Patents

Literature

46results about How to "Reduce idle wait time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

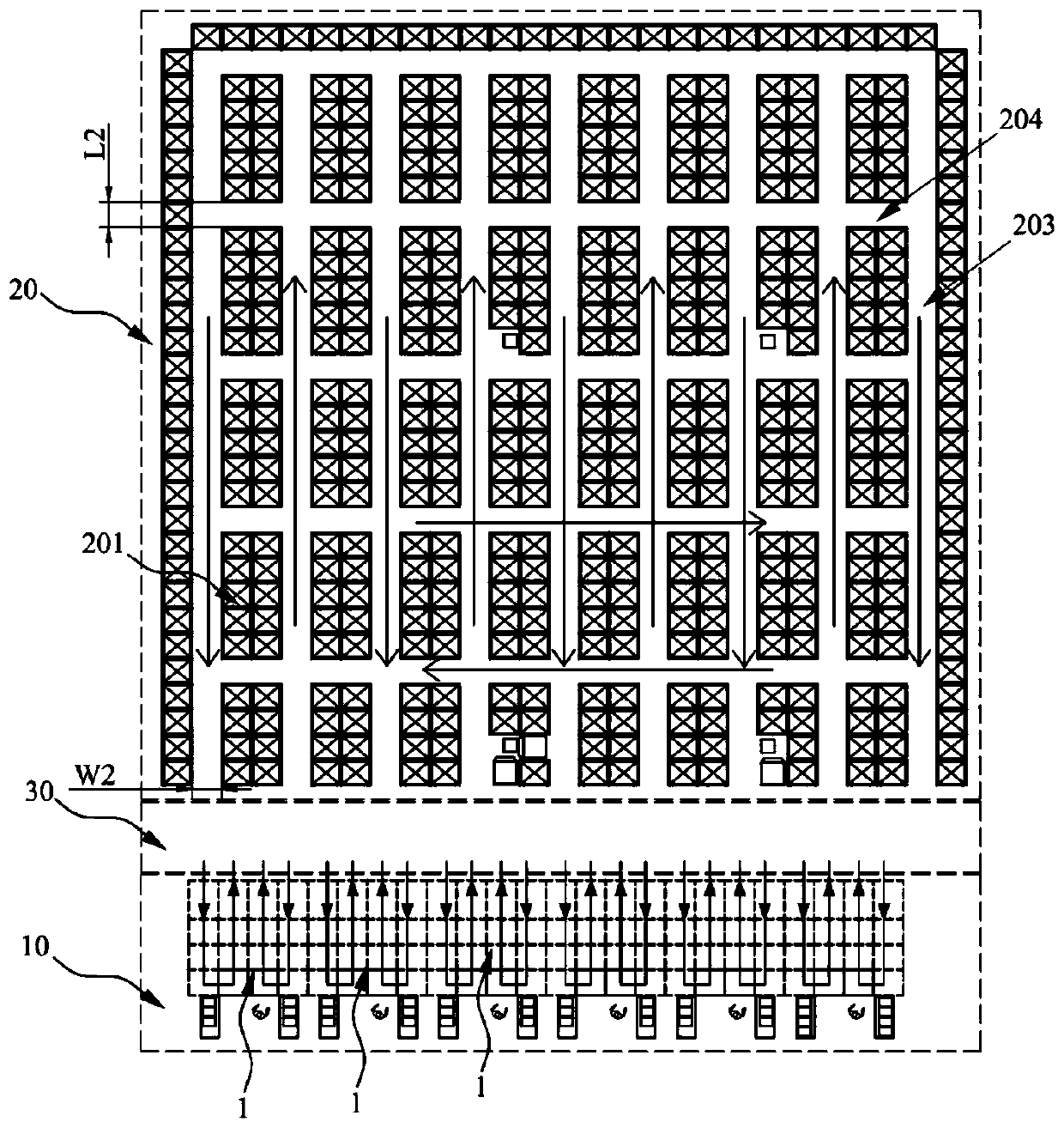

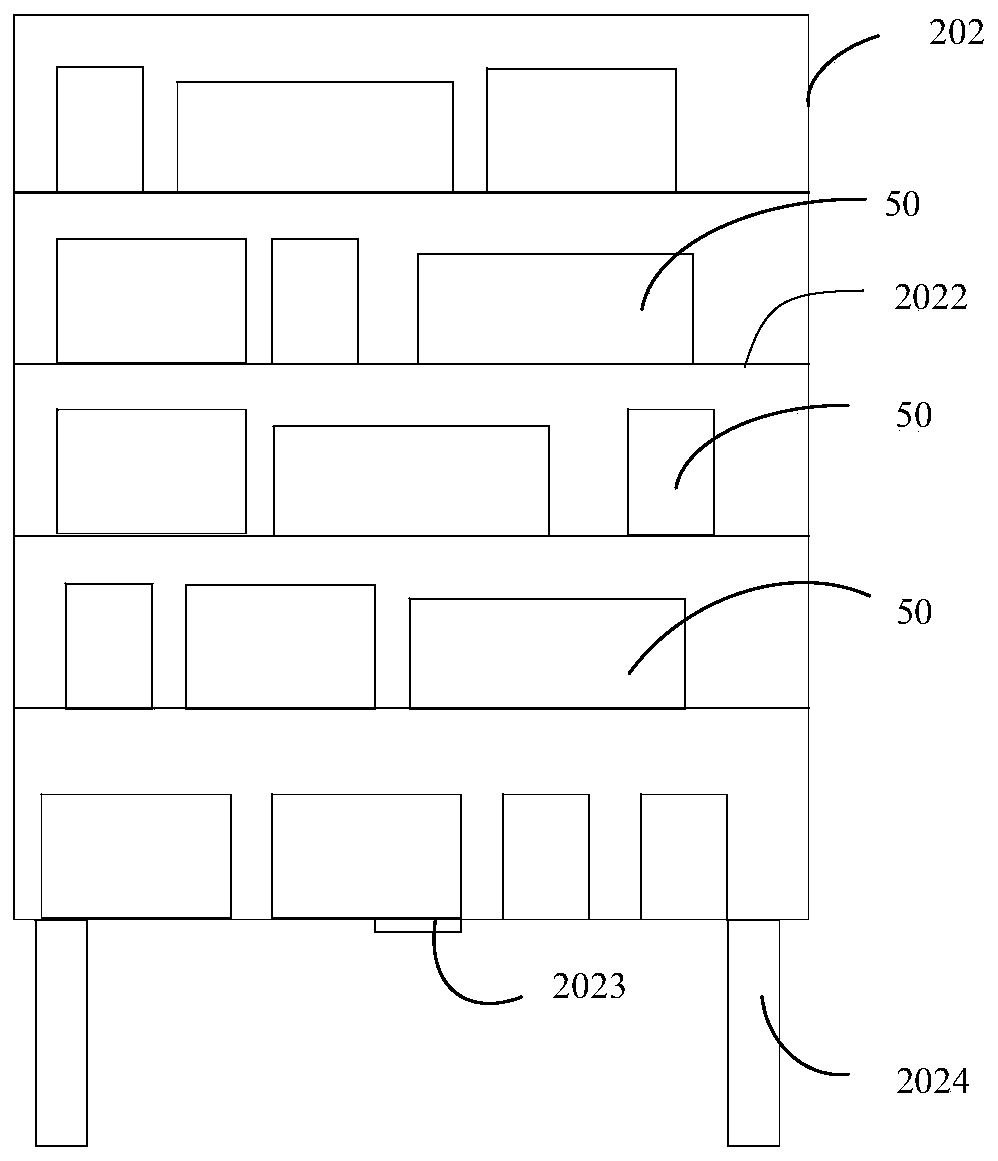

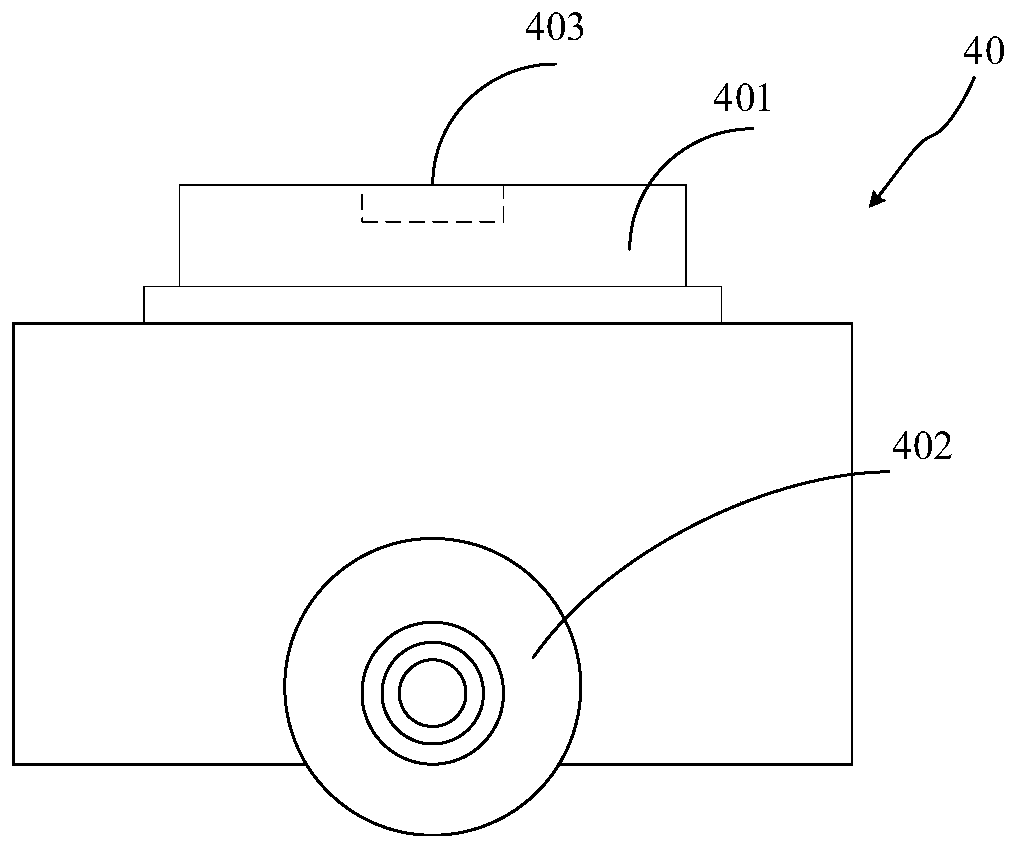

Sorting area and stock sorting system

The invention belongs to the technical field of storage logistics, and particularly discloses a sorting area and a stock sorting system. The sorting area comprises one or two sorting stations, at least one sorting station comprises two sorting channels and two sorting points located on the two sorting channels correspondingly, the sorting points allow a sorting main body to sort target cargos, thesorting channels allow a sorting robot to enter the sorting stations, pass through the sorting points in the sorting stations and then are away from the passage path of the sorting stations, and thestock sorting system comprises the sorting area and the stock sorting system, the goods sorting efficiency can be improved.

