Patents

Literature

73results about How to "Improve space factor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rotating Electrical Machine

ActiveUS20090267441A1Improve Radiation PerformanceImprove space factorWindings insulation shape/form/constructionMagnetic circuitElectrical and Electronics engineeringElectric machine

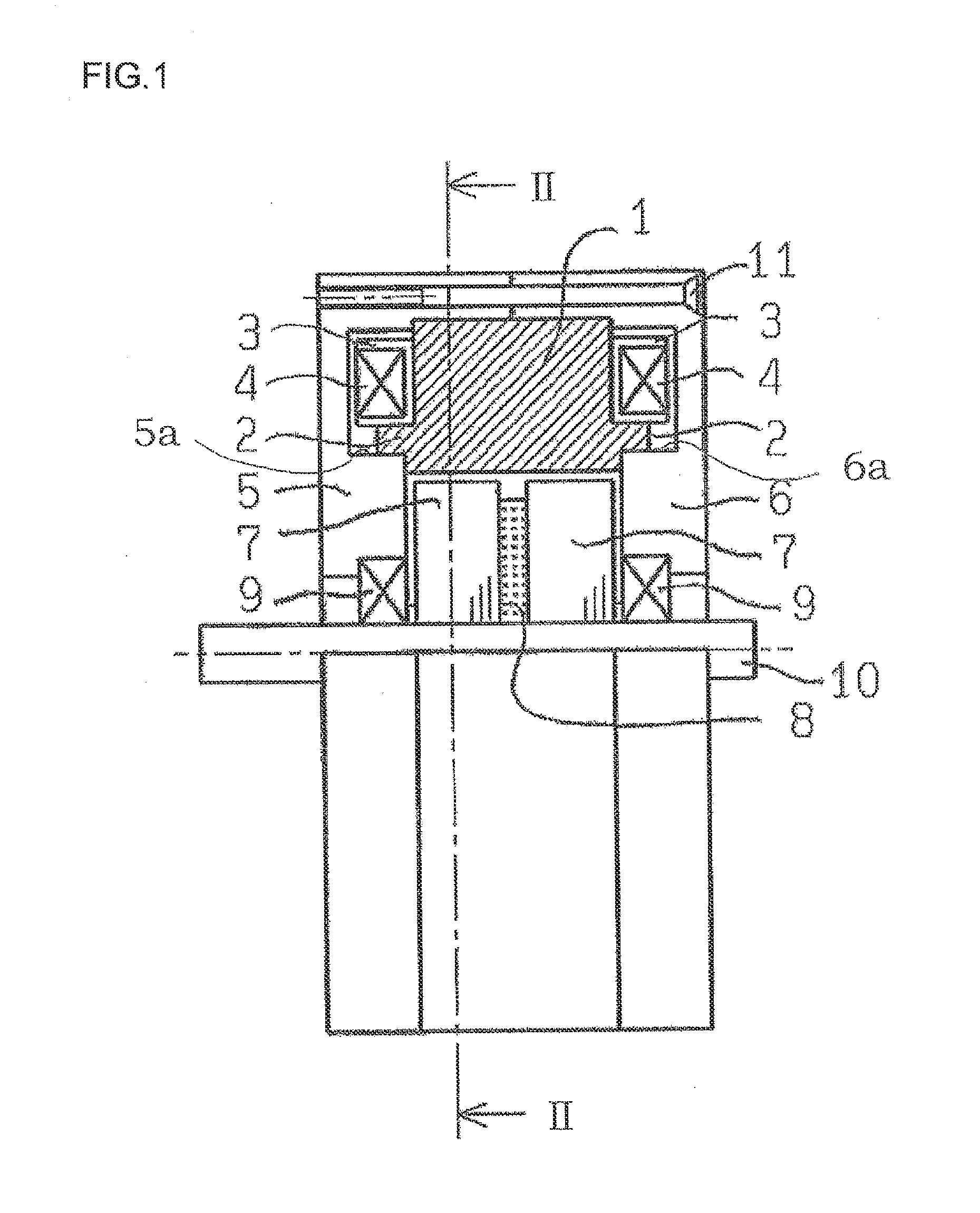

A rotating electrical machine includes a stator including at least two element coils of the same phase each having a plurality of turns and connected to each other through a coil-to-coil connection wire, the element coils being arranged in adjacent slots, respectively; and a rotor rotatably provided to the stator through a gap. The element coils of the same phase are fitted in the adjacent slots so that wound around portions of the element coils partially overlap each other. The coil-to-coil connection wire connects at a coil end portion conductor wires extending from linear conductor wire portions of innermost wires of the element coils contained in the slots.

Owner:HITACHI ASTEMO LTD

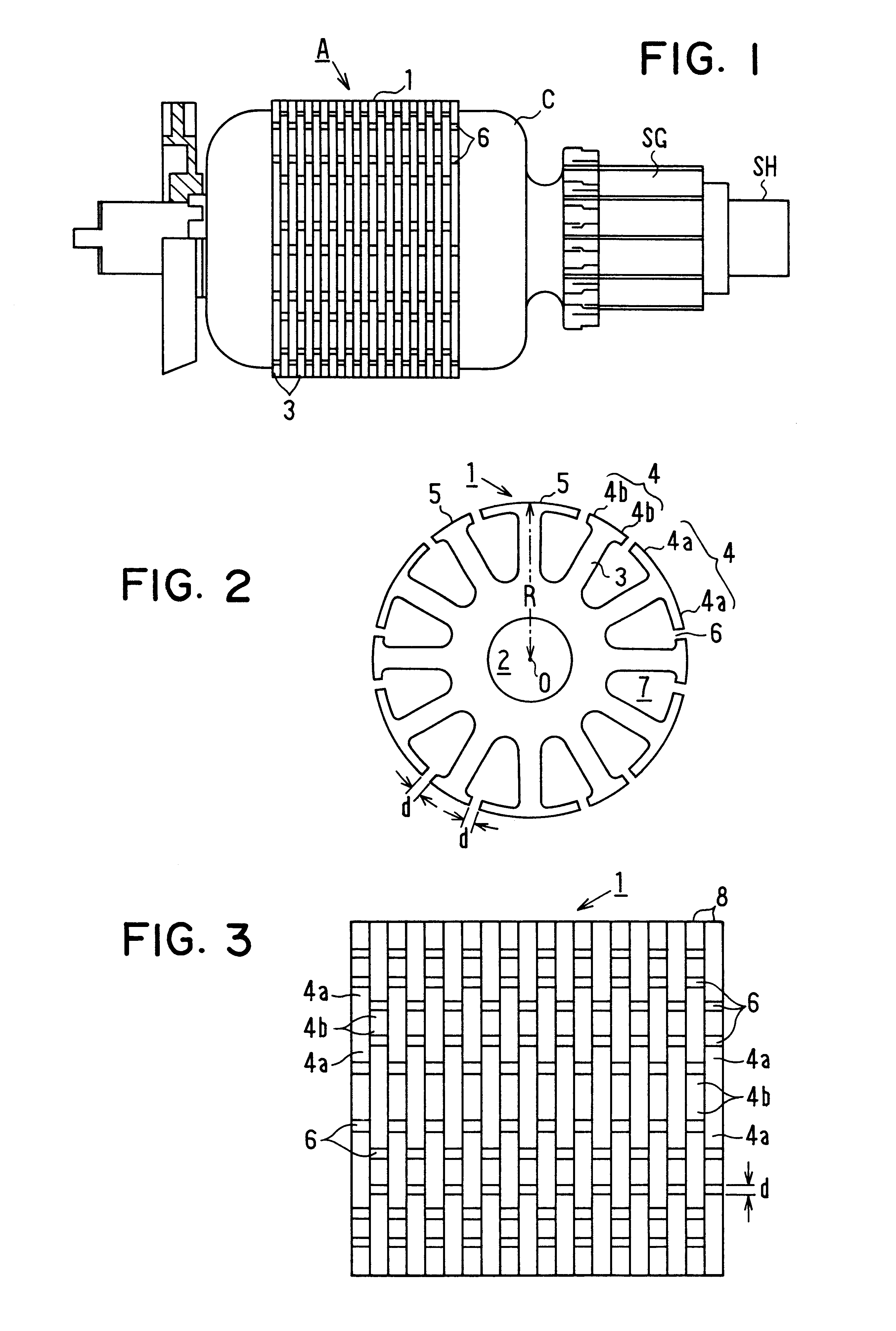

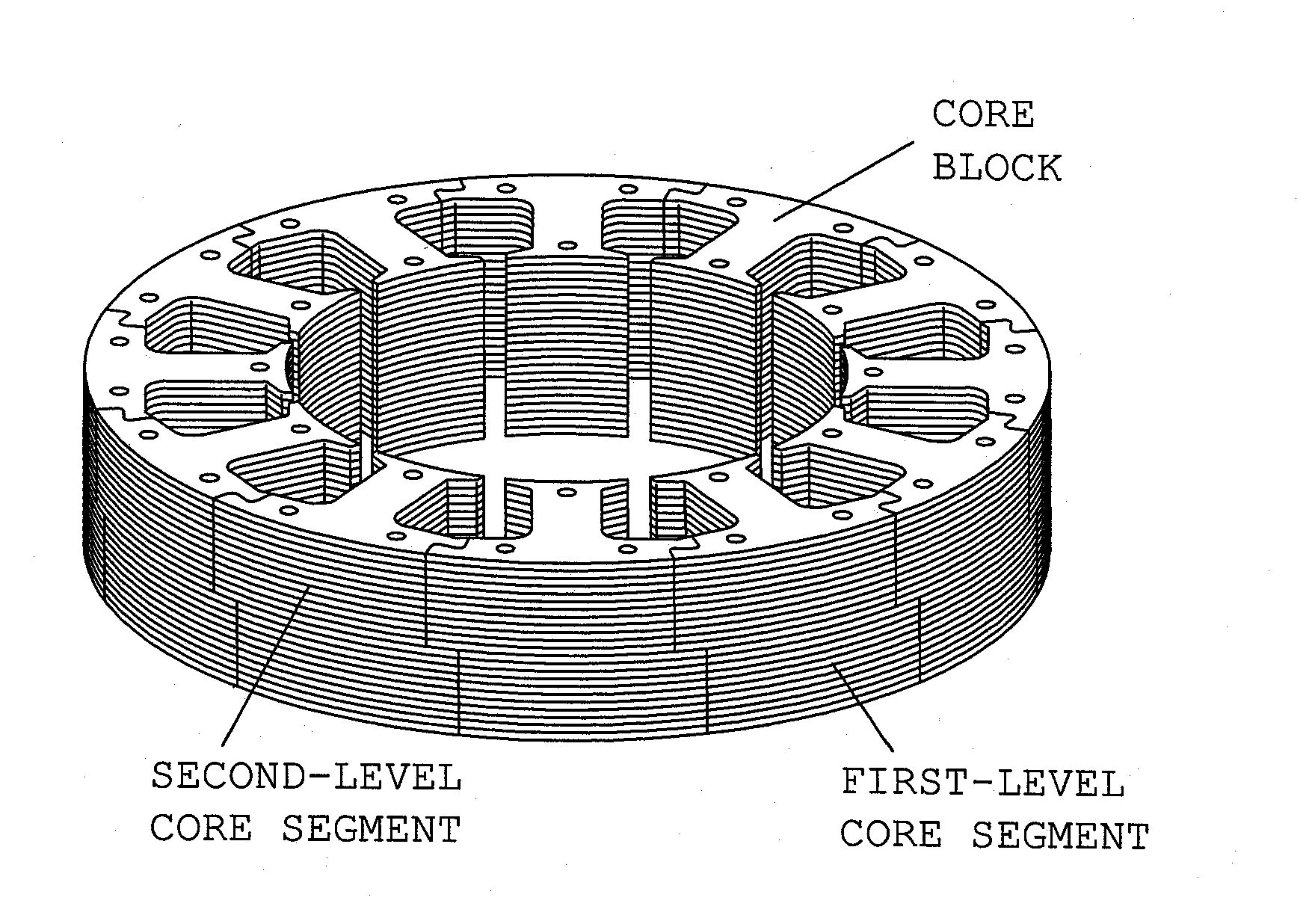

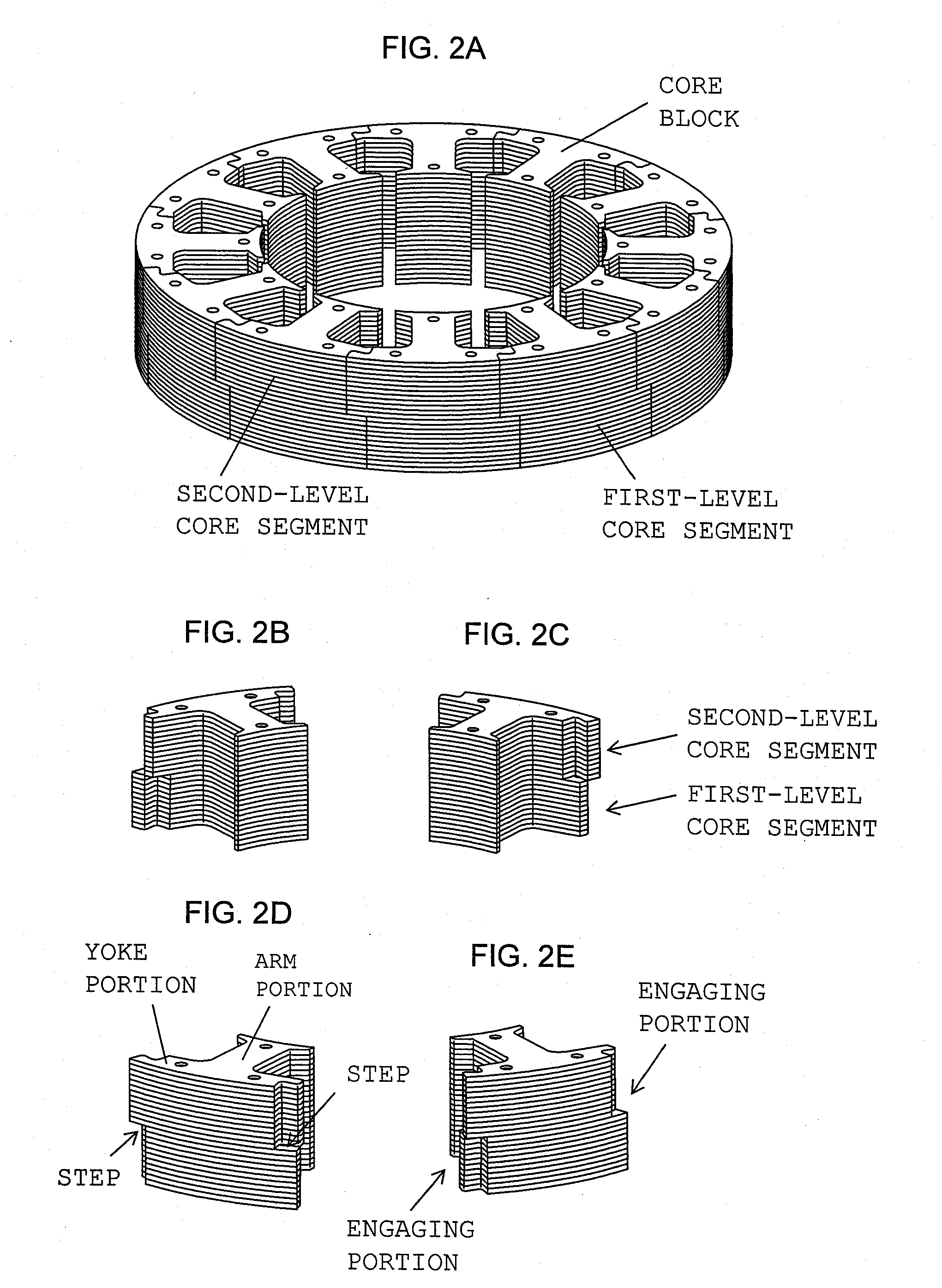

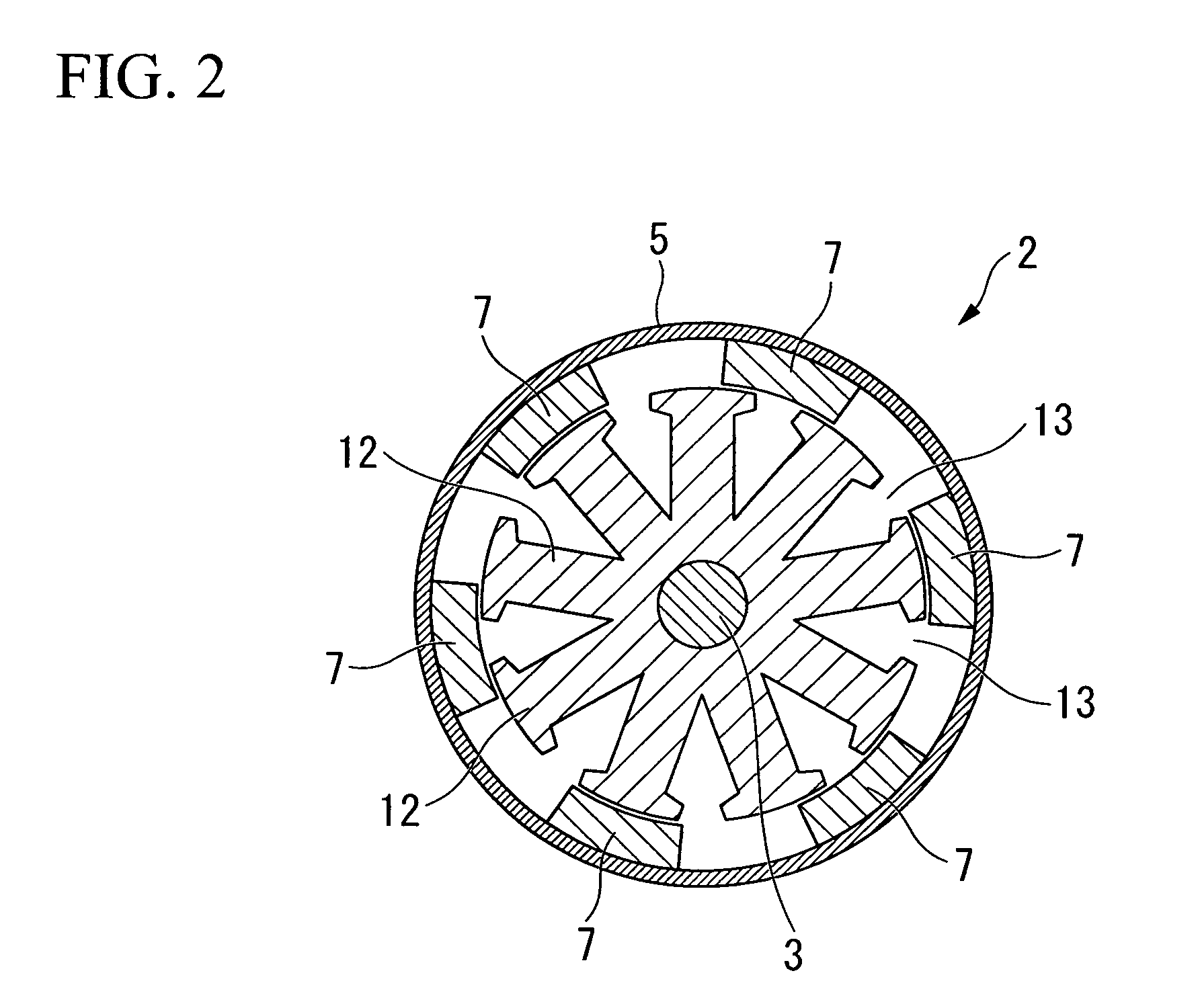

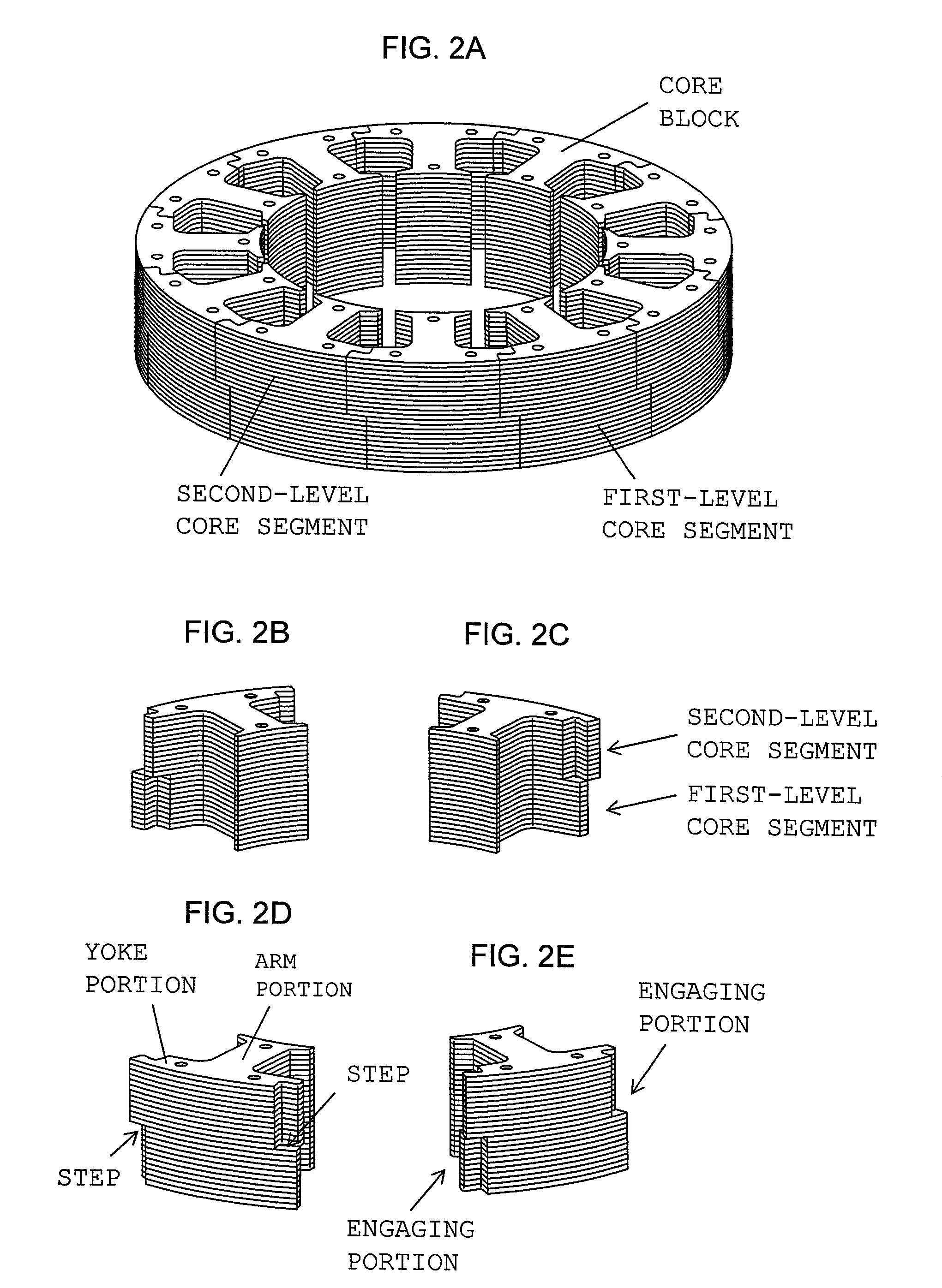

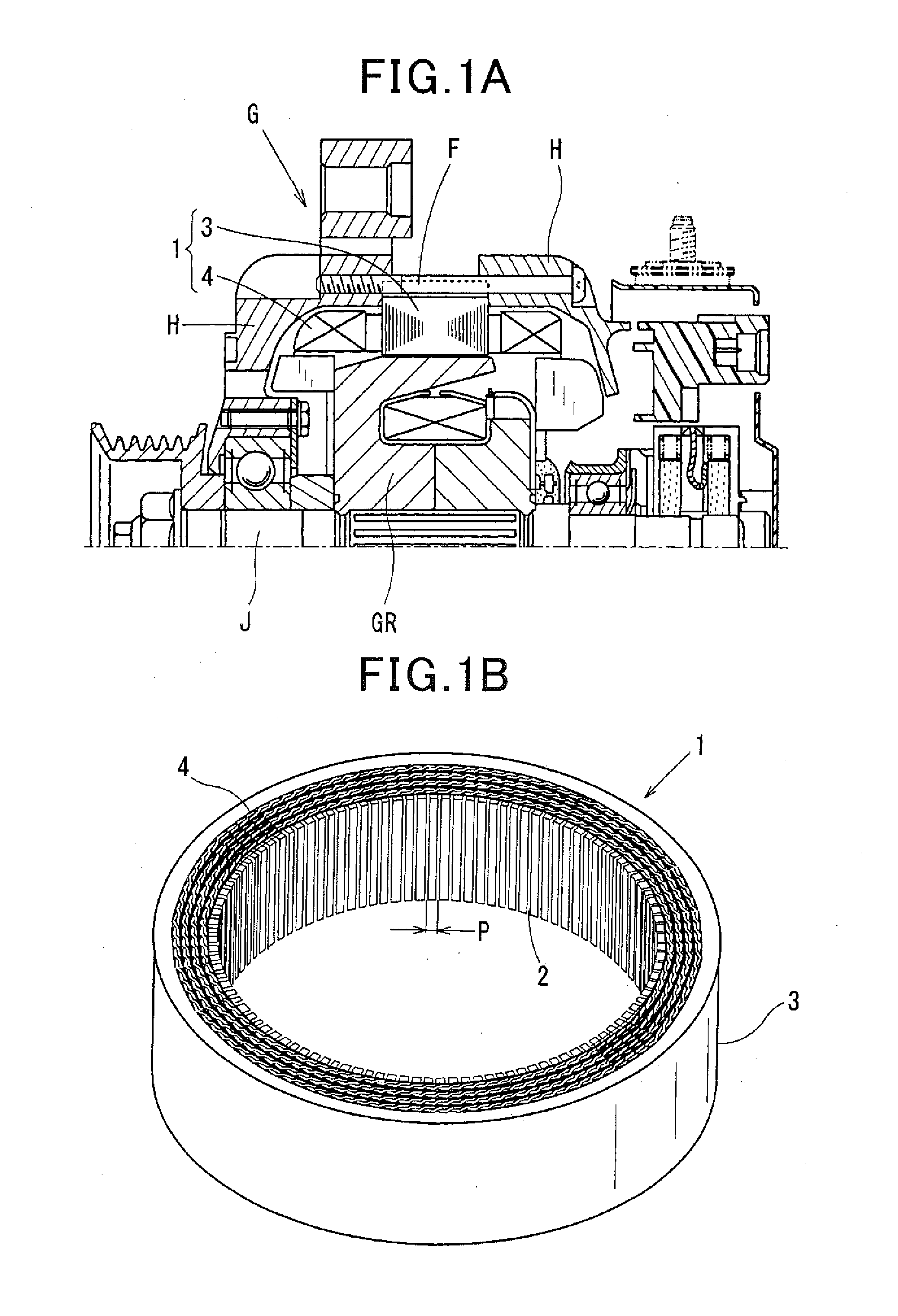

Core sheet, core and method of manufacturing an armature

InactiveUS6242835B1Improve space factorLess cogging in the torqueWindingsMagnetic circuit rotating partsEngineeringConductor Coil

