Patents

Literature

38results about How to "Flattening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

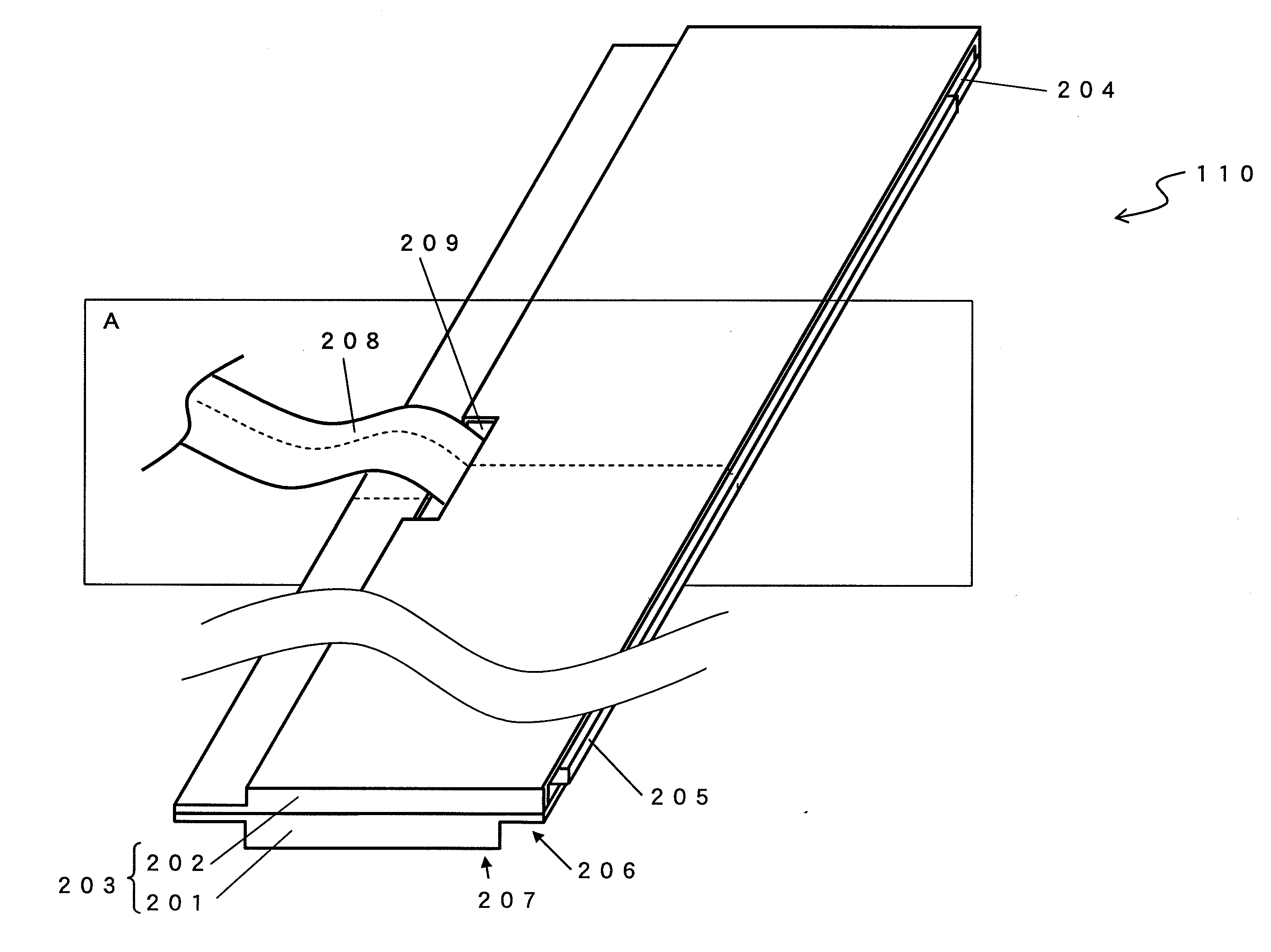

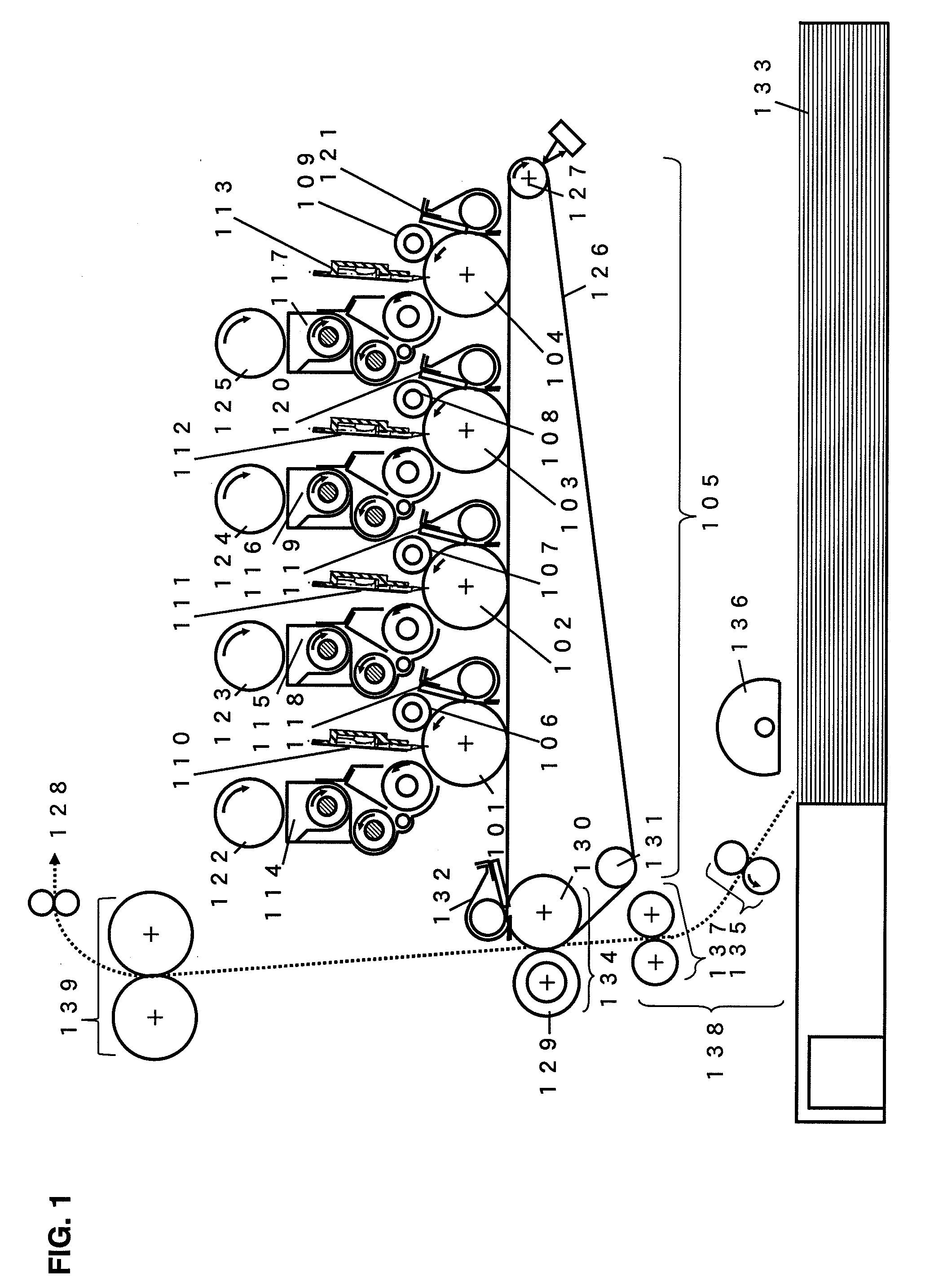

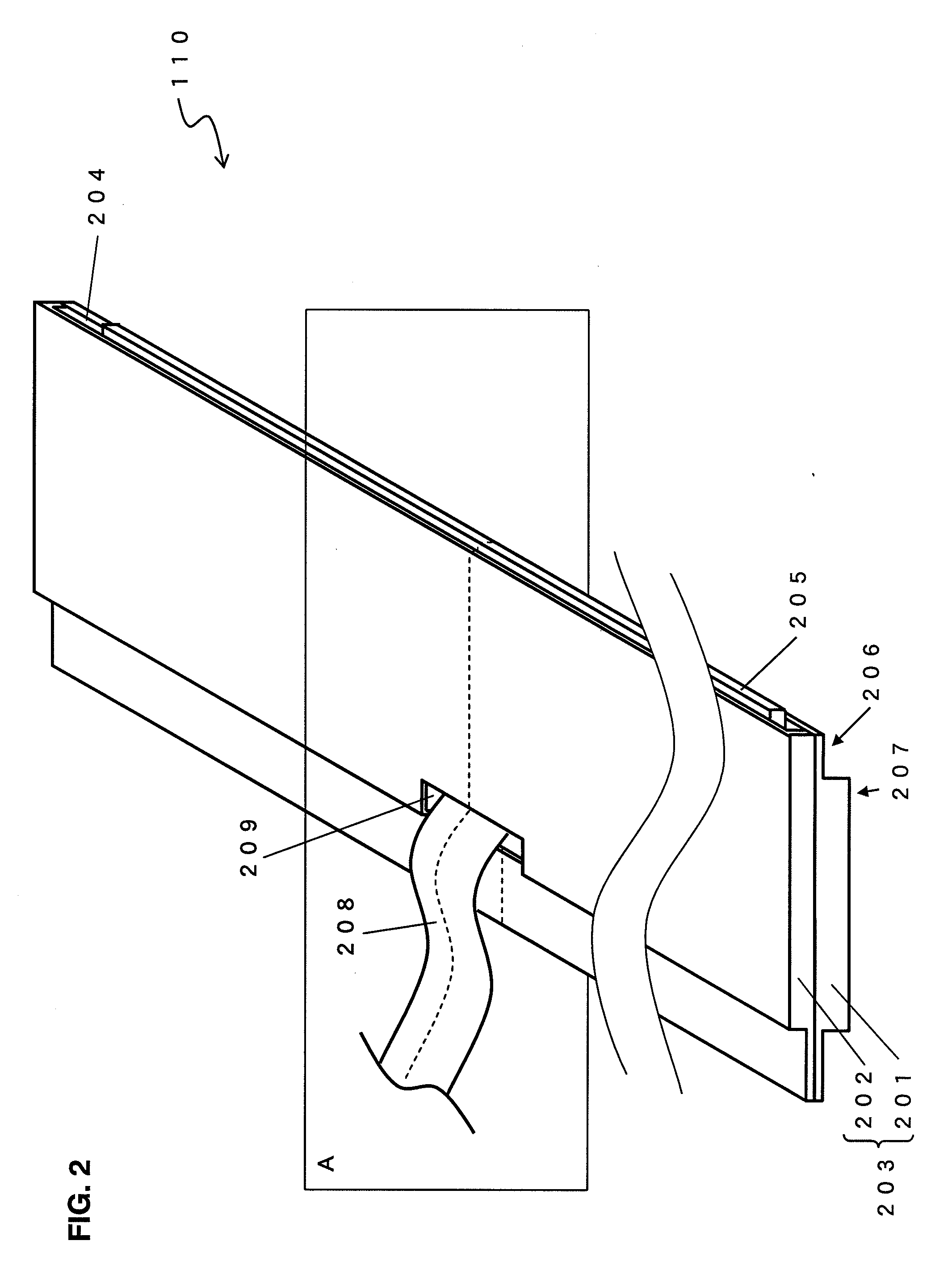

Image forming device

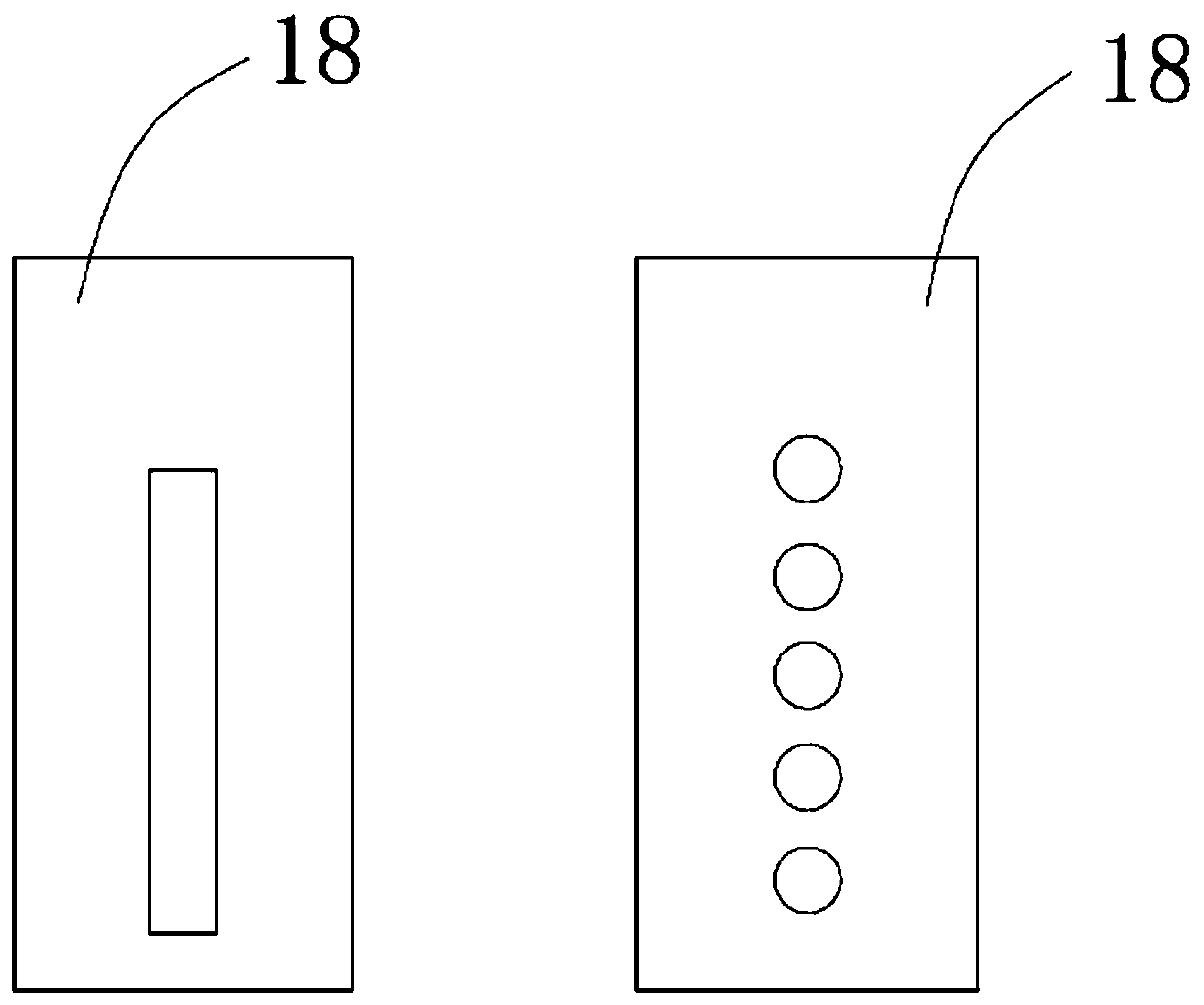

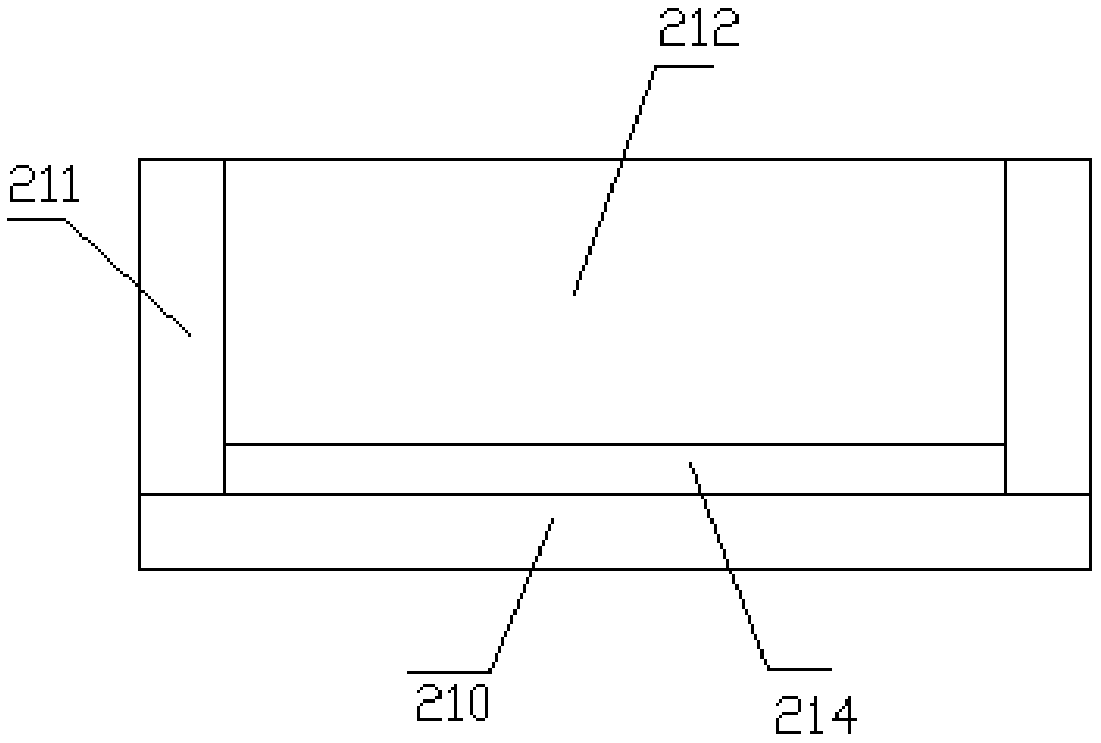

InactiveUS20090027896A1Small sizeFlatteningVehicle interior lightingProtective devices for lightingDistortionReduced size

A downsized and flattened exposure device is provided. A substrate (301) is supported only at either one side in the width direction (403) of the substrate surface that is orthogonal to the direction of the row and supported by only one enclosing member (201) at least in the section in the direction of the row of light emitting elements (401) where the light emitting elements (401) are arranged. With this structure, even if the substrate is supported at multiple points, the substrate is subject to almost no distortion due to multipoint support, allowing the substrate to have a reduced size in the width direction, further downsizing and flattening the exposure device.