Owner:BEIJING JIZHIJIA TECH CO LTD

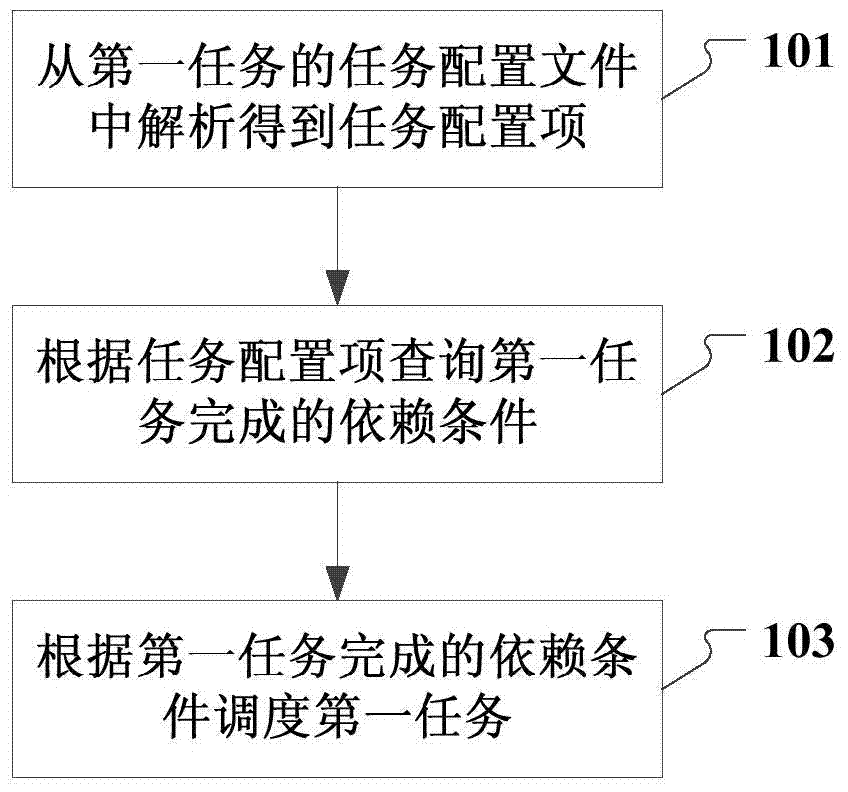

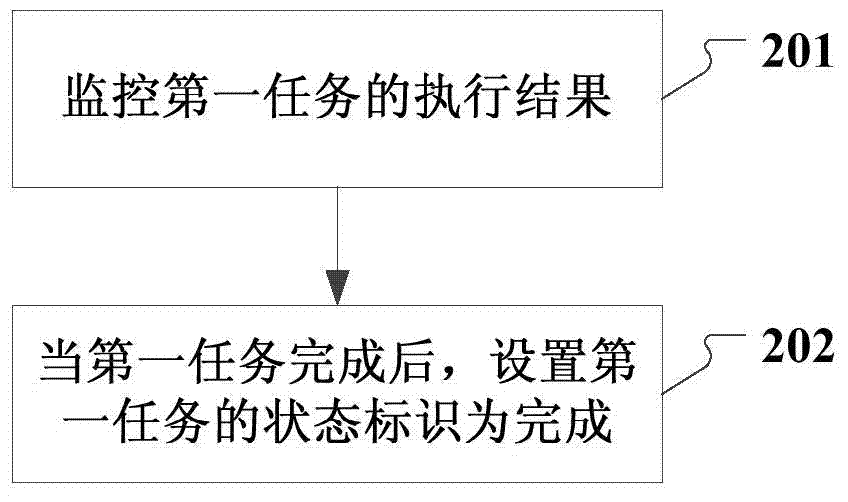

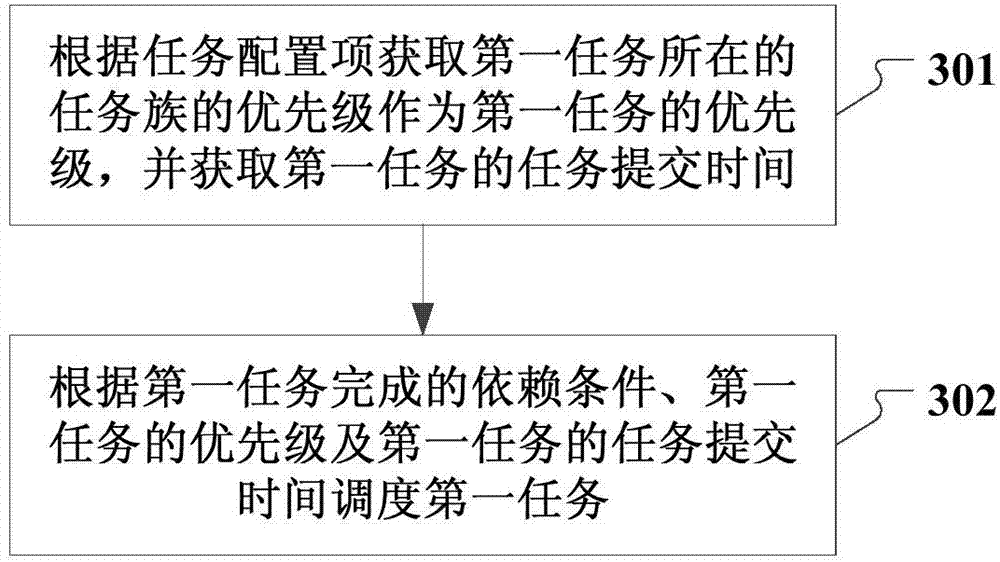

Task scheduling method and device

InactiveCN104714838AReduce complexityImprove system efficiencyProgram initiation/switchingDistributed computingConfiguration item