Owner:ASMO CO LTD

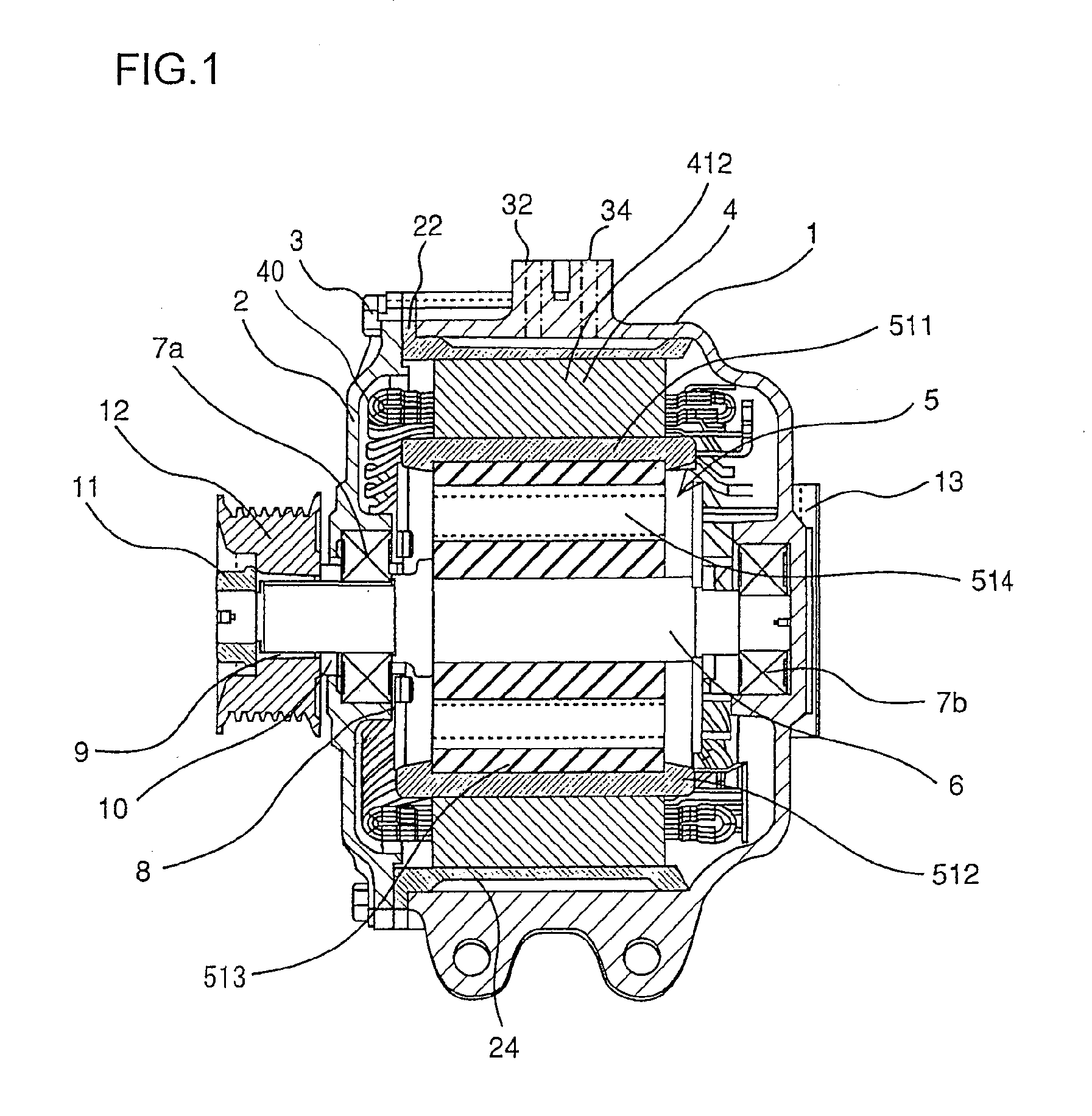

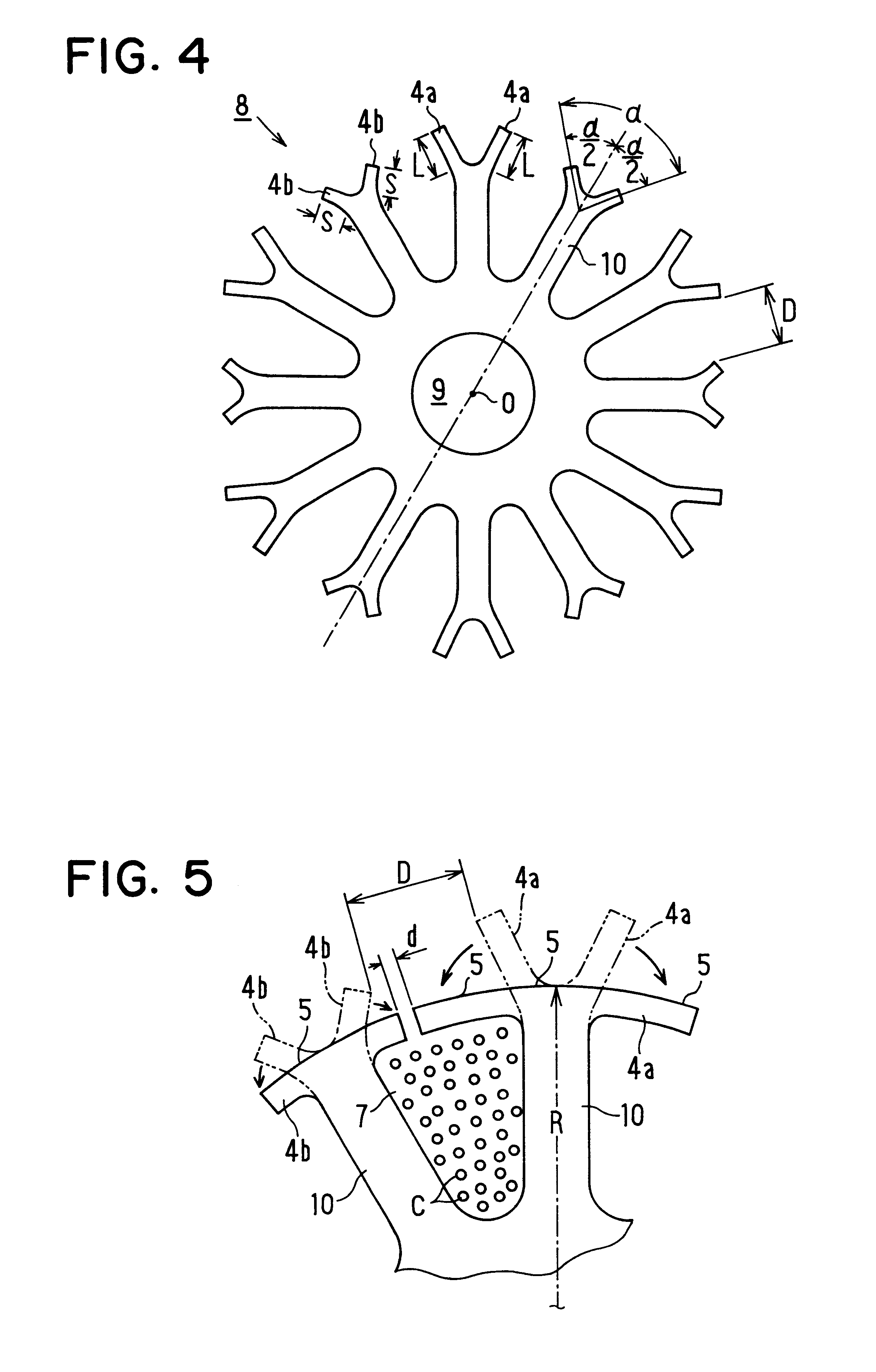

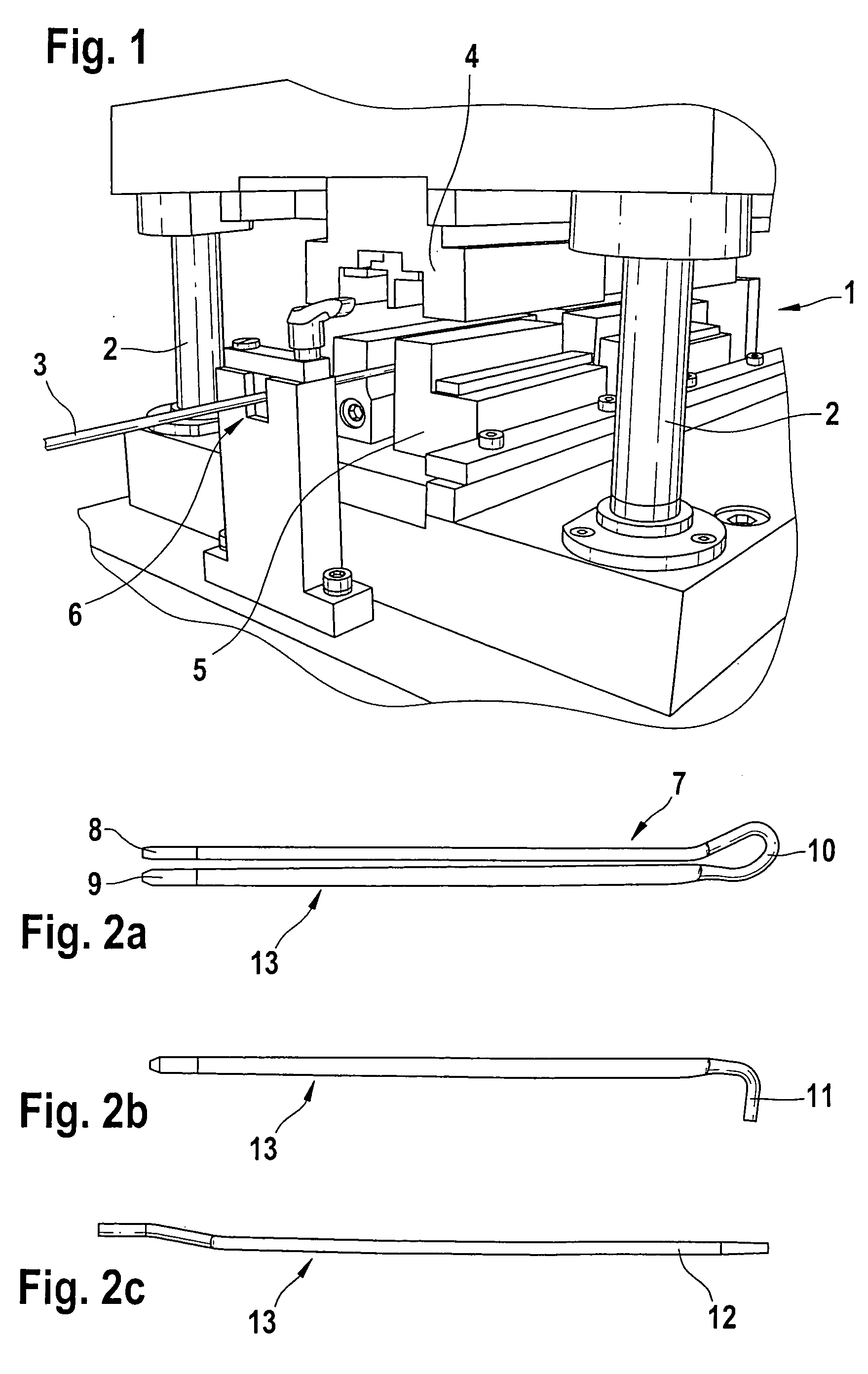

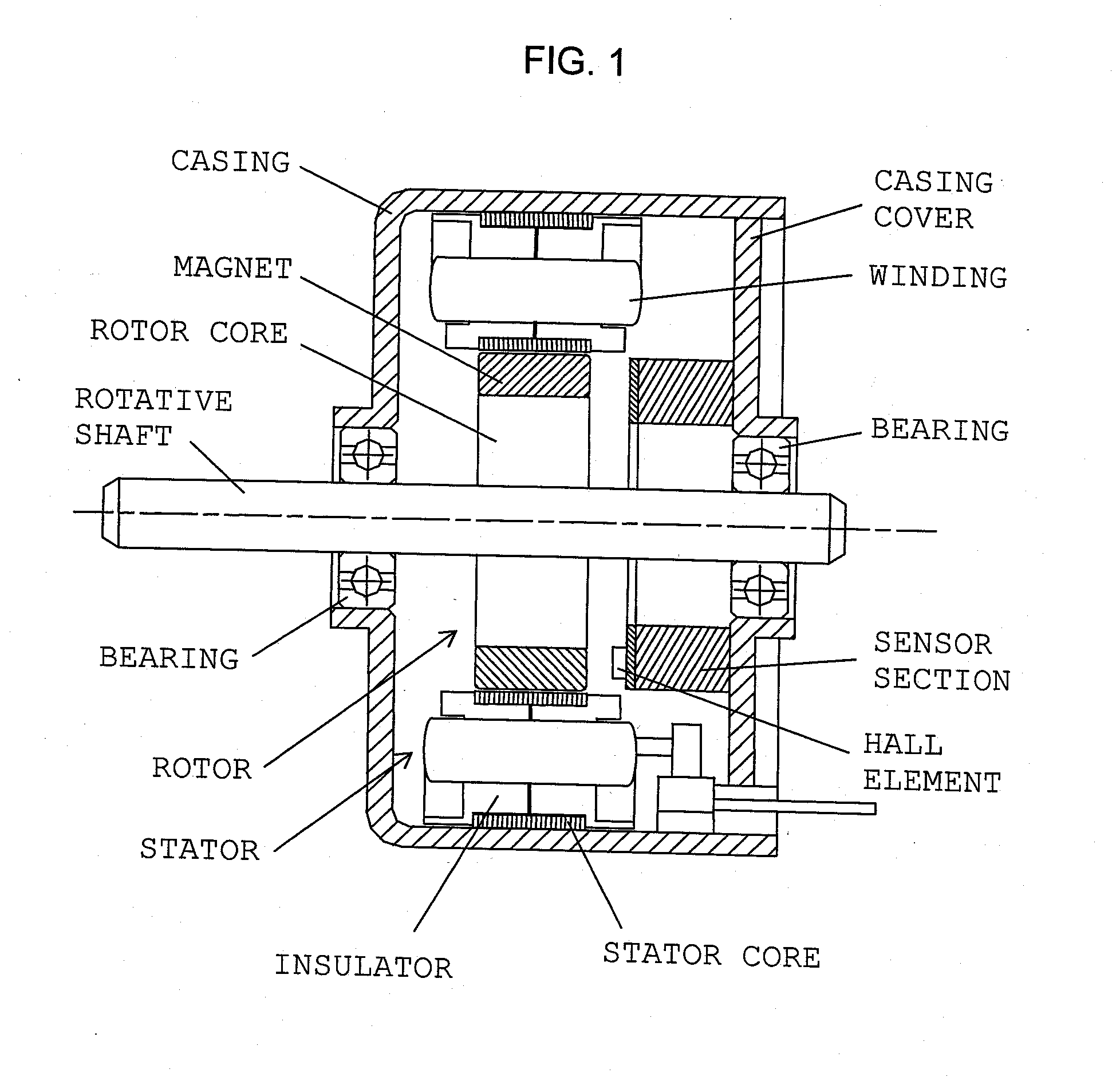

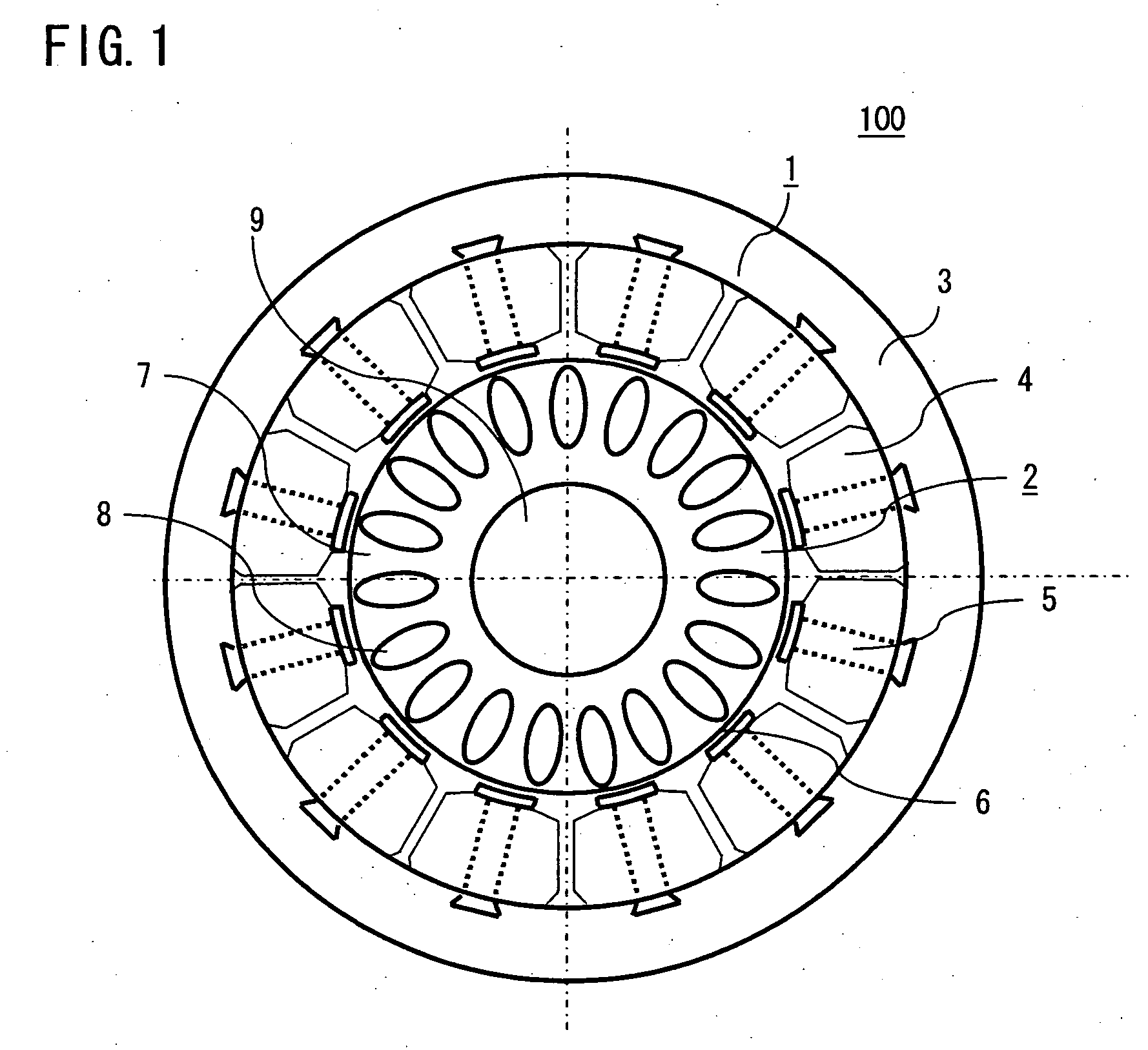

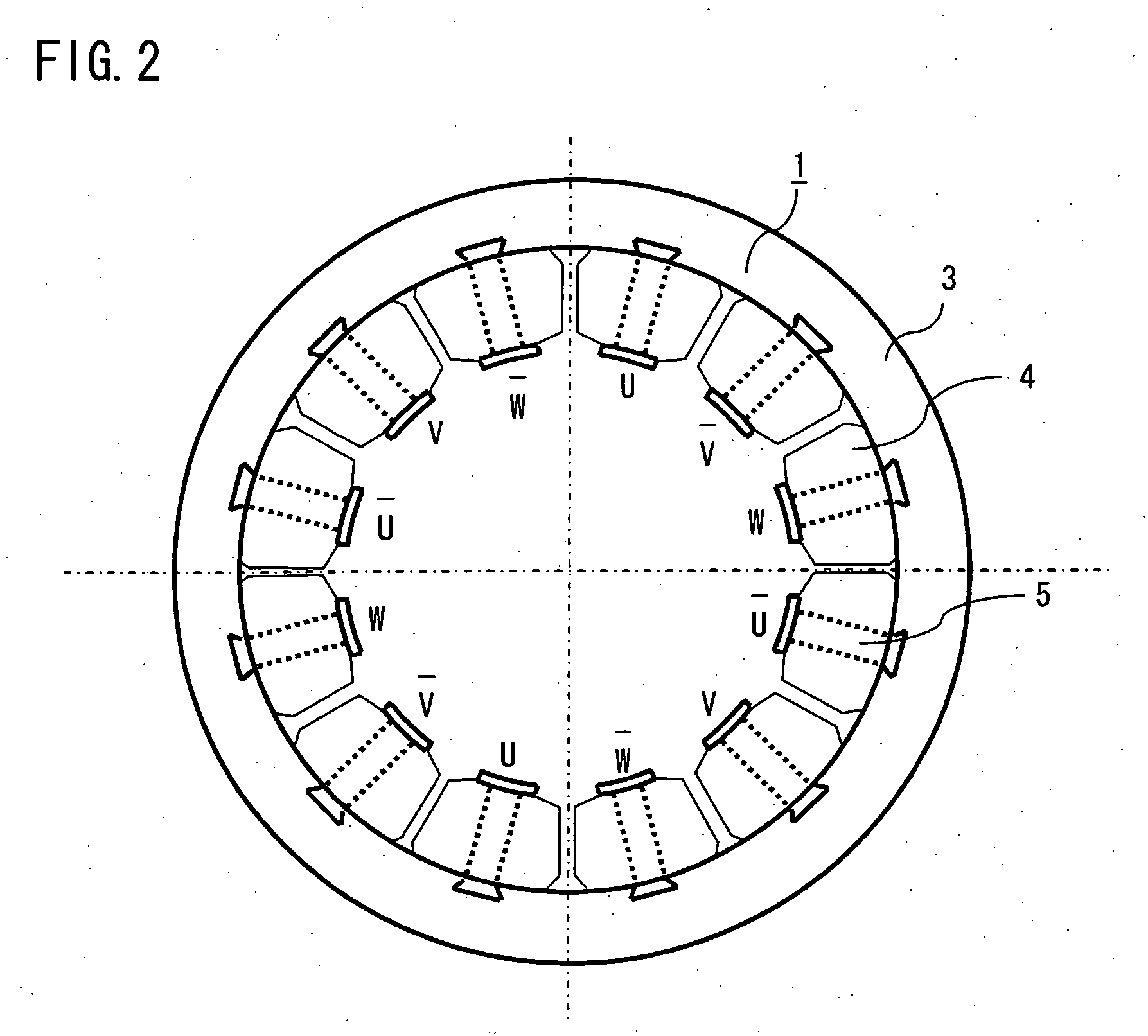

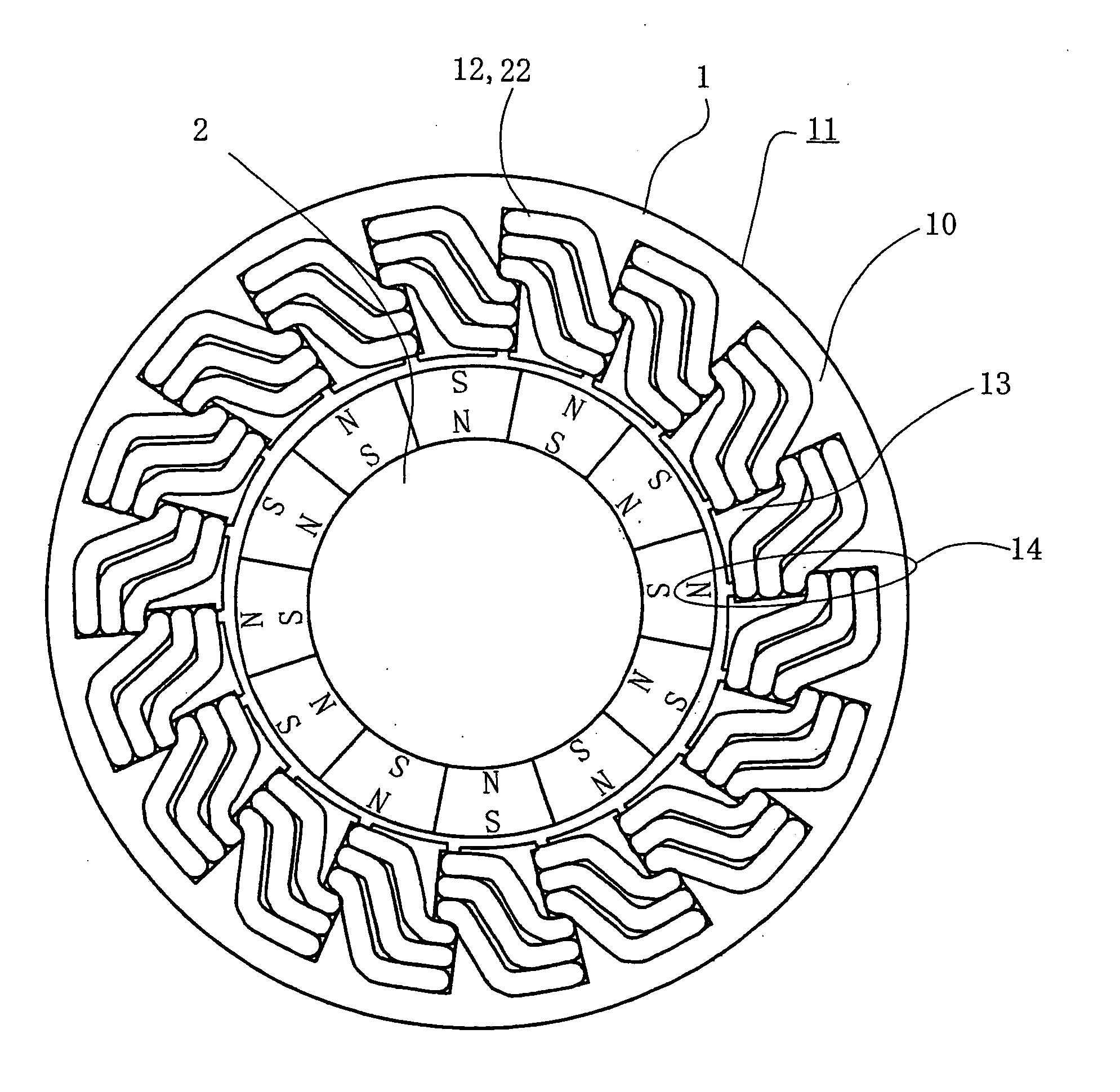

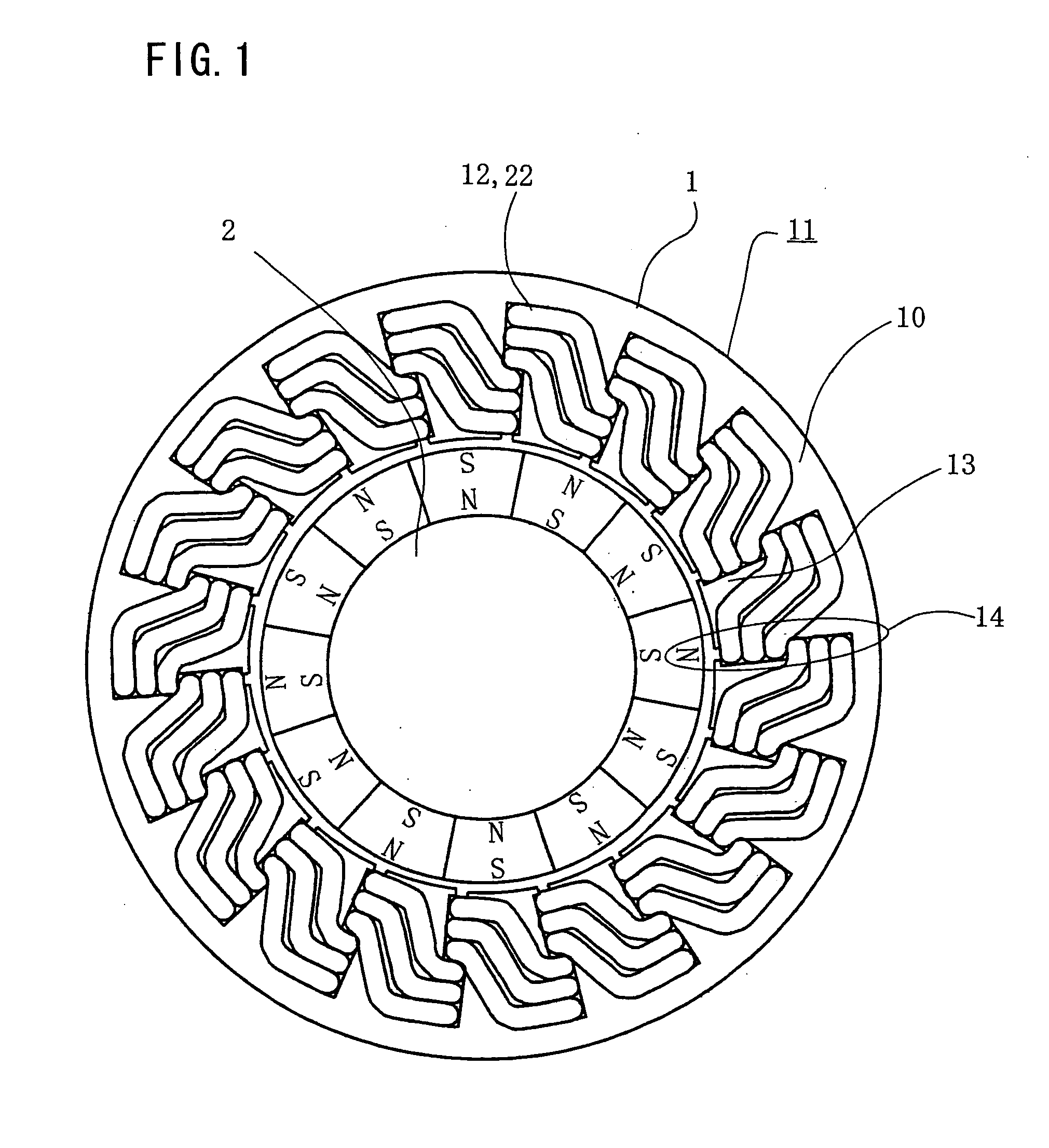

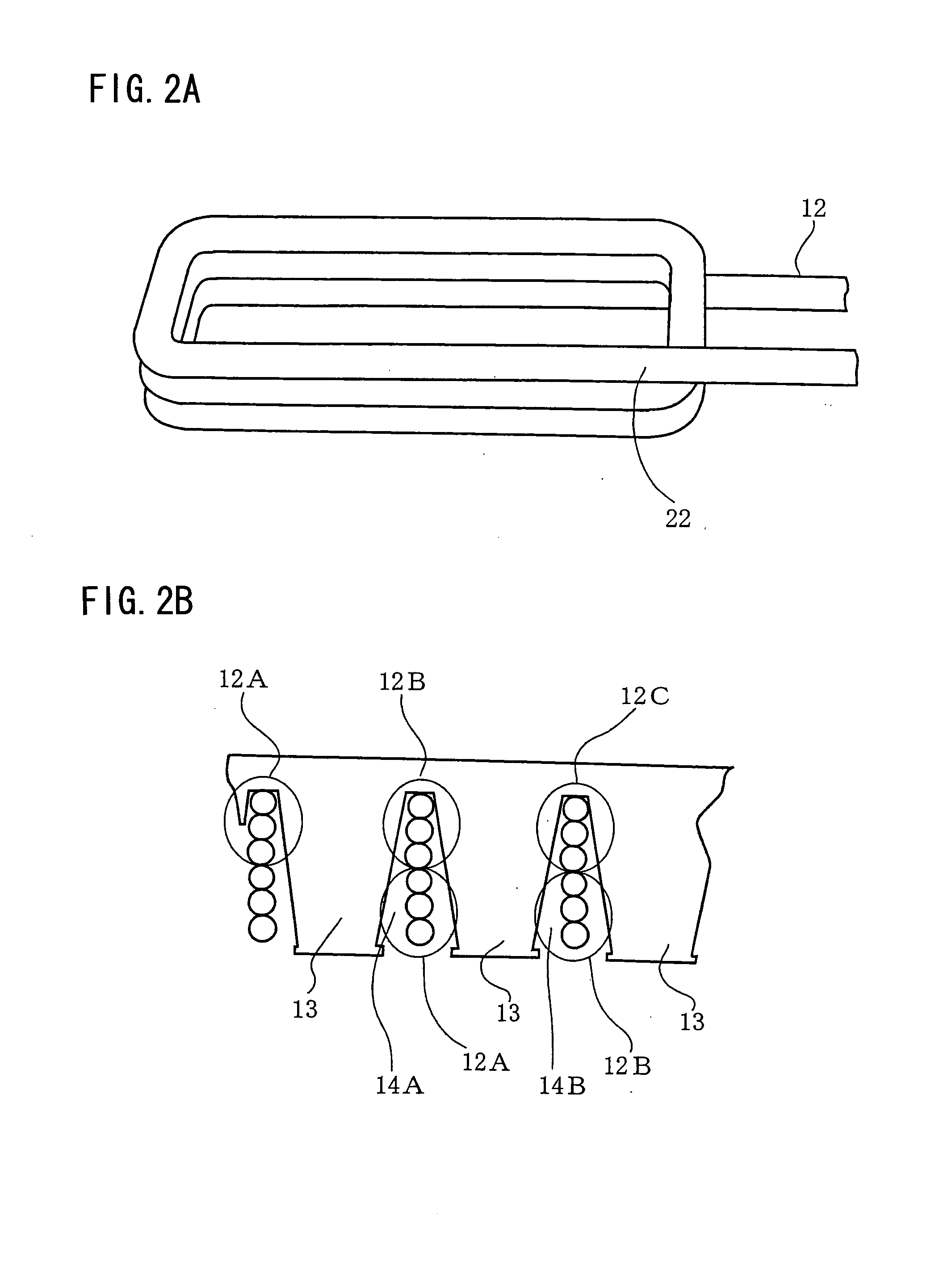

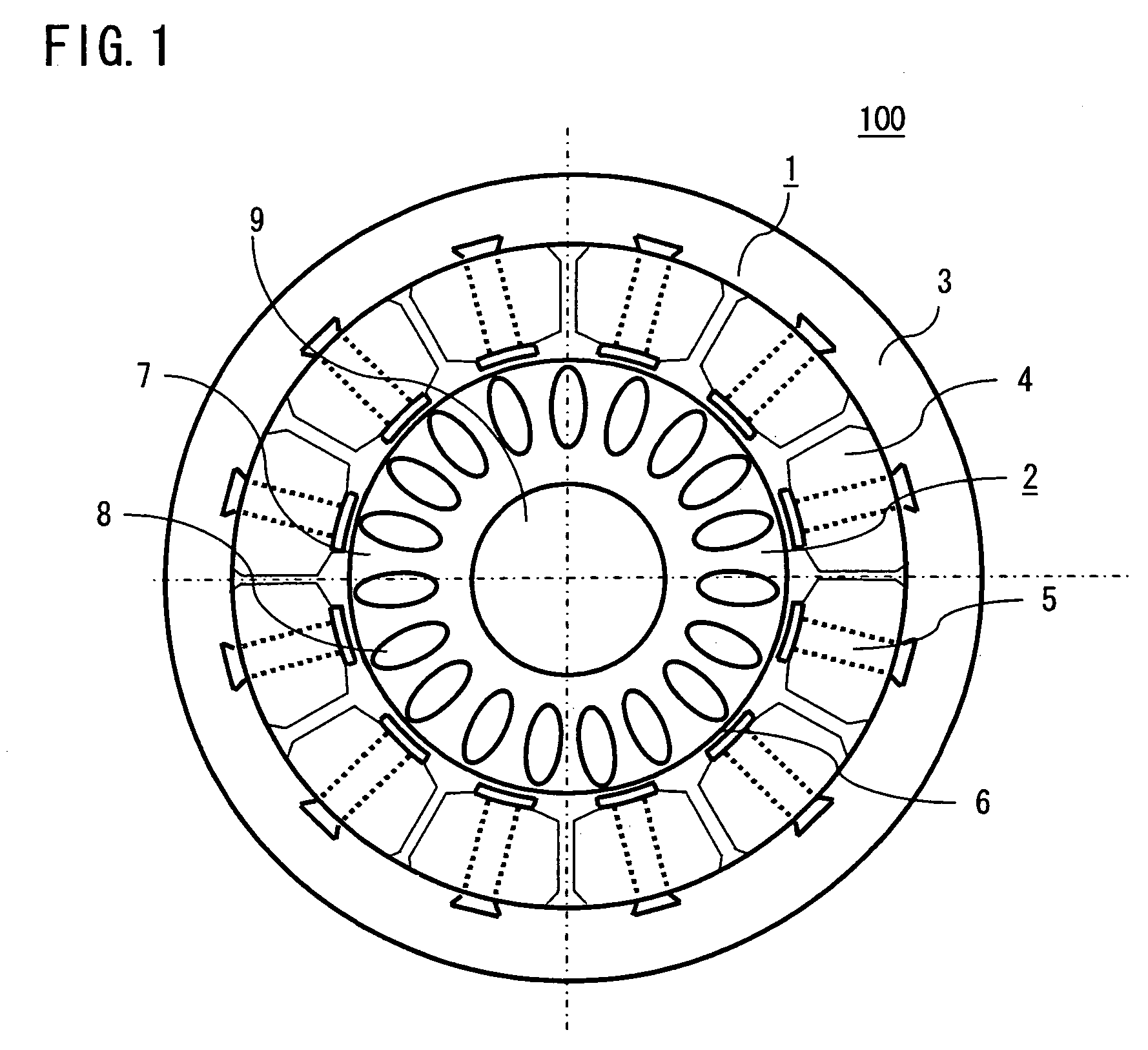

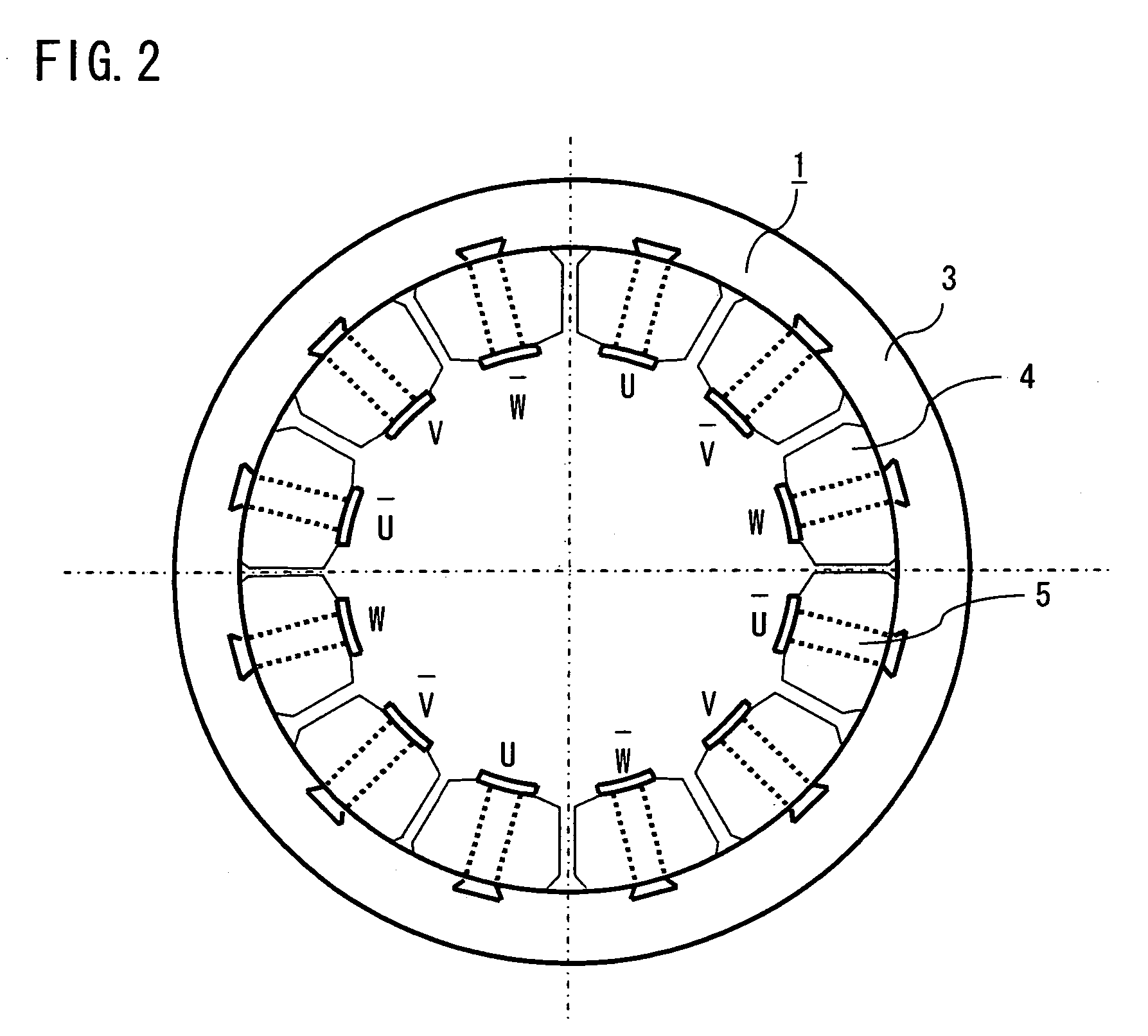

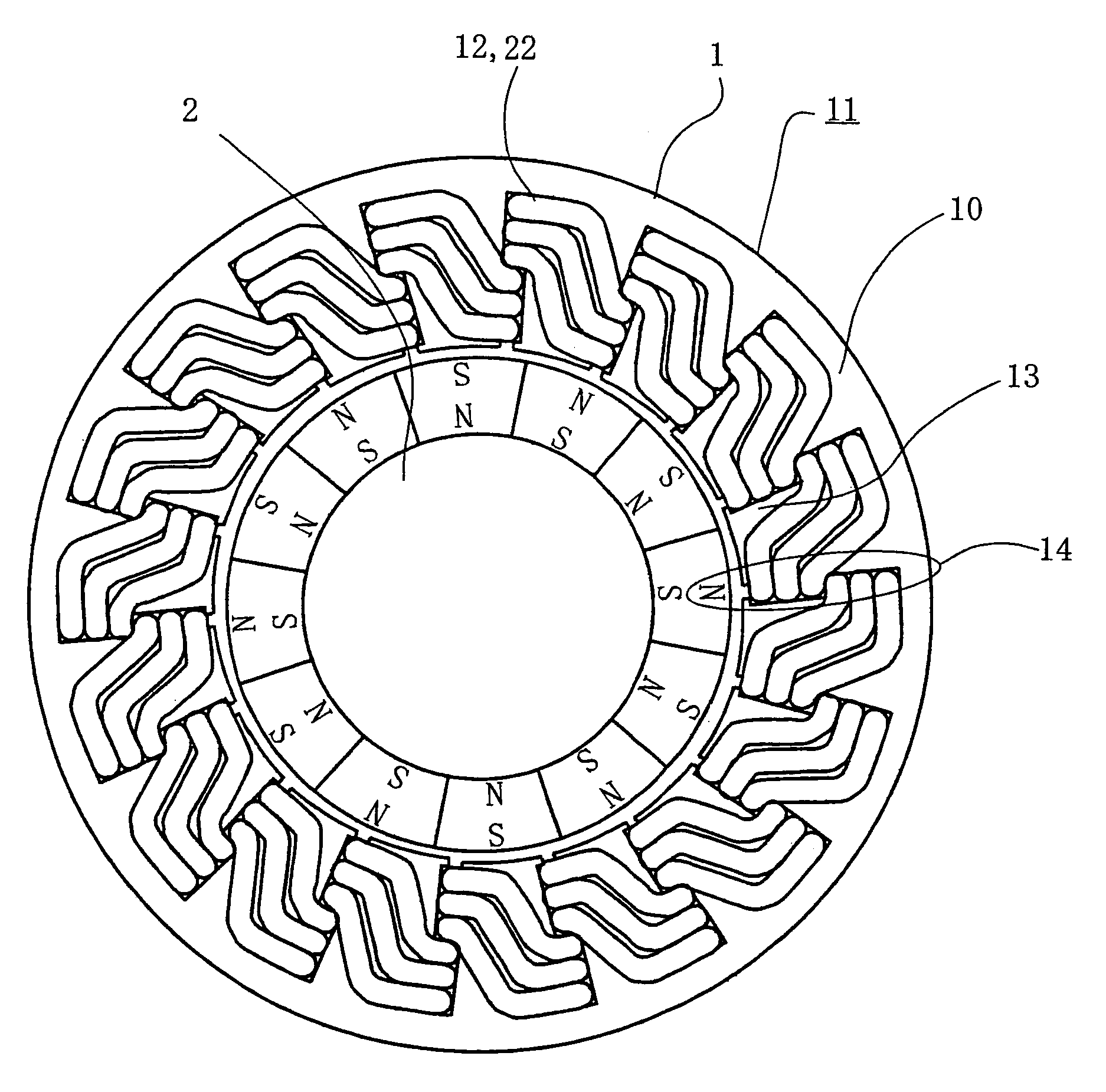

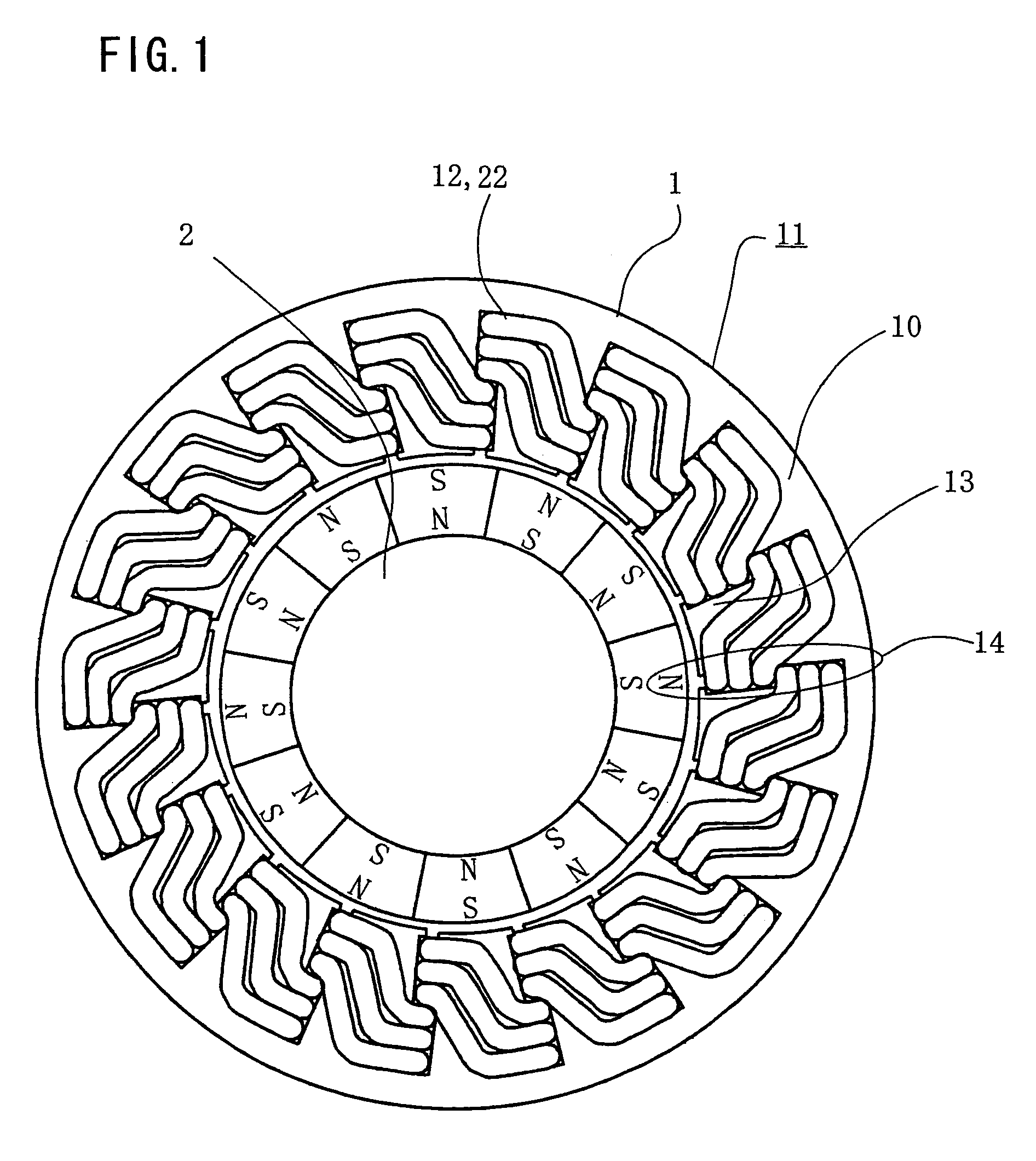

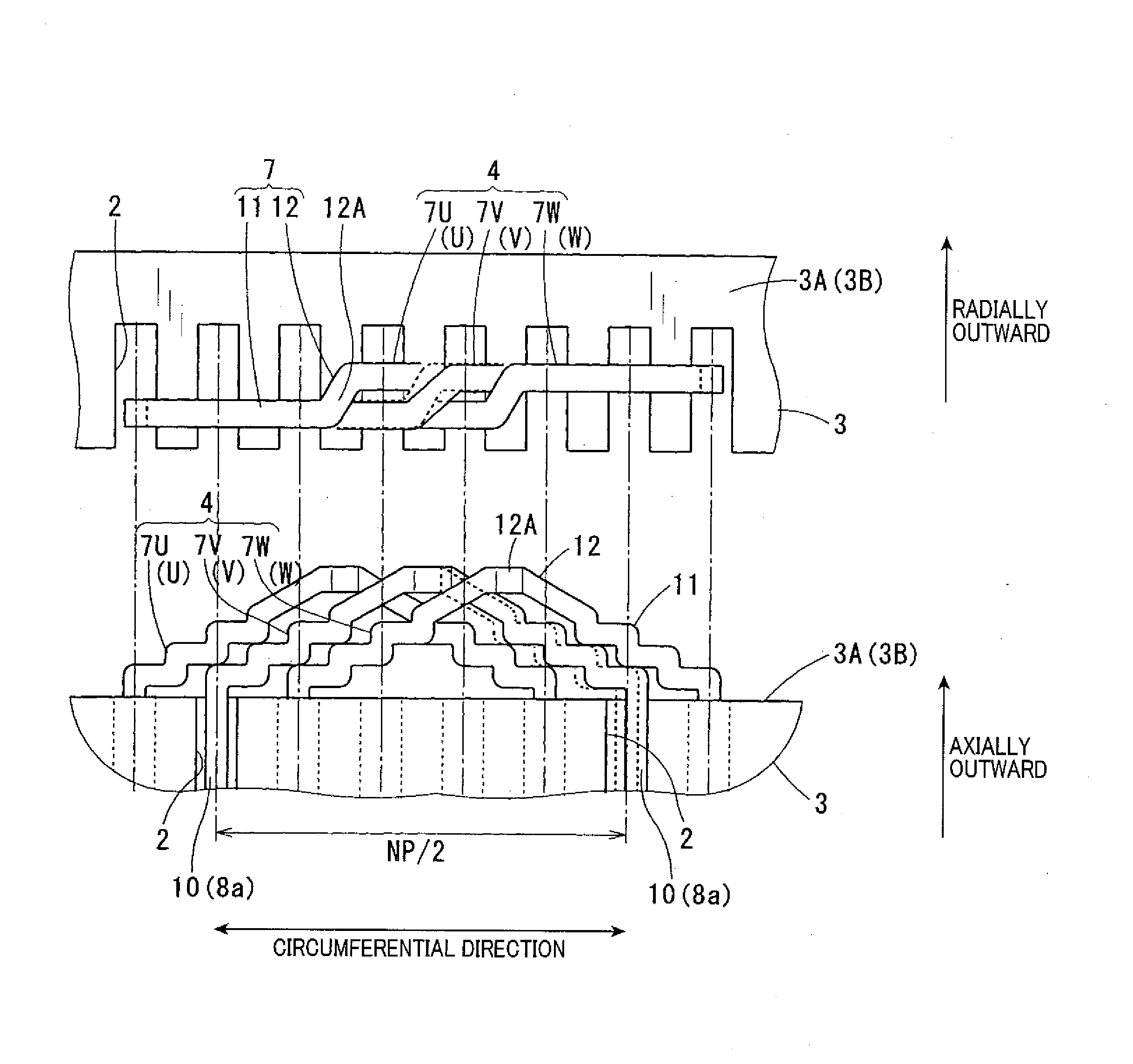

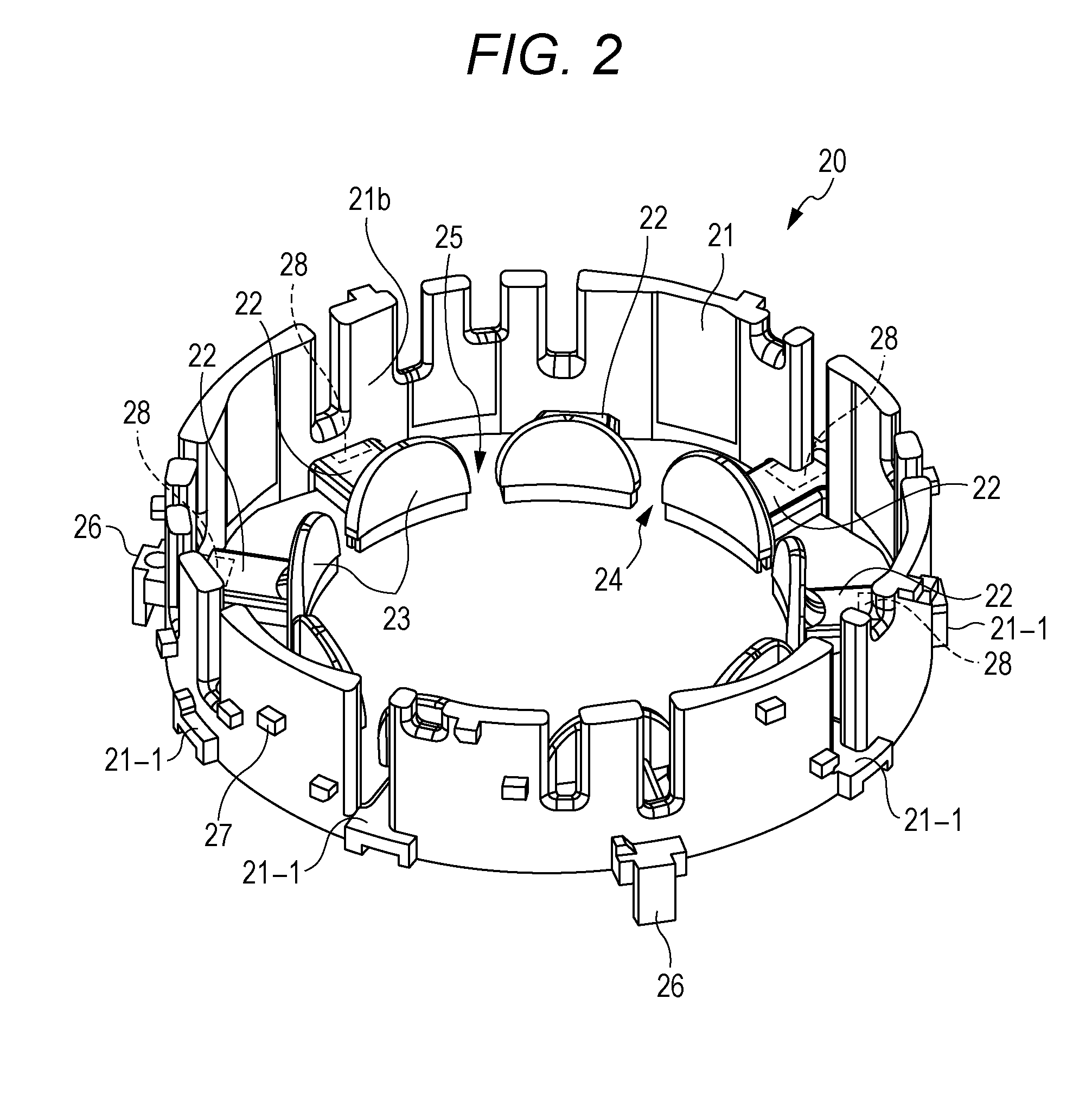

Rotary electric machine stator

InactiveUS6984911B2Improve space factorIncrease the number of lapsSynchronous generatorsWindings insulation shape/form/constructionElectric machinePhysics