Owner:PANASONIC CORP

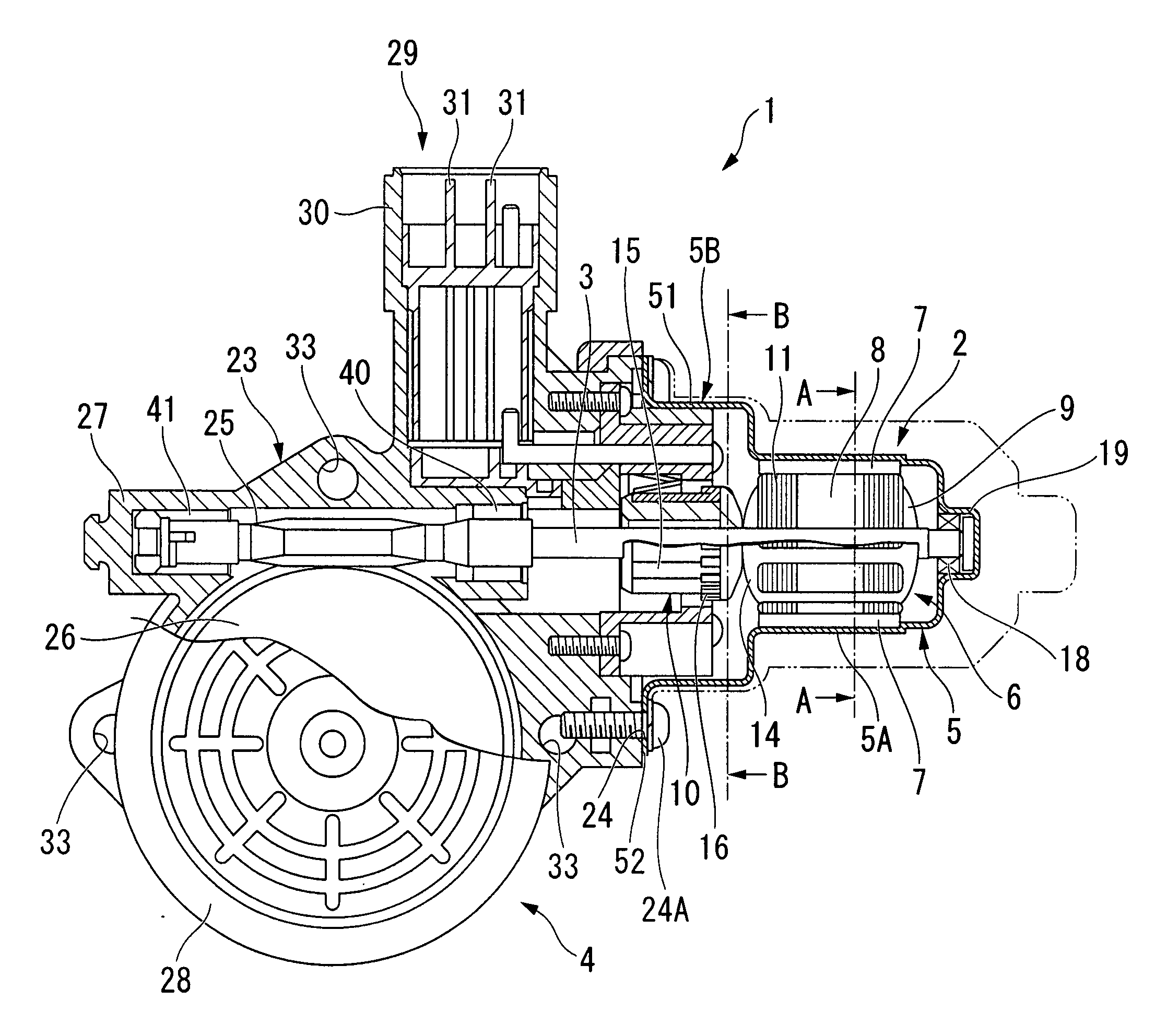

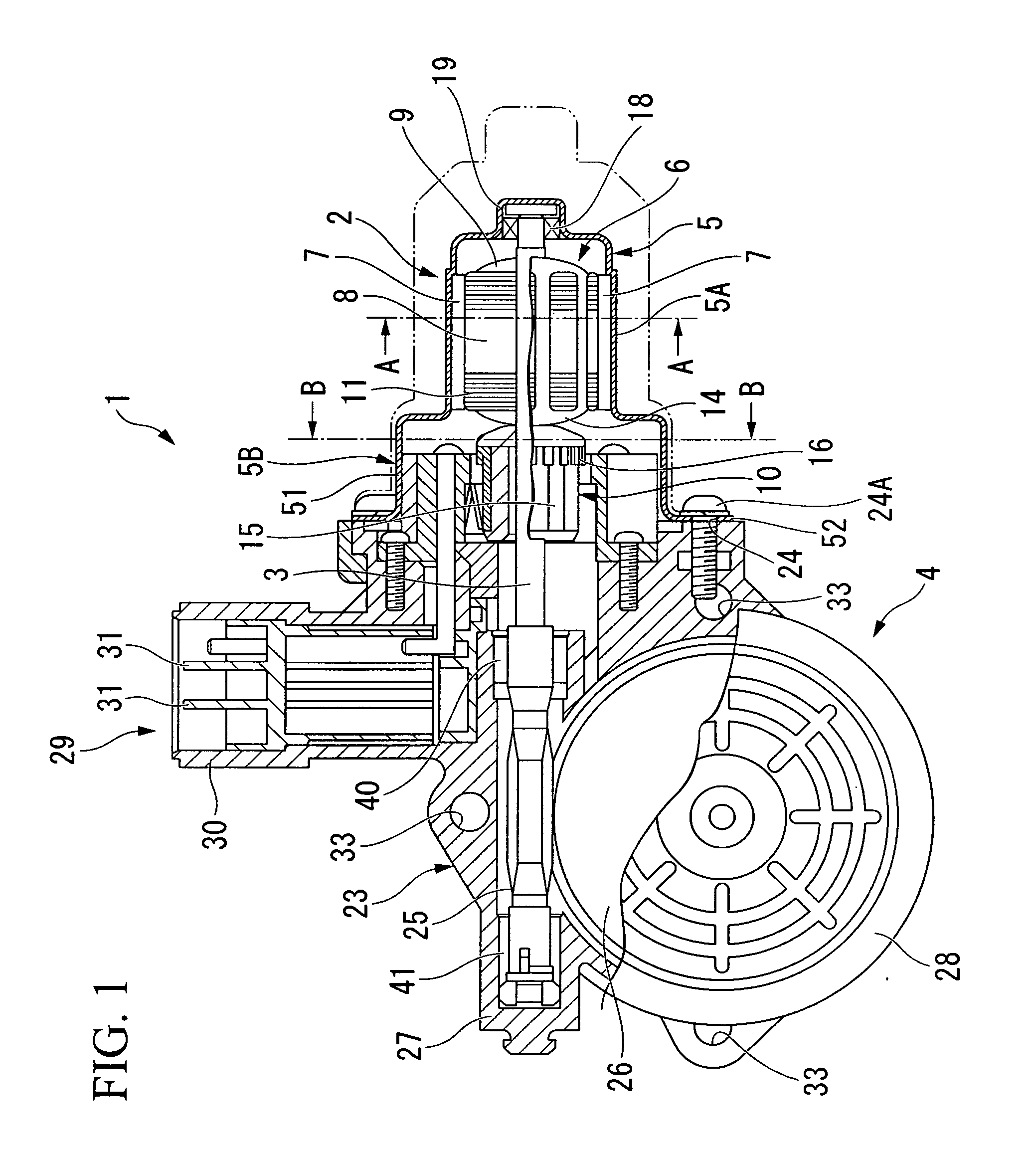

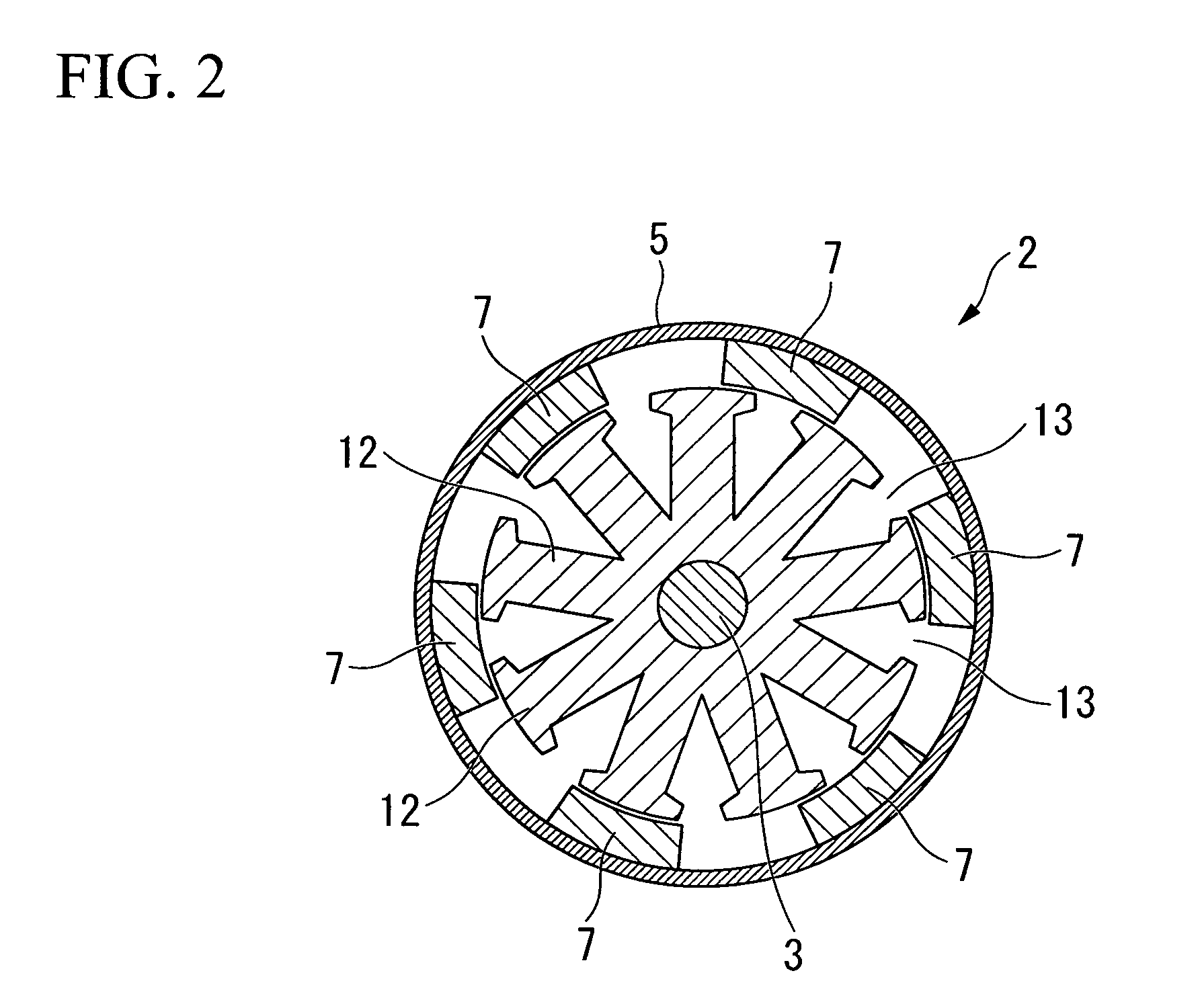

Direct current motor

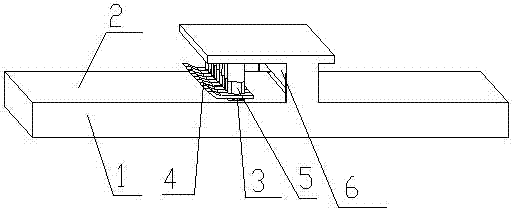

ActiveUS20100052440A1FlatteningIncrease in sizeWindingsMagnetic circuitElectrical polaritySliding contact

A direct current motor with brushes in which an armature is provided with a rotating shaft that is supported by a yoke housing, an armature core that is fitted and fixed to a rotating shaft from the outer side, and a commutator that is provided on the rotating shaft adjacent to the armature core with nine segments arranged in the circumferential direction. The armature core has nine teeth that extend in the radial direction in a radial pattern and nine slots that are formed between the teeth and extend in the axial direction, the segments having the same polarity are connected with short-circuiting members, and a pair of brushes that make sliding contact with the segments is disposed so as to be mutually point symmetric centered on the rotating shaft. According to the preset invention, it is possible to effectively achieve flattening of the direct current motor.

