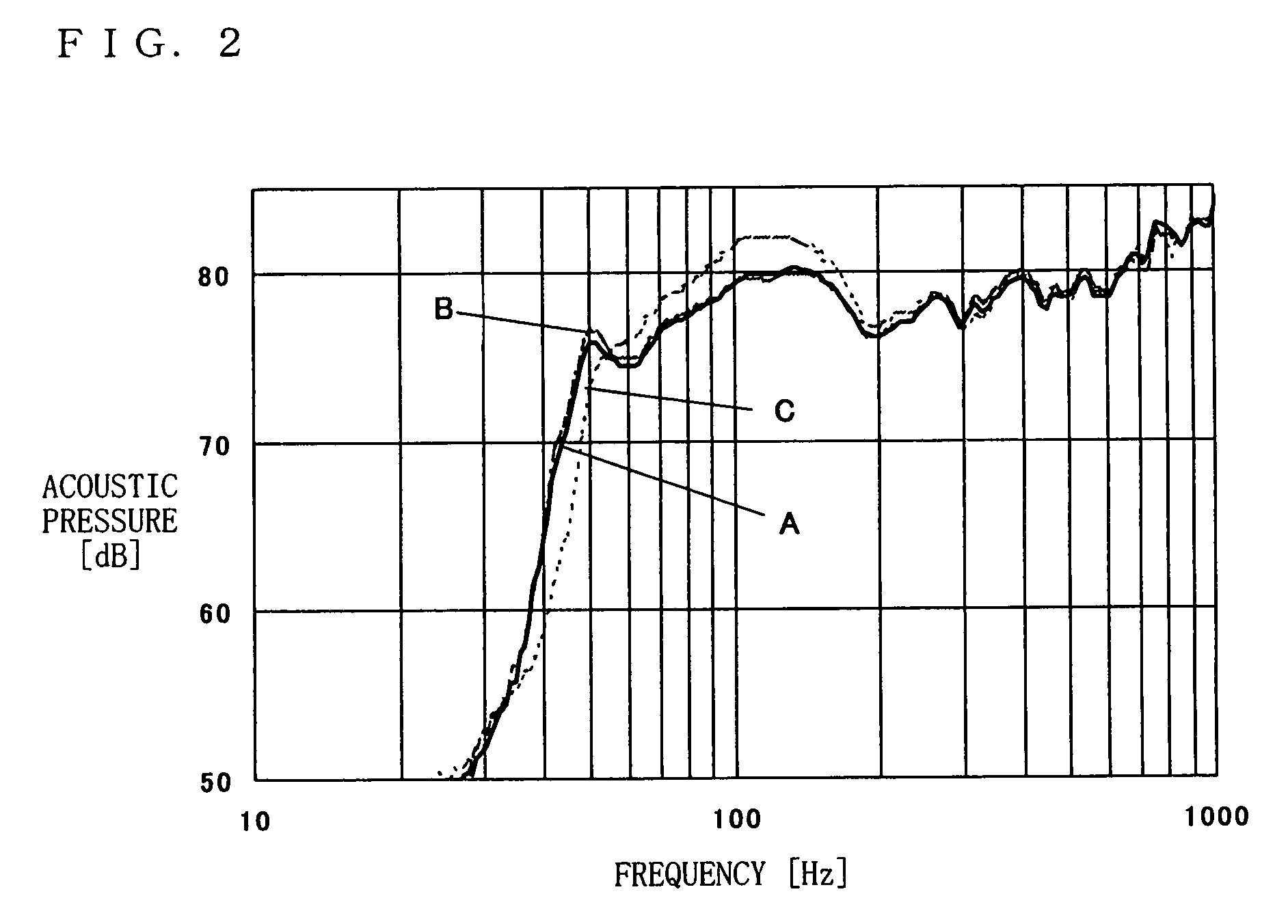

Loudspeaker system

ActiveUS7974423B2Improve performanceAdjustable pressureSubstation equipmentFrequency/directions obtaining arrangementsAeroshellLoudspeaker

A loudspeaker system comprises a cabinet, a speaker unit, a package body, a filler gas, and an absorbent. The speaker unit is mounted in the cabinet. At least one package body is disposed in a vacant space inside of the cabinet and is structured by a bag body for sealing materials thereinto from outside thereof. A predetermined amount of the filler gas is sealed into the package body. A predetermined amount of the absorbent is sealed into the package body and physically absorbs the filler gas.

Owner:PANASONIC CORP

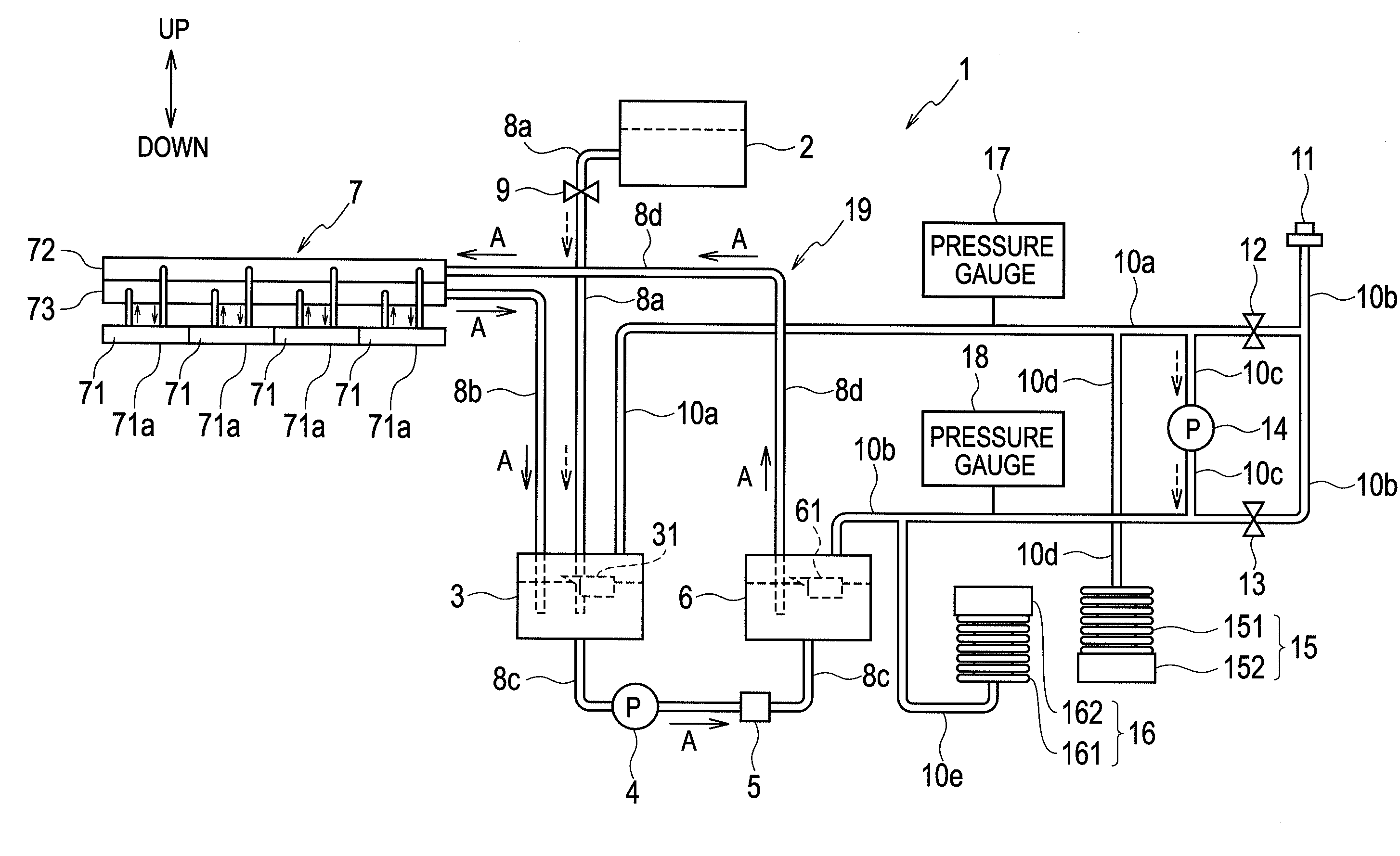

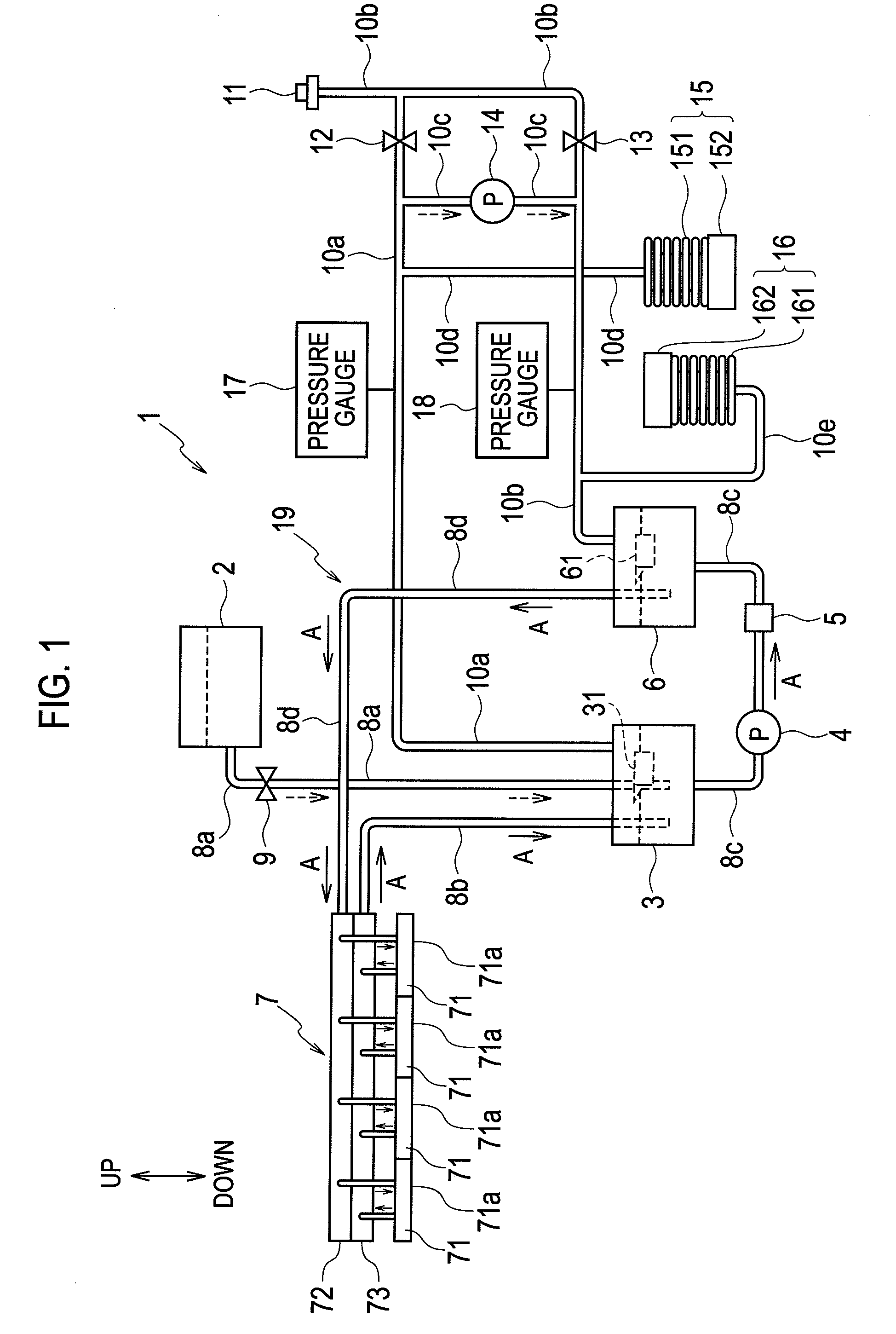

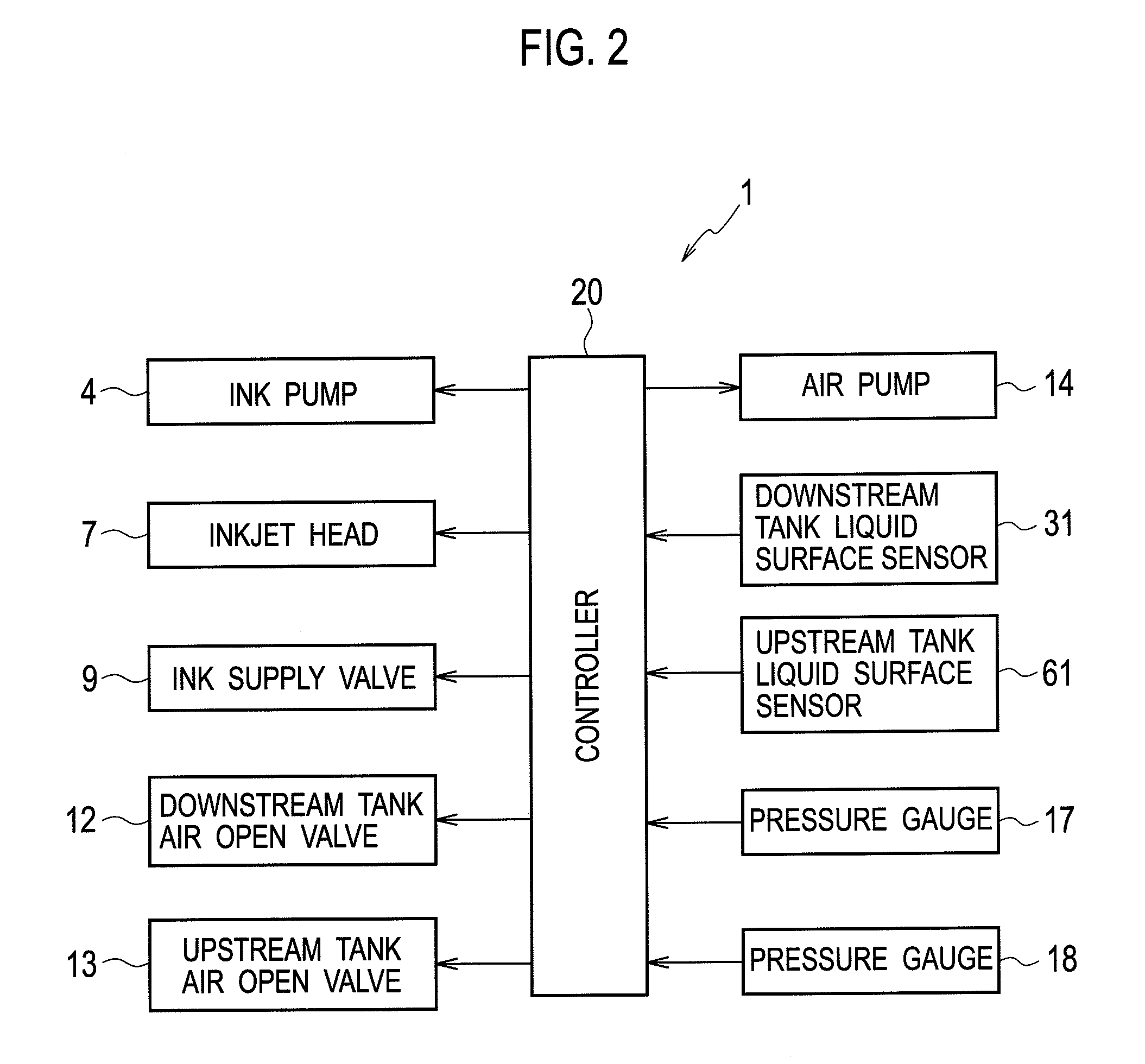

Inkjet printing apparatus

InactiveUS20120188314A1Flow passage resistance is thereby highIncrease in sizeOther printing apparatusEngineeringPressurizer

An inkjet printing apparatus includes: an inkjet head configured to discharge ink; a first tank configured to store ink to be supplied to the inkjet head; a second tank configured to store ink not consumed by the inkjet head; an ink circulation path for circulation of ink among the first tank, the inkjet head, and the second tank; a pressurizer configured to provide the first and second tanks with a pressure for the circulation of ink through the ink circulation path; a first pressure adjuster configured to adjust a pressure inside the first tank during the circulation of ink; and a second pressure adjuster configured to adjust a pressure inside the second tank during the circulation of ink.

