Stator cramp machining device

A processing device and buckle technology, applied in the field of mechanical processing, can solve problems such as low efficiency and poor processing continuity, and achieve the effect of high process efficiency and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

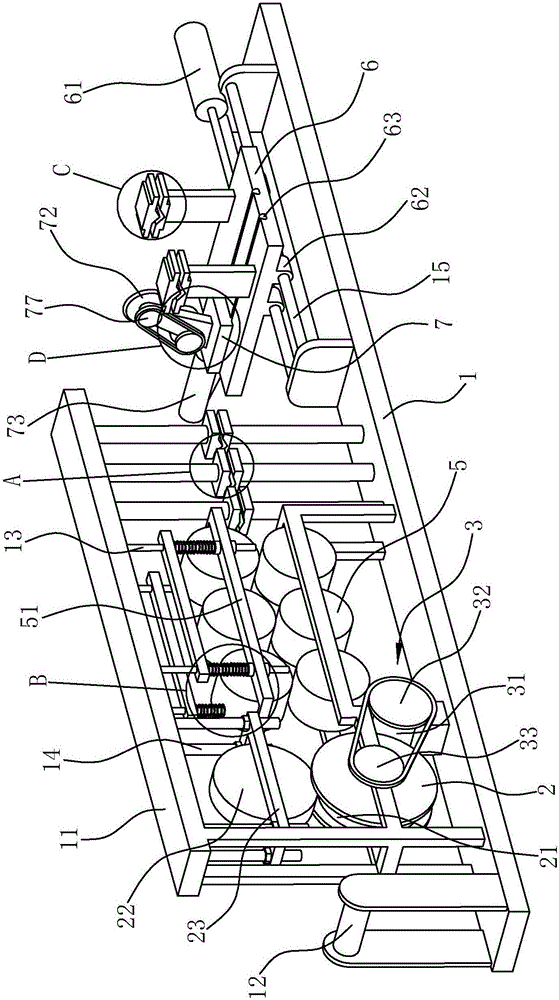

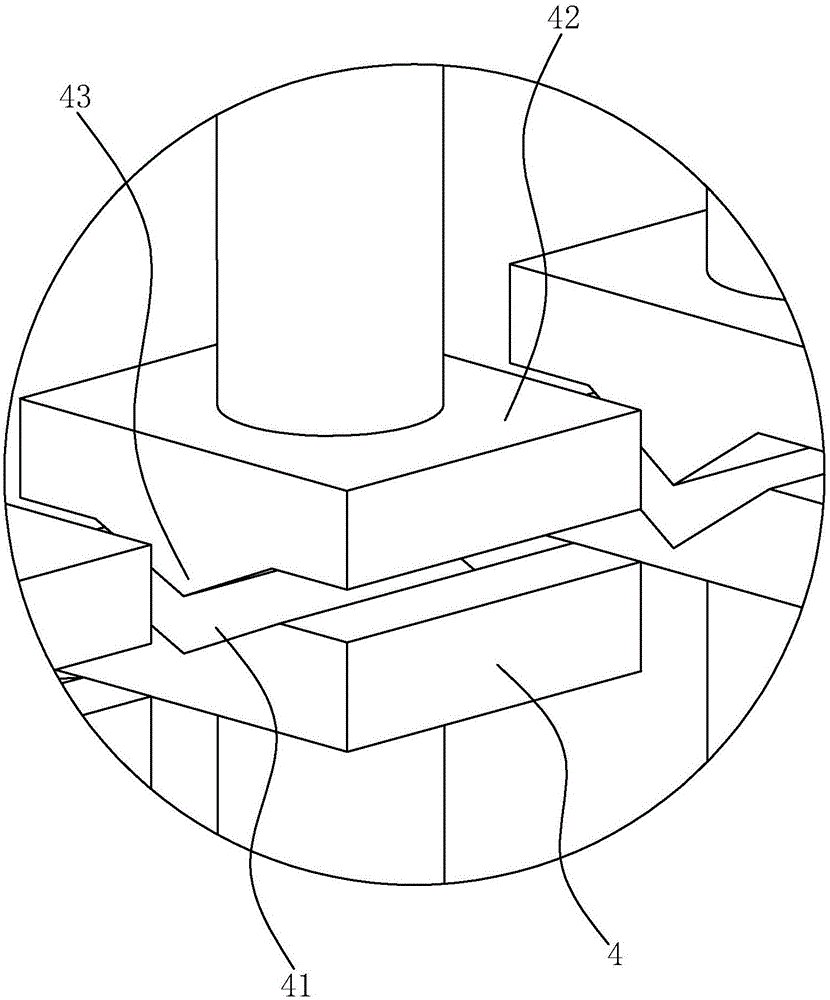

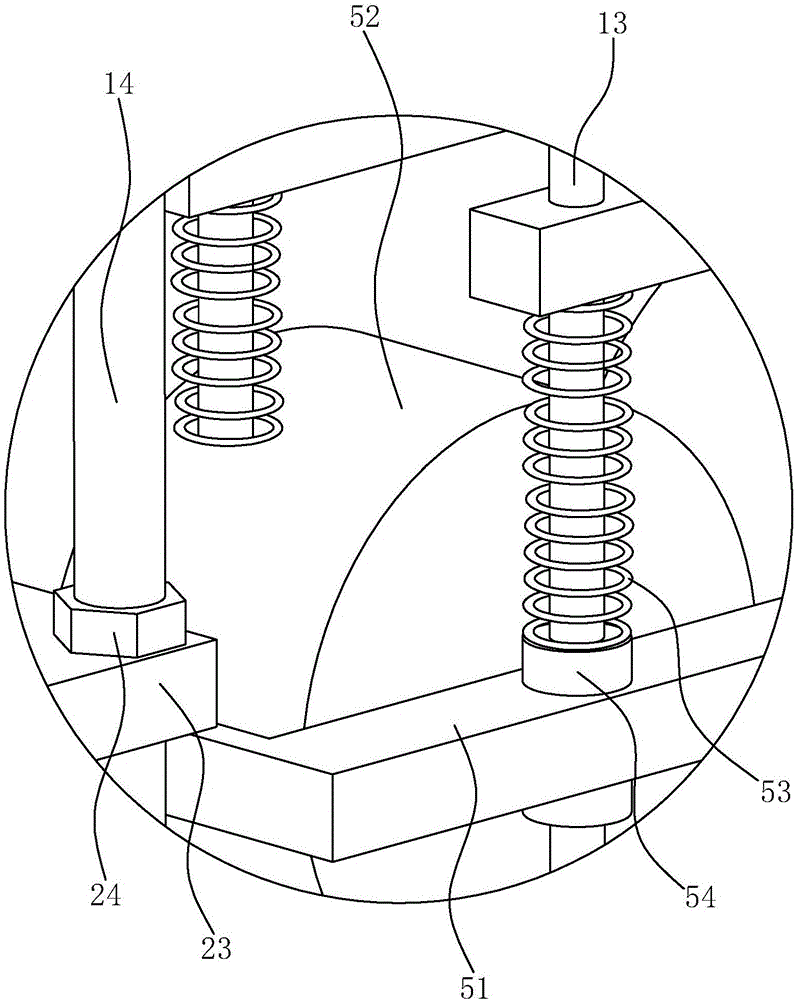

[0028] like Figure 1 to Figure 6 As shown, a stator buckle processing device includes a strip-shaped base 1, which is connected with a frame 11, and the front end of the base 1 is rotatably connected with a positioning shaft 12 for positioning the stainless steel sheet reel. The drive wheel 2 is connected in rotation, and the frame 11 is rotatably connected with a driven wheel 22 that can press the stainless steel sheet on the drive wheel 2 above the drive wheel 2, and the frame 11 is provided with a driving member that can drive the drive wheel 2 to rotate 3. A number of lower mold bases 4 are fixedly connected along the length direction on the base 1, and the upper sides of the lower mold bases 4 are provided with formi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com