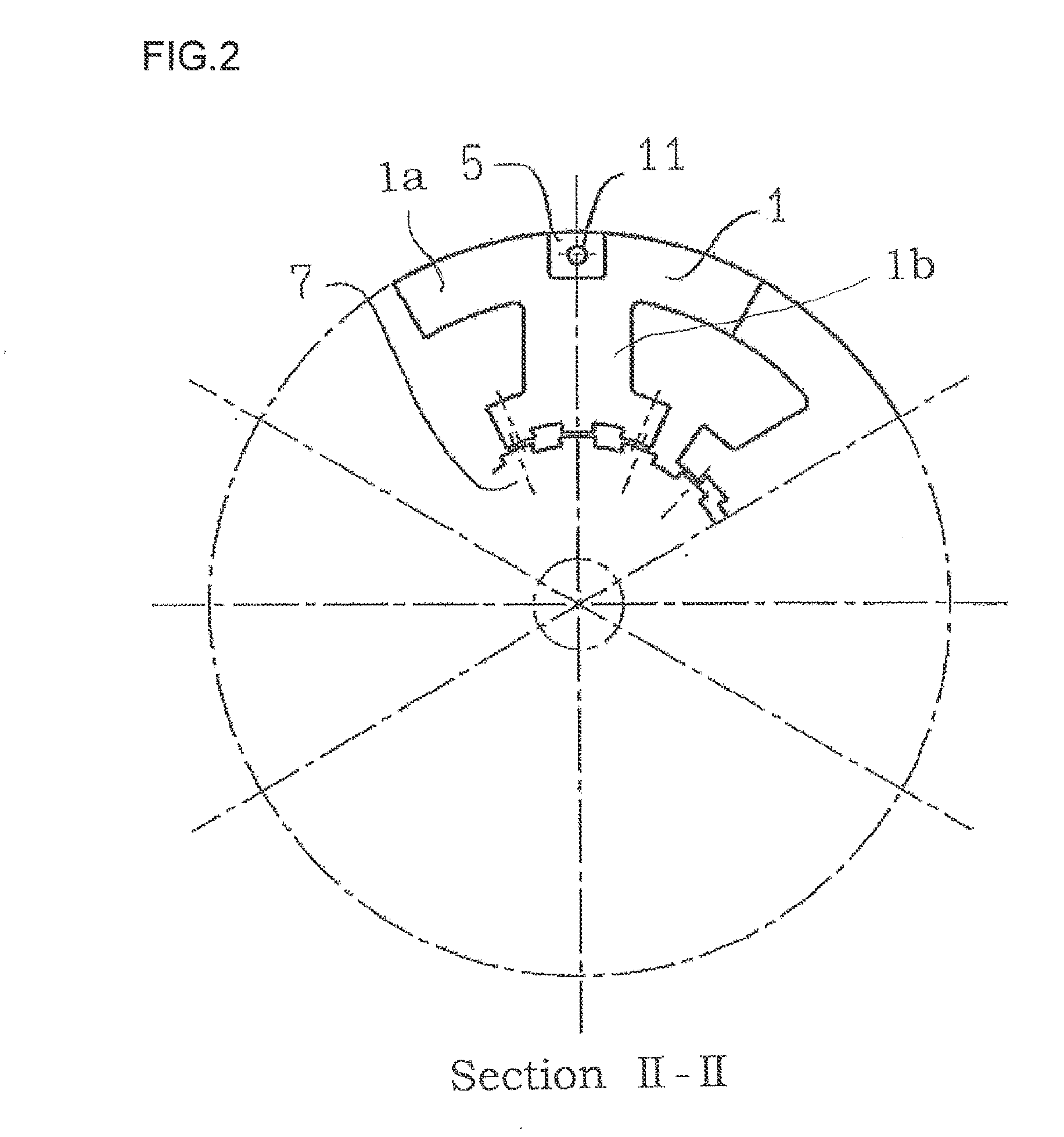

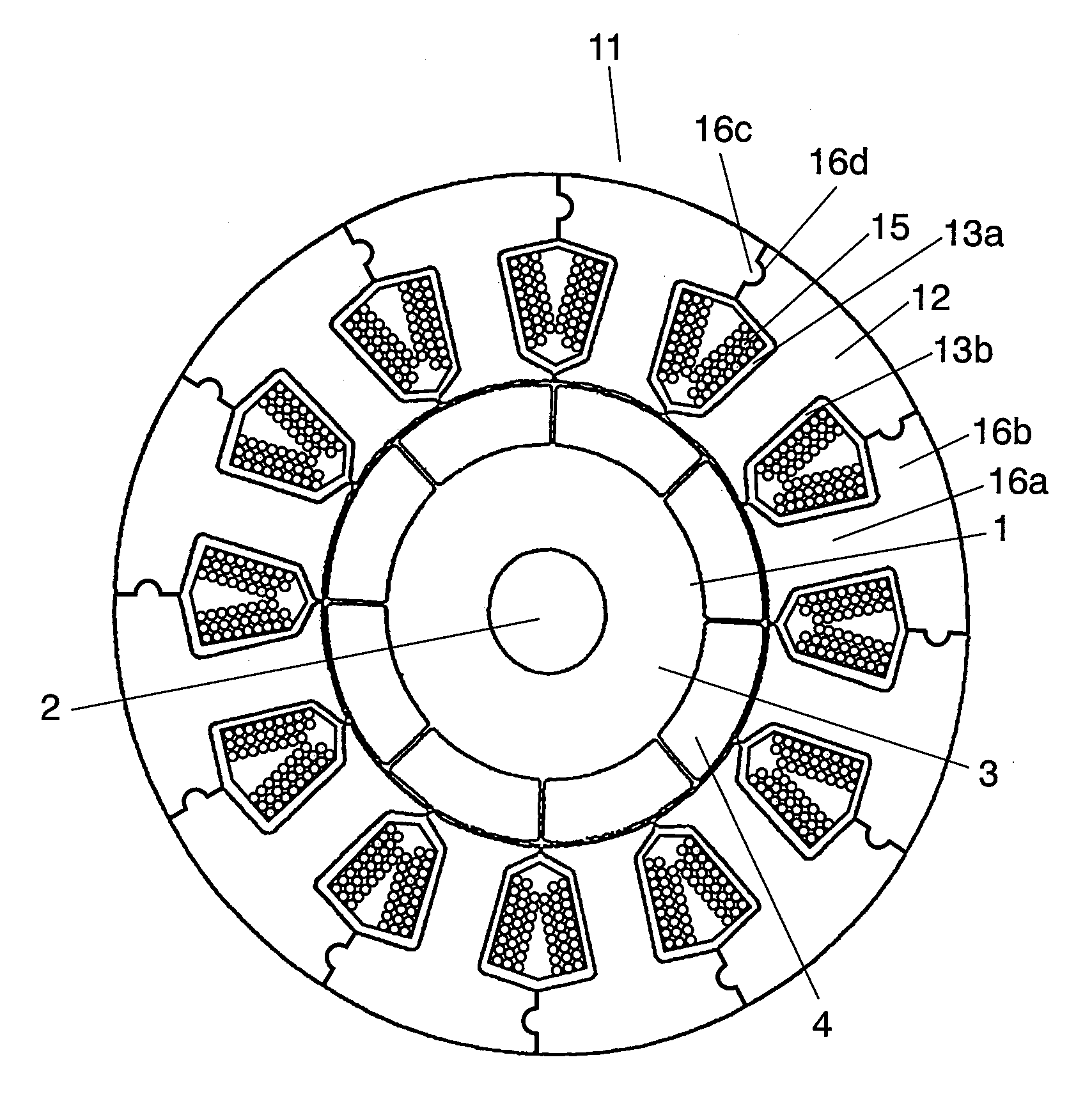

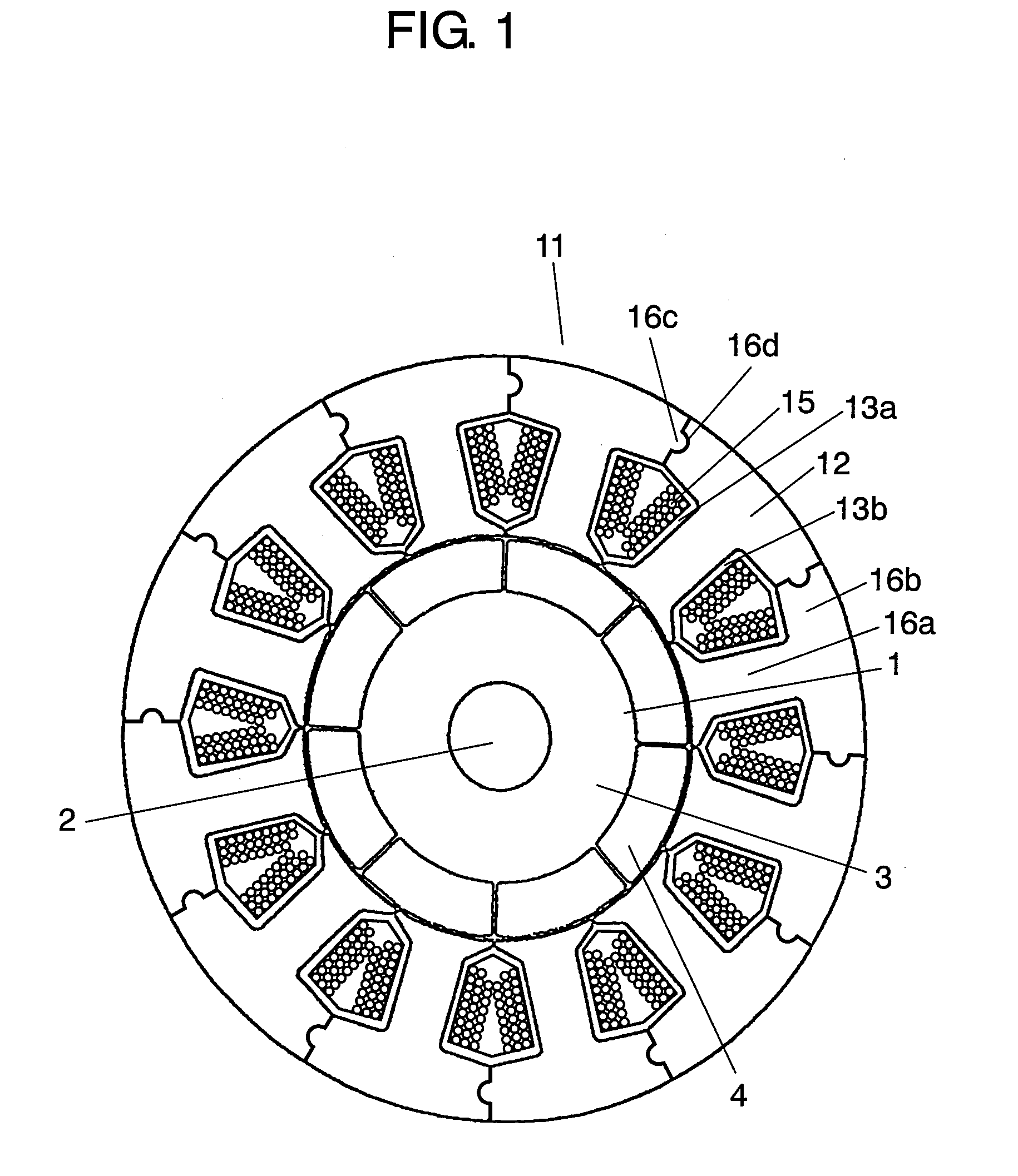

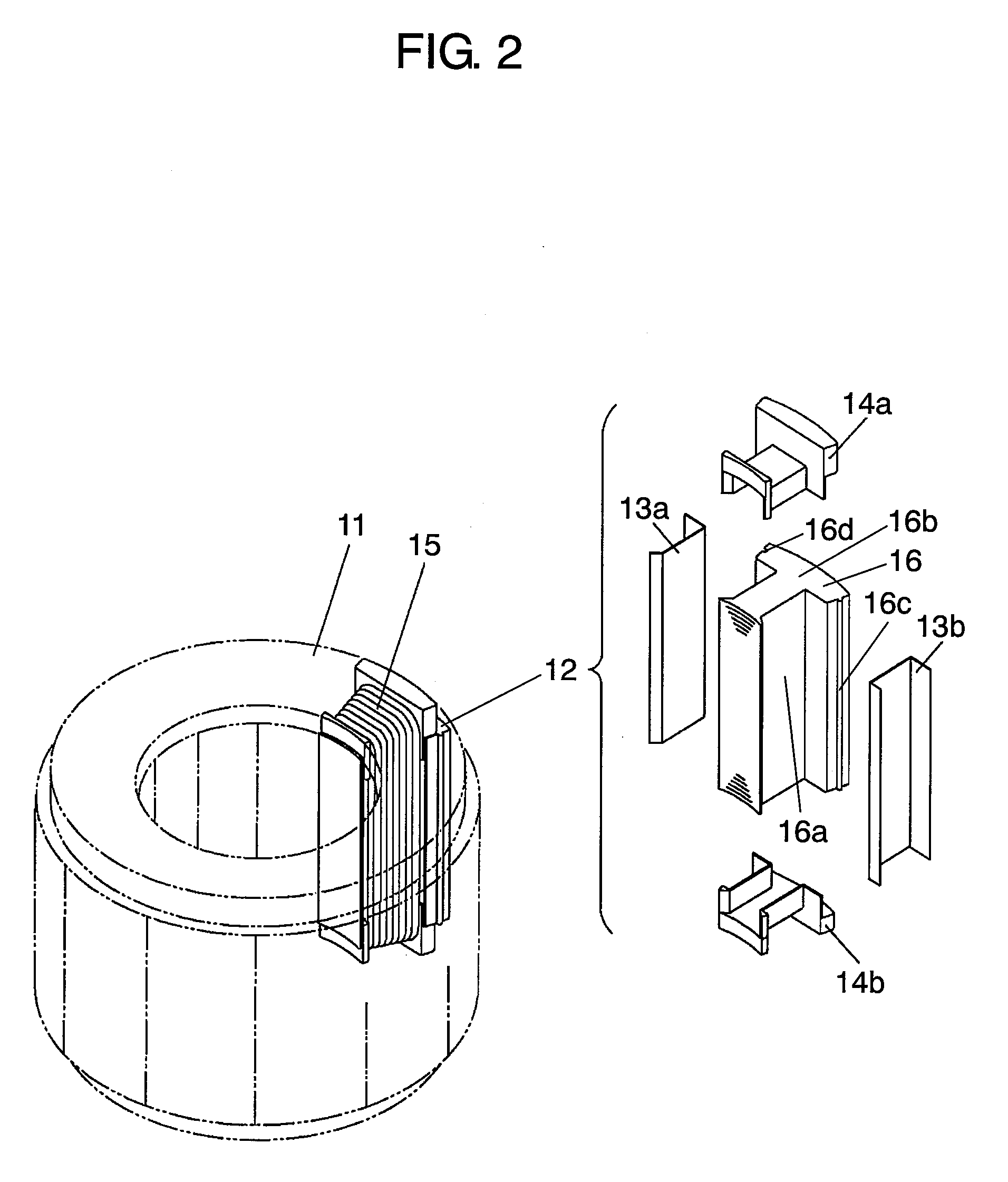

A stator for use in a rotating electrical machine is constituted by arranging the prescribed number of stator units in the circumferential direction of a stator core having a circular ring shape. The stator units provide magnetic teeth that project inwardly in the radial direction of the stator core. Coils are wound about the magnetic teeth via insulating members. Each of the insulating members arranges thick portions that slightly project opposite to each other in the width direction of the magnetic tooth, wherein the thick portions are shifted in positions in the thickness direction of the stator core with respect to opposite sides of the magnetic teeth arranged opposite to each other. Thus, it is possible to noticeably improve the space factor in the stator.

Owner:HONDA MOTOR CO LTD

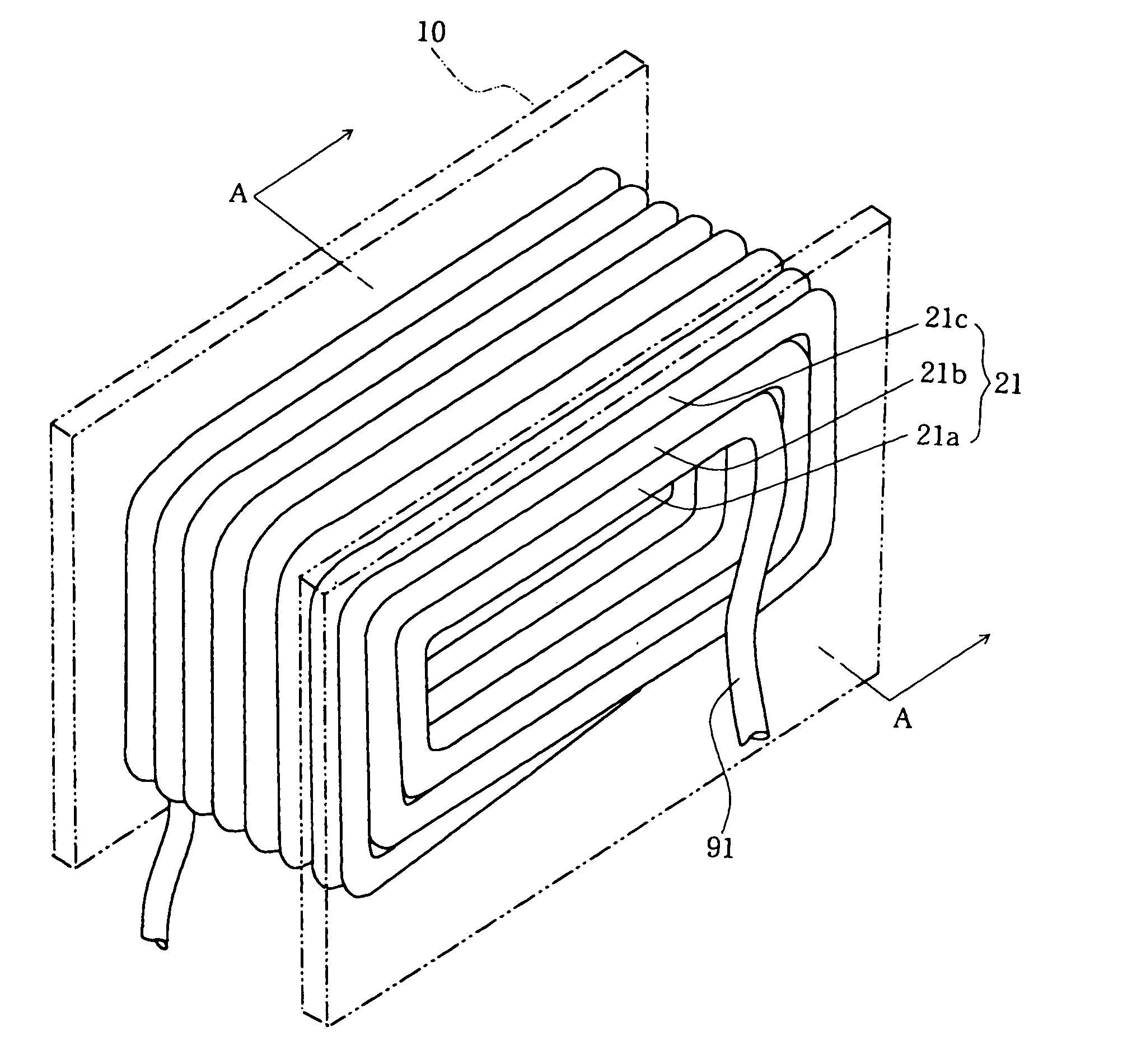

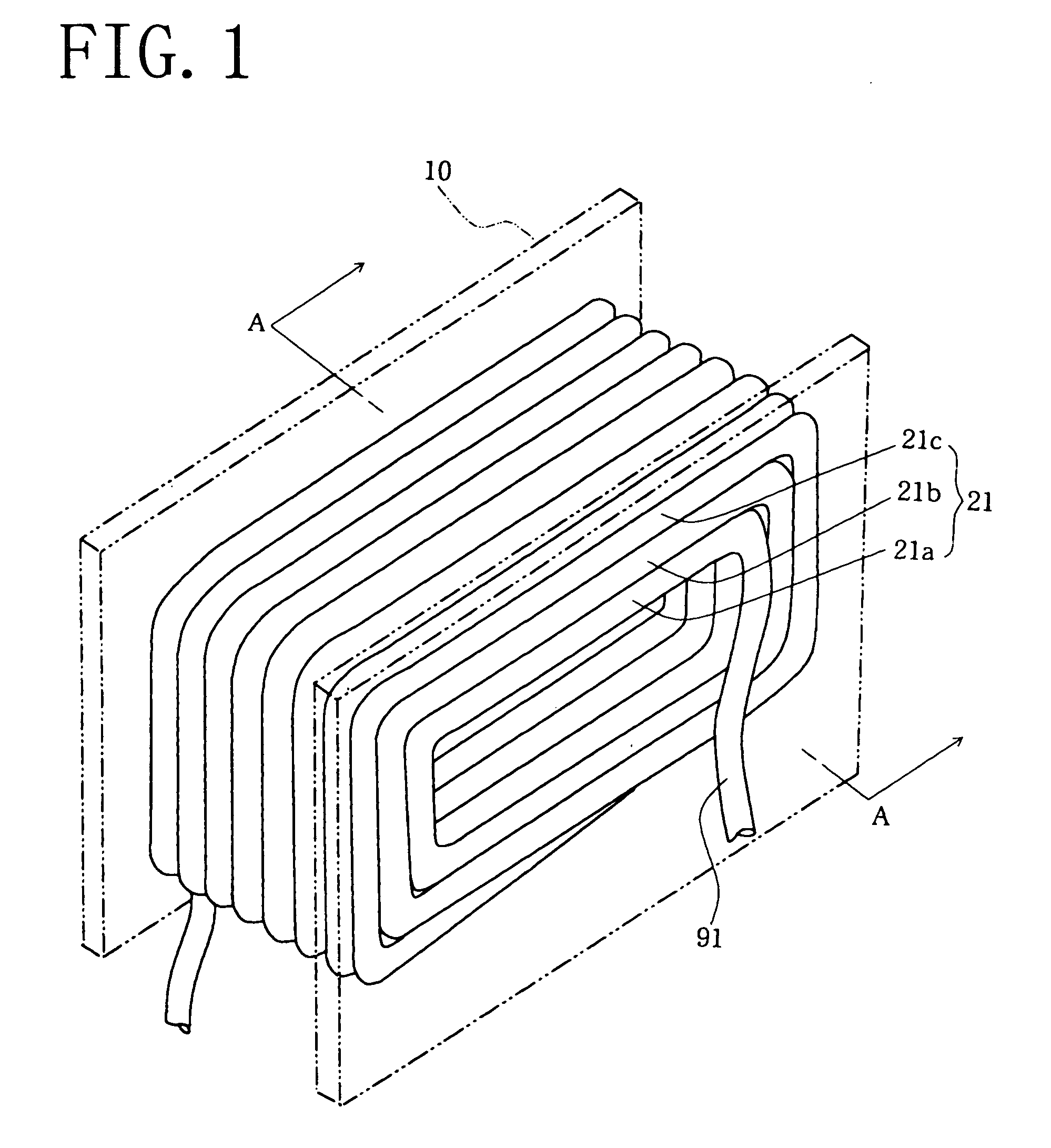

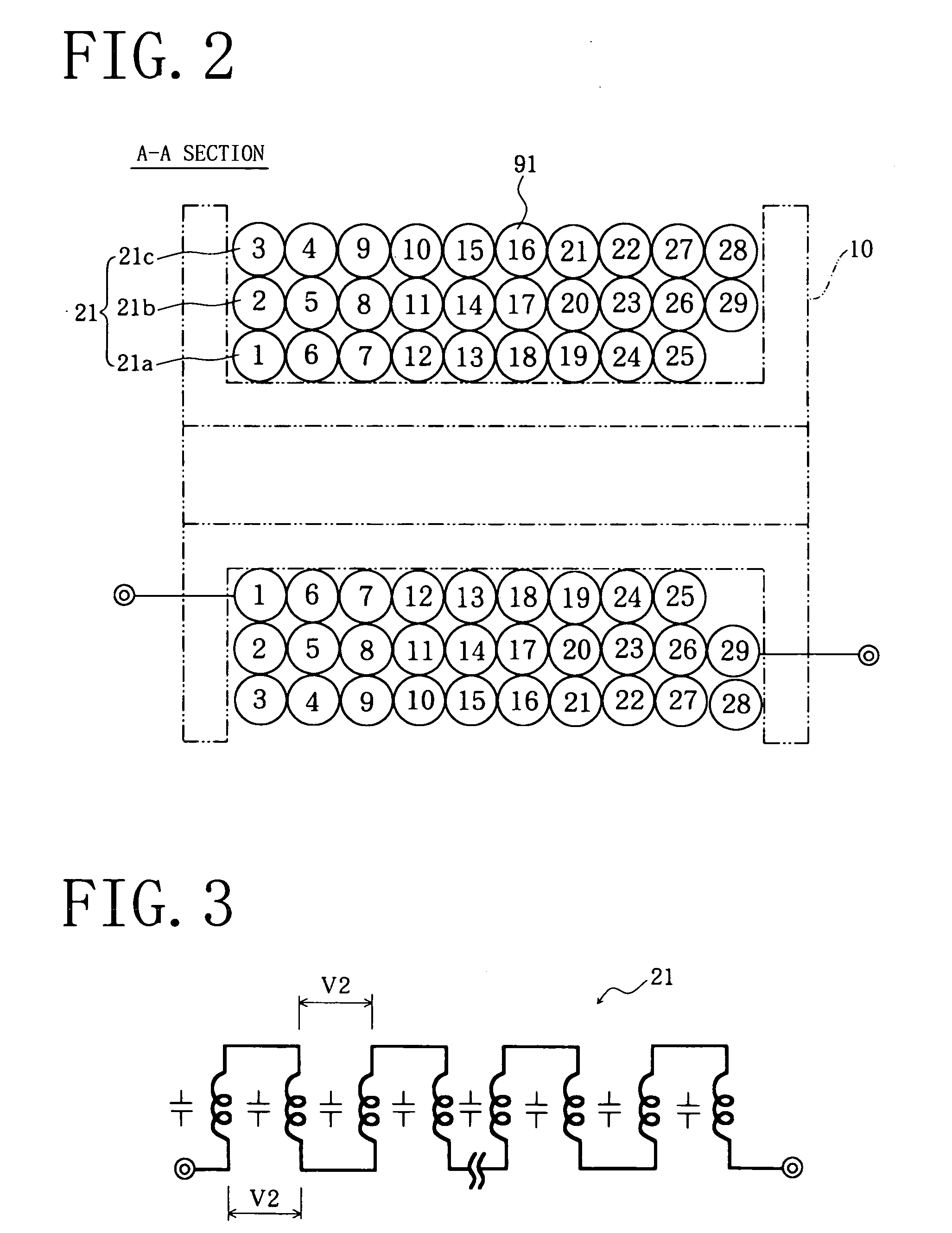

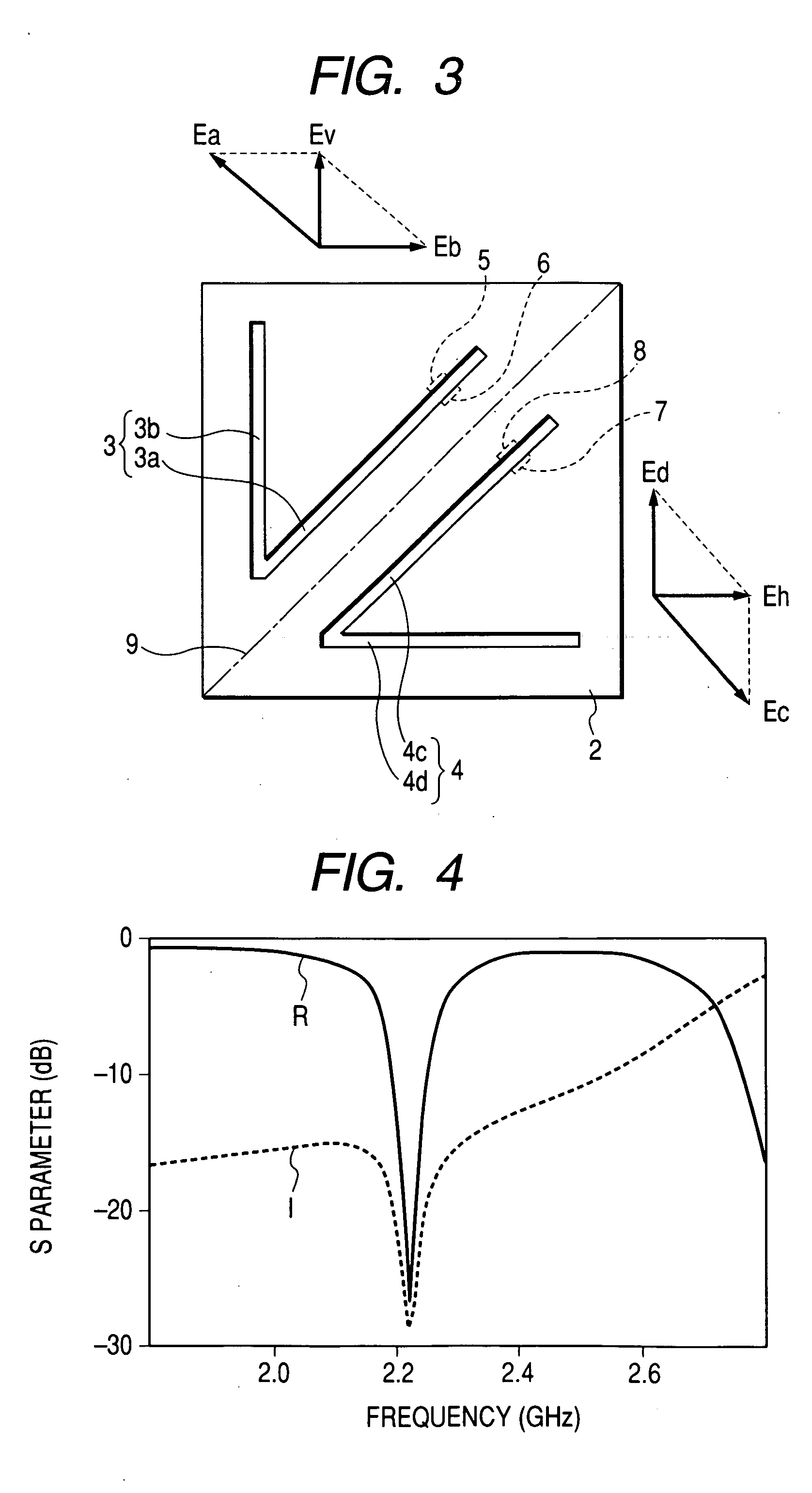

Air-core coil and manufacturing method thereof

InactiveUS20050212644A1Stray capacitySolve large capacityCircuit-breaking switches for excess currentsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

The present invention provides an air-core coil 21 wherein one conductor is wound into a spiral form to thereby form consecutively, axially of the coil, a plurality of unit turn portions (25, 26, 27) which are different from each other in inner peripheral length and to form, axially of the coil, unit coil portions comprising the plurality of unit turn portions (25, 26, 27) to produce a partly finished coil 20, and thereafter the partly finished coil 20 is compressed to force the unit turn portion of small inner peripheral length inwardly of the unit turn portion of great inner peripheral length from among the unit turn portions providing each of the unit coil portions to thereby make each of the unit coil portions multi-layered. Thus the air-core coil 21 exhibits a smaller voltage across layers than conventionally and excellent frequency characteristics.