Owner:RISO KAGAKU CORP

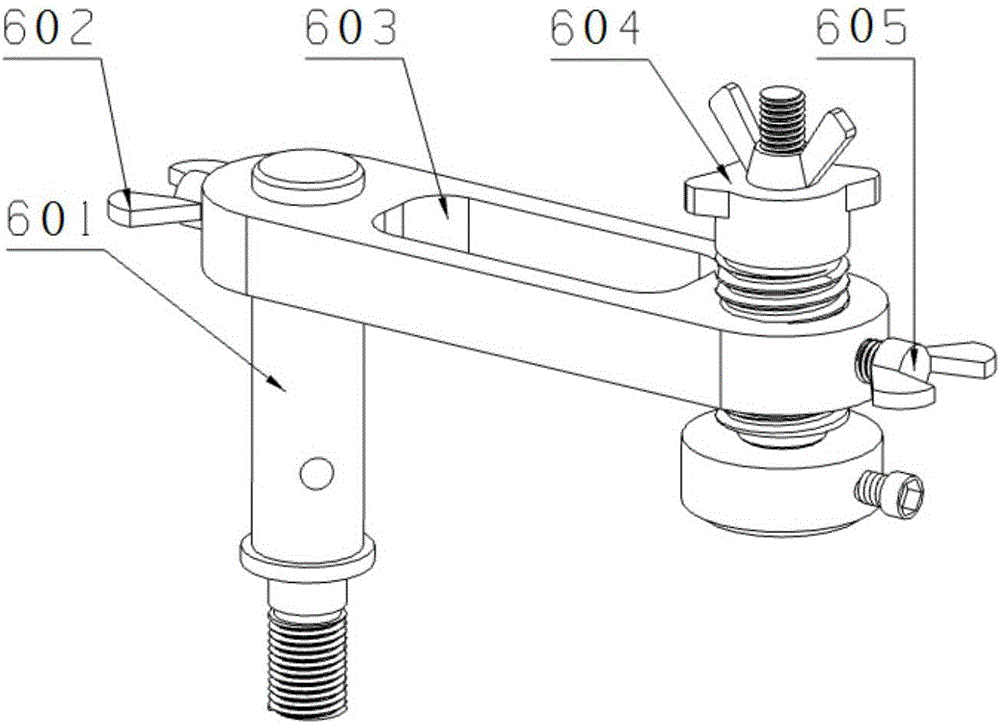

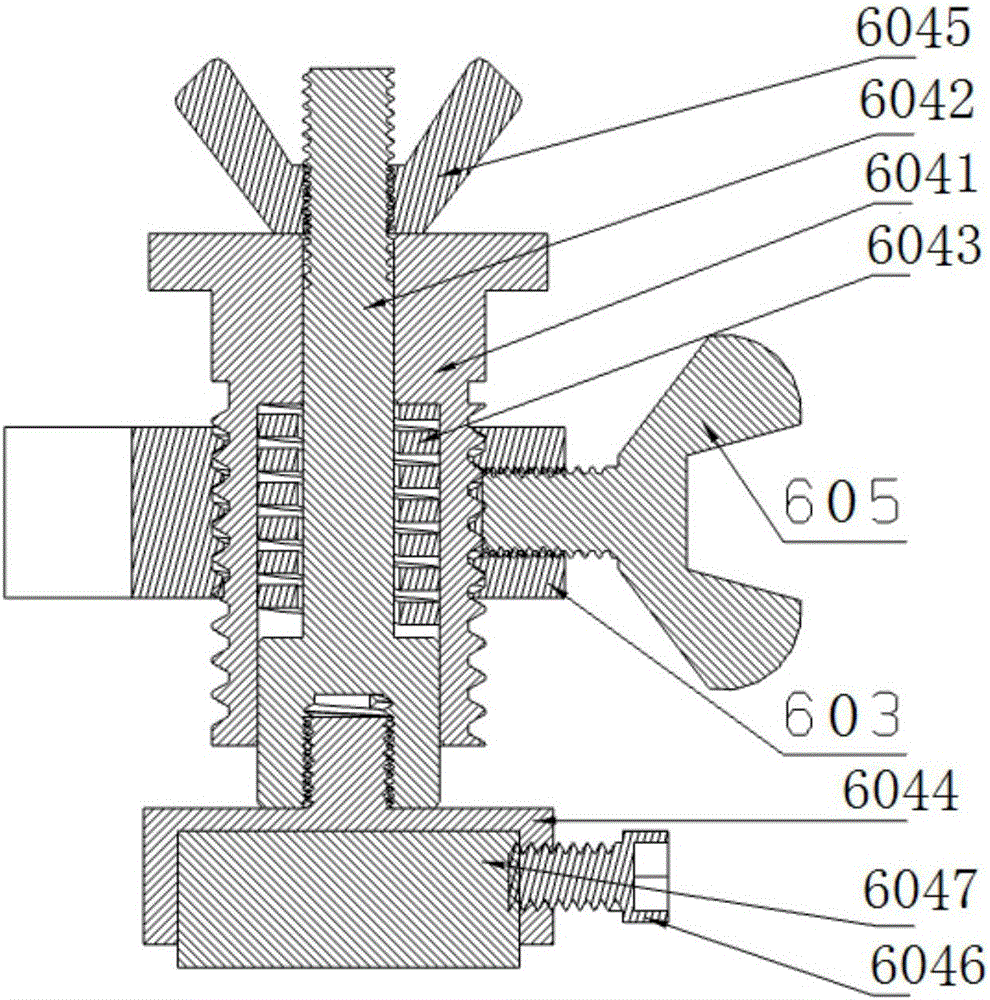

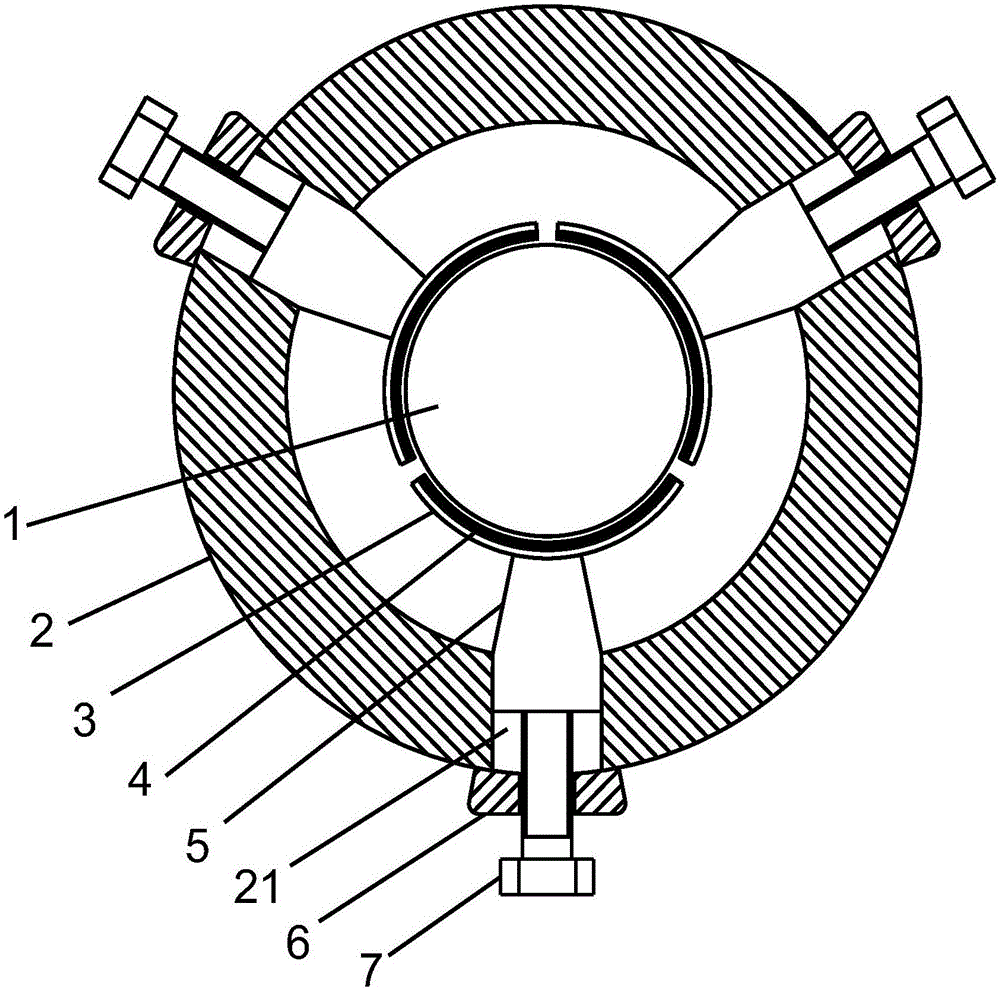

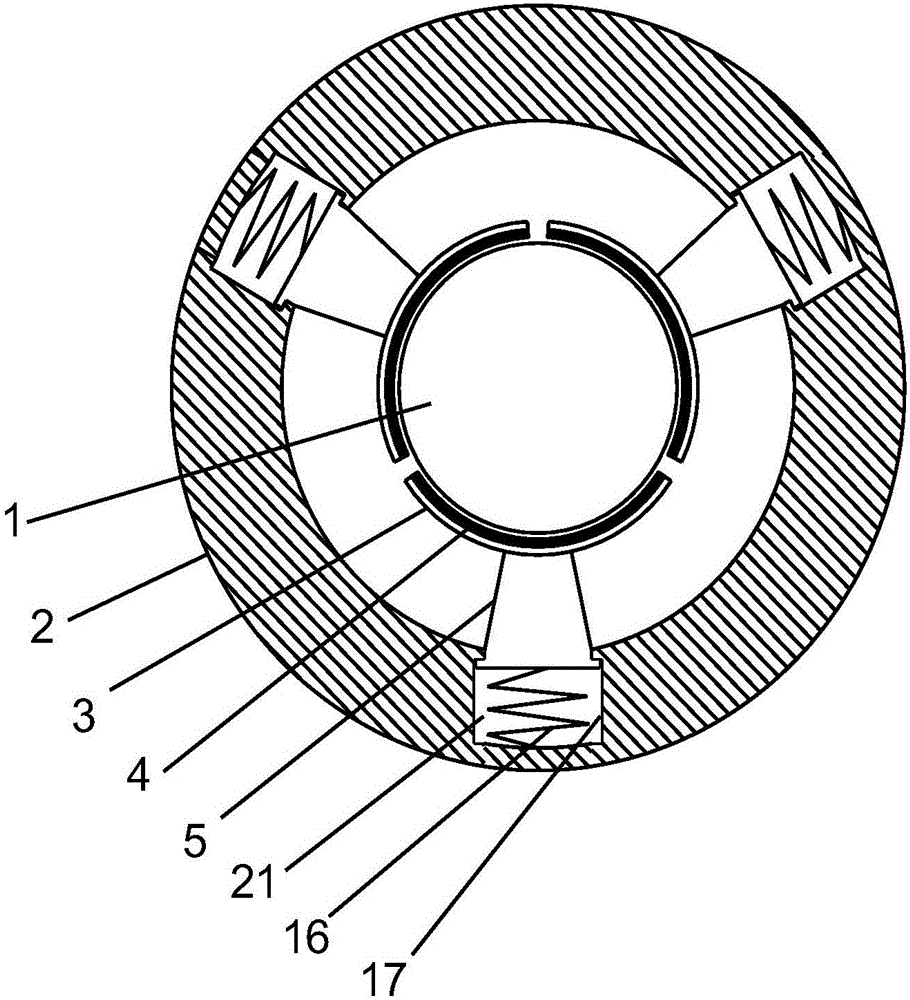

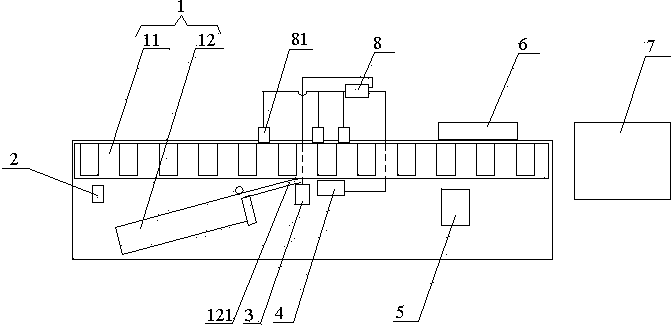

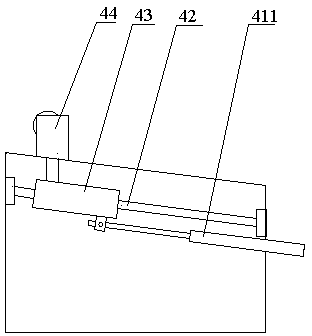

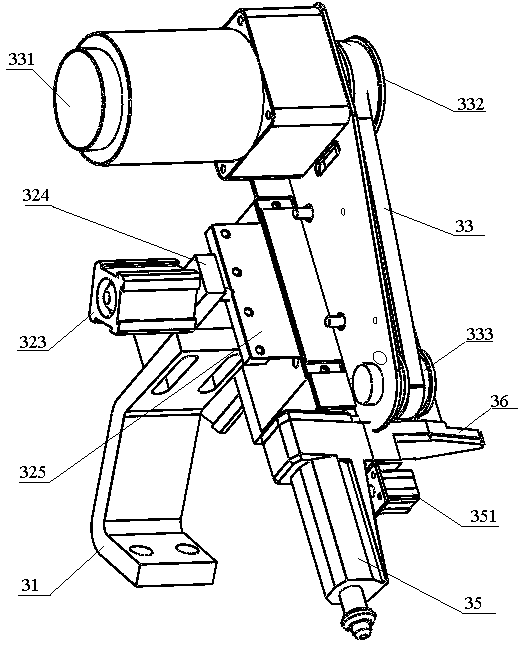

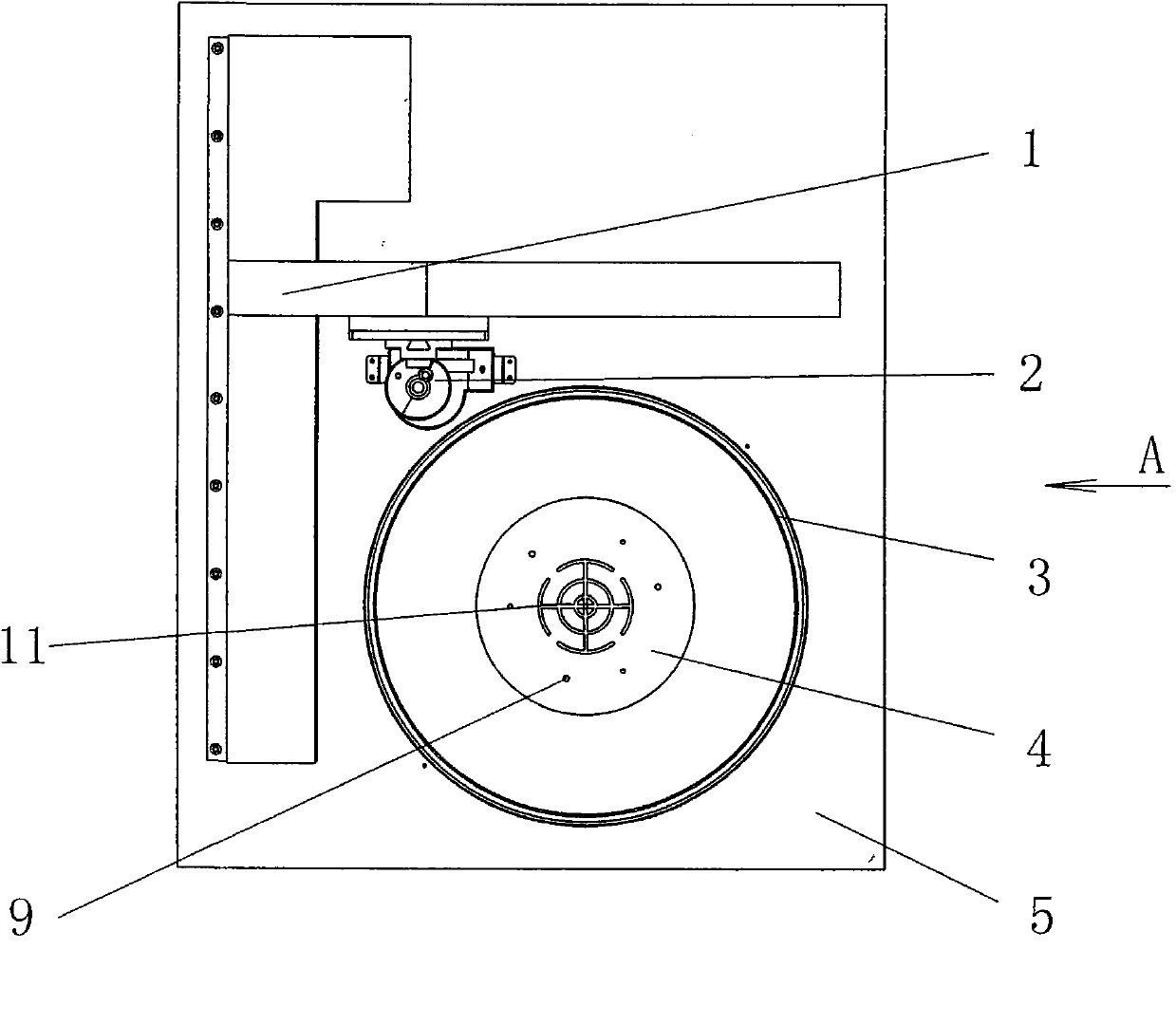

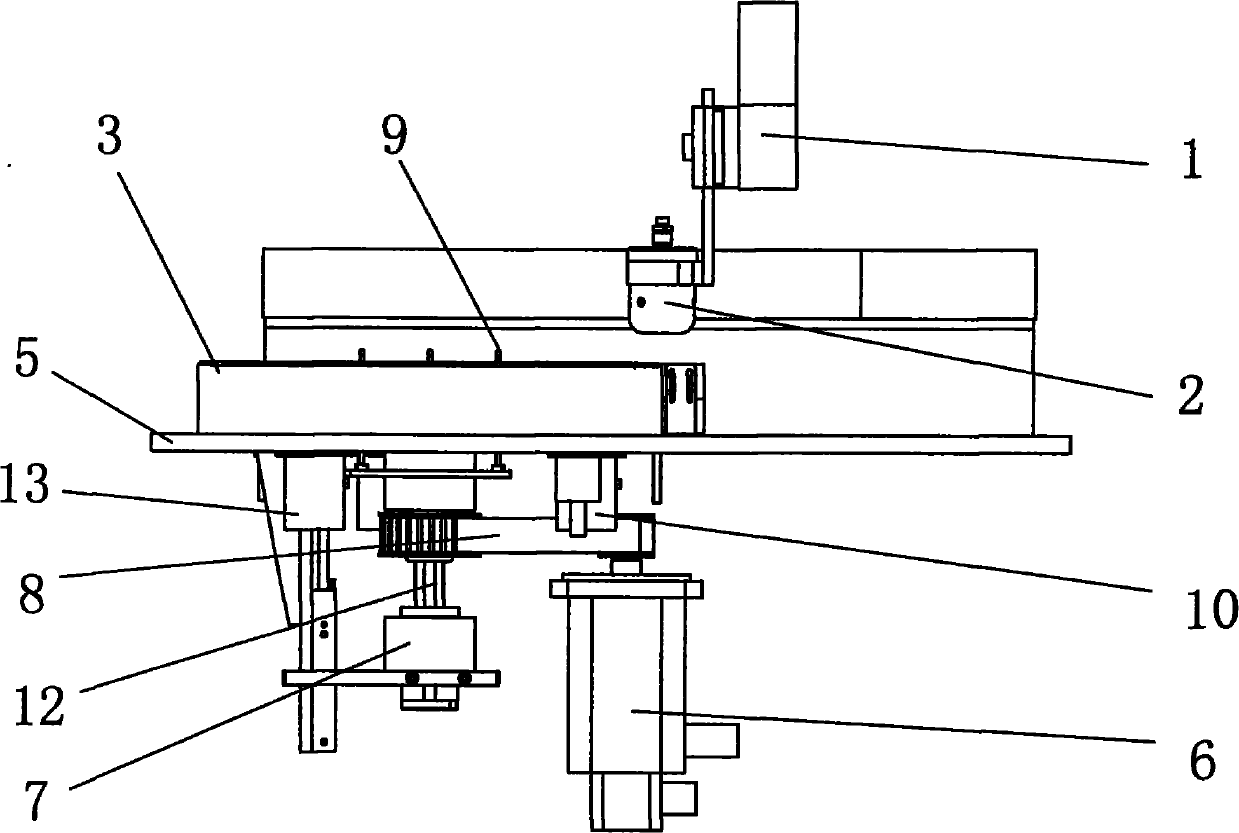

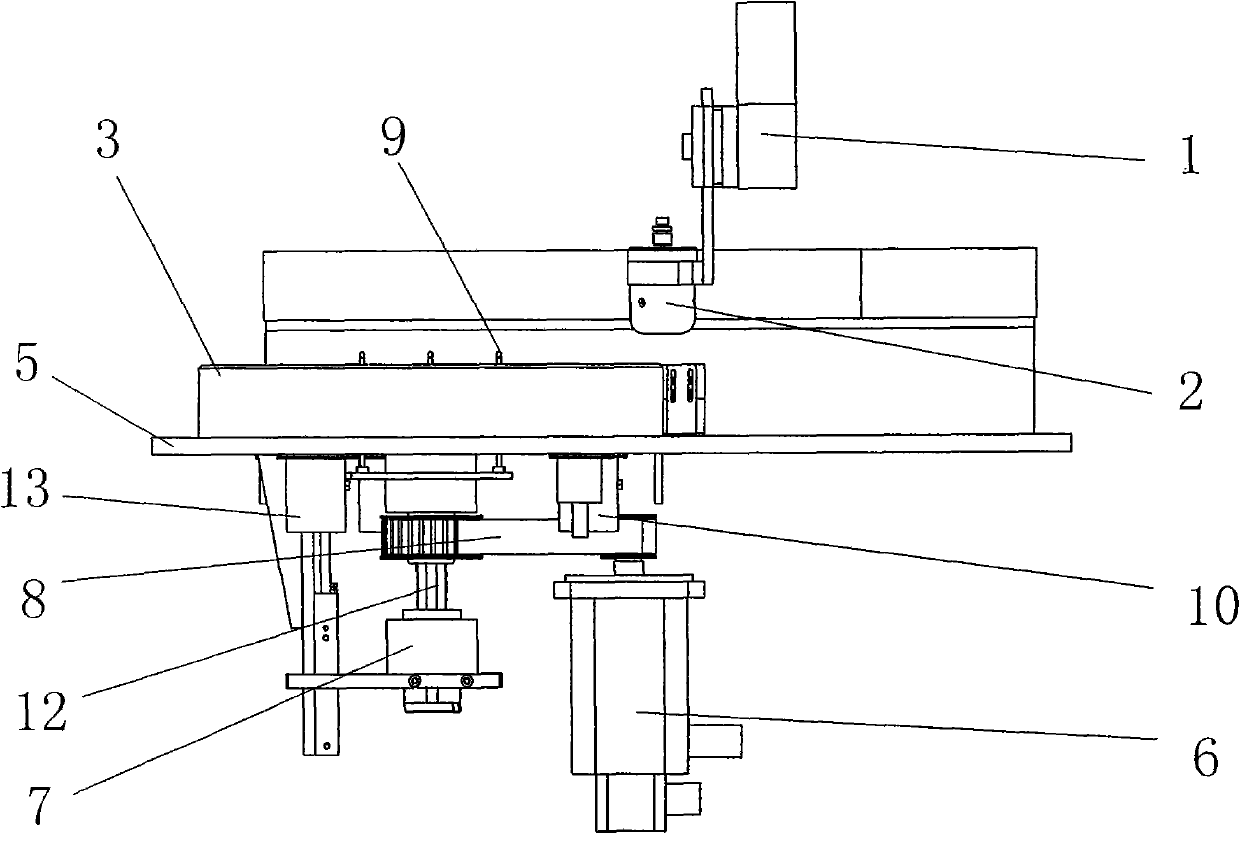

Metallographic phase grinding sample pressure adjusting device and metallographic phase grinding and polishing device and method

ActiveCN105904336AAchieve polishAdjustable speedLapping machinesWork carriersPulp and paper industryFastener

The invention relates to the technical field of metallographic phase grinding, in particular to a metallographic phase grinding sample pressure adjusting device and a metallographic phase grinding and polishing device and method. The metallographic phase grinding sample pressure adjusting device comprises a fixed rod, a rotary connection rod and a sample clamping mechanism which are all sequentially connected; the sample clamping mechanism comprises an adjusting sleeve, a pin shaft arranged in the adjusting sleeve, a fastener installed at the upper end of the pin shaft, a spring arranged on the pin shaft in a sleeving manner and pressed in the adjusting sleeve through the pin shaft, and a sample clamping sleeve detachably installed at the lower end of the pin shaft and used for clamping a metallographic phase sample. The metallographic phase grinding and polishing device comprises the metallographic phase grinding sample pressure adjusting device, a cushion plate, a grinding and polishing disk and a motor. During grinding and polishing, firstly, pressure is preset, and then by adjusting the fastener of the pin shaft to be connected with the adjusting sleeve, the pressure is loaded onto the metallographic phase sample. According to the metallographic phase grinding sample pressure adjusting device and the metallographic phase grinding and polishing device and method, one or more metallographic phase samples can be pre-ground and polished on the same equipment, and pressure acting on the samples is adjustable and can be automatically released.

Owner:NORTHEASTERN UNIV

Positive airway pressure system and method for treatment of sleeping disorder in patient

InactiveUS20060009708A1Increase pressureAdjustable pressureElectroencephalographyOperating means/releasing devices for valvesPositive airway pressurePhysical medicine and rehabilitation

Described are a positive airway pressure system and method for treatment of a sleeping disorder in a patient. The system includes a generator, a sensor and a processing arrangement. The generator supplies airflow and applies a pressure at to an airway of a patient. The sensor measures data corresponding to patient's breathing patterns. The processing arrangement analyzes the breathing patterns to determine whether the breathing patterns are indicative of at least one of the following patient's states: (i) a regular breathing state, (ii) a sleep disorder breathing state, (iii) a REM sleep state and (iv) a troubled wakefulness state. The processing arrangement adjusts the applied pressure as a function of the patient's state.

Owner:NEW YORK UNIV

Hand power tool

InactiveUS20070295522A1Tension variesImprove user friendlinessPortable percussive toolsPortable power-driven toolsHand heldPower tool

In a hand power tool having a housing which at least in part comprises an inner housing and an outer housing, and in which the inner housing and the outer housing are spaced apart from one another, at least one damping element is provided between the inner housing and the outer housing, so that the inner housing and the outer housing are decoupled from one another.

Owner:ROBERT BOSCH GMBH

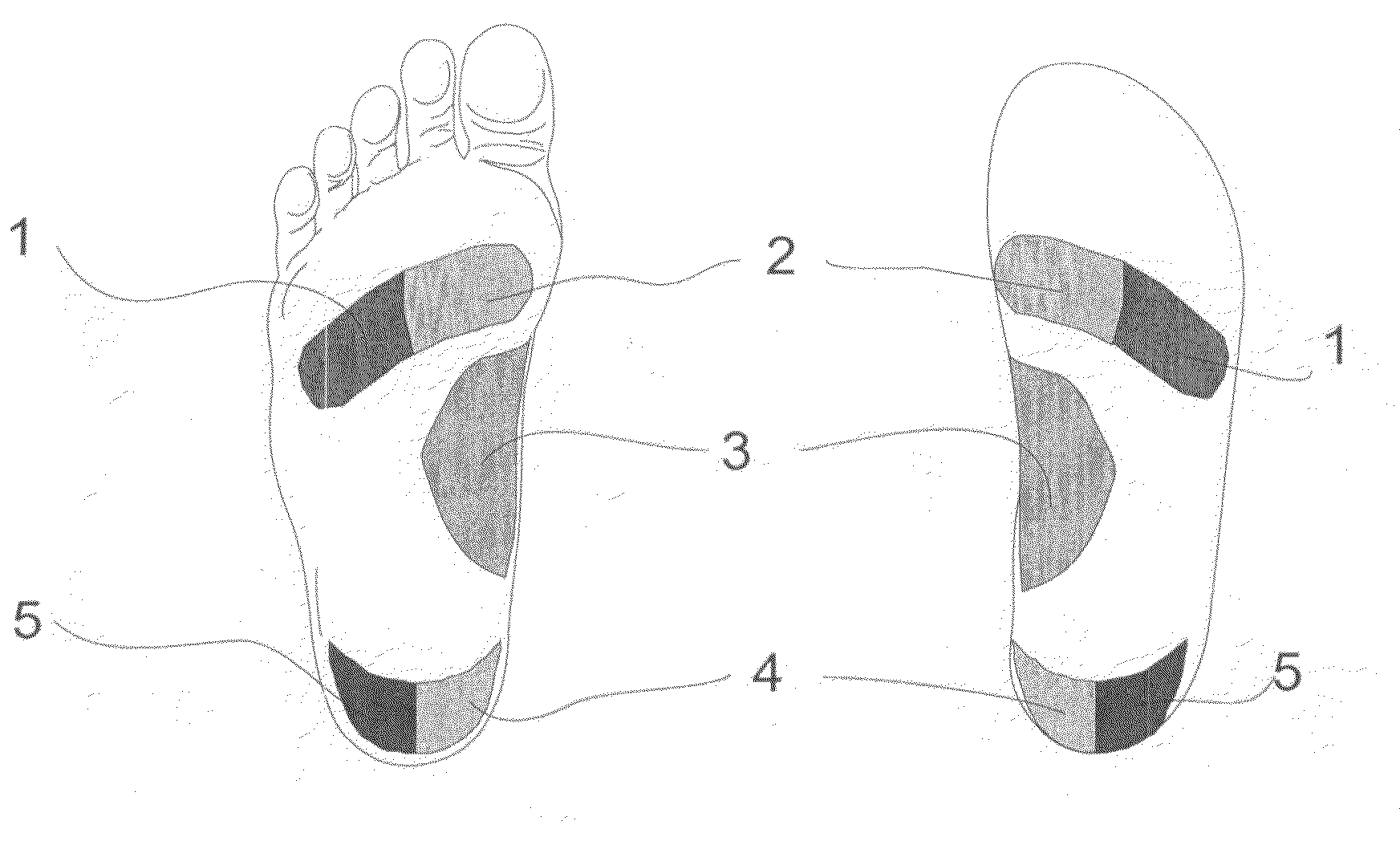

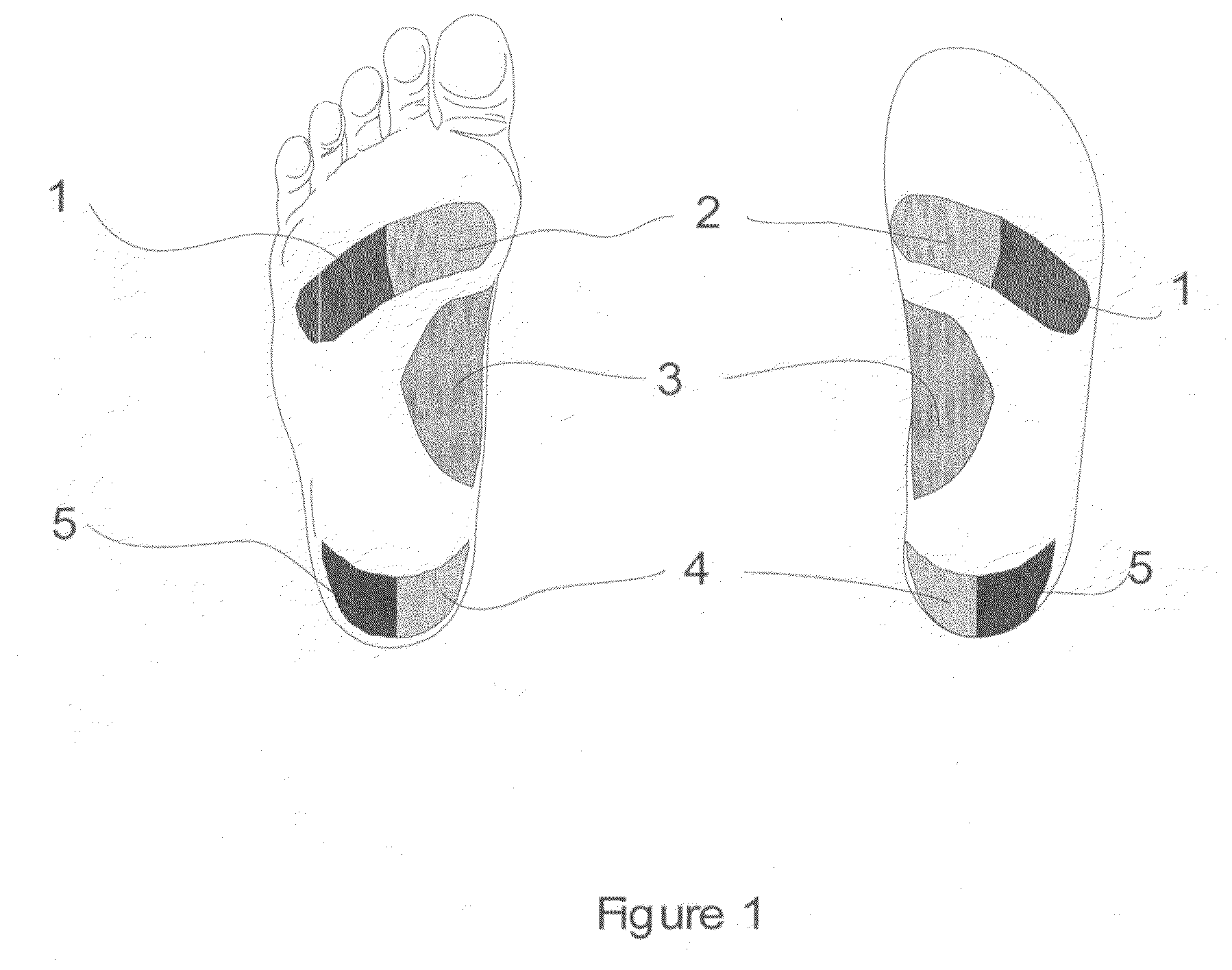

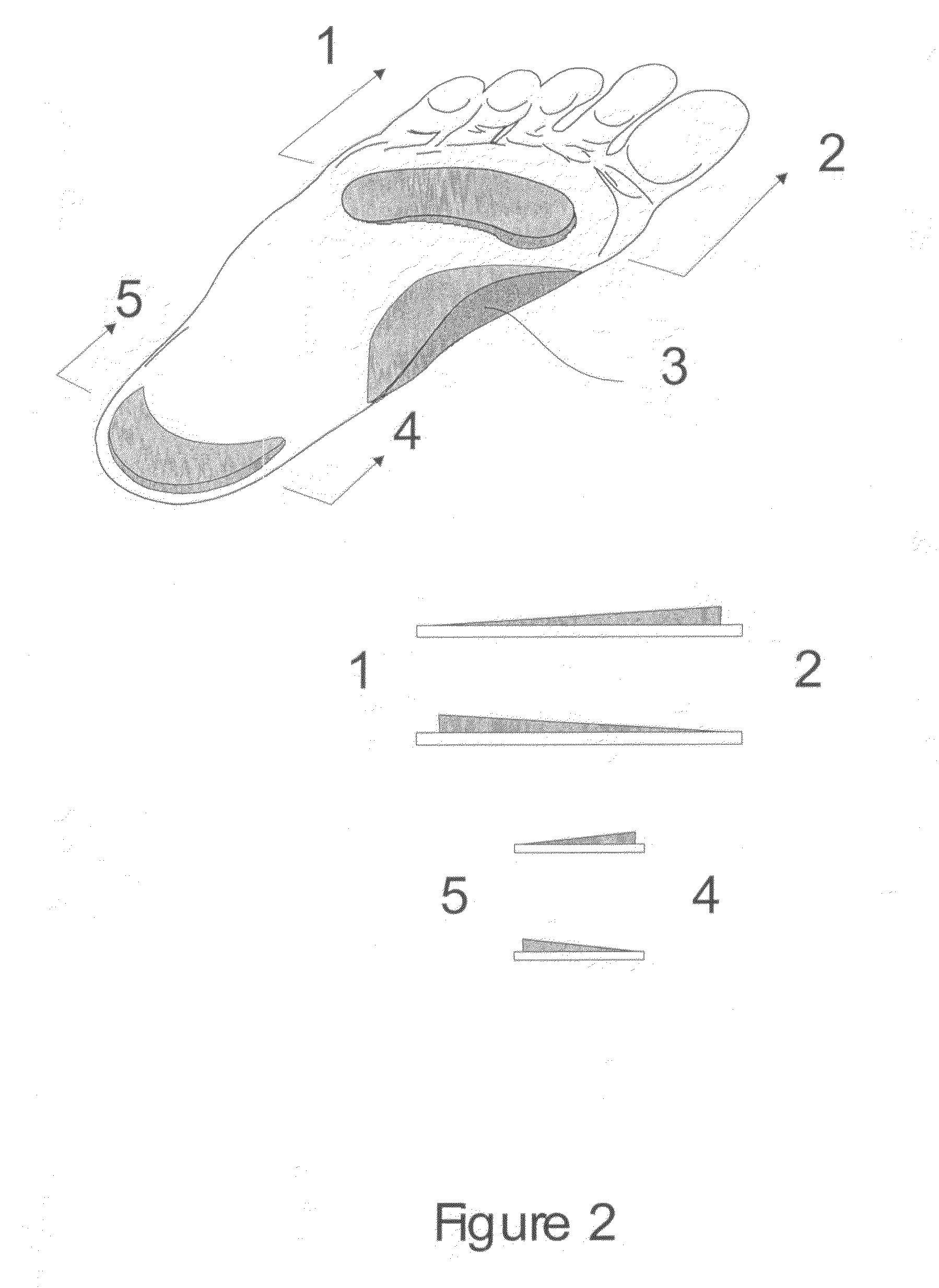

Adjustable pneumatic cell foot orthosis

InactiveUS20080229611A1Readily and inexpensivelyPrevent wrong actionSolesInsolesEngineeringFoot orthosis

A device that can be inserted into footwear, or used as part of footwear that is designed to correct foot and ankle pathologies through user adjustable, strategically located fluid chamber or chambers.