Owner:MITSUBA CORP

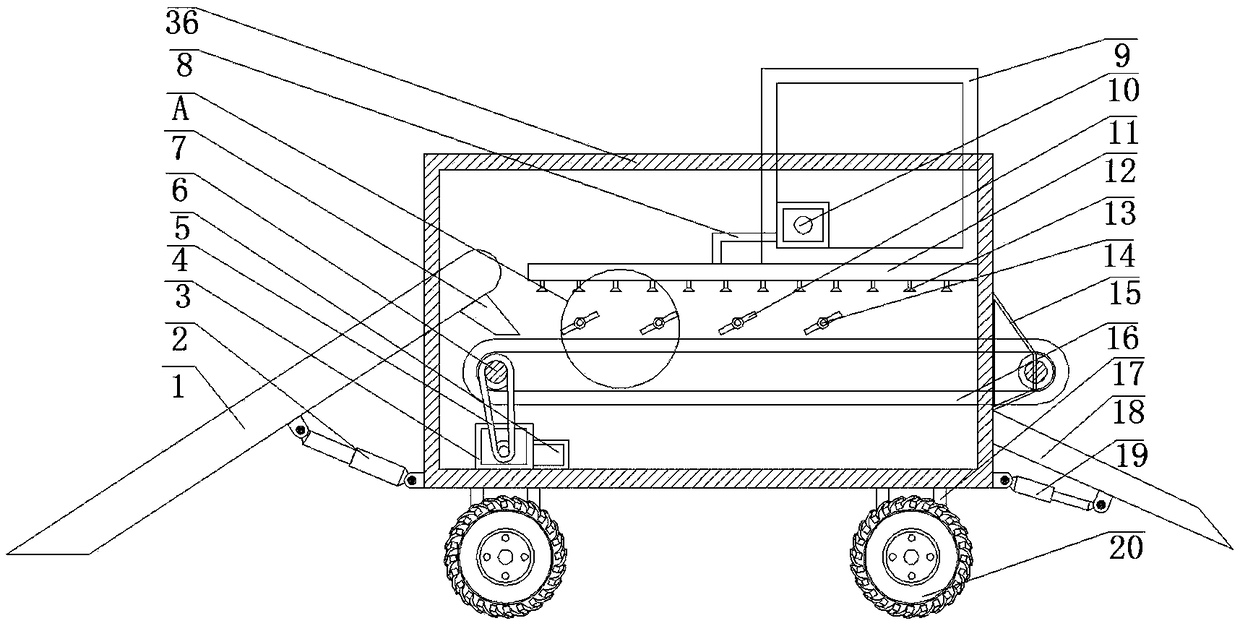

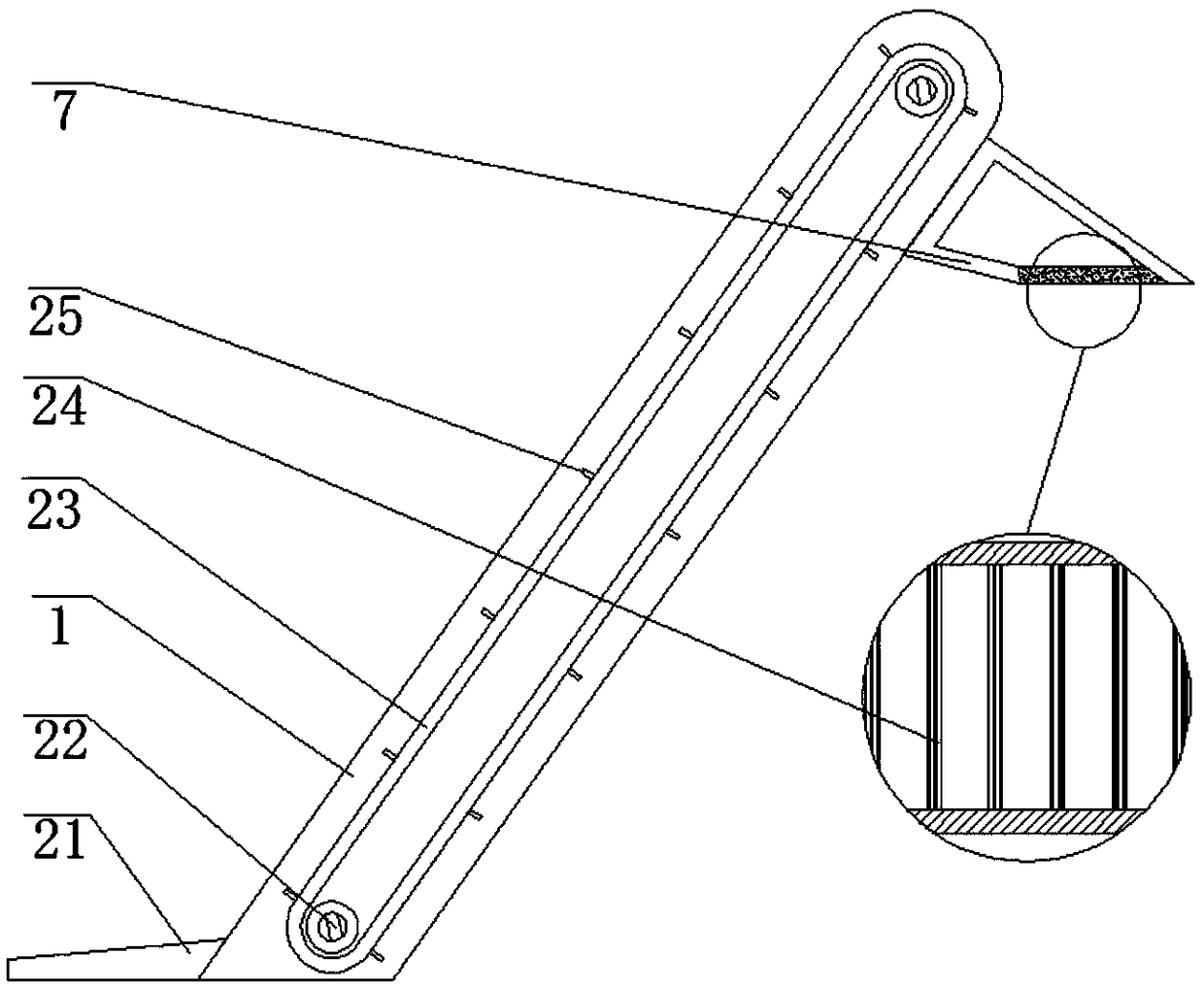

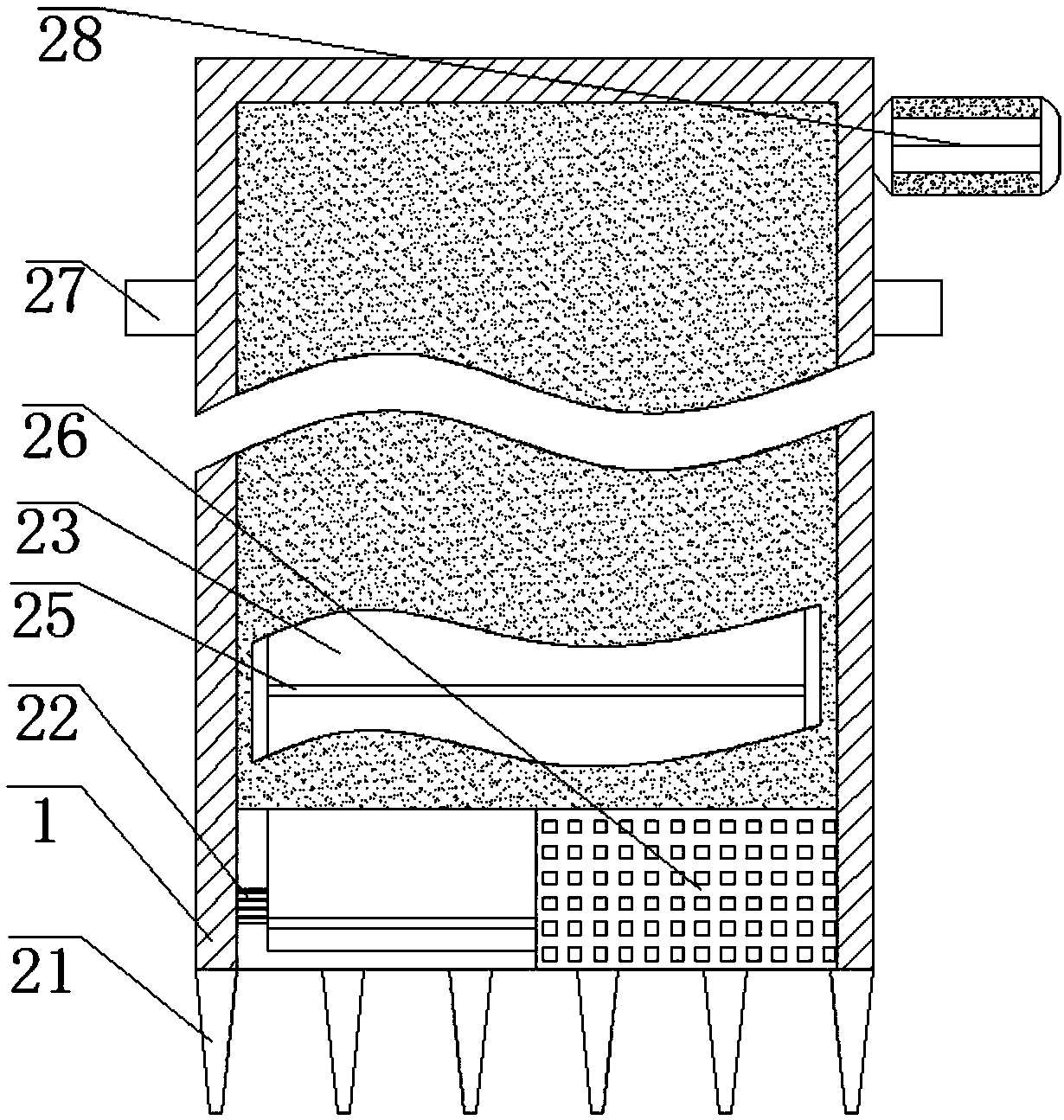

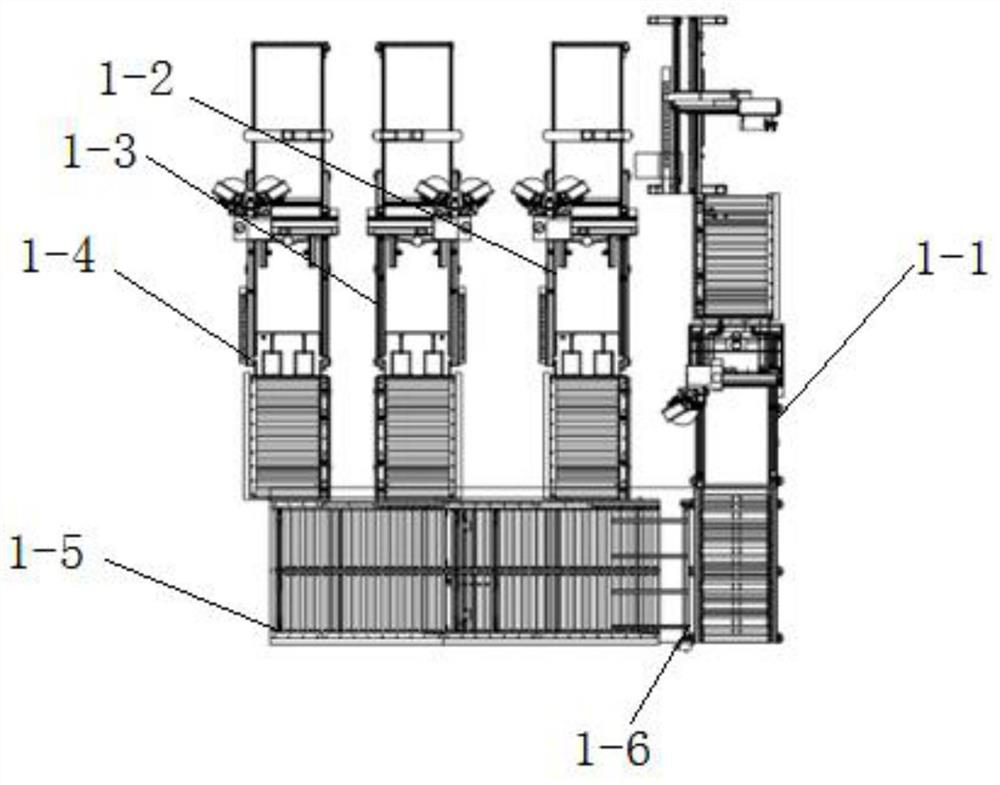

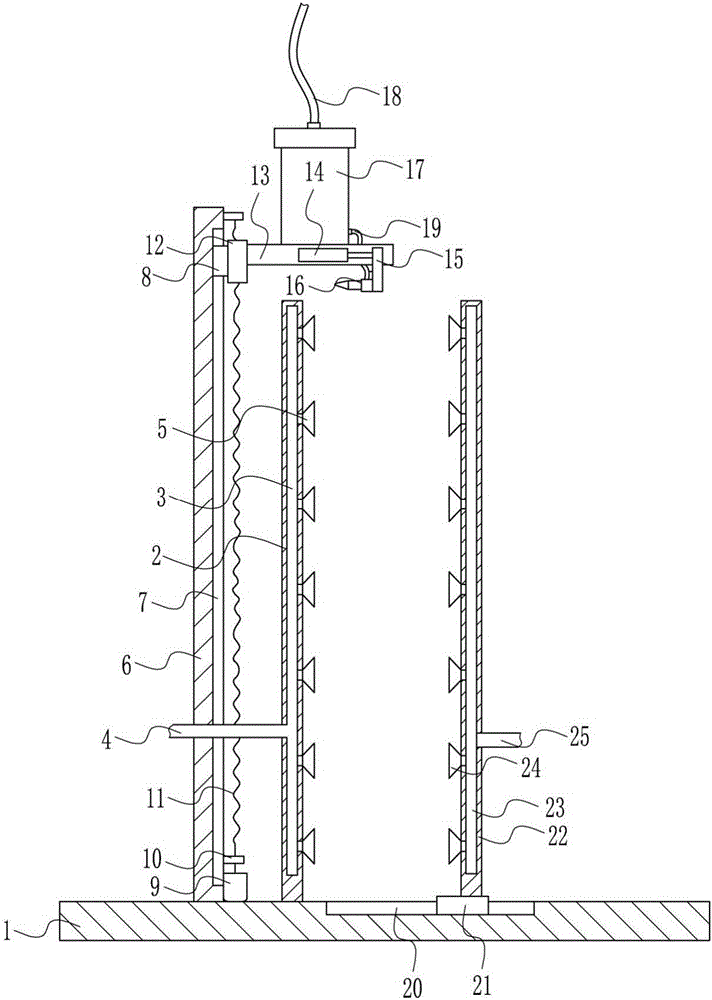

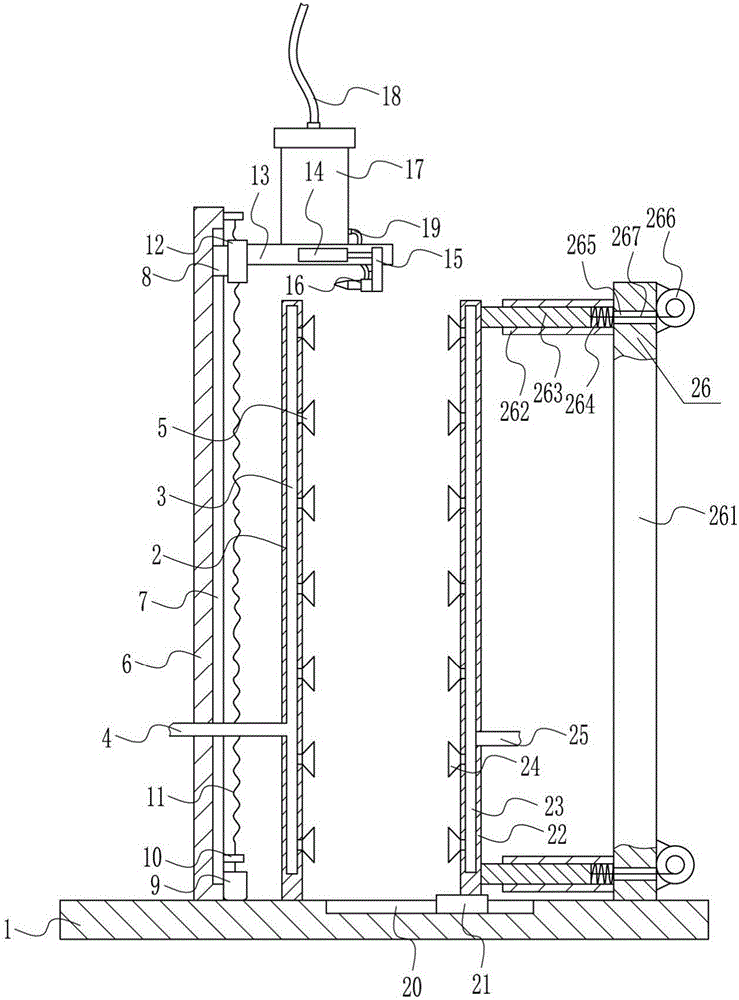

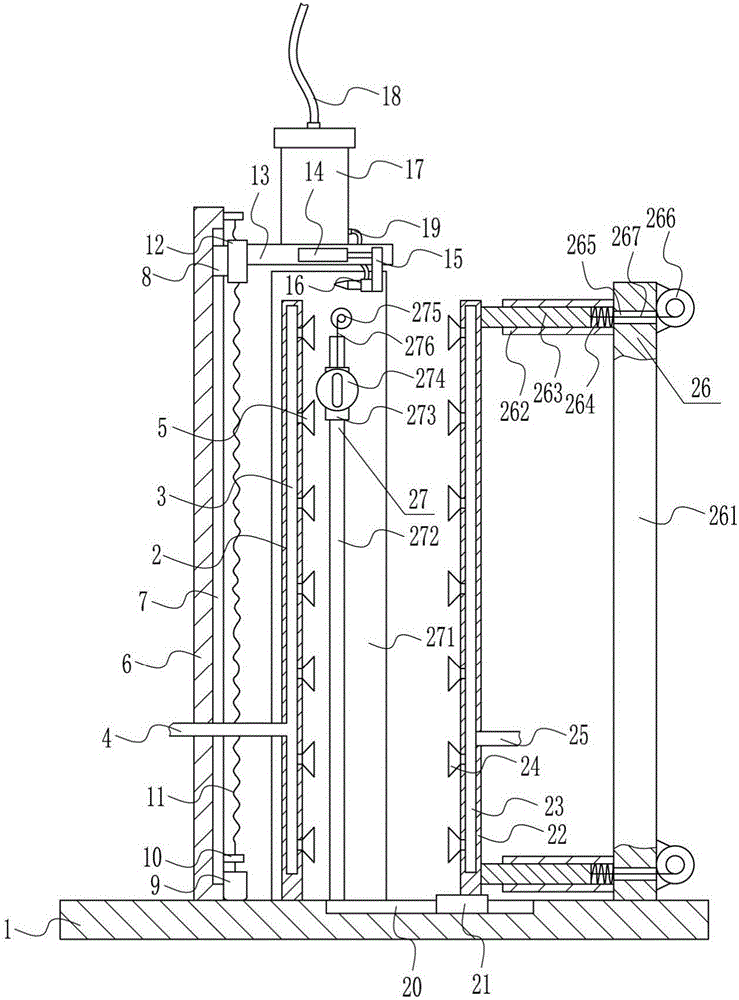

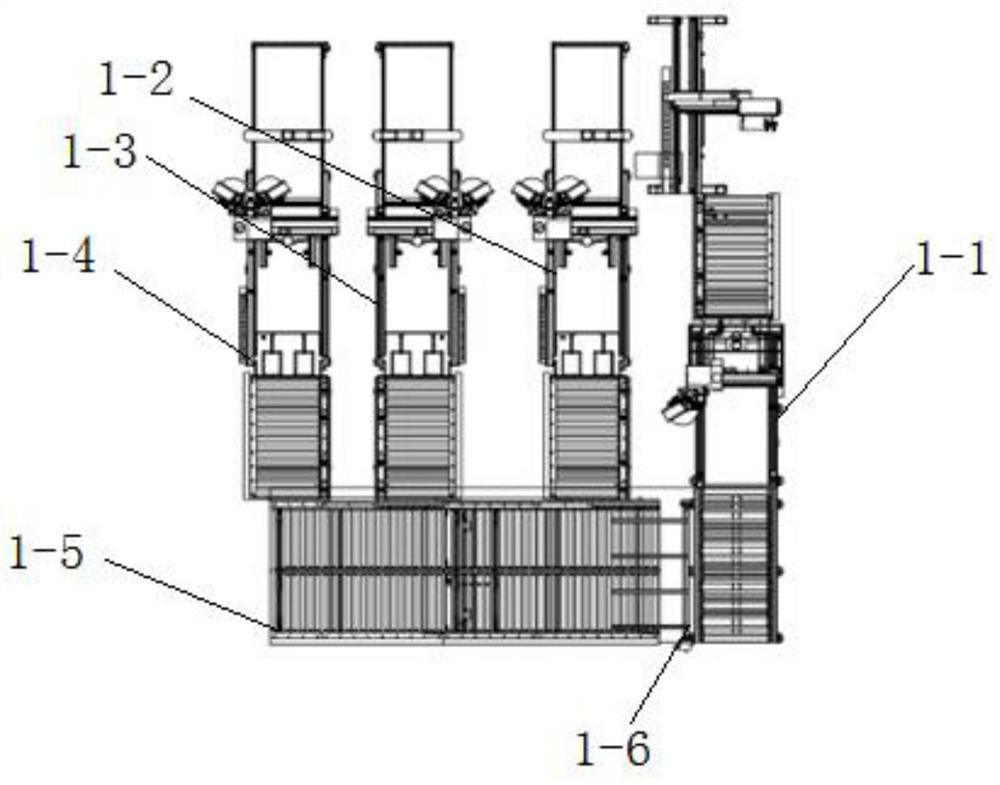

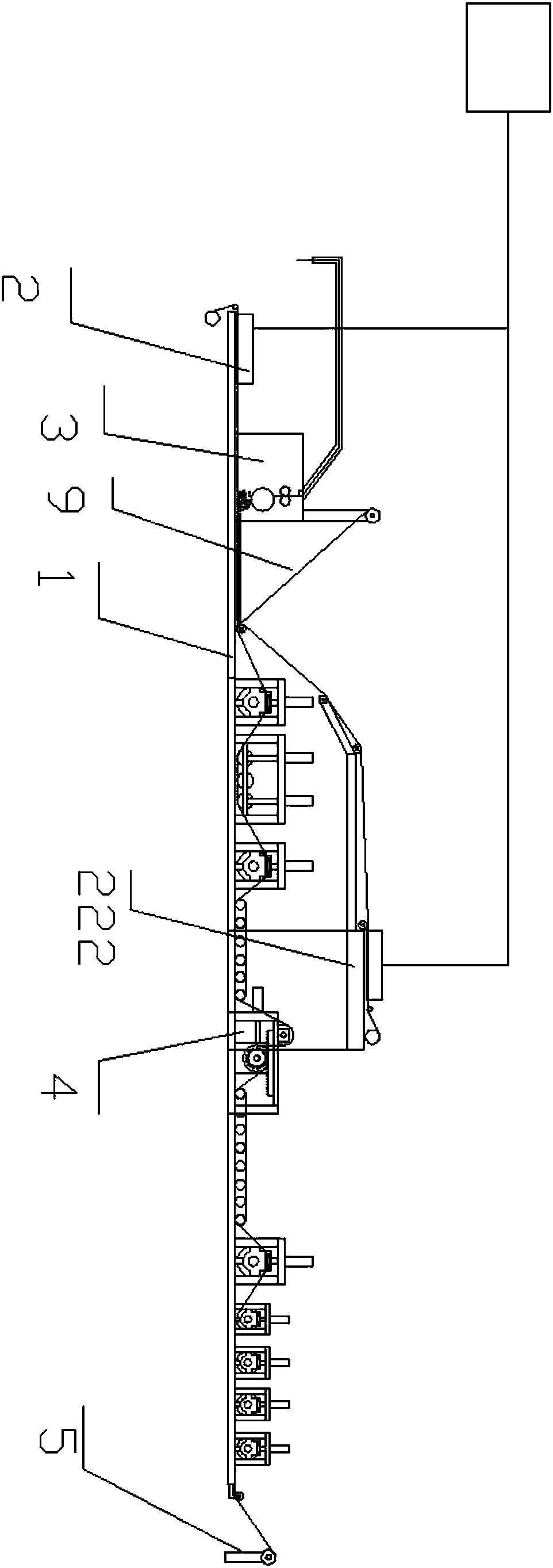

Extraction device for remediation of heavy metal contaminated soil

PendingCN109500077AEfficient removalPrevent interference with internal operationsSoil lifting machinesSpadesEngineeringConveyor belt

The invention belongs to the technical field of buildings, in particular to an extraction device for remediation of heavy metal contaminated soil. The problems that the extraction device for remediation of the heavy metal contaminated soil is single in structure and holes are liable to block are solved, and according to the following scheme, the extraction device comprises a carriage; the two endsof the bottom of the carriage are connected with two wheel brackets by bolts, and the inner walls of the both sides of the four wheel brackets are sleeved with two wheel rotating shafts through bearings; the two ends of the peripheral walls of the two wheel rotating shafts are connected with wheels by bolts. In the extraction device, by using a turnover plate, the peripheral wall of a feeding conveyor belt is provided with a turnover rubber block; when the turnover rubber block runs to the bottom of the turnover plate, soil can be turned over with the turnover plate due to the blockage effectof the turnover rubber lock, so that the back side of the soil is sprayed subsequently; and the heavy metal contaminated soil can be sprayed with chelating agents overall effectively.

Owner:张锐

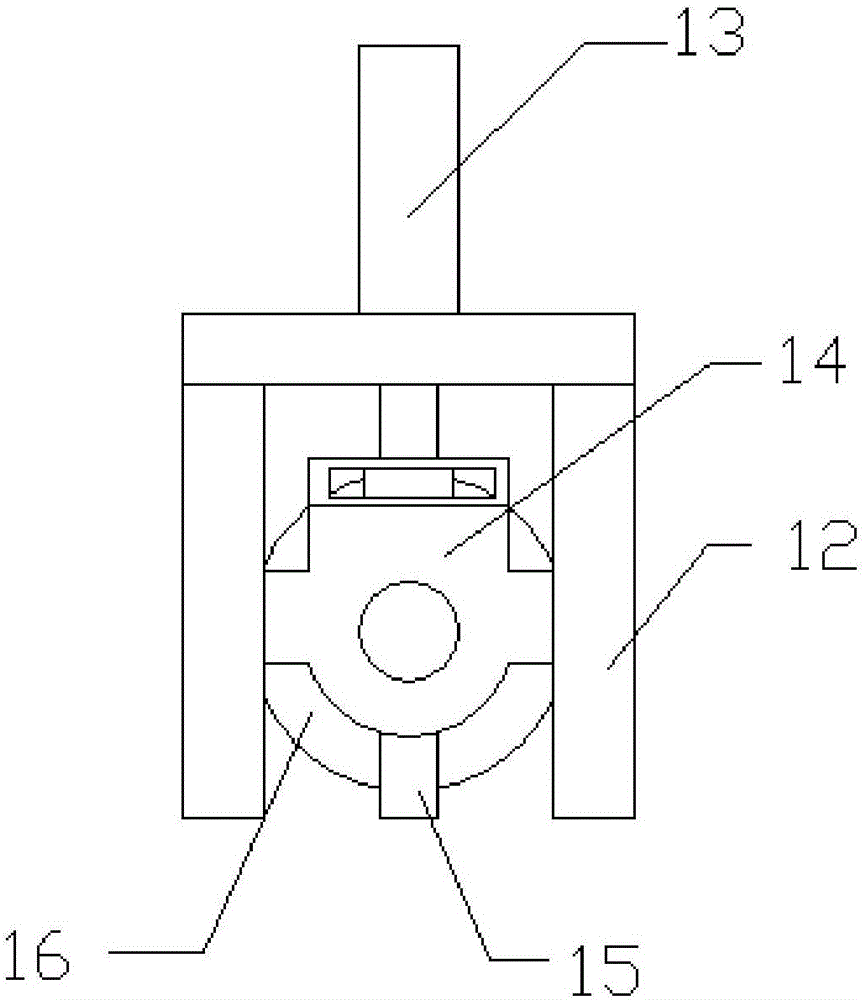

Heat sealing machine

InactiveCN103085334ANo deformationFlatteningBox making operationsPaper-makingEngineeringPlastic film

The invention discloses a heat sealing machine which comprises a frame, a base and a worktable. The worktable is arranged on the base, a cylinder is mounted on the lower portion of the worktable, a vertical cylinder is mounted on the frame, a space is reserved between the vertical cylinder and the base, a heating plate is arranged in the space, a flattening plate is covered on the lower portion of the heating plate, and the upper end of the heating plate is connected with the vertical cylinder through a sliding guide post. The heat sealing machine has the advantages that the flattening plate is covered on the lower portion of the heating plate and is pressed flat, the heating plate is electrically connected with a temperature adjusting button, the temperature needed by pressing is adjusted according to different plastic films, tightness of a seal is ensured, and a plastic film bag cannot deform and is fine in quality.

Owner:环球新材料(南通)股份有限公司

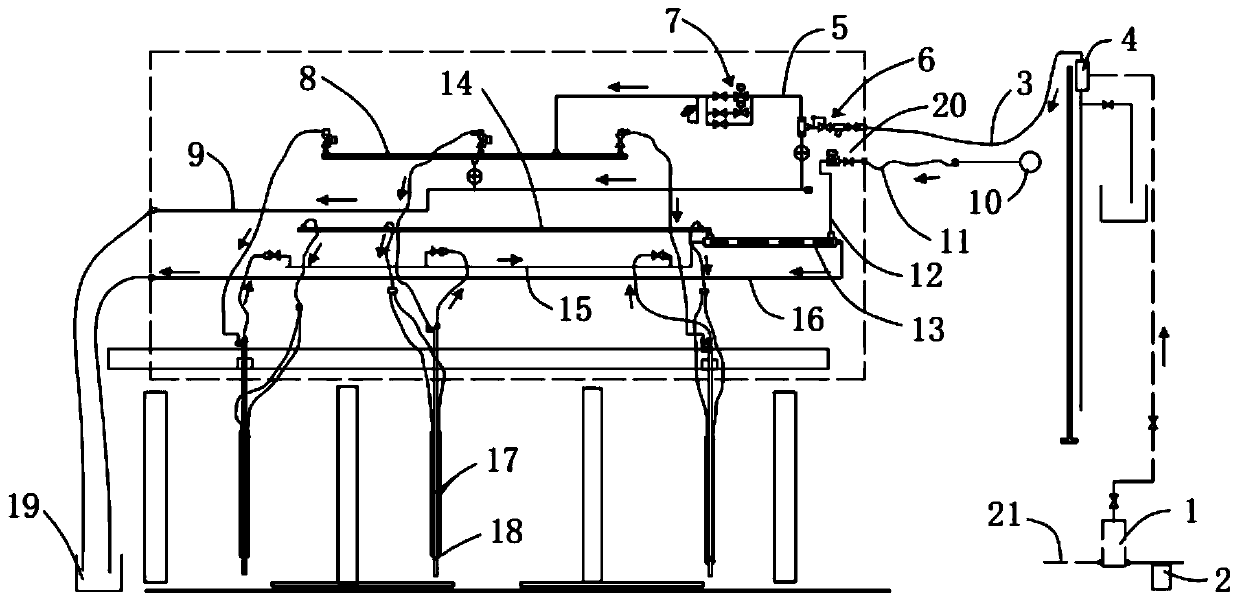

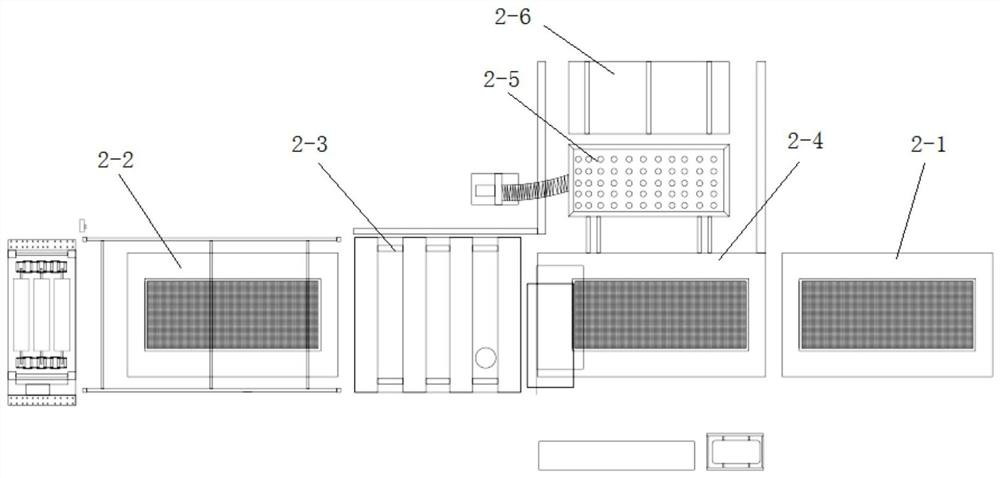

Carton cracking-proof line spraying system

InactiveCN110774658AFlatteningQuality improvementPaper-makingBox making operationsCondensed waterProcess engineering

The invention discloses a carton cracking-proof line spraying system. The carton cracking-proof line spraying system comprises a steam manufacturing device, a main pipeline for conveying steam, a flowopening and closing valve for opening and closing steam, a main control mechanism for controlling the steam flow pressure and an injection assembly for spraying steam; the carton cracking-proof linespraying system structurally comprises a steam manufacturing device and a conveying pipeline for conveying steam, a steam nozzle is mounted on the conveying pipeline, the steam is sprayed through thesteam nozzle and runs through a slot pressing line position on a corrugated paper, so that the original paper fiber at a folding position is softened, and the situation of cracking and breaking is avoided during folding. The pressing line is flat, a forming line is a straight line, the condition that a scissor opening is formed when the box is sealed is avoided, the generation of condensed water when the condensed water is sprayed to the carton corrugated paper is avoided by controlling the steam temperature and pressure in the main pipe and the steam temperature and pressure in the steam nozzle, the quality of the finished product of the carton is improved, and the overall production cost is reduced.

Owner:重庆随和印刷机械有限公司

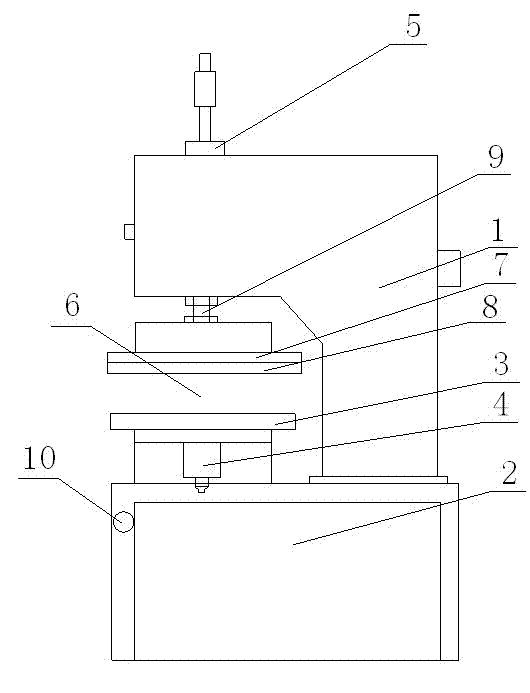

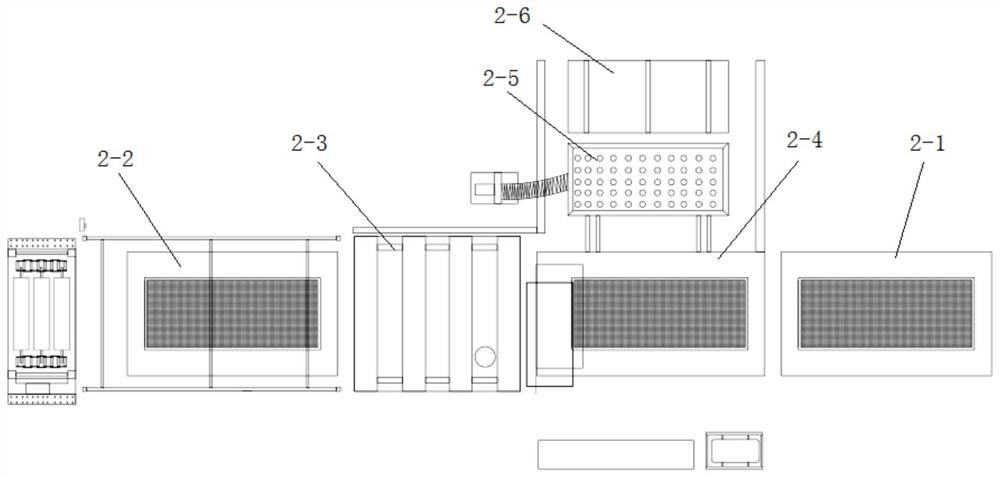

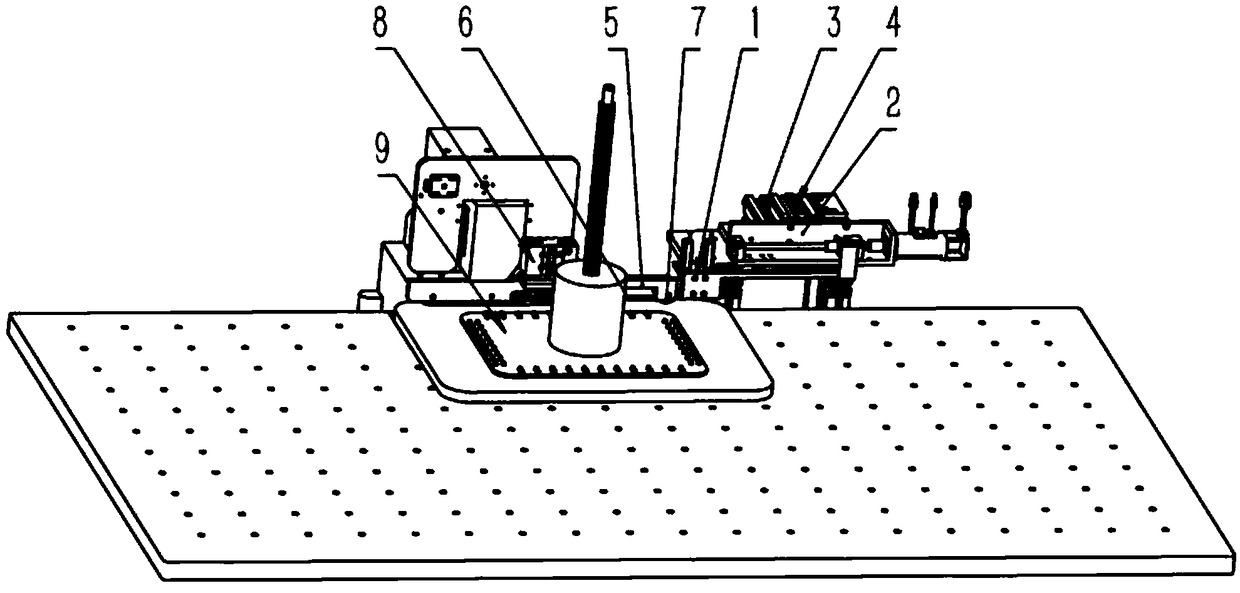

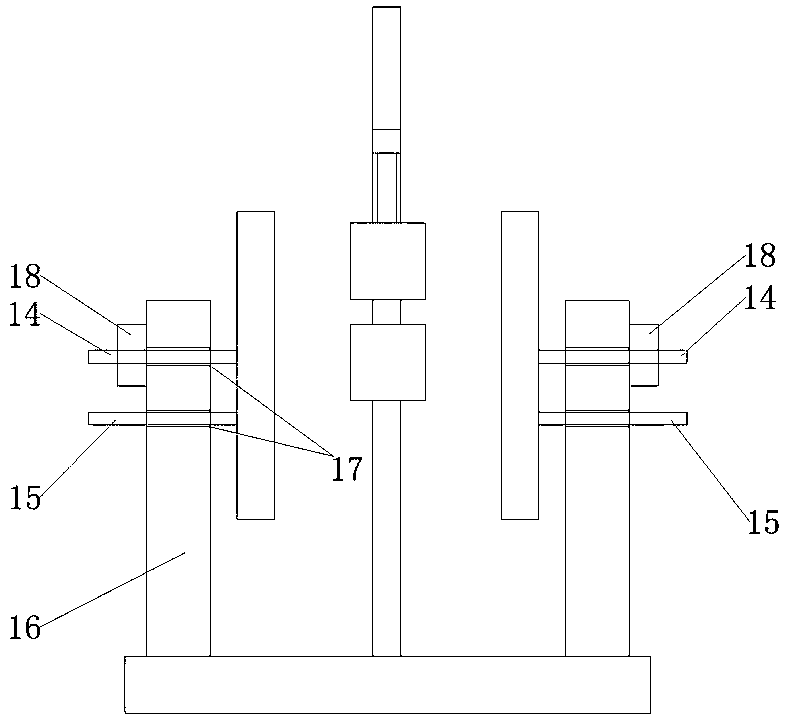

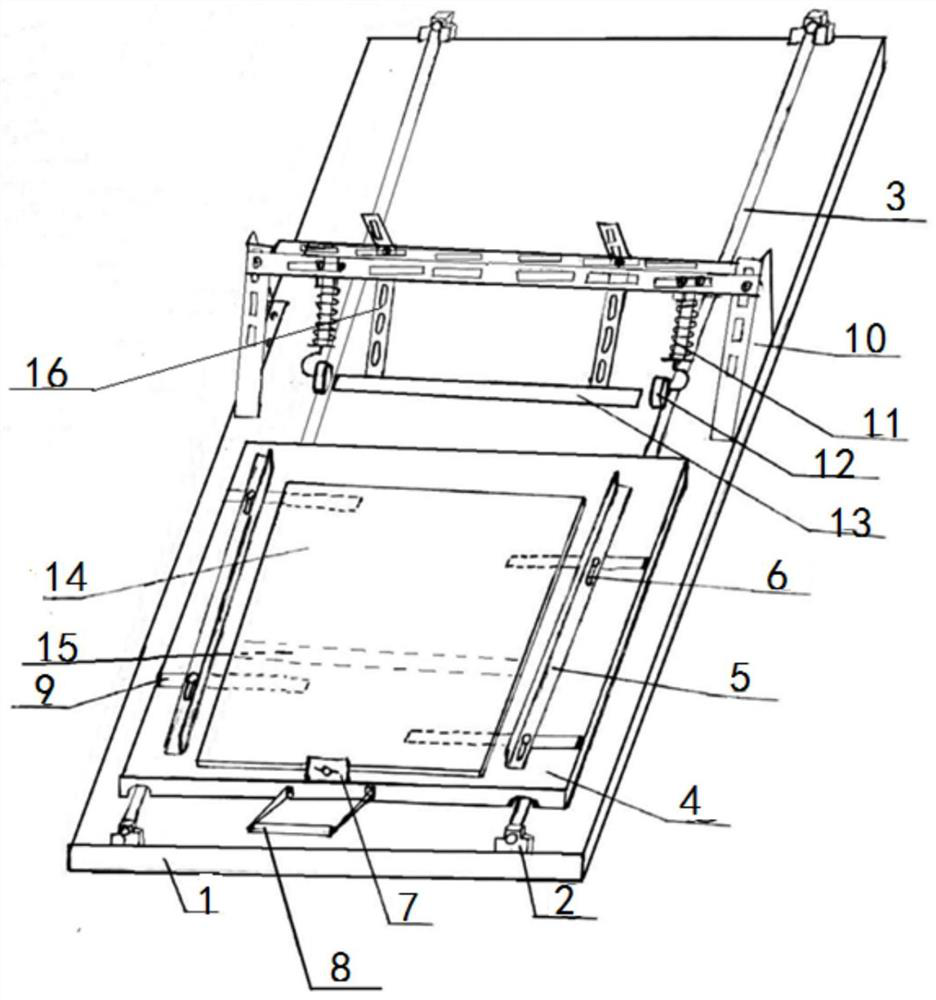

PCB soldering flake pulse hot press

PendingCN106852021ASimple structureEasy to operatePrinted circuit assemblingElectric heatingSoldering

The invention discloses a PCB soldering flake pulse hot pressing machine. The PCB soldering flake pulse hot pressing machine comprises one engine base, two vertical frames, one nose and one hot pressing head, wherein one operation platform is arranged on the engine base, and a circuit board tray used for placement of a PCB is arranged at the middle part above the operation platform; the lower ends of the two vertical frames are fixedly connected with the side part of the operation platform, and the nose is arranged at the upper ends of the two vertical frames; the hot pressing head is arranged at the lower end of the nose, and the lower end of the hot pressing head corresponds to the circuit board tray; one air cylinder is arranged in the nose, and a telescopic rod of the air cylinder is connected with the hot pressing head and used for driving the hot pressing head to press down in a pulsed way or go up to reset; and the hot pressing head is internally provided with one electric heating device used for heating the hot pressing head to a set working temperature. The PCB soldering flake pulse hot pressing machine disclosed by the invention has the advantages that a soldering flake or bonding pad can be laminated, leveled and tightened on the PCB, so that welding yield of an electronic component can be improved.