Owner:SHT CO LTD

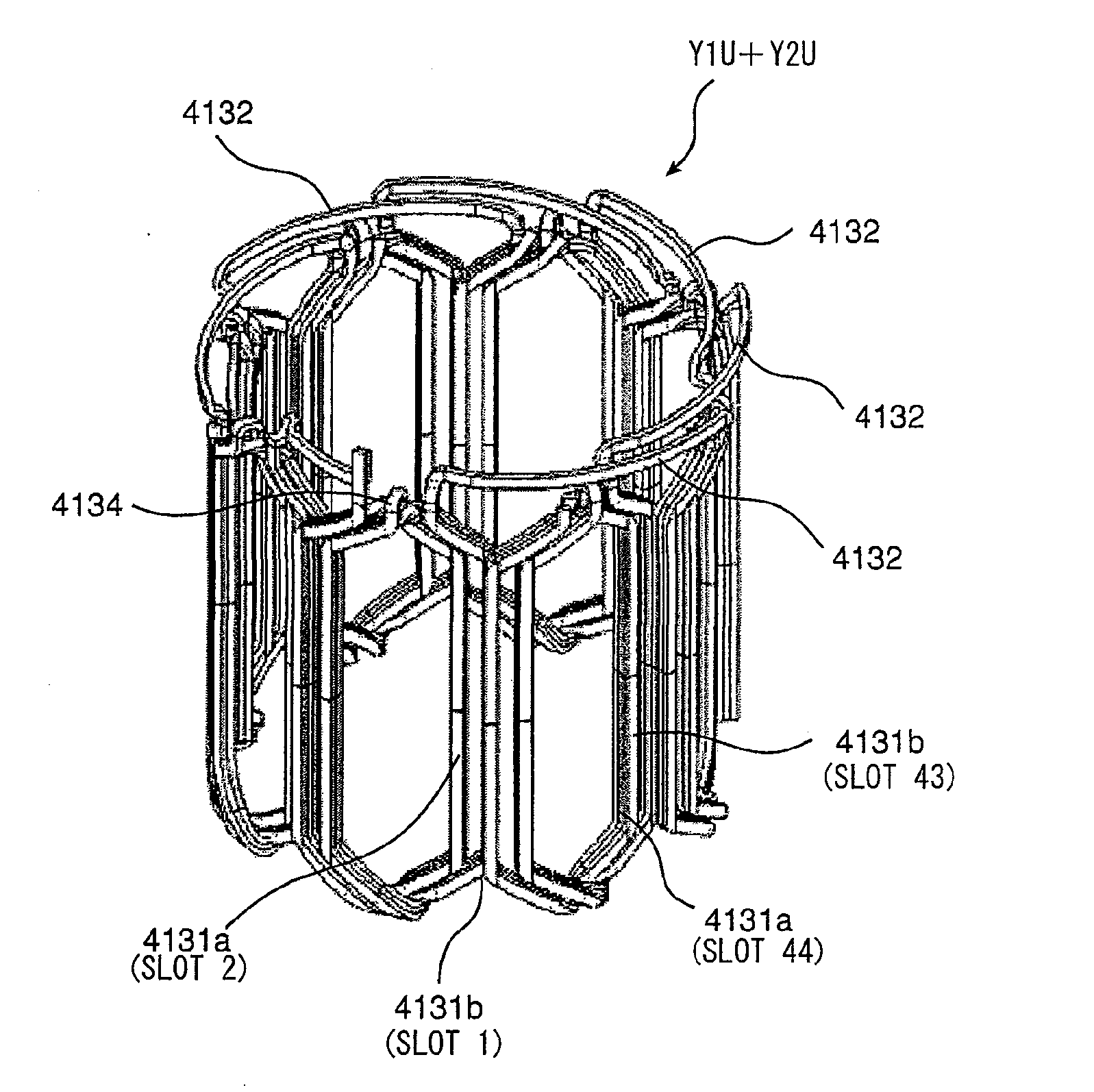

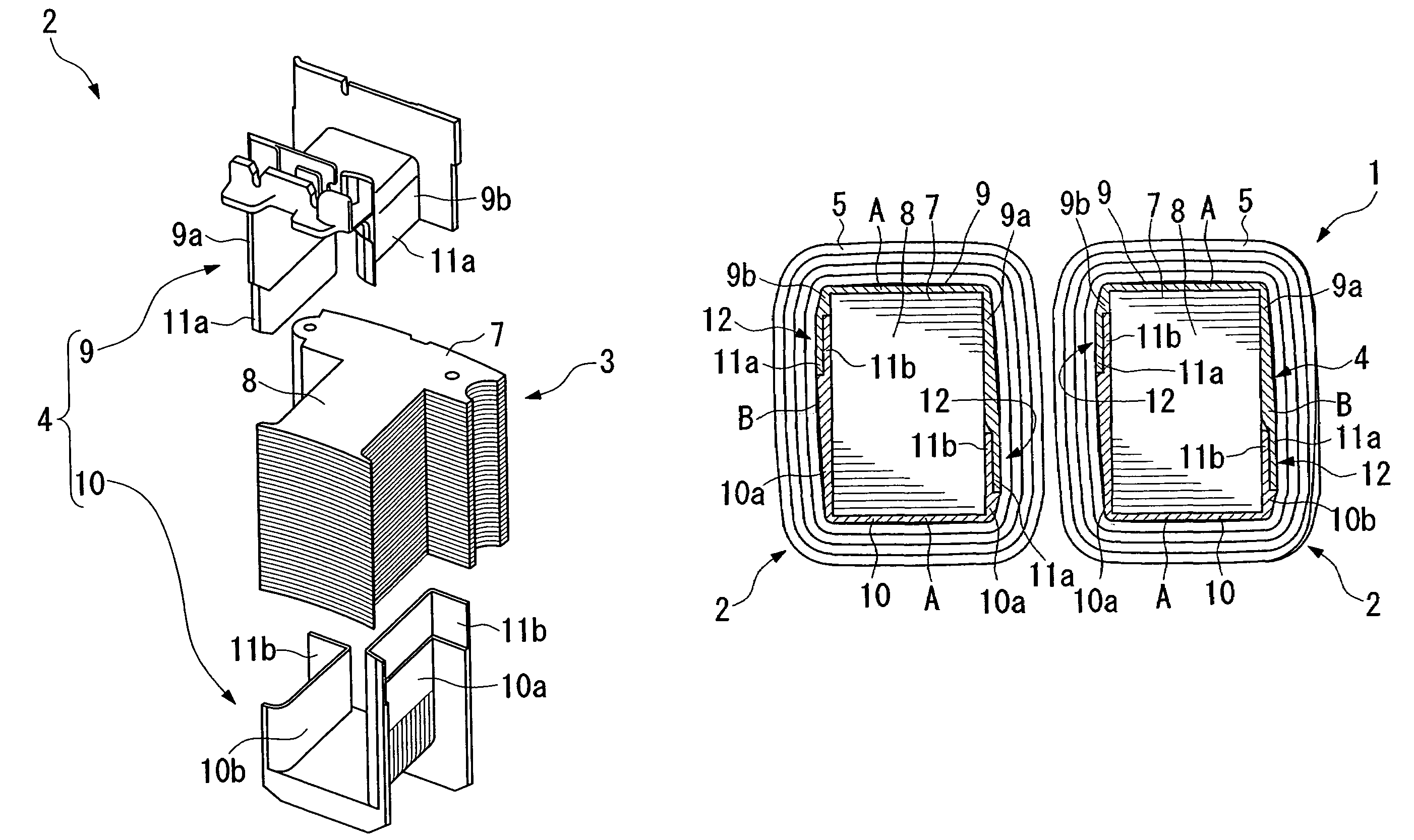

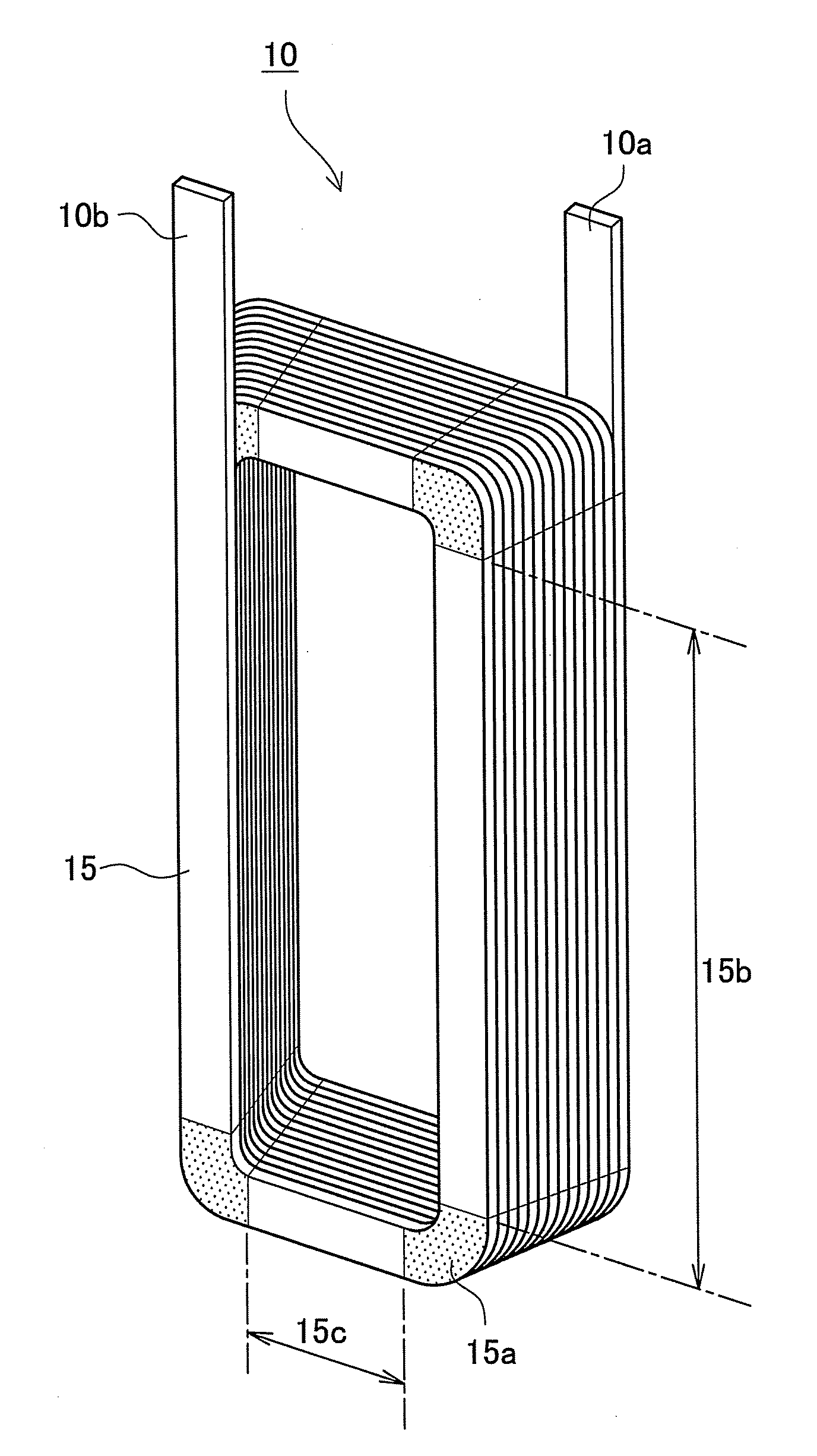

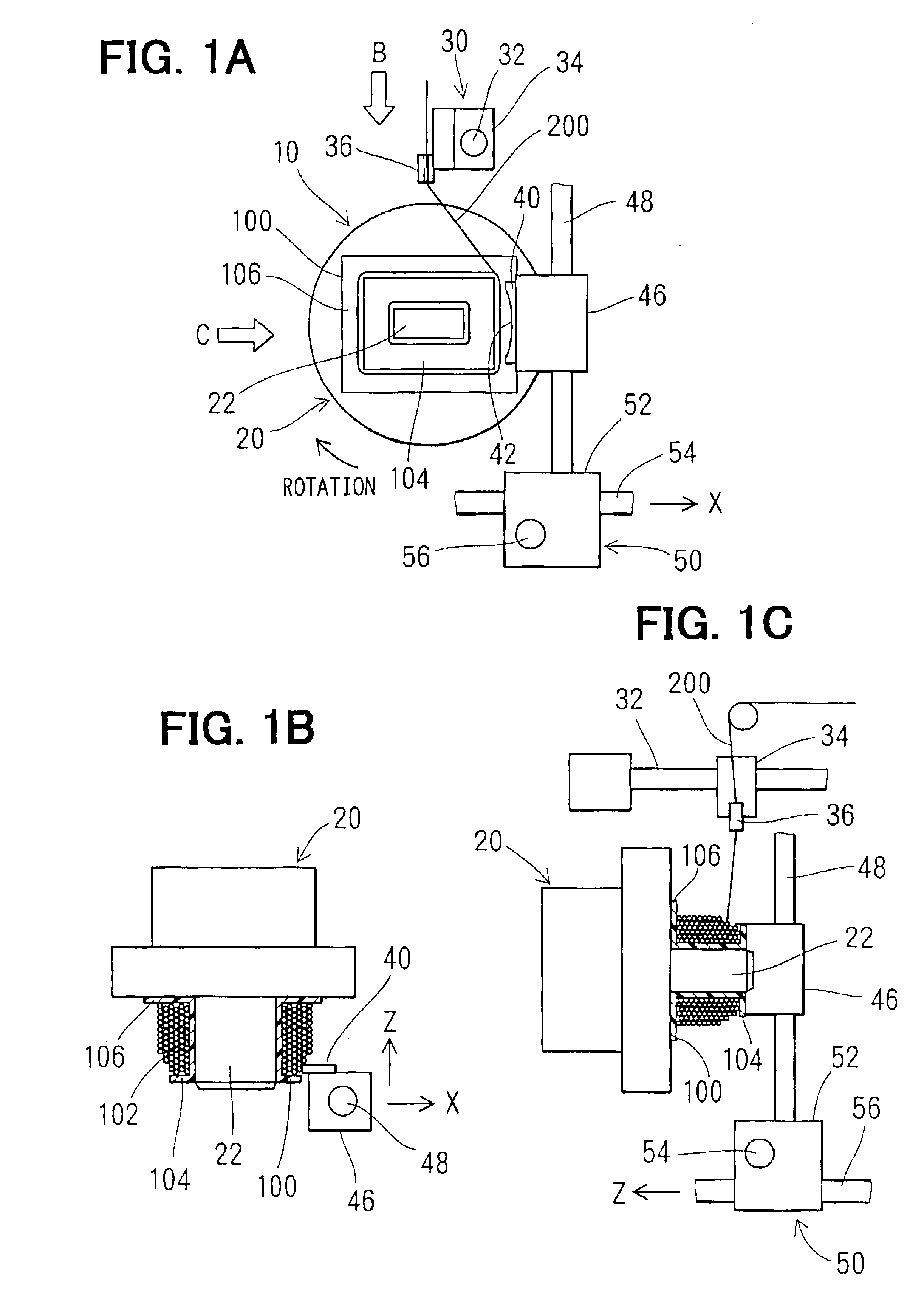

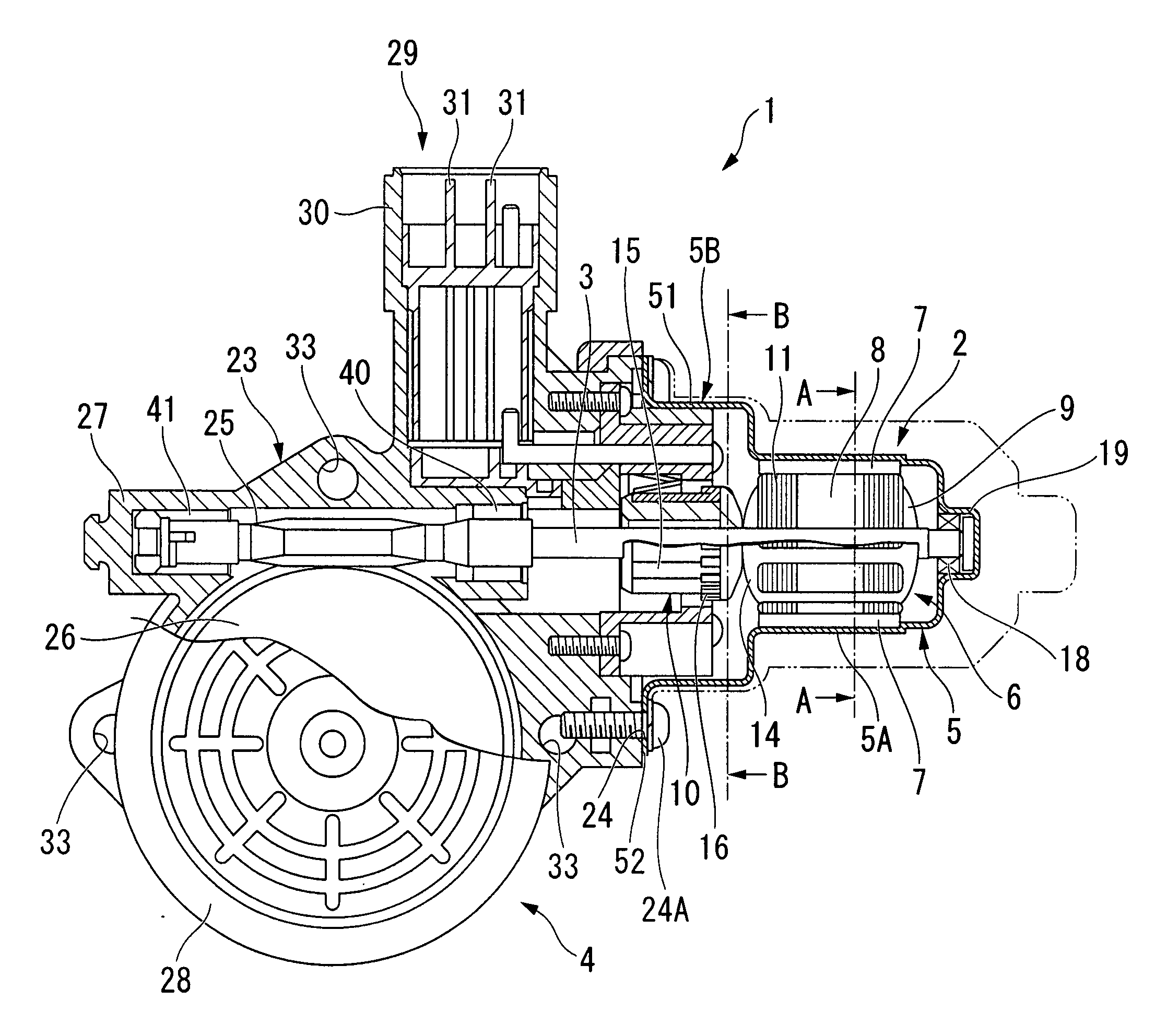

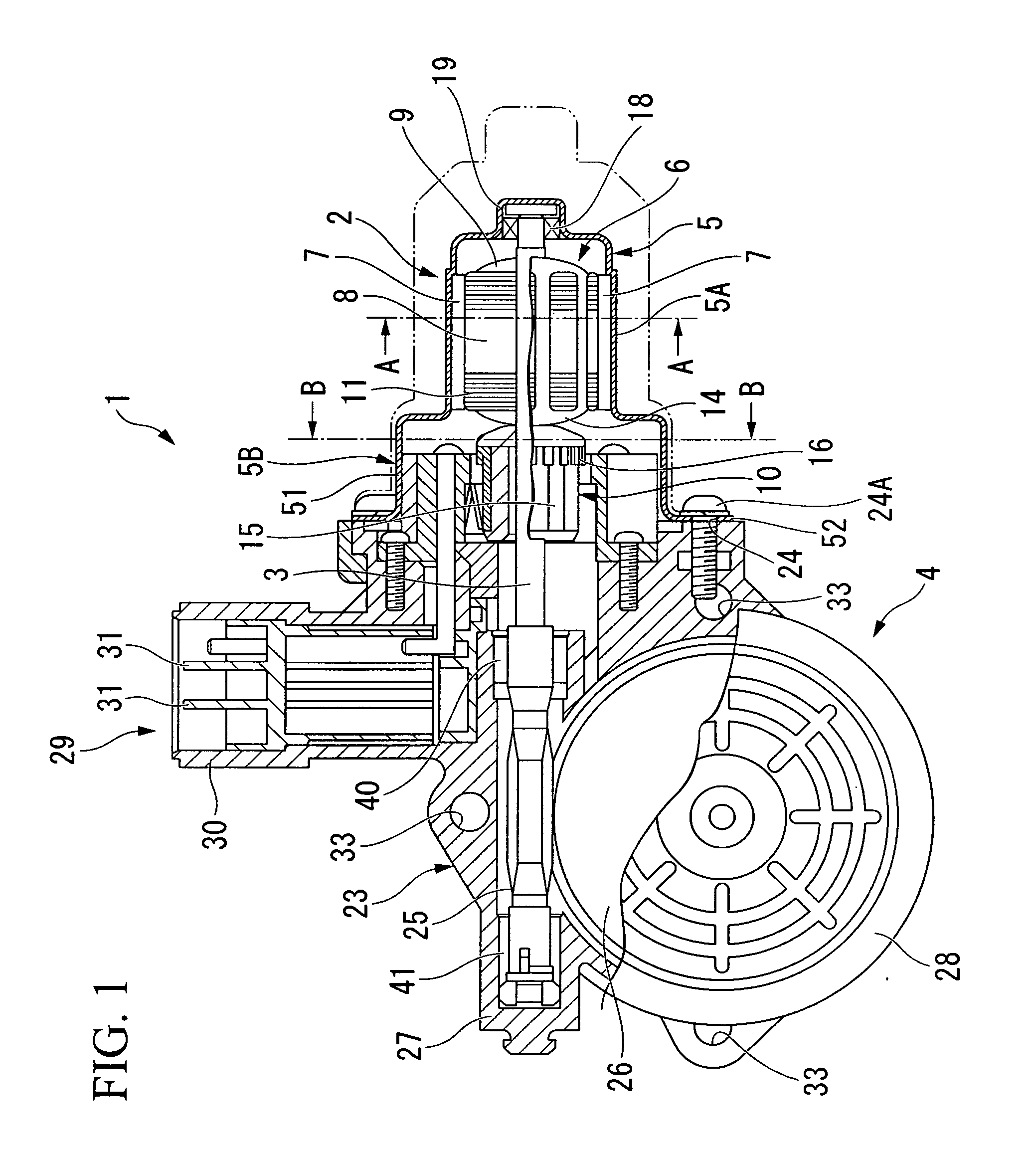

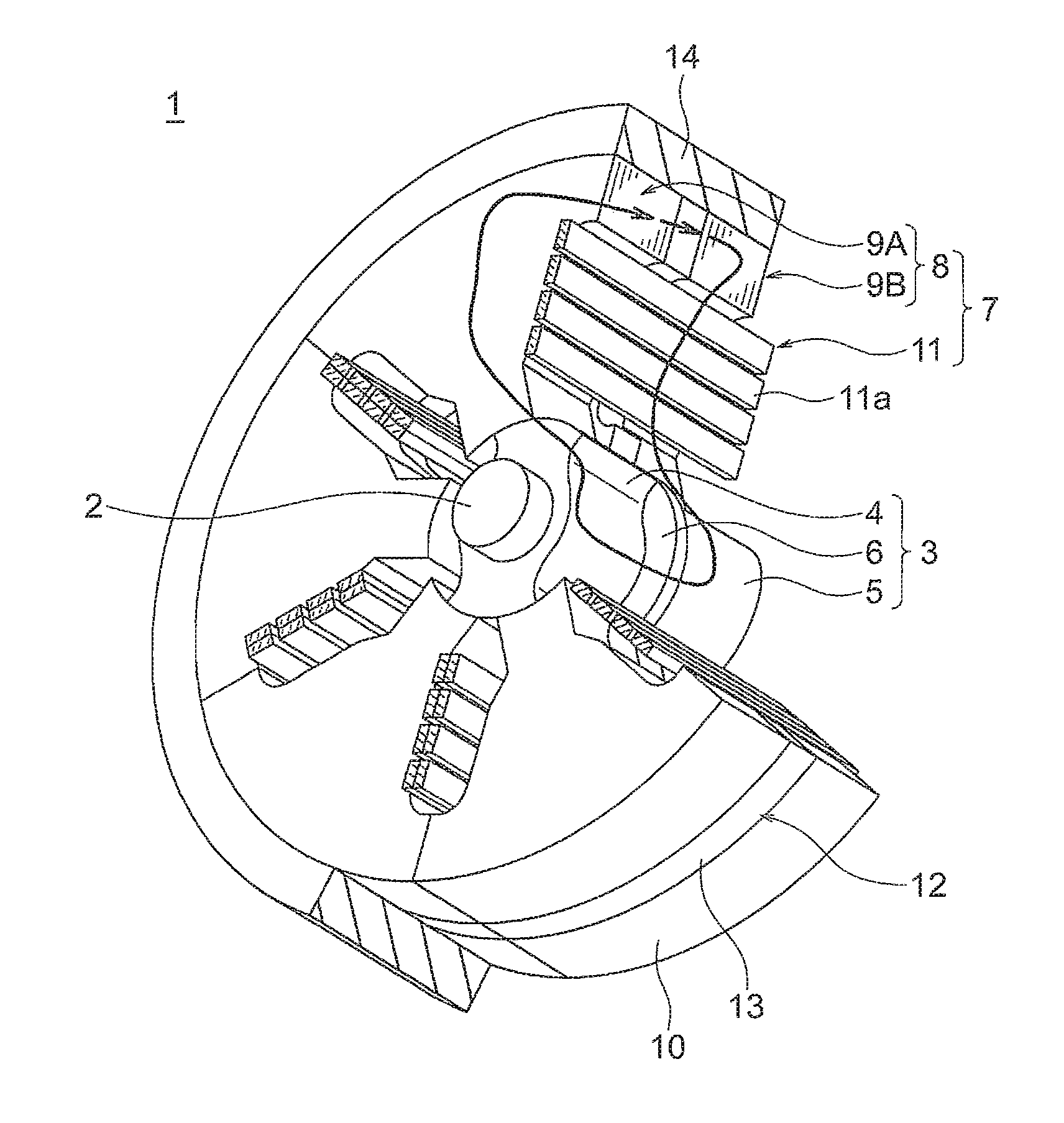

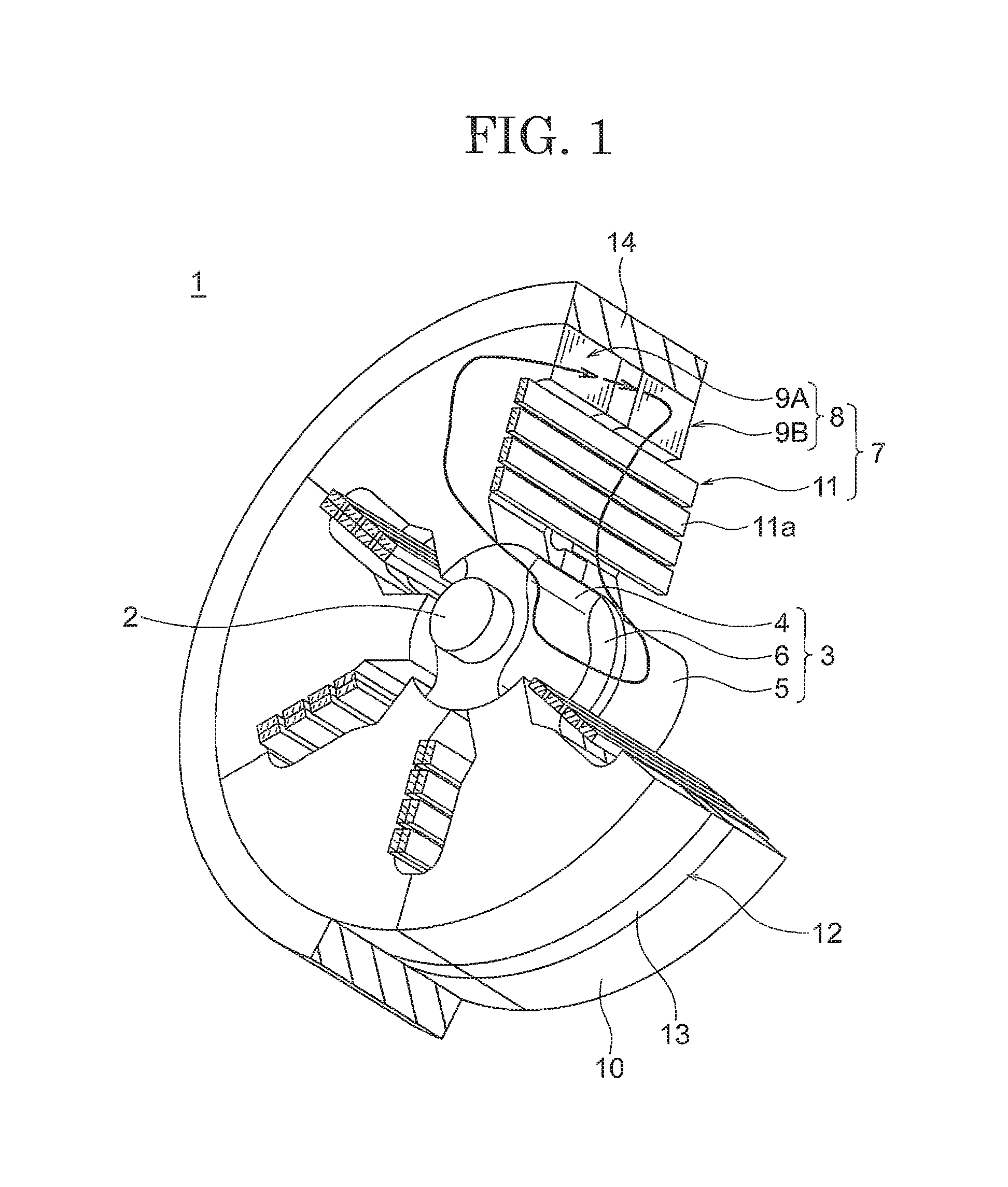

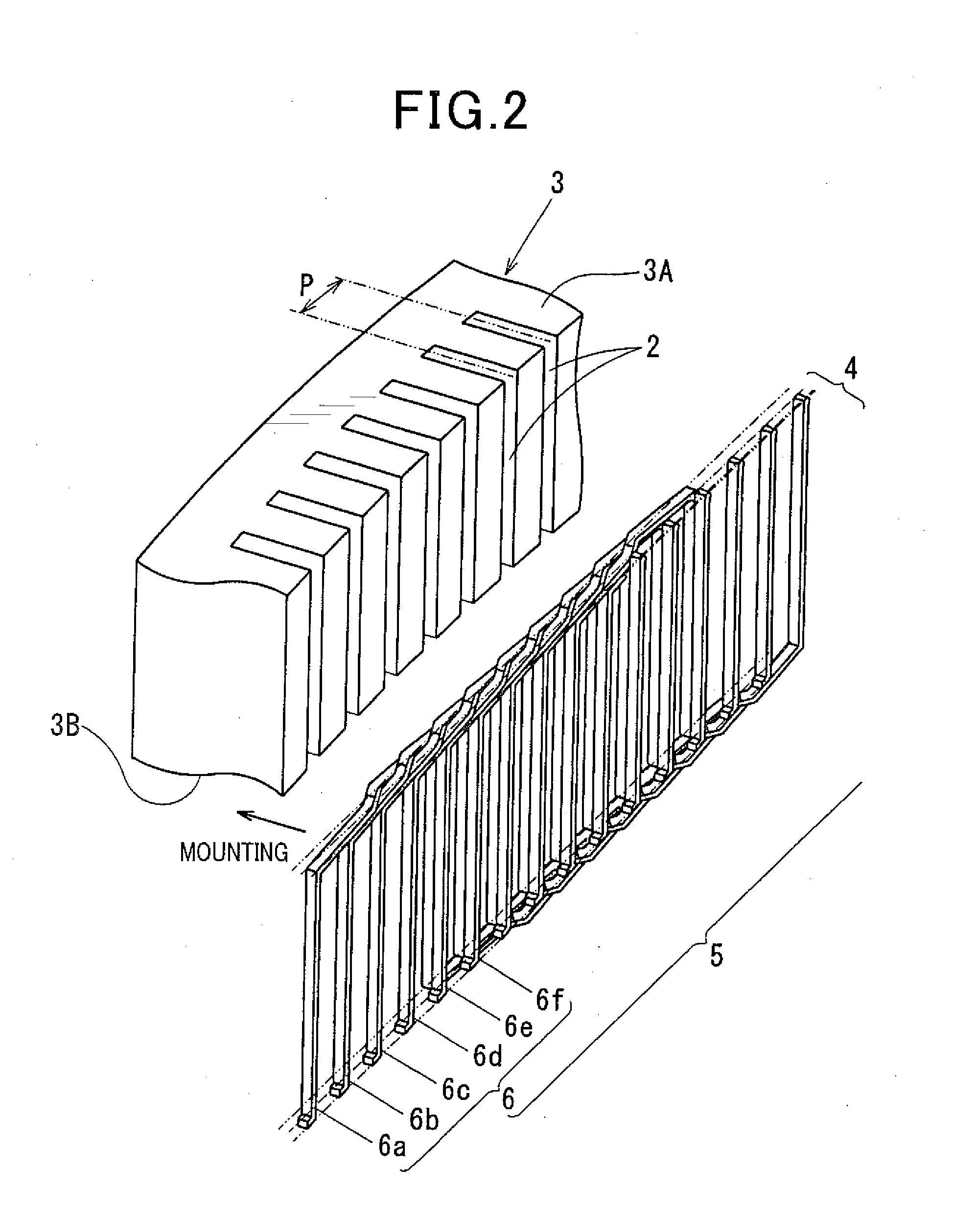

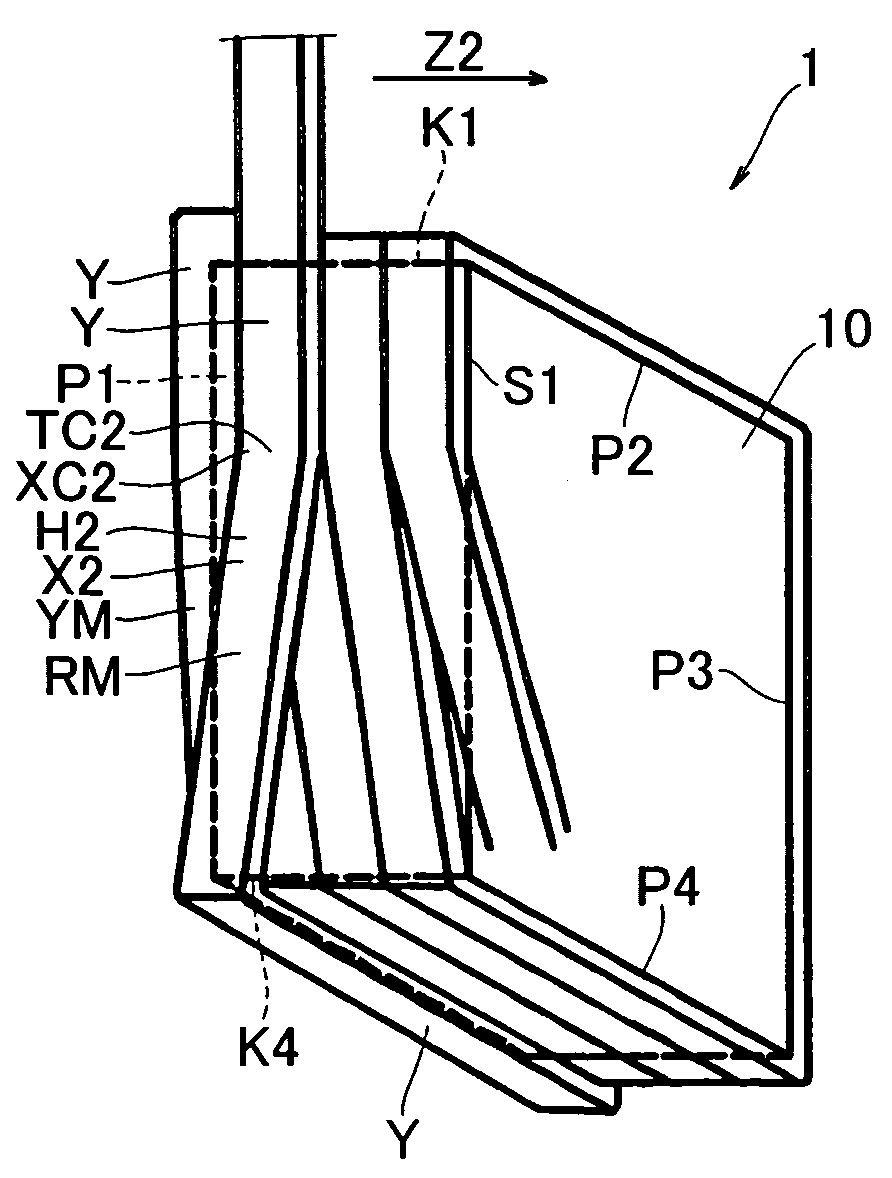

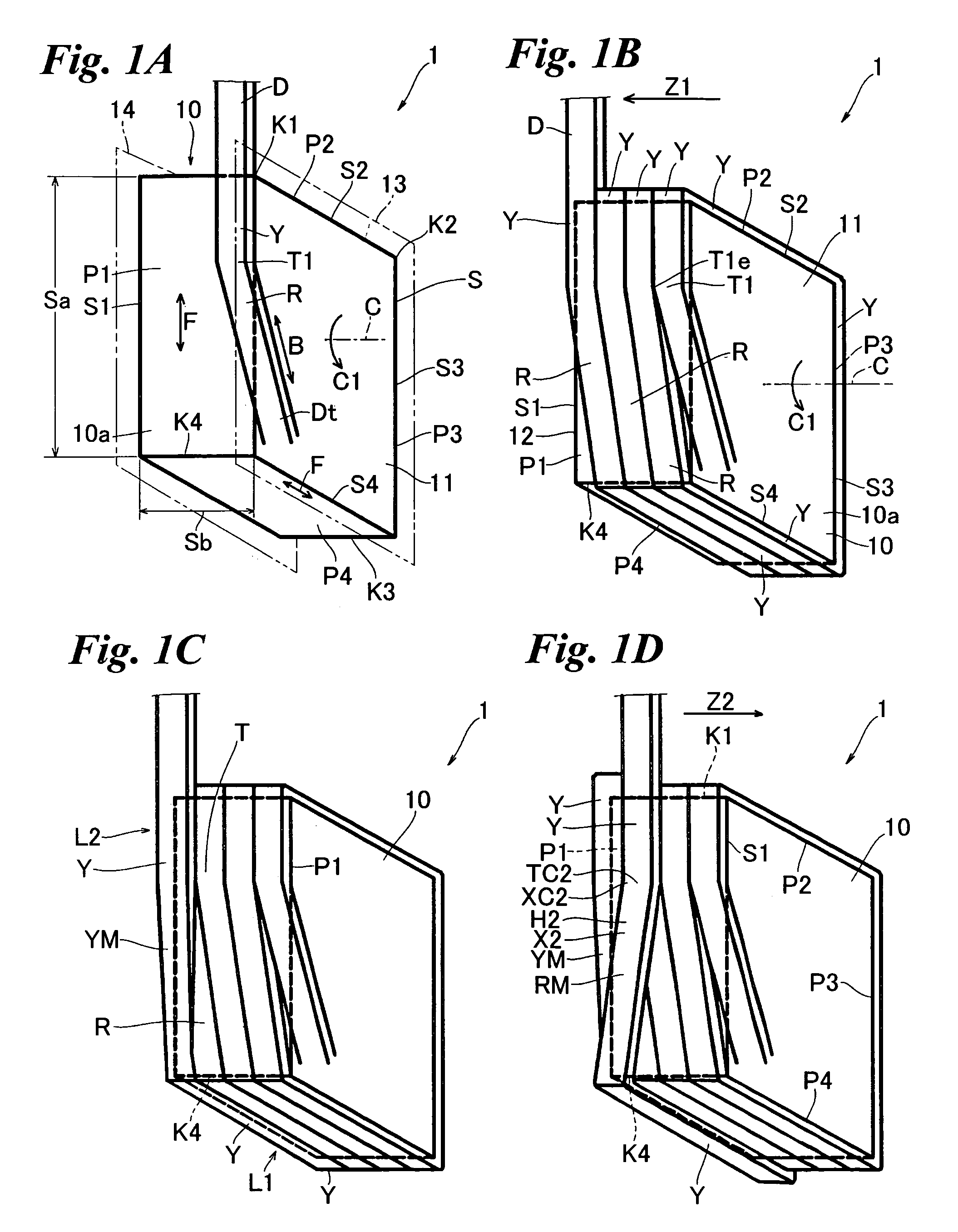

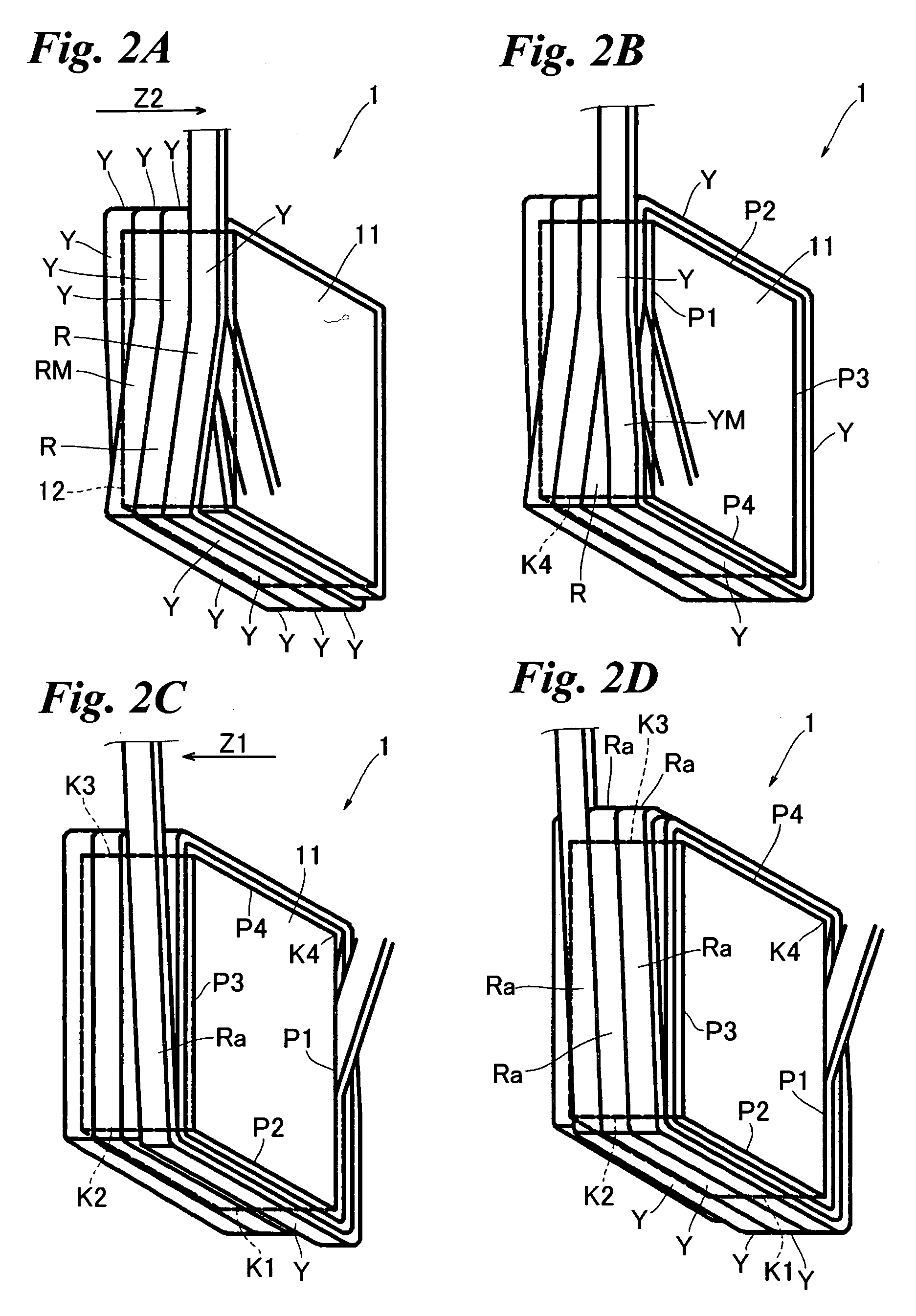

Coil production method, coil of motor, and stator of motor

InactiveUS20100026133A1Reduce thicknessHigh space factorSynchronous machinesAsynchronous induction motorsStatorElectrical conductor

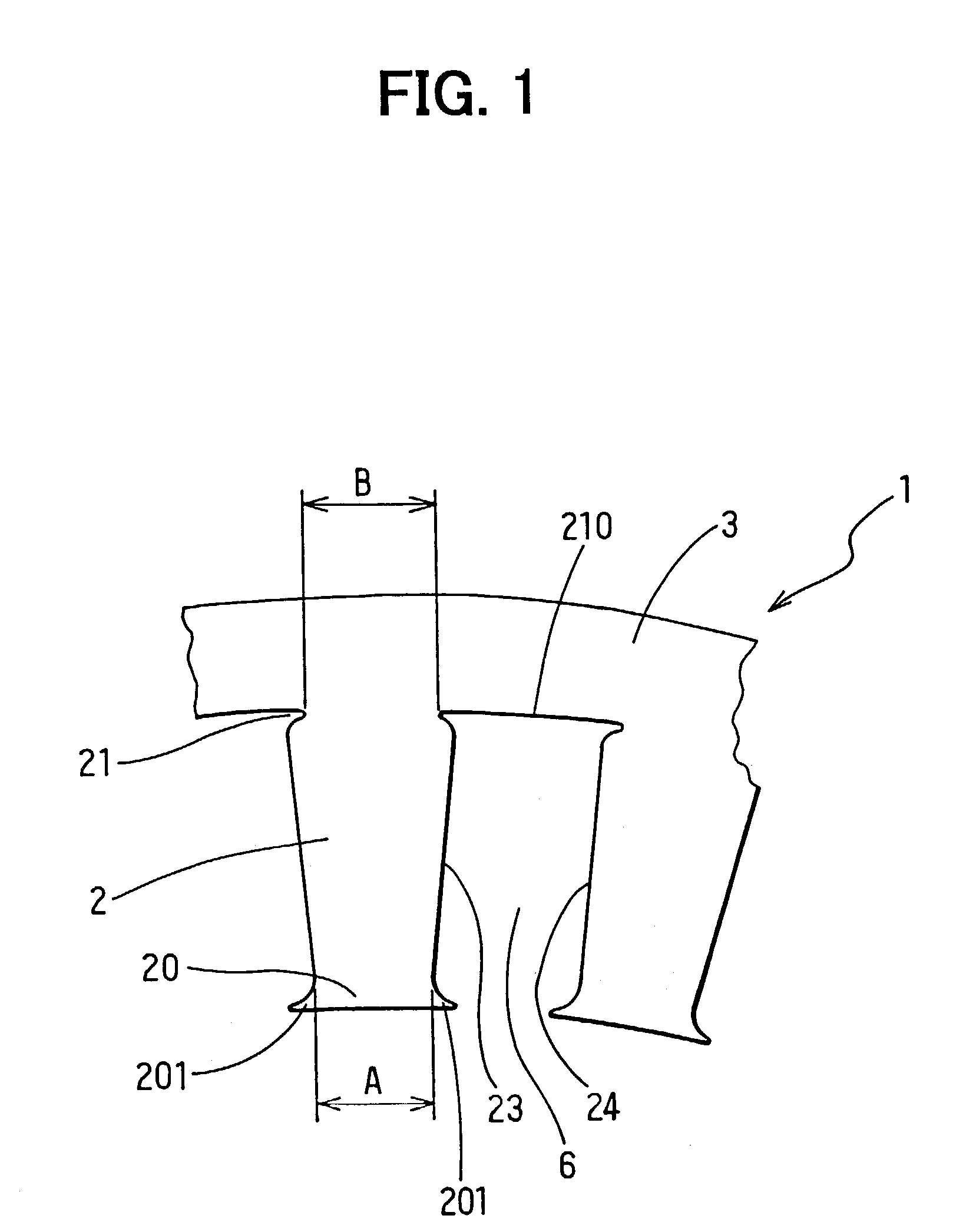

A coil production method capable of improving the space factor of a rectangular conductor with respect to the slot of a stator core, a coil of a motor, and a stator of a motor. The coil production method in which one surface of a rectangular conductor is brought into contact with a shaft with guide, and edgewise bending is performed along the curved surface of the shaft, wherein a deforming mechanism for reducing the plate thickness of a plate thickness changed portion corresponding to each of four corners of a coil over the entire width of the rectangular conductor is provided, the deformation mechanism is used to deform the plate thickness changing portion, and the plate thickness changing portion of the rectangular conductor is edgewise-bent to form a coil.

Owner:TOYOTA JIDOSHA KK

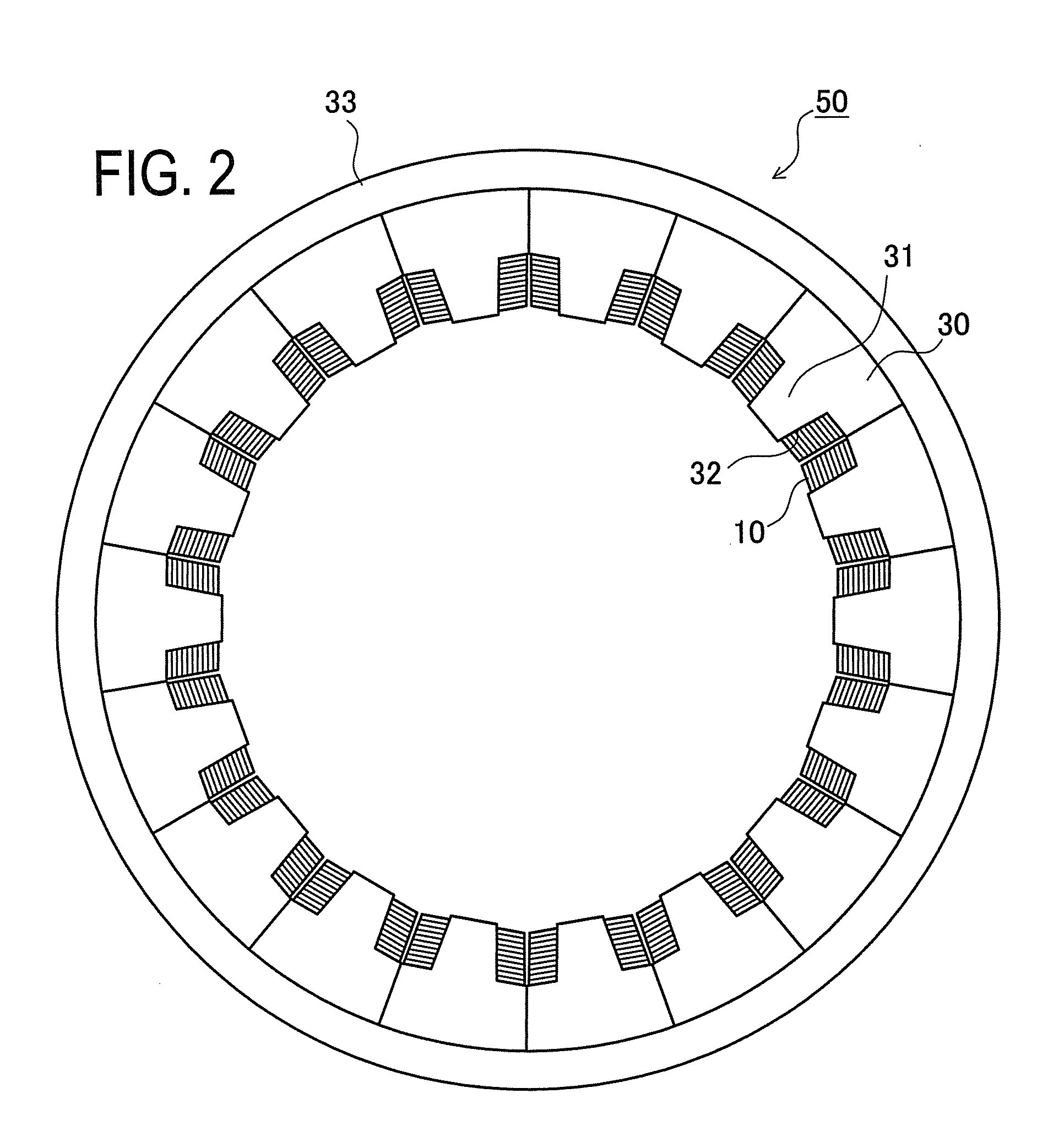

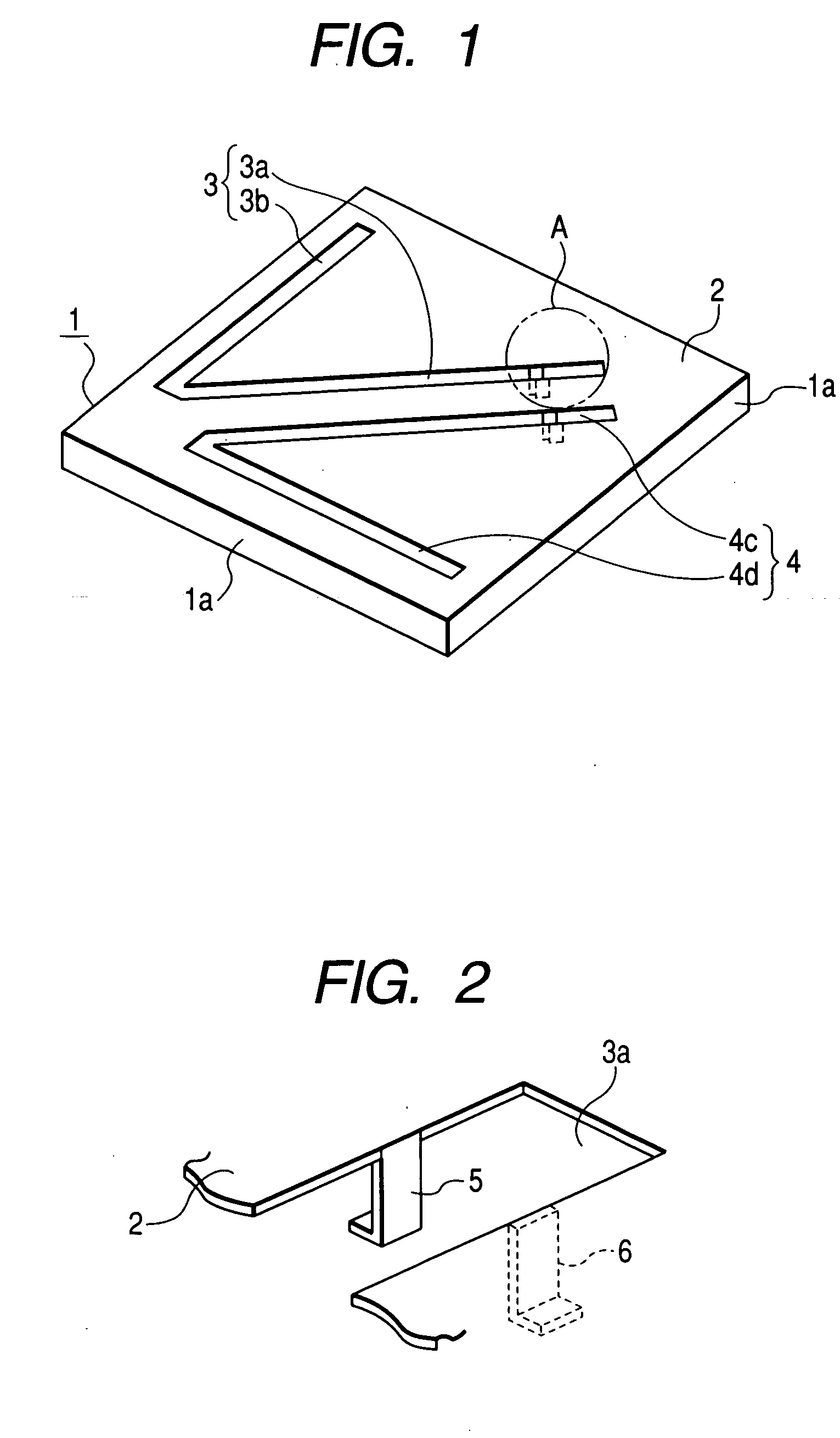

Antenna device with improved isolation characteristic

ActiveUS20060132373A1Without sacrificing isolation characteristicSmall sizeAntenna arraysSlot antennasGround lineFeed line

A pair of radiating slots open in a flat metal plate having a square shape to be line-symmetrically arranged with respect to a symmetry axis, and power feeding lines and ground lines are provided at power feeding positions of the respective radiating slots. The respective radiating slots have first slot portions and second slot portions that contact at 45 degrees and linearly extend, respectively. Both the radiating slots are arranged in a back-to-back manner that edges of the first slot portions face each other, and the second slot portions extend in a direction to be separated from each other along two sides of the flat metal plate. Further, a polarization direction of an electric wave to be generated by one radiating slot and a polarization direction of an electric wave to be generated by the other radiating slot are set to be perpendicular to each other.