Owner:CHINA MOBILE GROUP SICHUAN

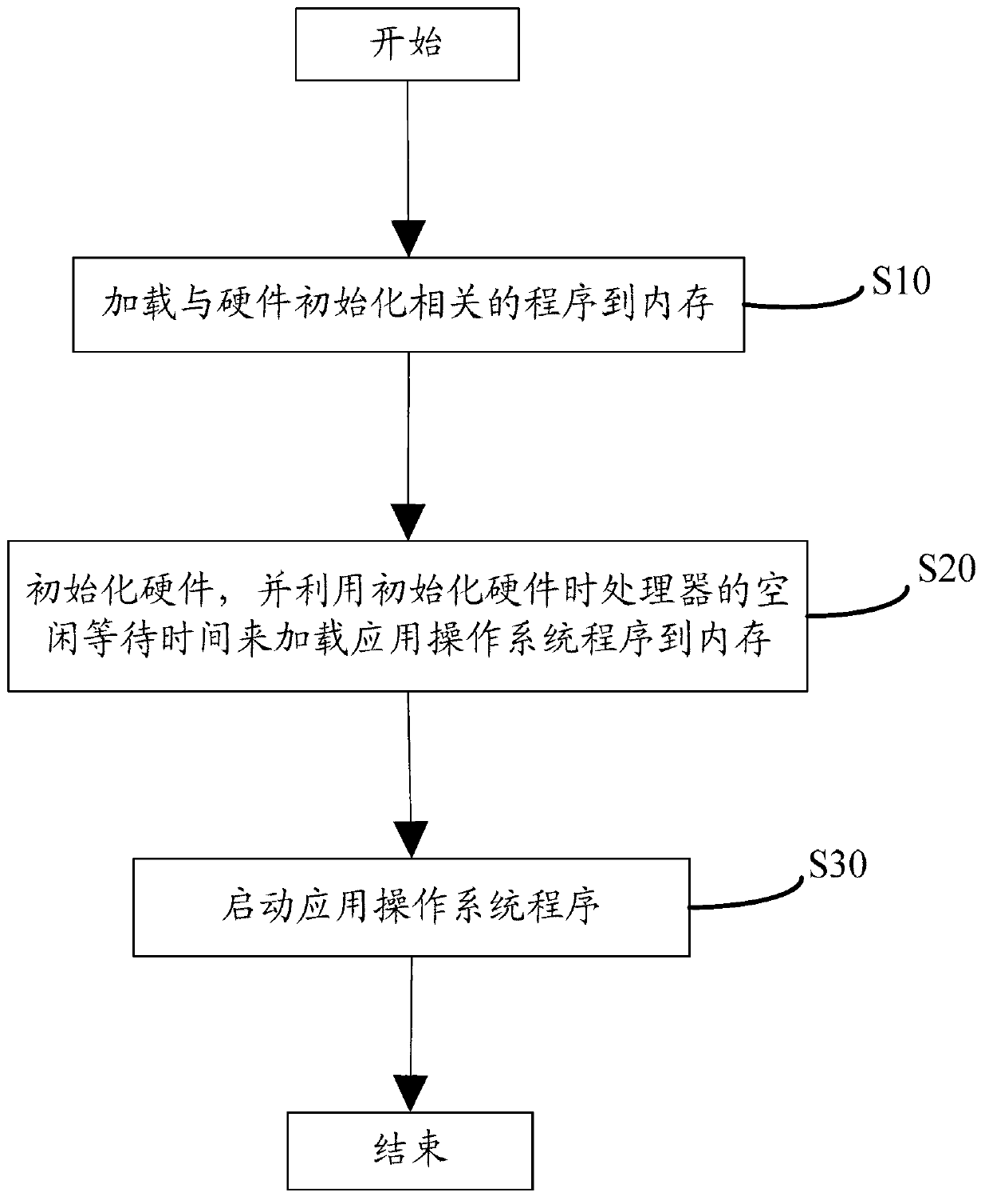

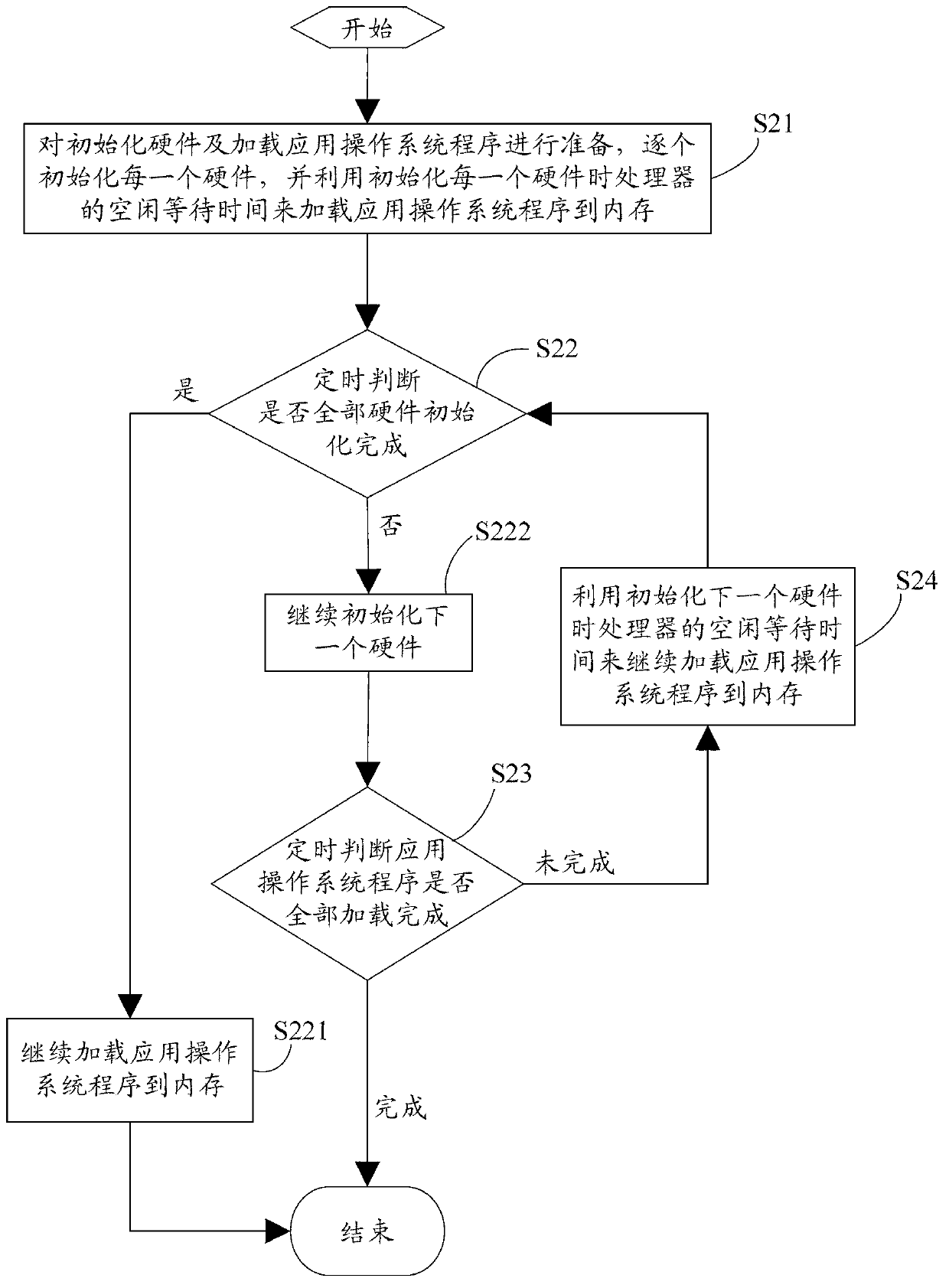

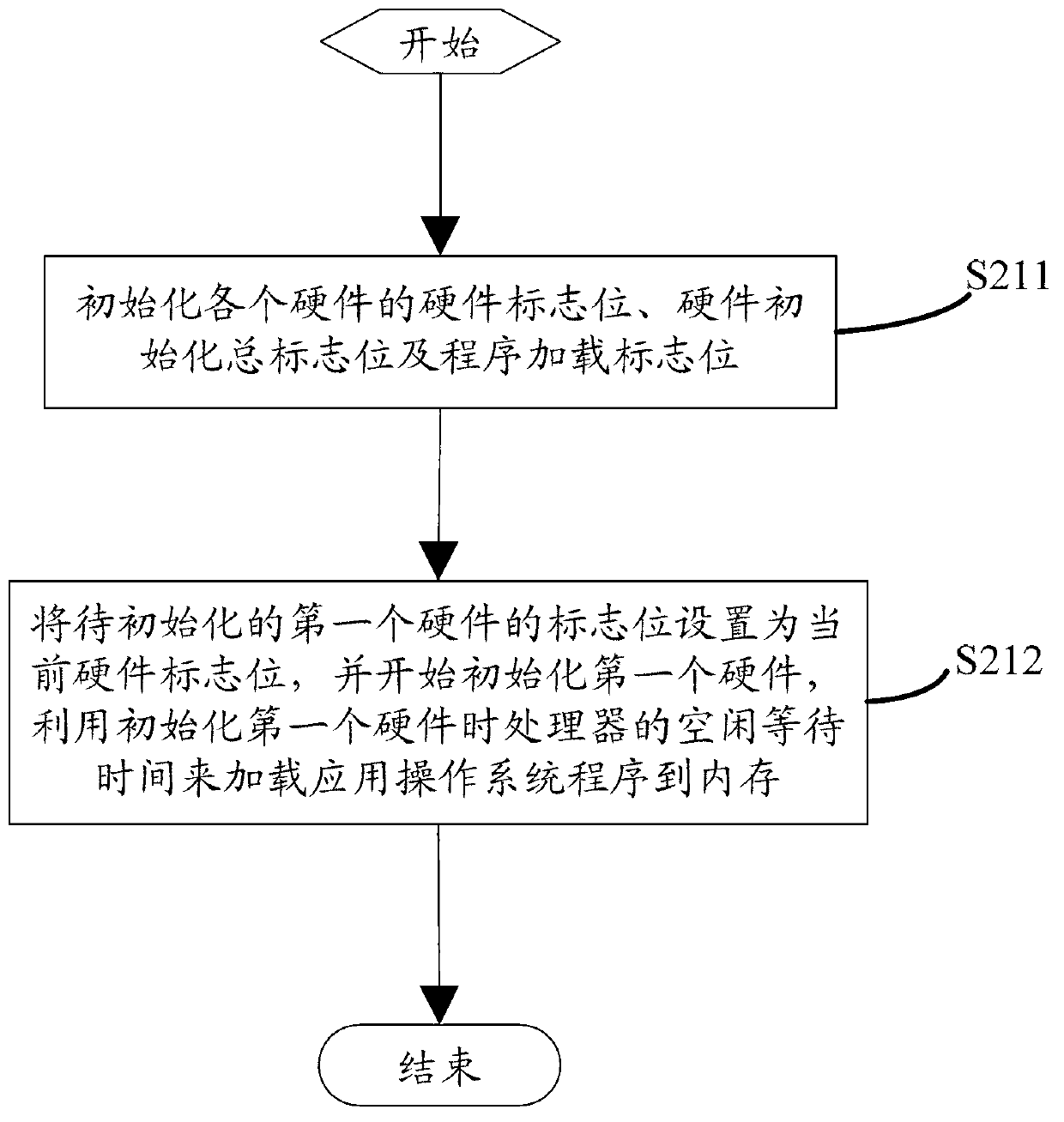

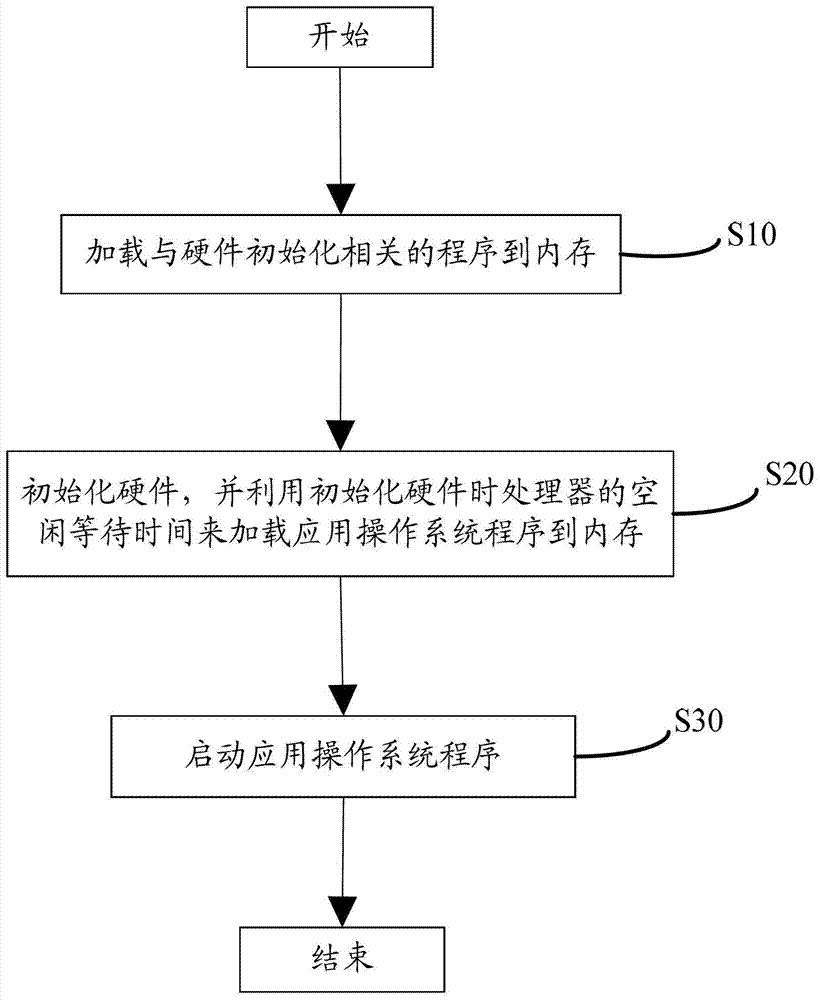

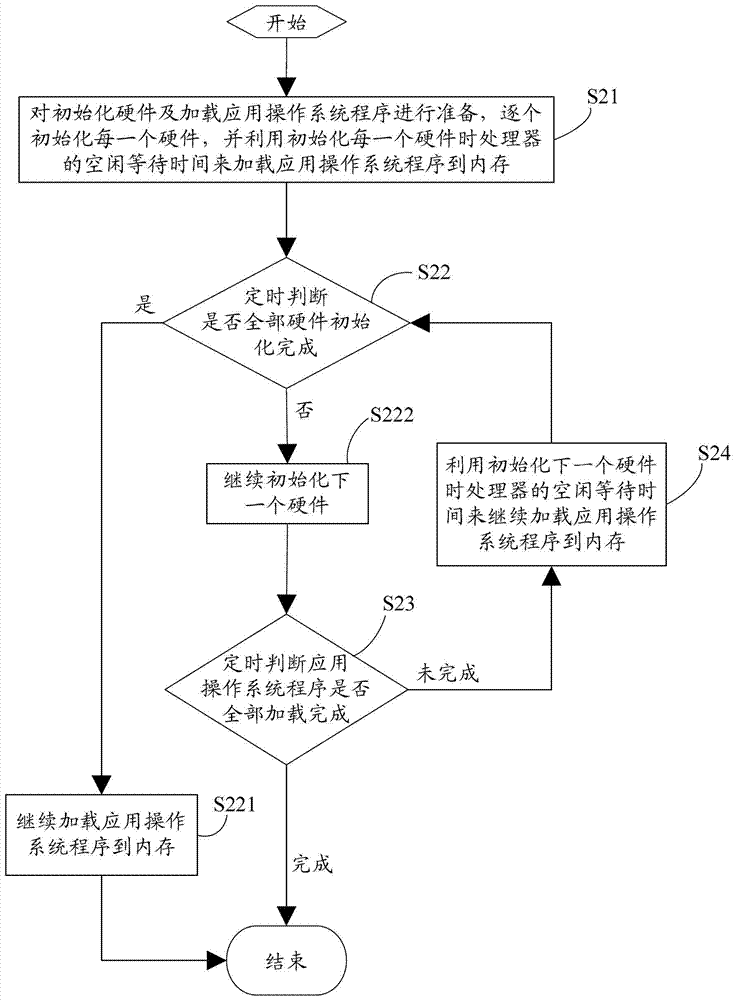

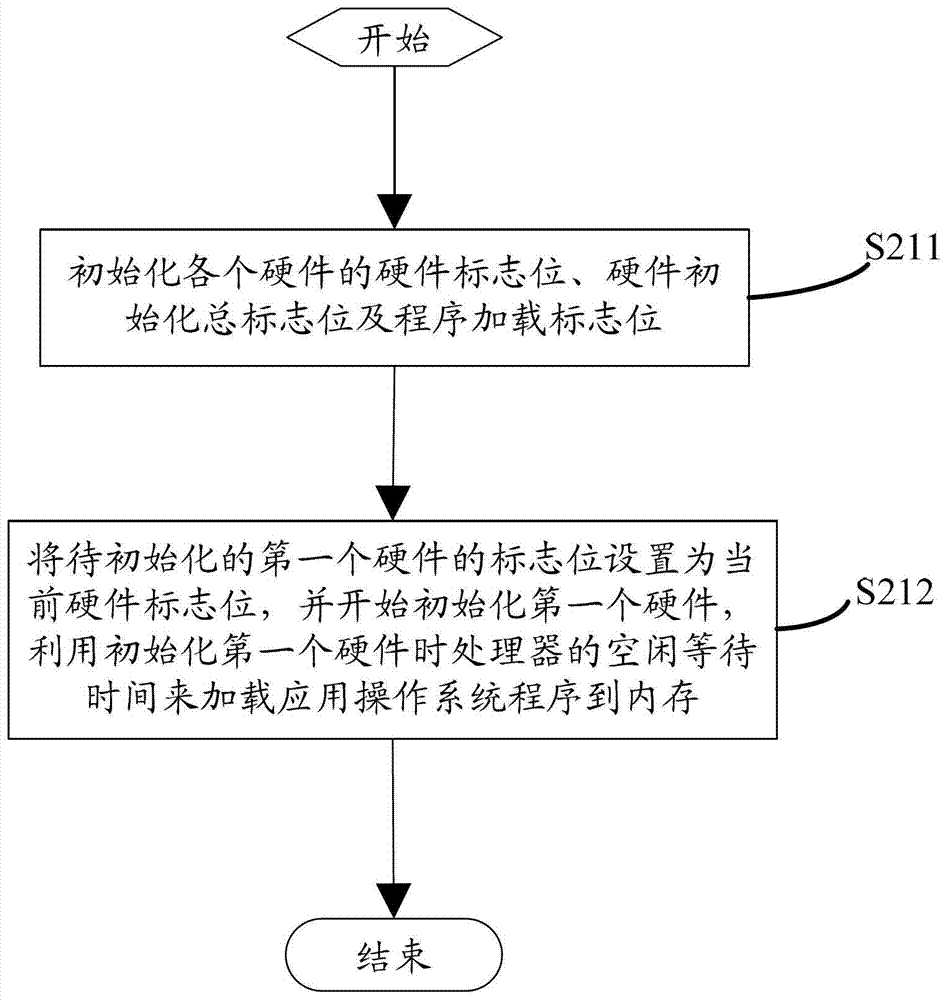

Method and system for fast boot of television

ActiveCN103002343AReduce boot timeImprove boot speedProgram loading/initiatingSelective content distributionComputer hardwareCable television

The invention provides a method for a fast boot of a television. The method for the fast boot of the television includes steps: loading a program related to hardware initialization to an internal storage; initializing hardware and using idle wait time of a processor during the initialization of the hardware to load an application operating program to the internal storage; and booting the application operating program after the hardware initialization and the application operating program loading are completed. The invention further provides a system for the fast boot of the television. By adopting the method and the system for the fast boot of the television, when the television boots, the idle wait time of the processor during the initialization of the hardware can be used fully, boot wait time is saved, a boot speed is improved greatly, and product competitiveness is increased.