Owner:东莞市仪锐电子有限公司

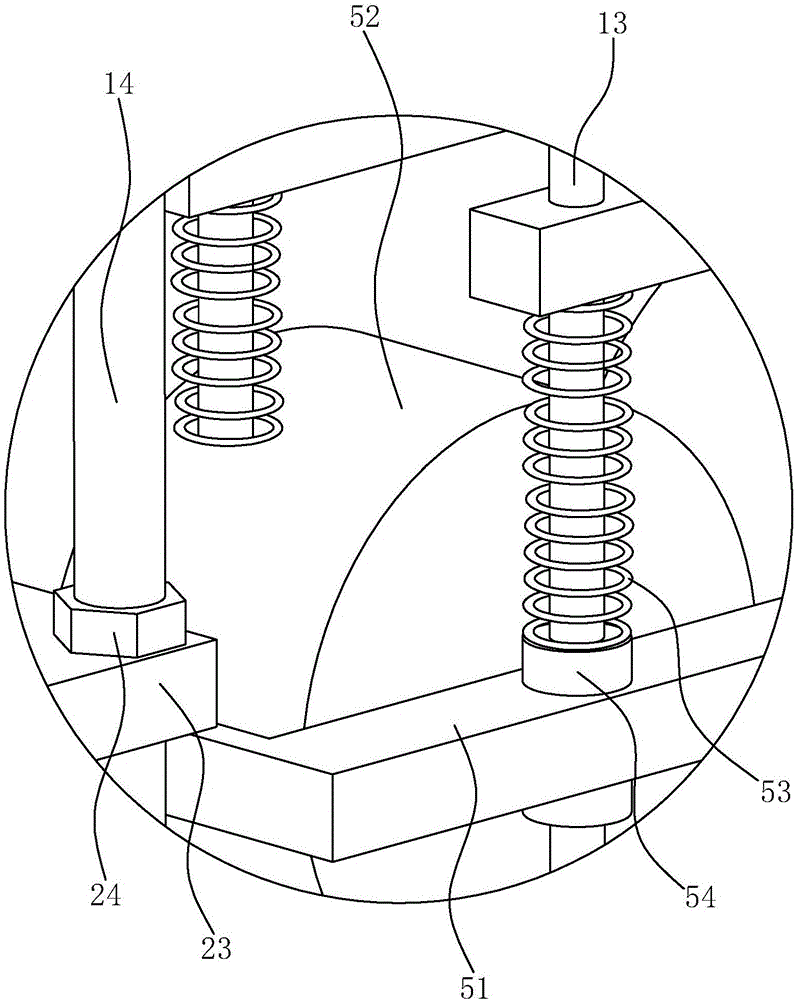

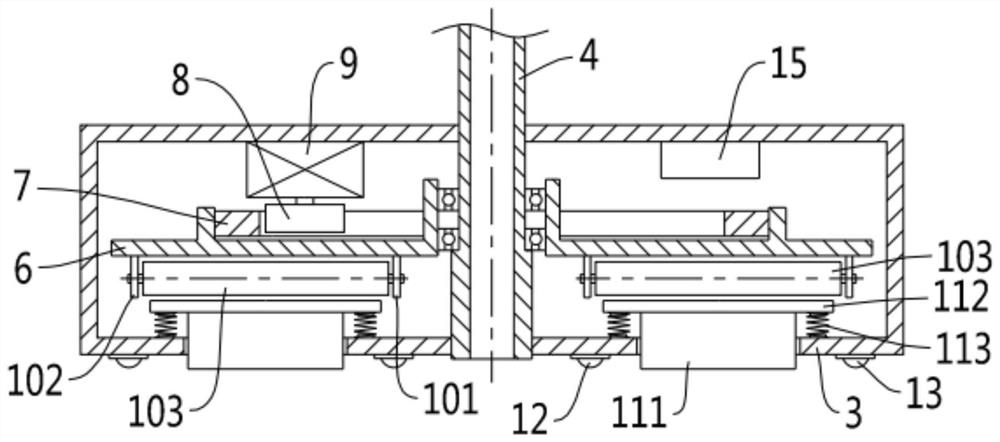

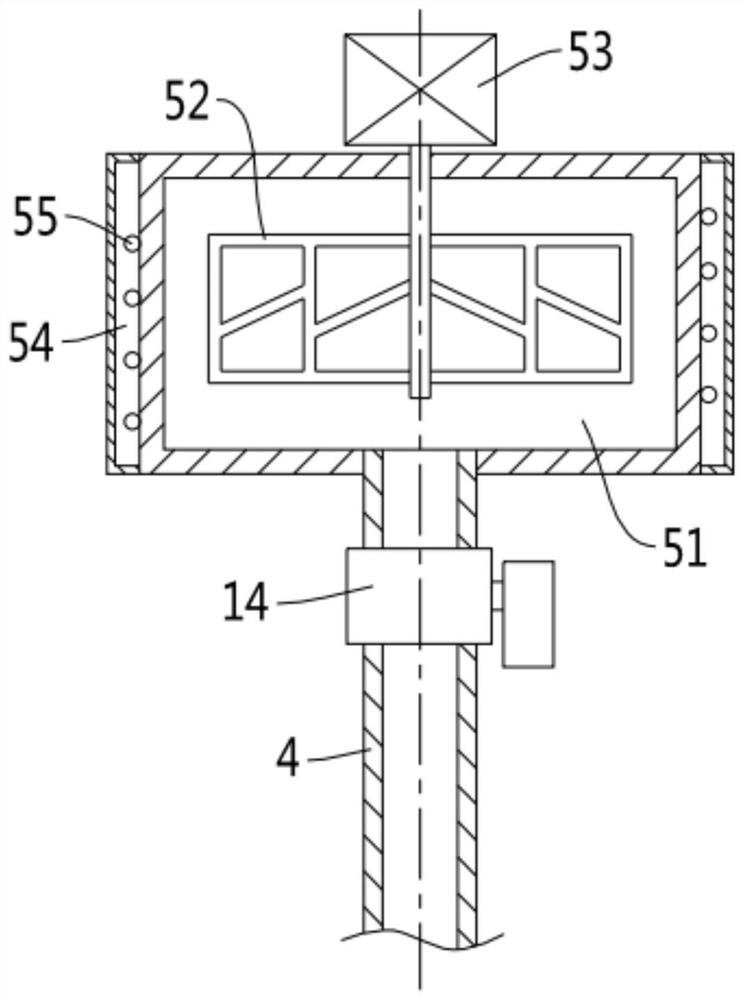

Press-fit auxiliary device used after gluing and used for electronic product production