Owner:ALPS ALPINE CO LTD

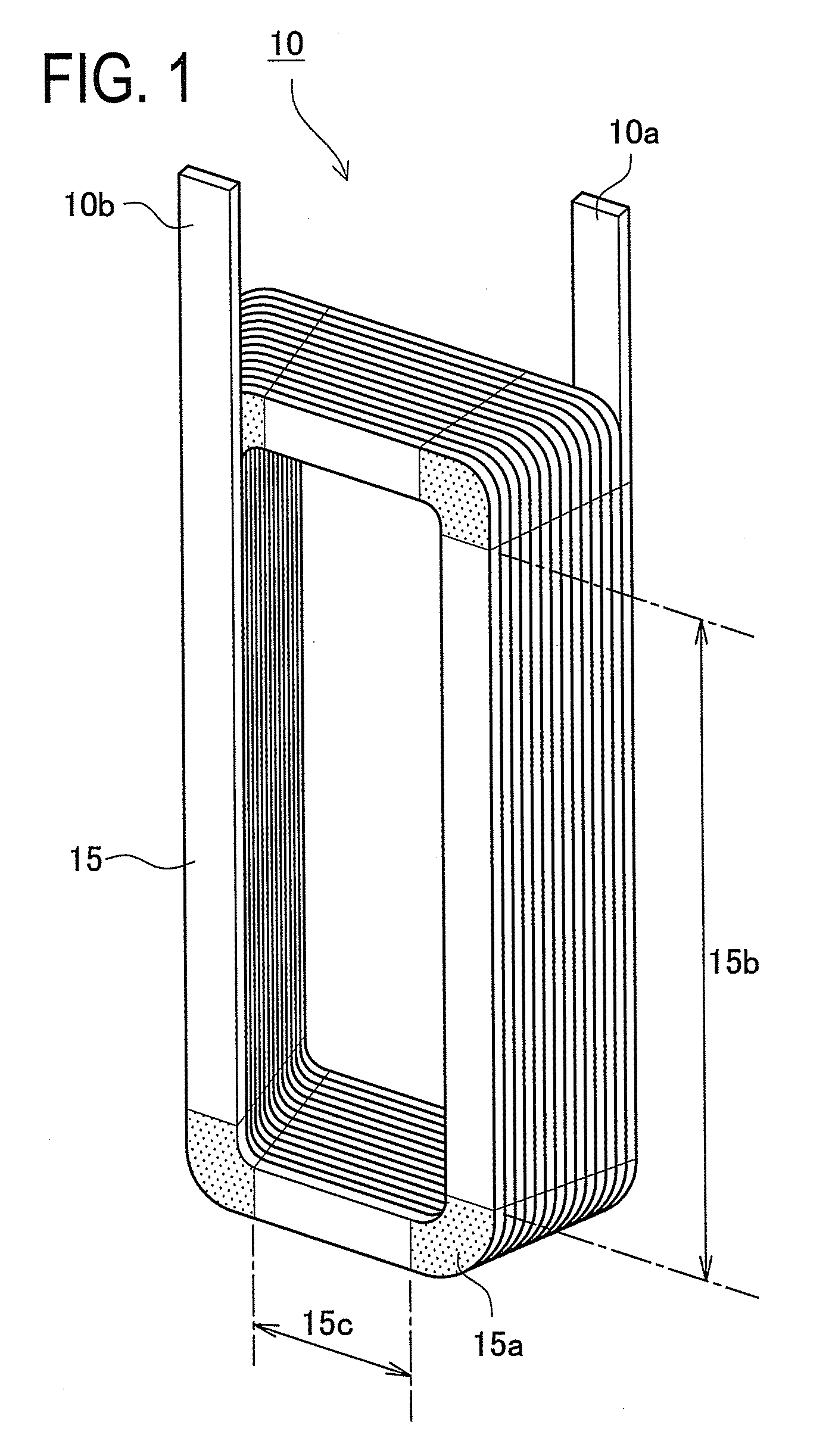

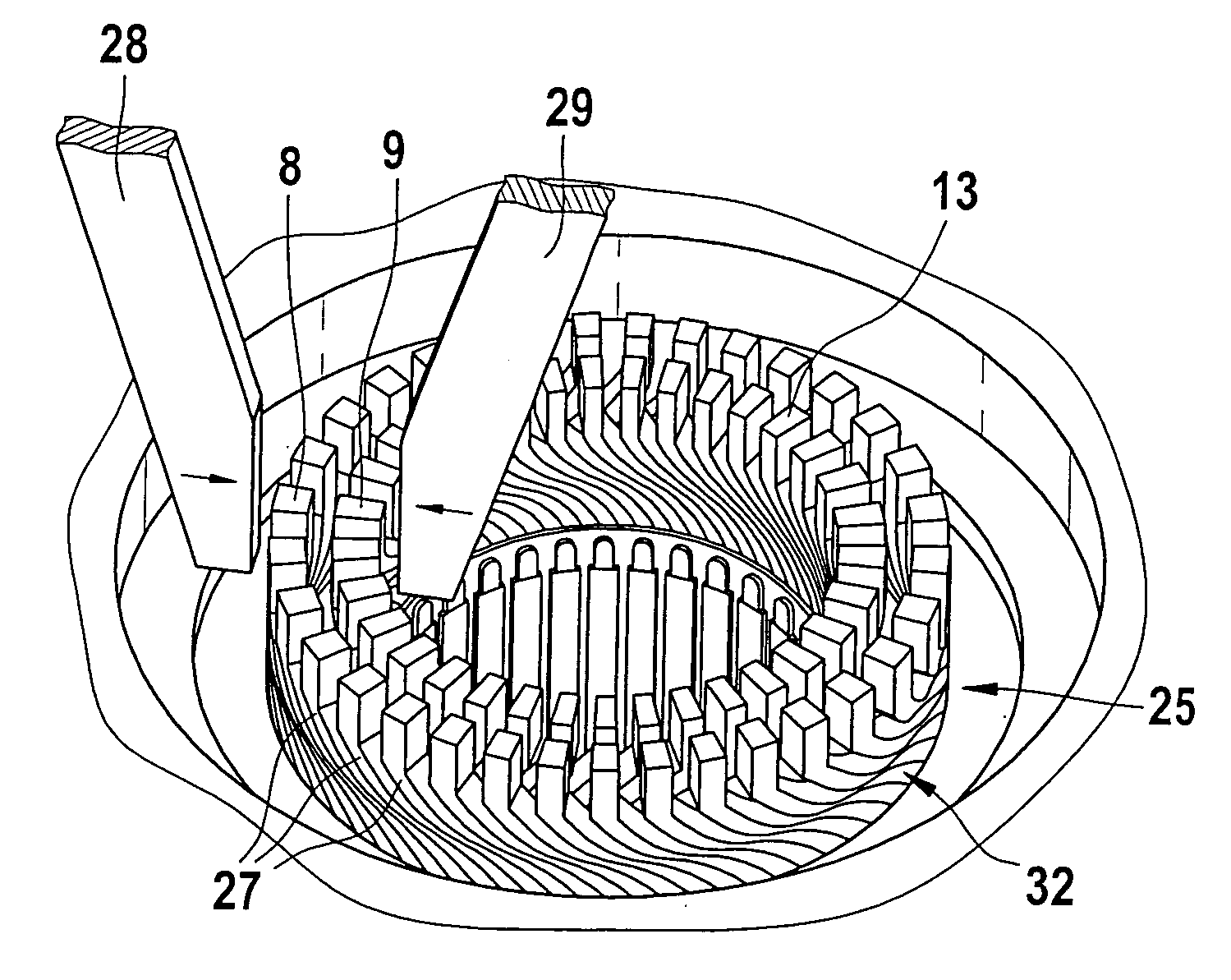

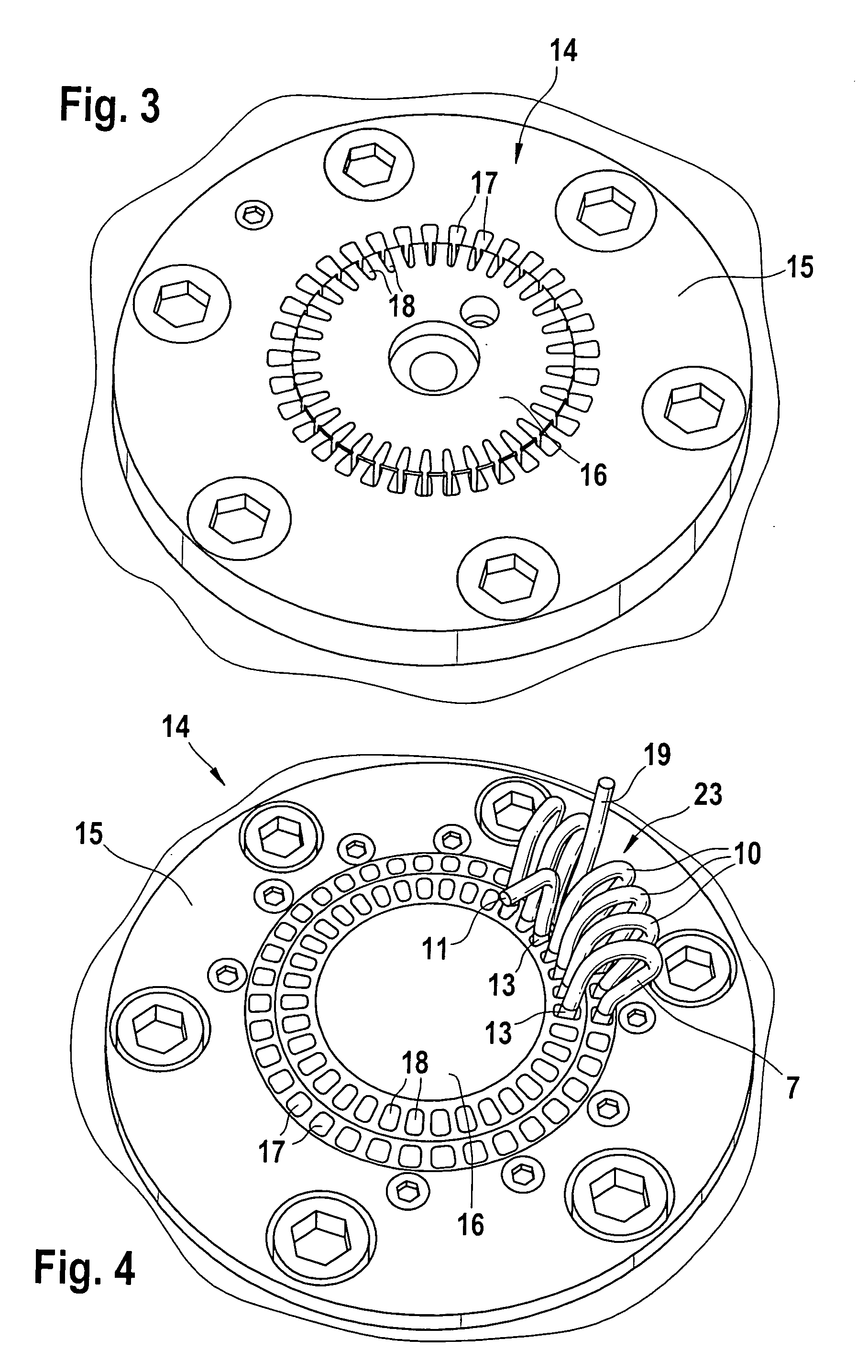

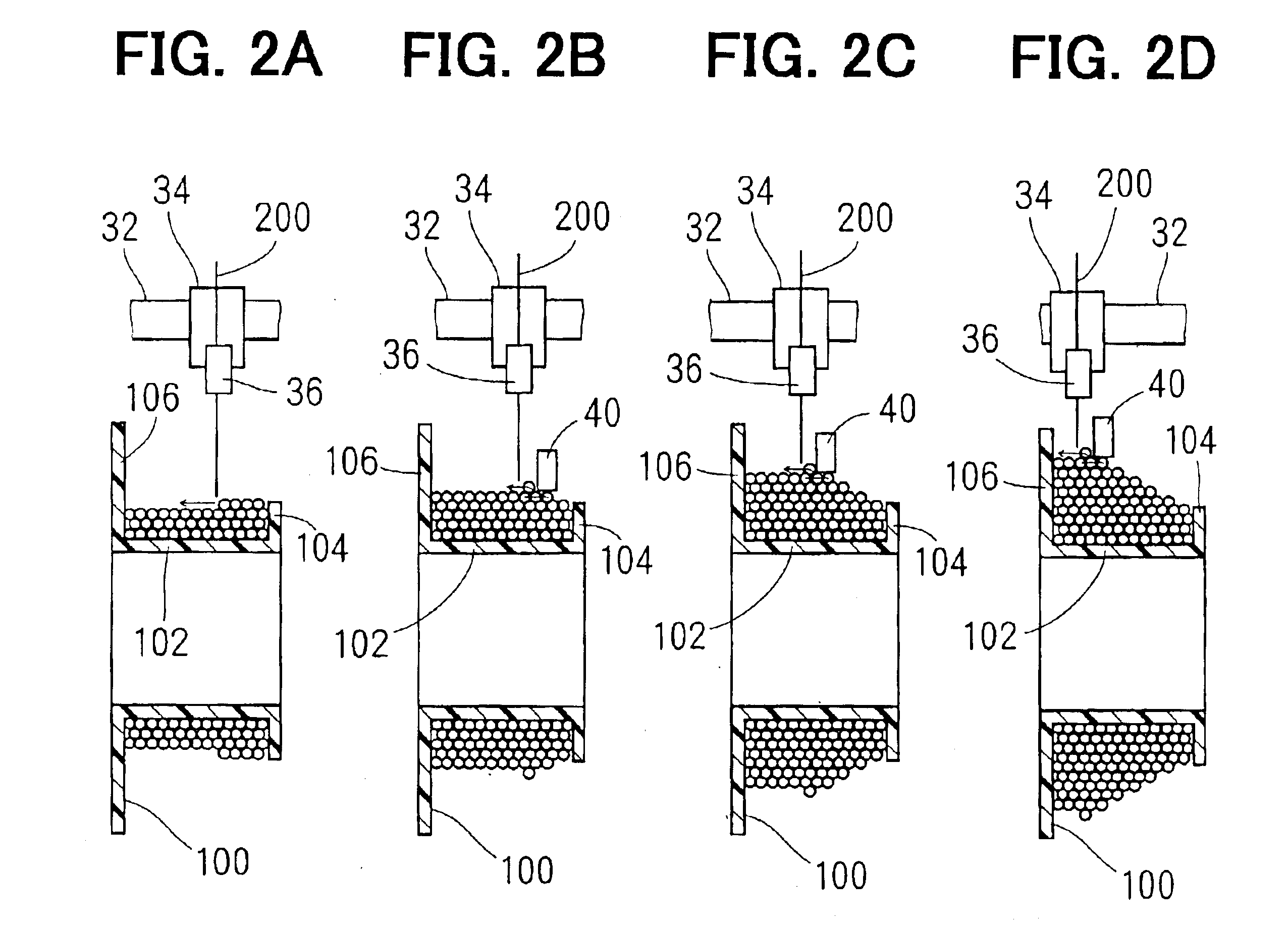

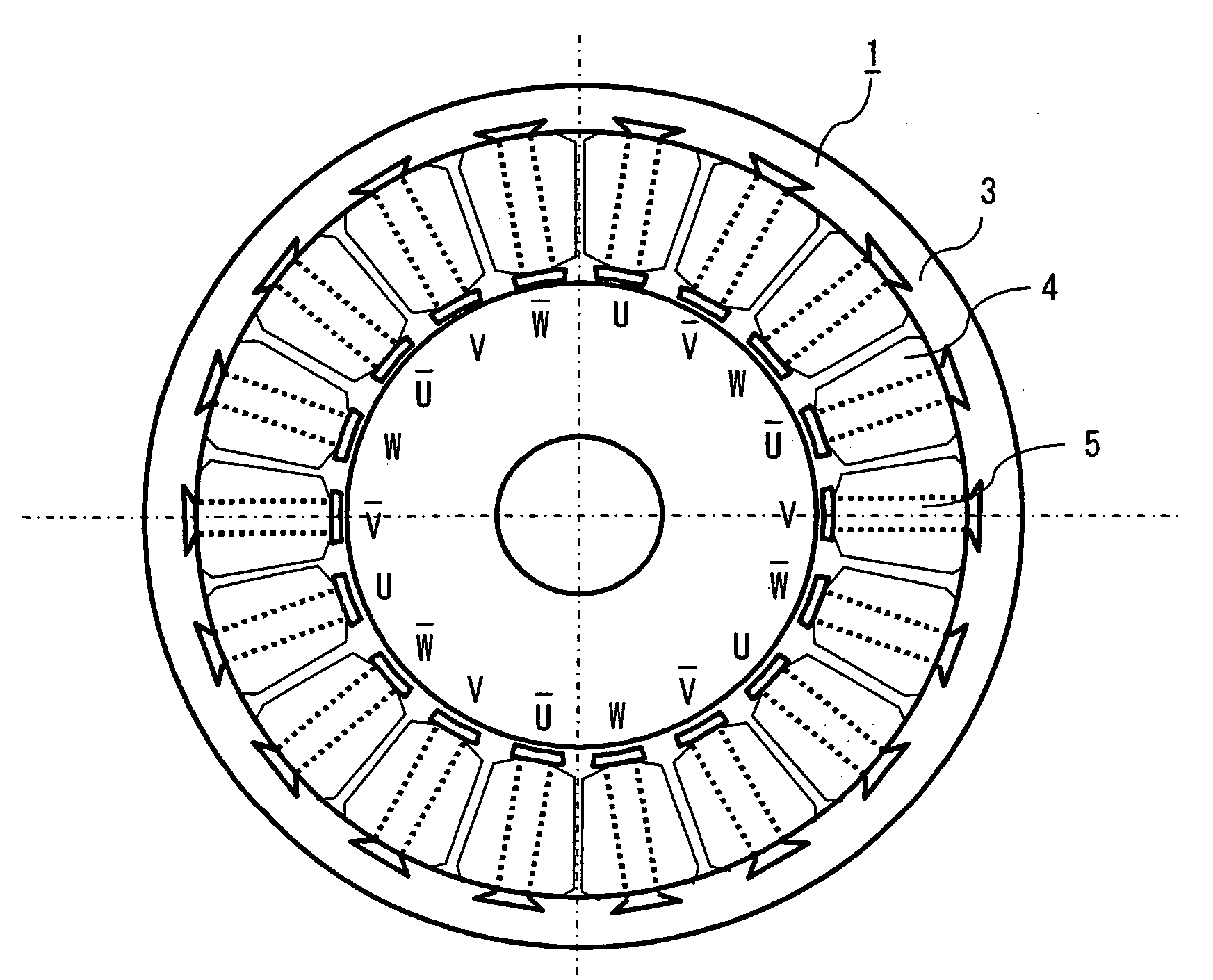

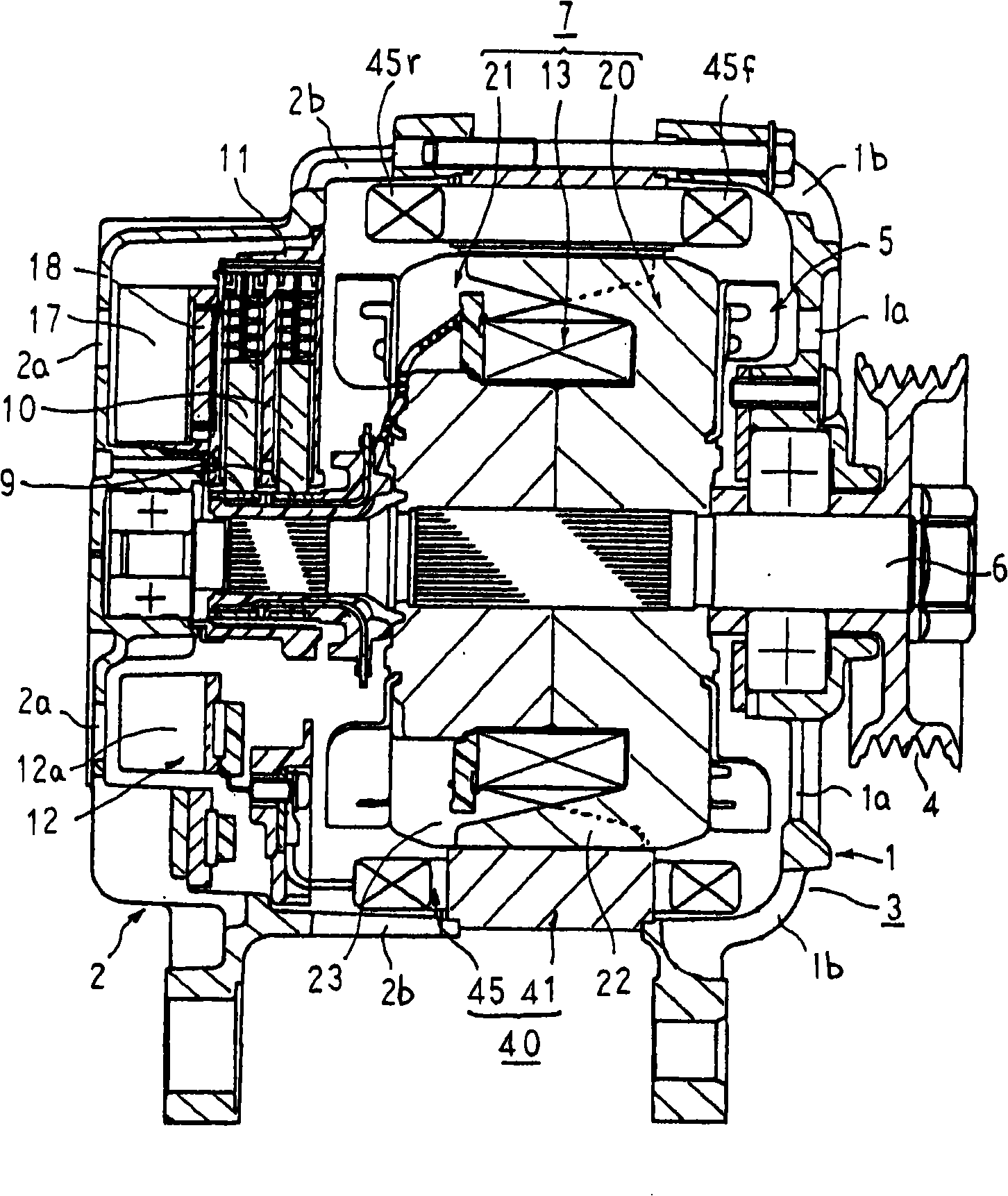

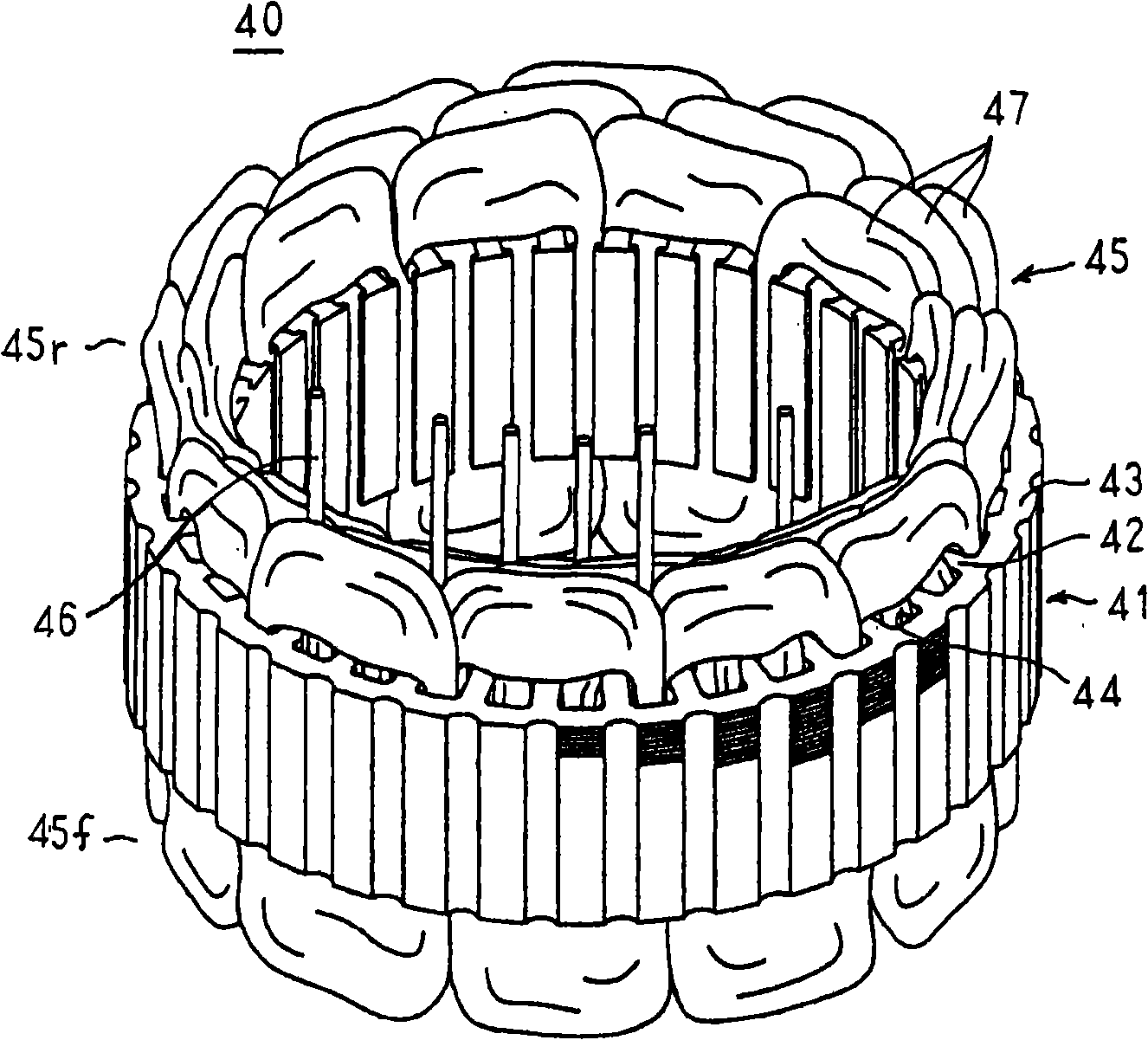

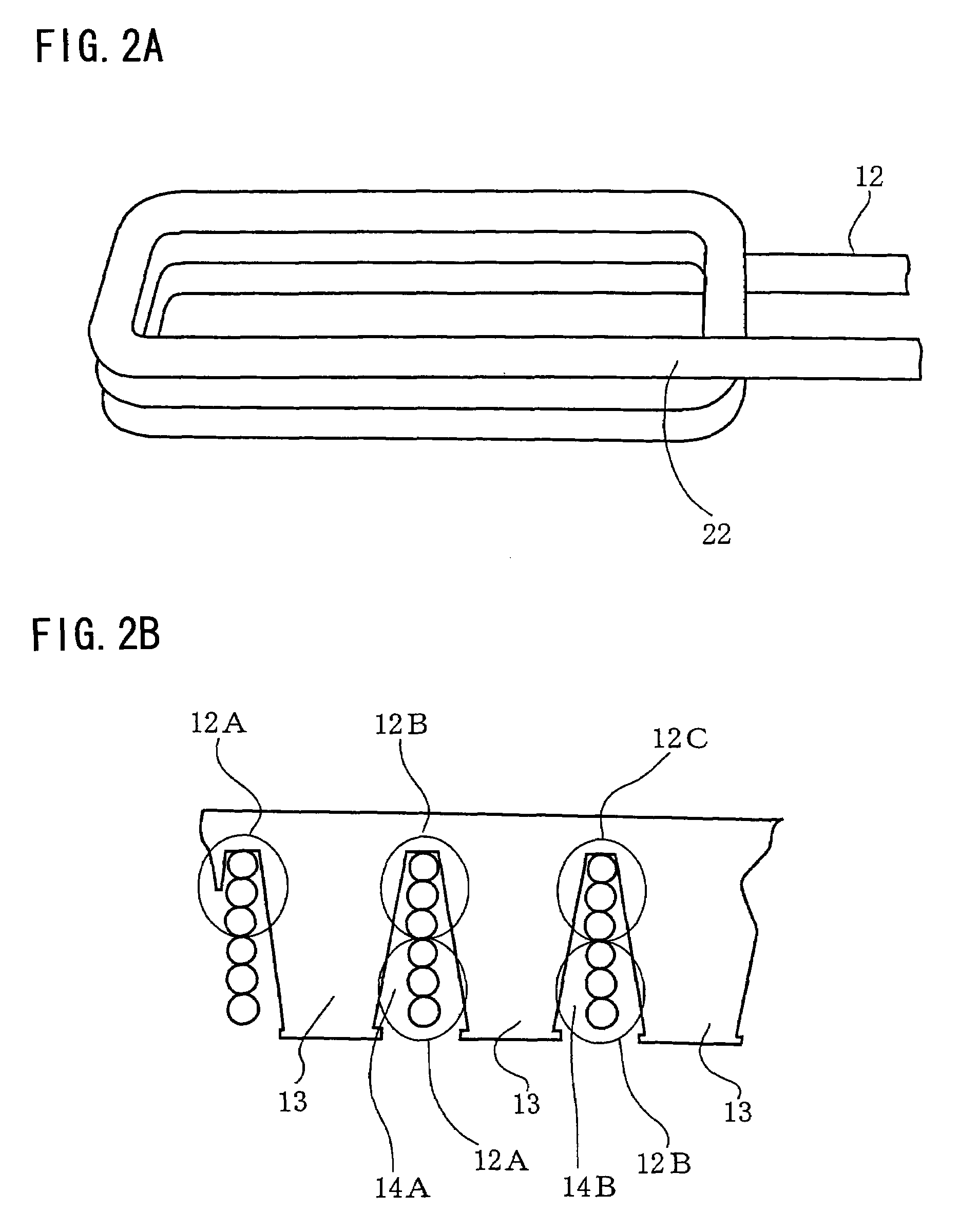

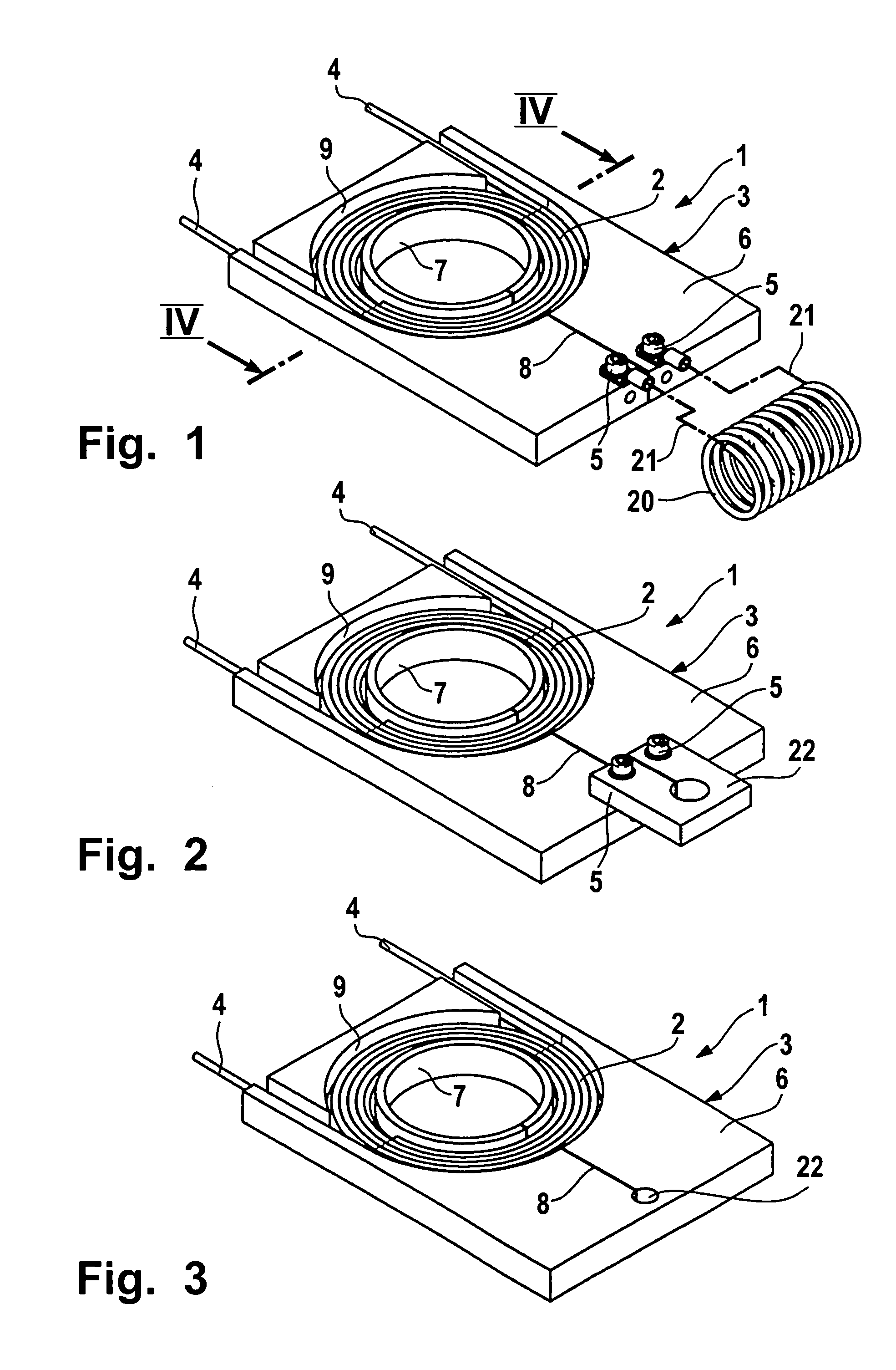

Method for producing coils and coil circuits

InactiveUS20060001327A1Reduced structureImprove space factorSynchronous machinesAsynchronous induction motorsElectric machineEngineering

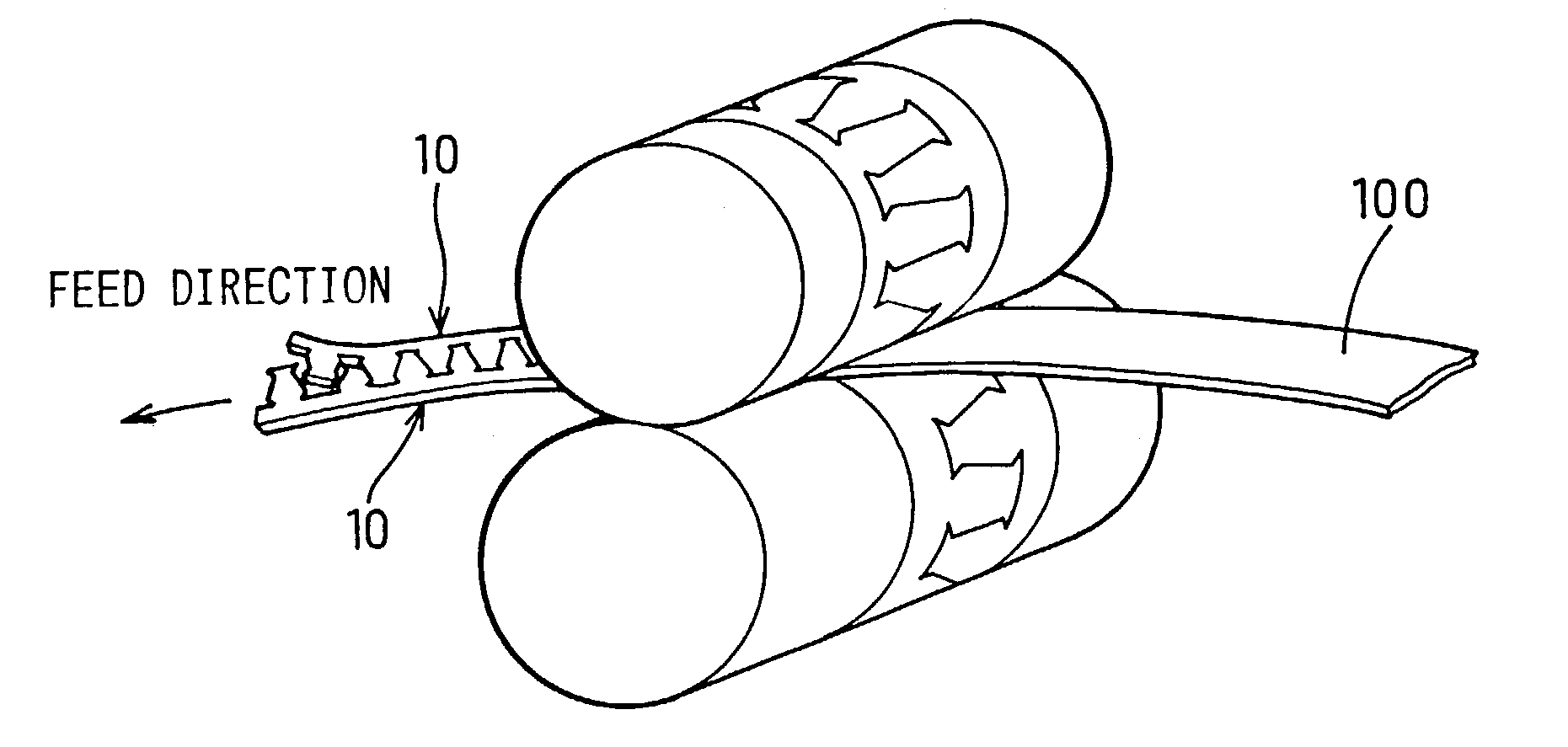

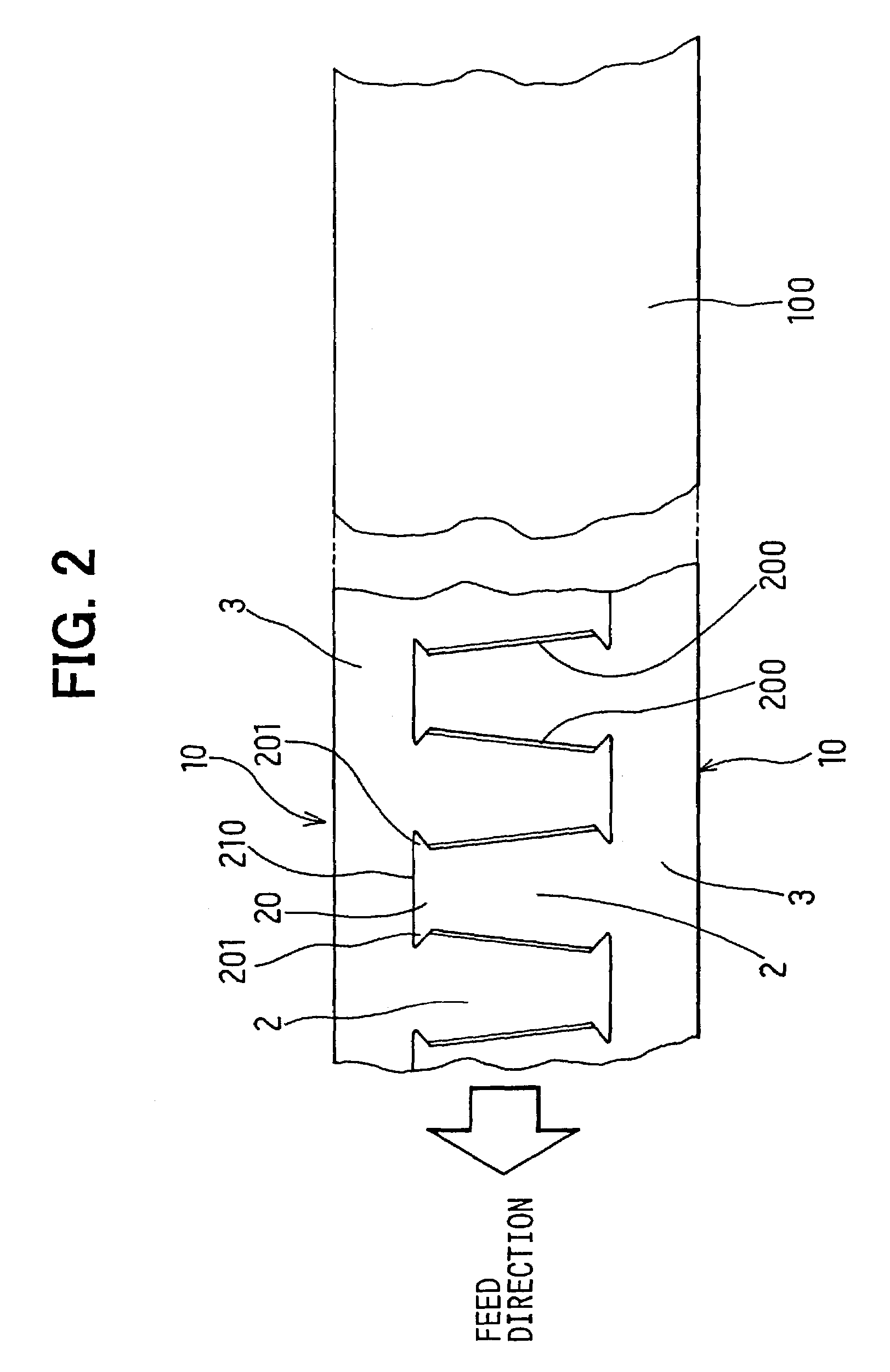

The present invention relates to a method for manufacturing multiphase windings (32) of an electric machine, in which the following process steps are carried out. Cross-sectional profiles (13) that increase the slot space factor are stamped onto wire elements (7, 11, 12). Offsetting dies (14, 26) are loaded with stamped wire elements (7) to constitute the winding (32), stamped wire elements (11) to constitute an integrated star point (21), and stamped wire elements (12) for supplying current to the winding (32). The offsetting dies (14, 26) offset the stamped wire elements (7, 11, 12) in their end regions. An interconnection of the integrated star point (21) is produced by thermally attaching (30) the stamped wire elements (11) for the integrated star point (21)to a connecting ring (40) on an inside (41) of a finished winding head (20).

Owner:ROBERT BOSCH GMBH

Core block, and magnetic pole core using core blocks for motor

InactiveUS20100231084A1High material utilizationEasy windingMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesMechanical engineering

Owner:MABUCHI MOTOR

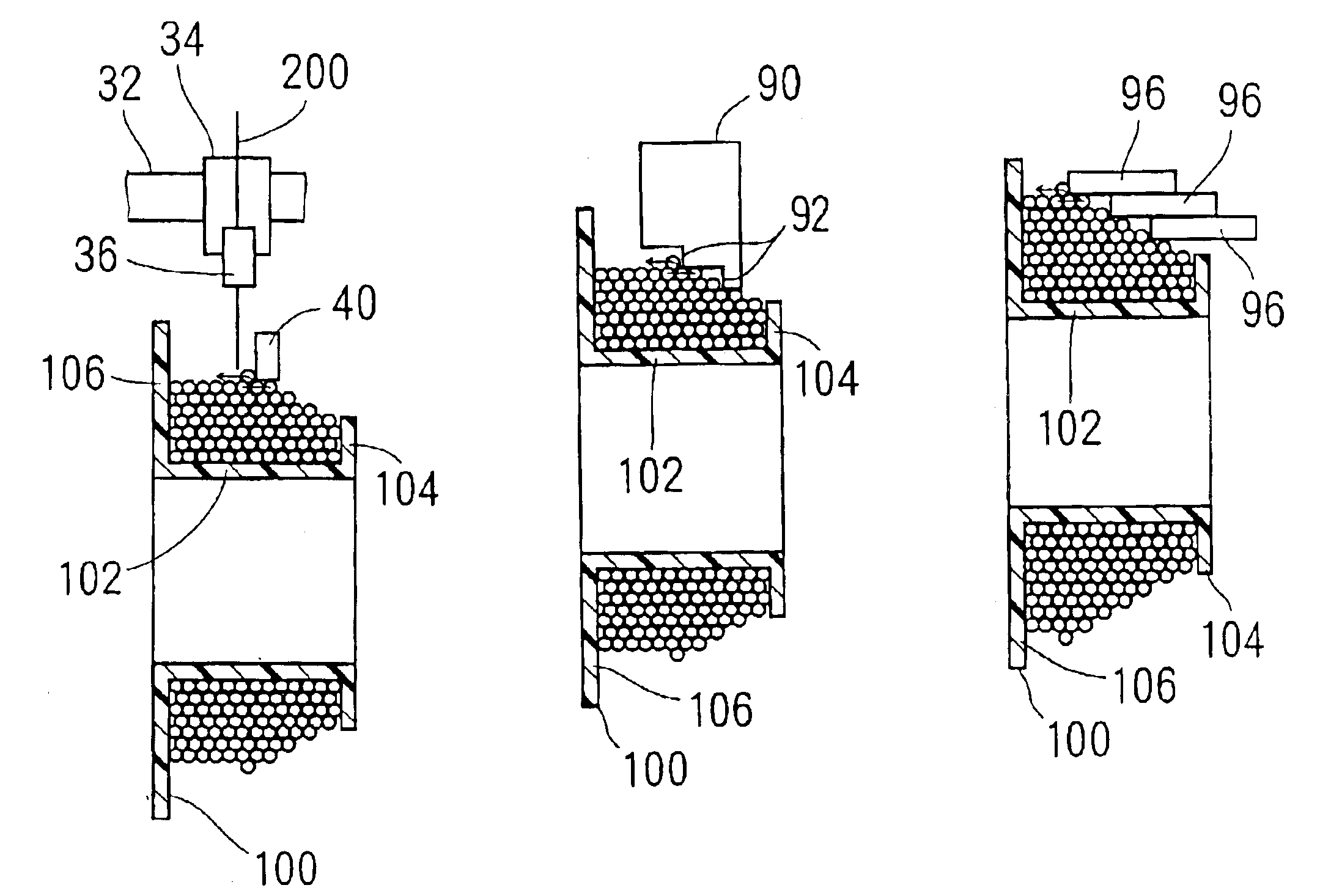

Apparatus and method for winding multi-layer coil in trapezoidal winding space

InactiveUS6910654B2Improve space factorEasy windingFilament handlingManufacturing dynamo-electric machinesBobbinSurface coil

A multi-layer coil is wound around a bobbin having a center pillar and a small and a large flanges connected to longitudinal ends of the center pillar. A winding space having a trapezoidal cross-section in a plane cut through the center axis of the bobbin is formed outside the center pillar between both flanges. To wind the multi-layer coil in this winding space, a turning position where a layer of the coil moves up to a higher layer is set by a position setter, and the turning position is automatically shifted layer by layer to form a sloped outer surface of the coil. The coil is wound in a shape fitting the trapezoidal winding space without reducing the winding speed. The space factor of the coil in the winding space is improved, making the coil compact in size.

