Insertion box pasting mold and using method thereof

A mold and box insertion technology, which is applied in box making operations, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of time-consuming and material consumption in the production process, low quality of inserting boxes, and low production efficiency, and achieves improved adhesion. effect, reduce material consumption and labor consumption, and facilitate the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

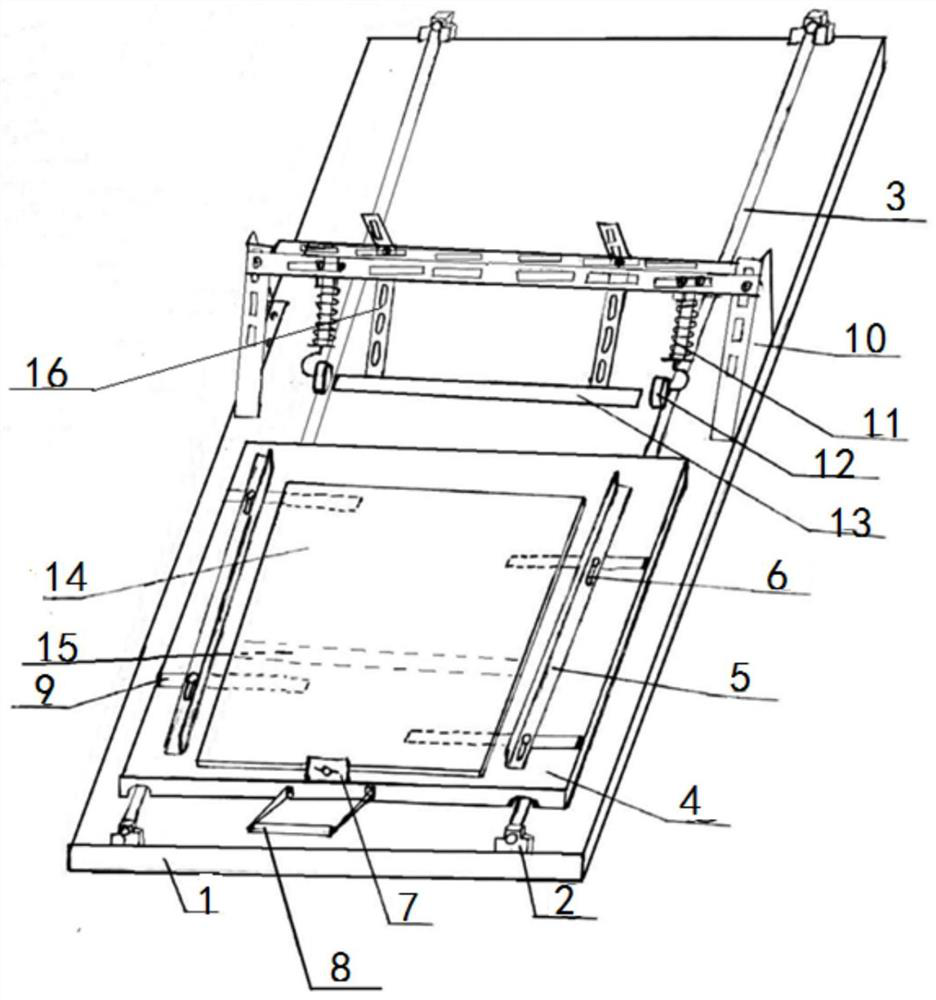

[0046] refer to figure 1 , a plug-in box sticking mold provided by the present invention includes an operation platform 4 connected to the base 1 through a sliding structure, and a spreader mold 14 is connected to the operating platform 4 through a turnable spreader mold clamp 7, and the spreader mold 14 Both sides are connected with a width limiting plate 5 through an adjustment structure, and a locking buckle 6 is connected to the width limiting plate 5, and a baffle plate 15 is connected to the bottom of the supporting plate mold 14 through a detachable connector; the base 1 is also connected to a bridge frame 10 , the bridge frame 10 is connected with a pressing structure for pressing the sticking surface of the plug-in box and a box-unloading structure for removing the pasted plug-in box from the supporting plate mold 14 .

[0047] When using the insert box sticking mold in this application to process the insert box, firstly according to the width of the insert box, the w...

Embodiment 2

[0052] Based on Example 1, with reference to figure 1 , the sliding structure of this embodiment includes a slide bar 3 support 2 connected to the base 1, a slide bar 3 is connected to the slide bar 3 support 2, and a displacement groove 9 that is engaged with the slide bar 3 is provided at the bottom of the operating platform 4.

[0053] When pushing the operating platform 4 to move forward or return to the initial position, the operating platform 4 can slide on the slide bar 3 through the displacement groove 9 at the bottom.

[0054] This application makes the operation platform 4 move by setting the displacement groove 9 at the bottom of the operation platform 4, which simplifies the installation method of the sliding structure and reduces the production cost of the whole equipment. Platform 4 is more stable during sliding.

Embodiment 3

[0056] Based on Example 1, with reference to figure 1 , the adjustment structure of this embodiment includes a slide rail arranged on the operating platform 4 , a slide block that moves in cooperation with the slide rail is connected to the width limiting plate 5 , and the slide block is connected with the locking buckle 6 .

[0057] When it is necessary to adjust the distance between the width limiting plates 5 to fit the width of the box, the staff releases the locking buckle 6 and pushes the width limiting plates 5 to make the slider connected to the bottom of the width limiting plates 5 Move in the slide rail, after the width limiting plate 5 moves to the specified position, the staff can lock and fix the width limiting plate 5 through the locking buckle 6, the installation structure is simple, and the operation is also very convenient. The fixing effect of the width limiting plate 5 is also very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com