Stitching equipment for shoe product and process for implementing stitching by adopting same

A product and equipment technology, which is applied in the field of sewing equipment for shoe products, can solve problems such as uneven force on beading, impact on yield, and time-consuming problems, and achieve the effects of increasing yield, reducing requirements, and reducing training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

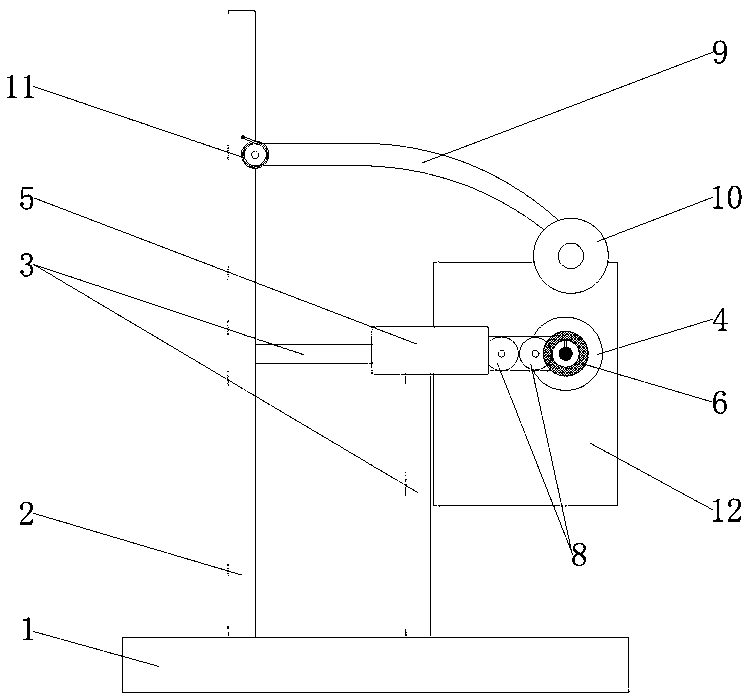

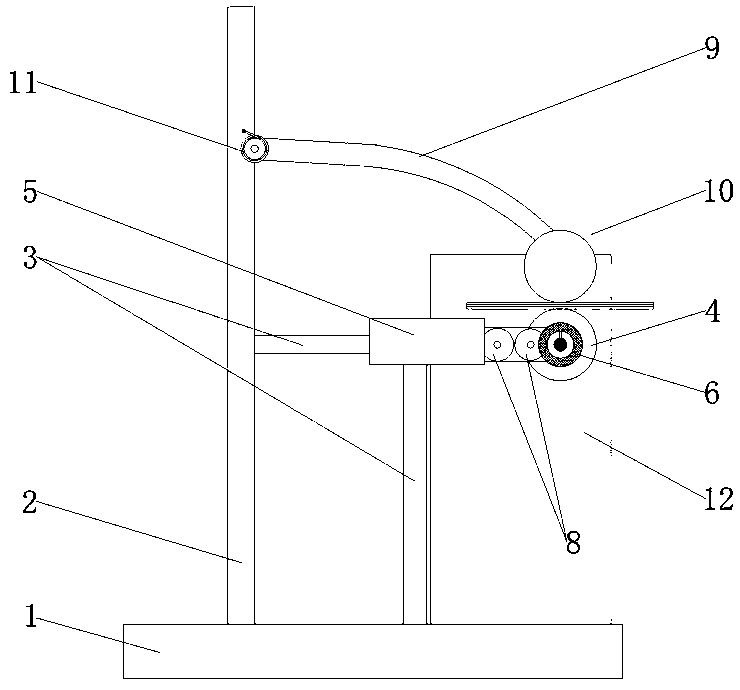

[0018] refer to figure 1 As shown, the above-mentioned pre-tensioning mechanism has two implementation modes: Mode 1: the pre-tensioning mechanism is the second bracket 9, and the second bracket 9 presses the driving wheel 4 downward by its own weight. Mode 2: The pre-tightening mechanism is a torsion spring 11 hinged at the swing joint between the second bracket 9 and the main bracket 2 .

[0019] refer to figure 1 , figure 2 As shown, in order to facilitate pressing, the second bracket 9 protrudes downward in an arc shape, and the driven wheel 10 is arranged at the end of the second bracket 9 .

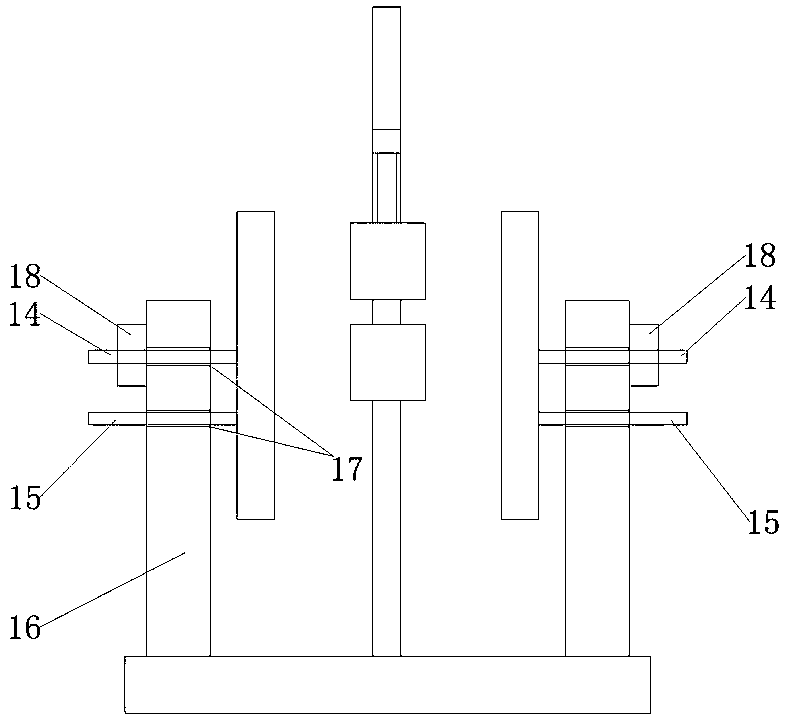

[0020] refer to figure 1 , image 3 As shown, in order to be able to adjust the limit plate 12, and to regulate the direction in which the shoes are pulled through the limit plate 12, so that the pressing edge 13 is more uniform and regular, both sides of the first bracket 3 and the second bracket 9 are provided with limit stops. Support 16, limit plate 12 is arranged on the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com