Owner:DENSO CORP

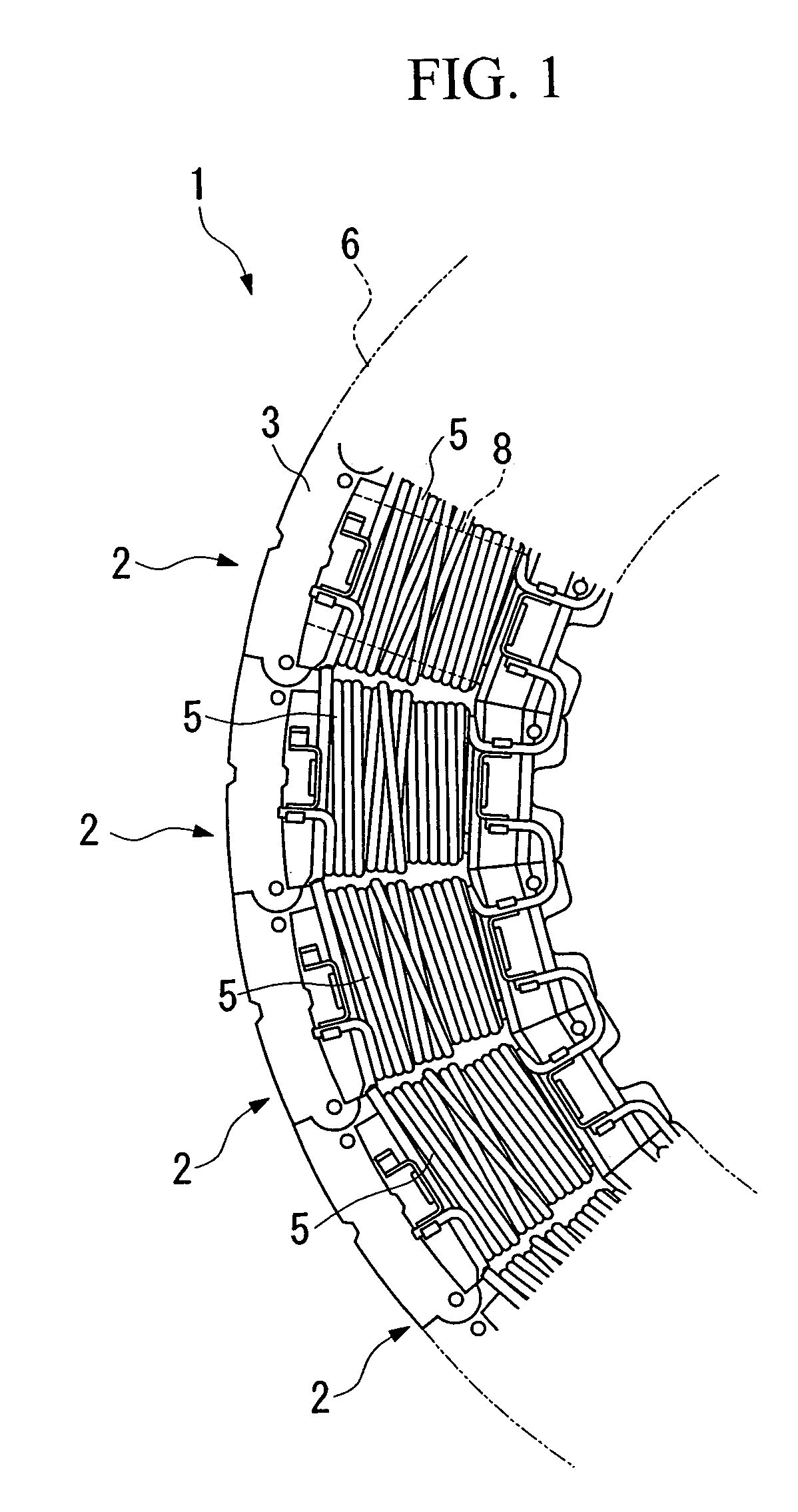

Electric rotating machine

InactiveUS20060192457A1Easy to operateImprove productivityWindingsMagnetic circuit rotating partsThumb oppositionEngineering

An electric rotating machine comprises: a stator in which a coil is wound on a plurality of teeth in concentrated winding, and the coil is connected to a three-phase power supply; and a rotor disposed in opposition to the teeth of the stator; wherein a ratio between the number of poles and the number of slots of the stator is 1:3. There is no higher harmonics of magnetomotive force in low order close to fundamental wave, thus enabling efficient operation of the electric rotating machine. Furthermore, owing to the stator of concentrated winding, it is possible to provide an electric rotating machine of high productivity with small coil end, high mass production, and high space factor.

Owner:MITSUBISHI ELECTRIC CORP

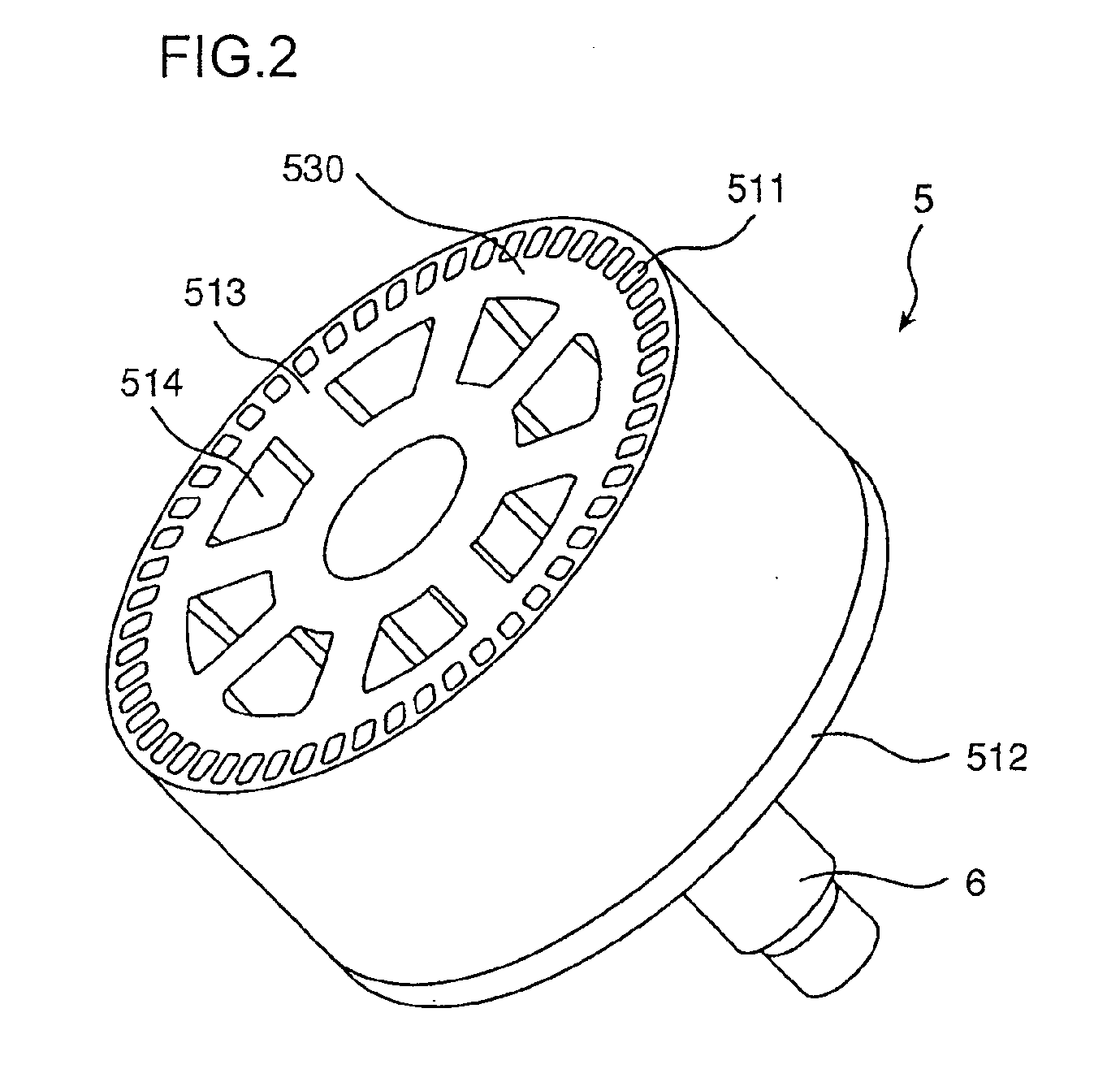

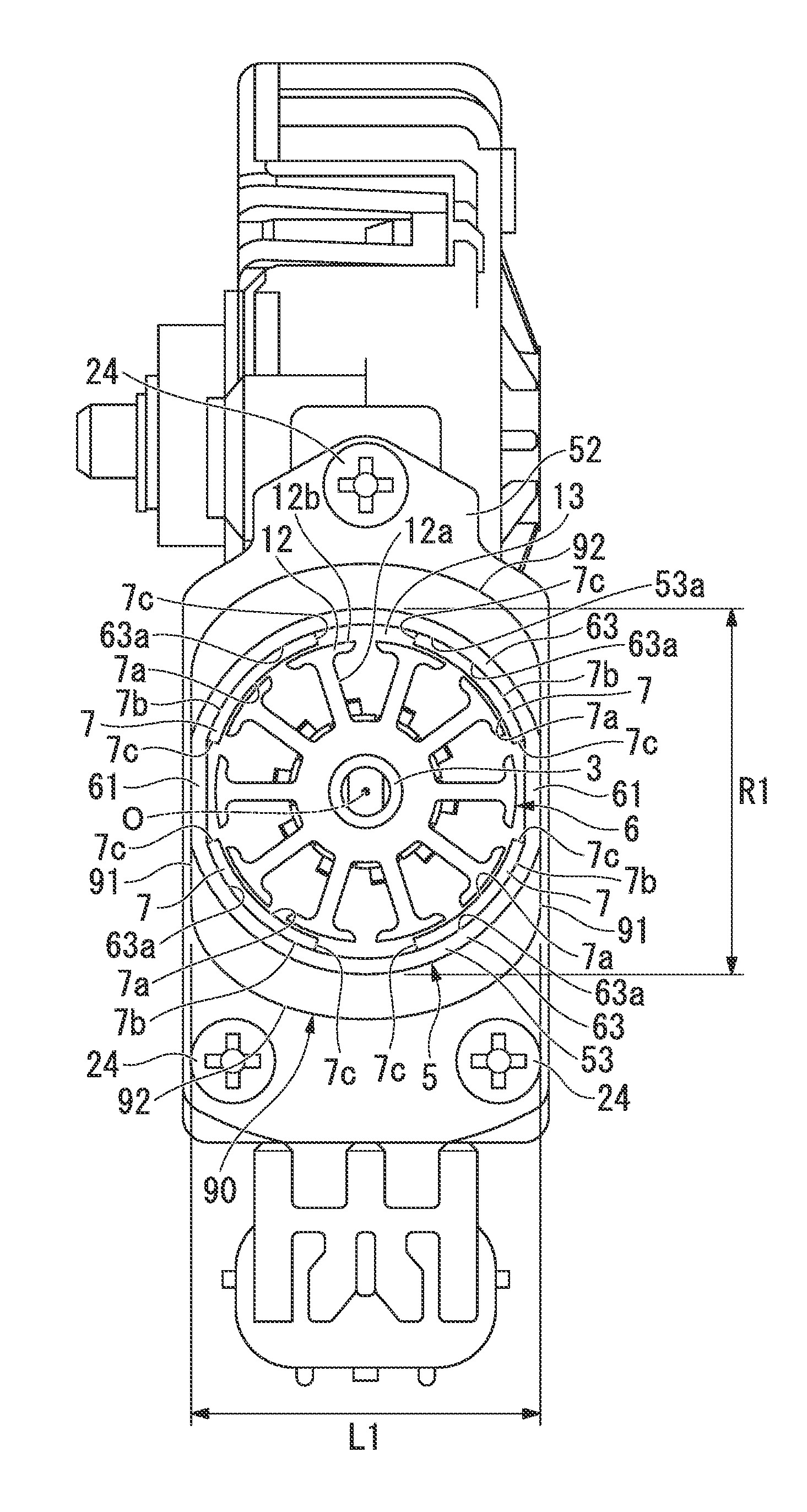

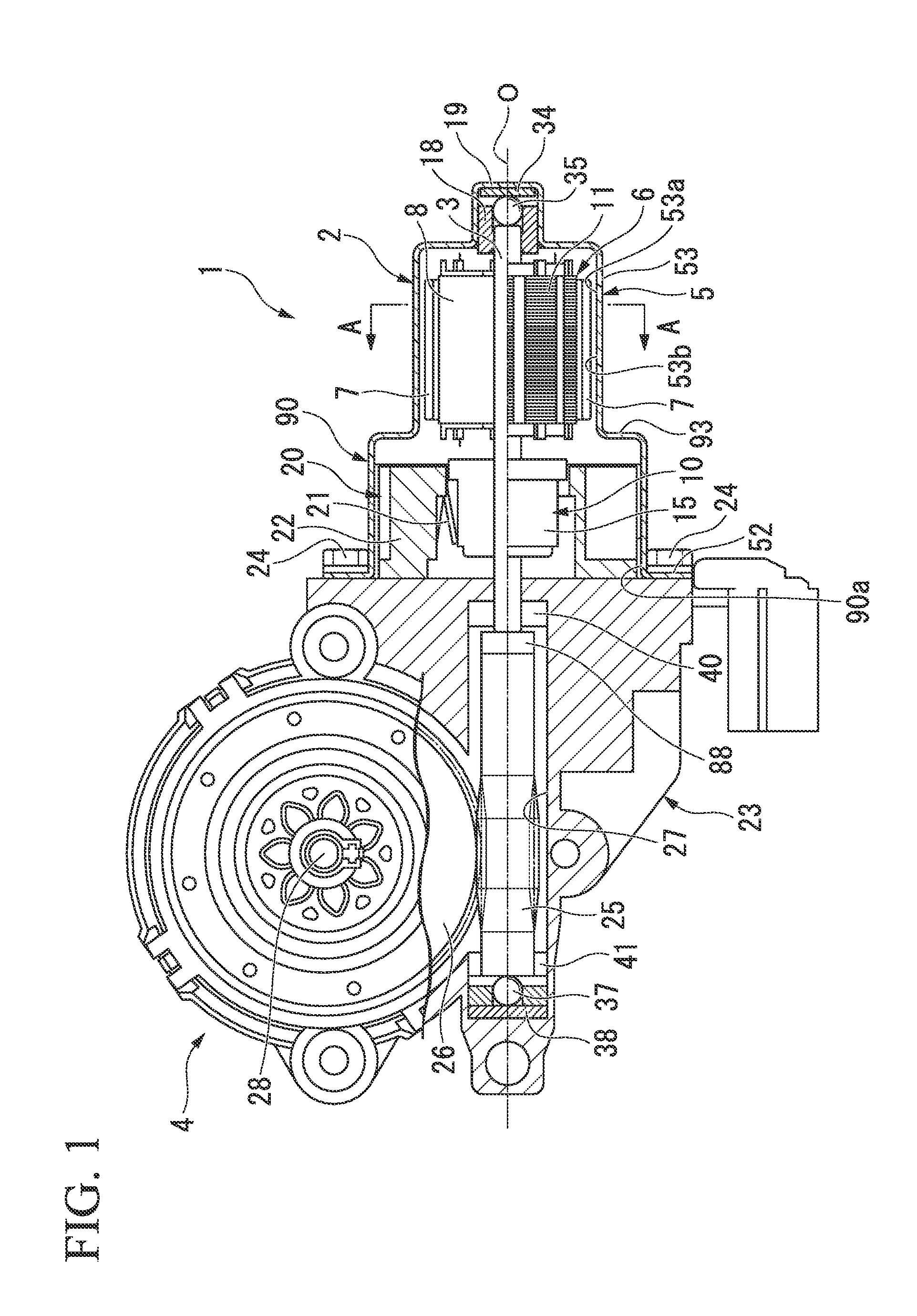

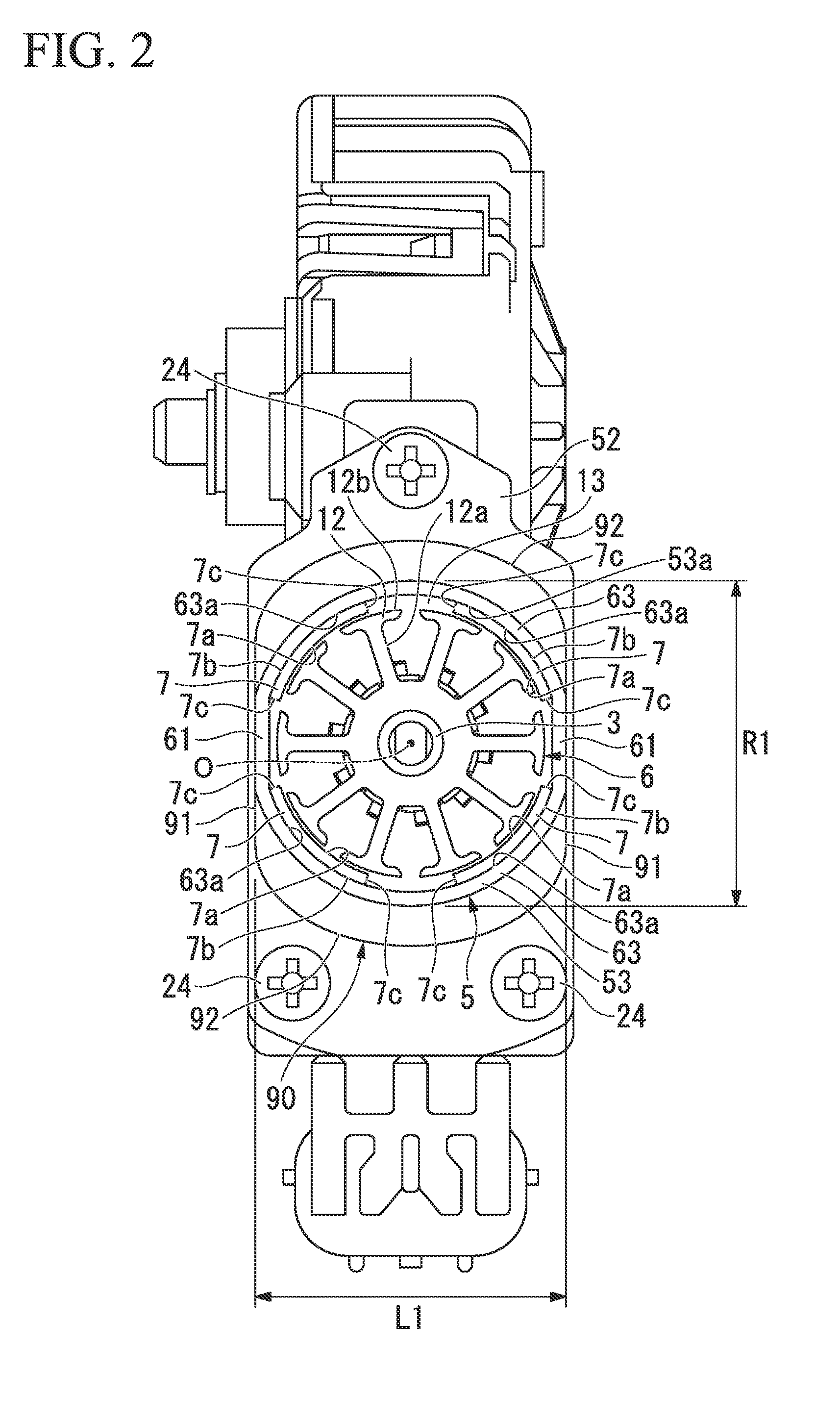

Direct current motor

ActiveUS20100052440A1FlatteningIncrease in sizeWindingsMagnetic circuitElectrical polaritySliding contact

A direct current motor with brushes in which an armature is provided with a rotating shaft that is supported by a yoke housing, an armature core that is fitted and fixed to a rotating shaft from the outer side, and a commutator that is provided on the rotating shaft adjacent to the armature core with nine segments arranged in the circumferential direction. The armature core has nine teeth that extend in the radial direction in a radial pattern and nine slots that are formed between the teeth and extend in the axial direction, the segments having the same polarity are connected with short-circuiting members, and a pair of brushes that make sliding contact with the segments is disposed so as to be mutually point symmetric centered on the rotating shaft. According to the preset invention, it is possible to effectively achieve flattening of the direct current motor.

Owner:MITSUBA CORP

Electric motor

ActiveUS20150130329A1Small sizeImprove balanceMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetElectric motor

An electric motor includes a yoke having a cylindrical section, two pairs of permanent magnets disposed at an inner circumferential surface of the cylindrical section to oppose each other, and an armature rotatably supported further inside in a radial direction than the permanent magnets, wherein at least a pair of first flat sections opposing each other in the radial direction are formed at the cylindrical section, and the permanent magnets are disposed at positions distant from the first flat sections.

Owner:MITSUBA CORP

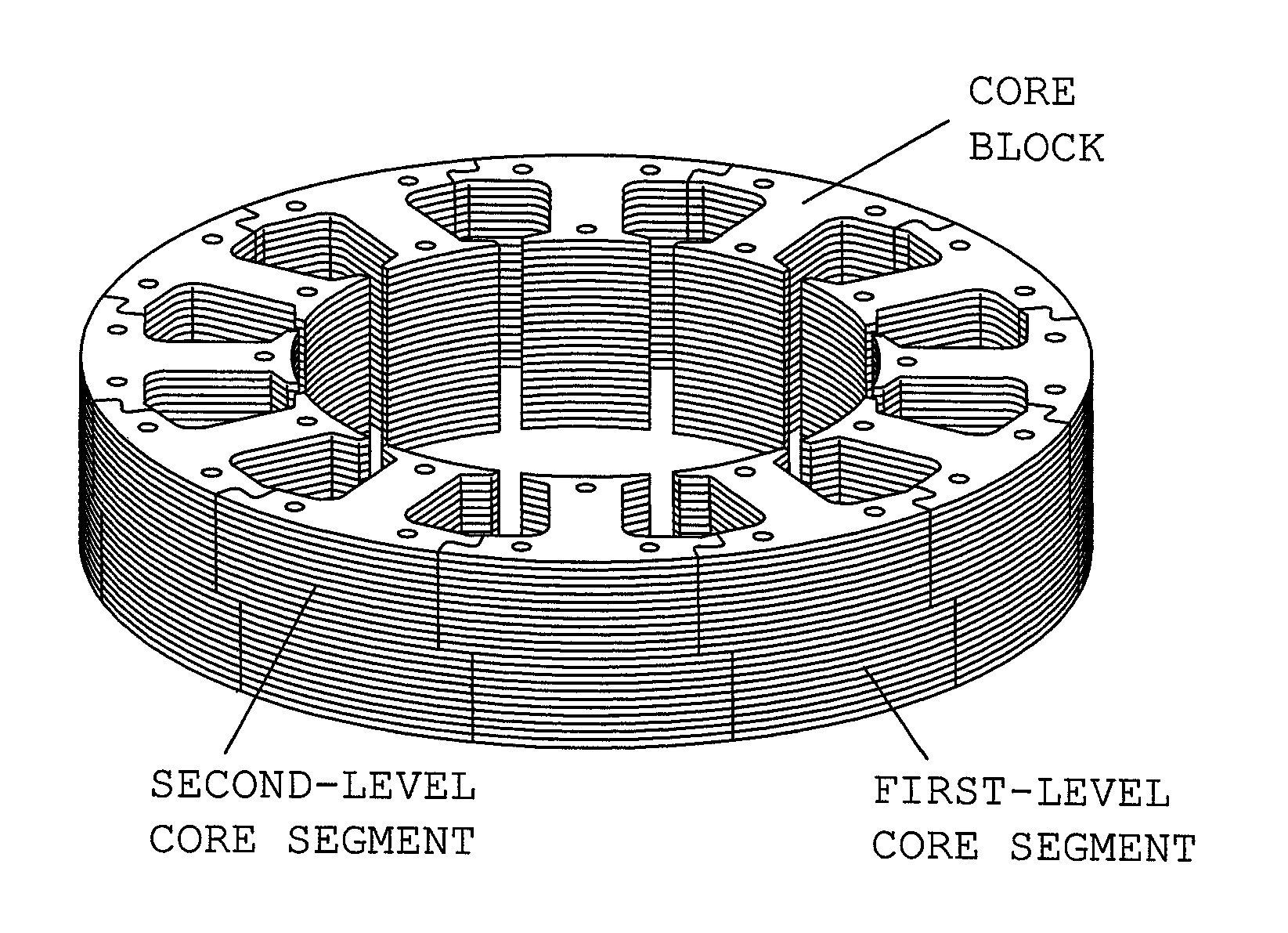

Core block, and magnetic pole core using core blocks for motor

InactiveUS8456055B2High material utilizationEasy windingMagnetic circuit rotating partsMagnetic polesMechanical engineering

Owner:MABUCHI MOTOR

Rotating electrical machine

InactiveUS20140117790A1Increase the facing areaImprove space factorMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsHigh torqueMechanical engineering

An electrical machine having high torque and reliability and low cost, has a stator and rotor facing each other via an air gap, and a bracket at each of both shaft-direction end surfaces of the stator and rotor. The stator core is formed of a dust core, and a stator side guide portion projecting in the shaft direction concentrically with an inner peripheral portion of the stator, is provided on each of both side surface portions of the stator core, a bracket side guide portion, which is fitted to the stator side guide portion, is provided at each of the brackets, and the air gap is secured by making the stator side guide portion fitted to the bracket side guide portion.

Owner:NIPPON PISTONRING CO LTD

Method of manufacturing stator core of vehicle rotary electric machine

InactiveUS7010846B2High yieldLower manufacturing requirementsWindings insulation shape/form/constructionMagnetic circuit rotating partsElectric machineMagnetic reluctance

Each tooth of a stator core has circumferential projections at an inner tooth edge and circumferential notches at a base portion adjacent to a core back. A width of the teeth at the base portion is larger than a width of the same at the tooth edge. Therefore, the magnetic reluctance of the teeth does not increase. In addition, a plurality of the magnetic strips can be formed from a long and thin magnetic sheet. This increases the yield percentage of the magnetic strip and reduces a manpower of manufacturing the magnetic strip. Further, the notches make it easy to wind the magnetic strip into a cylindrical core.

Owner:DENSO CORP

Stator and Motor, to Which the Stator is Applied, and Method of Manufacturing the Stator

InactiveUS20080315710A1Improve space factorImprove efficiencyWindingsMagnetic circuit stationary partsEngineeringConductor Coil

There is provided a stator in which a plurality of divided stators are annularly combined with each other, and each divided stator includes: a divided lamination iron core having teeth portion and a yoke portion, and constructed by laminating electromagnetic steel sheets divided by the teeth unit; insulating bodies provided at the divided lamination iron core; and concentrated winding wound around the divided lamination iron core through the insulating body. In this case, the divided lamination iron core is held by the insulating bodies and the concentrated winding.

Owner:PANASONIC CORP

Stator of rotating electric machine and manufacturing method of the stator

ActiveUS20050264123A1Ease of coil assemblyImprove space factorSynchronous generatorsMagnetic circuit stationary partsElectrical conductorElectric machine

Owner:MITSUBISHI ELECTRIC CORP

Induction machine

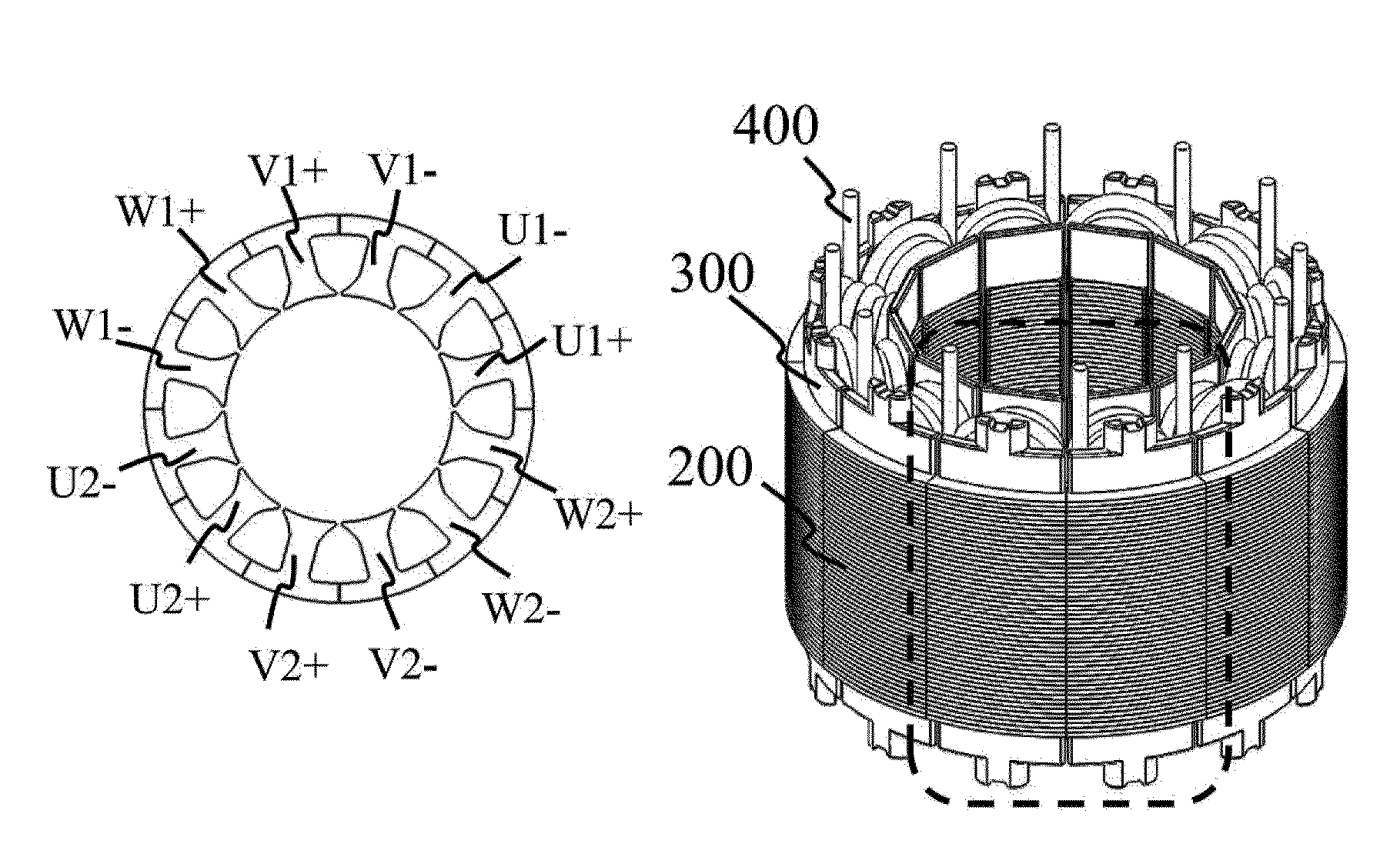

InactiveUS7642685B2Improve productivityEasy to operateWindingsSynchronous motorsProduction rateMagnetomotive force

An electric rotating machine comprises: a stator in which a coil is wound on a plurality of teeth in concentrated winding, and the coil is connected to a three-phase power supply; and a rotor disposed in opposition to the teeth of the stator; wherein a ratio between the number of poles and the number of slots of the stator is 1:3. There is no higher harmonics of magnetomotive force in low order close to fundamental wave, thus enabling efficient operation of the electric rotating machine. Furthermore, owing to the stator of concentrated winding, it is possible to provide an electric rotating machine of high productivity with small coil end, high mass production, and high space factor.

Owner:MITSUBISHI ELECTRIC CORP

AC generator for vehicle

ActiveCN101316054AAvoid temperature riseImproved resistance to thermal degradationMagnetic circuit stationary partsCooling/ventillation arrangementLong axisEngineering

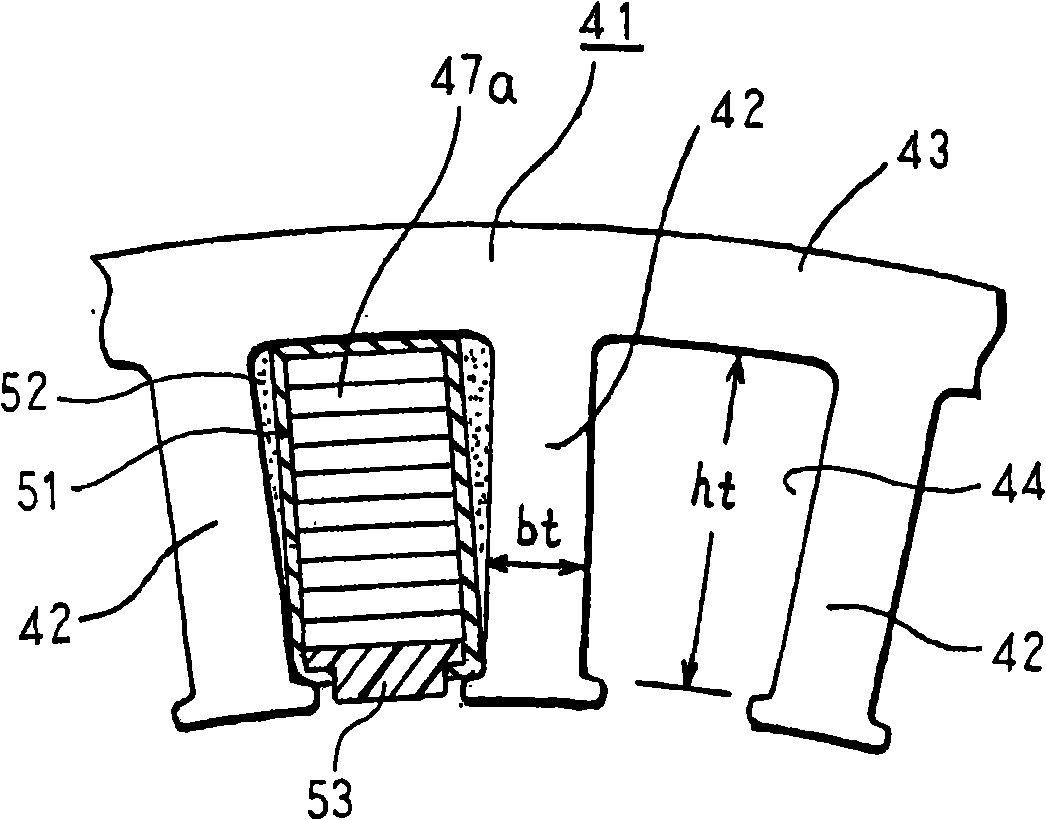

In a stator core, the radial length (ht) and the width (bt) of a rack part meets that the ratio of bt and ht is less than 0.4 and more than 0.15. A stator winding is provided with a plurality of windings which are respectively winded on a trough group consisting of the troughs of the stator core with specific trough numbers. Each winding is formed by winding the conductive wires on the trough group by equal parts at the left side and the right side, wherein, the conductive wires extend out of the two ends of the trough and respectively inserted into the troughs with the distance of specific trough number and at two sides of the circumferential direction by equal parts at the left side and the right side of the circumference. Furthermore, the trough receiving parts of the conductive wires are received in the troughs by multi-layer in a state that the long axis direction with flat sections and the circumferential direction are consistent in the radial direction and arranged as a line.

Owner:MITSUBISHI ELECTRIC CORP

Antenna module whose antenna characteristics are not adversely affected by a mother board

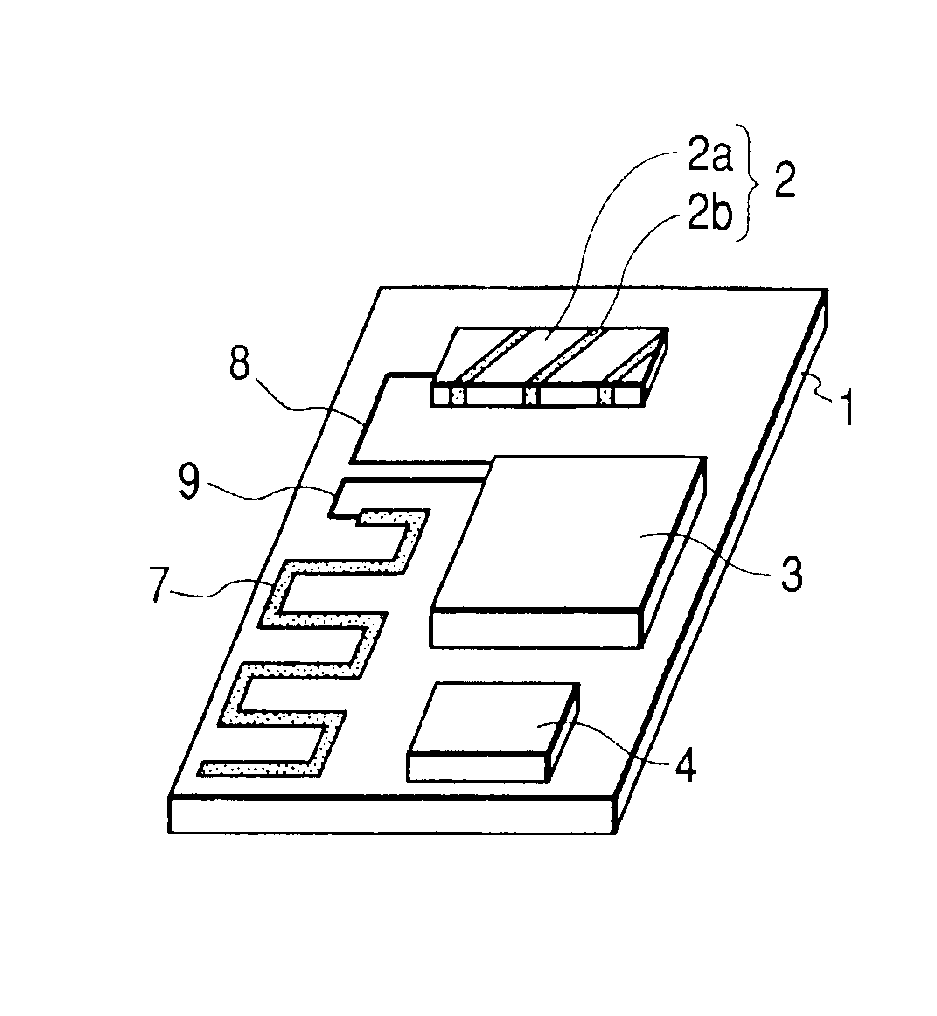

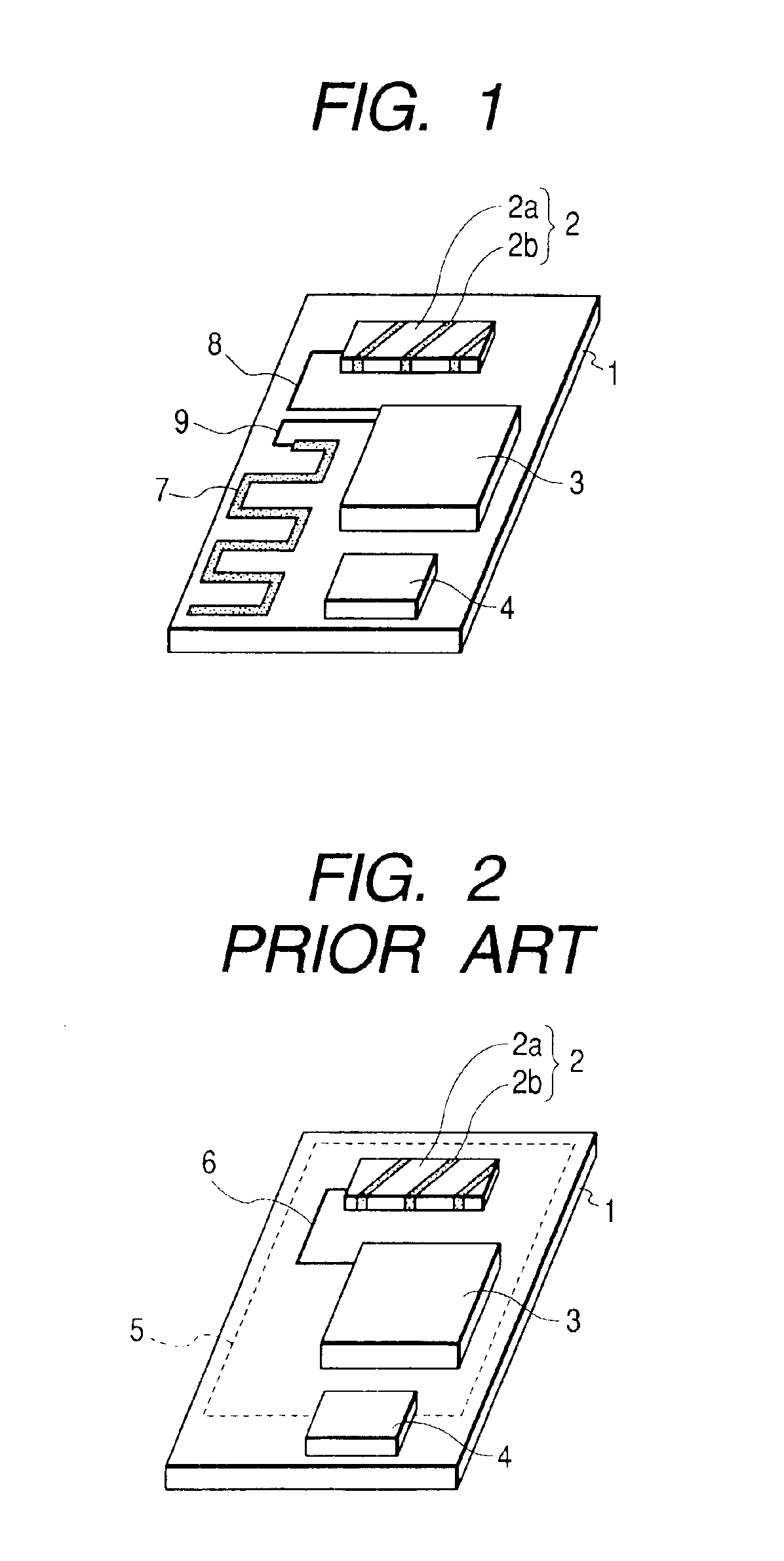

InactiveUS6882319B2Small sizeEasy impedance matchingAntenna supports/mountingsRadiating elements structural formsElectrical conductorEngineering

A chip-type antenna and a snaked, band-shaped conductor as a pair of radiation elements fed at the center, a circuit unit having a transmission / reception circuit that is connected to respective feeder lines for the radiation elements, and a connector that connects, to an external circuit, lead lines leading from the circuit unit are arranged on an insulative substrate to be mounted on a mother board. The pair of radiation elements extend along two adjoining sides of the insulative substrate so as to generally assume an L-shape in a plan view.