Owner:CHIODO CHRISTOPHER P +3

Device for testing deflagrability of condensed fire detonator under condition of high termerature and high pressure

InactiveCN1873411AAccurate and reliable ignitionSimple structureChemical analysis using combustionFuel testingDetonatorEngineering

The invention relates to a high temperature high pressure environment condensation explosive deflagrability testing device that includes testing canister, testing column, flame igniter and flame igniter end plate. The device also includes pressure adjusting jar and pressure adjusting end plate, the pressure adjusting piston. Several testing holes are set on the side wall of testing canister. Exhaust line, charging pipeline, pressure sensor and a group of speed sensor are inserted into the testing hole. The invention is simple structure, and the temperature and pressure is adjustable. It could reliably and accurately test the ignition for explosive in high temperature and high pressure environment.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI +1

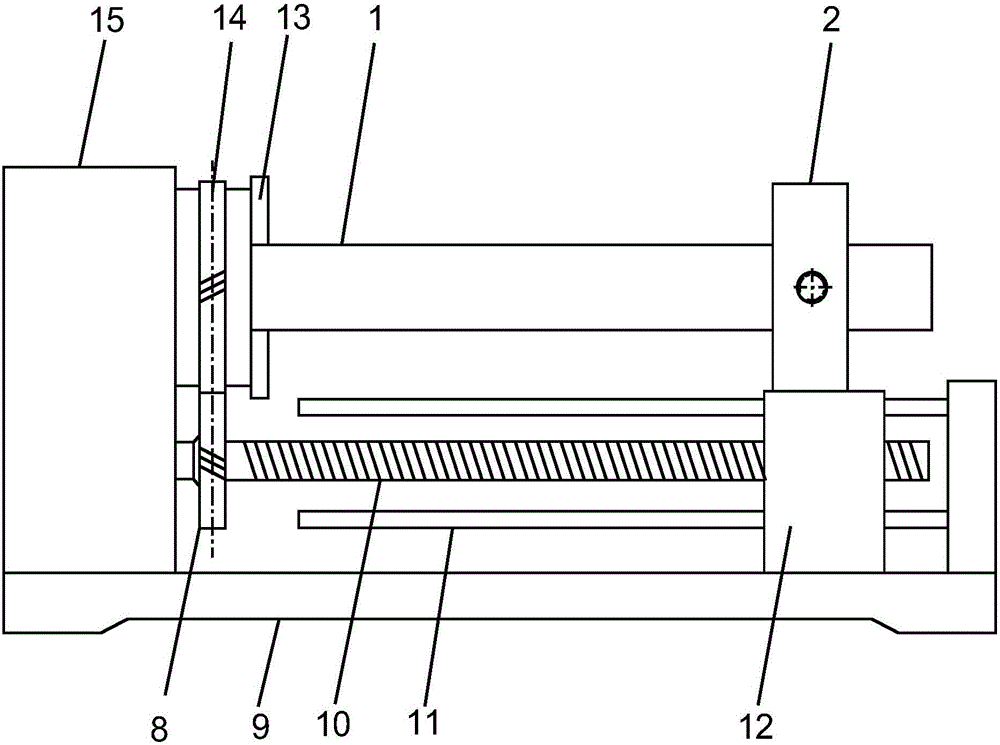

Oil drill rod circumferential surface rust removing device

ActiveCN106363510AQuick installationAdjustable pressureGrinding carriagesRevolution surface grinding machinesScrew threadPetroleum

The invention discloses an oil drill rod circumferential surface dust removing device which comprises a machine frame, a power box, a three-jaw chuck and an annular plate. Holding plates are arranged in the annular plate. The holding plates are three arc plates which are formed after the whole annular plate is equally divided into three parts. The inner surface of each holding plate is provided with polishing abrasive paper. The middle of the outer surface of each holding plate is connected with a sliding block in a welded mode. The annular plates are provided with three equally-divided cylindrical holes. The sliding blocks are arranged in the cylindrical holes. Bosses are fixedly arranged outside the cylindrical holes. First thread holes are formed in the bosses. Bolts are arranged in the first thread holes. The annular plates are fixed to a sliding base in a welded mode. The sliding base is arranged on the machine frame and can move on the machine frame in parallel. The sliding base is provided with a second thread hole. A screw rod is arranged in the second thread hole. A screw rod is arranged in the second thread hole. A gear is connected to the left end of the screw rod. The outer circumference of the three-jaw chuck is provided with an annular rack. The rack is engaged with the gear. According to the oil drill rod circumferential surface dust removing device, the polishing strength can be adjusted, it is ensured that dust on the surface of a drill rod is thoroughly removed, and the efficiency is higher.