Owner:泉州市欣百亚智能科技有限公司

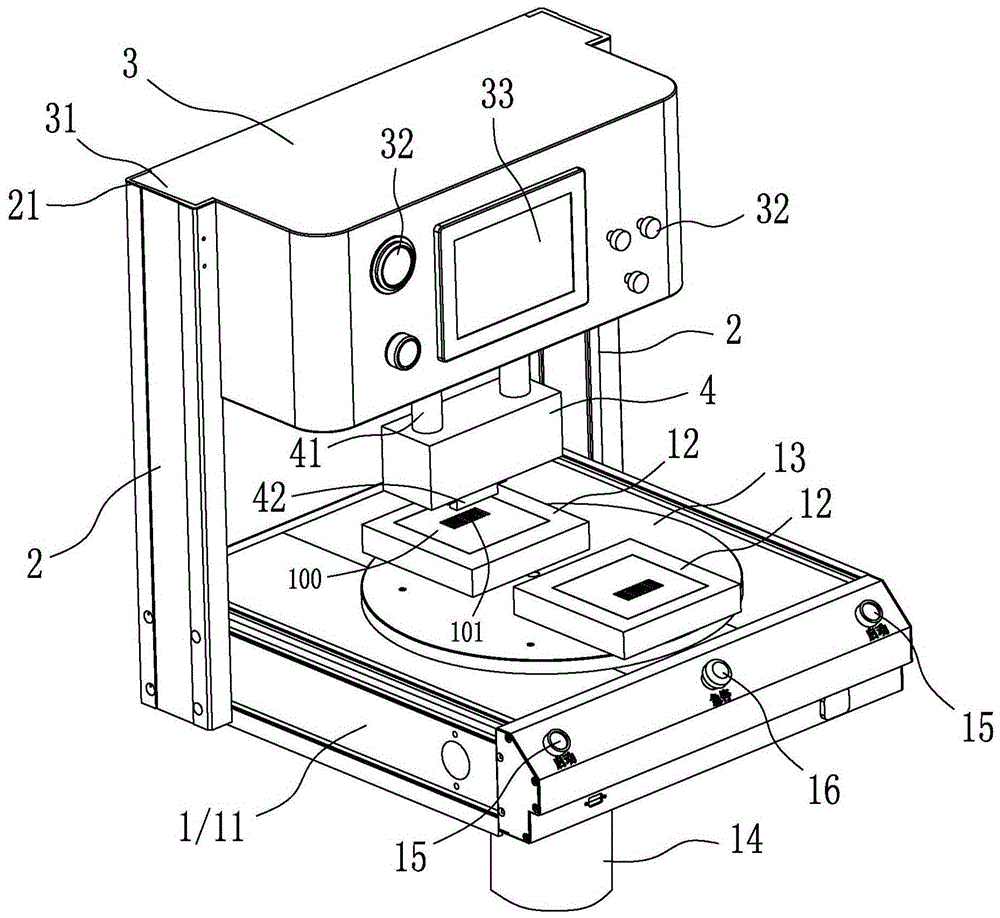

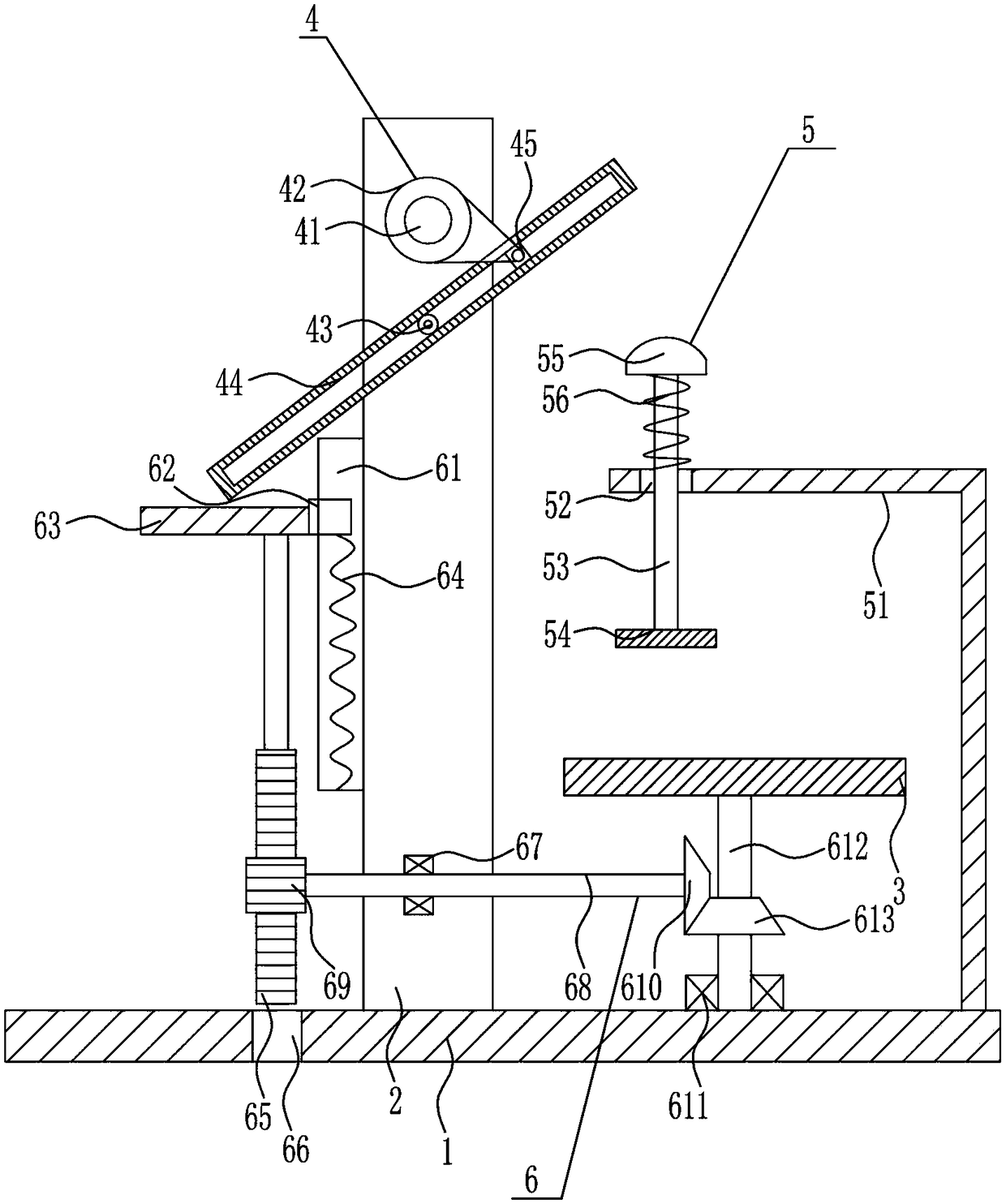

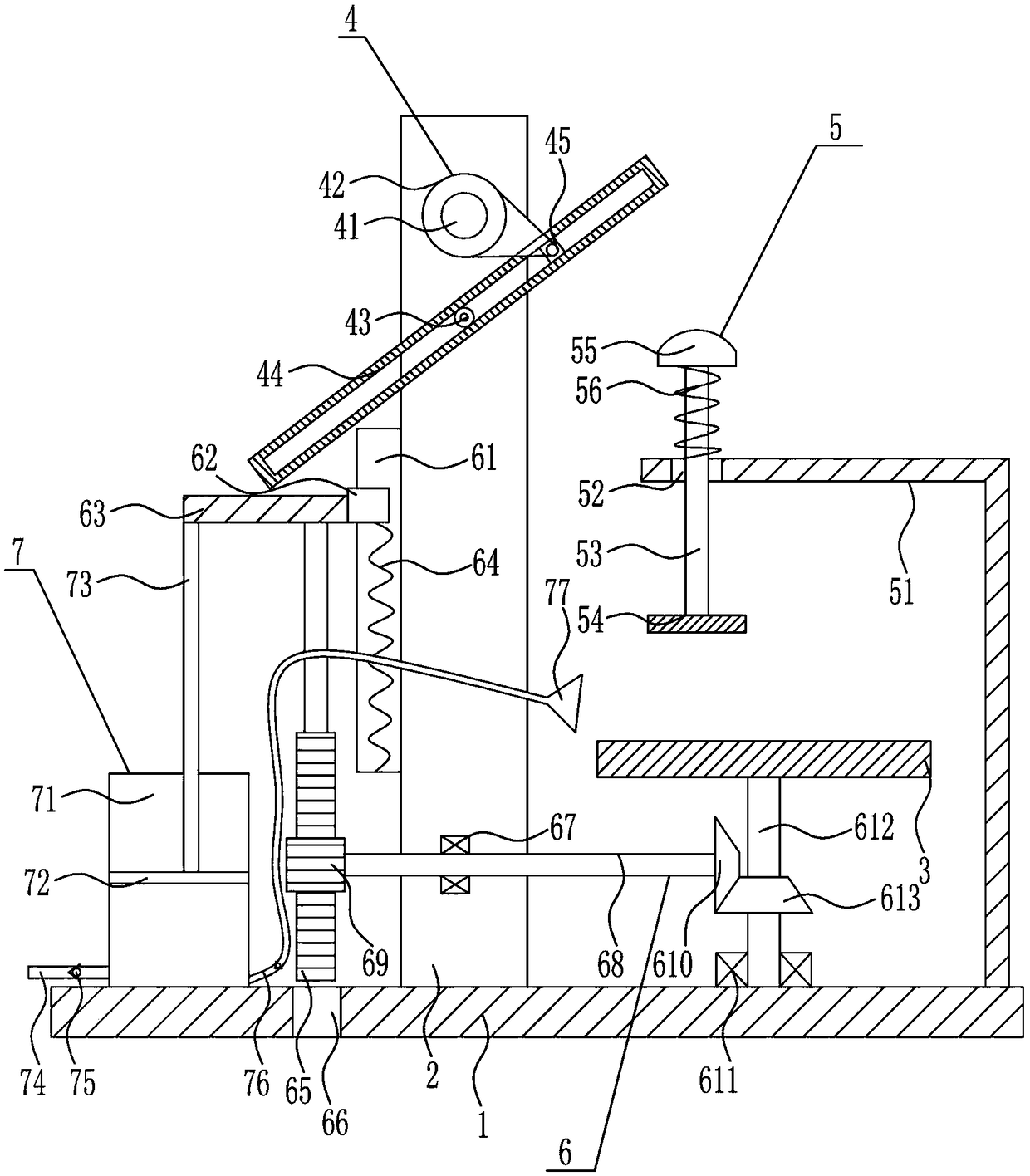

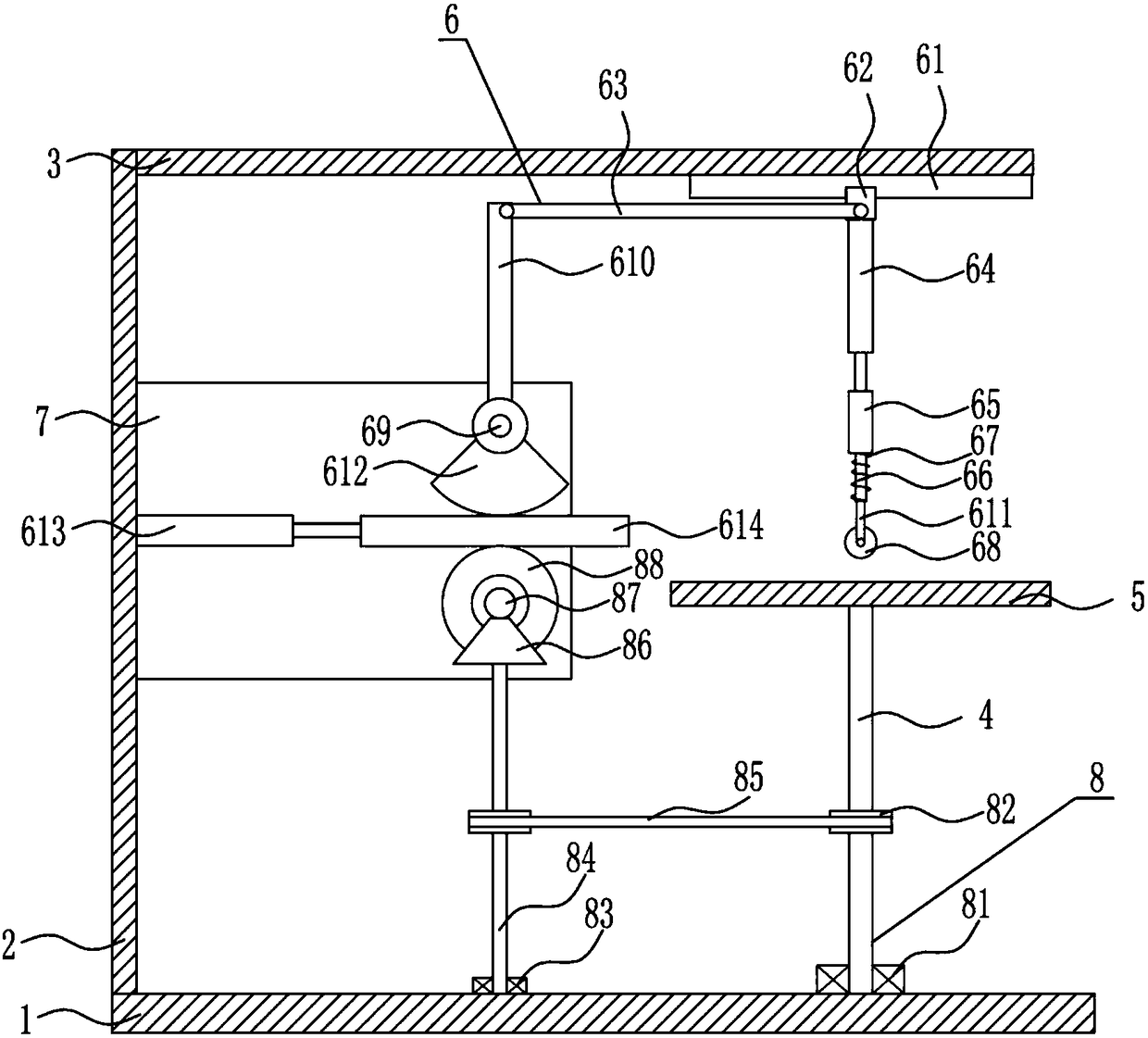

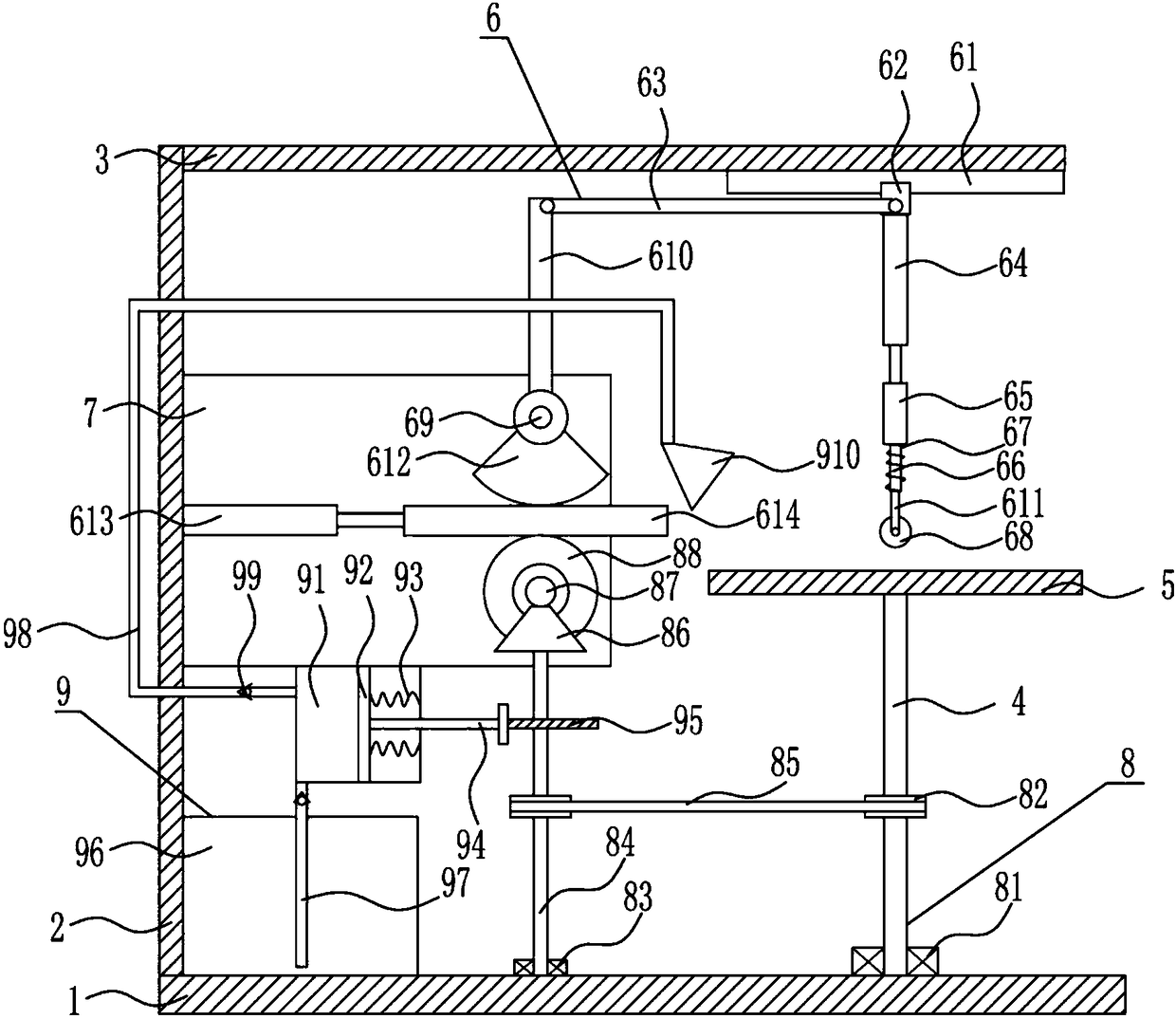

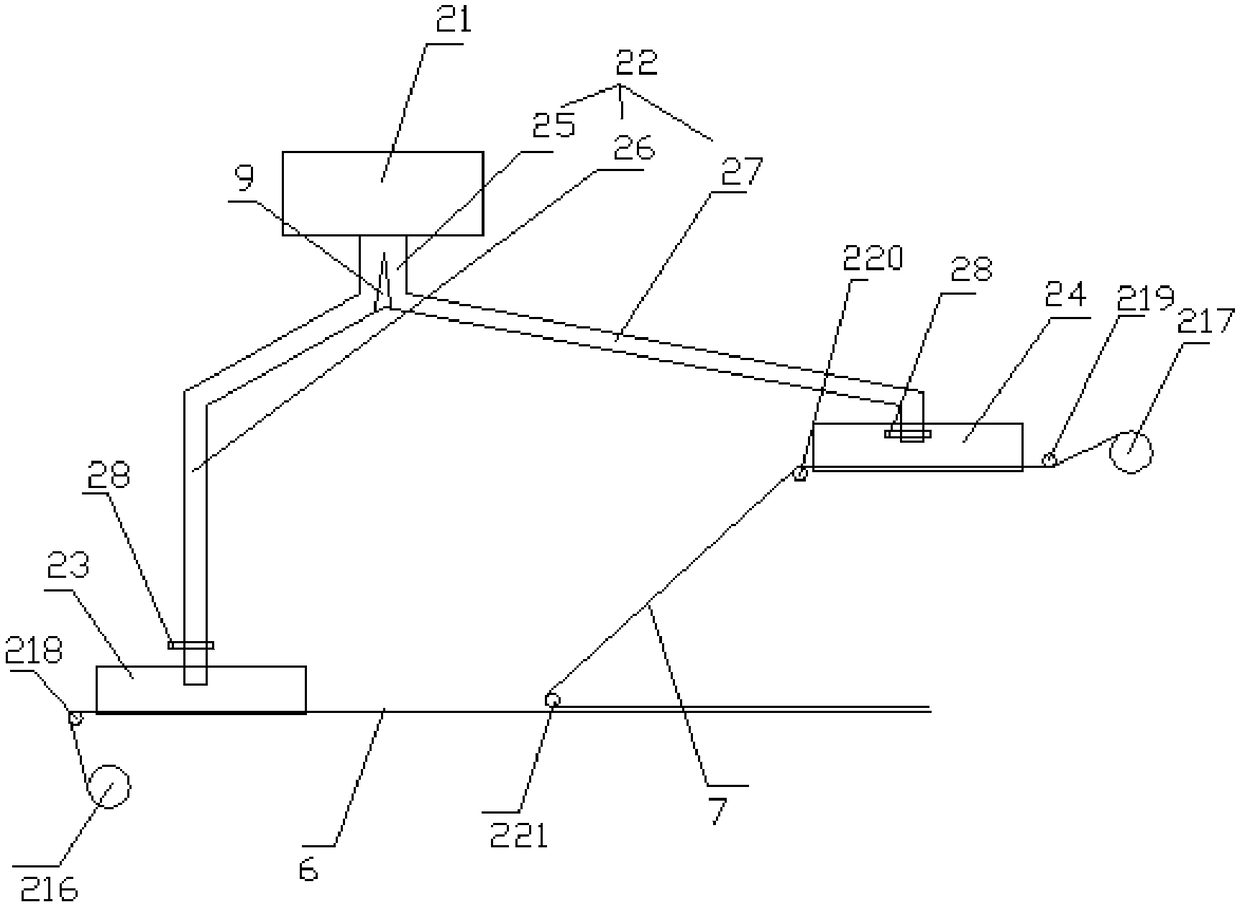

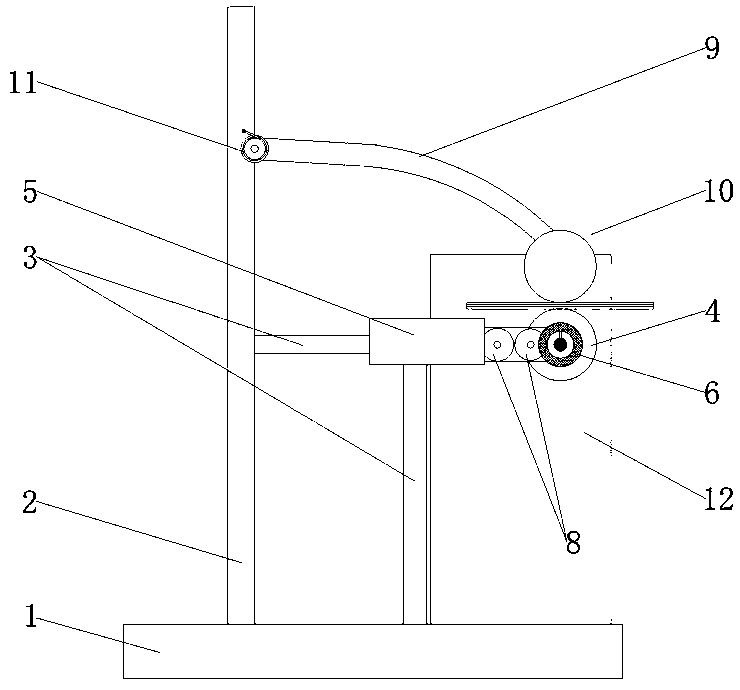

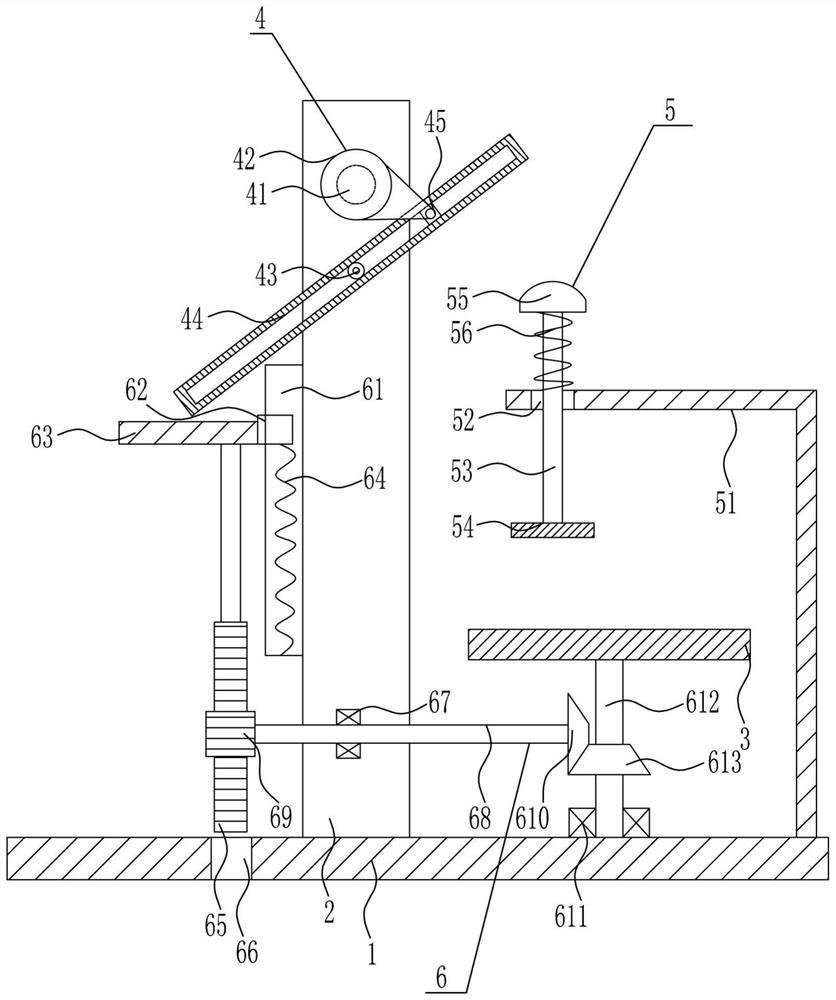

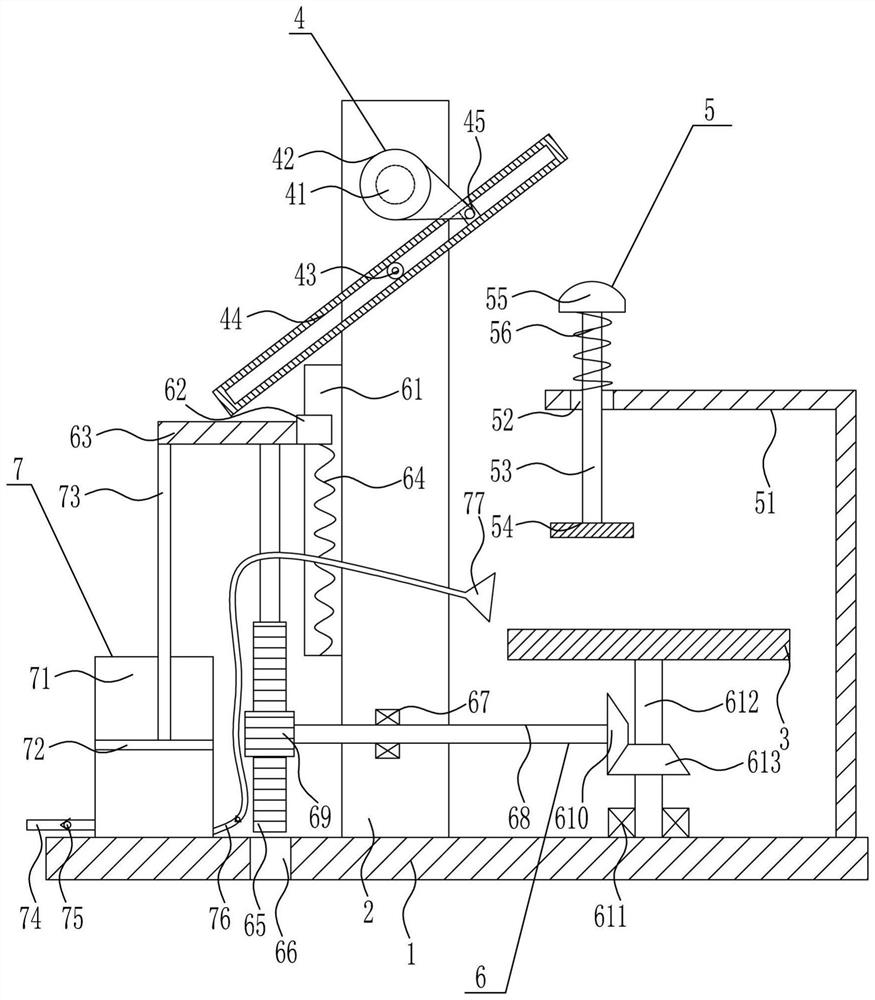

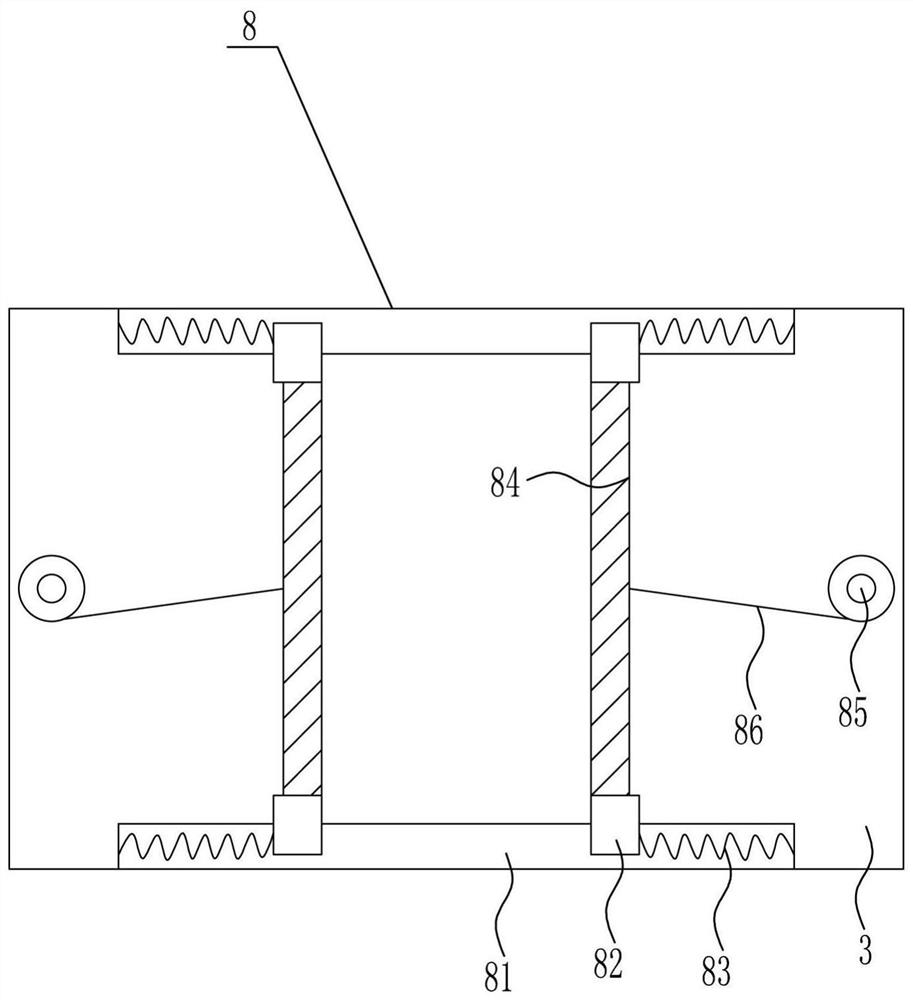

Medical movable denture mold manufacturing equipment

The invention relates to sampling equipment, particularly to medical movable denture mold manufacturing equipment, which comprises a linkage hot-pressing mechanism, a linkage spraying mechanism and ahot-pressing recovery mechanism, can press a denture mold male mold into a female mold outer molding cavity, can enable the female mold outer molding cavity to deform in an accelerated mode, can spraya female mold coating material to a female mold outer molding cavity, and can press the female mold outer molding cavity to be flat, wherein the linkage hot-pressing mechanism is connected with the linkage spraying mechanism, and the hot-pressing recovery mechanism is connected with the linkage hot-pressing mechanism.

