Carton cracking-proof line spraying system

A sprinkler system and anti-explosion line technology, which is applied in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of carton surface paper burst line, poor carton forming, low pass rate, etc. Production cost, effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

[0023] It should be noted that, unless otherwise specified, the technical terms or scientific terms used in this application shall have the usual meanings understood by those skilled in the art to which the present invention belongs.

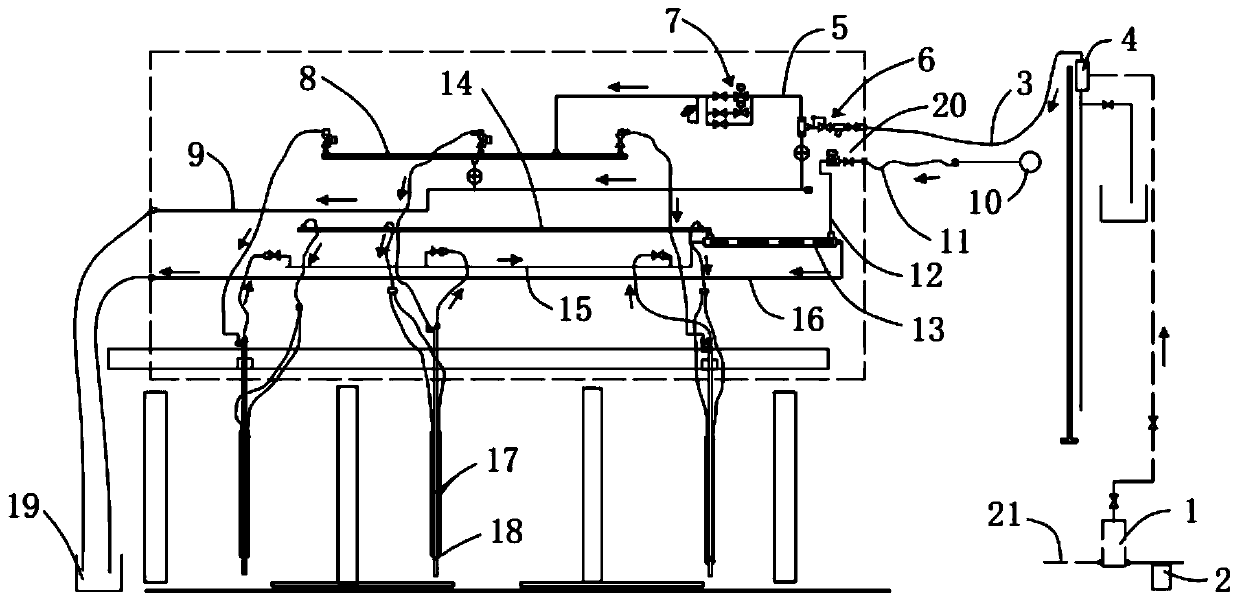

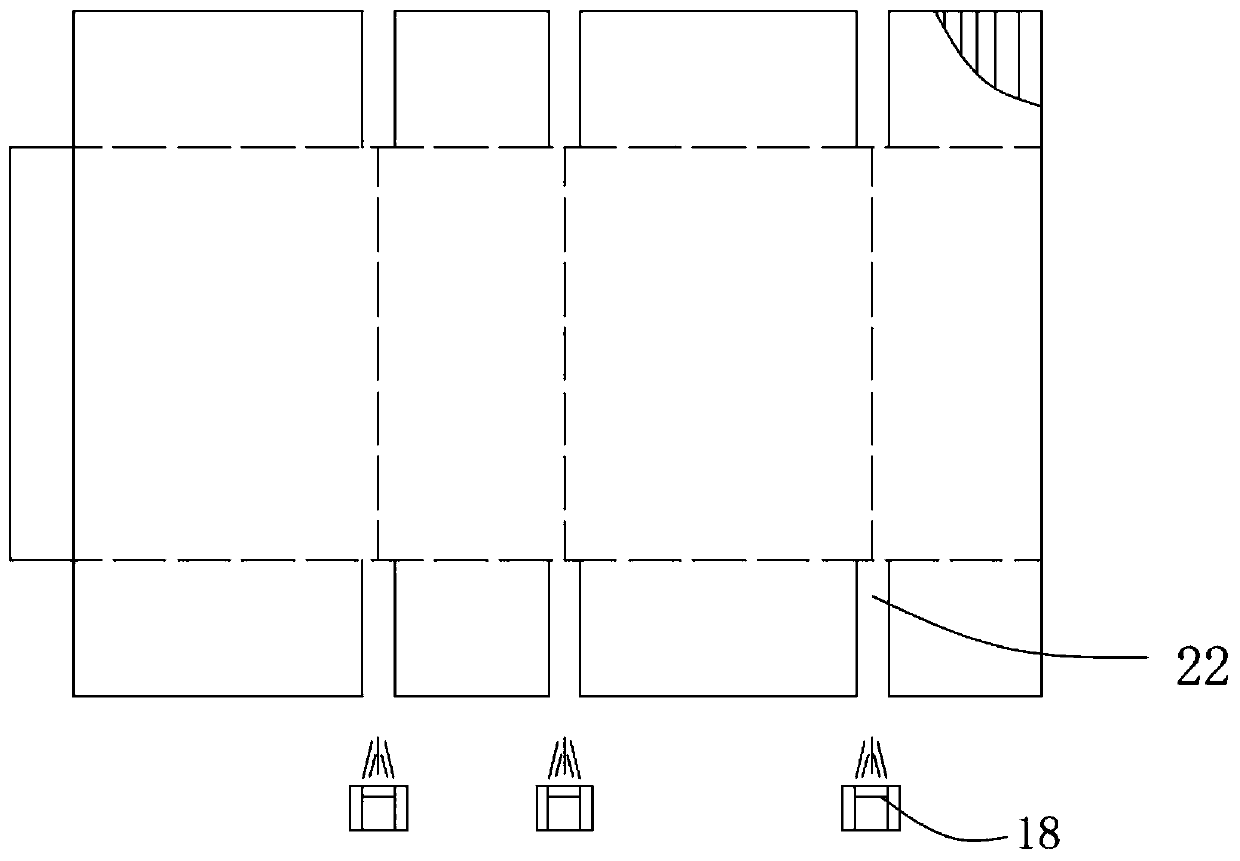

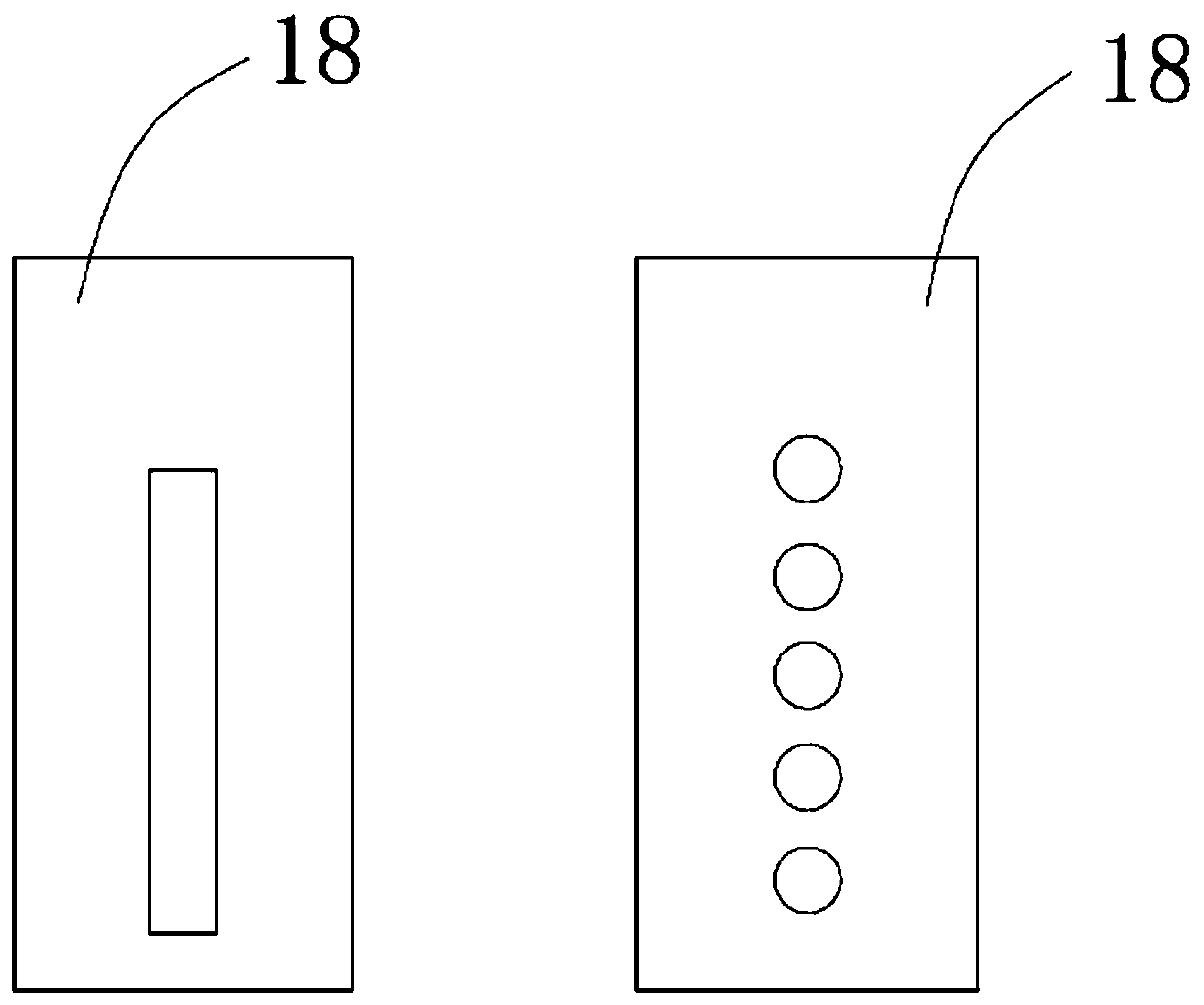

[0024] Such as figure 1 As shown, the arrow in the figure is the direction of medium flow, and other components in the figure are common components in this field, such as stop valve and pressure regulating valve; a carton explosion-proof line spray system, characterized in that: It includes a steam production device, a main pipeline 3 for transporting steam, a flow on-off valve 4 fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com