Owner:江苏省德诚测控设备有限公司 +1

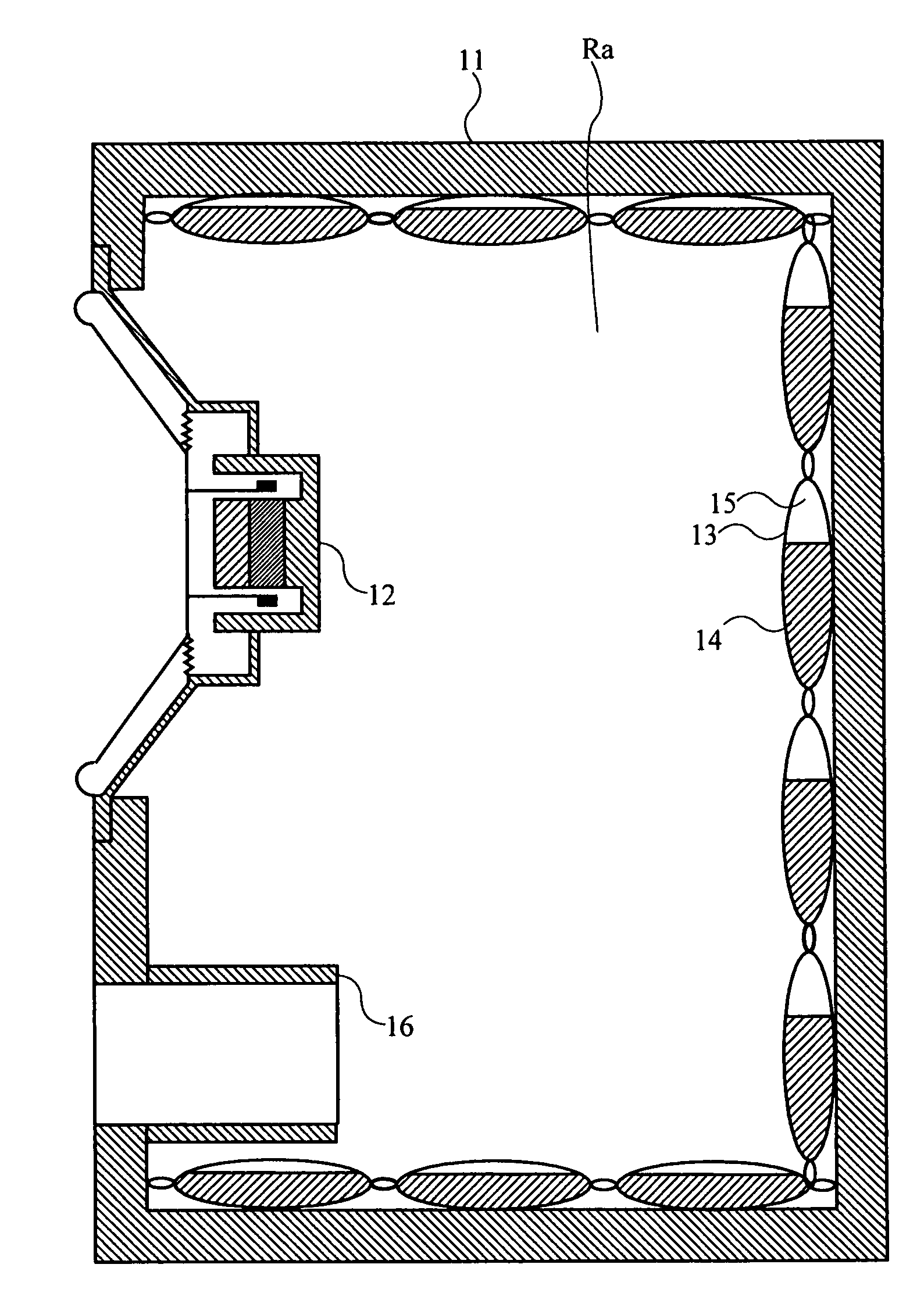

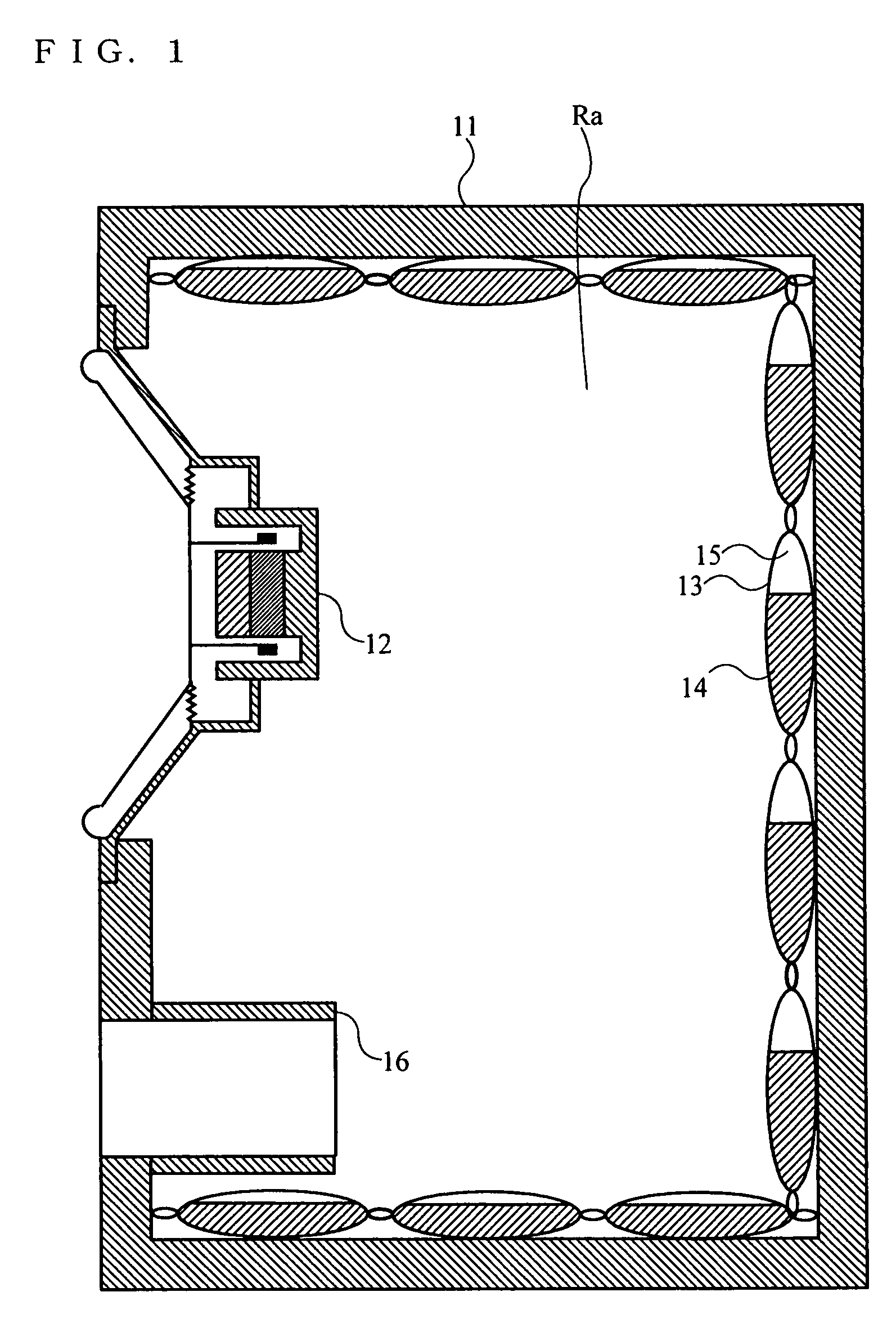

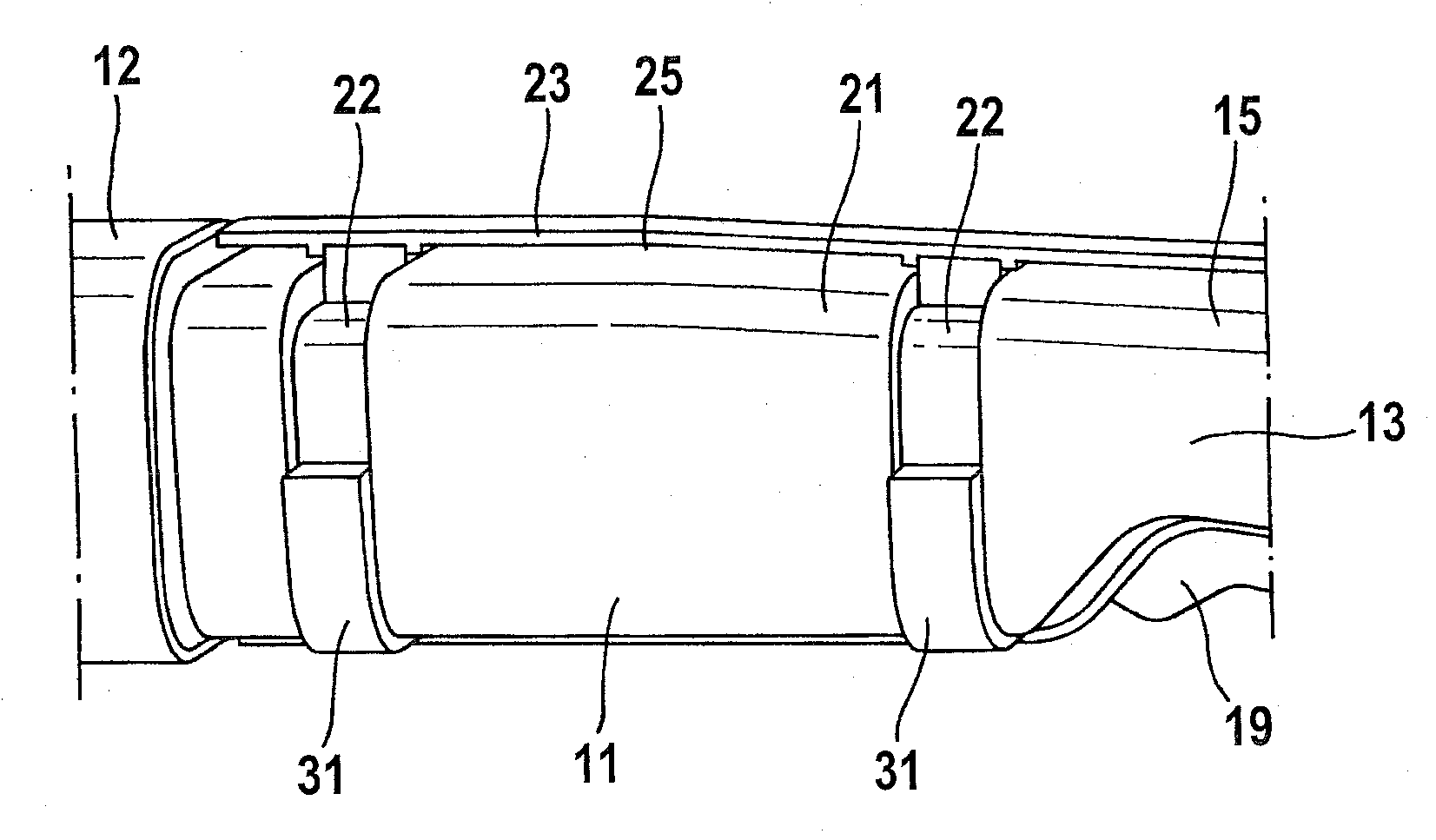

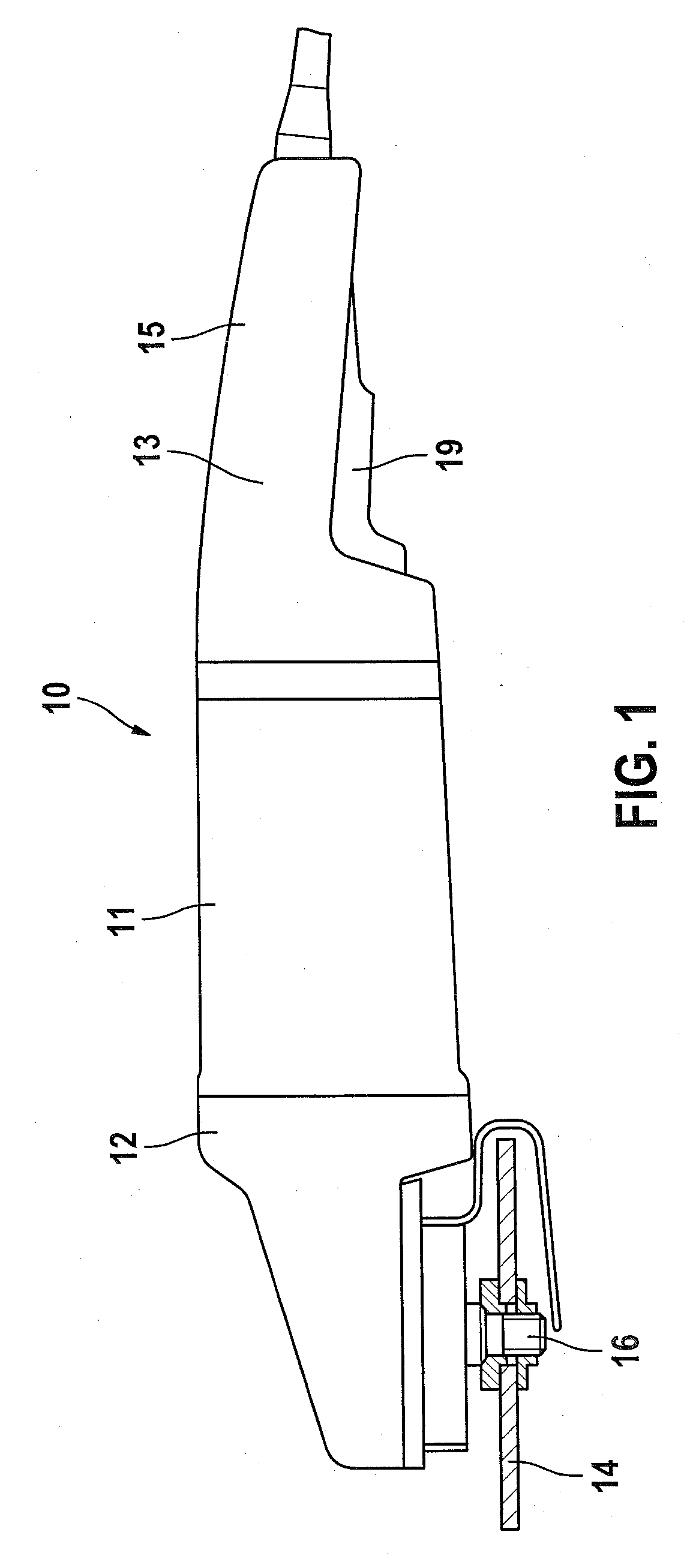

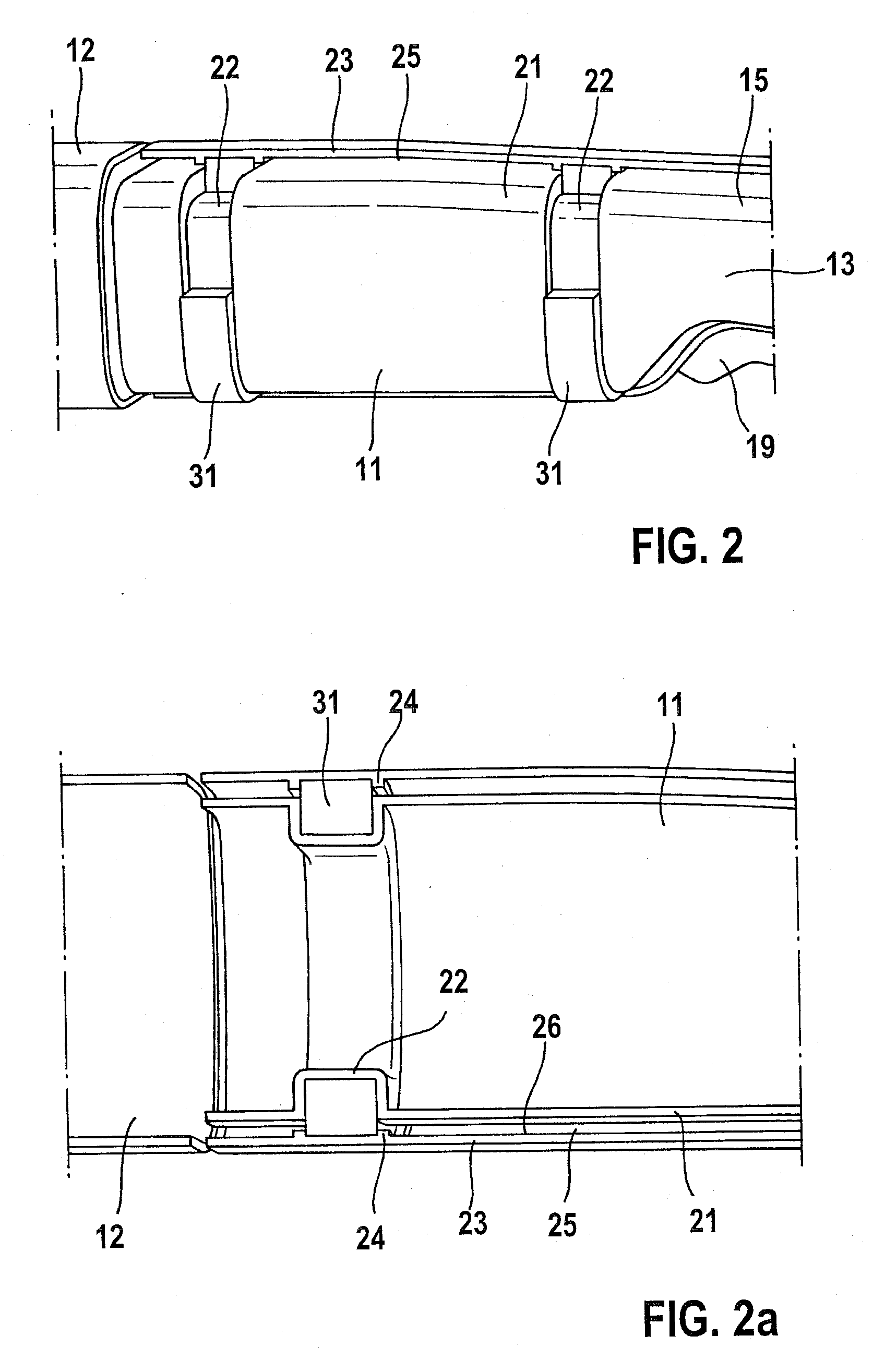

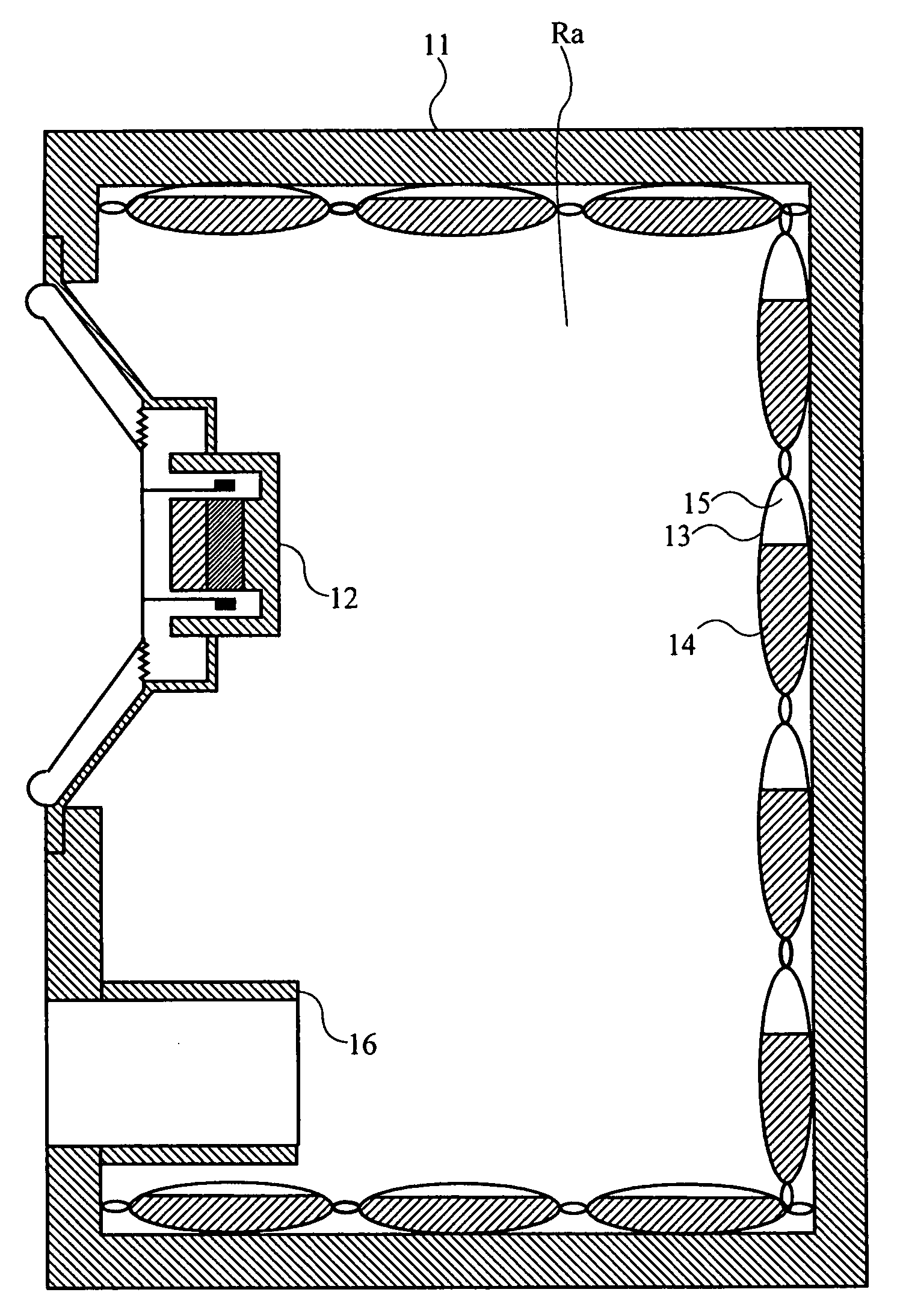

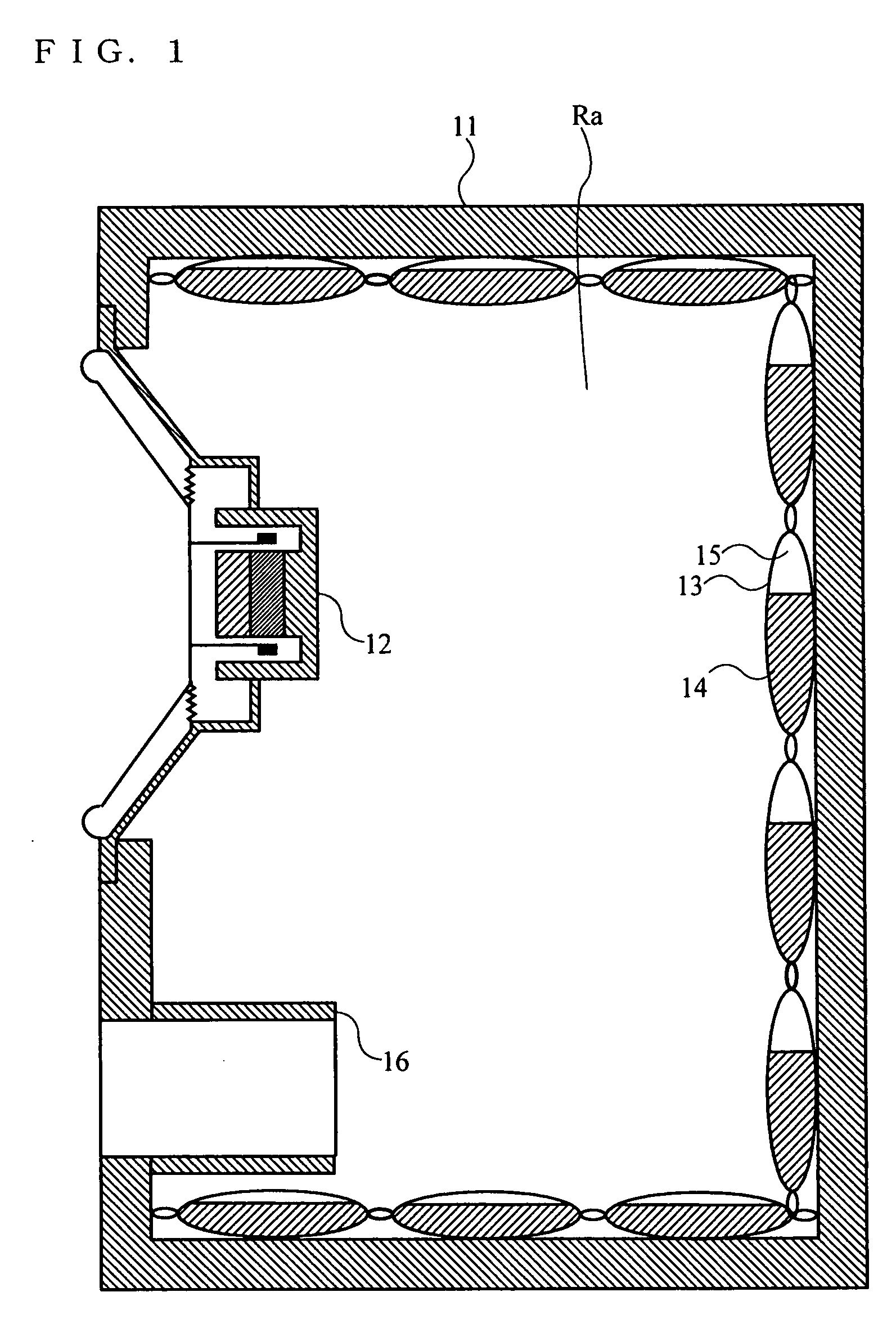

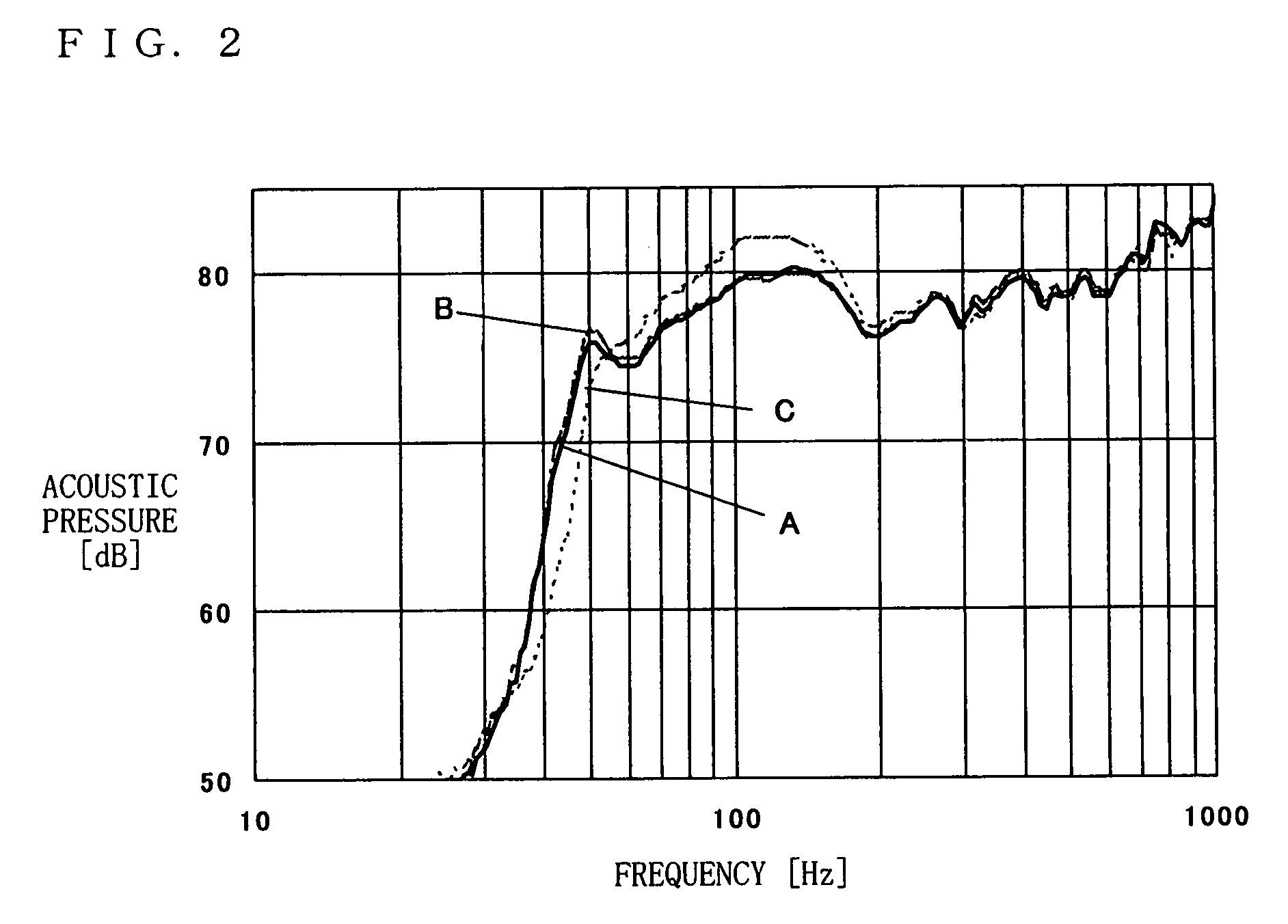

Loudspeaker System

ActiveUS20070286449A1Improve performanceAdjustable pressureSubstation equipmentFrequency/directions obtaining arrangementsEngineeringLoudspeaker

A loudspeaker system comprises a cabinet (11), a speaker unit (12), a package body (13), a filler gas (15), and an absorbent (14). The speaker unit (12) is mounted in the cabinet (11). At least one package body (13) is disposed in a vacant space (Ra) inside of the cabinet (11) and is structured by a bag body for sealing materials thereinto from outside thereof. A predetermined amount of the filler gas (15) is sealed into the package body (13). A predetermined amount of the absorbent (14) is sealed into the package body (13) and physically absorbs the filler gas (15).

Owner:PANASONIC CORP

Board splicing machine

The invention discloses a board splicing machine. The board splicing machine comprises a machine frame and a board conveying device installed on the machine frame, wherein the board conveying device comprises a bottom board conveying belt for conveying bottom boards forwards, and a side board conveying groove formed in one side of the bottom board conveying belt, and one side, close to the bottom board conveying belt, of the front end of the side board conveying groove is provided with a side board outlet; a gluing device is arranged beside the inlet end of the bottom board conveying belt; an aligning device corresponding to the side board outlet is arranged in front of the side board outlet, and an induction device corresponding to the aligning device and inducting the positions of the bottom boards is further installed on the portion, beside the bottom board conveying belt, of the machine frame; a nail gun is arranged between the side board outlet and the aligning device; the board conveying device, the aligning device and the nail gun are further connected with a control device, and the input end of the control device is connected with the induction device; a pressing and connecting device for pressing and airing the bottom boards and side boards is arranged in front of the outlet end of the bottom board conveying belt. The board splicing machine is reasonable in structure and convenient to use, the machining efficiency can be substantially improved, consumption of wood can be reduced, and cost can be saved.