Owner:徐桂申

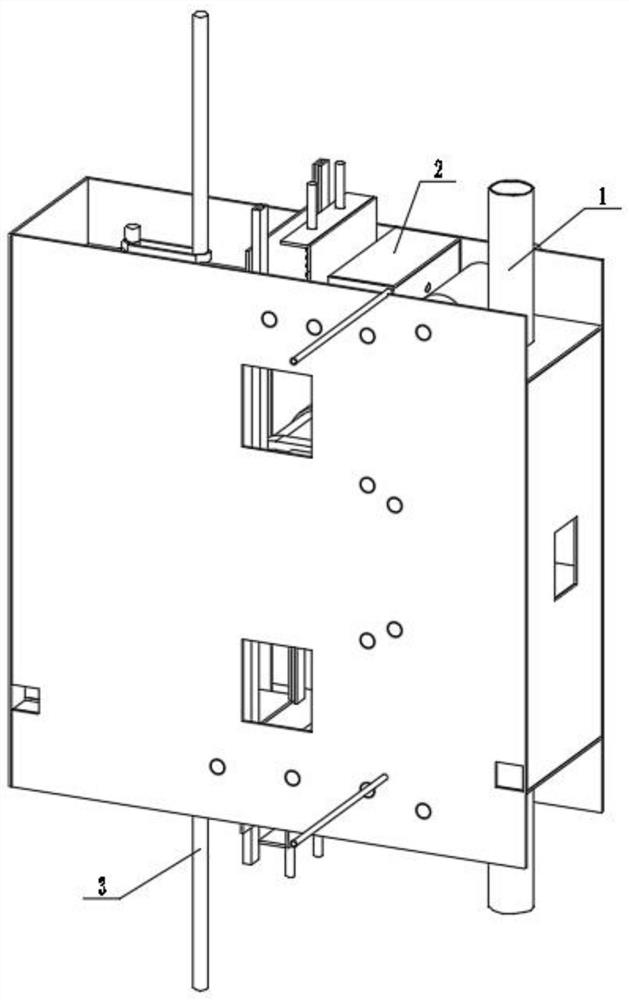

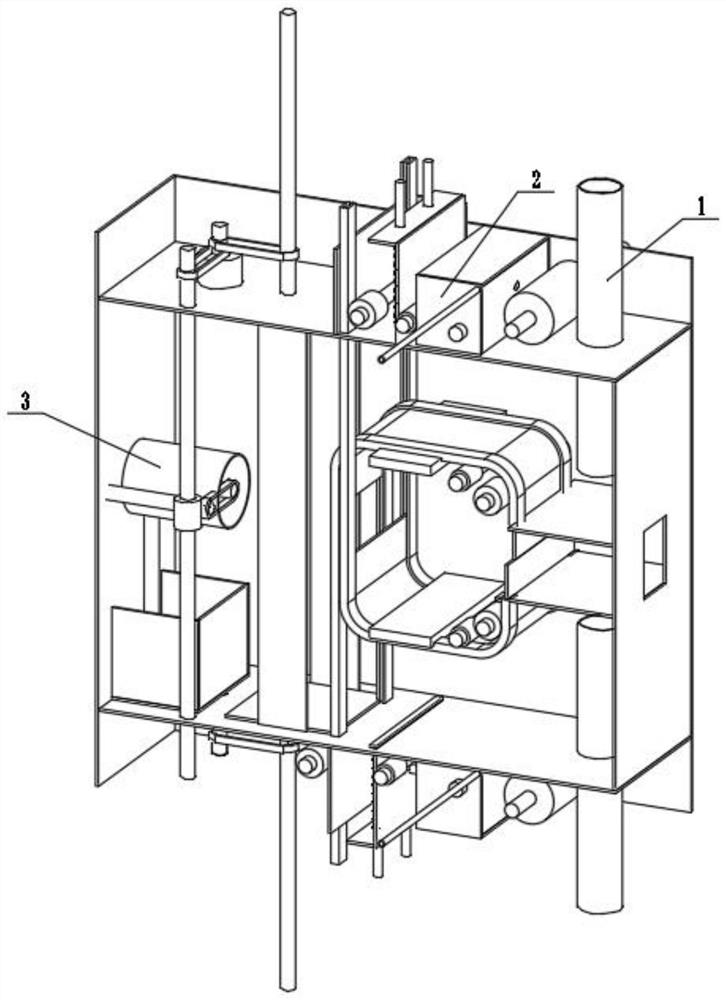

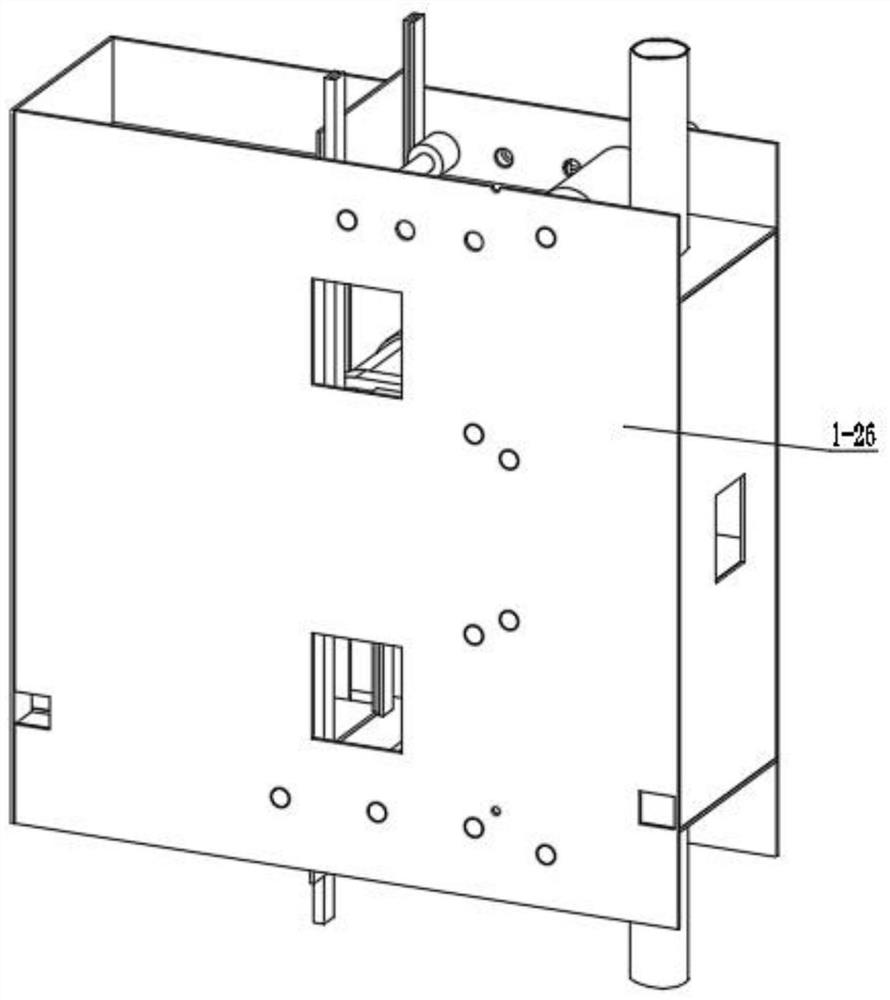

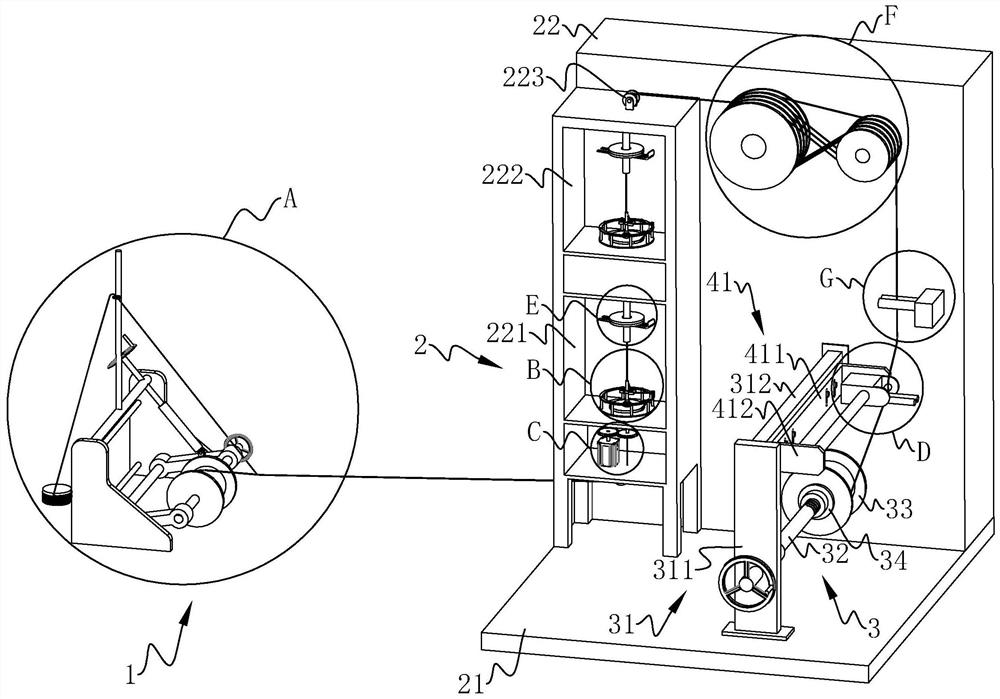

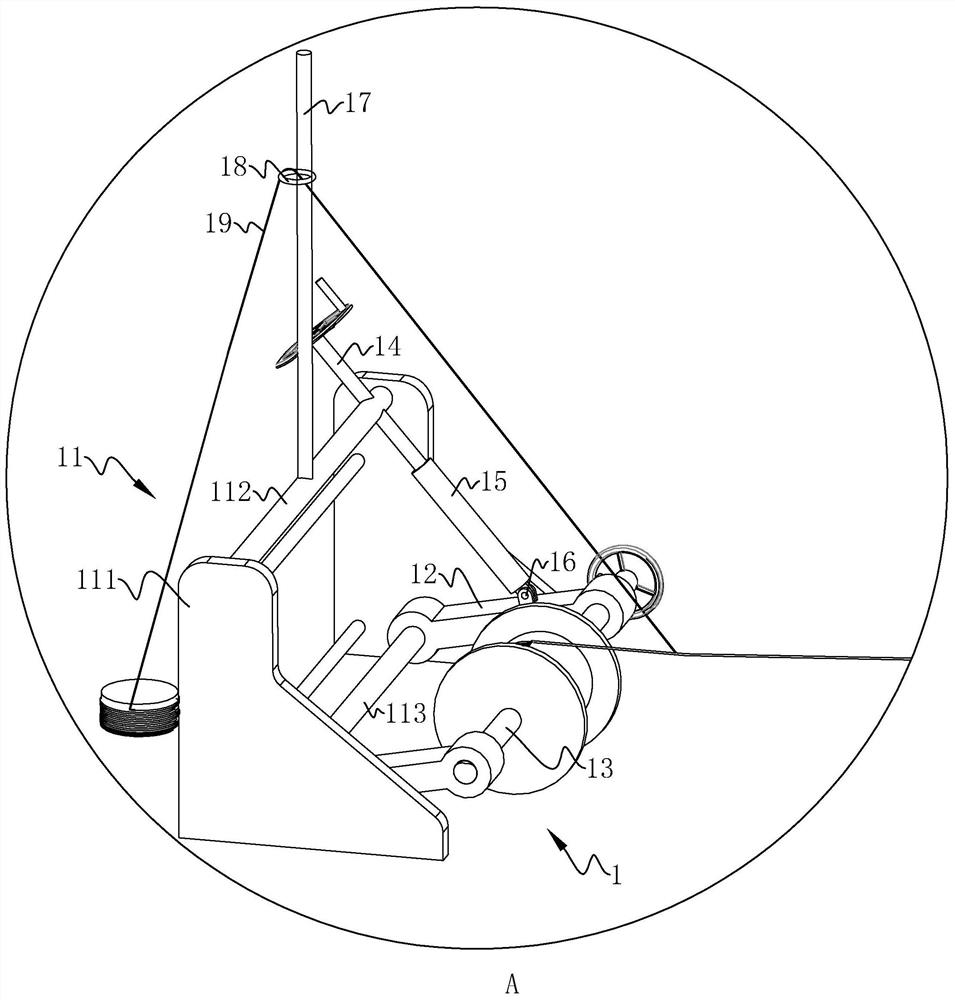

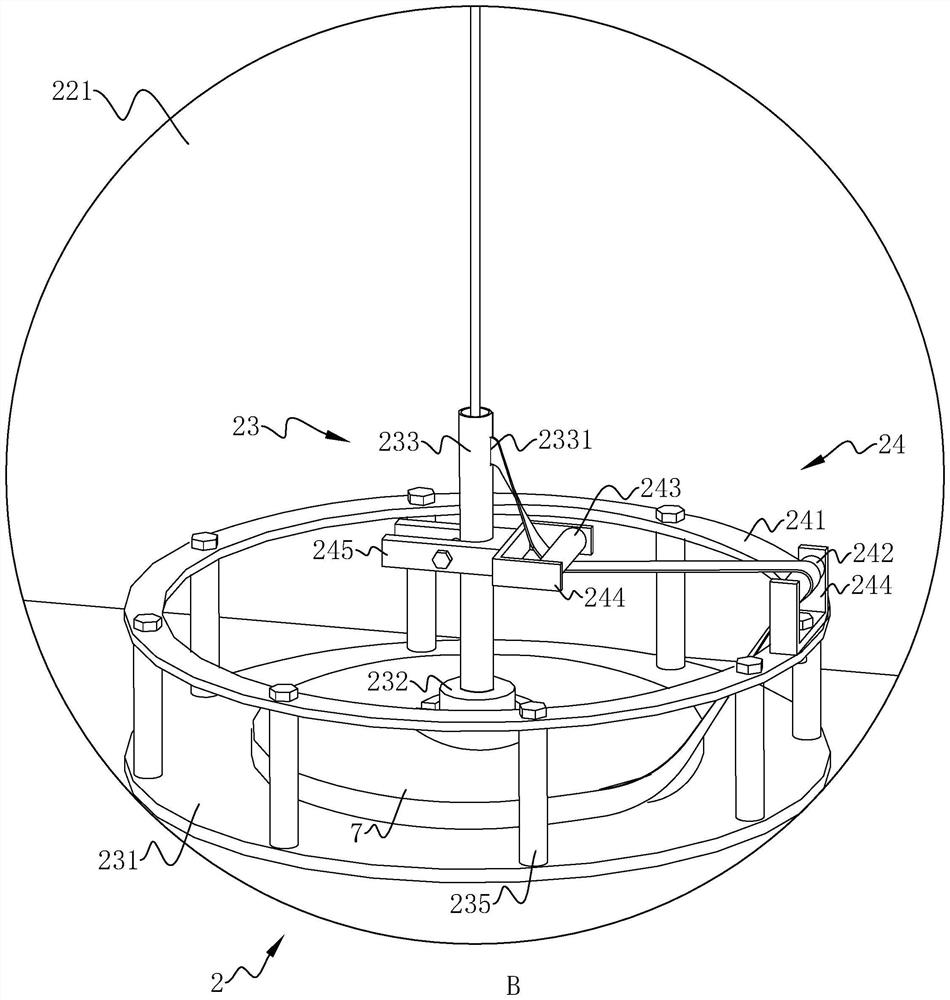

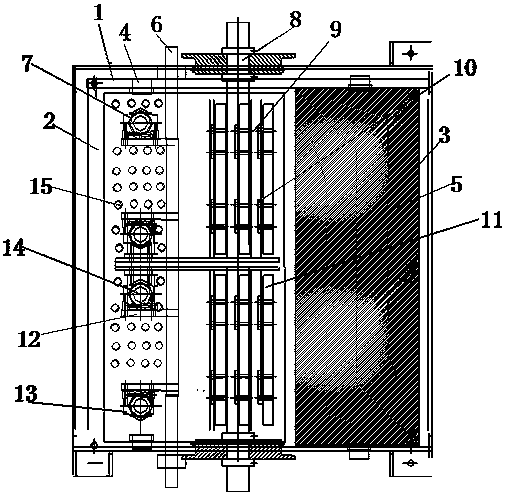

Cable insulation layer shrinkage processing device and process

InactiveCN111696729ANot prone to burrs, etc.Improve protectionFilament handlingInsulating conductors/cablesPolyesterInsulation layer

The invention relates to a cable insulation layer shrinkage processing device and process. The device comprises a cable supply mechanism, a film coating mechanism and a winding mechanism, wherein thecable supply mechanism is used for supplying cables, the film coating structure comprises a chassis, a box body fixedly connected with the chassis, a first working chamber formed in the box body and afilm coating assembly arranged in the first working chamber, the box body is provided with a wire inlet communicated with a first workshop, an upper surface of the box body is provided with a wire outlet, the coating assembly is used for coating a polyester film on a cable, and the winding mechanism is used for winding the coated cable. The device has the effect of preventing burrs from appearingon a cross section of a cable insulation layer.

Owner:北京朝阳隆华电线电缆有限公司

Production method of woodcarving inlaid door panels subjected to film pressing

PendingCN112025903AReduce idle wait timeShorten the timeDecorative surface effectsWood working apparatusPlastic forming machineNumerical control

The invention discloses a production method of woodcarving inlaid door panels subjected to film pressing. The production method of the woodcarving inlaid door panels subjected to film pressing comprises the following steps: (1) carving door panel substrates by means of a numerical control carving machine provided with a rear surface carving machine station and at least two front surface carving machine stations, making the door panel substrates sequentially enter the rear surface carving machine station to complete rear surface carving, then turning over the door panel substrates to front surfaces by an overturning part, conveying the door panel substrates to one spare front surface carving machine station through a conveyor belt for front surface pattern carving at the same time, keepingthe rear surface carving time of the door panel substrates short, and carving corresponding inlaid core panels; (2) conducting surface polishing on the carved door panel substrates and inlaid core panels; (3) conducting glue-spraying and airing on the door panel substrates and the inlaid core panels which are subjected to surface polishing; (4) conducting PVC high-temperature coating on the aireddoor panel substrates and inlaid core panels by means of a plastic forming machine; and (5) bonding the inlaid core panels and inlaid grooves of the door panel substrates by means of glue, and conducting pressing and fixing. The production method of the woodcarving inlaid door panels subjected to film pressing is simple in process, the production efficiency of the door panels can be improved, andthe production cost is reduced.

Owner:上海速居科技集团有限公司

Hardware plate laminating auxiliary equipment

InactiveCN108340610APress evenlyFlatteningMaterial gluingDirt cleaningEngineeringAssistive equipment

Owner:谢曼娟

Manufacturing method of wood carving film-pressing door plank

PendingCN112025902AReduce idle wait timeShorten the timeProfiling/shaping machinesWood veneer joiningSanderNumerical control

The invention discloses a manufacturing method of a wood carving film-pressing door plank.The manufacturing method comprises the following steps that step one. a numerical control carving machine comprising a reverse side carving machine position and at least two front side carving machine positions is used for carving a door plank base material, the reverse side carving machine position is used for carving reverse side patterns and hinge holes in the door plank base materials continuously entering in sequence, the door plank base material with the reverse side being carved is turned to the front side by a turning part and is sent to the idle front side carving machine positions by a conveying belt for front side pattern caving, and the time for carving the reverse side of the door plank base material is less than the time for carving the front side of the door plank base material; step two. the door plank base material with the front side and the reverse side being carved is put intoa special-shaped sanding machine to be subjected to surface burr polishing, and surface burrs are removed; step three. surface glue spraying operation is performed on the polished door plank base material, and the polished door plank base material is placed and aired; and step four. the aired door plank base material is fed into a plastic vacuum forming machine to be subjected to PVC (polyvinyl chloride) high-temperature film coating. The manufacturing method can reduce labor cost and improve manufacturing efficiency.

Owner:上海速居科技集团有限公司

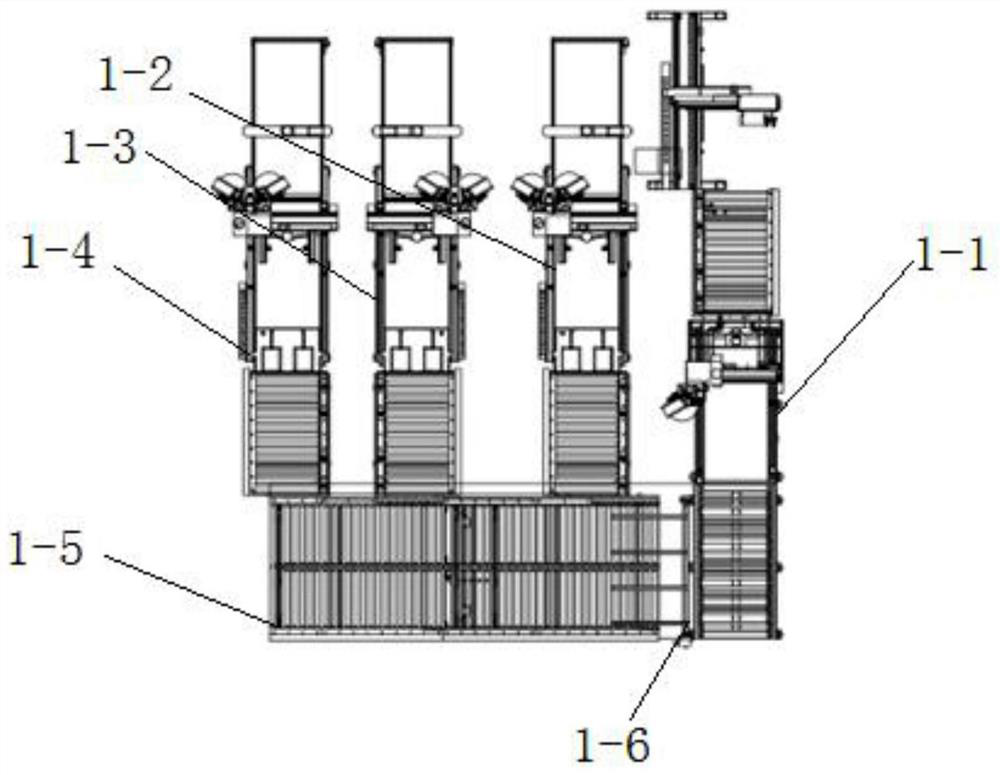

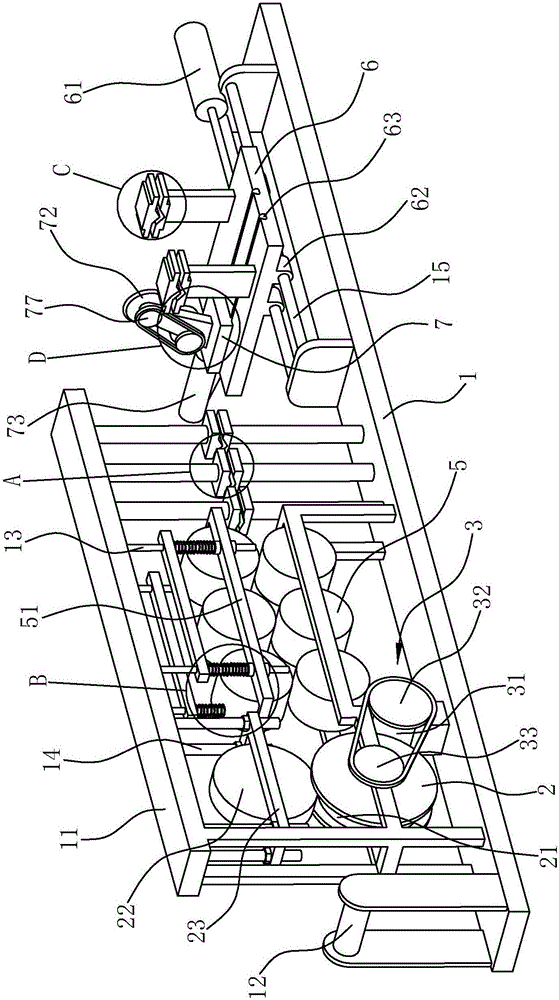

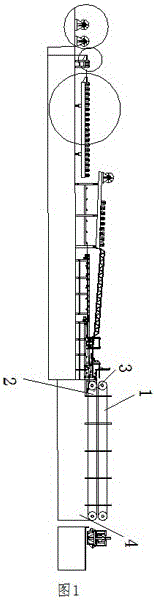

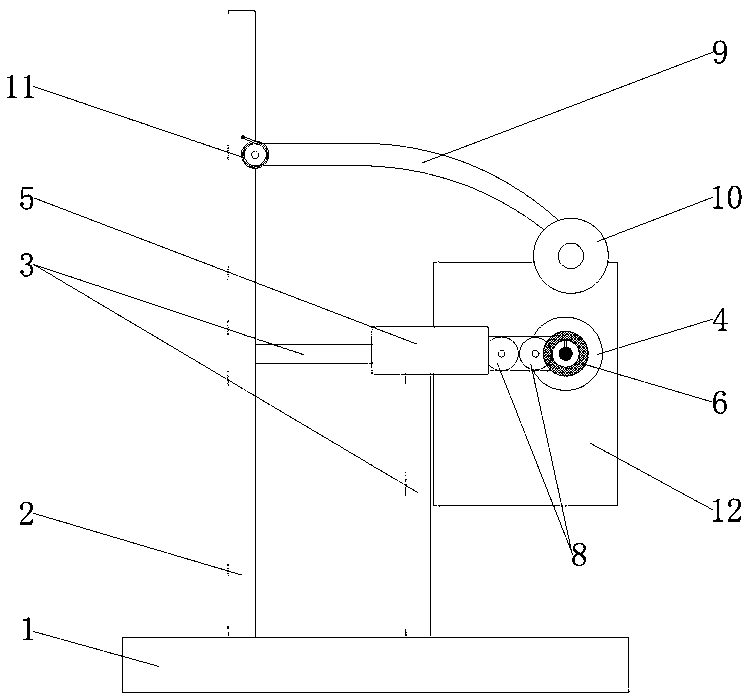

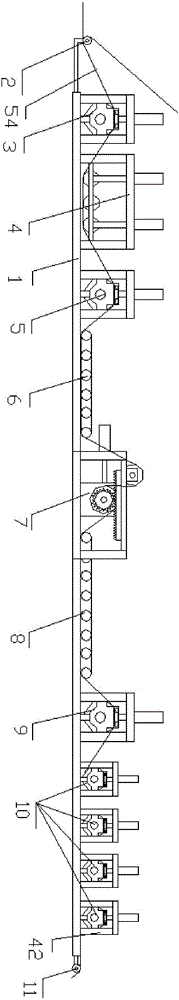

Stator cramp machining device

InactiveCN106078219AMeet the process requirementsAvoid cracks and other damageShaping toolsMetal-working feeding devicesDrive wheelEngineering

The invention provides a stator cramp machining device, belongs to the technical field of machining and solves the problem of low efficiency caused by poor machining continuity of a conventional stator cramp. The stator cramp machining device comprises a base, wherein a frame is connected with the base; a driving wheel is rotationally connected with the base; a driven wheel is rotationally connected with the frame and is located above the driving wheel; a plurality of lower die bases are fixedly connected with the base; forming grooves with V-shaped cross sections are formed in the lower die bases; a plurality of upper die bases are fixedly connected with the frame; the upper die bases correspond to the lower die bases one to one; each of the upper die bases is provided with a compression moulding bulge; a longitudinal moving base is connected with the rear end of the frame in a sliding way; a transverse moving base is connected with the longitudinal moving base in a sliding way; and a cutter head is rotationally connected with the transverse moving base. The machining device provided by the invention can automatically finish compression moulding and cutting of the stator cramp, and is high in working efficiency and degree of automation.

Owner:ZHEJIANG OCEAN UNIV

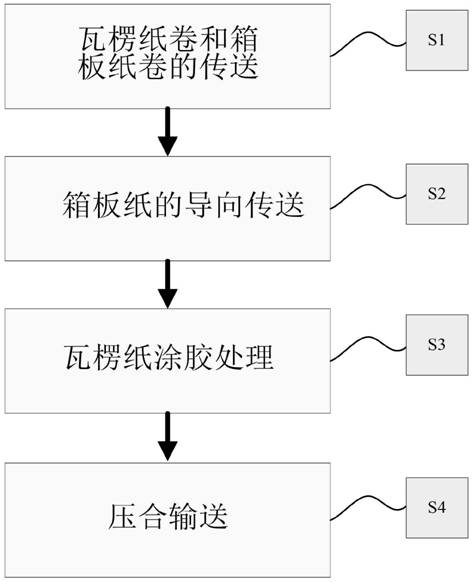

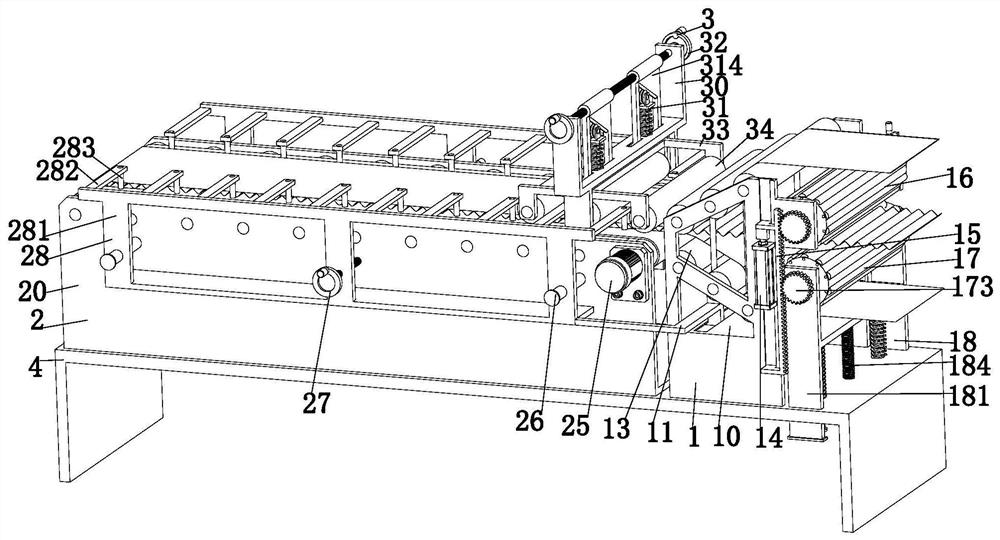

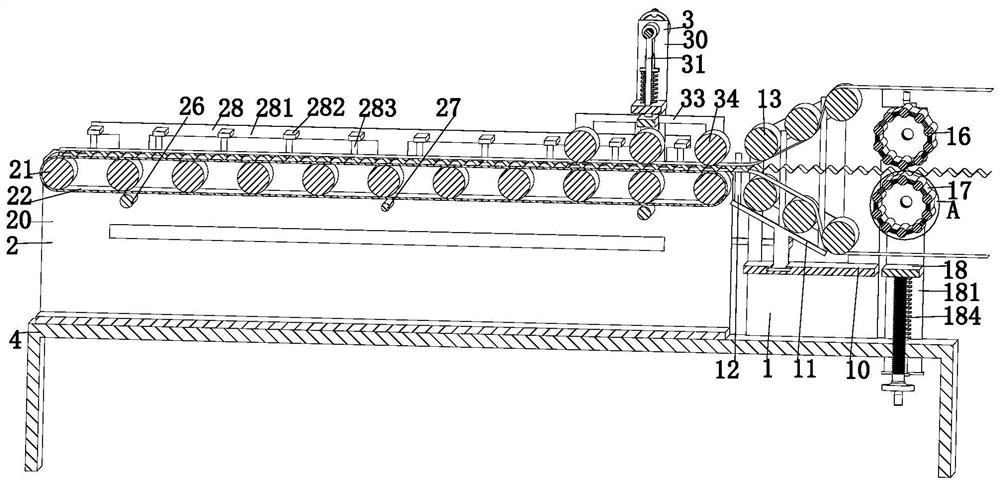

Logistics packaging box corrugated board processing method

ActiveCN113478941ARealize spacing distance adjustmentMeet coating spacing requirementsBox making operationsPaper-makingCardboardLogistics management

The invention provides a logistics packaging box corrugated board processing method, which comprises a roll coating mechanism, a transmission mechanism, a rolling mechanism and a main beam cross frame. The problems as follows are solved: an existing device for coating corrugated paper with glue has limitation, only the corrugated paper with one height size can be coated during glue coating, and corresponding equipment needs to be replaced for coating treatment when the corrugated paper with different height sizes is replaced; the glue is prone to deposition and solidification in the coating process, the viscosity of glue is reduced, and the gluing quality of cardboard paper and corrugated paper is influenced; the coating flow rate of glue is difficult to control, the edges of corrugated paper and cardboard paper cannot be aligned, applied and glued easily due to the fact that the corrugated paper and the cardboard paper do not have a guide movement track in the conveying process, deviation can occur, and the forming quality of the corrugated paper board is affected; and the height cannot be adjusted in the rolling, applying and gluing process of the corrugated paper board, and the pressing requirements of corrugated boards with different thicknesses cannot be met.