Owner:SHENZHEN TCL NEW-TECH CO LTD

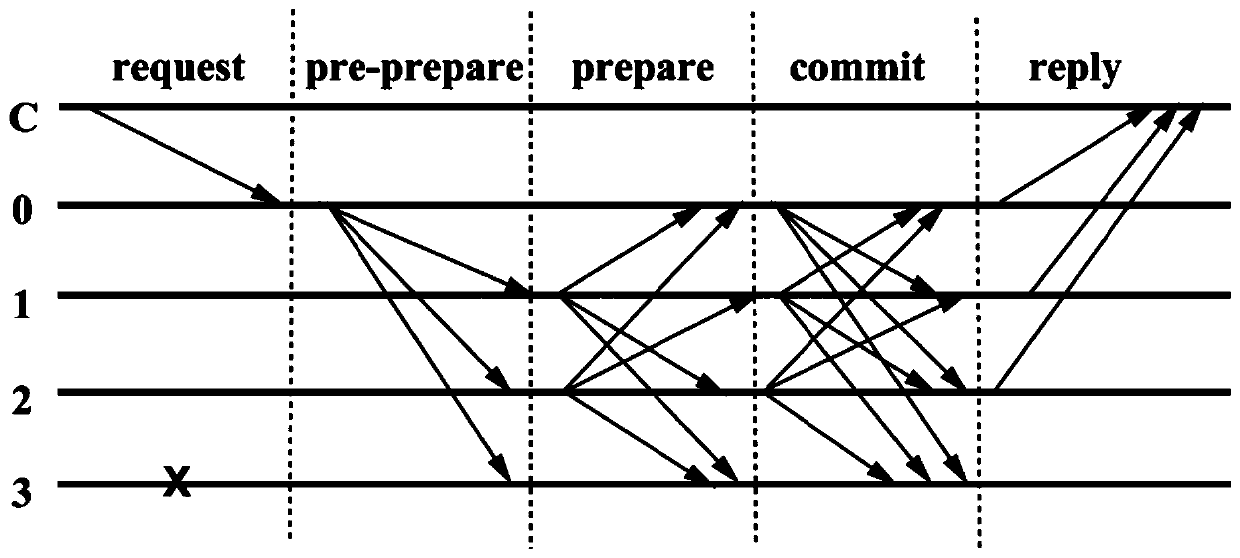

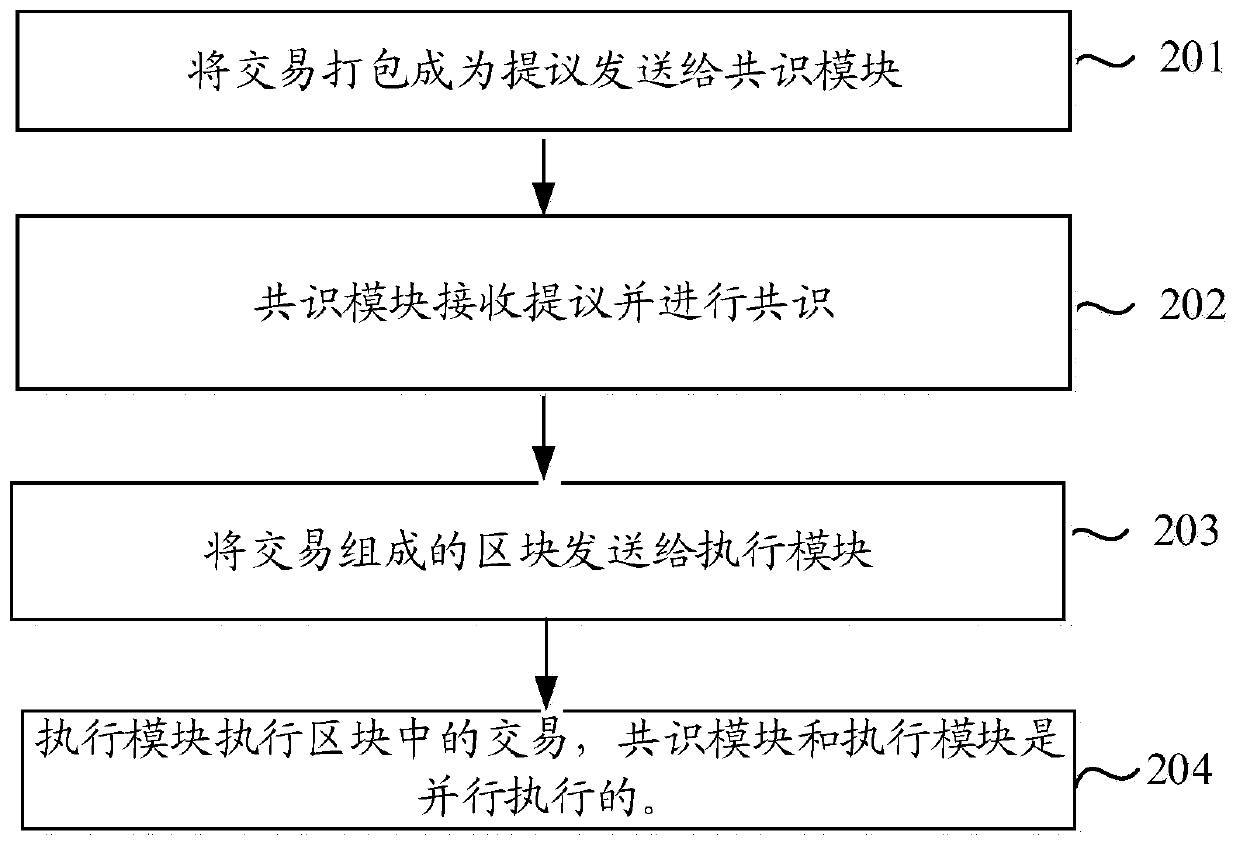

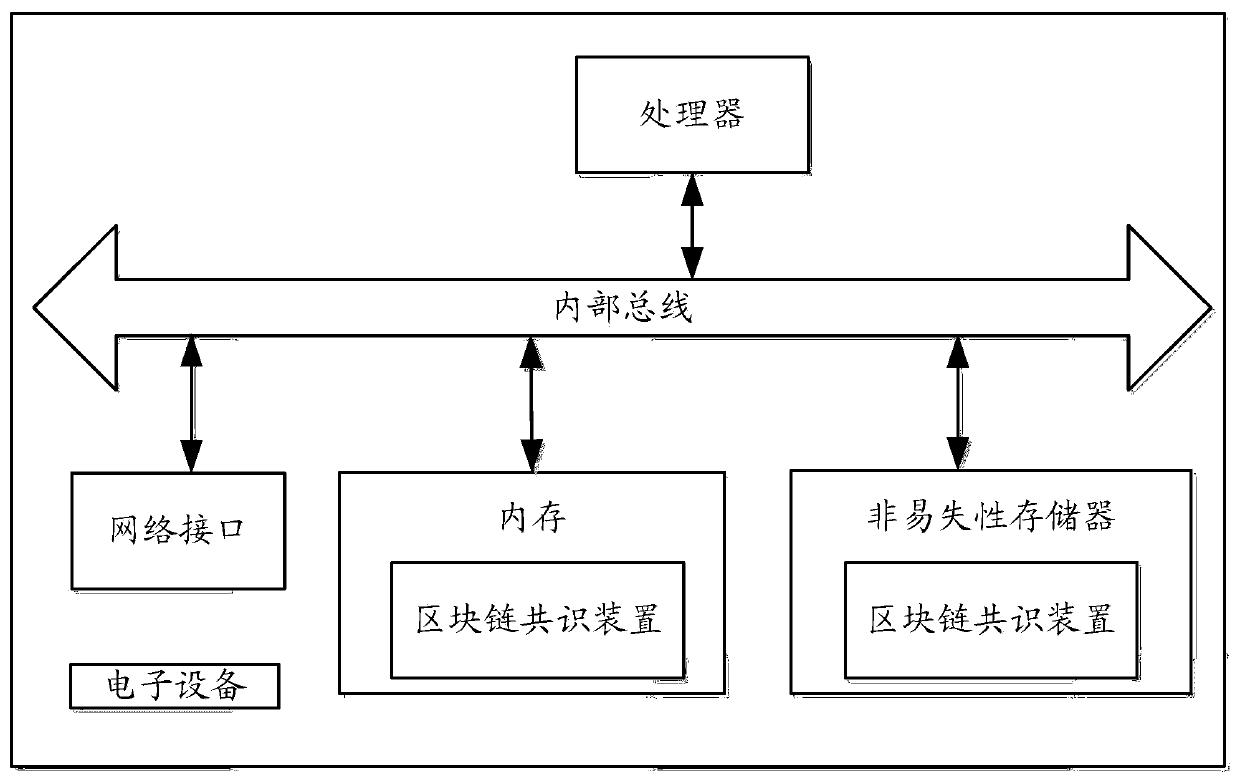

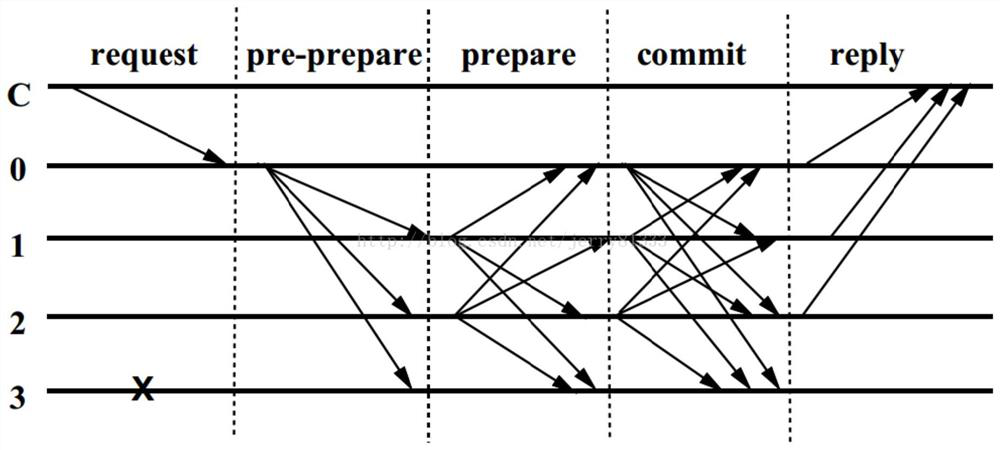

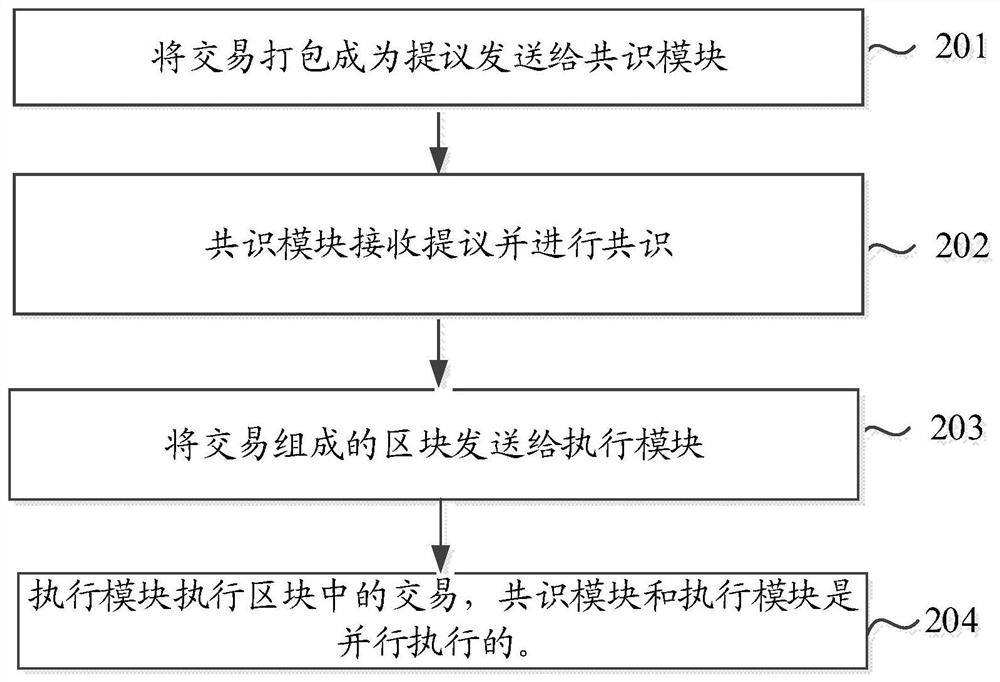

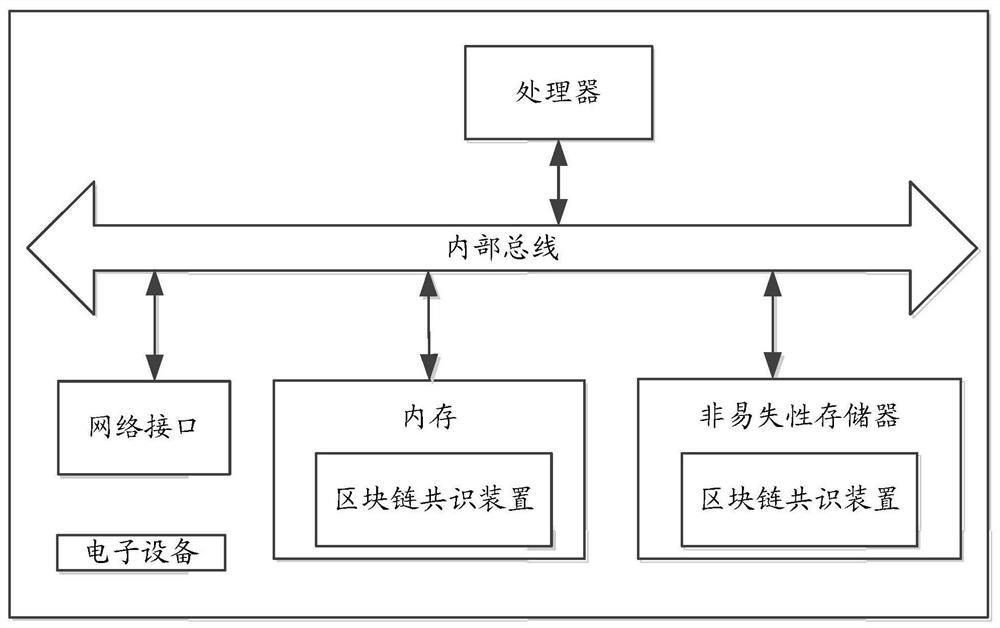

Parallel execution block chain consensus method and device and electronic equipment

ActiveCN110020859AReduce idle wait timeImprove work efficiencySpecial service provision for substationPayment protocolsIdle timeComputer module

Embodiments of the invention disclose a parallel execution block chain consensus method and device, and electronic equipment. The method comprises the steps of packaging a transaction into a proposal,and sending the proposal to a consensus module; enabling the consensus module to receive the proposal and carry out consensus; sending a block composed of the transactions to an execution module; enabling the execution module to execute a transaction in the block, wherein the consensus module and the execution module are executed in parallel. According to the method provided by the embodiment ofthe invention, the idle time of the execution module is reduced, and the working efficiency of the system is improved.

