Method for preparing bearing steel

A technology of bearing steel and ton steel, which is applied in the field of bearing steel preparation, can solve the problems that the steel performance is difficult to meet the strict standard requirements, and the non-metallic inclusions are unevenly distributed, so as to reduce the deoxidation task, ensure cooling, and reduce the harm of phosphorus Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

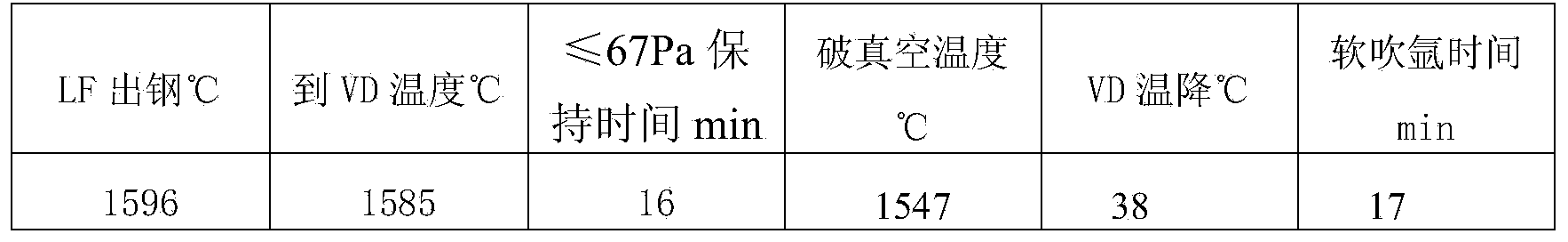

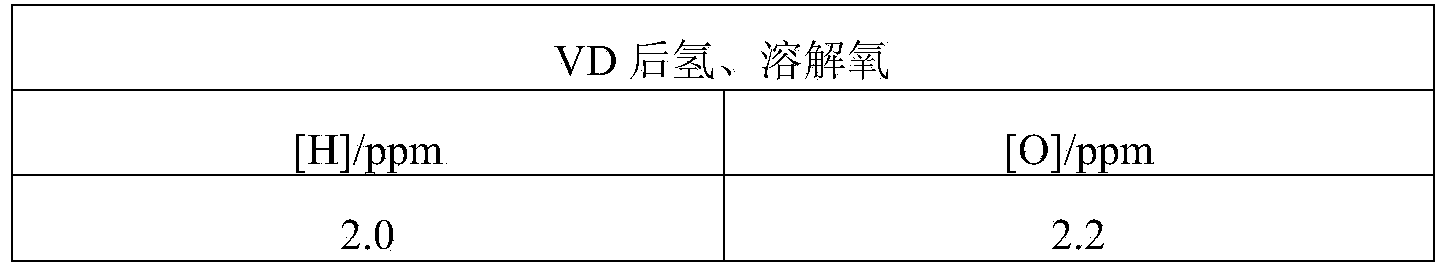

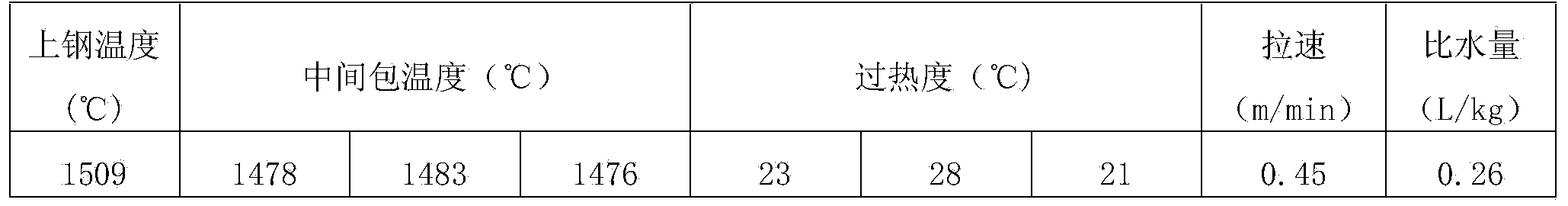

[0041] The preparation of embodiment 1, GCr15 bearing steel comprises steps as follows:

[0042] (1) Smelting and alloying

[0043] 50t electric furnace smelting

[0044] Requirements for the smelting process: produce during the good furnace service period, do not repair the furnace during the smelting process, do not use new ladles and new slag wire ladles; the baking temperature of the ladle before use is ≥800°C, and the oxygen pressure at the oxygen lance outlet is 1.2MPa;

[0045] The ingredients of the electric furnace are as shown in Table 1:

[0046] Table 1. Ingredients list Unit: (t)

[0047] lime

light burnt dolomite

scrap steel

molten iron

2.0

0.3

19.60

35

[0048] Electric furnace melting carbon: 1.06%, melting phosphorus 0.018%.

[0049] End point composition of electric furnace: end point carbon 0.37%, end point phosphorus 0.008%.

[0050] Tapping alloying: tap lime, fluorite and slagging agent (calcium aluminat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com