Owner:ALPS ALPINE CO LTD

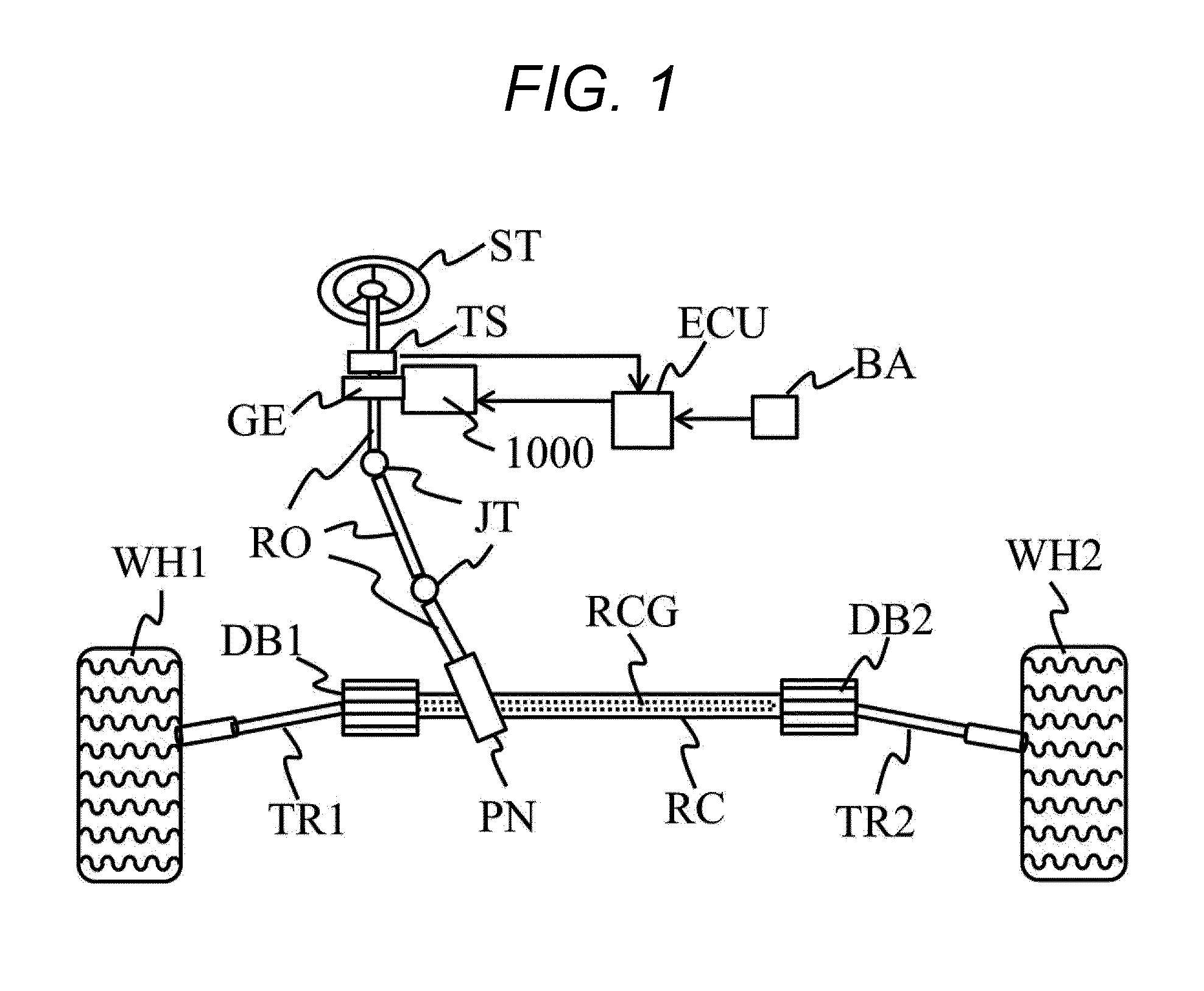

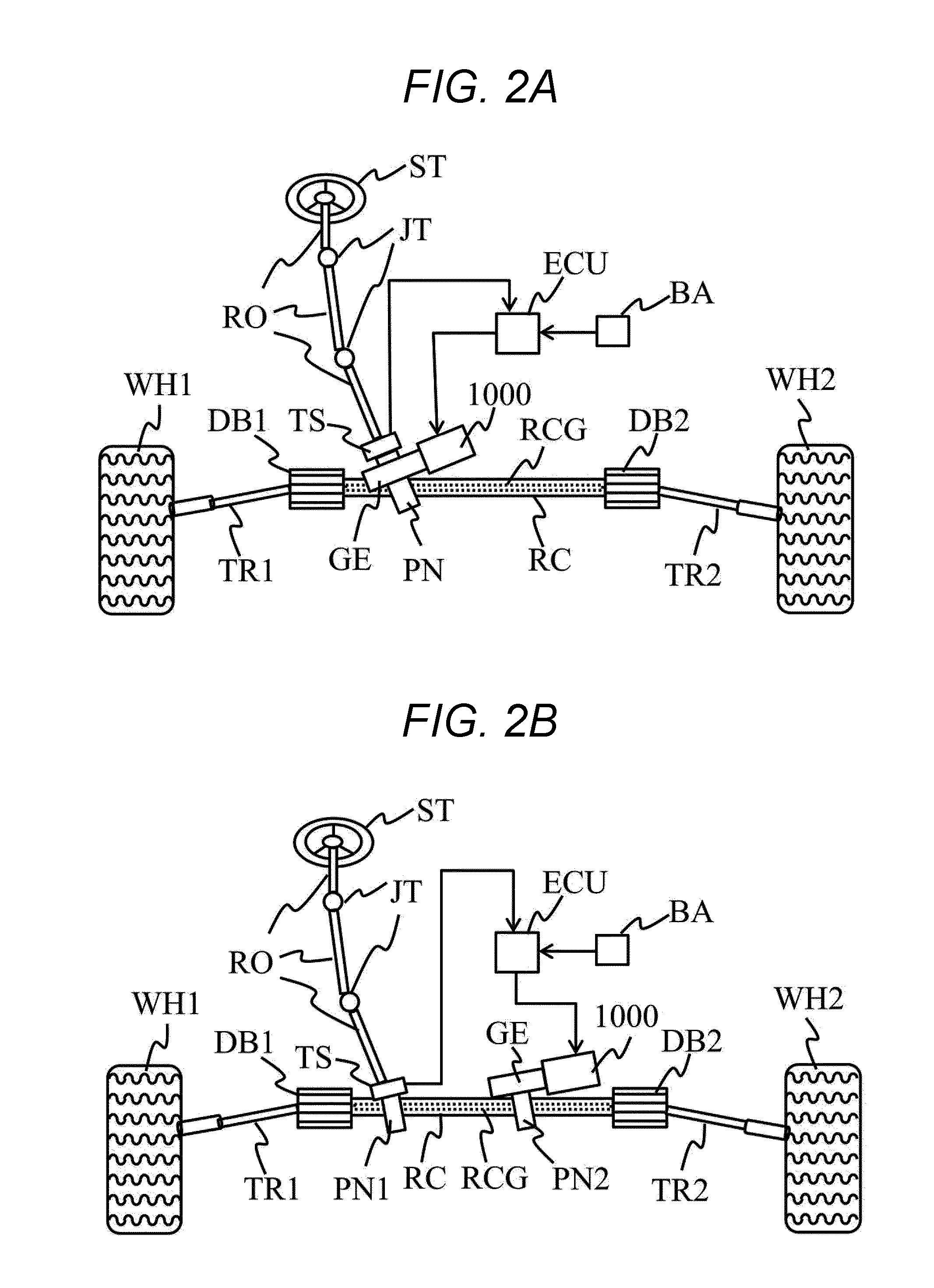

Rotating electrical machine and electric power steering system using the same

InactiveUS20140084728A1Alleviating cogging torque torqueAlleviating torque torque rippleSynchronous machines with stationary armatures and rotating magnetsWindings conductor shape/form/constructionElectric power steeringElectric power system

Owner:HITACHI AUTOMOTIVE SYST LTD

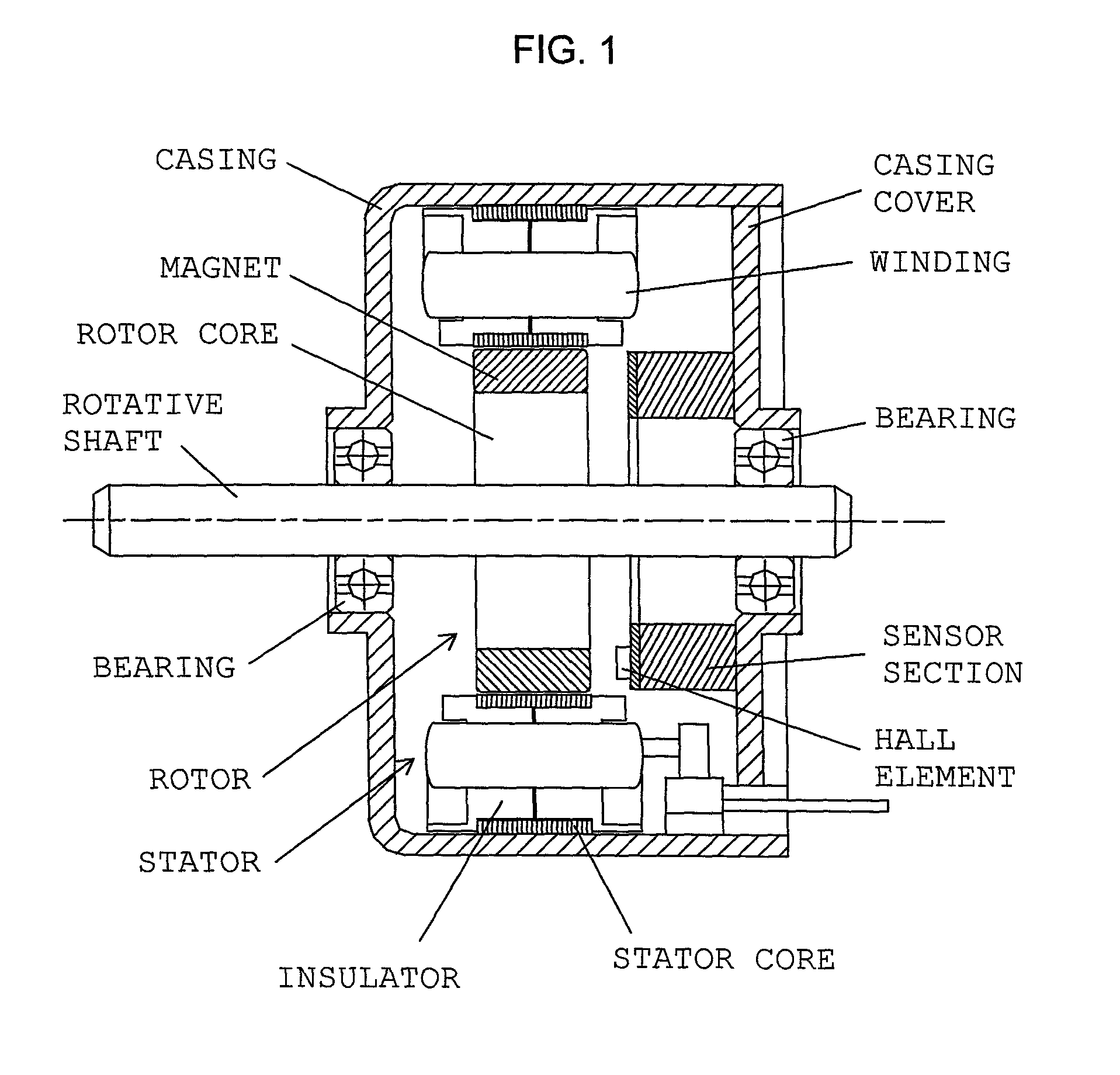

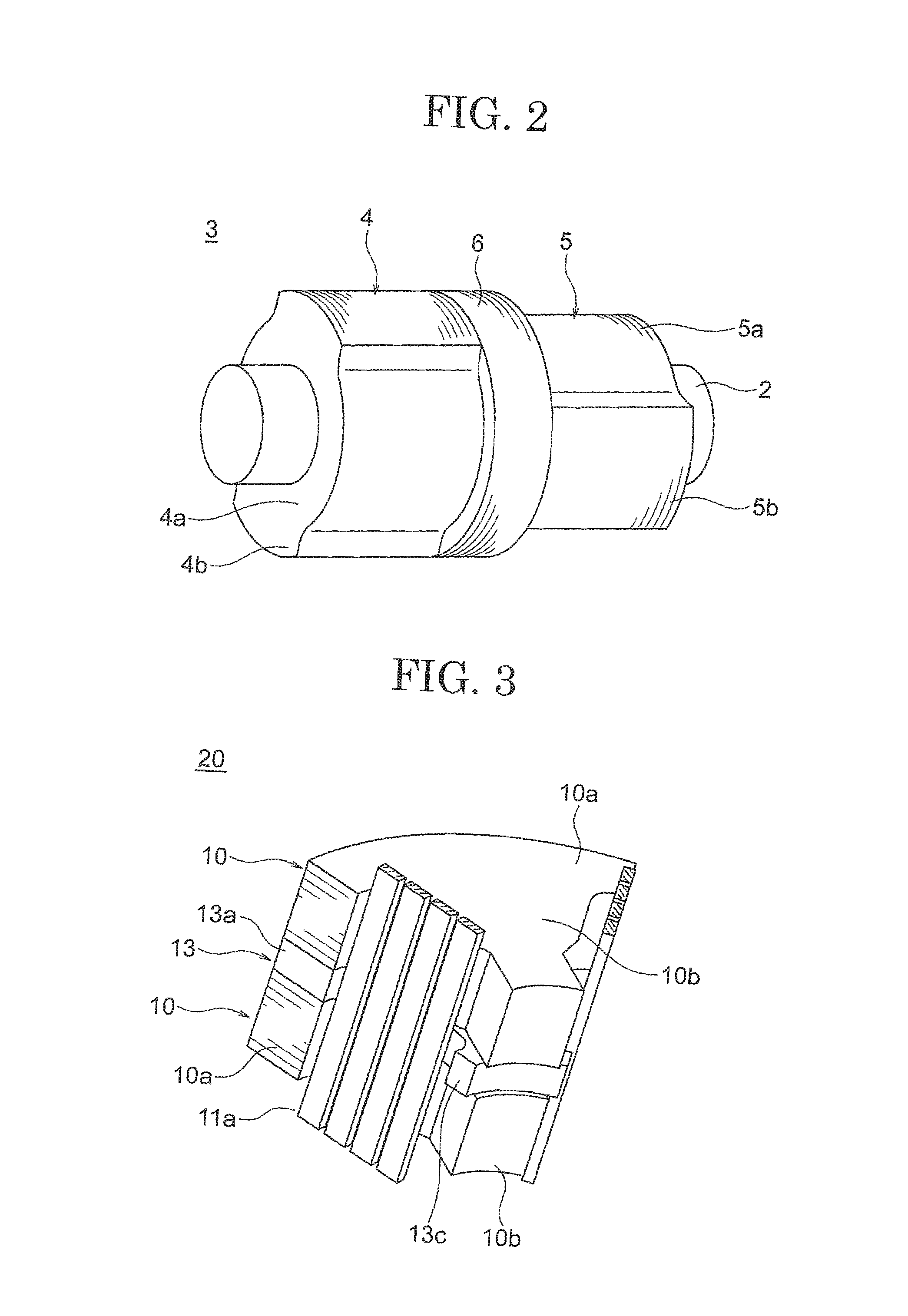

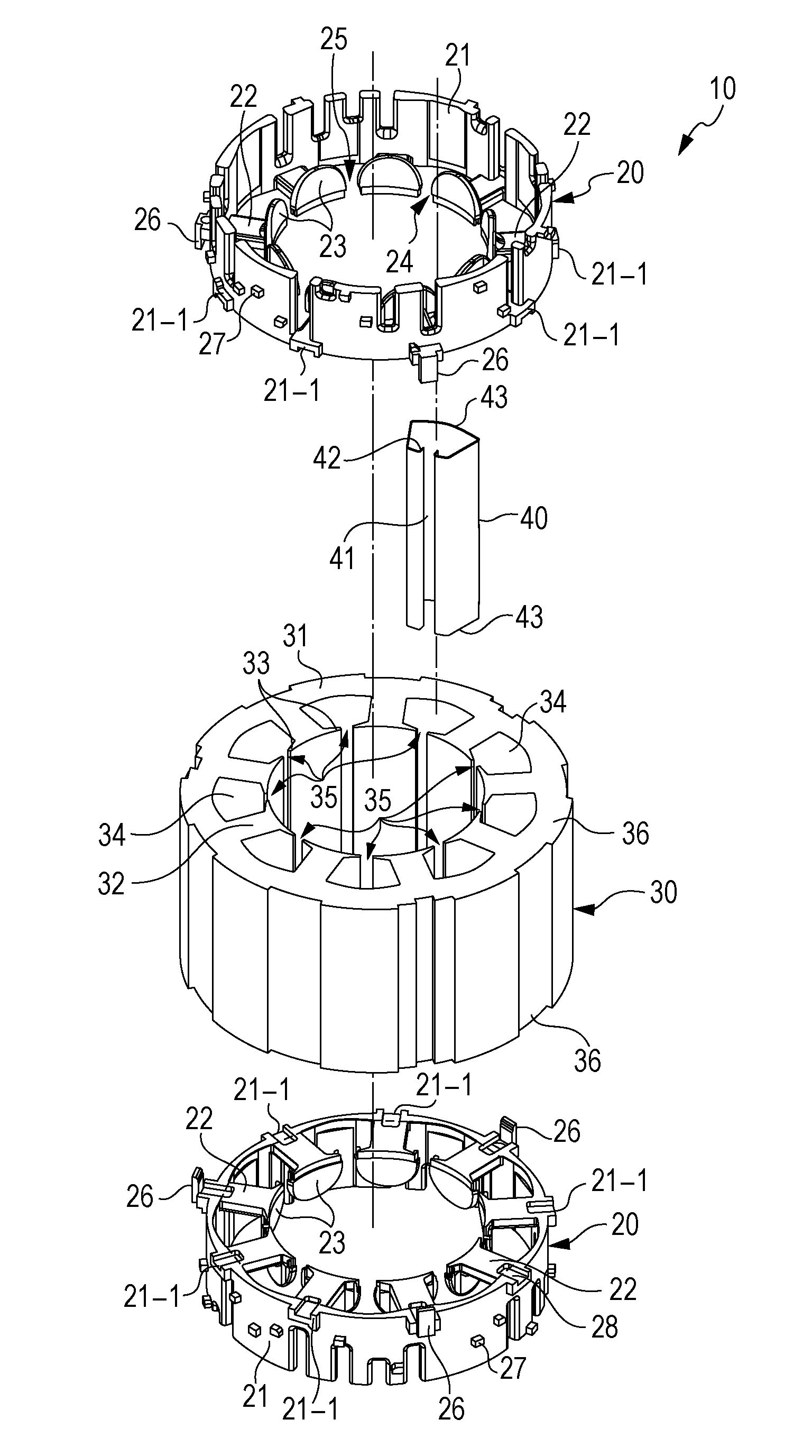

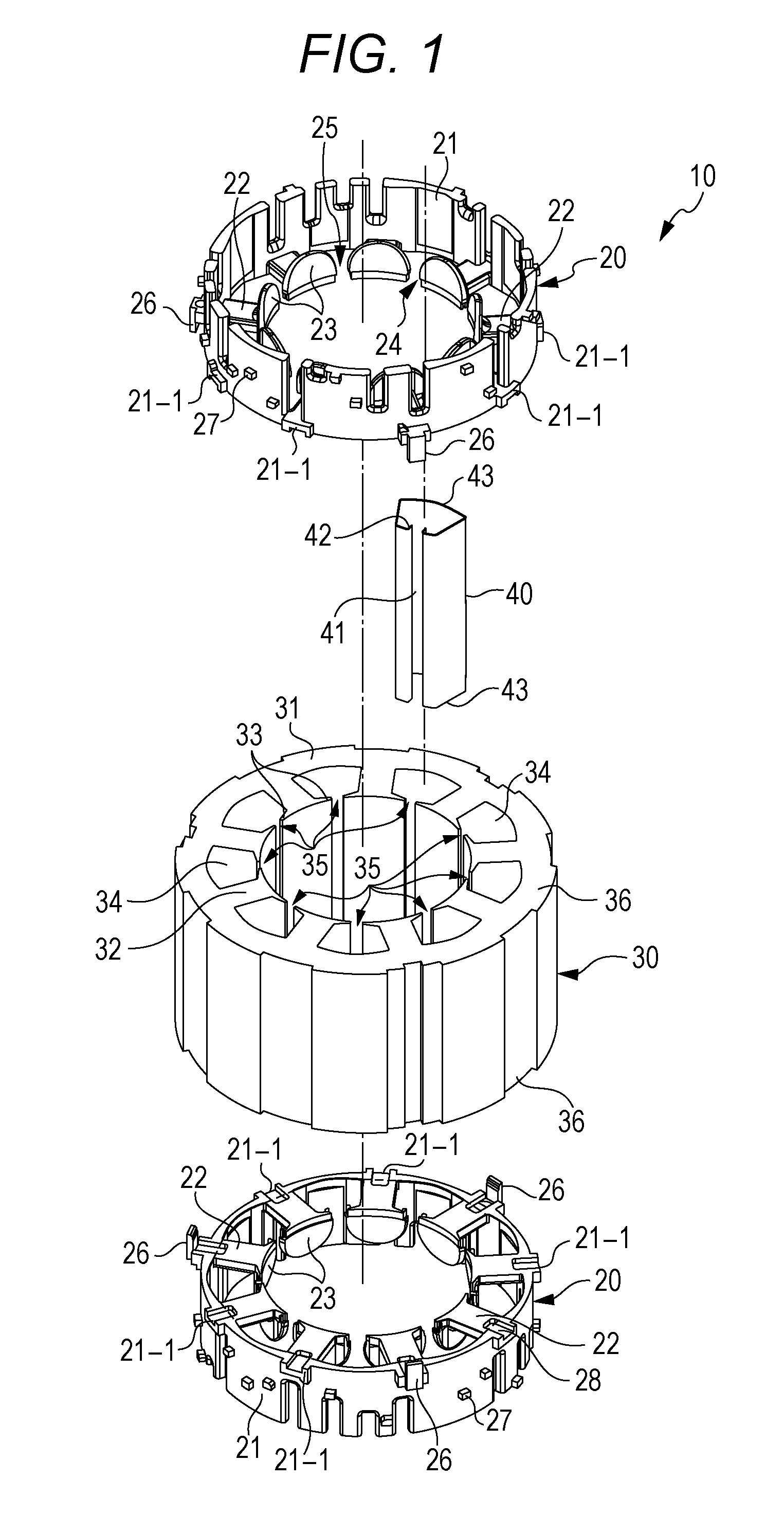

Magnetic inductor electric motor and manufacturing method therefor

ActiveUS20160248308A1Increase productionIncrease axial dimensionMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringInductor

A first stator core and a second stator ore are configured by arranging core block pairs into an annular shape, the core block pairs being configured by stacking together core blocks so as to be spaced apart axially, each of the core blocks including a core back portion and one tooth, and a permanent magnet is configured so as to be divided into a plurality of magnet blocks that each include: a base portion; one shaft portion that protrudes radially inward from an inner circumferential surface of the base portion; and flange portions that protrude on two circumferential sides from a radially inner end portion of the shaft portion, the magnet blocks being held between the core block pairs such that the base portion and the shaft portion are positioned inside the core block pairs and such that the flange portions protrude circumferentially from the core block pairs.

Owner:MITSUBISHI ELECTRIC CORP

Stator of rotating electric machine and manufacturing method of the stator

ActiveUS7239059B2Ease of coil assemblyImprove space factorSynchronous generatorsAsynchronous induction motorsElectrical conductorElectric machine

Owner:MITSUBISHI ELECTRIC CORP

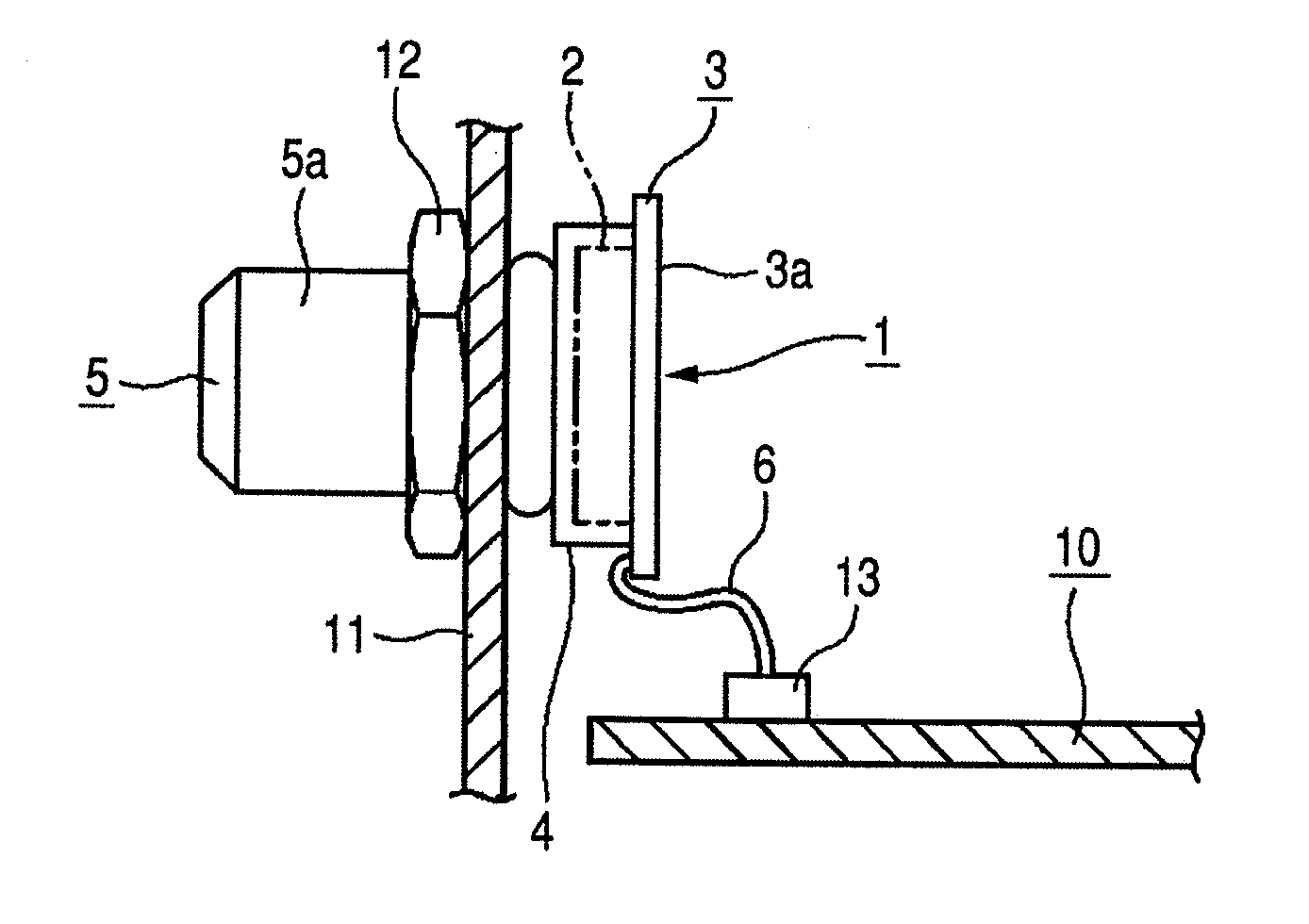

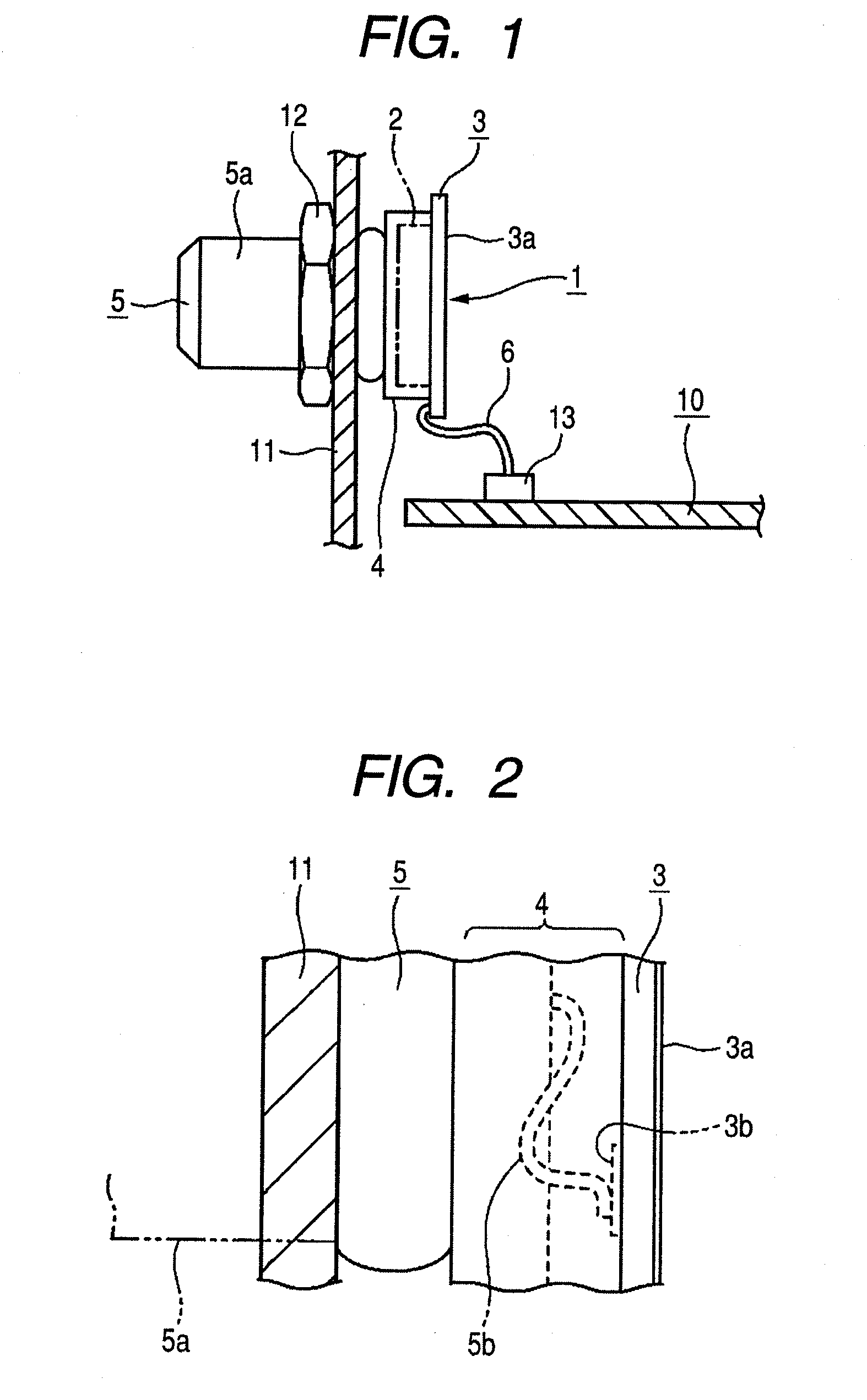

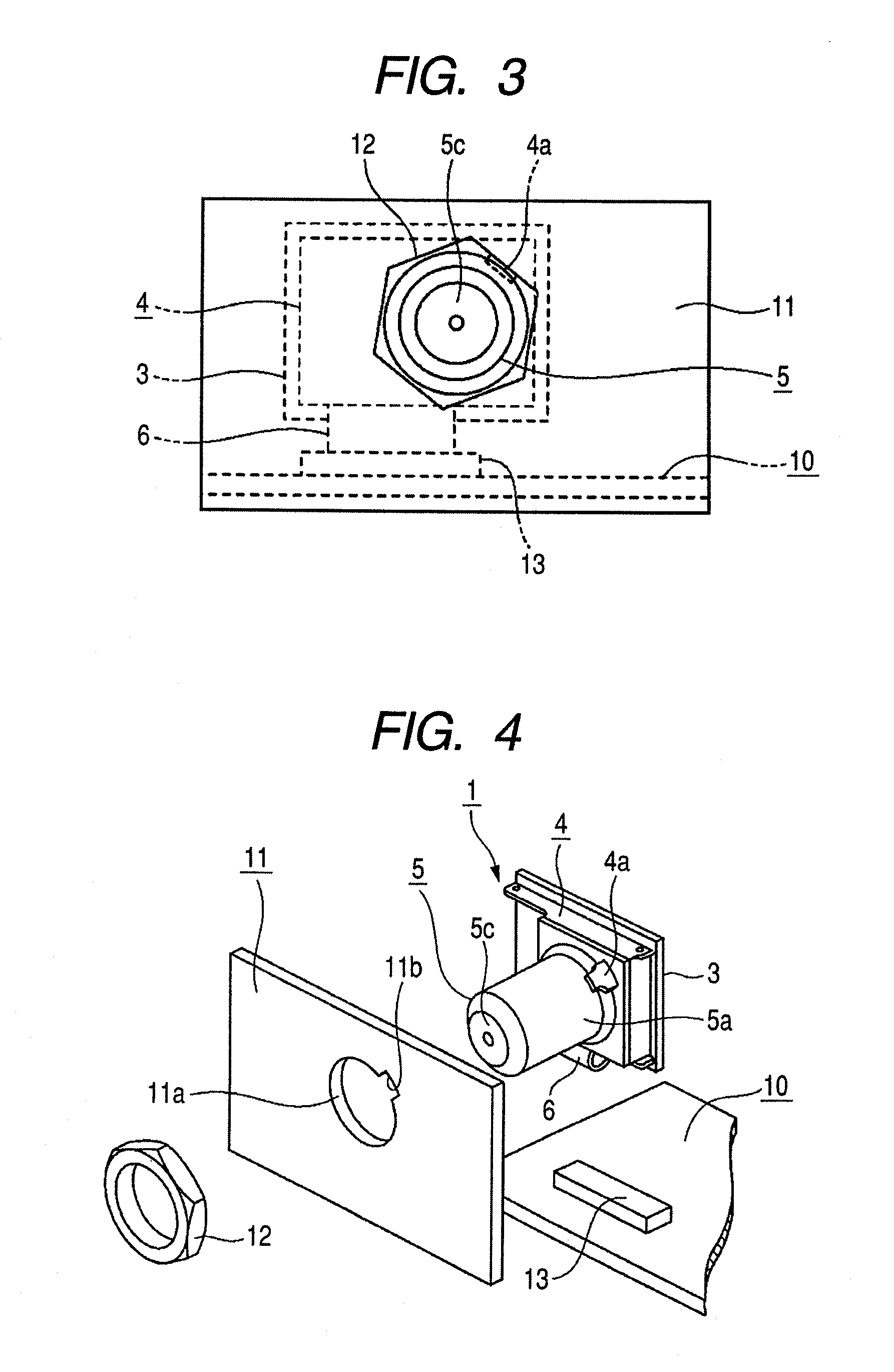

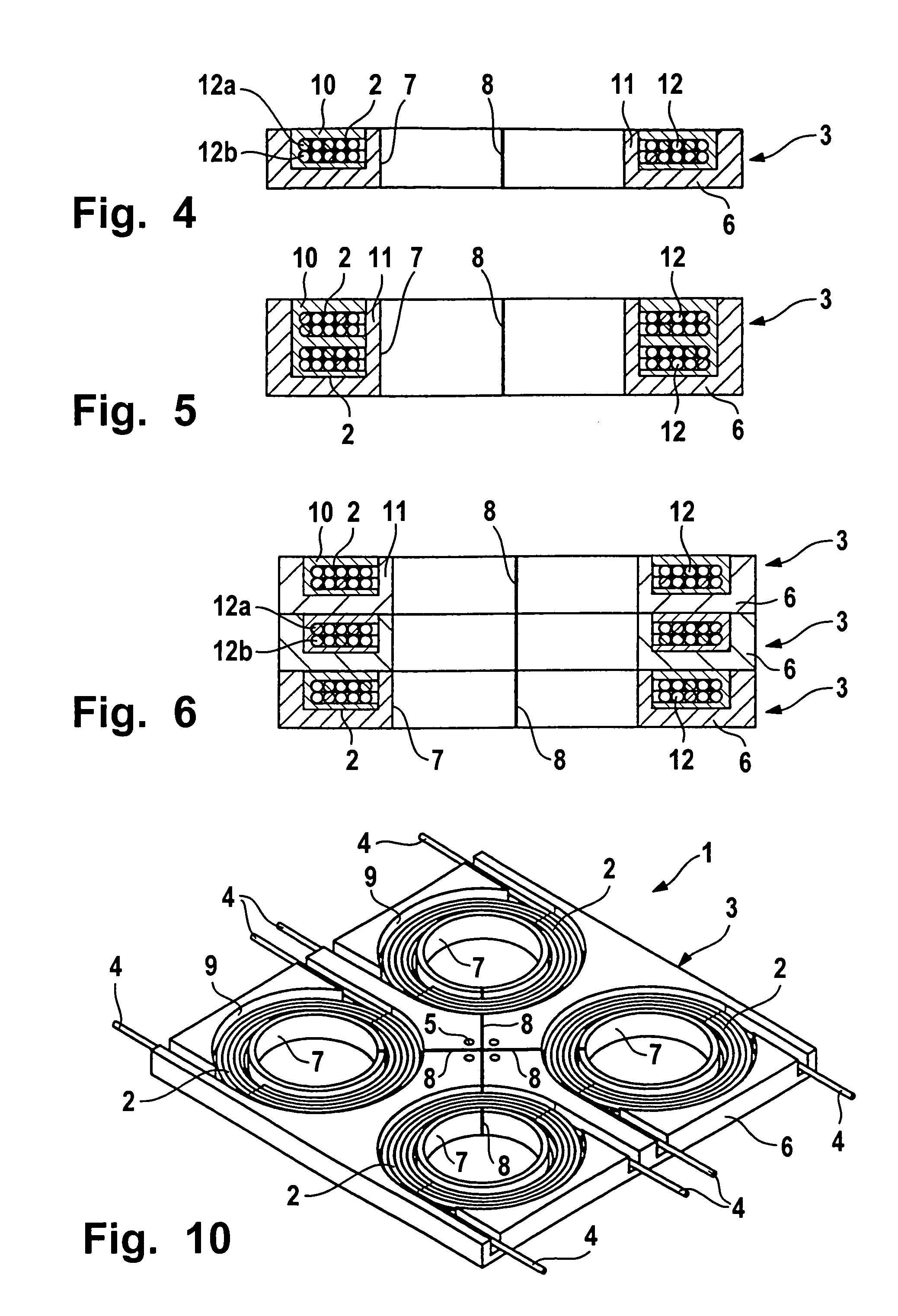

Mounting structure of electronic circuit unit

InactiveUS20100315183A1Increase freedomImprove space factorTelevision system detailsResonant circuit detailsEngineeringFlexible cable

A mounting structure of an electronic circuit unit includes a circuit board provided with a high frequency circuit, a metallic casing mounted on the circuit board to cover the high frequency circuit, an F type connector fixed to the casing and protruding approximately perpendicularly to the circuit board, and a flexible cable having one end portion connected to the circuit board. In a state in which the F type connector passes through a mounting hole formed through a set-side panel to protrude outward, at least one of the casing and the F type connector is fixed to the set-side panel by a fixing member, and the other end portion of the flexible cable is connected to a mother board.

Owner:ALPS ALPINE CO LTD

Stator for rotating electric machine

ActiveUS20150229174A1Improve rigidityHigh reliabilitySynchronous machinesAsynchronous induction motorsEngineeringMulti phase

A stator includes a multi-phase stator coil comprised of phase windings. Each of the phase windings is formed of a continuous electric conductor and includes in-slot portions and coil end portions. Each of the in-slot portions is received in one of slots of a stator core. Each of the coil end portions is located outside the slots so as to connect one adjacent pair of the in-slot portions. Each of the coil end portions includes at least one oblique part that extends obliquely at an oblique angle with respect to either an axial direction or a circumferential direction of the stator core. The oblique angles of the oblique parts of the coil end portions in at least one of the phase windings of the stator coil are set to be different from the oblique angles of the oblique parts of the coil end portions in the other phase windings.

Owner:DENSO CORP

Electric motor

ActiveUS20150035404A1Improve space factorIncrease radial thicknessWindings insulation shape/form/constructionSynchronous machinesEngineeringFlange

The electric motor includes a rotor and a stator, the stator having a conductive wire wound thereon via a stator core and insulators. The insulators include an annular outer peripheral wall portion with the conductive wire run on an outer periphery side of the peripheral wall portion, a plurality of winding body portions protruding radially from the outer peripheral wall portion, and an inner flange portion. The outer peripheral wall portion on the winding body portion side includes an outer peripheral surface formed in an arc shape. The radial thickness of the outer peripheral wall portion is increasingly greater toward the circumferential center of the winding body portions.