Owner:河北简工科技有限公司

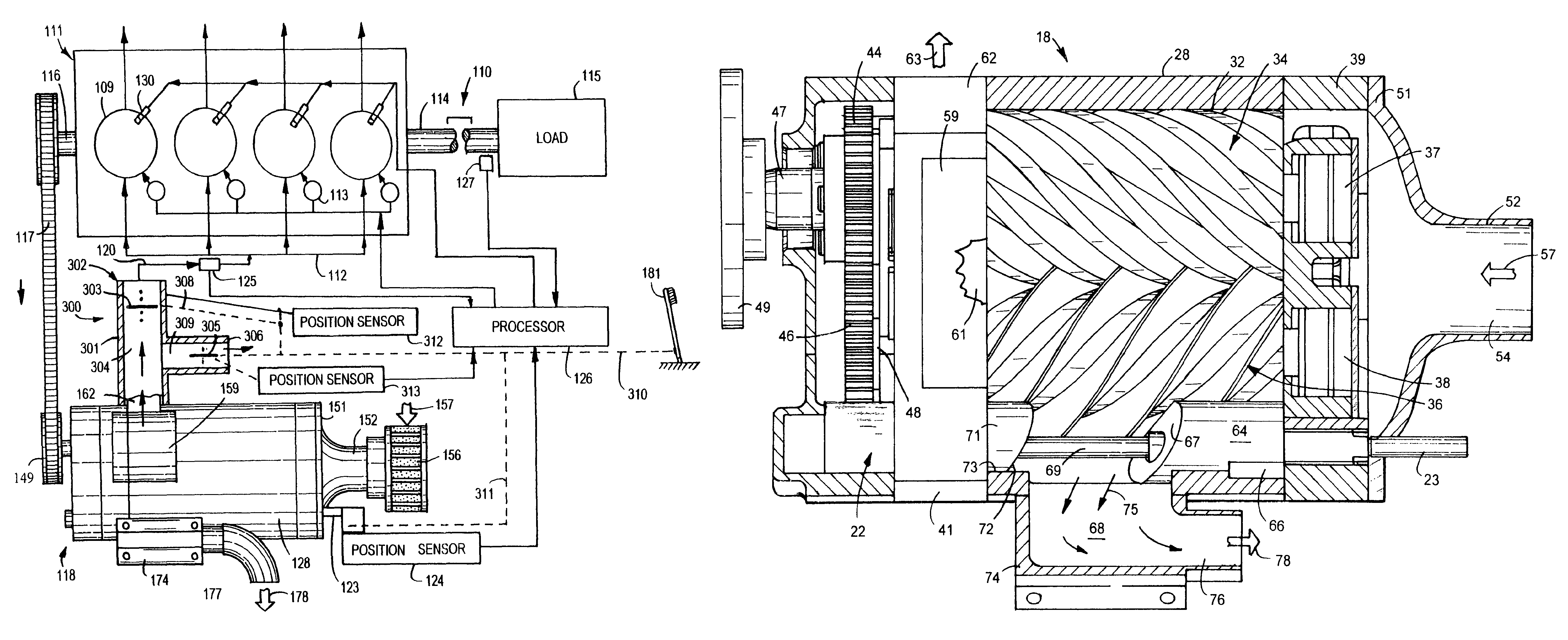

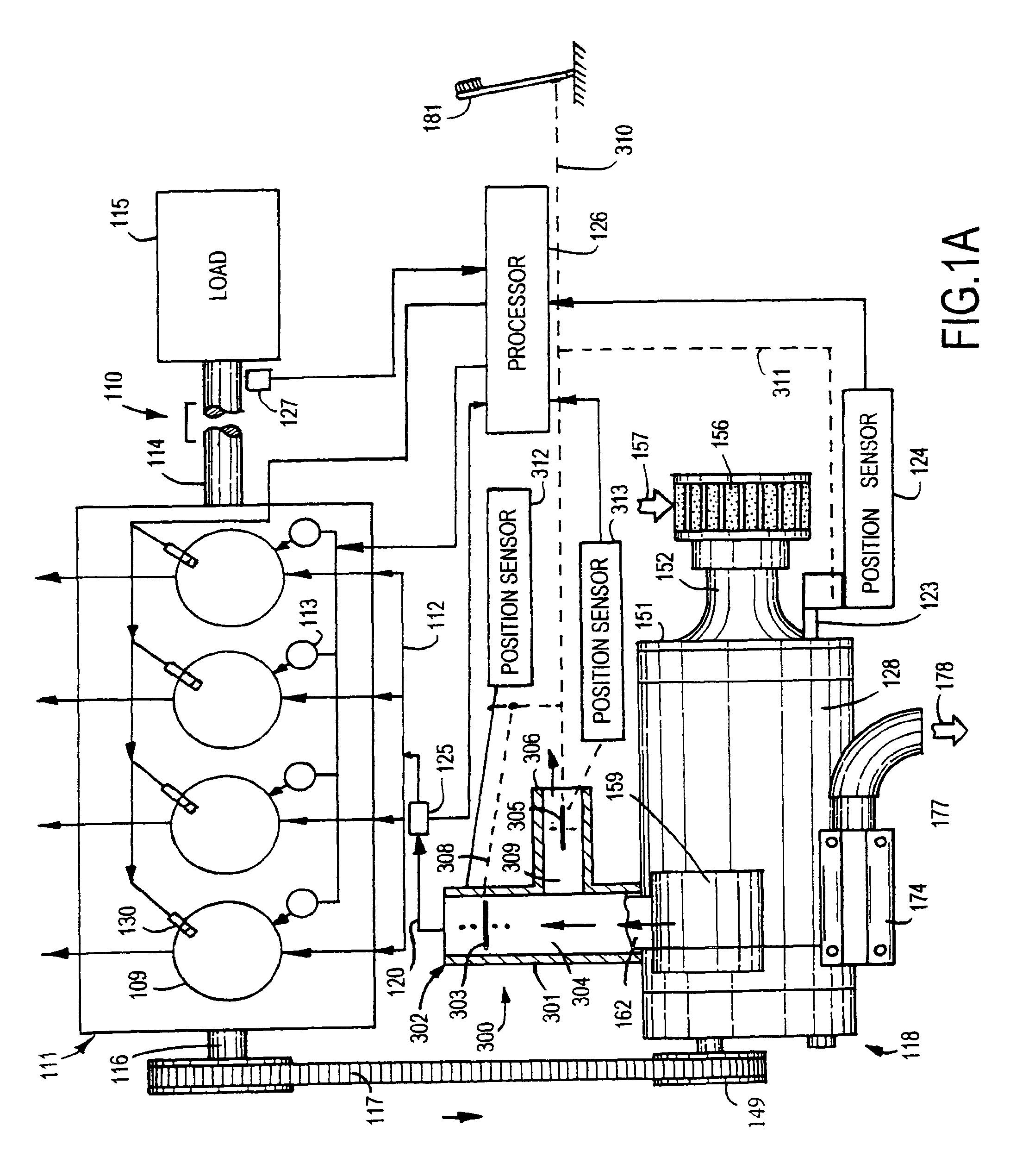

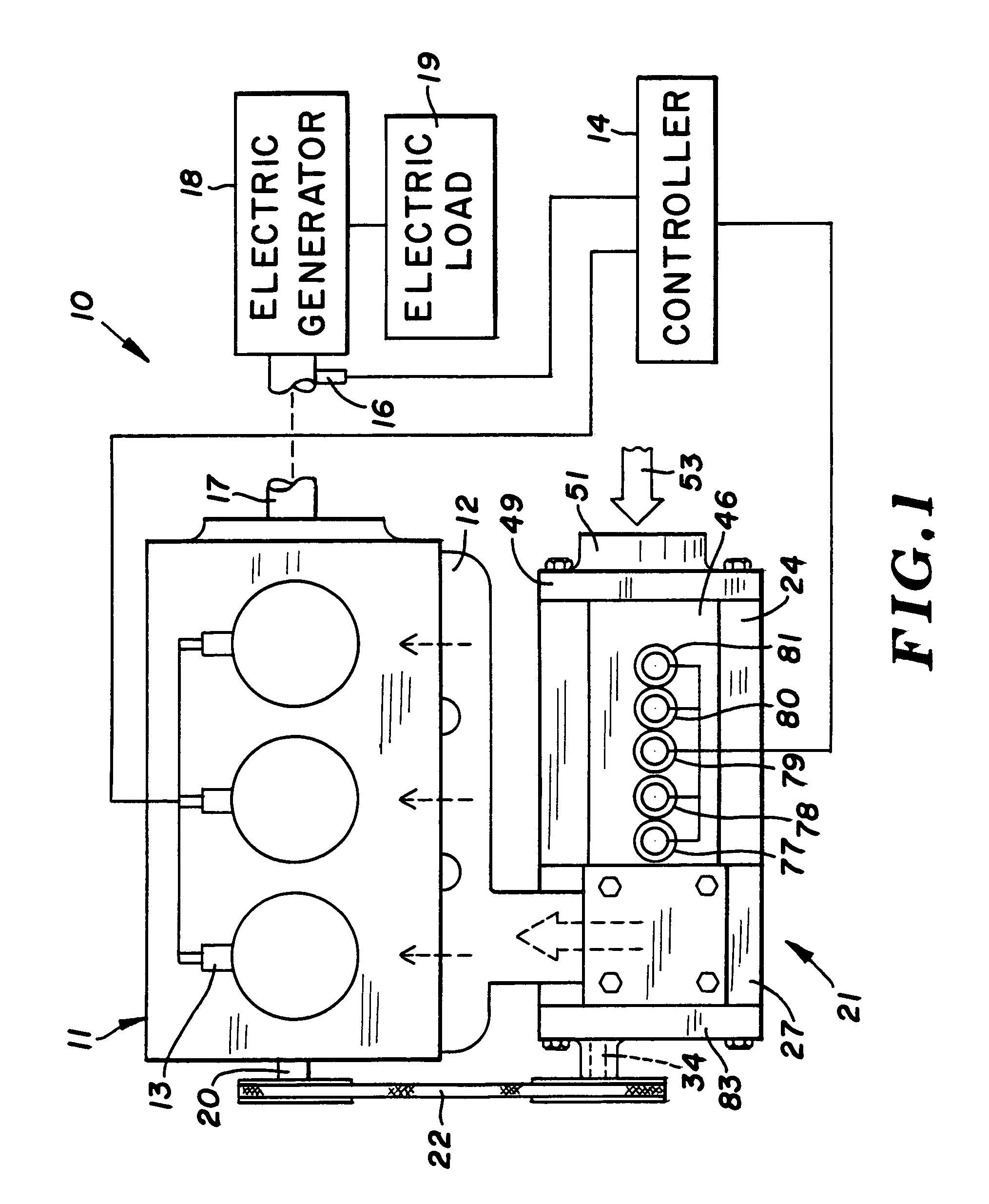

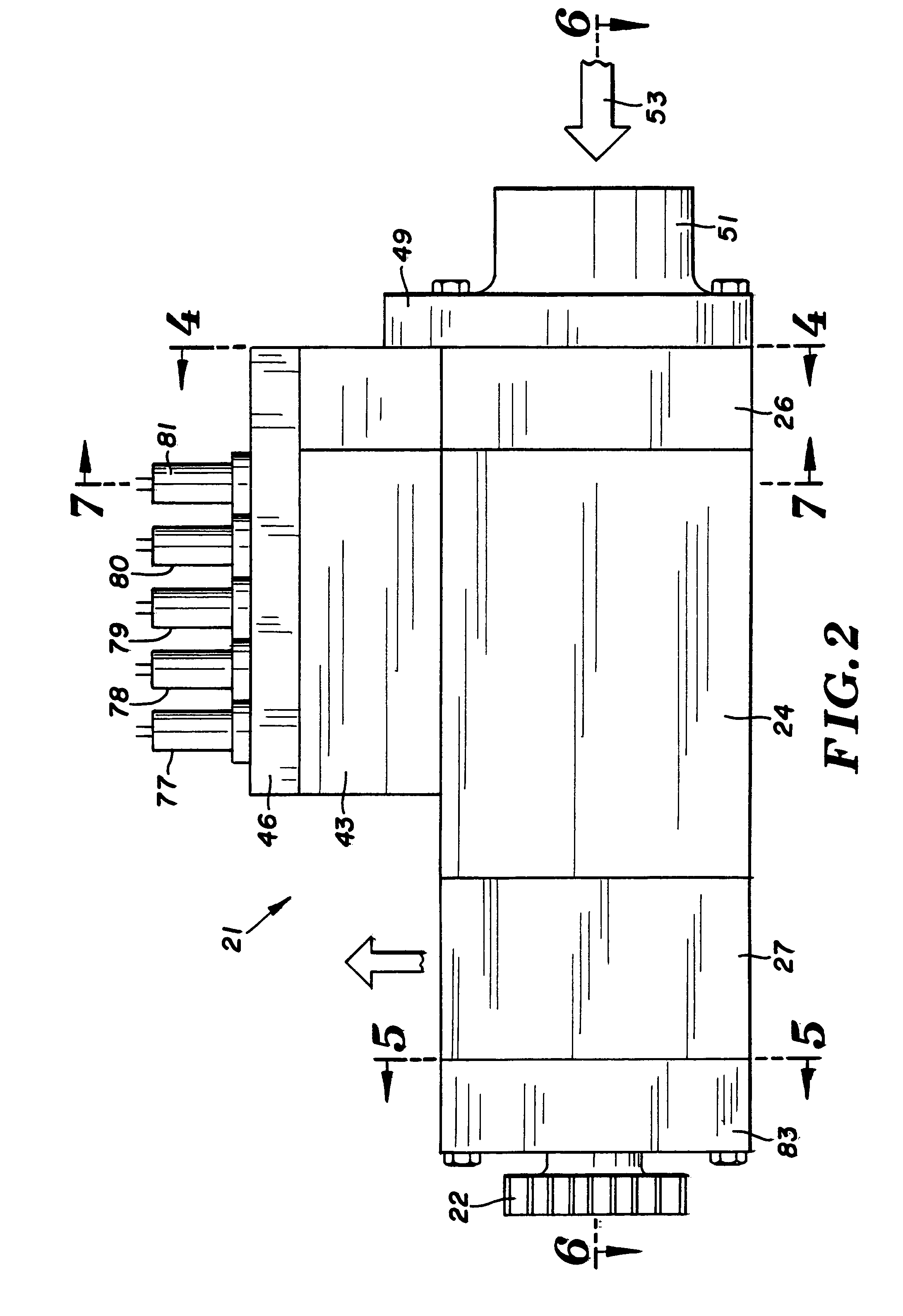

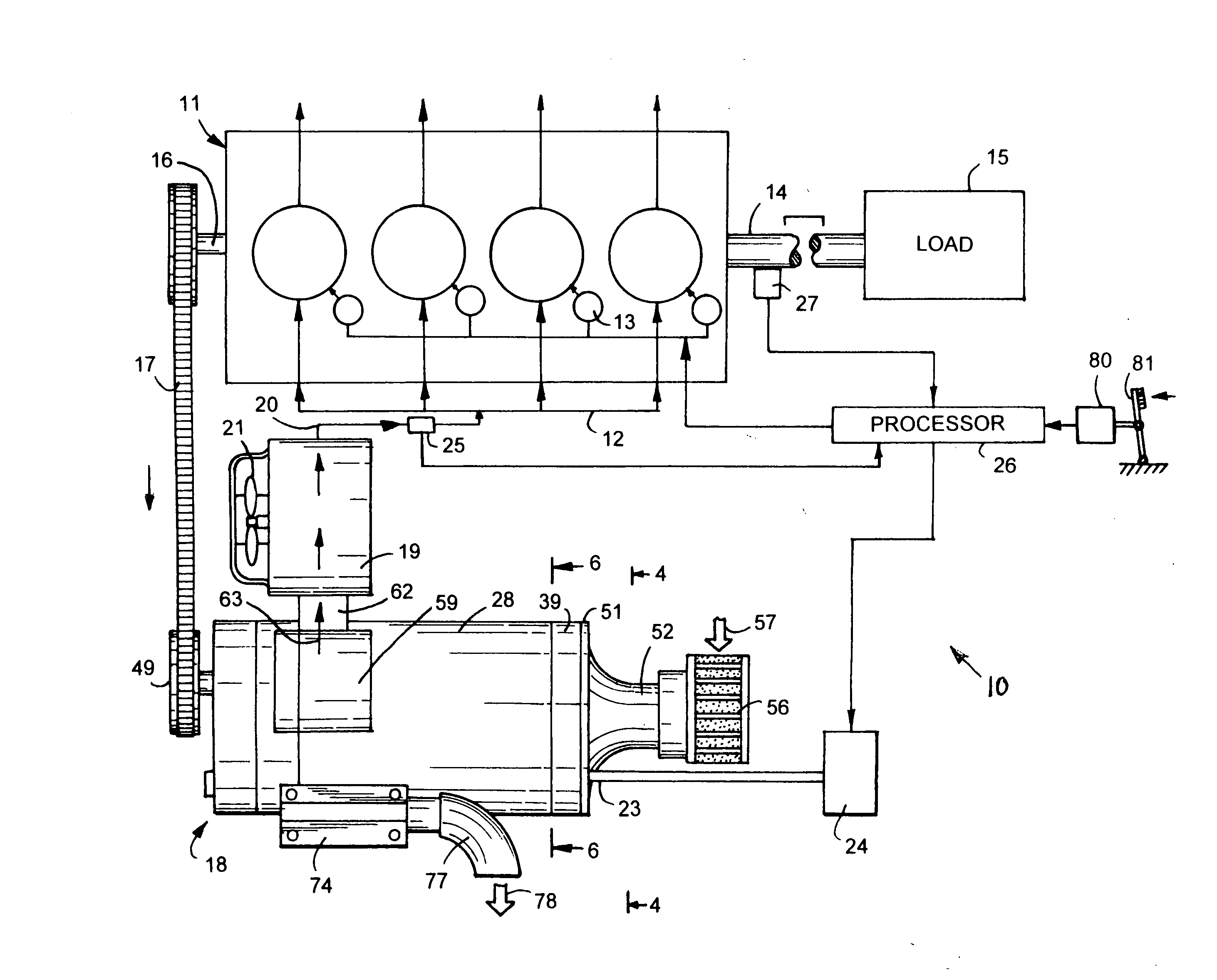

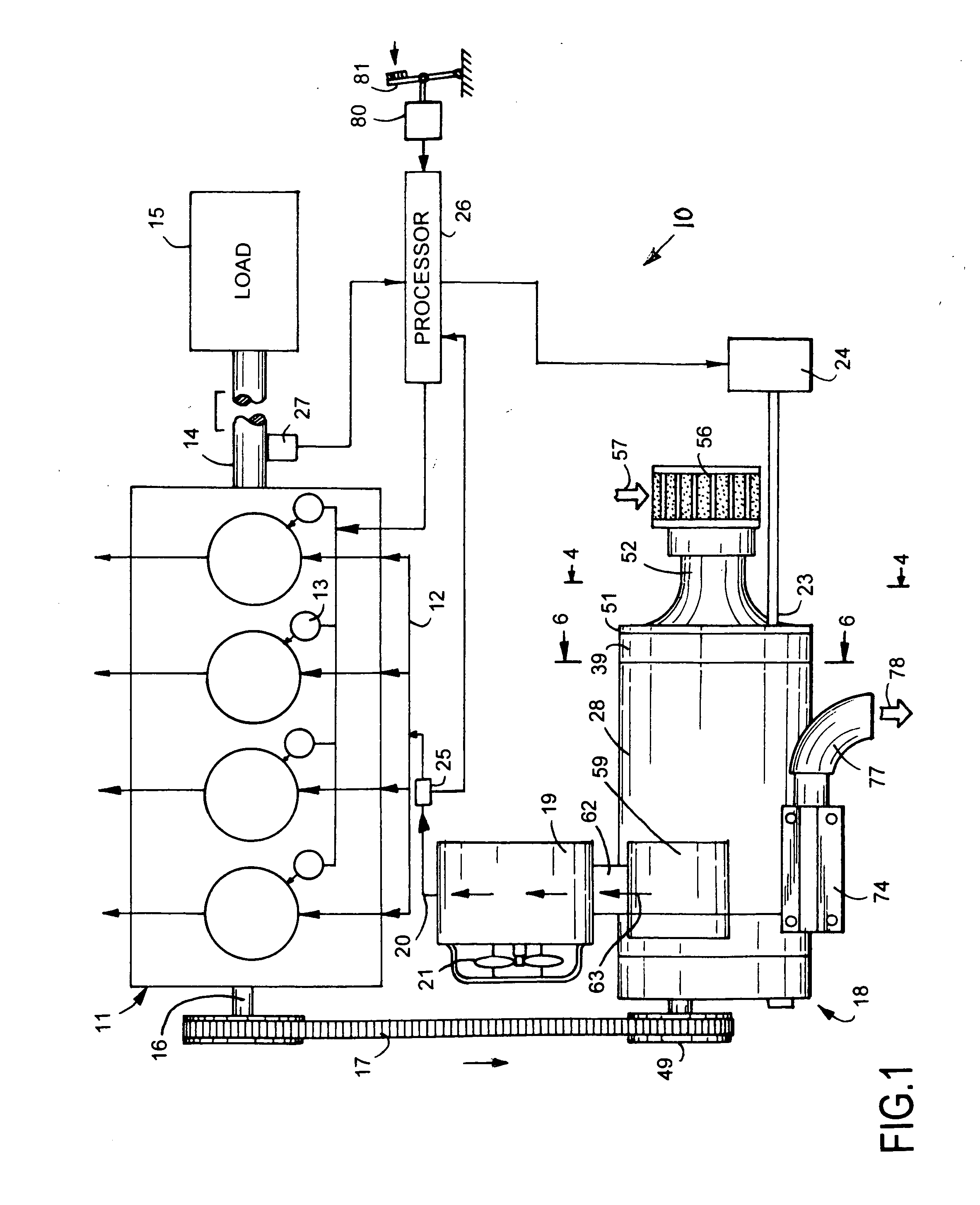

Internal combustion engine and supercharger

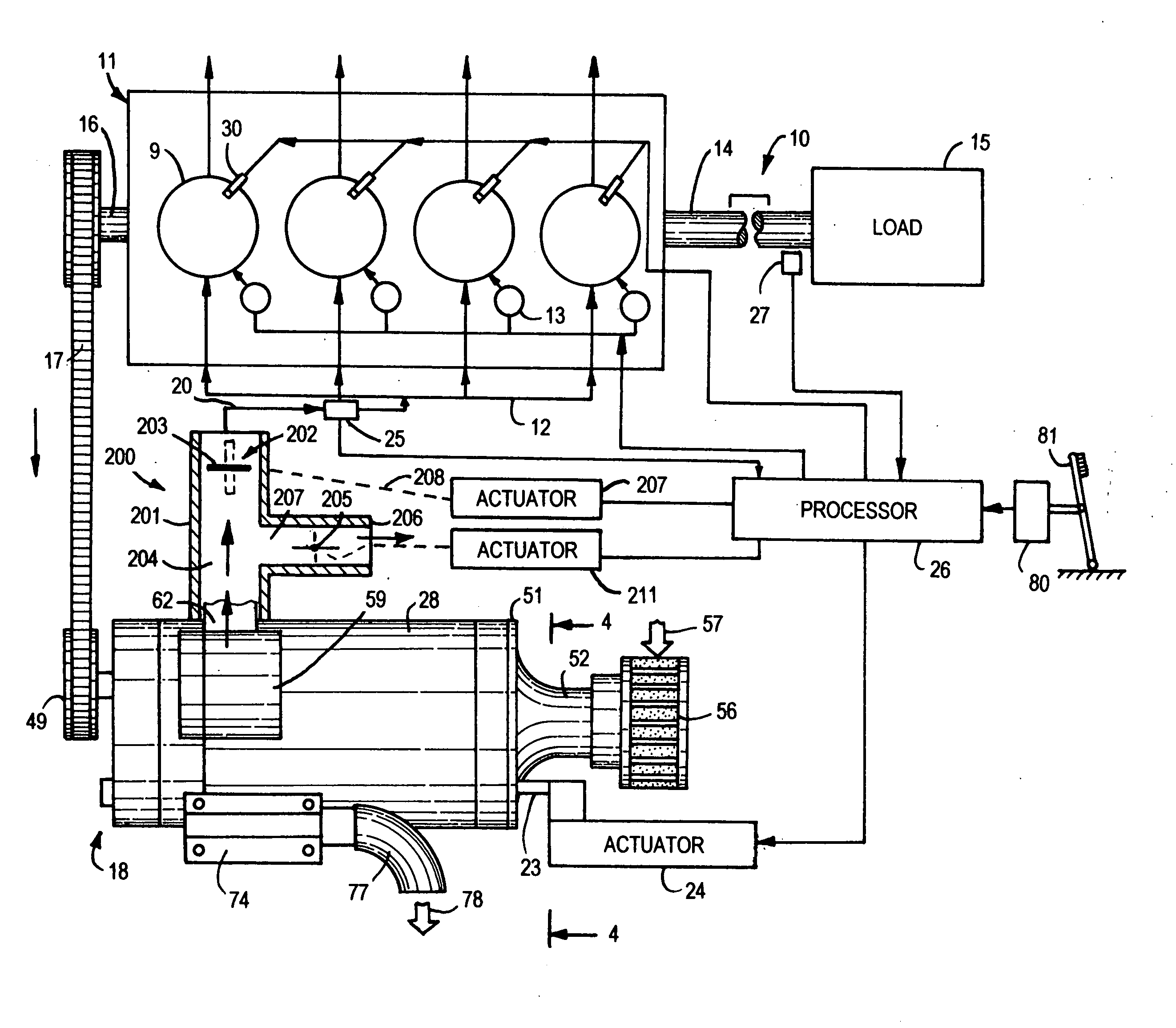

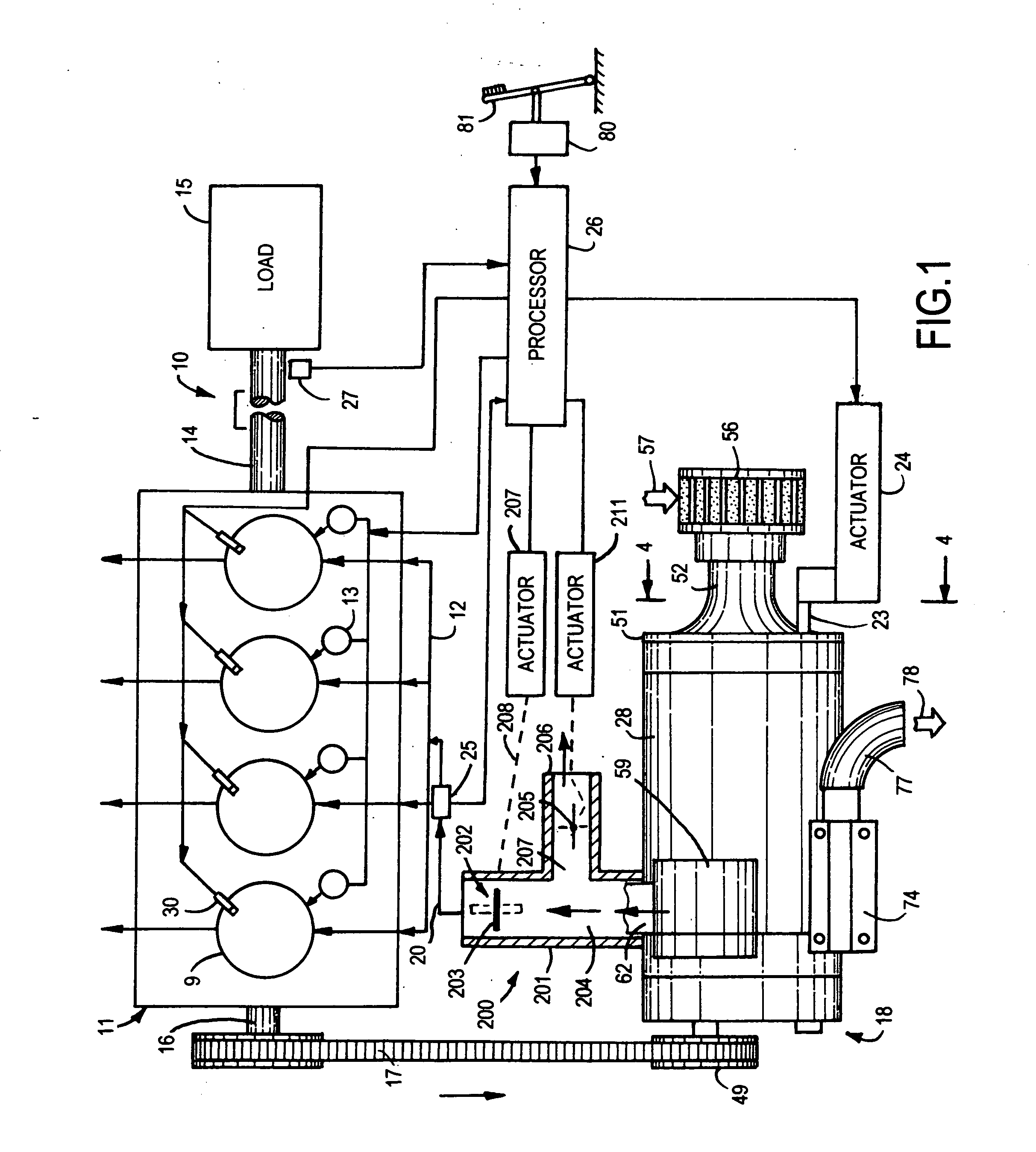

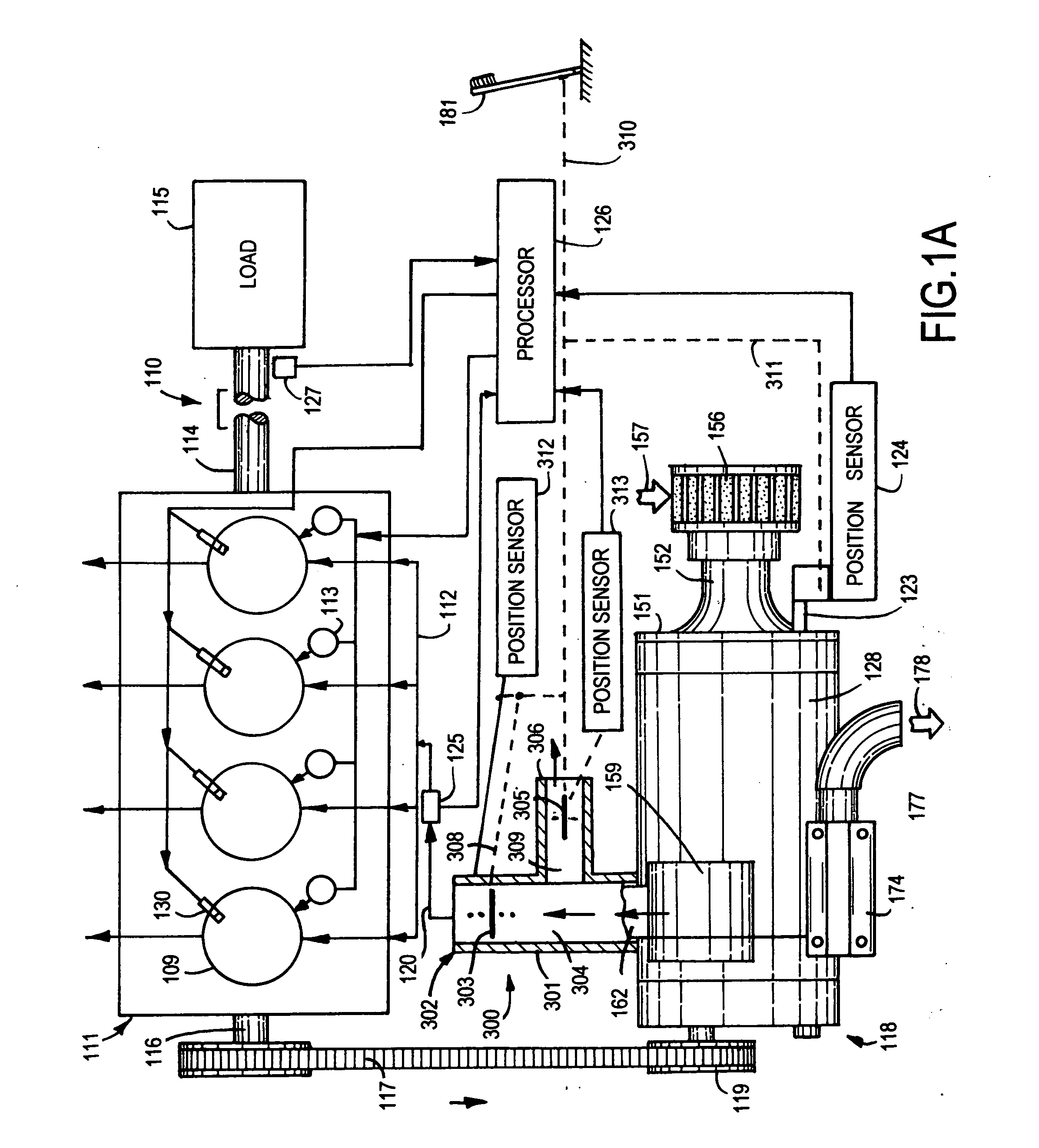

ActiveUS8539769B2Reduce the temperatureImprove power to weight ratioElectrical controlInternal combustion piston enginesAtmospheric airAtmospheric pressure

An internal combustion engine drivably connected to a variable displacement and variable internal compression ratio supercharger that supplies varying amounts of air to the engine air intake manifold that can range selectively from below through above atmospheric pressures responsive to the power requirements of the engine. The supercharger has a pair of rotors concurrently driven by the engine to move air to the engine. A slide assembly associated with screw rotors is movable with a controller relative to the rotors to bypass air to atmosphere and regulate the amount of air and pressure of the air above atmospheric pressure compressed by the screw rotors to the engine to increase the engine's efficiency. When operating at part-load unboosted, a throttle valve is operable to control the air mass flowing to the air intake manifold below atmospheric pressure to control the power of the engine.

Owner:HANSEN ENGINE

Internal combustion engine and supercharger

ActiveUS20110083647A1Efficient supplyImprove power to weight ratioElectrical controlInternal combustion piston enginesAtmospheric airEngineering

An internal combustion engine drivably connected to a variable displacement and variable internal compression ratio supercharger that supplies varying amounts of air to the engine air intake manifold that can range selectively from below through above atmospheric pressures responsive to the power requirements of the engine. The supercharger has a pair of rotors concurrently driven by the engine to move air to the engine. A slide assembly associated with screw rotors is movable with a controller relative to the rotors to bypass air to atmosphere and regulate the amount of air and pressure of the air above atmospheric pressure compressed by the screw rotors to the engine to increase the engine's efficiency. When operating at part-load unboosted, a throttle valve is operable to control the air mass flowing to the air intake manifold below atmospheric pressure to control the power of the engine.

Owner:HANSEN ENGINE

Diesel engine and supercharger

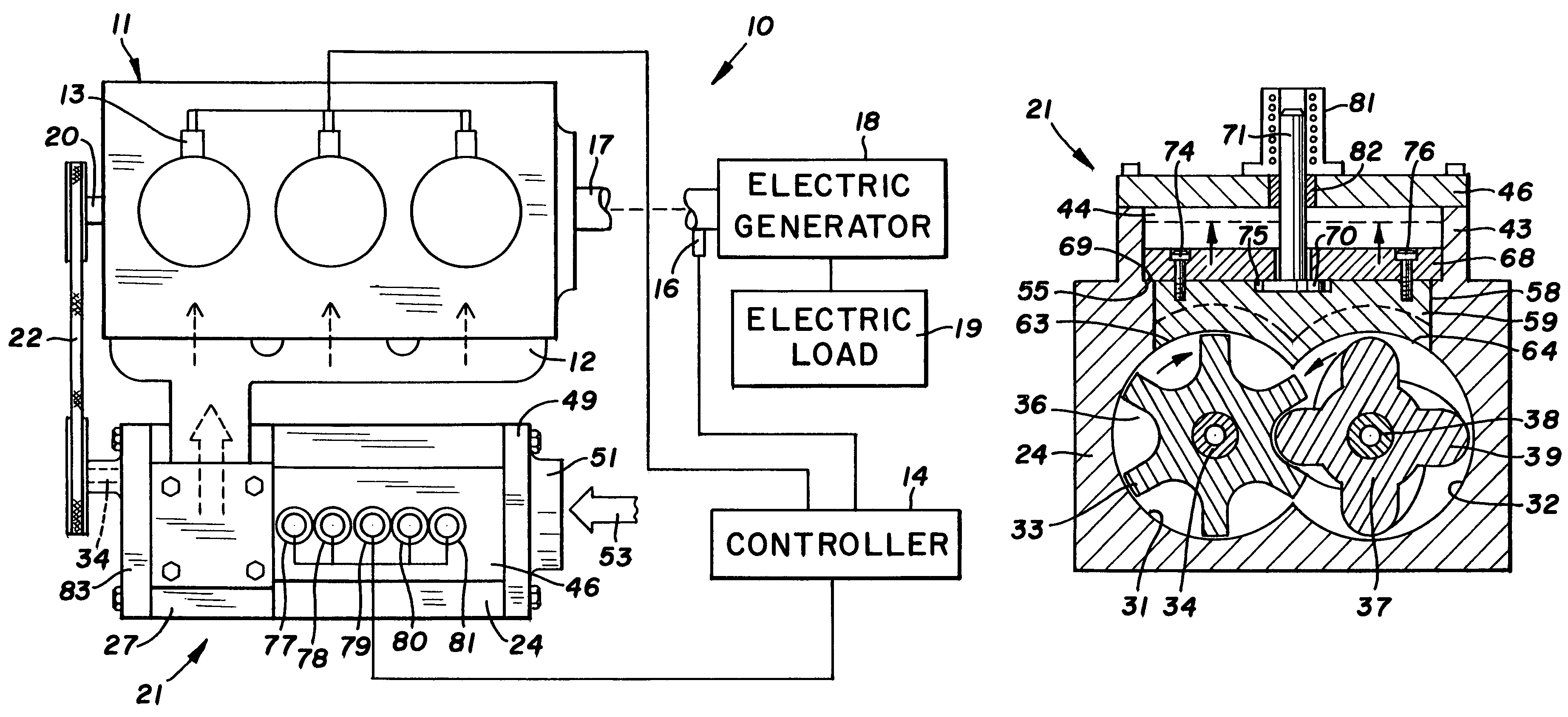

InactiveUS7726285B1Facilitate cold startingLow parasitic lossRotary/oscillating piston combinations for elastic fluidsElectrical controlTwo-stroke diesel engineDiesel engine

A four stroke diesel engine combined with a supercharger is operable to supply varying amounts of air to the engine responsive to the load on the engine. The supercharger has a pair of rotors driven by the engine operable to move air to the engine. Gates associated with the rotors control the amount of air and pressure of the air moved by the rotors to the diesel engine.

Owner:HANSEN ENGINE

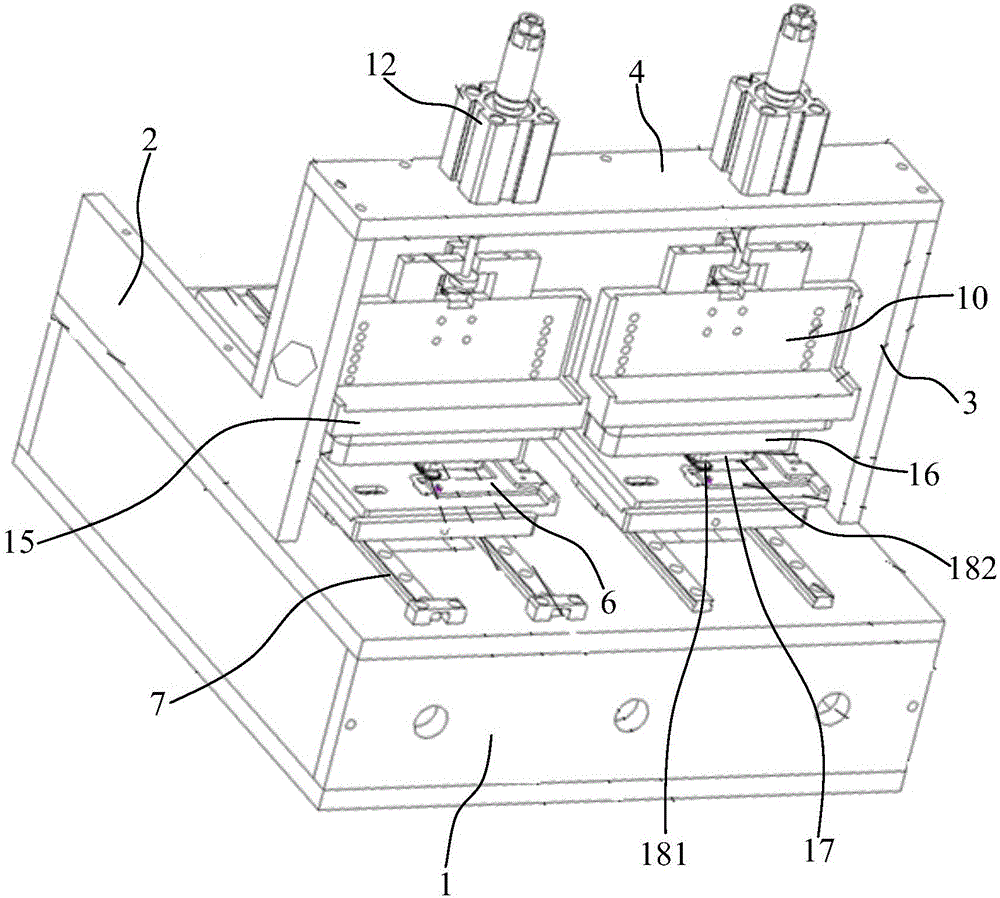

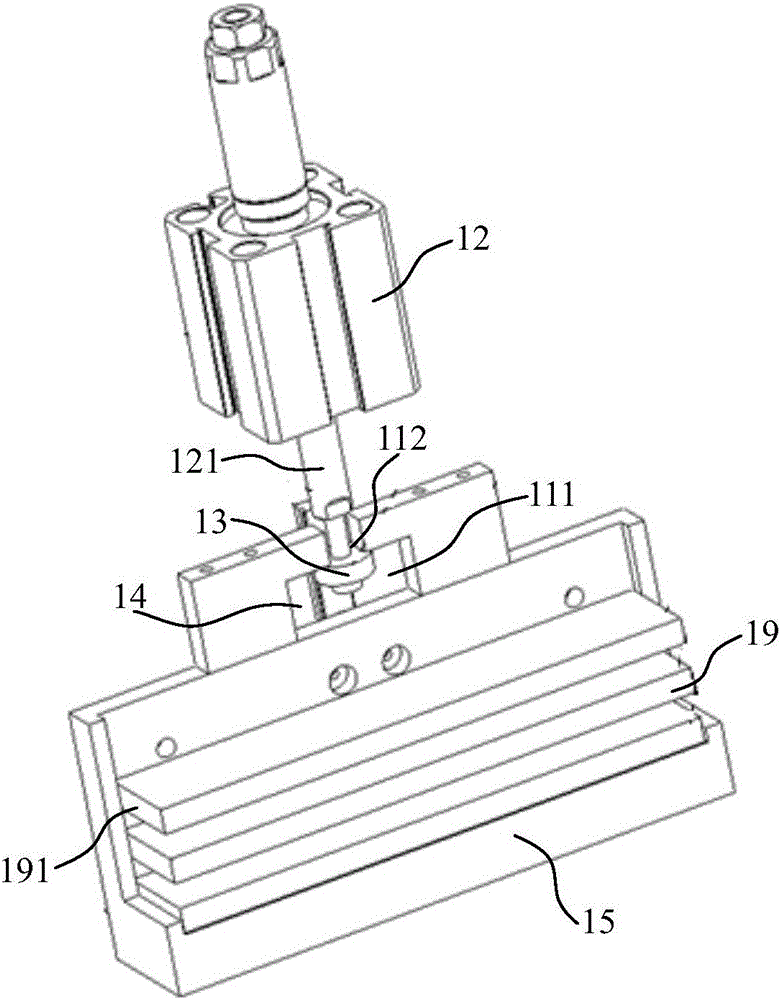

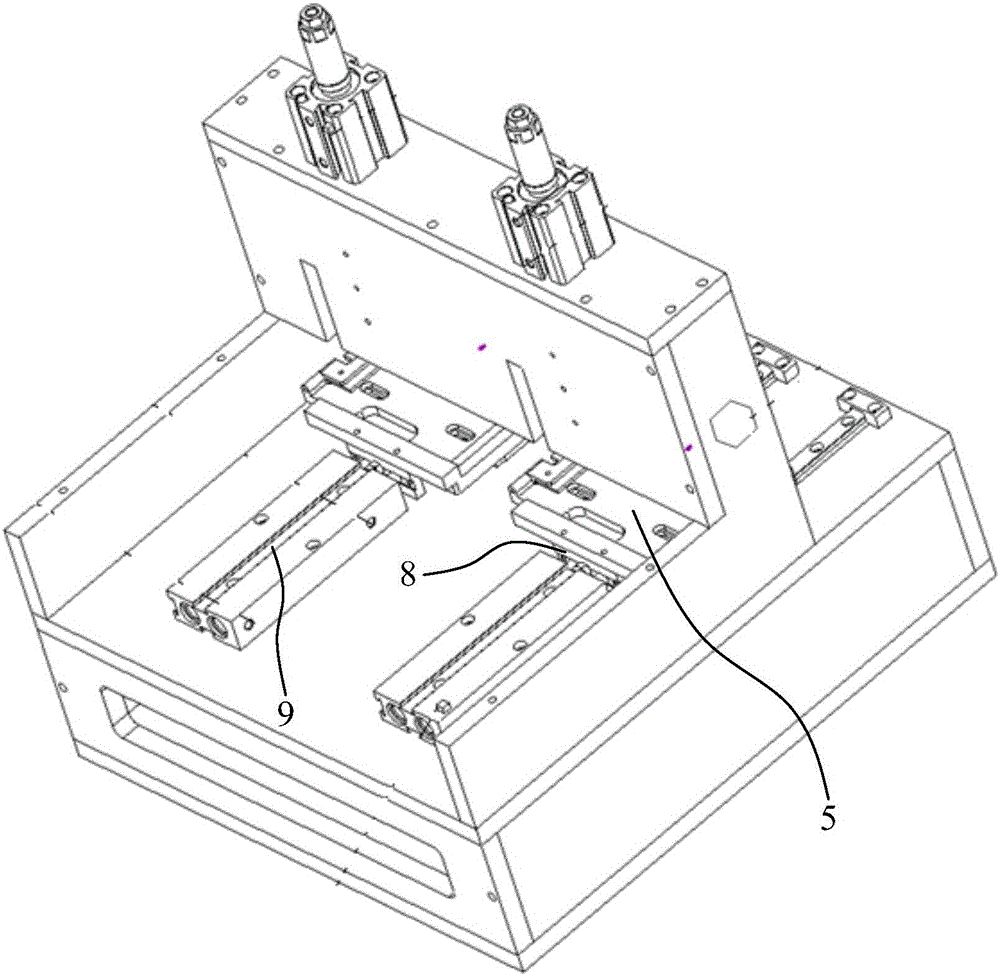

High-reliability pressure-adjusting automatic testing apparatus for fingerprint module group

InactiveCN105891626AImprove stabilityAdjustable pressureEnvironmental/reliability testsElectricityInverted-T shape

The invention discloses a high-reliability pressure-adjusting automatic testing apparatus for a fingerprint module group. The automatic testing apparatus comprises a pedestal, a left support plate, a right support plate, a horizontal bridge plate, at least one horizontal objective table and a switching board installed on the horizontal objective table. The horizontal bridge plate is fixed between the respective upper ends of the left support plate and the right support plate. At least one lifting plate is arranged between the horizontal bridge plate and the horizontal bridge plate; and an inverted-T-shaped through hole is formed in the upper end of the lifting plate and is formed by a penetrating connecting hole and a rectangular through hole. A hanging plate is installed on the front end surface of the lifting plate; a plastic cavity box is installed at the lower end surface of the hanging plate; and a left cylinder, a right cylinder, and a testing pressing head seta are arranged in the cavity of the plastic cavity box respectively; and a testing pressing head for detecting an electrical performance of the fingerprint module group is fixed at the testing pressing head. According to the invention, the force applied on a product force can be adjusted and controlled; and products for testing are diversified. After testing by multiple times, the testing apparatus with the pressure applying tool can have a stable testing result; and testing results are consistent.