Owner:杭州秘猿科技有限公司

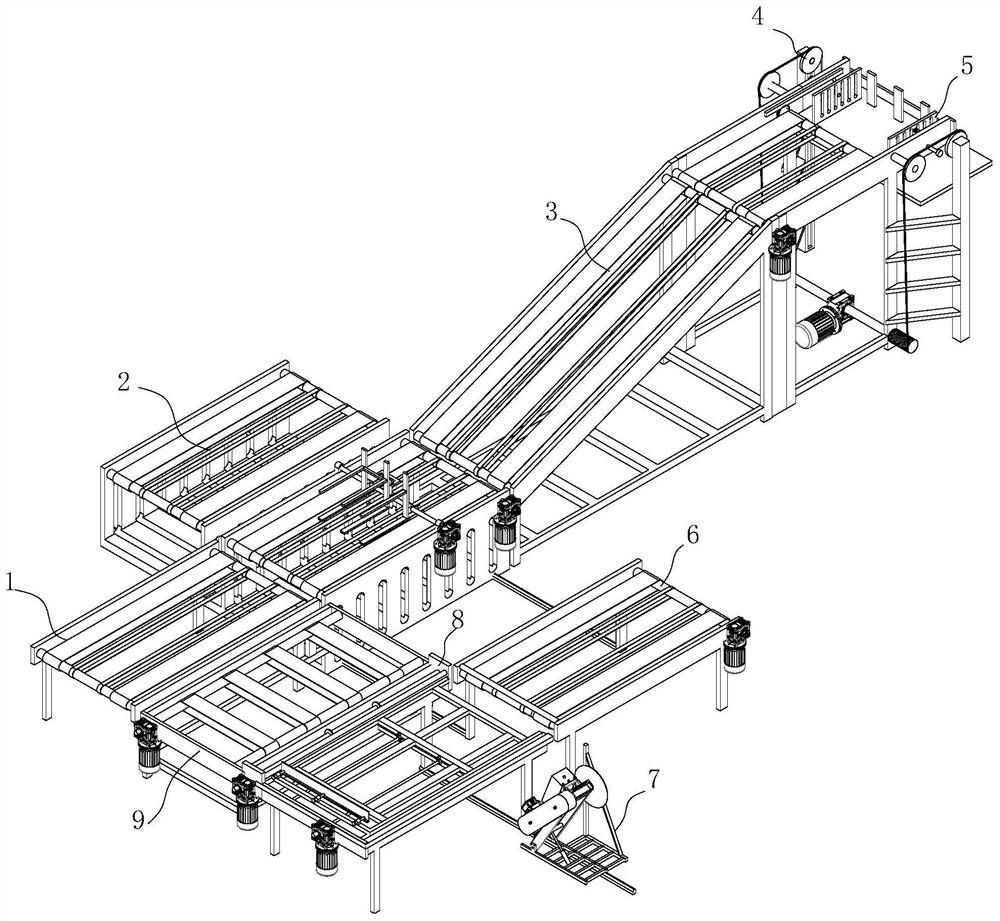

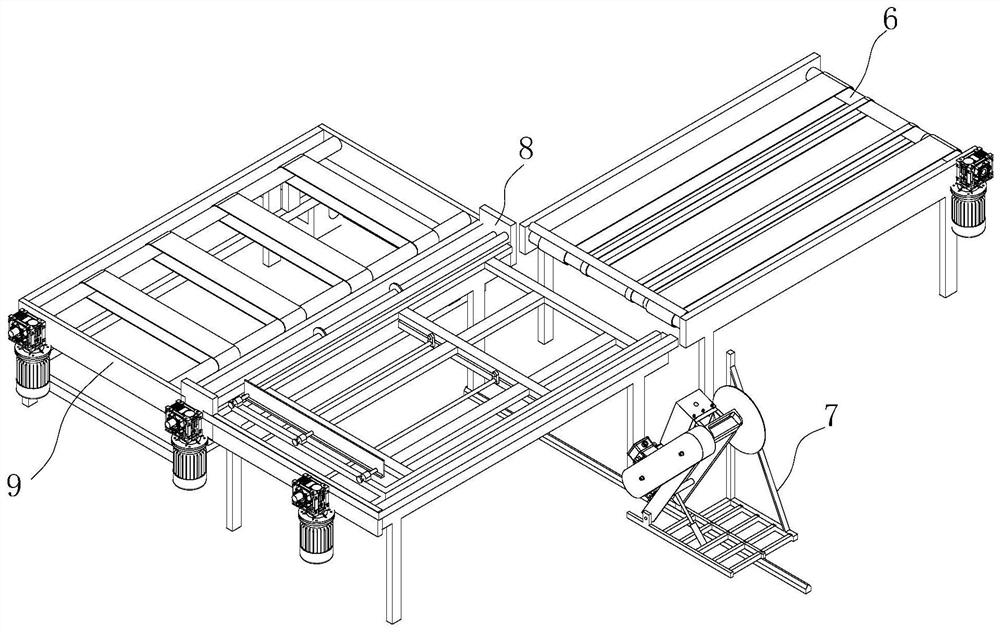

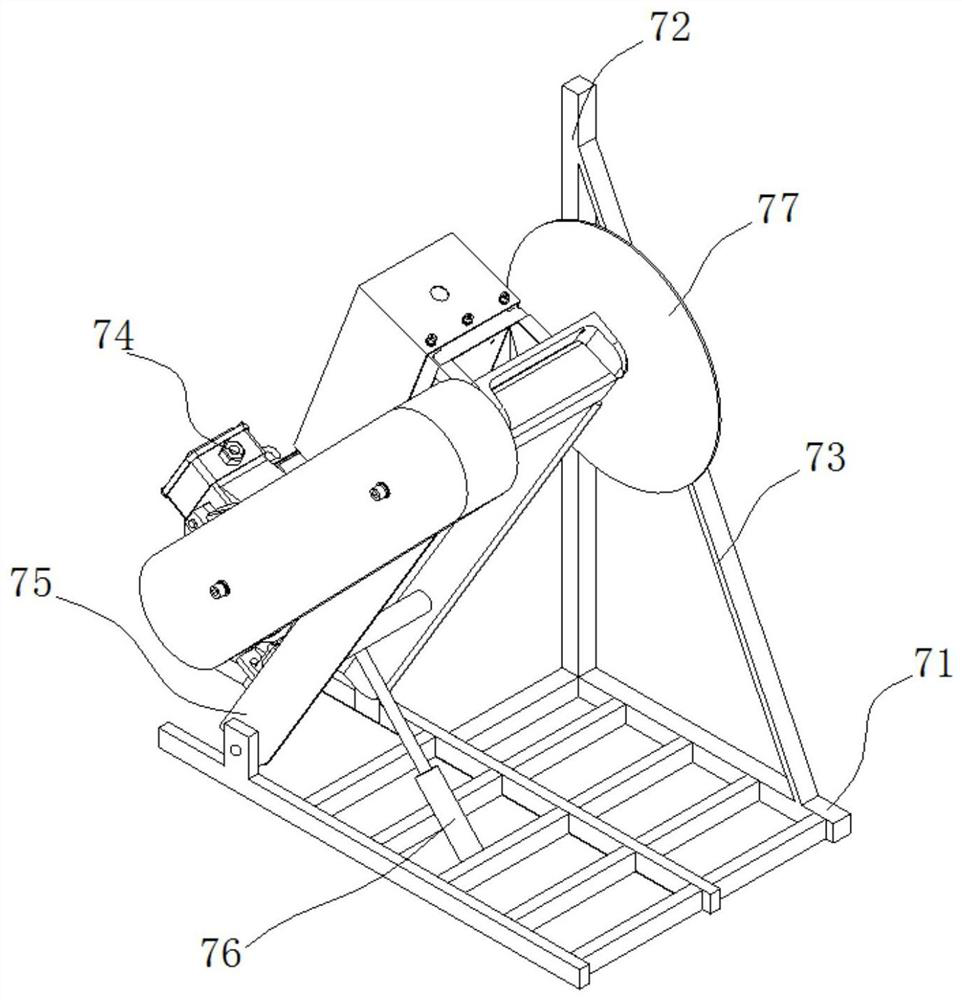

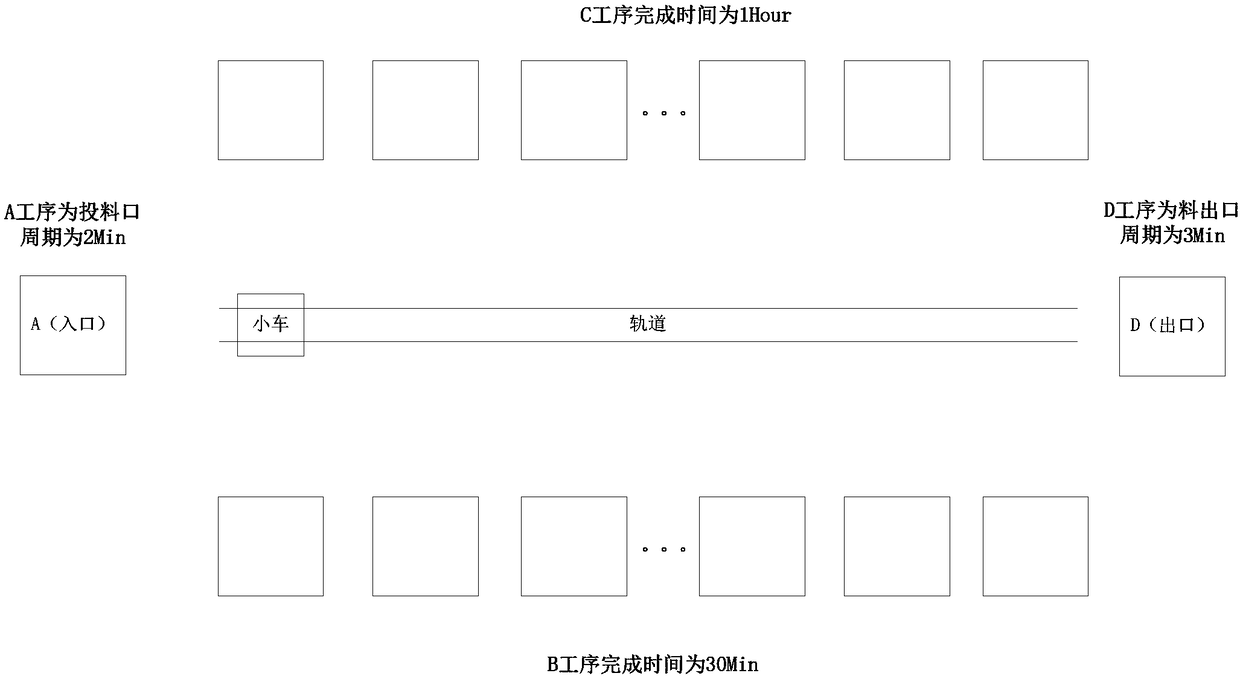

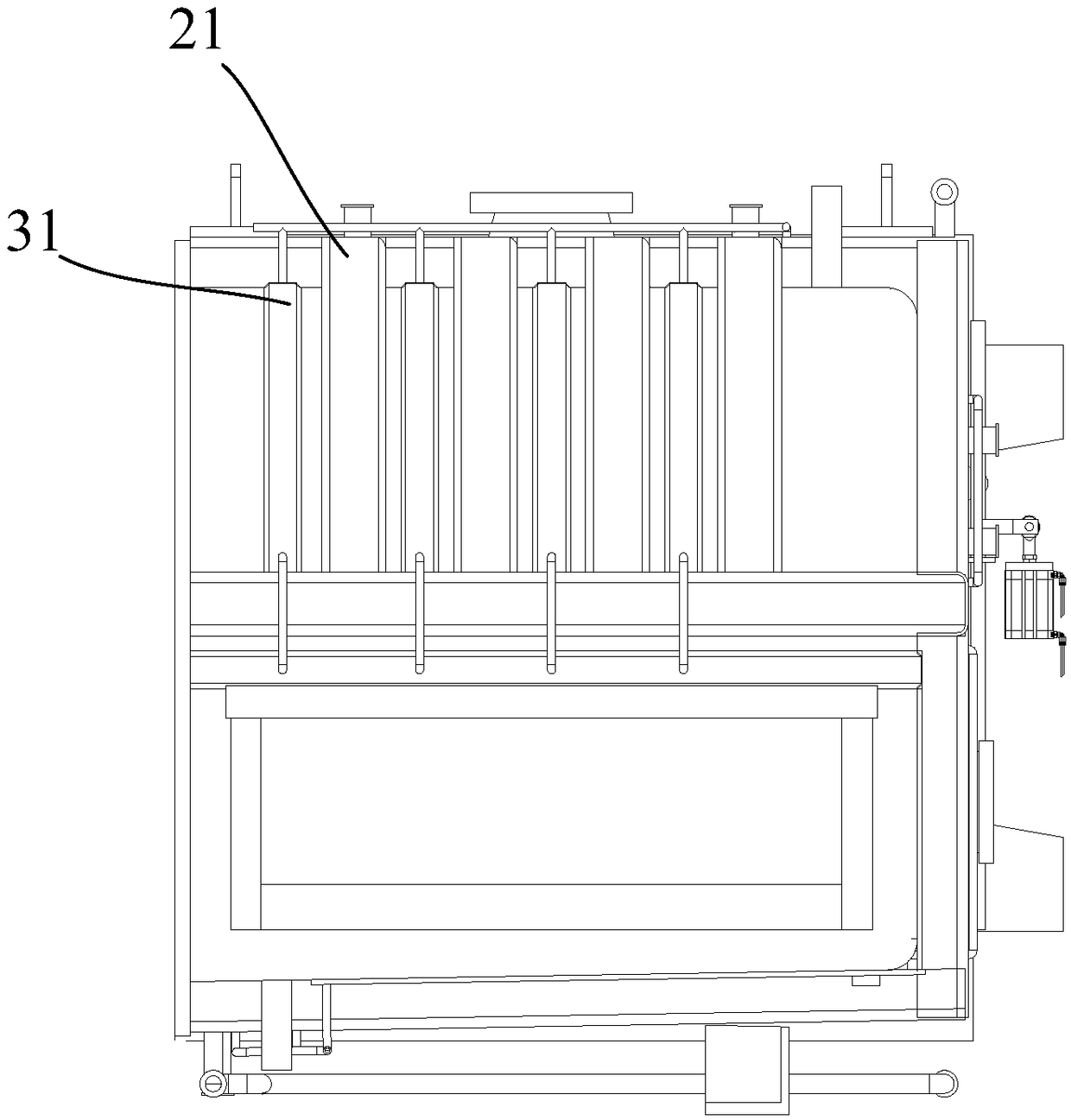

Paperboard processing line

InactiveCN111807107AImprove cutting efficiencyFunctionalOverturning articlesPile receiversPaperboardStructural engineering