Owner:FUJITSU GENERAL LTD

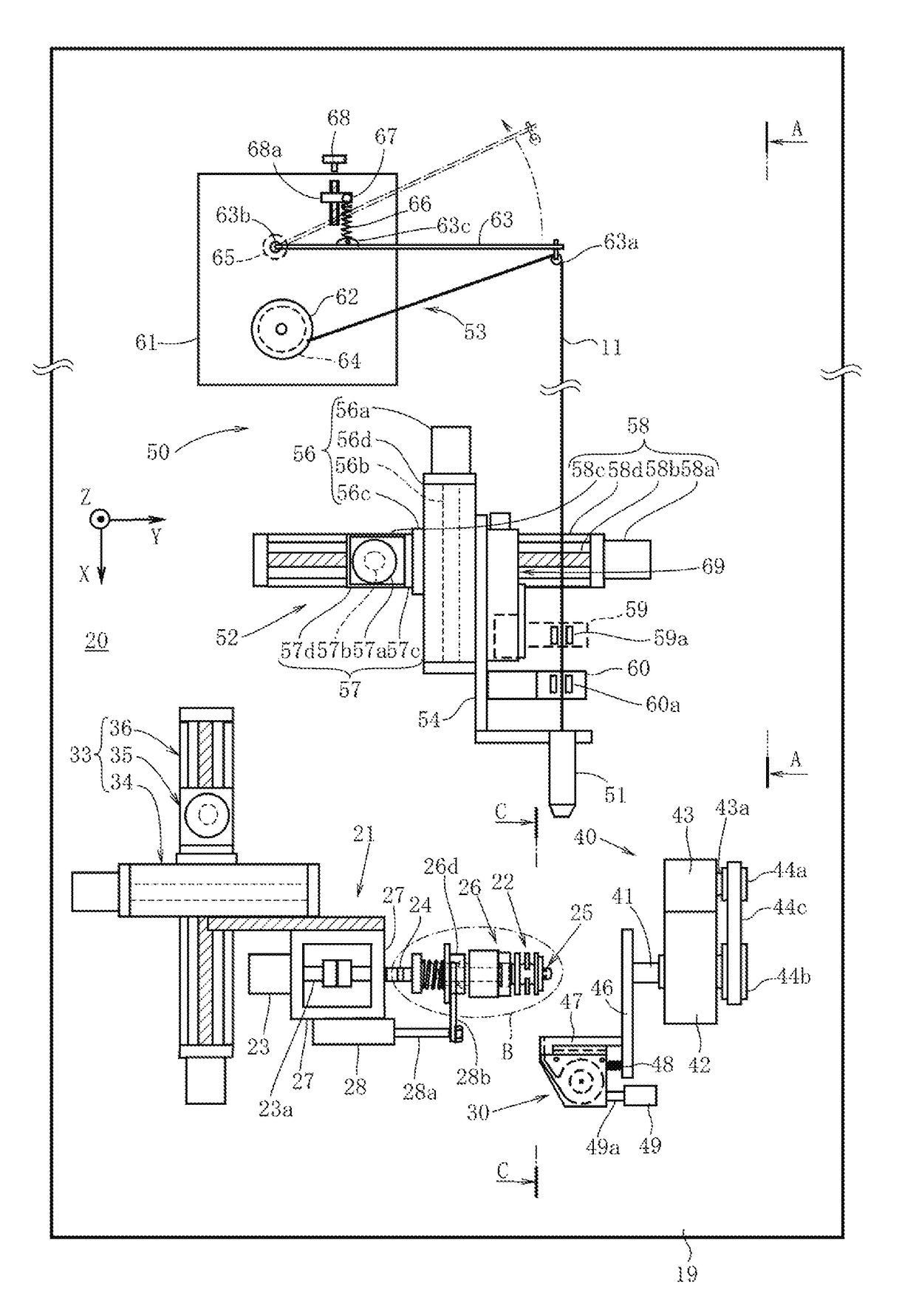

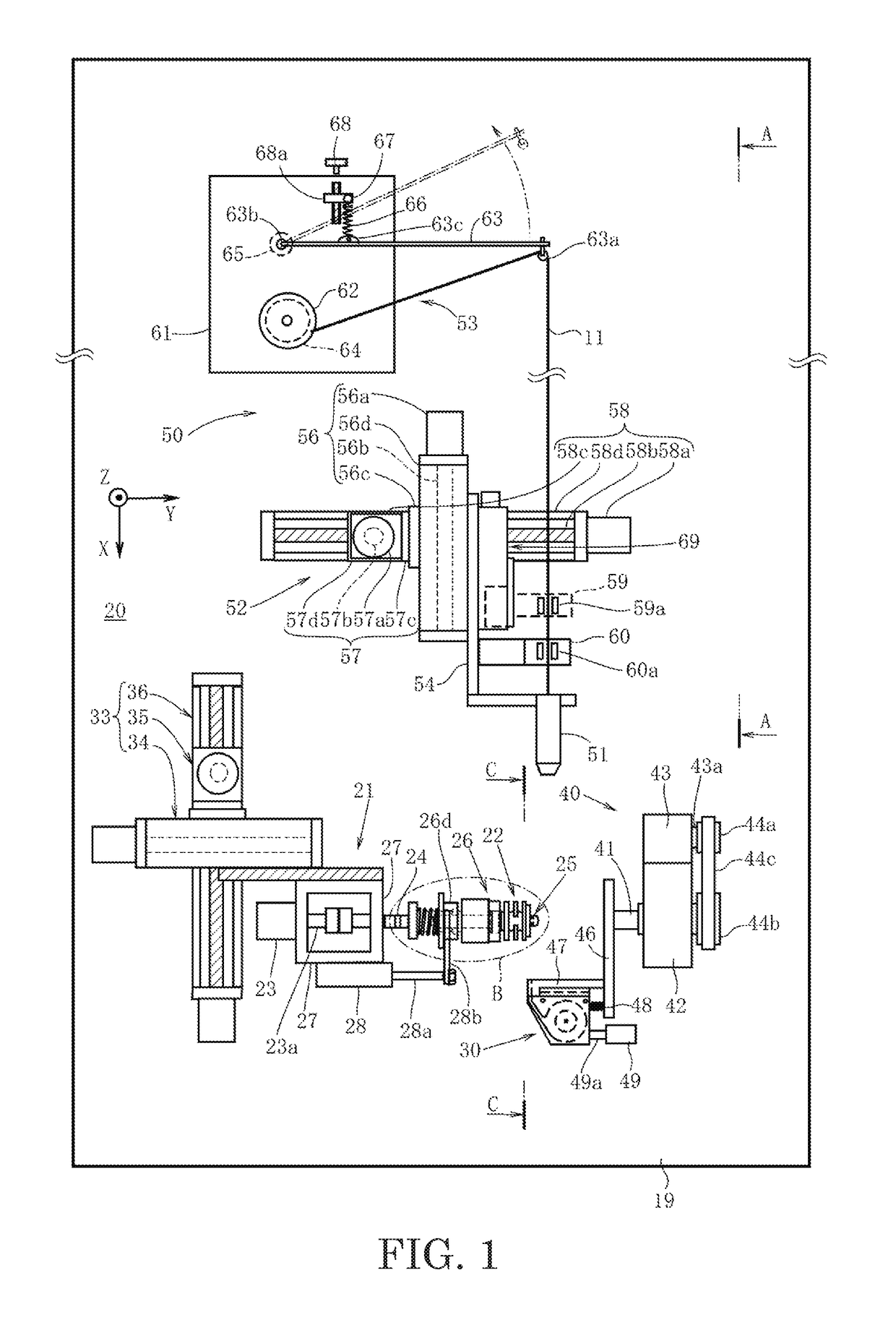

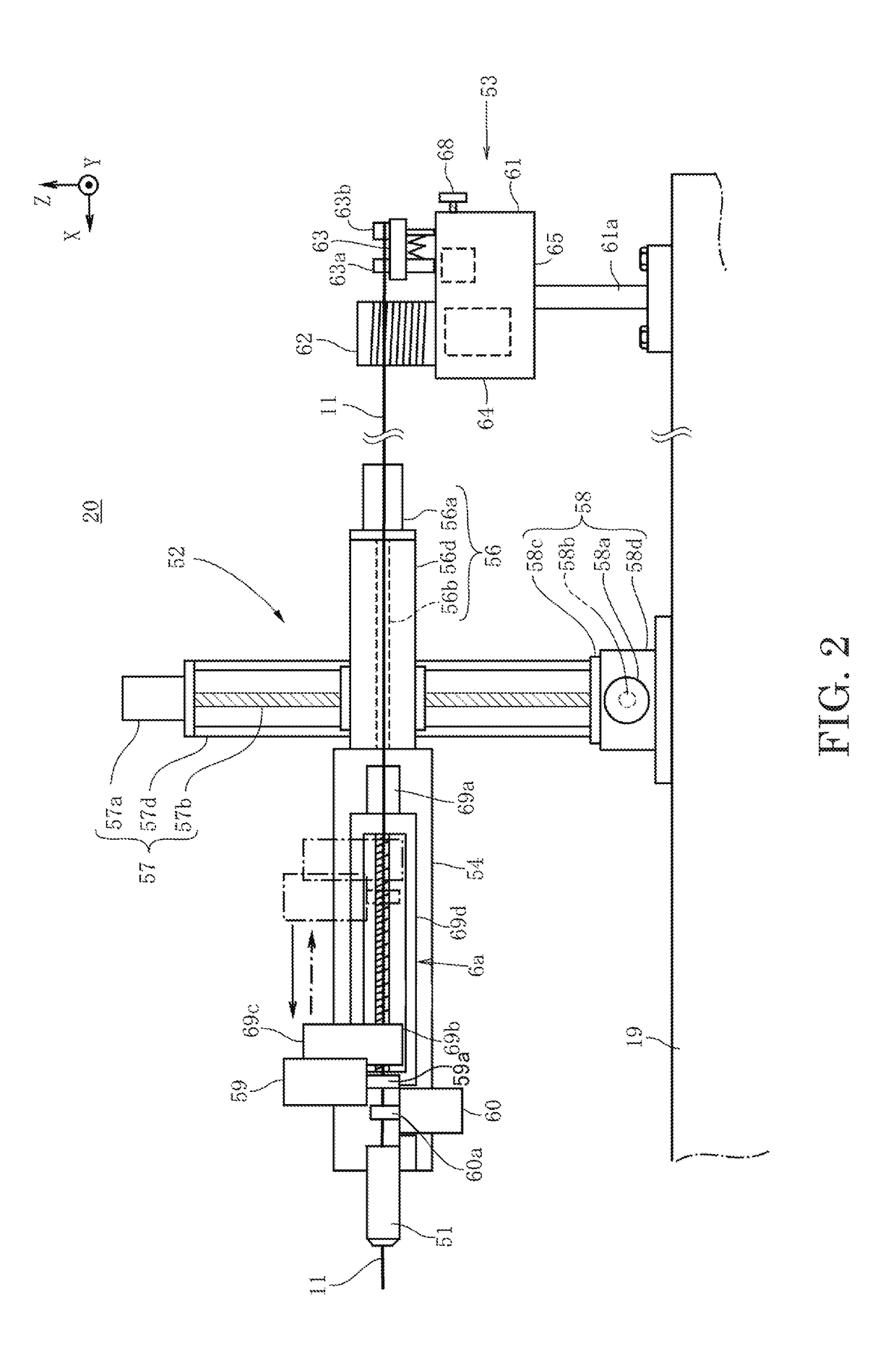

Coil winding device and method for manufacturing coil

ActiveUS20180053599A1Improve space factorEasy to shapeTransformers/inductances detailsCoils manufactureEngineeringMechanical engineering

A coil winding device includes a wire rod delivering machine configured to deliver a wire rod through a nozzle, a wire storing jig configured to store the wire rod delivered from the nozzle, a wire-wound member around which the wire rod is wound, a wire-wound-member rotation mechanism configured to rotate the wire-wound member to wind the wire rod delivered from the nozzle around the wire-wound member, and a wire-storing-jig turning mechanism configured to turn the wire storing jig around a rotation axis of the wire-wound member to wind the wire rod delivered from the wire storing jig around the wire-wound member. The rotation axis of the wire-wound member and a wire-storing central axis of the wire storing jig are mutually orthogonal.

Owner:NITTOKU CO LTD

Multilayer aligned-winding coil

ActiveUS7626478B2Improve space factorIncrease spacingTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringConductor Coil

Owner:NITTOH ELECTRIC

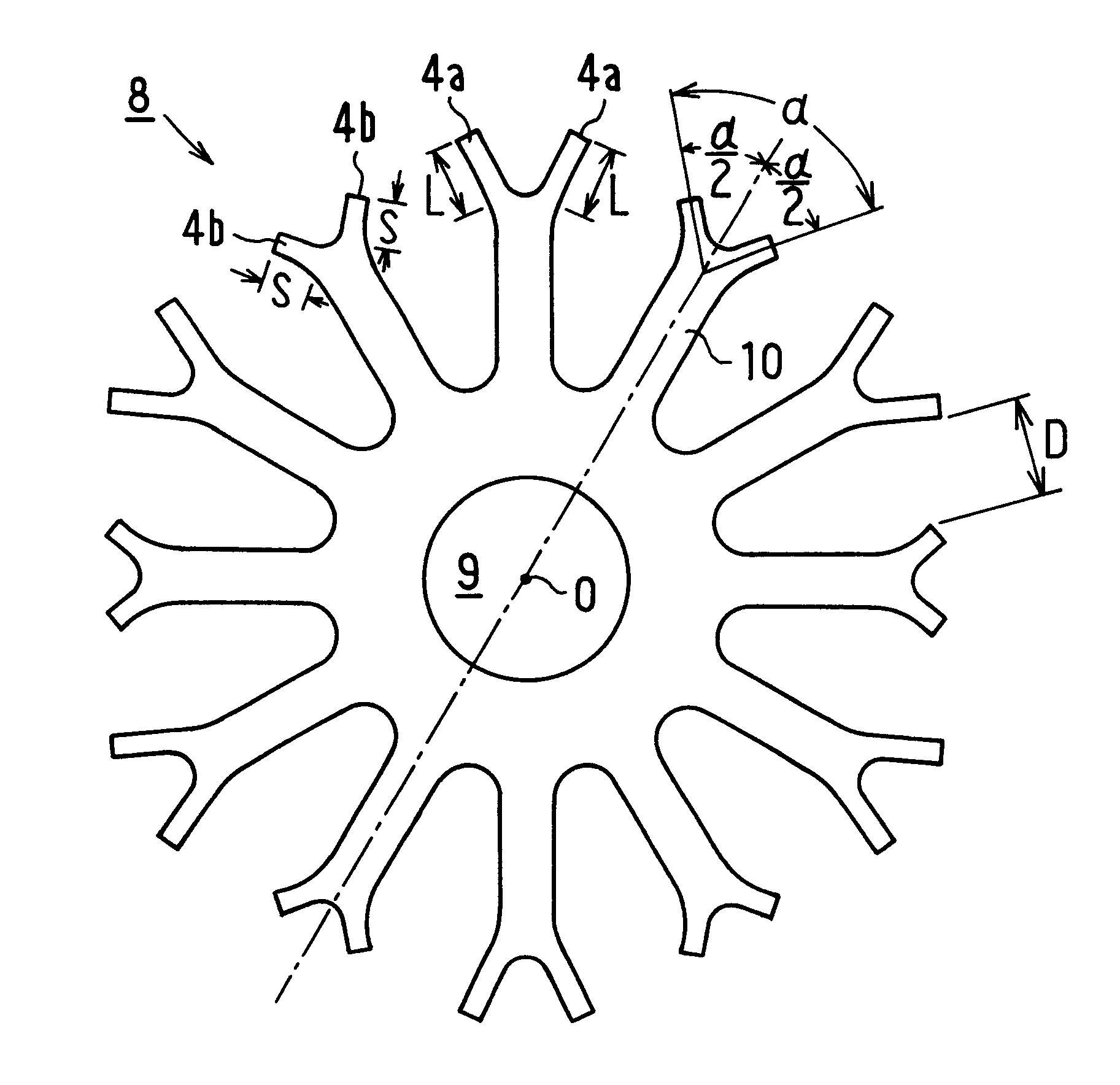

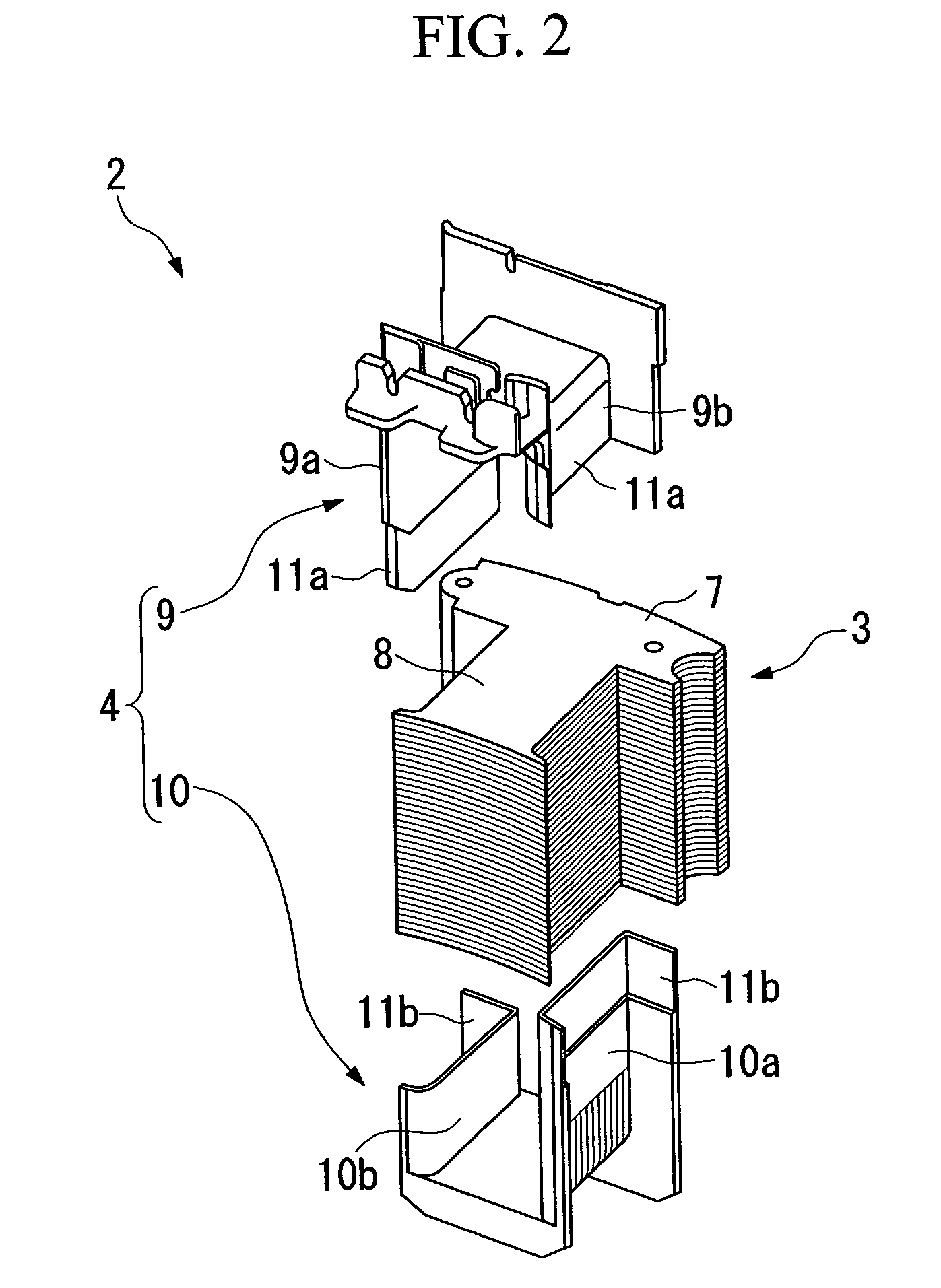

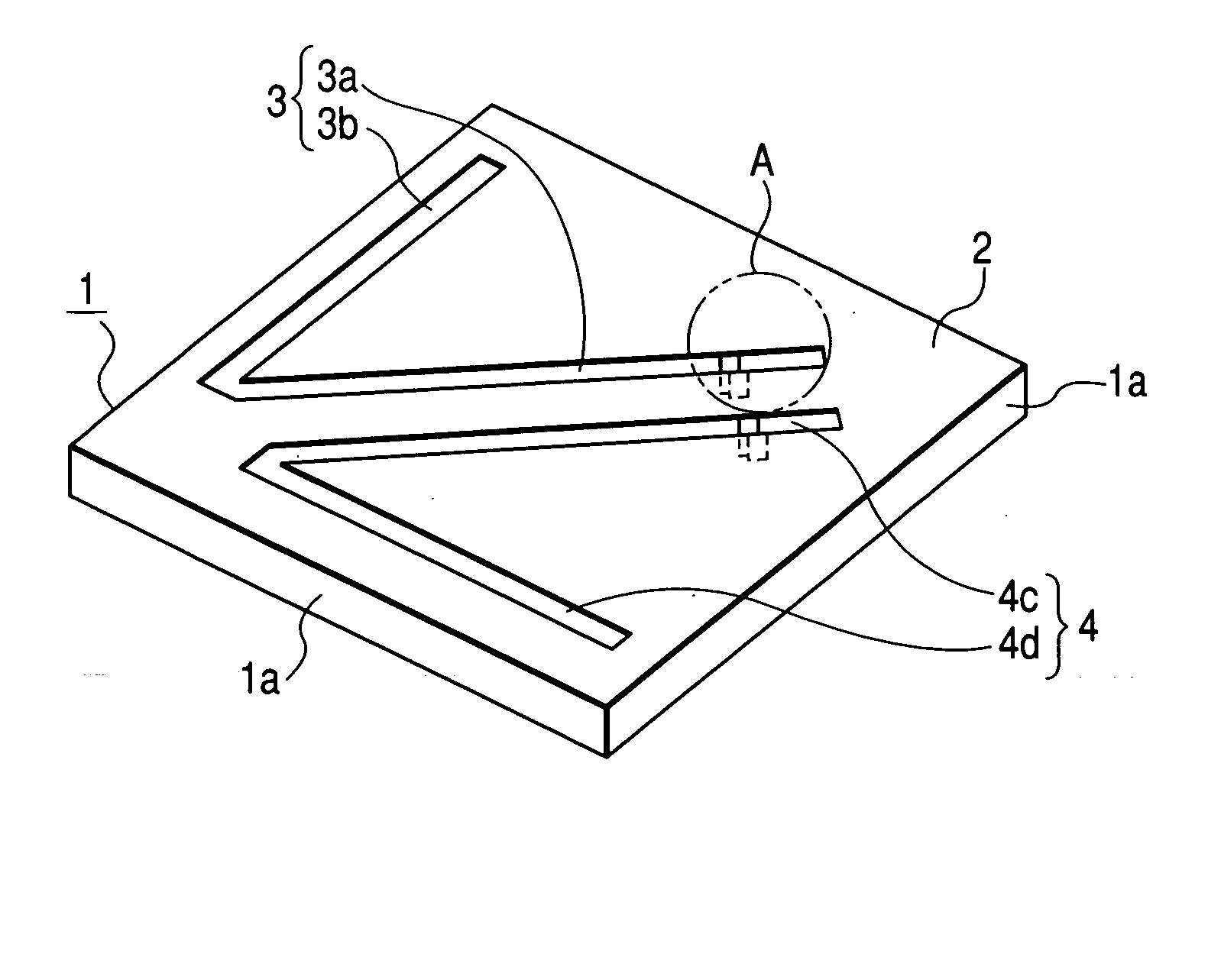

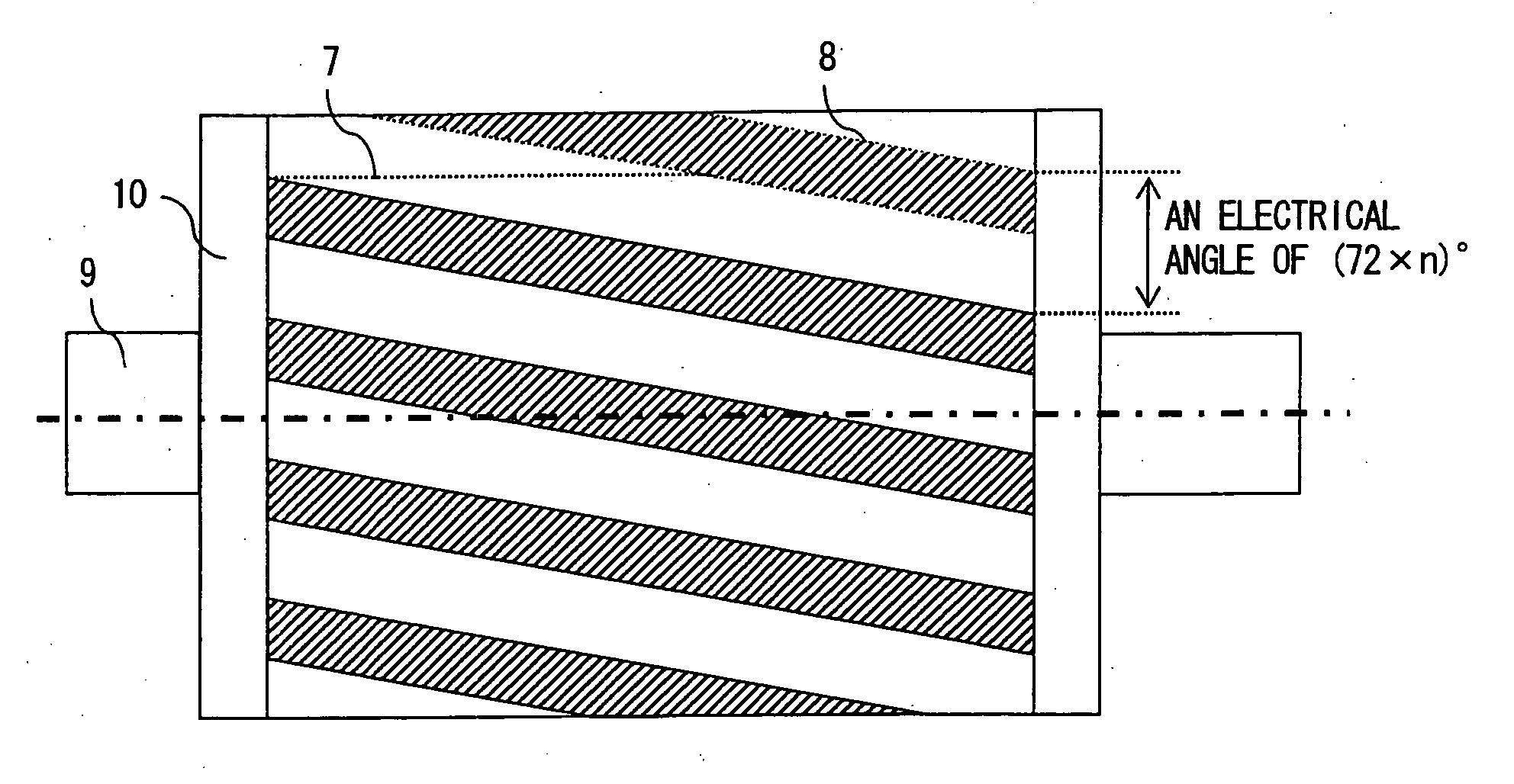

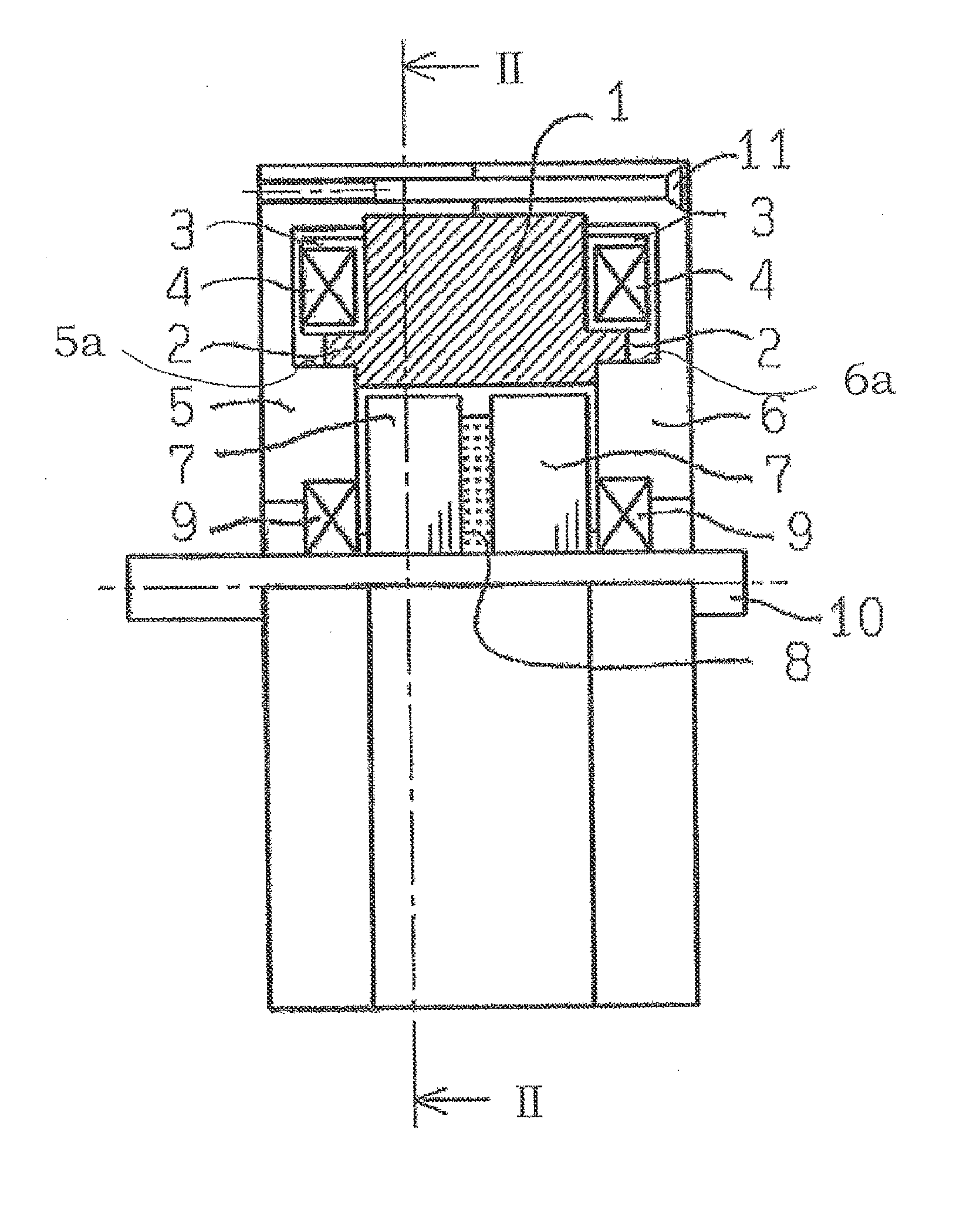

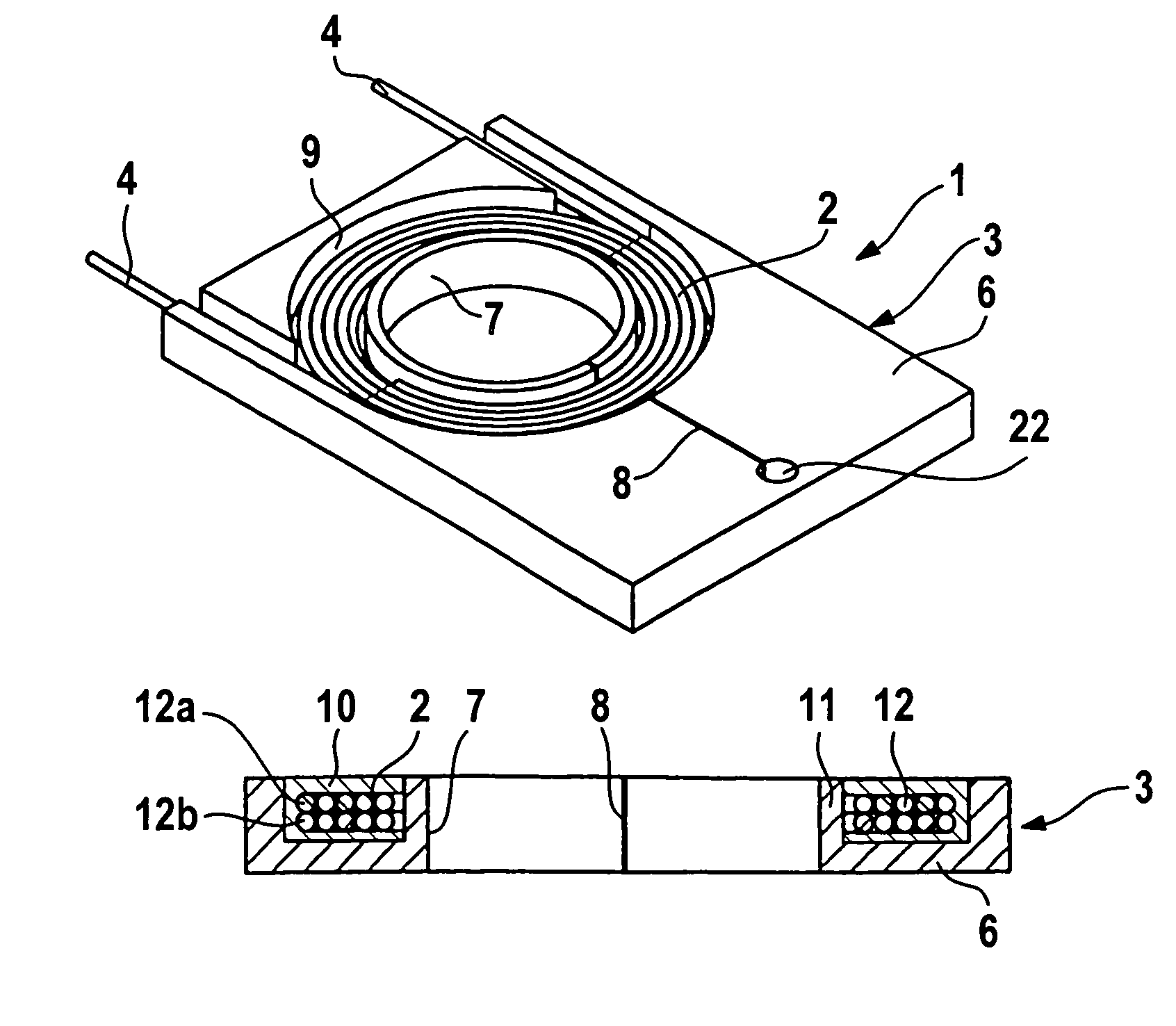

Transformer for producing high electrical currents

ActiveUS7012497B2Speed up the transfer processImprove conductivityMagnetic bodiesTransformers/inductances coils/windings/connectionsElectrically conductiveMagnet

A transformer (1) serves to produce high electrical currents, in particular, for transforming high alternating and power pulse currents for producing magnetic fields in magnetic technology for magnetizing magnets and magnetic systems, as well as in conversion technology for forming electrically conductive materials by means of a magnetic field. The transformer has at least one primary coil (2) and at least one secondary part (3), which are connected with bus bars (4, 5). The secondary part (3) of the transformer (1) includes at least one electrically conductive plate (6), in which at least one cut-out penetrating the plate (6) is disposed. At least one slit (8) originating from the cut-out (7) is provided, which separates the plate (6) on one side of each cut-out (7) into two parts and produces the required bus bar (5).

Owner:MAGNET PHYSIK DR STEINGROEVER

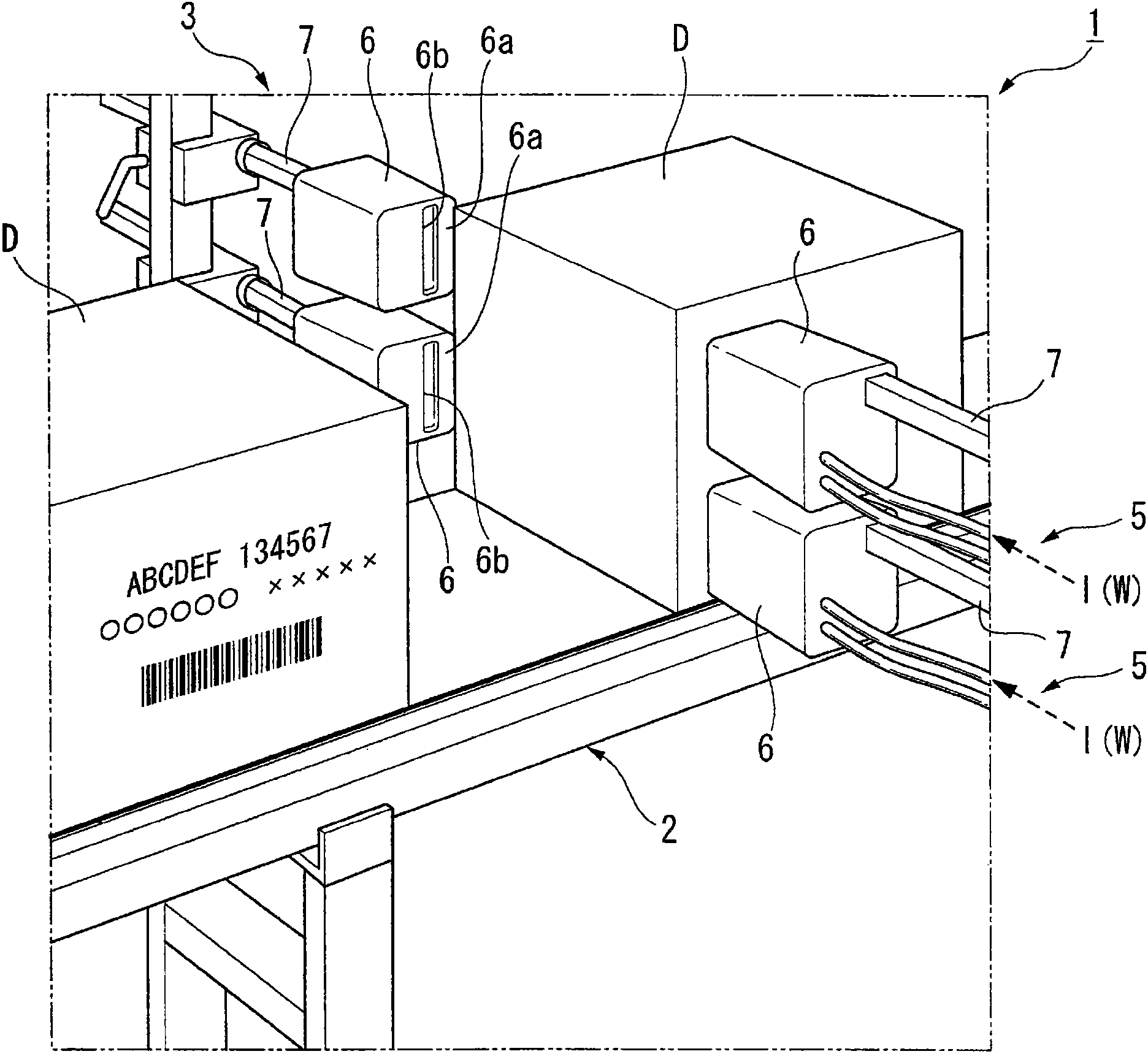

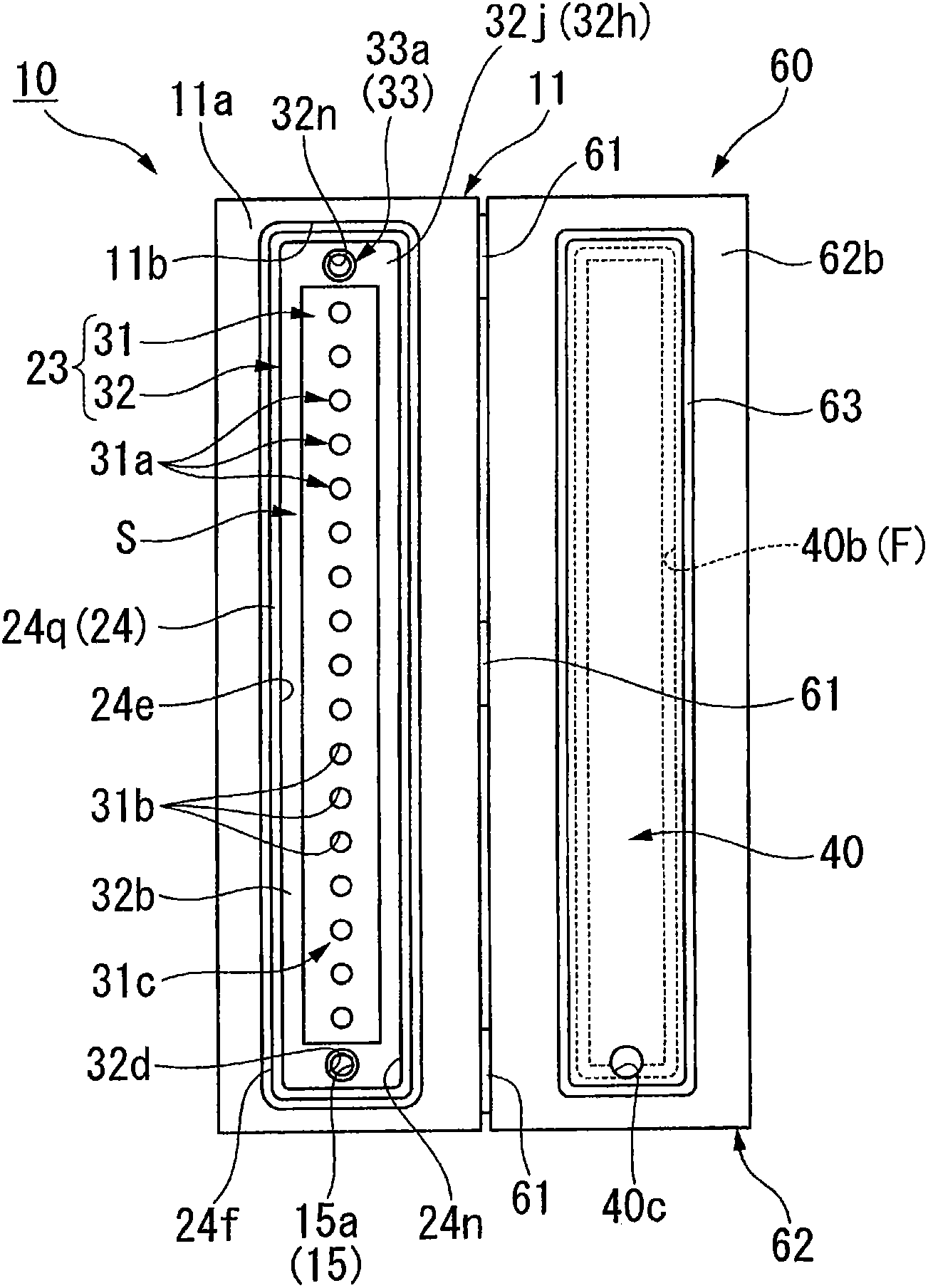

Liquid jetting head, liquid jetting recording apparatus, and method for filling liquid jetting head with liquid

The space factor of a liquid jetting head is improved, and the degree of freedom in designing a liquid jetting recording apparatus is improved. Performance of recovering a surplus liquid is improved with a simple configuration, contamination due to the surplus liquid is eliminated, the liquid jetting recording apparatus is initially filled, and liquid jetting after the liquid filling is stabilized. The liquid jetting head is provided with: a wall section (24), which surrounds the periphery of a jetting port row and protrudes in the same direction as the opening direction of a jetting port; an opening / closing mechanism (60), which has a cover member (62) that can open / close an opening section (24n) formed by the wall section (24), configures a closed space between the wall section (24) and the jetting body (23) in the closed state, and exposes the jetting port to the outside in the opened state; an absorber (40), which is provided on a rear surface (62b) of the cover member (62) and absorbs the liquid spilled out from the jetting port; a suction channel (15), which has a suction port (15a) opened to the closed space and is connected to an external suction apparatus (8); and a section (33) opened to atmosphere, which can perform switching between opening and blocking of the closed space to and from the outside.

Owner:SII PRINTEK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com