Owner:JIANGSU A KERR BIOLOGICAL RECOGNITION TECH CO LTD

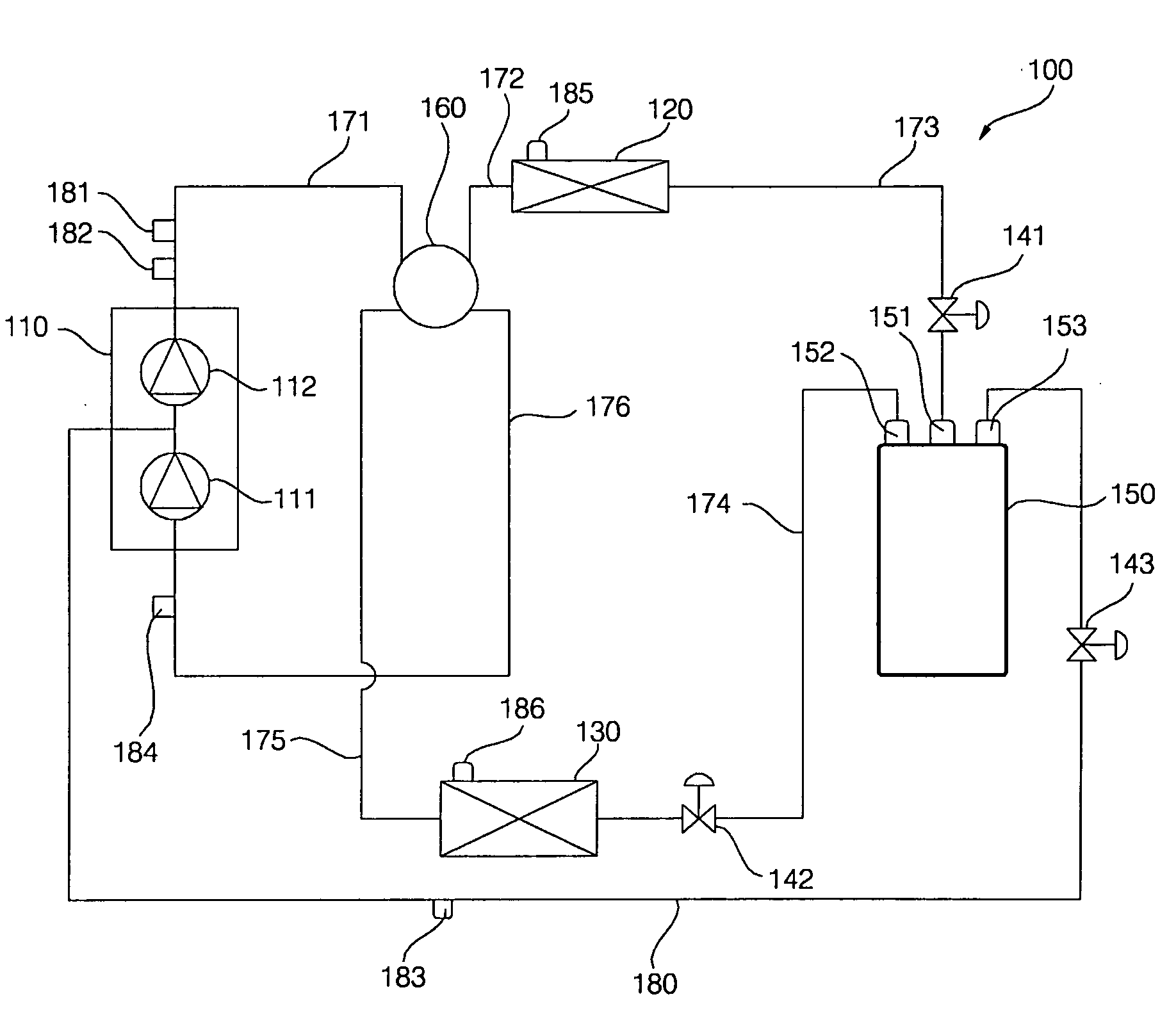

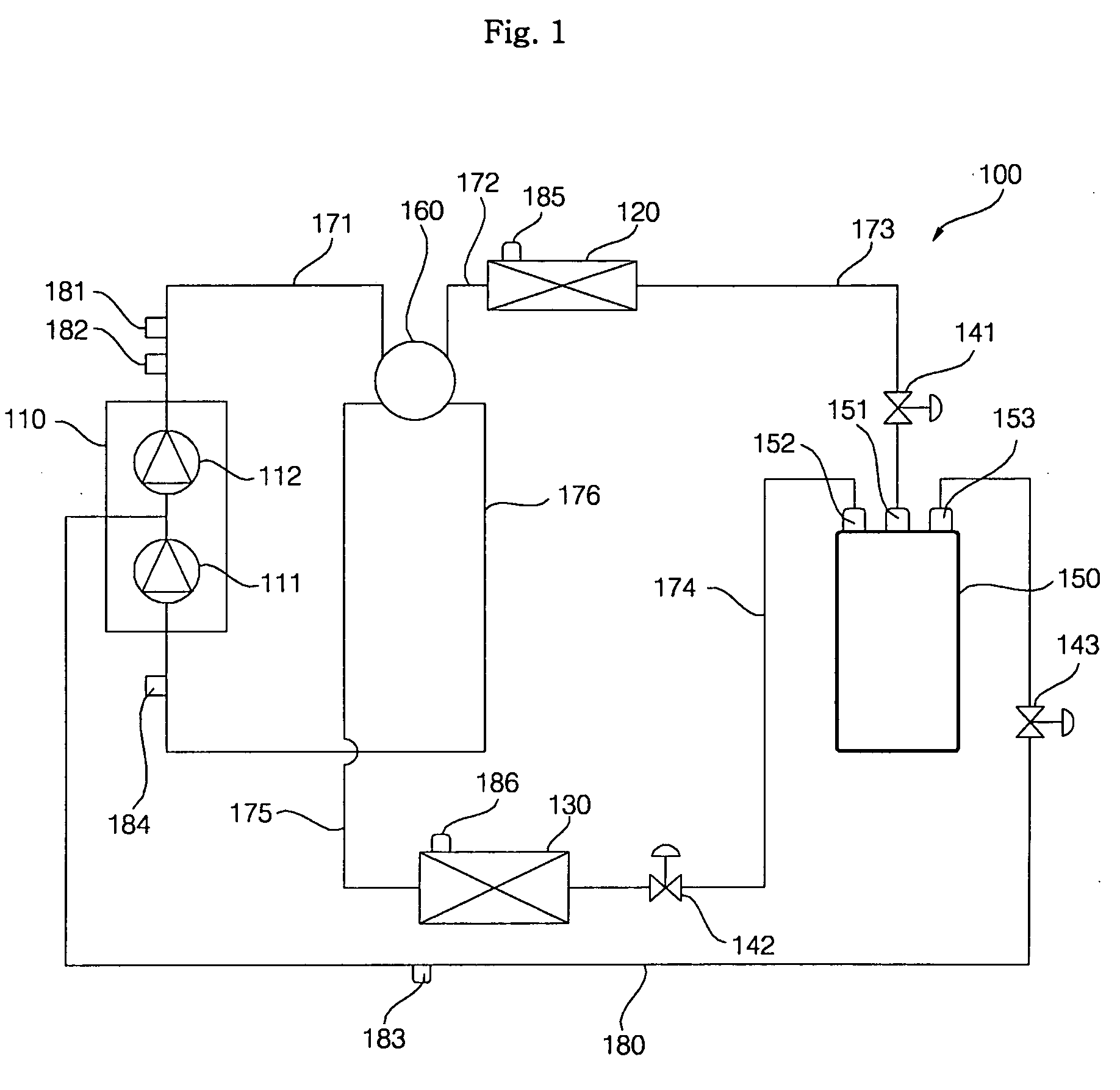

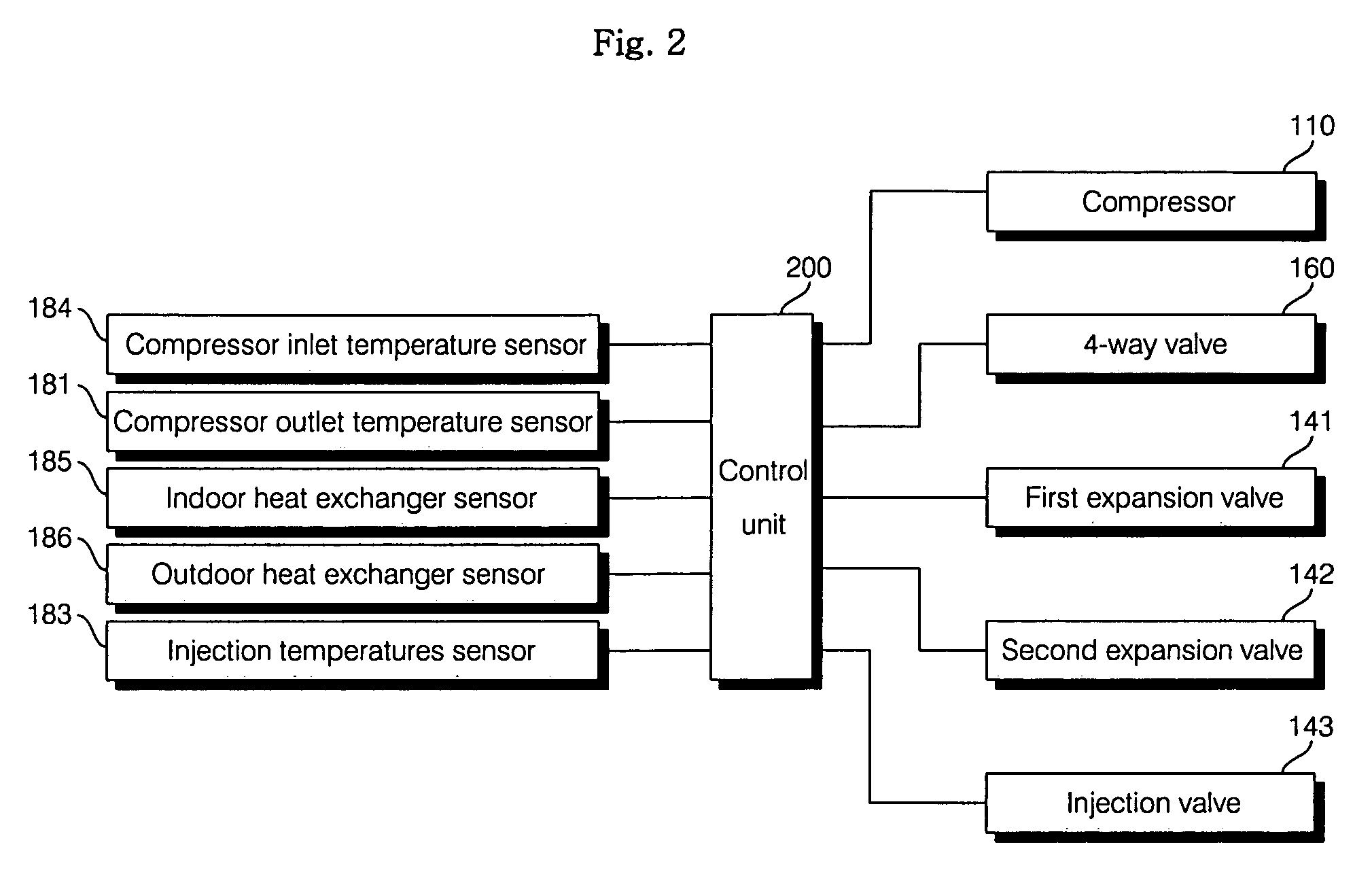

Air conditioning system

InactiveUS20090158764A1Reduce the amount requiredAdjustable pressureMechanical apparatusCompression machines with non-reversible cycleRefrigerantEngineering

Owner:LG ELECTRONICS INC

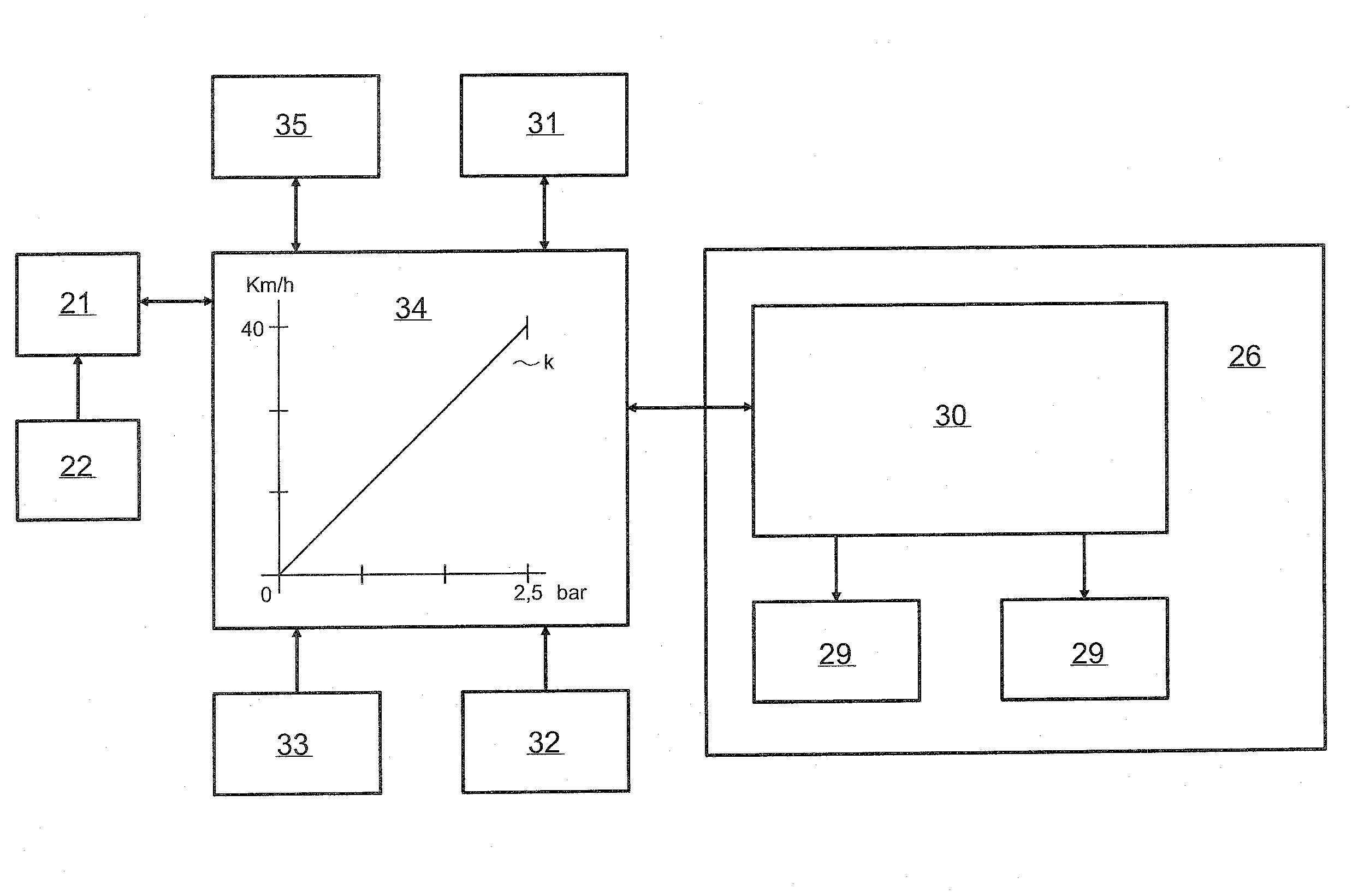

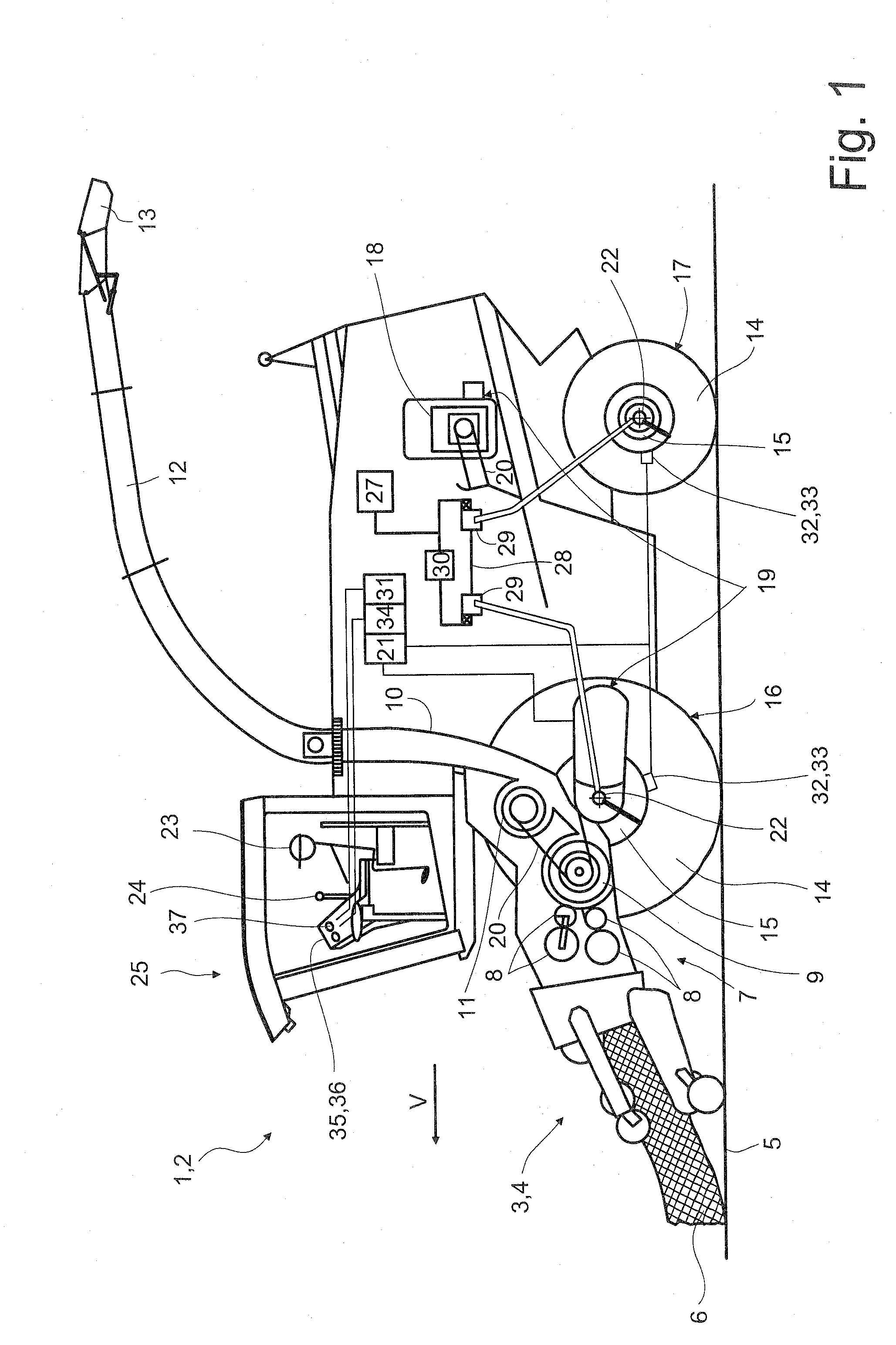

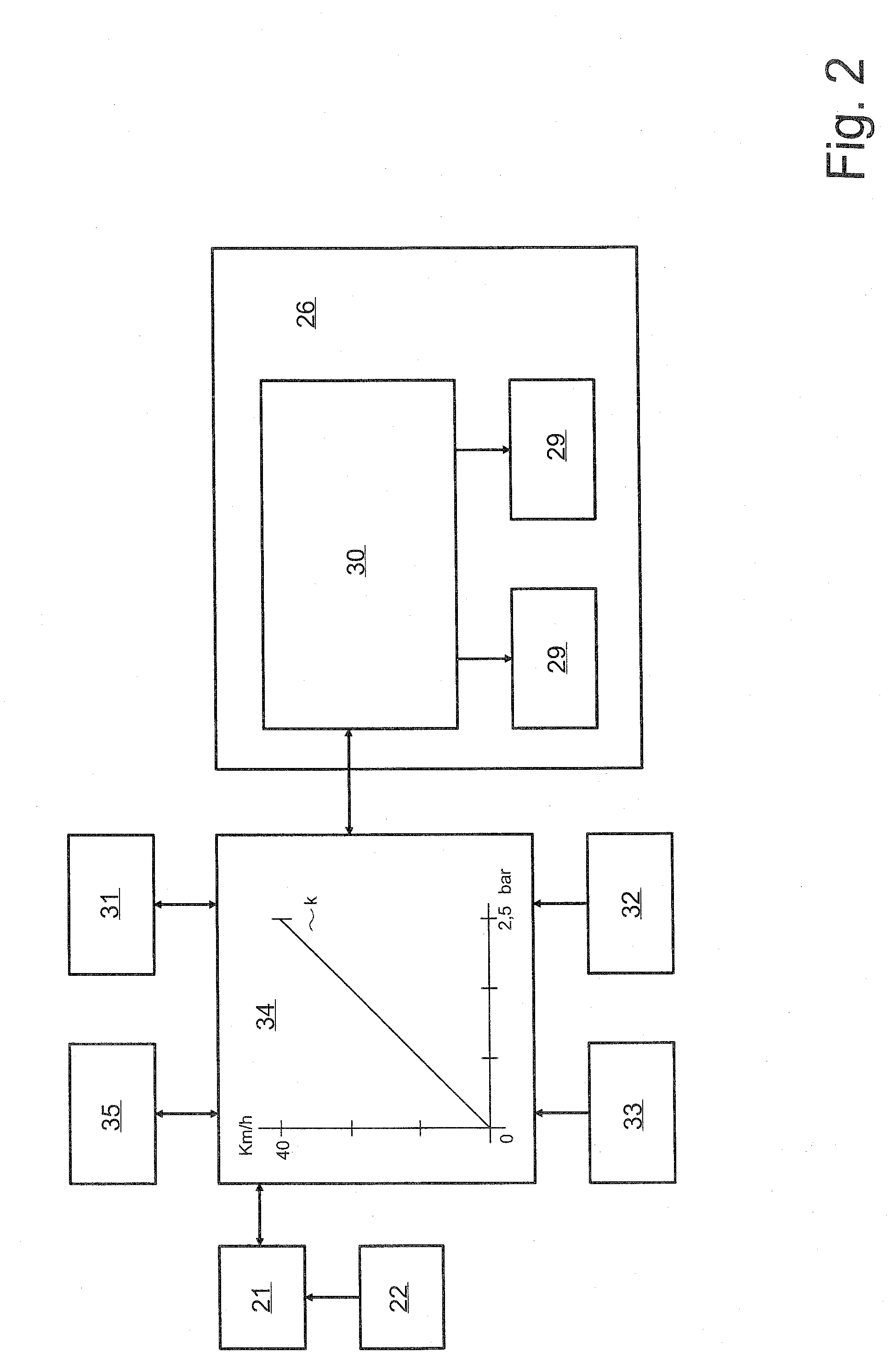

Agricultural working machine

ActiveUS20090030581A1Avoids disadvantageAdjustable pressureVehicle testingAgricultural vehiclesGround speedForage harvester

The present invention relates to an agricultural working machine (2), in particular a forage harvester (1) with a device for adjusting the ground speed v, with which the maximum ground speed v of the agricultural working machine (2) is determined as a function of the tire pressure of at least one tire (14).

