[0011] Accordingly, the object of the present invention is to provide a bag-filling packaging

machine that performs gas replacement assuredly and in a stable fashion.

[0012] More specifically, the object of the present invention is to provide a bag-filling packaging

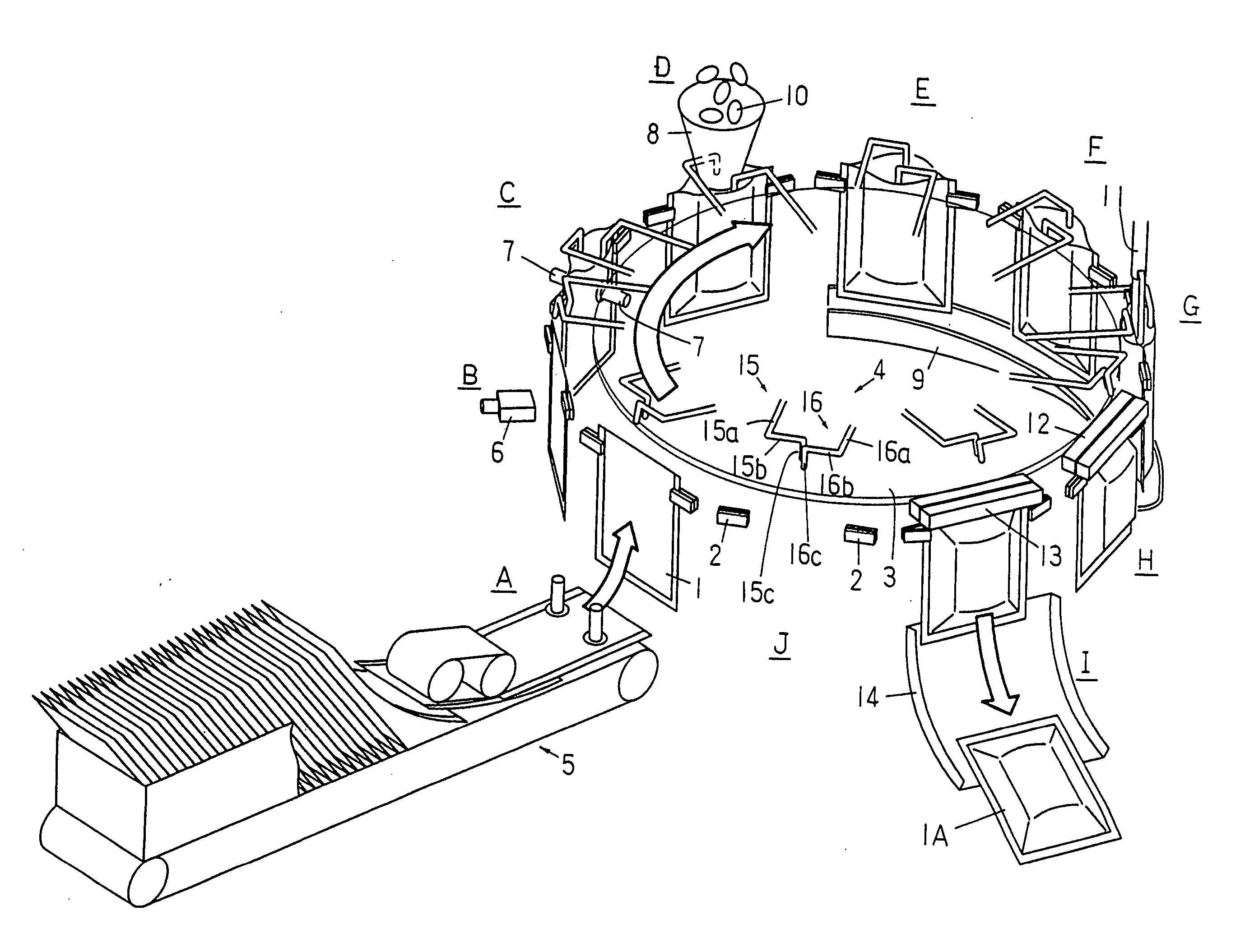

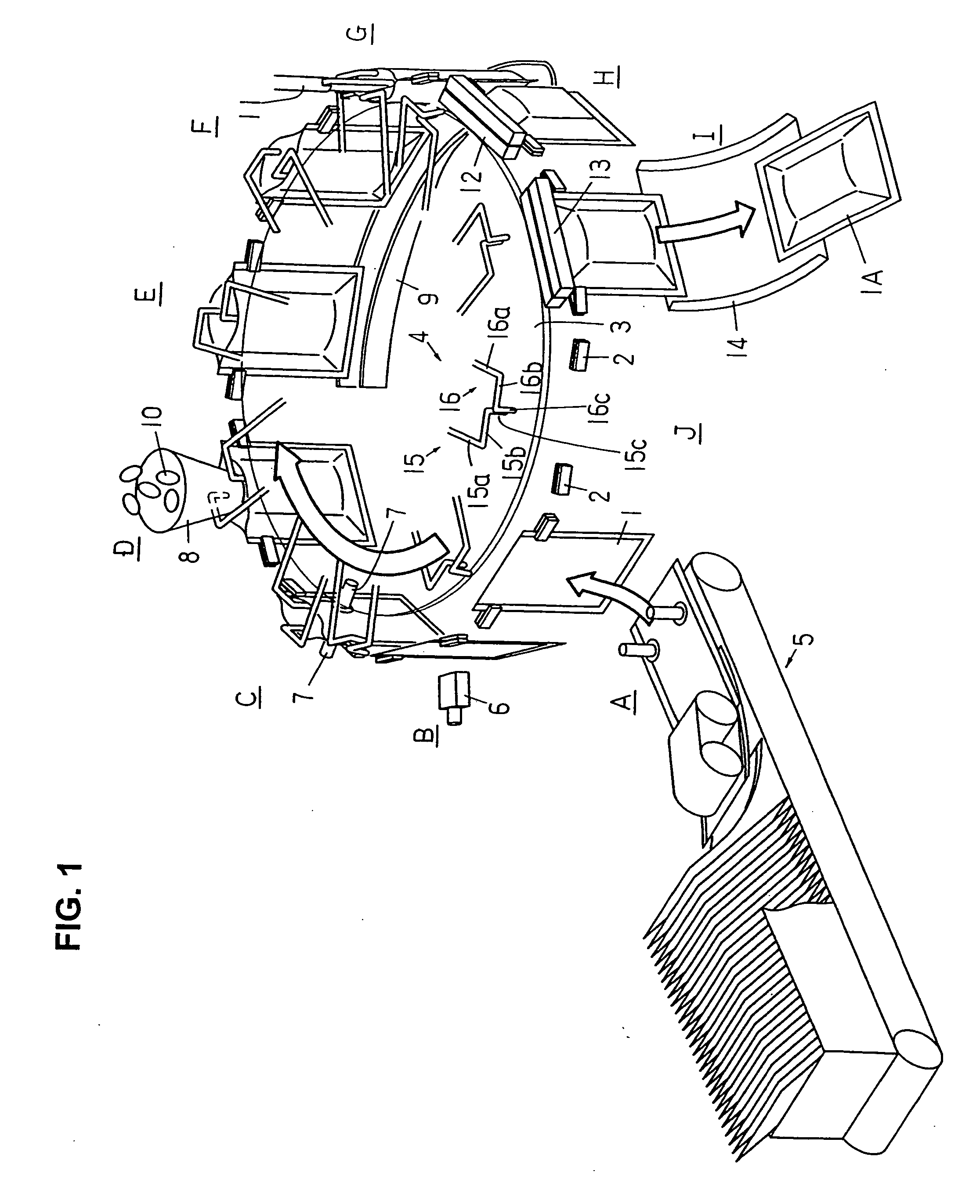

machine that includes a plurality of pairs of

grippers for gripping the edges of both sides of supplied bags and suspendingly holding the bags, at equal intervals along a horizontal endless bag conveyance path, so as to revolvingly move the pairs of grippers in one direction, either continuously or intermittently in each of the such intervals, and so as to successively perform various packaging operations, such as opening the bag mouths, filling the bags with the contents to be packaged, and sealing the bag mouths, on the bags held by the pairs of grippers; and in this type of packaging

machine, the present invention assuredly and stably performs gas replacement, without compromising production efficiency, and without impairing the degree of freedom in the packaging operations.

[0024] As seen from the above, in the bag-filling packaging machine of the present invention, guide members are provided so as to correspond respectively to the pairs of grippers, the guide members are designed so that they not only function to keep the bag mouth opened but also function as gas replacement nozzles, the gas replacement time period is set to be long, over which entire time period it is possible to continuously perform blow-in of an inactive gas or the like into the bags and, as necessary, air removal and gas replacement for the bags is performed assuredly and stably for all of the bags. With the guide members that function as bag mouth opener and also function as gas replacement nozzles, gas replacement can be performed without making the relevant structures overly complex.