Owner:佛山市傲彩包装制品有限公司

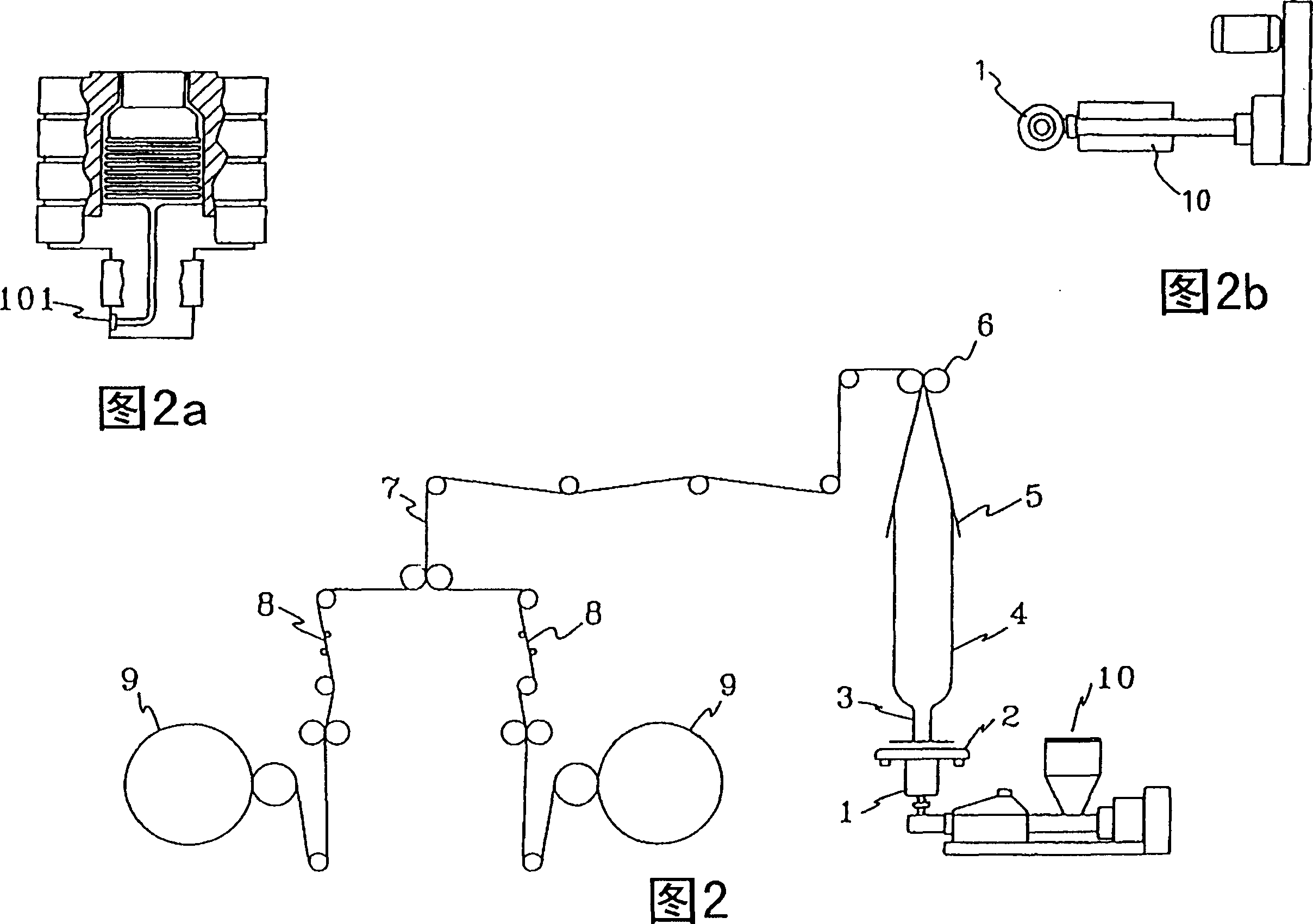

Environment protecting paper

An environment protection type paper is made up from natural inorganic ore powder 56-80 wt.%, polyethylene 43-18 wt.% and assistant 1-2 wt.% through proportionally mixing, squeezing and pugging, then granulating; high-temp. extruding, soflening and discharging via O-shaped nozzle to become tubular film, cooling to 80-120 deg.C; filling compressed air into tubular film for expanding it, making the tubular film extend, and streching the tabular film to obtain the paper with bidirectional strength.

Owner:LUNG MENG ENVIRONMENTAL FRIENDLY PAPER PROD HONG KONG HLDG

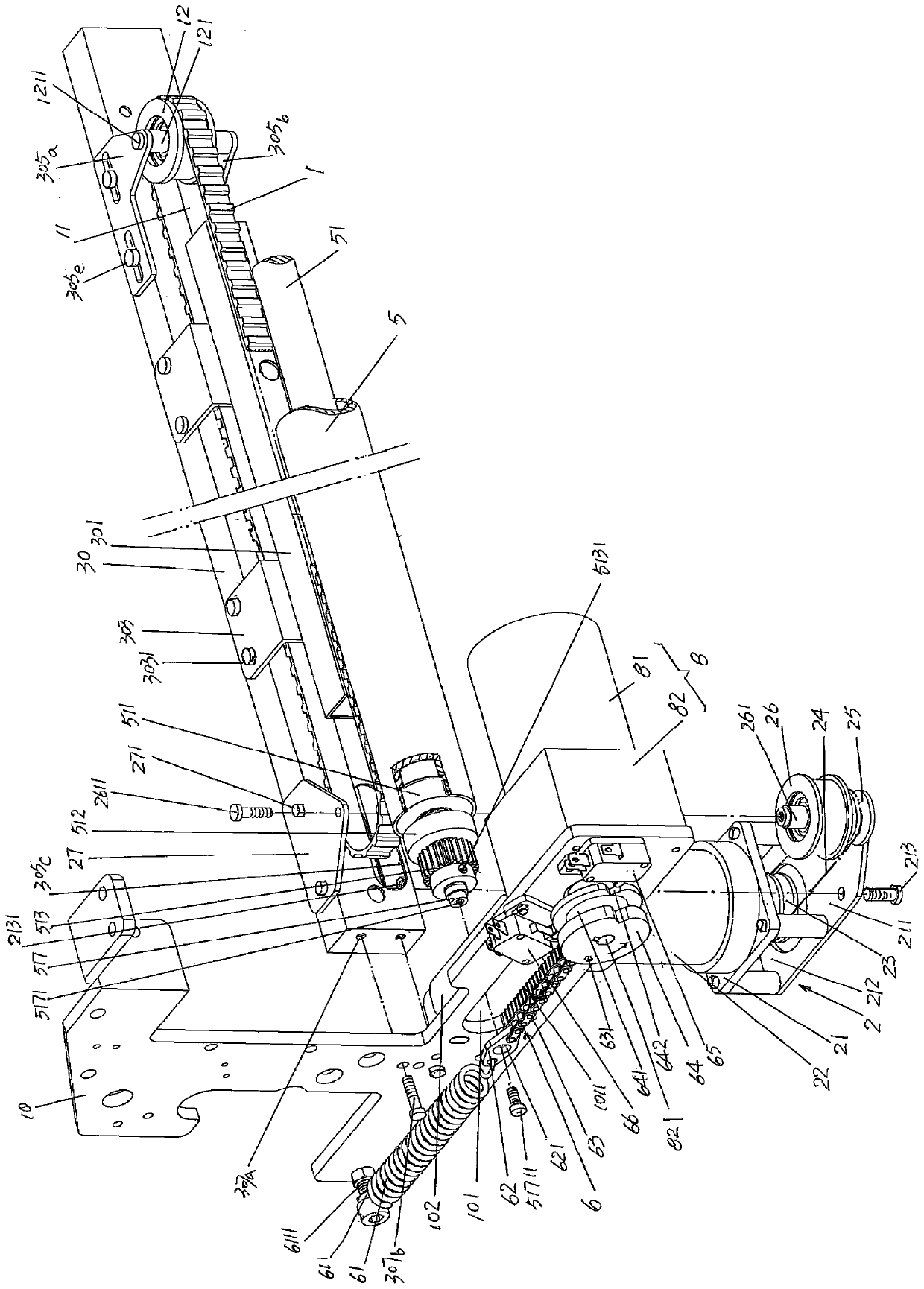

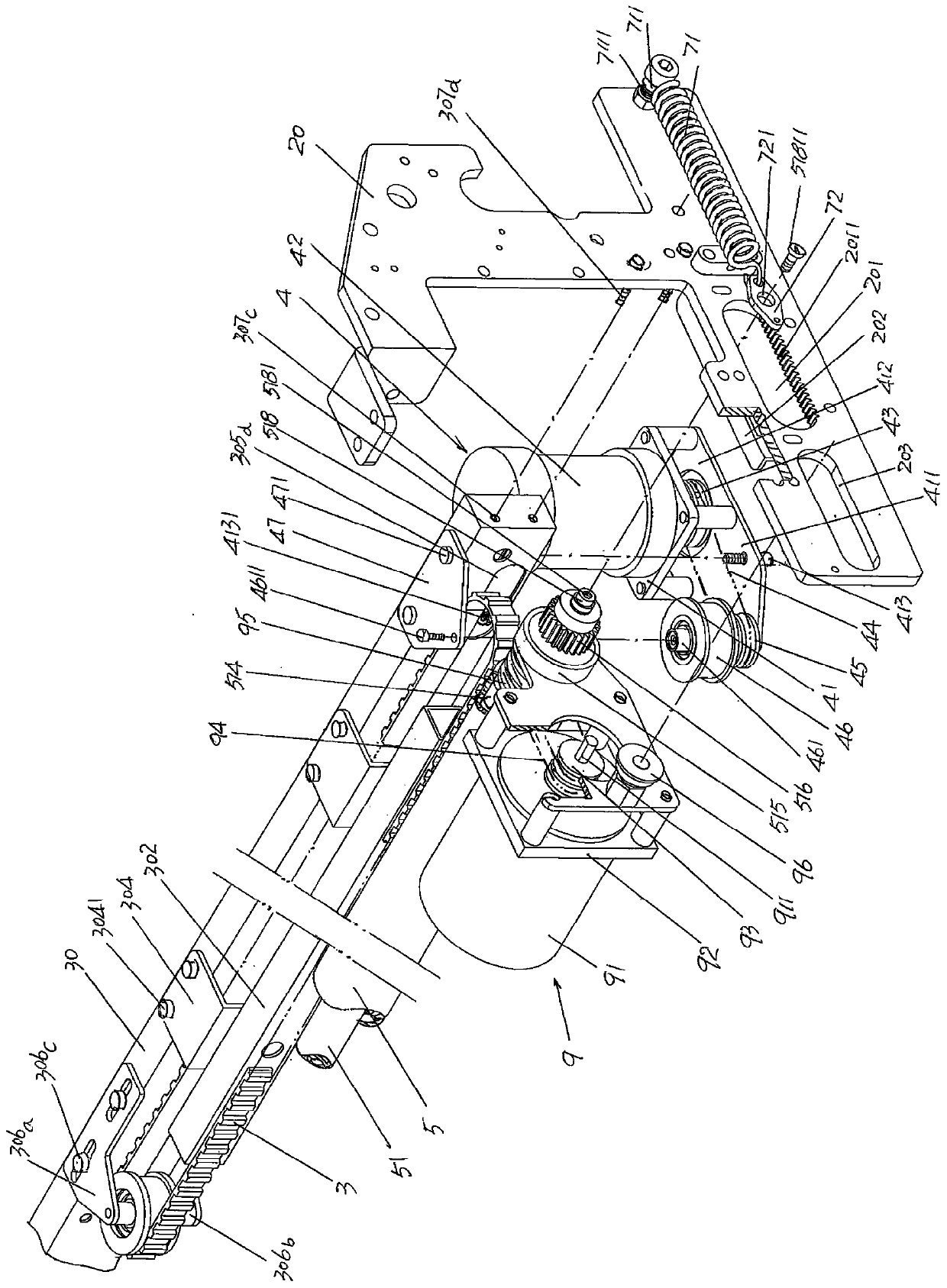

Lower edge unfolding device of spreading machine with cloth pressing function

PendingCN111170052AThere will be no scrappingFull stripping flat strippingUnfolding thin materialsWebs handlingChain linkIndustrial engineering

The invention discloses a lower edge unfolding device of a spreading machine with a cloth pressing function, and belongs to the technical field of clothing machinery. The lower edge unfolding device of the spreading machine with the cloth pressing function comprises a tenter left wallboard, a tenter right wallboard, a tenter, a left edge unfolding toothed belt, a left edge unfolding toothed belt driving mechanism, a right edge unfolding toothed belt and a right edge unfolding toothed belt driving mechanism, and is characterized by further comprising a cloth pressing roller, a cloth pressing roller shaft left tensioning and loosening mechanism, a cloth pressing roller shaft right tensioning and loosening mechanism, a chain reel driving mechanism and a cloth pressing roller driving mechanism. The cloth pressing roller is arranged on a cloth pressing roller supporting shaft, the cloth pressing roller shaft left tensioning and loosening mechanism is arranged on the left side of the left wallboard of the tenter, the cloth pressing roller shaft right tensioning and loosening mechanism is arranged on the right side of the right wallboard of the tenter, the chain reel driving mechanism isarranged on the right side of the front end of the left wallboard of the tenter, and the cloth pressing roller driving mechanism is arranged at the front end of the right wallboard. The hemming edgeson the two sides of cloth are fully unfolded and flattened, and the situation that subsequent processes are affected or even the cloth is scrapped is avoided.

Owner:苏州比阳特服装设备有限公司

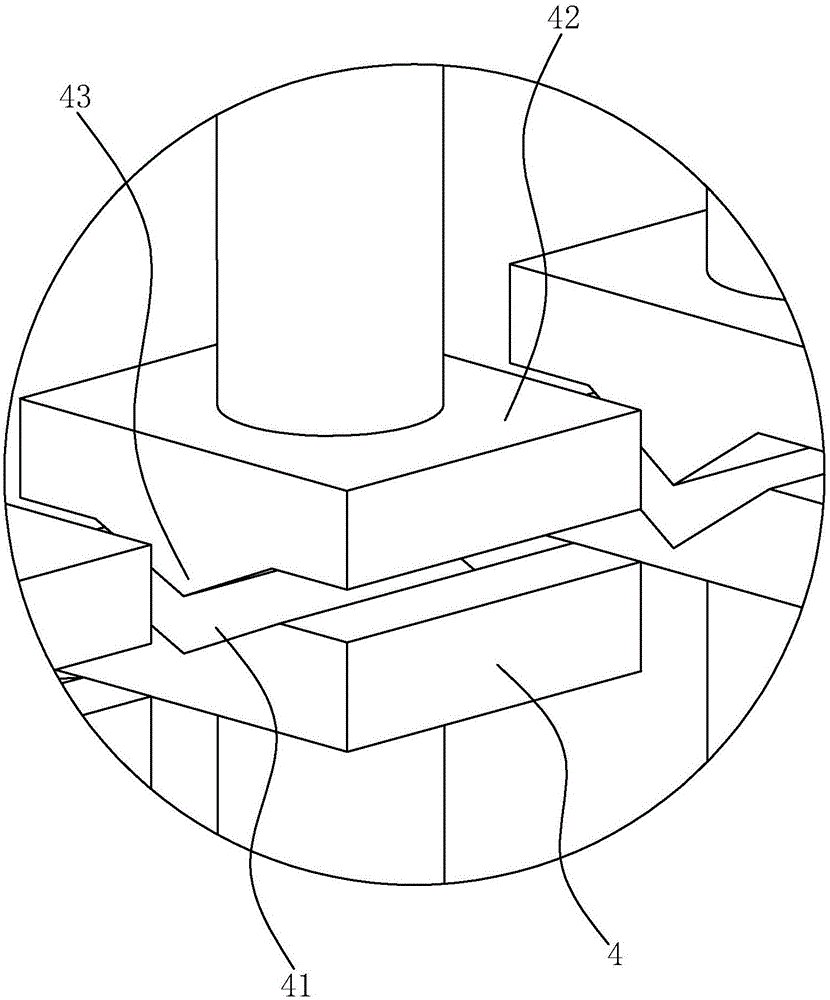

Compression molding equipment for making preserved fruits through pulp of tamarindus indica

InactiveCN110150433ASimple structureEasy to useConfectionerySweetmeatsCompression moldingFixed frame

The invention discloses compression molding equipment for making preserved fruits through pulp of tamarindus indica. The compression molding equipment for making the preserved fruits through the pulpof the tamarindus indica comprises a fixed frame body, a movable compression pressing platform structure is arranged in the fixed frame body, a front-end flat compression structure is arranged in thefixed frame body, and a rear-end roller compression structure is arranged in the fixed frame body; the movable compression pressing platform structure comprises a first metal platform top provided with a rotary shaft and a second metal platform top, the first metal platform top is higher than the second metal platform top, annular lugs are arranged on the surface of the first metal platform top, and compression slant grains are uniformly distributed on the second metal platform top; the front-end flat compression structure comprises a fixed shaft arranged in the fixed frame body, a compressionfixed base structure arranged at the upper portion of the fixed shaft and a compression block arranged at the upper portion of the compression fixed base structure. The compression molding equipmenthas the advantages of being simple in structure, convenient to use, and capable of achieving flat compression and further improving the pickling quality.

Owner:滁州昭阳电信通讯设备科技有限公司

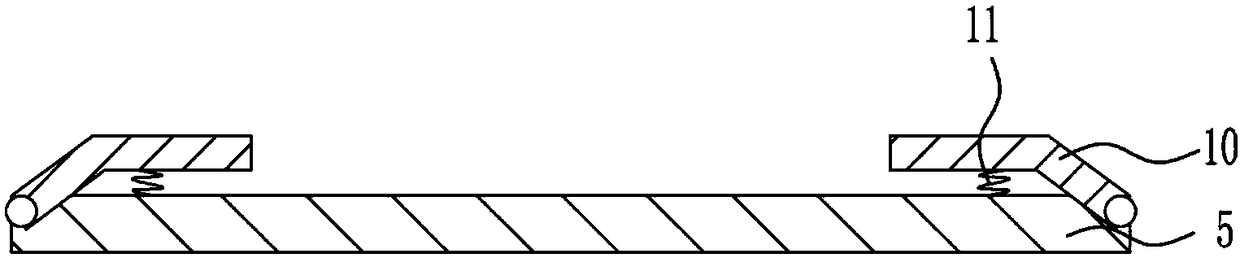

Steel belt type composite board unit

PendingCN107175877AReasonable and novel structure designFlatteningLaminationLamination apparatusSteel beltUpper floor

The invention discloses a steel belt type composite board unit, which relates to the technical field of mechanical equipment. The steel belt type composite board unit comprises an upper layer steel belt, a lower layer steel belt, rollers and a framework; the lower layer steel belt is arranged below the upper layer steel belt, and the upper layer steel belt and the lower layer steel belt are both in drive connection with the rollers at two sides; the upper layer steel belt, the lower layer steel belt and the rollers are all fixedly arranged on the framework. The steel belt type composite board unit is capable of overcoming abuses of the prior art, and is reasonable and novel in structural design; composite boards are pressed in a transfer process, and are pressed to be relatively flat; and the equipment is simple, the occupied size is small, maintenance is relatively convenient, and cost of the equipment is reduced.

Owner:上海呈杏机械制造有限公司

Dispensing and laminating device for assembling LED lamp

InactiveCN106838672AInflated stableReduce labor intensitySemiconductor devices for light sourcesEngineeringLED lamp

The invention belongs to the technical field of LED assembly, and in particular relates to a glue dispensing and pressing device for LED lamp assembly. The technical problem to be solved by the present invention is to provide a glue dispensing and pressing device for assembling LED lamps that can reduce the labor intensity of workers, improve assembly efficiency and is easy to use. In order to solve the above technical problems, the present invention provides such a glue dispensing and pressing device for LED light bar assembly, which includes a base plate, a fixing plate, a first air pipe, a first vacuum suction cup, a riser, a first slider, a first Motor, bearing seat, screw, nut, first mounting plate, etc.; the top of the bottom plate is vertically connected with a fixed plate by means of bolt connection, a first cavity is opened in the fixed plate, and a first cavity is connected to the left side of the fixed plate. trachea. In the present invention, glue is first applied to the LED lamp bracket by moving the glue outlet downwards, and then the LED lamp strip is pressed on the LED lamp bracket by moving the movable plate to the left.

Owner:冯晓栋

Asphalt laying device based on municipal road engineering

ActiveCN114457654AFlatteningImprove construction efficiencyRoads maintainenceRoad engineeringGear wheel

The invention discloses an asphalt laying device based on municipal road engineering, which comprises a machine body, the bottom of the machine body is provided with a bottom plate, the machine body is provided with a hollow feeding shaft, the lower end of the hollow feeding shaft extends out of the bottom plate, the upper end of the hollow feeding shaft is provided with a feeding unit, the hollow feeding shaft is rotatably connected with a disc, the upper end face of the disc is provided with a gear ring, and the gear ring is engaged with a gear. A first motor is arranged on the gear, a plurality of compression roller assemblies which are distributed in an annular array at equal intervals around the axis of the disc are arranged on the lower end face of the disc, each compression roller assembly is composed of an inner support, an outer support and a compression roller shaft, a floating assembly is arranged between every two adjacent compression roller assemblies, and each floating assembly is composed of a follow-up pressing block, a bearing plate and a compression spring; a first universal ball is arranged on the inner side of the floating assembly, and a second universal ball is arranged on the outer side of the floating assembly. The asphalt paving device is suitable for local repair of the road, flat in press fit, high in construction efficiency, complete in overall function and high in practicability.

Owner:浙江瑞帆建设有限公司

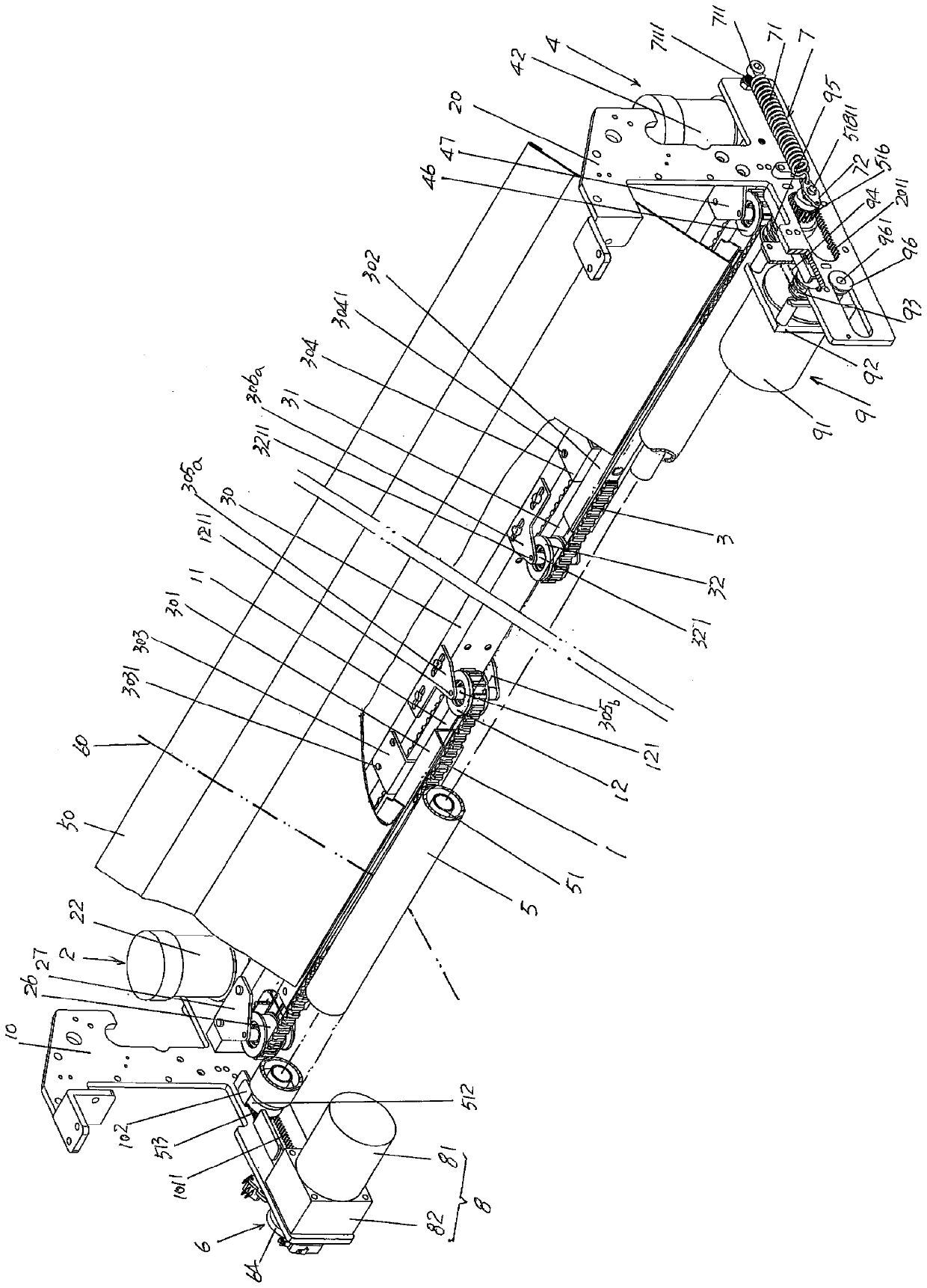

Covered edge sewing automatic trademark feeding device

PendingCN108103677AFlatteningHigh feed accuracyWorkpiece carriersWork-feeding meansEngineeringMechanical engineering

The invention discloses a covered edge sewing automatic trademark feeding device, and relates to the field of textile sewing equipment. The covered edge sewing automatic trademark feeding device comprises a trademark clamping hand, a trademark conveying component, a trademark pressing beam, a trademark pressing cylinder and a pressure plate, the trademark clamping hand and the trademark pressing beam are arranged on the same side of a worktable, the pressure plate is arranged on a tabletop of the worktable, the trademark clamping hand is fixed onto the trademark conveying component, the horizontal distance between the trademark clamping hand and the trademark pressing beam is adjusted by the trademark conveying component, the trademark conveying component is pushed by two trademark conveying cylinders, the feeding distance of the trademark clamping hand on the worktable is adjusted by the trademark conveying cylinders, a belt parallel to the worktable is arranged on the trademark pressing beam, a piston rod of the trademark pressing cylinder is fixed onto the trademark pressing beam, and the trademark pressing cylinder pushes the trademark pressing beam to press a trademark on theworktable. The covered edge sewing automatic trademark feeding device is high in feeding precision, smooth in trademark pressing and rolling, simple in integral structural design, easy to operate andmaintain and controllable in preparation cost, sewing and large-scale production are facilitated, and warping is avoided.