Owner:CLAAS SELBSTFAHRENDE ERNTEMASCHINEN GMBH

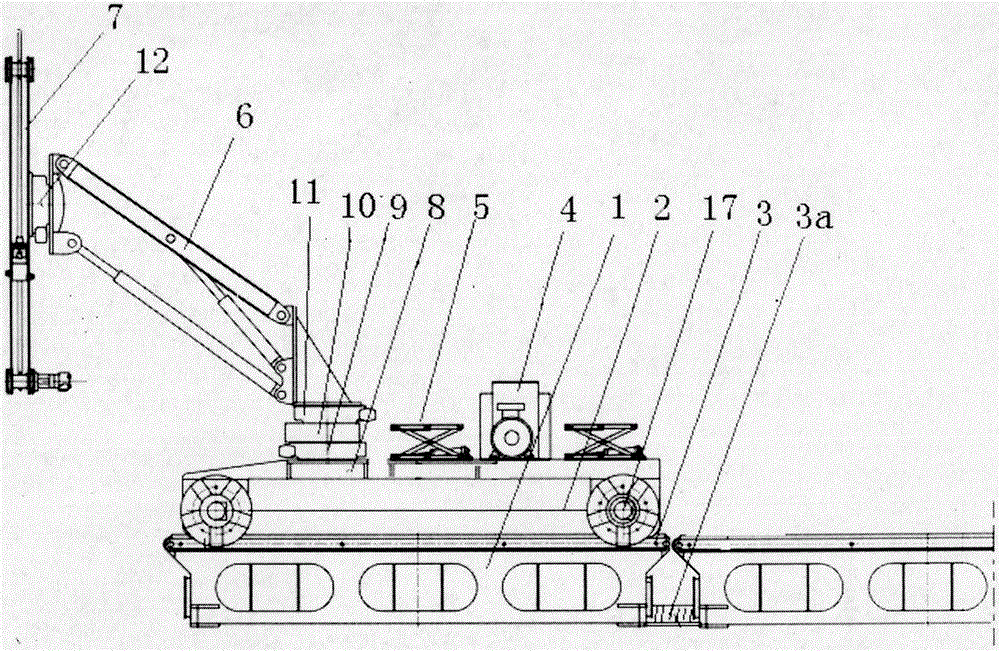

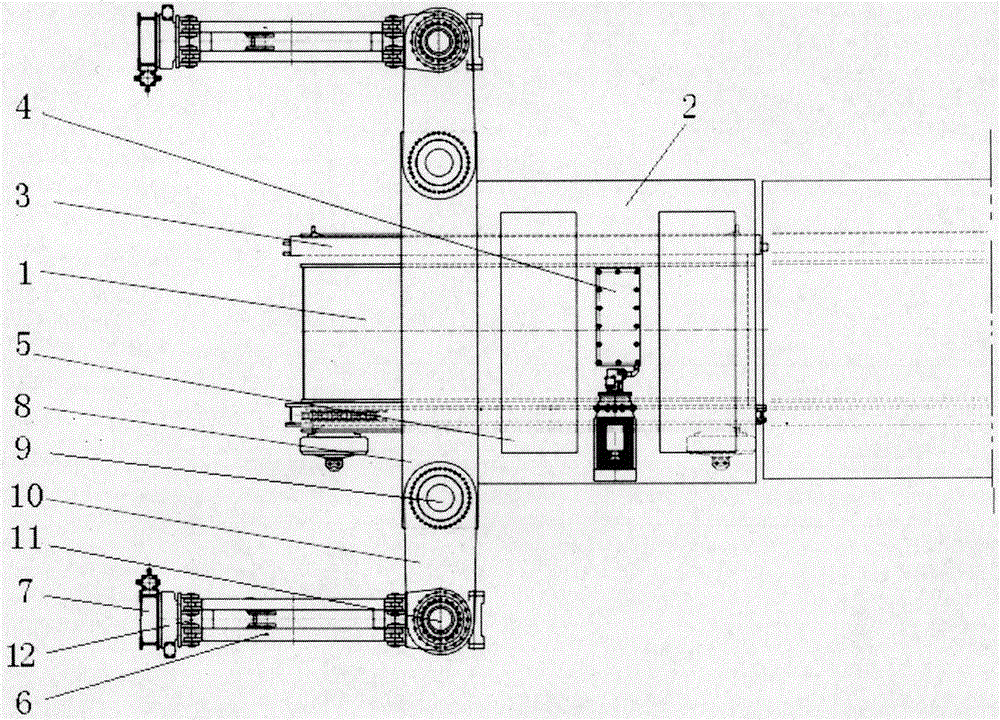

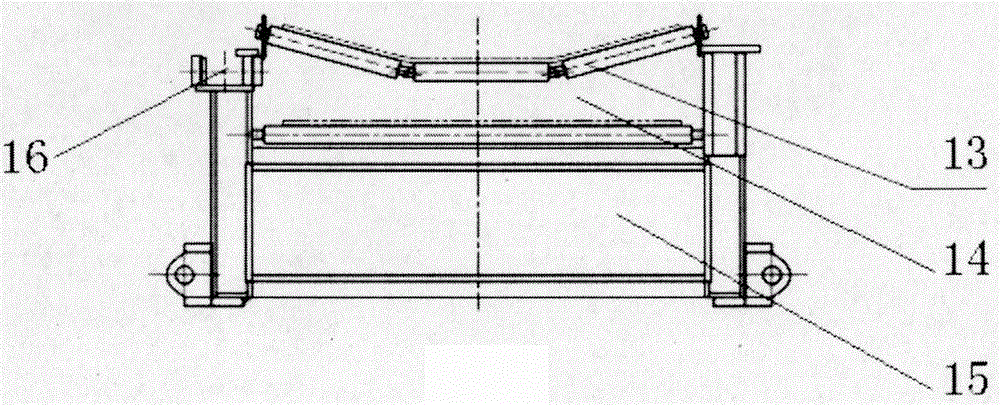

Roadway tunneling support robot, matching support and support method

PendingCN107524454ARealize support self-adjustmentGuaranteed not to deformTunnelsAnchoring boltsHydraulic pumpEngineering

The invention discloses a roadway excavation support robot suitable for coal mine roadway and tunnel construction technology, a matching multi-directional adjustable excavation support, and a conveyor for transporting multi-direction adjustable excavation supports, and proposes a support method at the same time; The excavation support robot is composed of the second transport underframe, walking frame, lifting platform, drilling and anchor manipulator, automatic positioning device, hydraulic pump station and hydraulic operating system; the adjustable support consists of beams, supporting leg cylinders, supporting cylinders, It consists of side beams and support frames; the conveyor is composed of a track with sleeve rollers or sleeve roller chains and a transport trolley running on the track; when working, the roadway excavation support robot is hinged with the tailstock of the roadheader, and then The tunnel boring machine moves together, and under the cover of the multi-directional adjustable tunneling support, bolt support is carried out on the top and two sides of the tunnel while tunneling, so as to achieve the purpose of parallel operation and double the operating rate of the tunnel boring machine, thereby improving Drilling speed.

Owner:左垒安

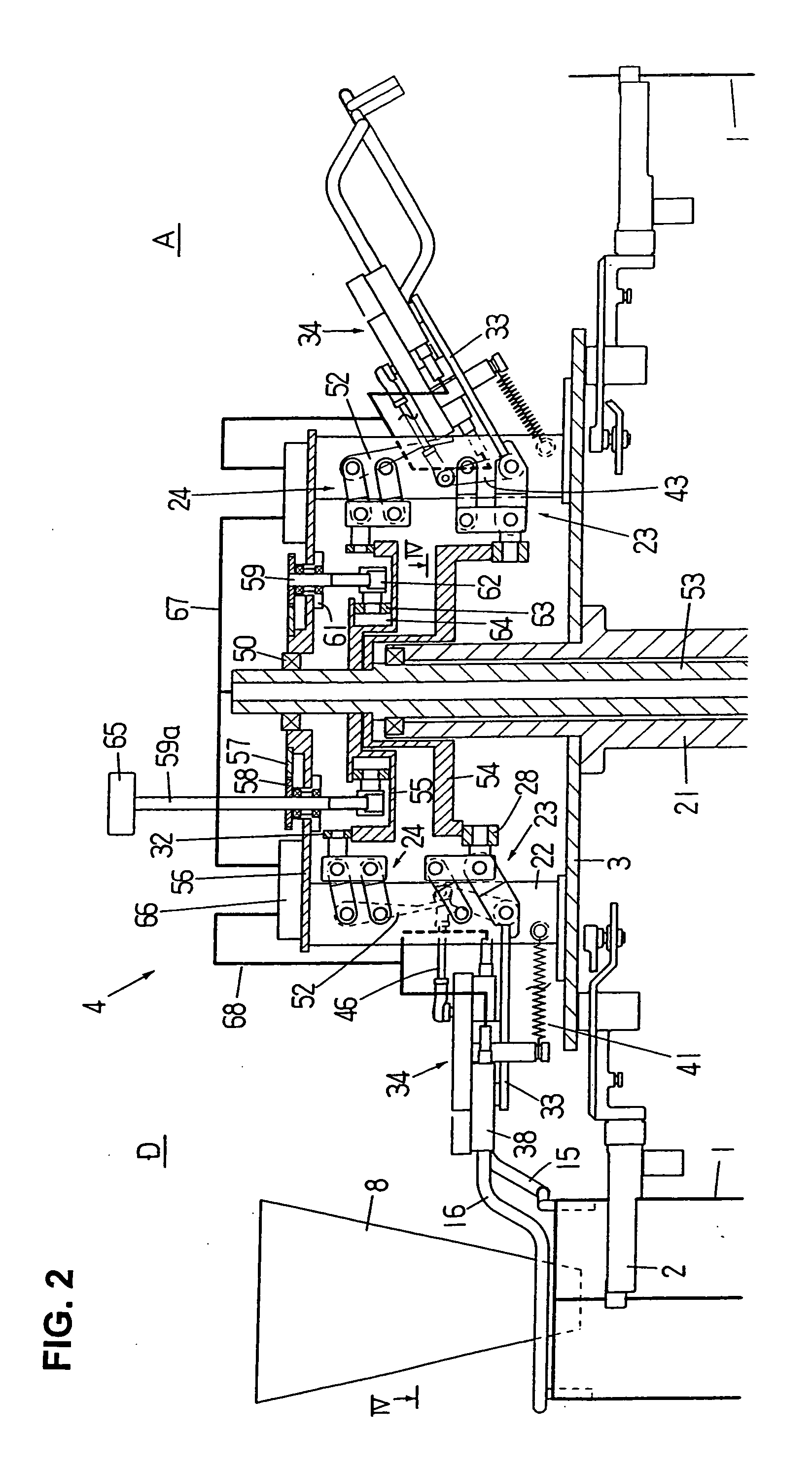

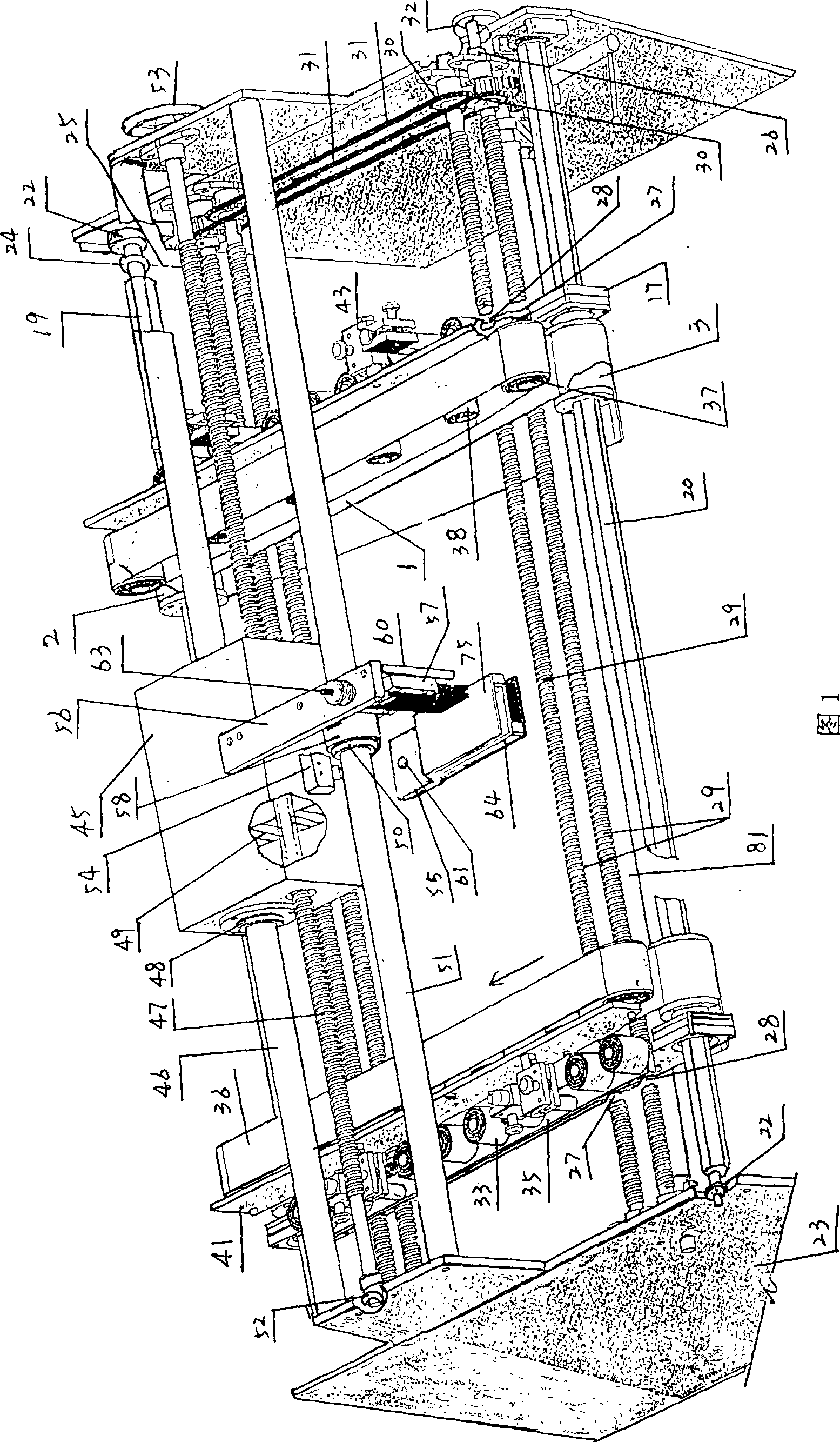

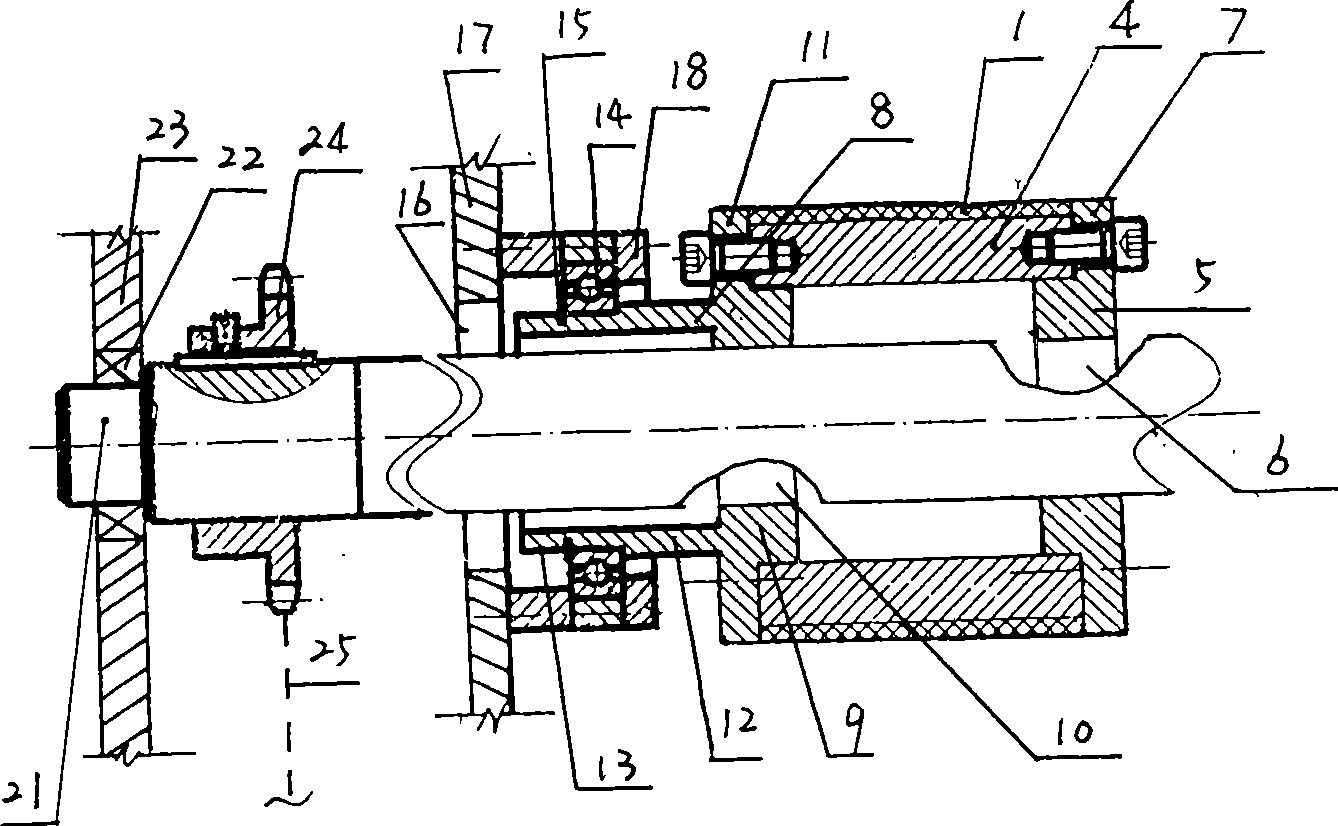

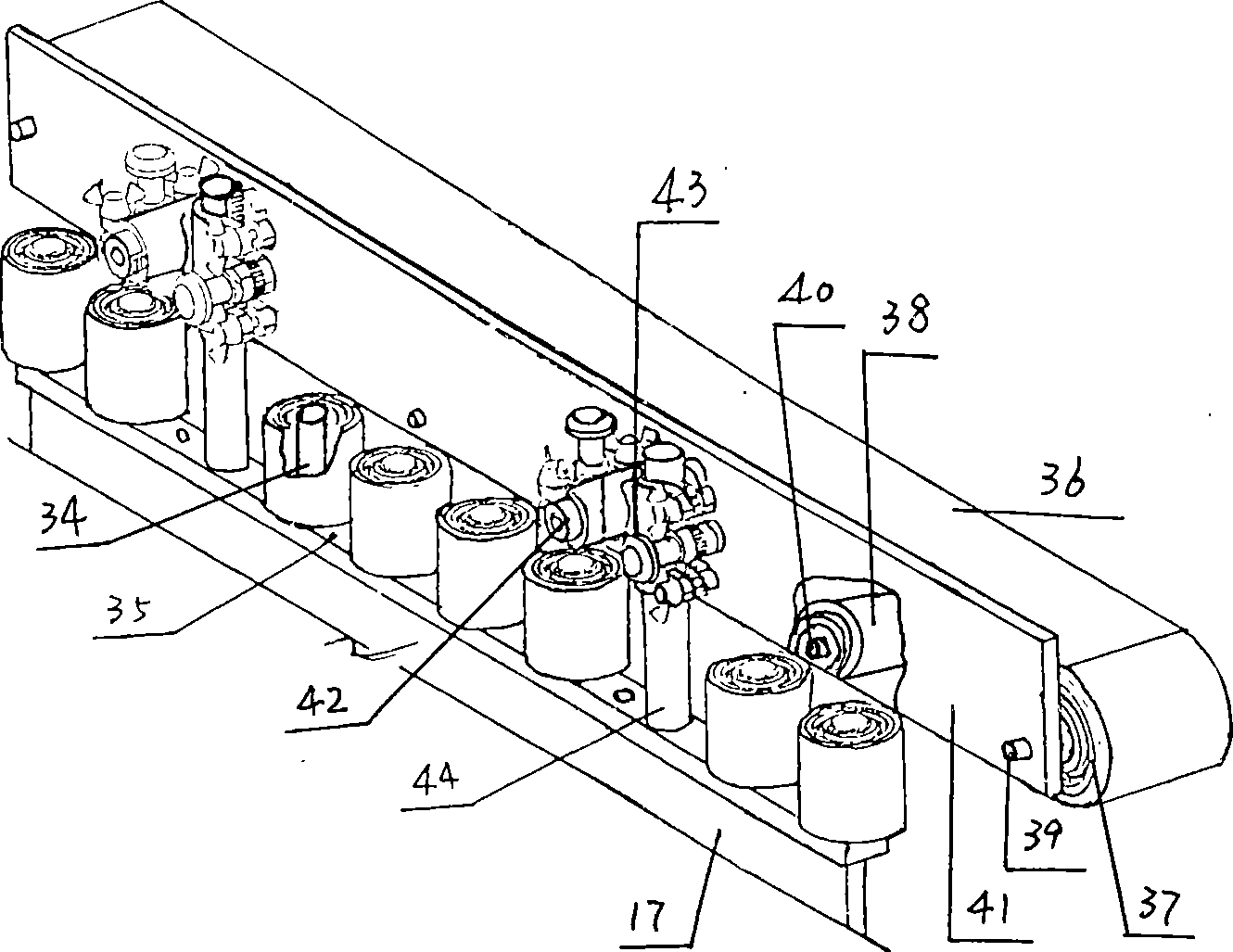

Nailing machine of corrugated case

InactiveCN101456265AQuality improvementAdjustable pressure partBox making operationsPaper-makingAxial displacementEngineering

The invention carton stapler for corrugated cases and belongs to the field of corrugated case manufacturing equipment. The carton stapler adopts a paper conveying mechanism which uses a hexagonal steel type transmission shaft to drive two small belts (1). A driving roller (2) and a driven roller (3) one each side of each small belt (1) are connected together through a small wall plate (17) on the same side, and each small belt (1) is also provided with a complete manual adjustment mechanism which adjusts axial displacement by using a threaded rod threaded rod shaft as well as an array roll type transverse positioning mechanism and a paper pressing belt (36) type paper pressing mechanism with a small roll (38), wherein the manual adjustment mechanism, the array roll type transverse positioning mechanism and the paper pressing belt (36) type paper pressing mechanism are all connected with the small wall plate (17) the transverse position of which can be adjusted. The carton stapler also adopts an automatic head nailing device which has a light controlled automatic system and is matched with the continuous paper conveying device. The transverse position of the automatic head nailing device is adjustable, the vertical position of a nail head holder (57) and the size of the paper pressure are adjustable, and a nail tongue (64) of a belt base plate (55) is changeable. The rollers can be changed easily and the transverse positions of the rollers can be adjusted conveniently, the friction is small, and the paper pressure is adjustable in terms of size. The carton stapler can not damage the surface of corrugaled board and the patterns on the surface of the corrugaled board, achieves excellent nailing quality, high efficiency and low energy consumption, and is convenient in adjustment and maintenance and is suitable to nail corrugaled boards with different thicknesses.

Owner:BEIJING INSTITUTE OF GRAPHIC COMMUNICATION

Internal combustion engine and supercharger

InactiveUS20110083432A1Improve power to weight ratioImprove engine efficiencyElectrical controlInternal combustion piston enginesCompression ratioDiesel fuel

A diesel or diesel-like internal combustion engine drivably connected to a variable internal compression ratio supercharger that supplies varying amounts of air to the engine responsive to the load requirements of the engine. The supercharger has a pair of rotors concurrently driven by the engine to move air to the engine. A slide assembly associated with screw rotors is movable with a controller relative to the rotors to bypass air to atmosphere and regulate the amount of air and pressure of the air compressed by the screw rotors to the engine to increase the engine's efficiency.

Owner:HANSEN ENGINE

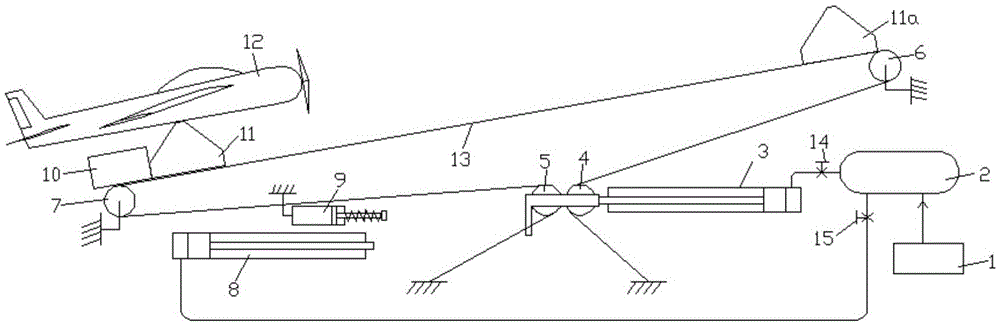

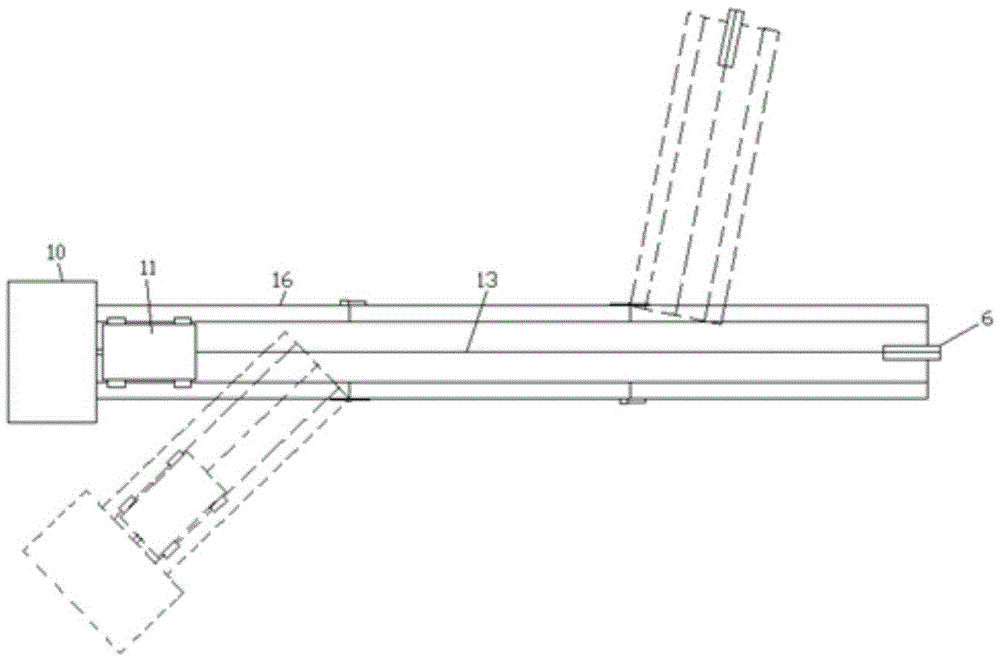

Pneumatic catapult-assisted take-off device and method used for unmanned plane

InactiveCN105460230AThere will be no unsafe factorsAvoid damageLaunching/towing gearCatapultEngineering

The invention belongs to the technical field of catapult-assisted take-off of aircrafts and particularly relates to a pneumatic catapult-assisted take-off device and method used for an unmanned plane. Rubber bands are adopted for most existing catapult devices in China, the service life of the rubber bands is short, the catapult weight of the catapult devices is low, the tail end catapulting speed of catapults is low, the maintenance cost is high, and the risk in the take-off stage is high; consequentially, the application and popularization of the catapults in the field of unmanned planes are limited, and the application range is narrow. By the adoption of the pneumatic catapult-assisted take-off device and method used for the unmanned plane, the unmanned plane is made to get rid of the limitation of airport conditions, the service life of an existing catapult is prolonged, and the catapult weight of the catapult is increased.

Owner:SHAANXI AIRCRAFT CORPORATION

Glue spraying processing device used in semiconductor manufacturing

InactiveCN102020234AAdjustable pressureSpray evenlyLiquid surface applicatorsPrecision positioning equipmentDevice formIsolation layer

The invention relates to a glue spraying processing technology in the micro electro mechanical system process, in particular to a glue spraying processing device used in the semiconductor manufacturing process, and the device formed by uniformly coating photoresist or a protection isolation layer on the wafer surface which is rough or is provided with deep holes, is applicable to three-dimensional packaging in the semiconductor field. A linear actuator is arranged above the unit base surface of the glue spraying processing device, the linear actuator is provided with a nozzle used for spraying glue onto a wafer, and the unit base surface is provided with a wafer carrying platform used for placing the wafer. The device is not only applicable to common photoinduced corrosion inhibitors but also applicable to photoinduced corrosion inhibitors with higher viscosity, the viscosity of the photoinduced corrosion inhibitor with higher viscosity can be reduced by diluting and blending, the photoinduced corrosion inhibitor is uniformly sprayed onto the wafer surface which is rough, and process requirements of the wafer to be processed are ensured.