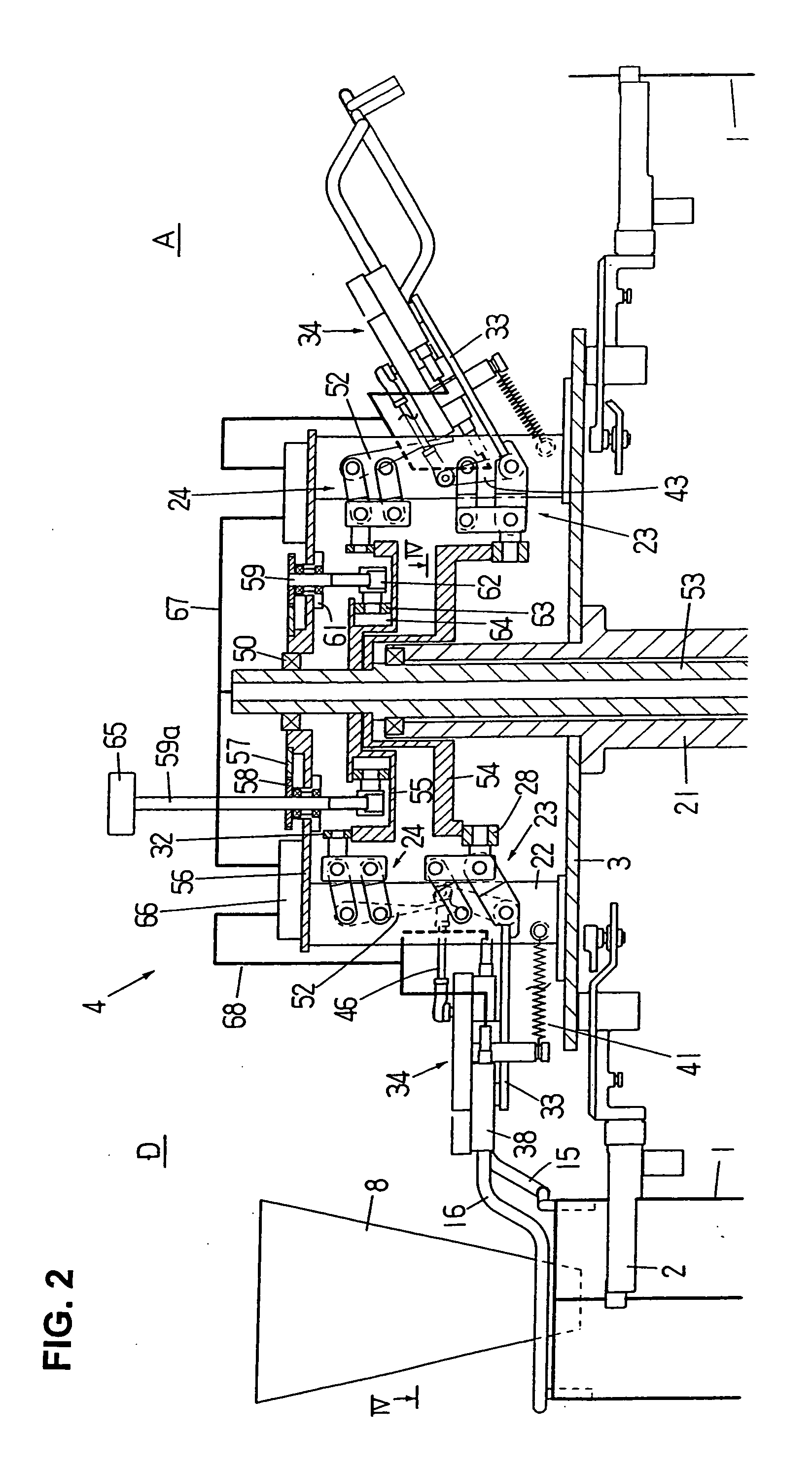

[0026] In addition, in the present invention, the guide member connected to the

gas supply source can be designed so that the gas blow-in pressure is adjustable. Thus, the blow-in volume during gas blowing into the bags can be adjusted. Accordingly, gas blow-in and air removal (vacuuming) can be appropriately combined, or the gas blow-in intensity can be suitably altered, so that gas replacement can be performed in an optimal pattern depending upon the type of the contents to be filled or upon the size of bags.

[0027] In the present invention, the guide portions of the pair of (or two) guide members are opened and closed (separation-proximity) in the interior of each bag, and the positions of the guide portions are preferably set so that, when in the

closed state, the two guide portions of the pair of (or two) guide members are positioned close to each other and aligned in the bag width direction substantially at the center of the bag mouth. As a result, the space occupied by the two guide portions in the direction perpendicular to the bag width direction is small or narrow; and as a consequence, when the distance between the gripper pair (or the distance between two grippers) is widened and the bag mouth is thus tensioned (pulled) laterally to the left and right with the guide members in the bag, the opening in the bag mouth becomes very narrow; as a result, the inflow of outside air into the bag and the outflow of gas from the bag interior are limited, and thus improved gas replacement can be executed.

[0029] In the present invention, further, both guide portions which are closed inside a bag are shifted in the bag width direction from the bag width center position and thus they are not exactly at the center of the bag mouth in terms of the width of the bag. Accordingly, when the two guide portions are open (separation) or close (proximity), when they are moved linearly in a direction perpendicular to the bag width direction as in the conventional opening members, the opened bag mouth would be distorted in the shape of a

parallelogram, and such

distortion would be relatively larger for the bag is small in width. In the present invention, in cases that the guide portions are close to each other, side by side, in the bag width direction at substantially the center of the opened bag mouth and then moved in mutually opposite directions along the circular arc-shaped paths, respectively, in a horizontal plane, and such circular arc-shaped paths are established so that both of them, in the middle, approach the center in the bag width direction, then when the bag width size is small, the movement distance of the guide portions is small, and the opening guide portions will approach the vicinity of the bag width center along the circular arc-shaped paths of the guide portion, and as a result, the

distortion in the opened bag mouth will be suppressed. When the bag width size is large, the guide movement distance is large, and the opening guide portions, after approaching the vicinity of the bag width center, are again moved away from the vicinity of the bag width center along the circular arc-shaped paths. Thus, though

distortion might appear in the opened bag mouth, it will not be much of a problem.

Login to View More

Login to View More  Login to View More

Login to View More