Owner:苏州匠博智能科技有限公司

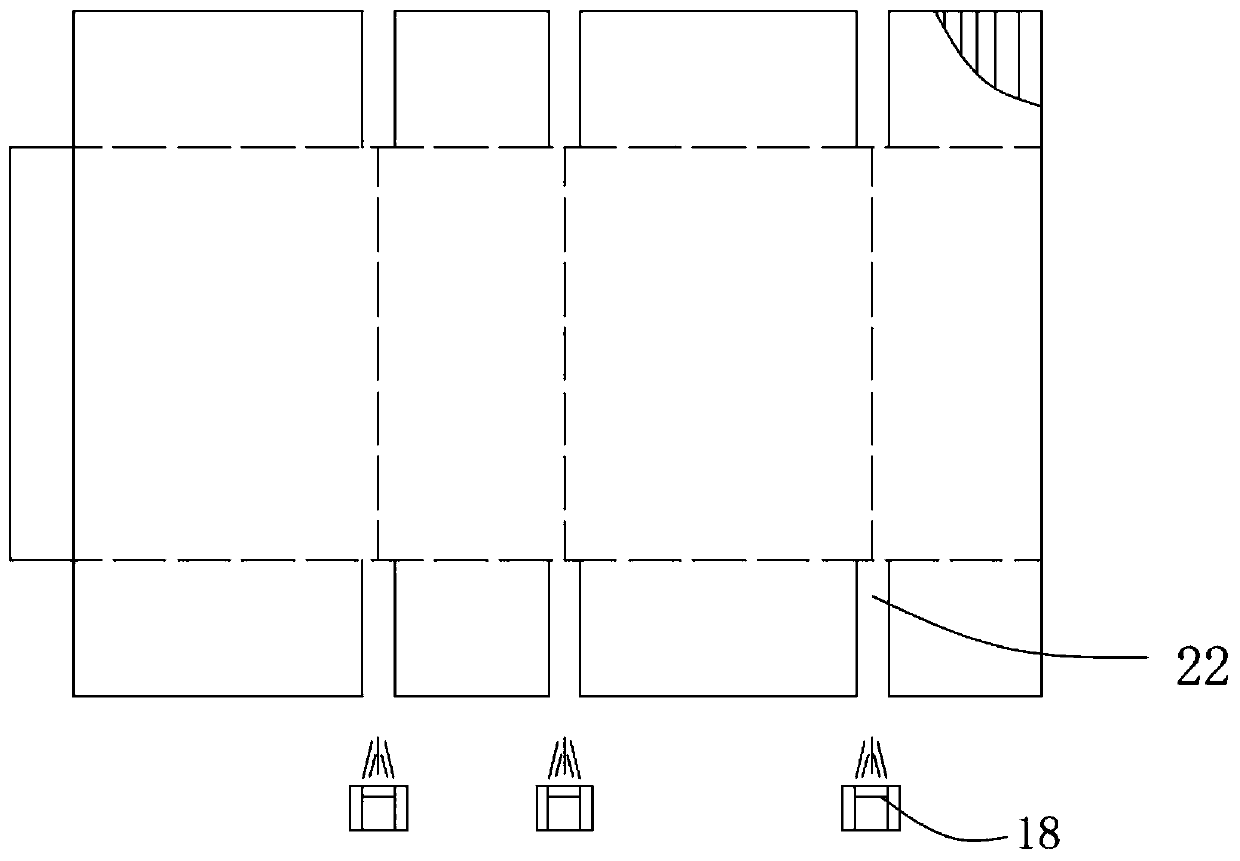

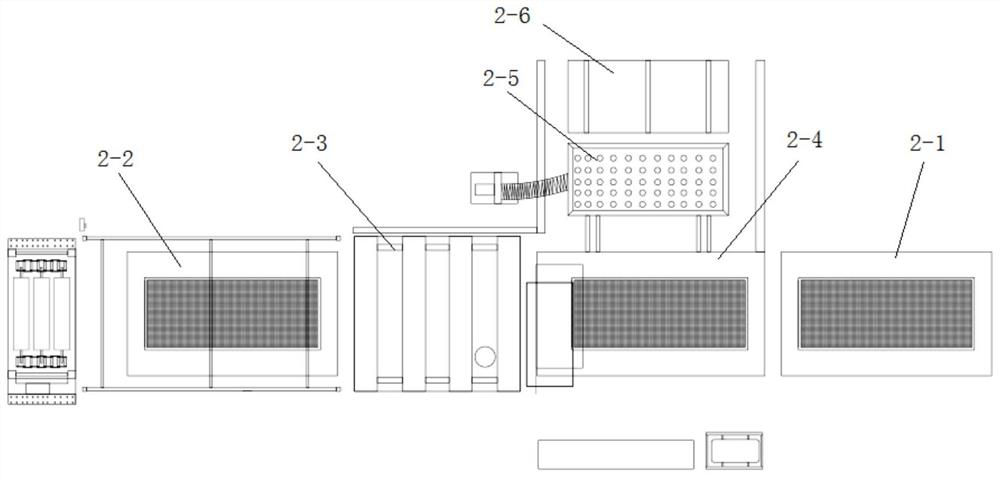

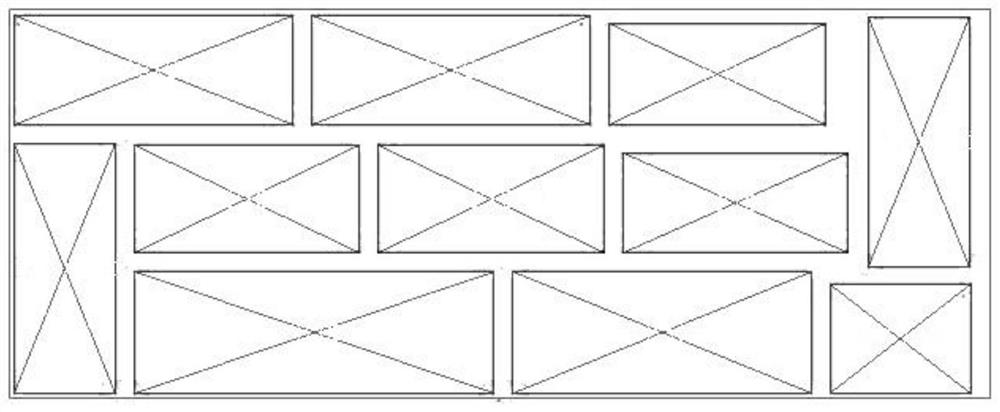

Efficient manufacturing method of wood carving film pressing door plate

PendingCN112008824AEfficient preparation methodReduce idle wait timeDecorative surface effectsLaminationNumerical controlFilm-coated tablet

The invention discloses an efficient manufacturing method of a wood carving film pressing door plate. The efficient manufacturing method comprises the following steps that a numerical control carvingmachine is used for carving the front face and the back face of a door plate base material; surface burr grinding is conducted on the door plate base material with the front face and the back face being carved, and surface burrs are removed; the surface glue spraying operation is conducted on the ground door plate base material, and the placing and airing are conducted; before a plurality of doorplate base materials to be subjected to high-temperature film coating are placed on a film coating workbench of a high-temperature film coating machine, the placing positions of the plurality of aireddoor plate base materials to be subjected to high-temperature film coating on a film coating station are reasonably planned and arranged in advance; according to a pre-planned layout, the door platebase materials to be subjected to high-temperature film coating are placed at designated positions of the film coating workbench; the surfaces of the plurality of door plate base materials are coveredwith a PVC film on the film coating workbench; and the film coating workbench drives the door plate base materials to enter the high-temperature film coating station for PVC high-temperature film coating. According to the efficient manufacturing method, the labor cost can be reduced, and the manufacturing efficiency can be improved.

Owner:上海速居科技集团有限公司

A kind of outer protective layer sheet production device

ActiveCN106585040BThe same amount of feedUniform feedingLaminationLamination apparatusEpoxyGlass fiber

Owner:江苏玖尚新材料有限公司

Novel fully-automatic plastic packaging machine

InactiveCN104494948AStrong surface adaptabilityGuaranteed flatnessWrappingWrapper twisting/gatheringPlastic packagingEngineering

The invention discloses a novel fully-automatic plastic packaging machine. The novel fully-automatic plastic packaging machine comprises a casing, a working plane, a power supply, a heating roller, a motor, a pressing plate, a spring and a guide rod, wherein the power supply is arranged in the casing; the casing is provided with the working plane; the heating roller is arranged in the casing, and the top part of the heating roller protrudes from the working plane; one side of the heating roller is connected with the motor; the pressing plate is arranged on the heating roller; the guide rod is arranged on the pressing plate; the spring sleeves the guide rod. By adopting the means, the novel fully-automatic plastic packaging machine has the advantages of being high in reliability, compact in structure, excellent in plastic package quality, flat to press, excellent in surface adaptability, little in noise, long in service life, and simple and convenient to operate, and has wide market prospect in the plastic package market.

Owner:常熟印刷厂有限公司

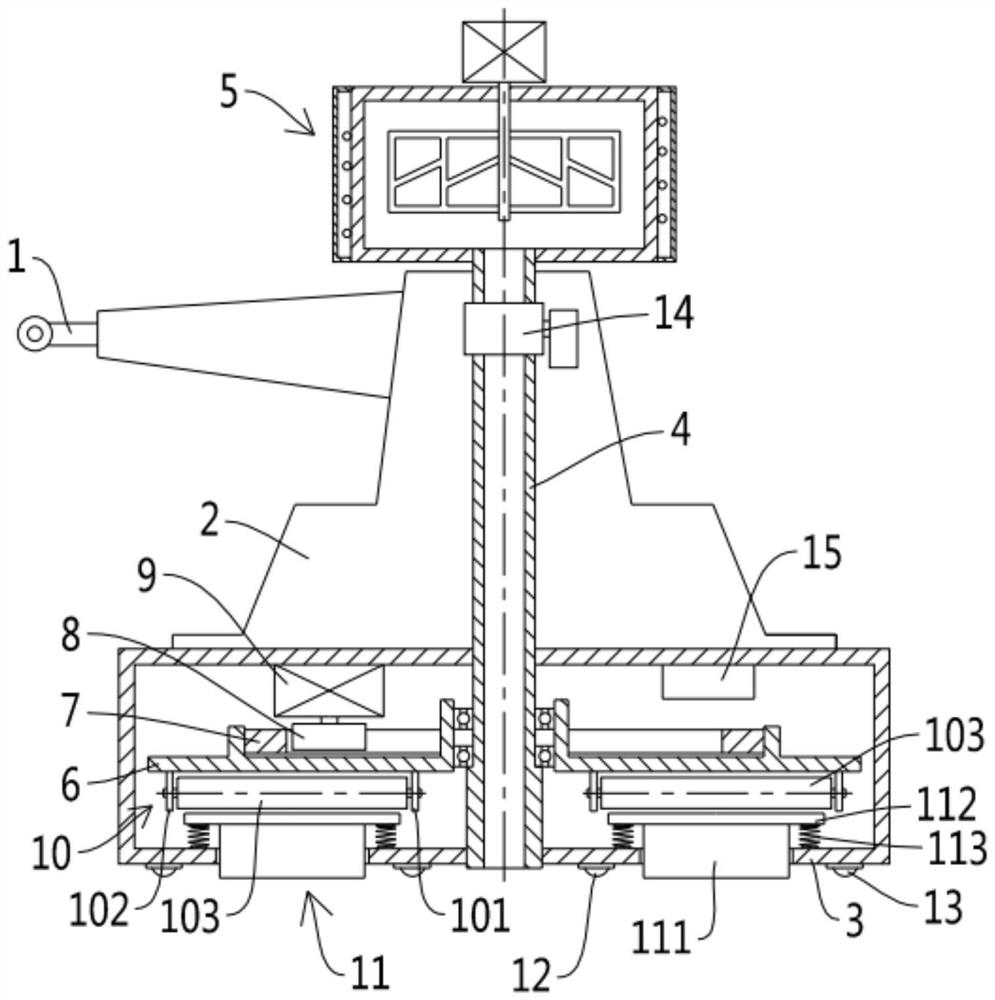

Stitching equipment for shoe product and process for implementing stitching by adopting same

The invention discloses stitching equipment for a shoe product. The stitching equipment comprises a base; a main bracket is arranged on the base; a first bracket is transversely arranged on the main bracket; a driving wheel is arranged on the first bracket; the driving wheel is provided with a driving motor and an electric heating mechanism; the electric heating mechanism prompts the driving wheelto generate heat; the driving motor drives the driving wheel to rotate; a second bracket is transversely arranged above the first bracket; the second bracket is in swing connection with the main bracket; a driven wheel is arranged on the second bracket in a manner of aligning with the driving wheel; and a pre-tightening mechanism is configured at the swing connection position to prompt the secondbracket to compress down on the driving wheel. The invention further discloses a process for implementing stitching by adopting the stitching equipment for the shoe product. The invention has the technical effects that a pressed edge formed by stitching is very flat; pressing is easier to operate; due to guarantee of the equipment, the demand for a worker for the stitching operation is reduced soas to benefit for reducing training cost and improving yield.

Owner:巨一集团有限公司

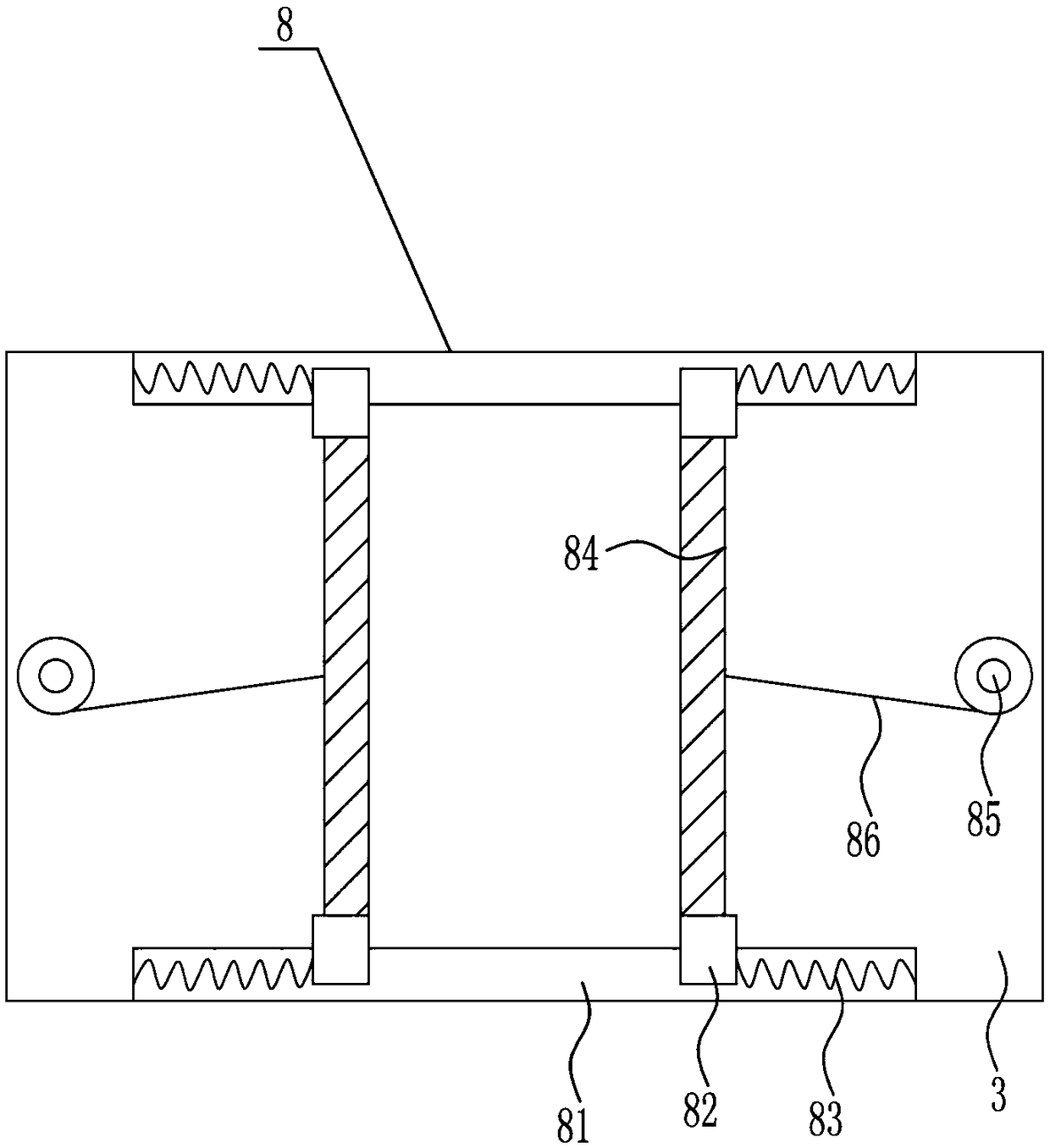

A post-glue pressing auxiliary device for the production of electronic products

ActiveCN108757672BFull pressingEasy to pressMaterial gluingMechanical engineeringIndustrial engineering

Owner:泉州市欣百亚智能科技有限公司

Insertion box pasting mold and using method thereof

PendingCN112172245AAvoid deformationReduce consumptionBox making operationsPaper-makingStructural engineeringMechanical engineering

The invention relates to the technical field of insertion box processing equipment, in particular to an insertion box pasting mold and a using method thereof. The insertion box pasting mold is used for improving the quality and production efficiency of insertion box pasting and reducing the production cost and comprises an operation platform connected to a base through a sliding structure, the operation platform is connected with a plate supporting mold through a supporting plate mold clamp capable of turning and combining, width limiting plates are connected to the two sides of a supporting plate mold through adjusting structures, locking buckles are connected to the width limiting plates, baffles are connected to the bottom of the supporting plate mold through detachable connecting pieces, the base is further connected with a bridge frame, and the bridge frame is connected with a pressing structure used for pressing the sticking face of the insertion box and a box disassembling structure used for disassembling the stuck insertion box from the supporting plate mold, and the using method of the insertion box pasting mold is that the insertion box is stuck on the basis of the structure. According to the insertion box pasting mold and the using method thereof, the production requirement can be met only through one supporting plate mold, consumption of materials and manpower is reduced, the flattening step is omitted as well, and automatic pulling-out of the insertion box is achieved.

Owner:河南省邮电科技有限公司

An integrated device for pressing and pasting financial bills

ActiveCN112937157BFacilitate subsequent posting workFlatteningBookbinding adhesiveBookbinding pressesEngineeringStructural engineering

The invention relates to an integrated device for pressing and pasting financial bills, which includes a base and a control cabinet. Self-locking wheels are arranged on the left and right sides under the base, a control cabinet is arranged on the left side of the front of the base, and a power supply box is arranged on the right side of the control cabinet. , a control panel is set in the upper middle of the front of the base, a workbench is set above the base, an atomizing device is set on the left side above the workbench, a pressing device is set on the right side of the atomizing device, a sticking device is set on the right side of the pressing device, and inside the workbench There is a conveyor table on the left side, a sloping plate on the right side of the conveyor table, smooth conveying rollers on the inner side of the connection between the right end of the conveyor table and the sloping plate, a pressing chamber on the right side of the swash plate, and a chute seat on the right side of the pressing chamber. The right side of the chute seat is provided with a baffle plate, the right side of the baffle plate is provided with a posting platform, and the right side of the posting platform is provided with an arc-shaped plate; the present invention has the advantages of smooth pressing, convenient and fast use, simple operation and neat posting.

Owner:JIYUAN POWER SUPPLY COMPANY OF STATE GRID HENAN ELECTRIC POWER

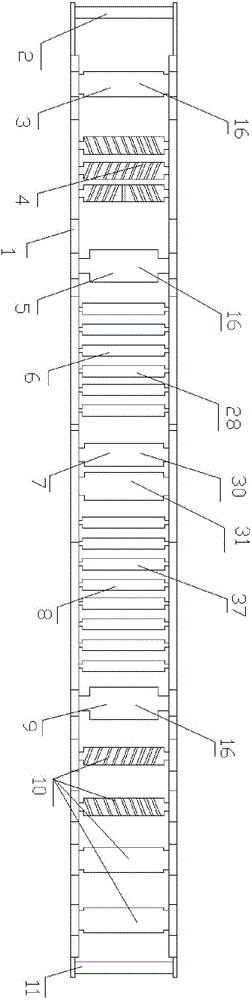

Roller press mechanism for external protection layer sheet production

ActiveCN106739425AGuaranteed flatnessQuality improvementLamination ancillary operationsLaminationProtection layerSheet material

The invention relates to a roller press mechanism for external protection layer sheet production. The roller press mechanism comprises a base, wherein a first reversing rotary shaft, a first reversing mechanism, a first laminating mechanism, a second reversing mechanism, a second laminating mechanism, a third reversing mechanism, a third laminating mechanism, a fourth reversing mechanism, an exhaust mechanism and a second reversing rotary shaft are sequentially arranged on the base; an external protection layer sheet to be laminated is sequentially reversed, laminated and exhausted through the first reversing rotary shaft, the first reversing mechanism, the first laminating mechanism, the second reversing mechanism, the second laminating mechanism, the third reversing mechanism, the third laminating mechanism, the fourth reversing mechanism, the exhaust mechanism and the second reversing rotary shaft, and is then collected and coiled through a coiling mechanism. The roller press mechanism is used for laminating and forming the external protection layer sheet, and is operated automatically, so that the work efficiency and the product quality are improved, and the smoothness of a product is improved.

Owner:江苏玖尚新材料有限公司

A kind of preparation method of rayon product imitation tencel

ActiveCN108560102BSmall shrinkageReduce deformationSucessive textile treatmentsDyeing processTextile printerDesizing

The invention discloses a method for preparing rayon product imitation tencel, comprising the following steps: weaving, singeing, enzymatic desizing, scouring, scouring and whitening, presetting, printing, baking, soft and non-ironing Finishing, calendering, pre-shrinking, and finished products. The shrinkage rate of the rayon product produced by the preparation method of the present invention is reduced, thereby reducing the deformation of the fabric when it is washed in the later stage; the pilling level is high, wear-resistant, and can achieve the smooth and wear-resistant effect of tencel; the wet strength is improved, which helps In the production process, the production efficiency is improved, the machine breakage is reduced, and the fabric holes are reduced during use; the product is used in a four-piece suit, replacing cotton and tencel products, and reducing the unit cost of the product.

Owner:NANJING MENGQIRUI DIGITAL WEAVING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com