Owner:SHENYANG KINGSEMI CO LTD

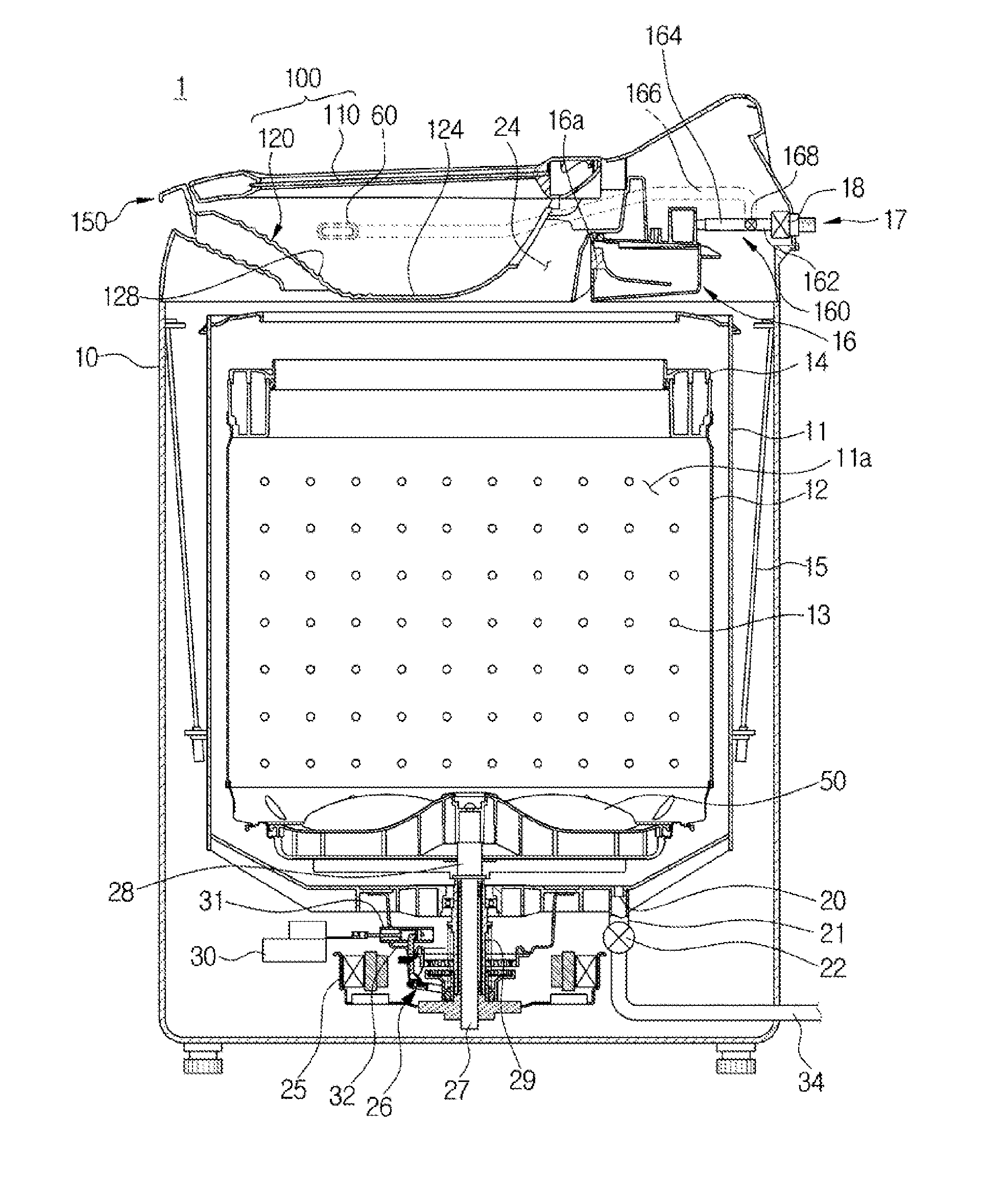

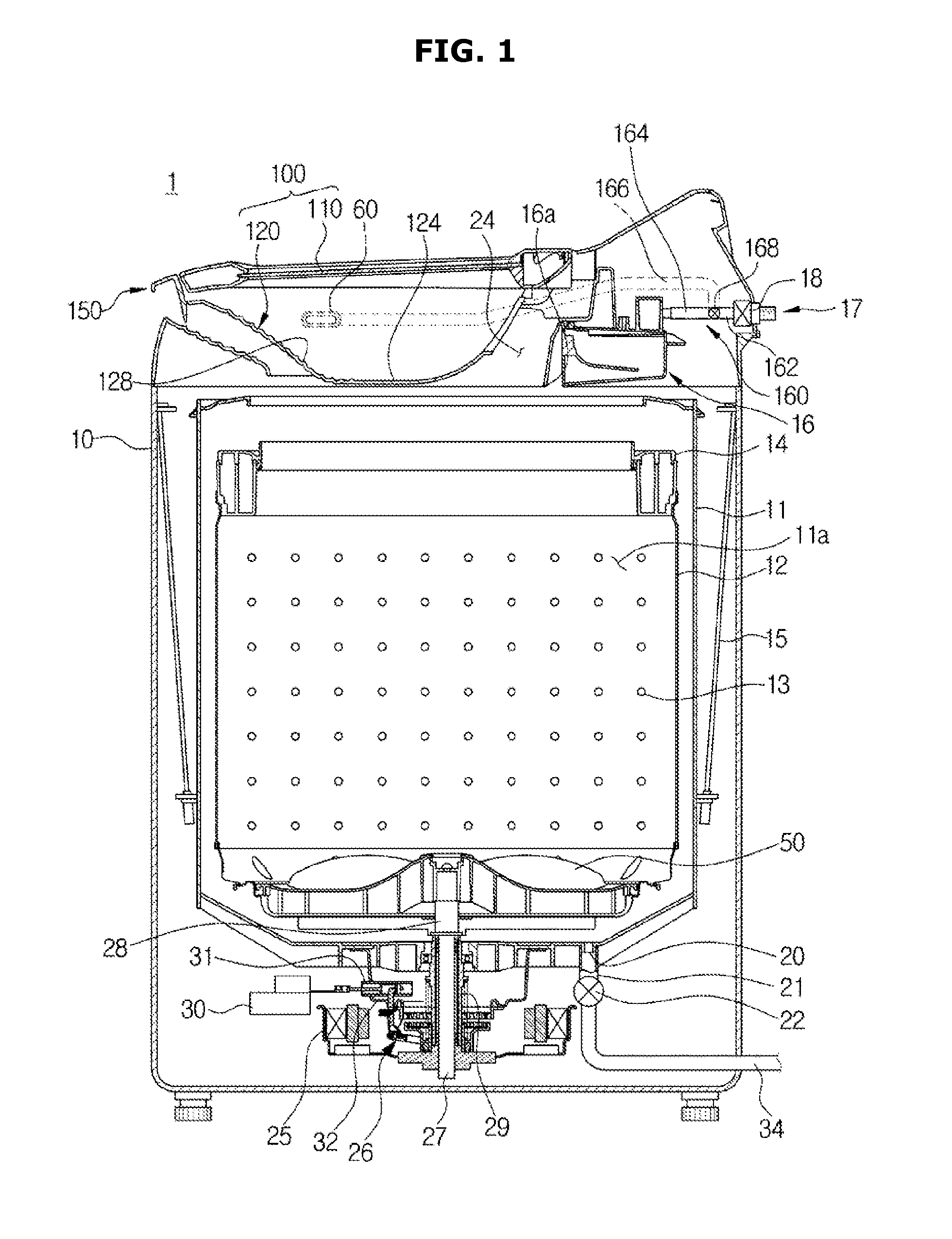

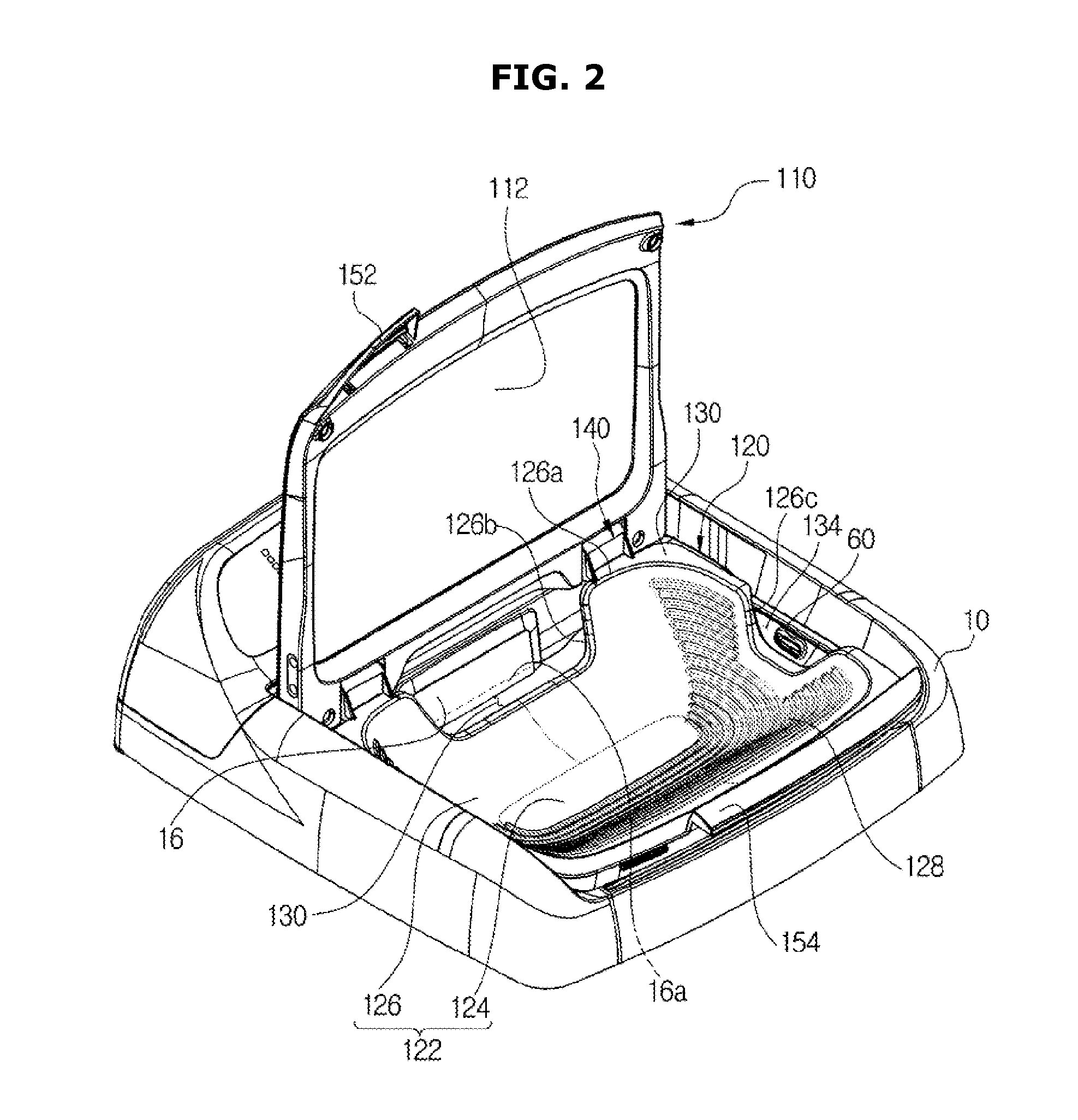

Washing machine and washing water supply device

ActiveUS20150247276A1Adjustable pressureImprove washing efficiencyHand rubbing apparatusWashing receptaclesEngineeringMechanical engineering

Provided is a washing machine including a main body having an opening and a door assembly disposed at the opening, wherein the door assembly includes a door that opens and closes the opening and an auxiliary washing unit having an auxiliary washing space in which hand-washing can be performed, and provided to pivot about one side of the door in an inside of the door. Through this configuration, separated washing spaces can be provided and separate hand-washing can be performed. Also, pressure of washing water supplied into the washing machine can be regulated so that water supply efficiency can be improved and a flow rate of the washing water can be adjusted.

Owner:SAMSUNG ELECTRONICS CO LTD

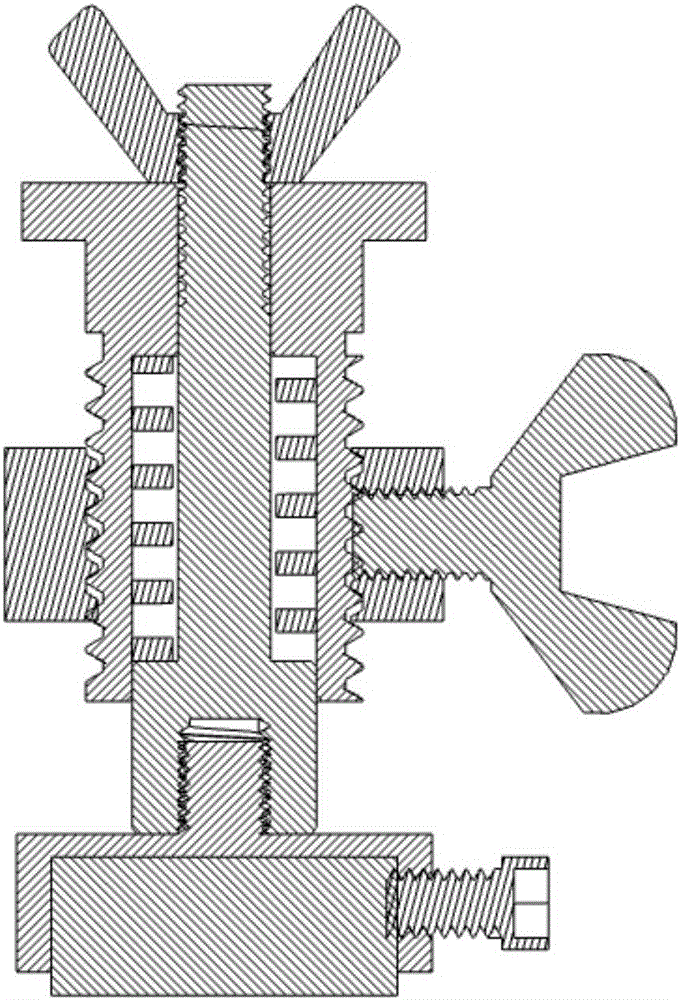

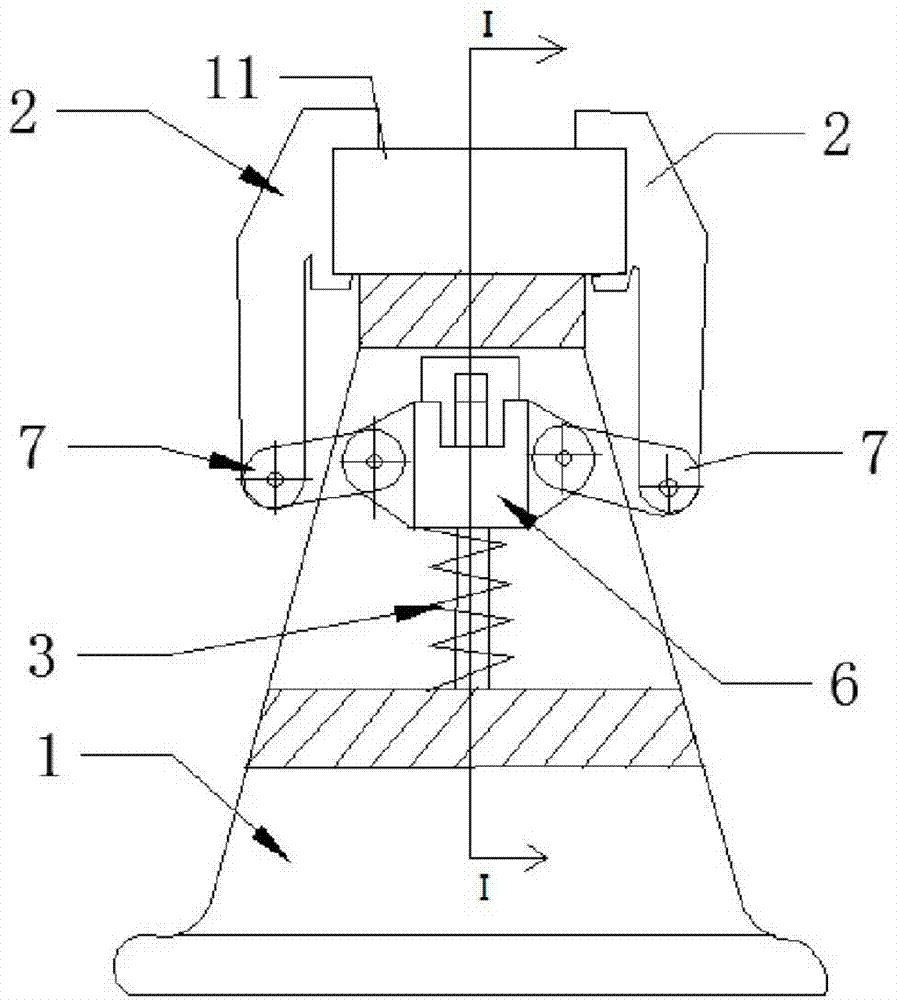

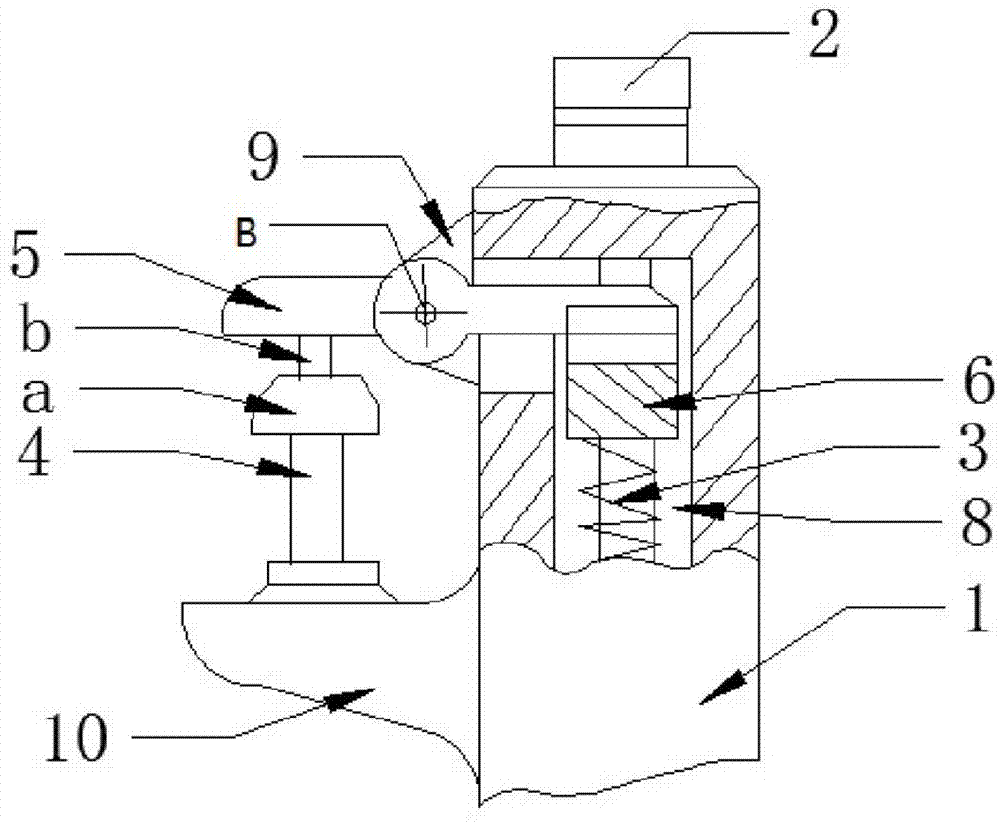

Screw lever type clamping mechanism

PendingCN104511768AEasy to lock and holdEasy to clamp and positionPositioning apparatusClampsIsosceles trapezoidEngineering

The invention discloses a screw lever type clamping mechanism which comprises a supporting table, a locking part and a driving part. The supporting table is of an isosceles trapezoid structure, a connecting plate and a supporting plate are arranged on one side face of the supporting table, and a slide rail is arranged in the supporting table. The driving part comprises a screw, a nut, a cap-shaped object, a first lever, a first pin, a first connecting member, a spring and second connecting members, wherein the screw is connected to the supporting plate through threads, the nut and the cap-shaped object are connected to the screw, the cap-shaped object is arranged above the nut, the first lever is connected to the connecting plate through the first pin, one end of the first lever abuts against the cap-shaped object, the other end of the first lever abuts against the first connecting member, the first connecting member is in sliding connection with the slide rail, the left end and the right end of the first connecting member are respectively connected two second connecting members through pins, and the spring is connected between the first connecting member and the slide rail. The locking part comprises a clamping claw provided with a limiting groove, wherein the clamping claw is connected with the second connecting members through pins. The screw lever type clamping mechanism is firm in structure and adjustable in locking pressure.

Owner:CHONGQING XIHUA BELT PULLEY MACHINERY MFG CO LTD

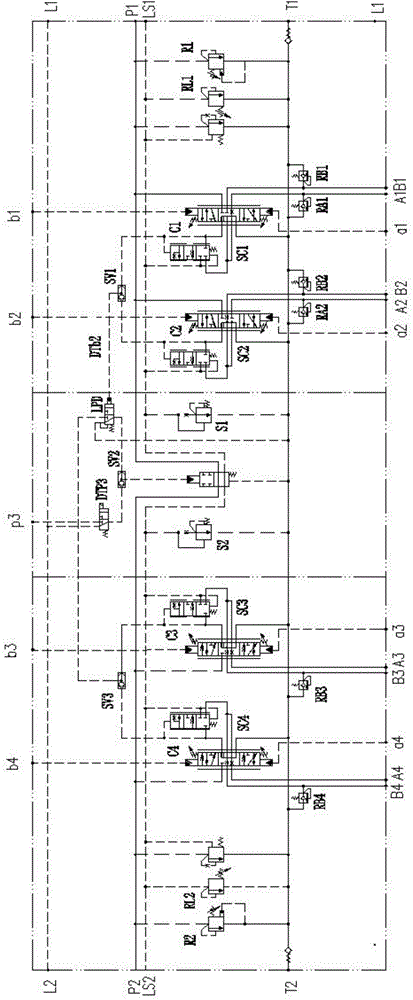

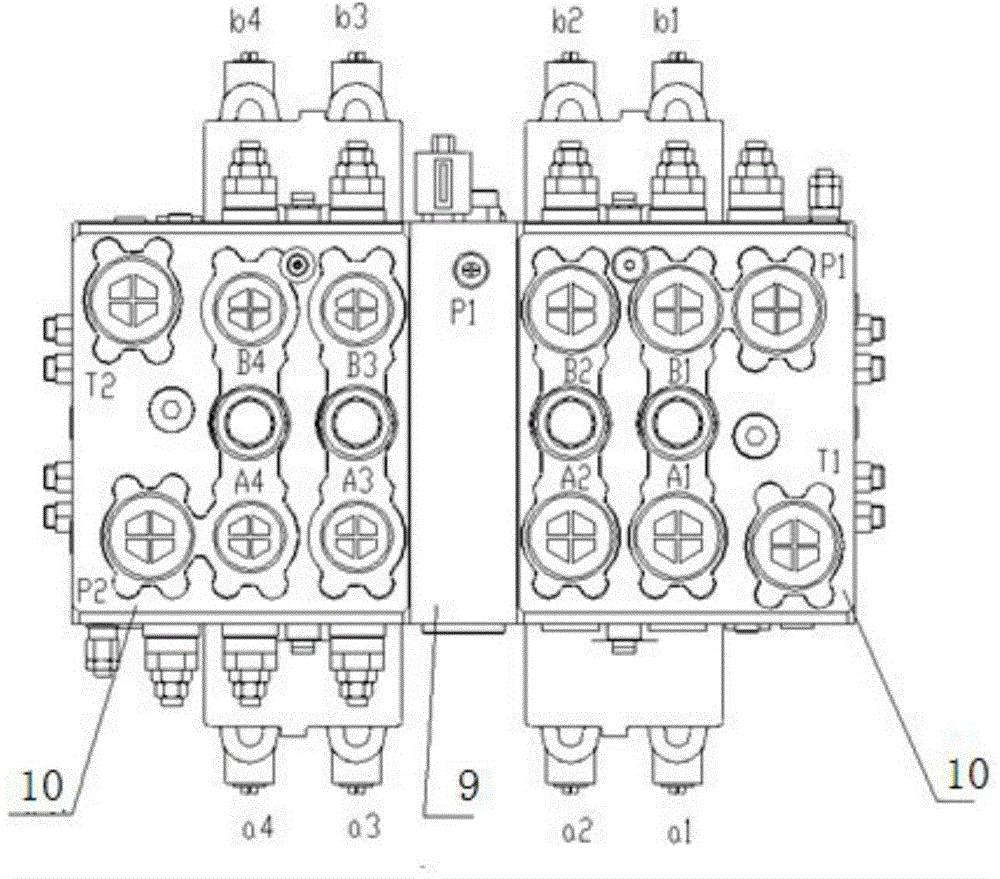

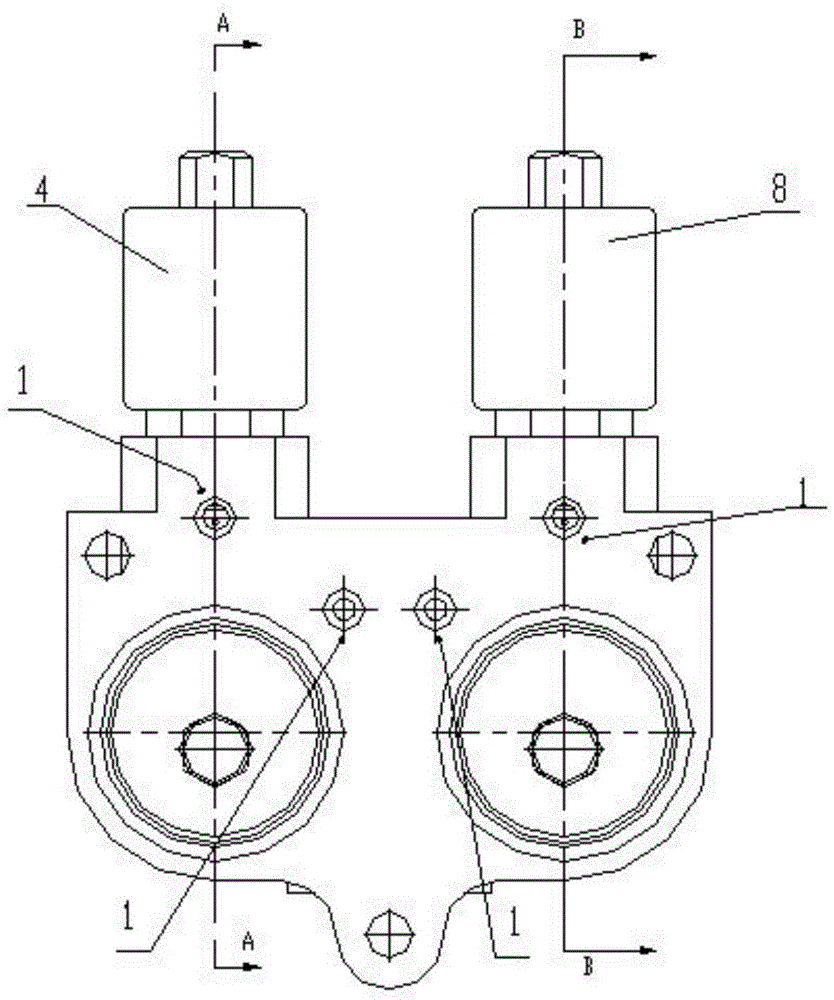

Valve back compensation type load-sensitive multitandem valve with bidirectional confluence function

ActiveCN104879336ARaise priorityLow priorityServomotor componentsServometer circuitsElectro hydraulicHigh load

The invention discloses a valve back compensation type load-sensitive multitandem valve with a bidirectional confluence function. The valve back compensation type load-sensitive multitandem valve comprises a confluence tandem and two oil inlet operation tandems arranged at two ends of the confluence tandem. The confluence tandem is provided with a confluence valve with the bidirectional confluence function and comprises an electromagnetic valve, a hydraulic control valve, a shuttle valve II and an electro-hydraulic joint control confluence switching valve, an oil inlet tandem and two operation tandems are integrated in each oil inlet operation tandem and each operation tandem comprises a reversing speed-regulation valve and a pressure compensation valve arranged at an outlet of the reversing speed-regulation valve. The confluence tandem is detachably connected with the oil inlet operation tandems on two sides. The output end of the electro-hydraulic joint control confluence switching valve in the confluence tandem is communicated with the operation tandems. The confluence tandem allows oil to flow bidirectionally from p1 to p2 or vice versa, flow speed range of the tandems is broadened, and the executing mechanisms can act more quickly. By the pressure compensation technology, the problem that high-load executing mechanisms have little flow or even no flow when the executing mechanisms act at the same is solved, and action stability is improved.

Owner:XCMG HYDRAULICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com