The invention provides a paperboard processing line. A paperboard cutting device is used for cutting a strip-shaped paperboard into paperboard blocks and stacking the paperboard blocks into a plurality of stacks; a paperboard stacking device comprises a conveying device and a stacking mechanism; the conveying device comprises a trolley, two fourth conveying mechanisms and an overturning mechanism,the trolley can move in the longitudinal direction, the two fourth conveying mechanisms are distributed at an interval in the longitudinal direction and used for receiving the paperboard blocks separated from a third conveying mechanism, and the overturning mechanism is used for overturning the paperboard stacks on one of the fourth conveying mechanisms by 180 degrees; a fifth conveying mechanismis used for receiving the paperboard blocks separated from the fourth conveying mechanism; and the stacking mechanism is used for stacking the paperboard stacks separated from the fifth conveying mechanism. According to the paperboard processing line, paperboards are stacked forwards and reversely alternately stack by stack instead of piece by piece, so that the stacking efficiency is greatly improved; and the automation degree of the processing line is high without manual guarding in the process, so that the labor cost is reduced while the labor intensity is reduced.

Owner:朱蓉

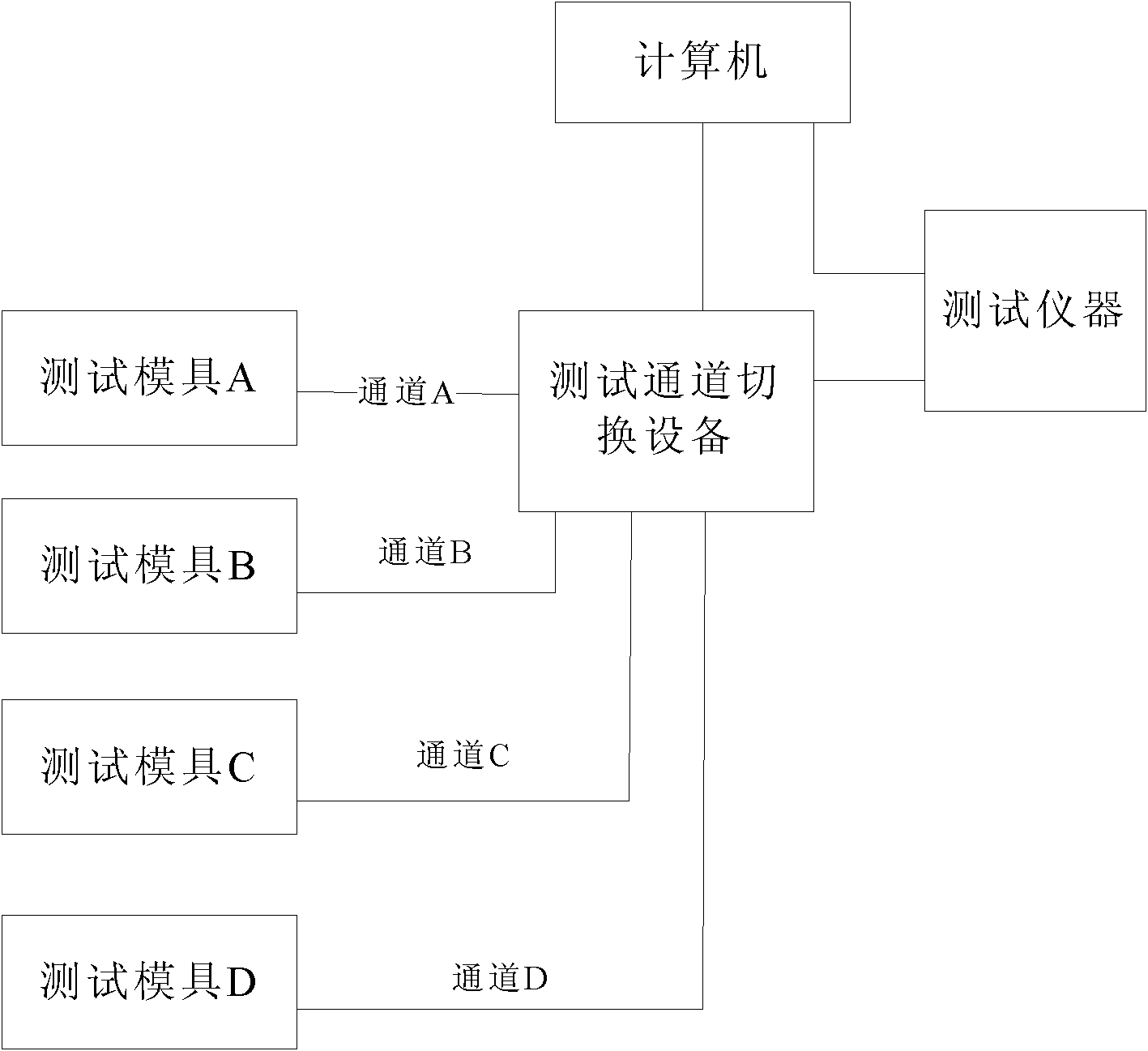

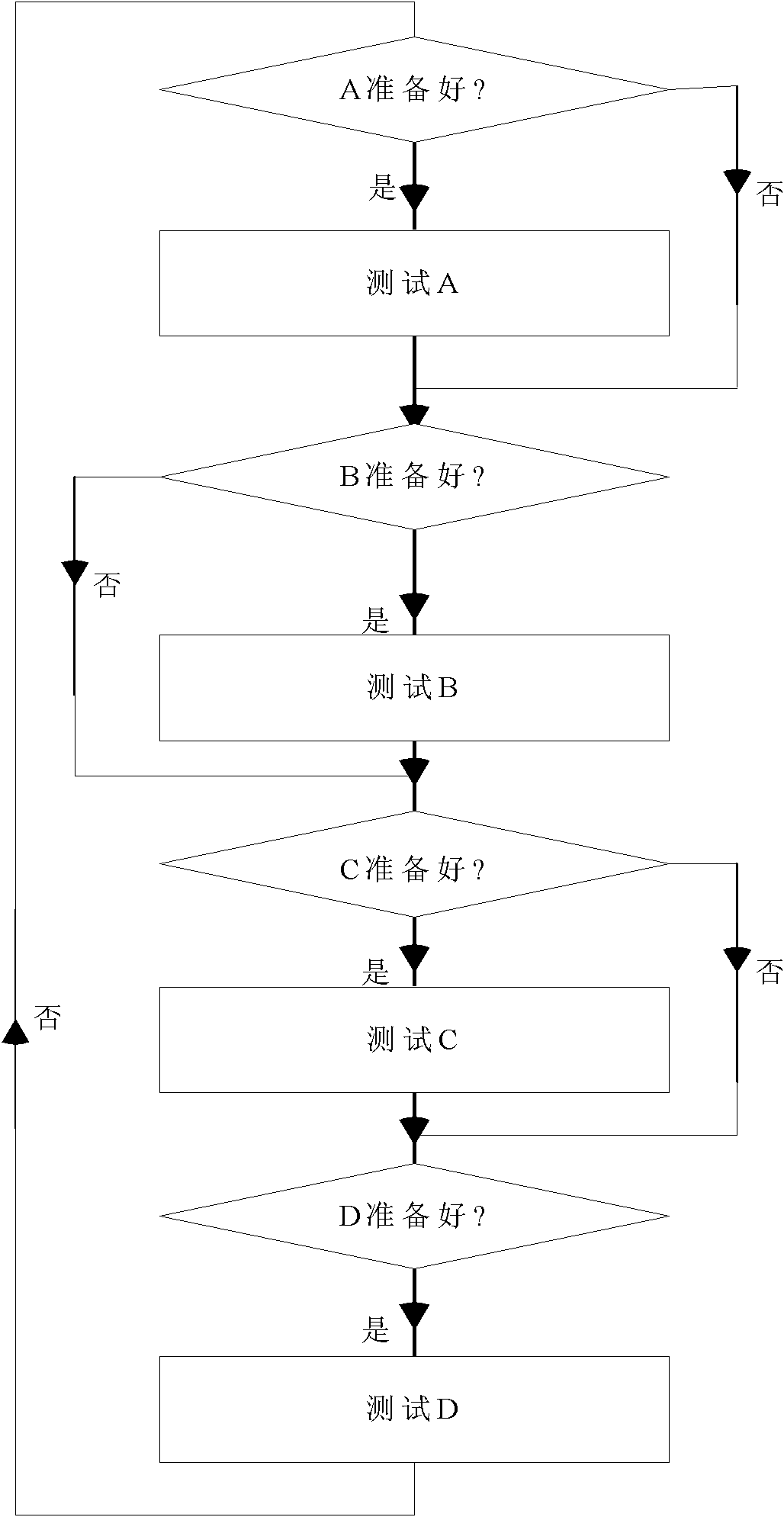

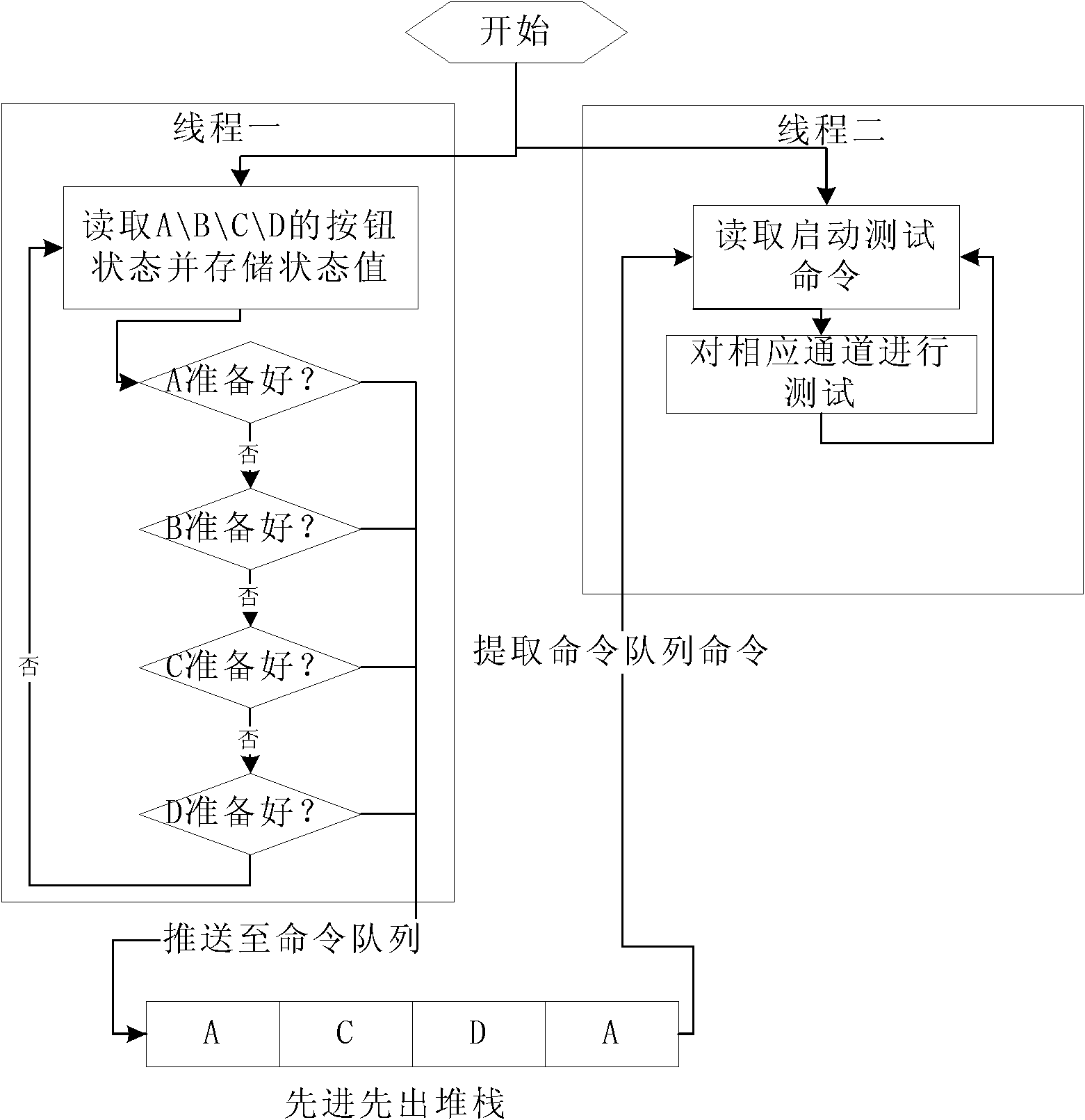

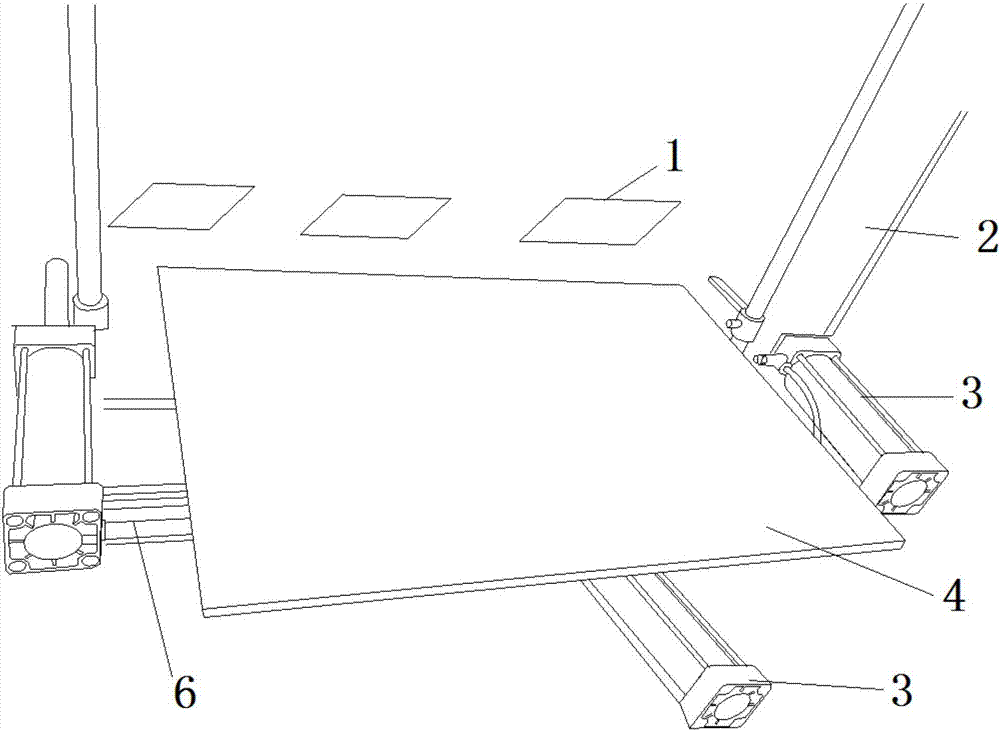

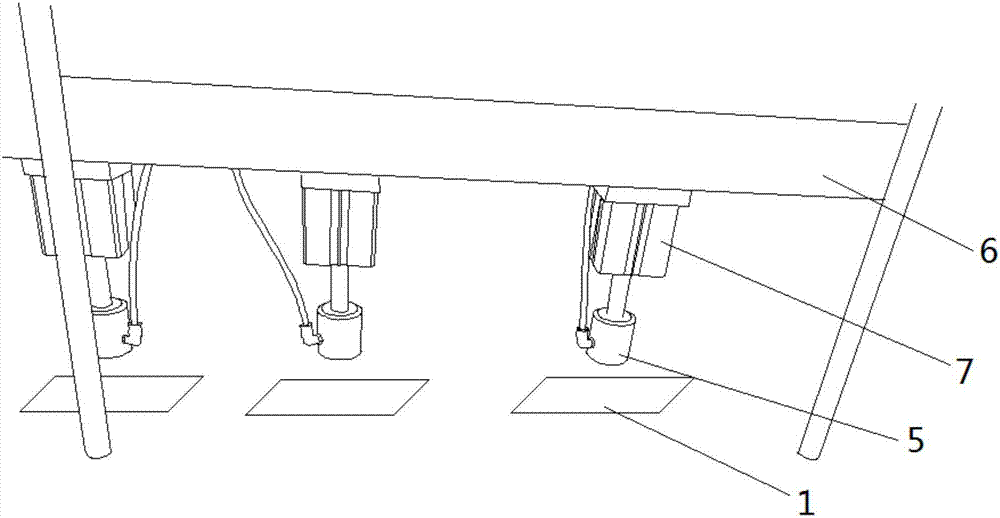

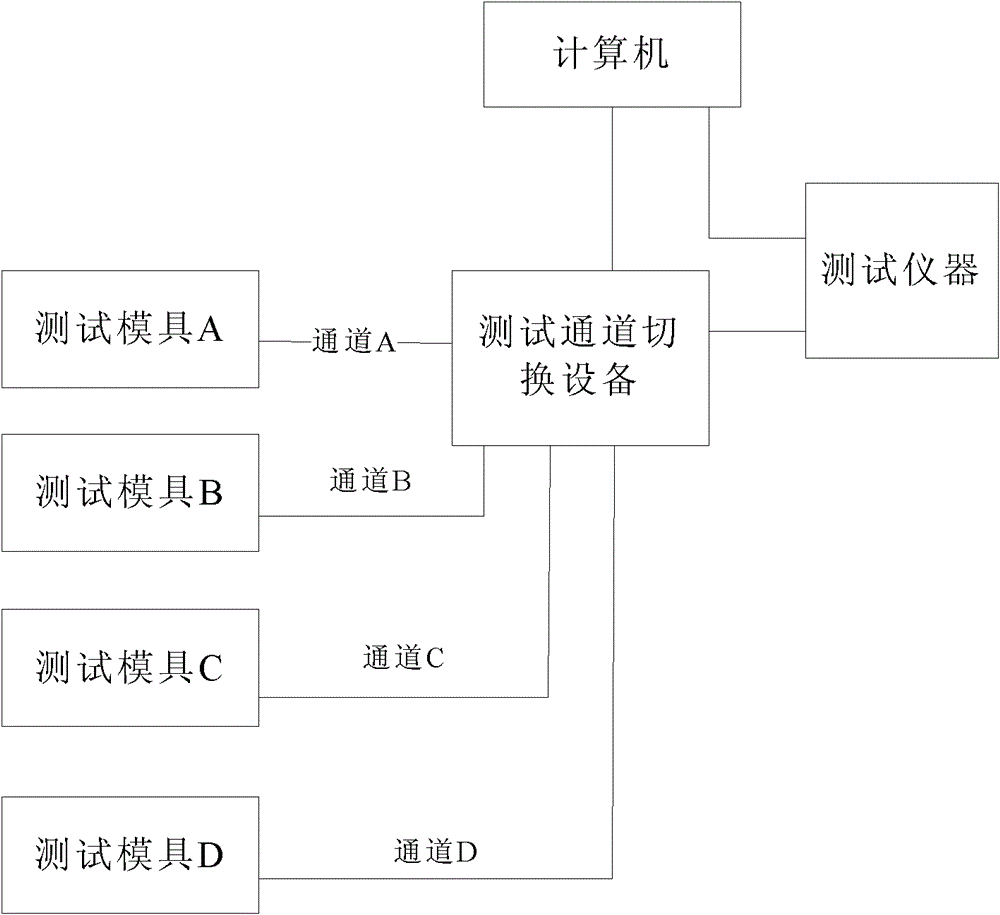

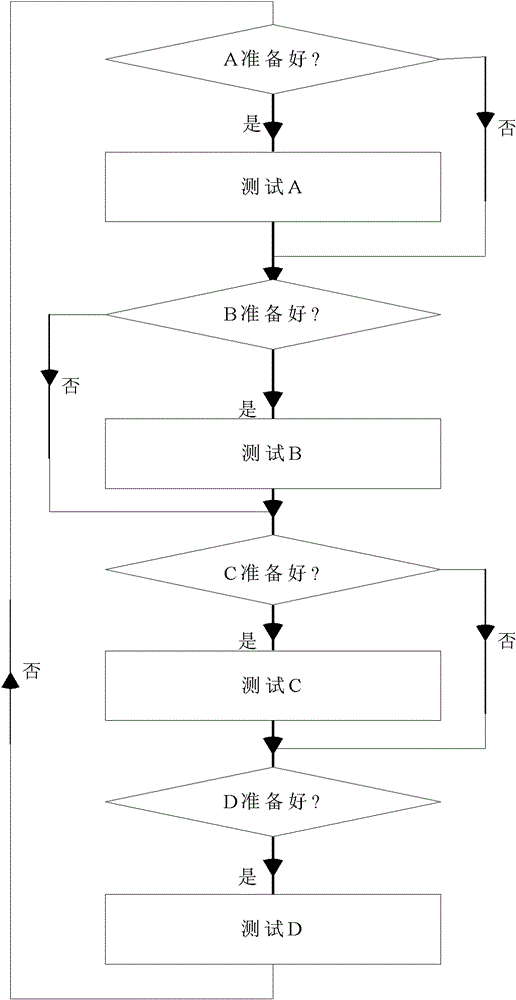

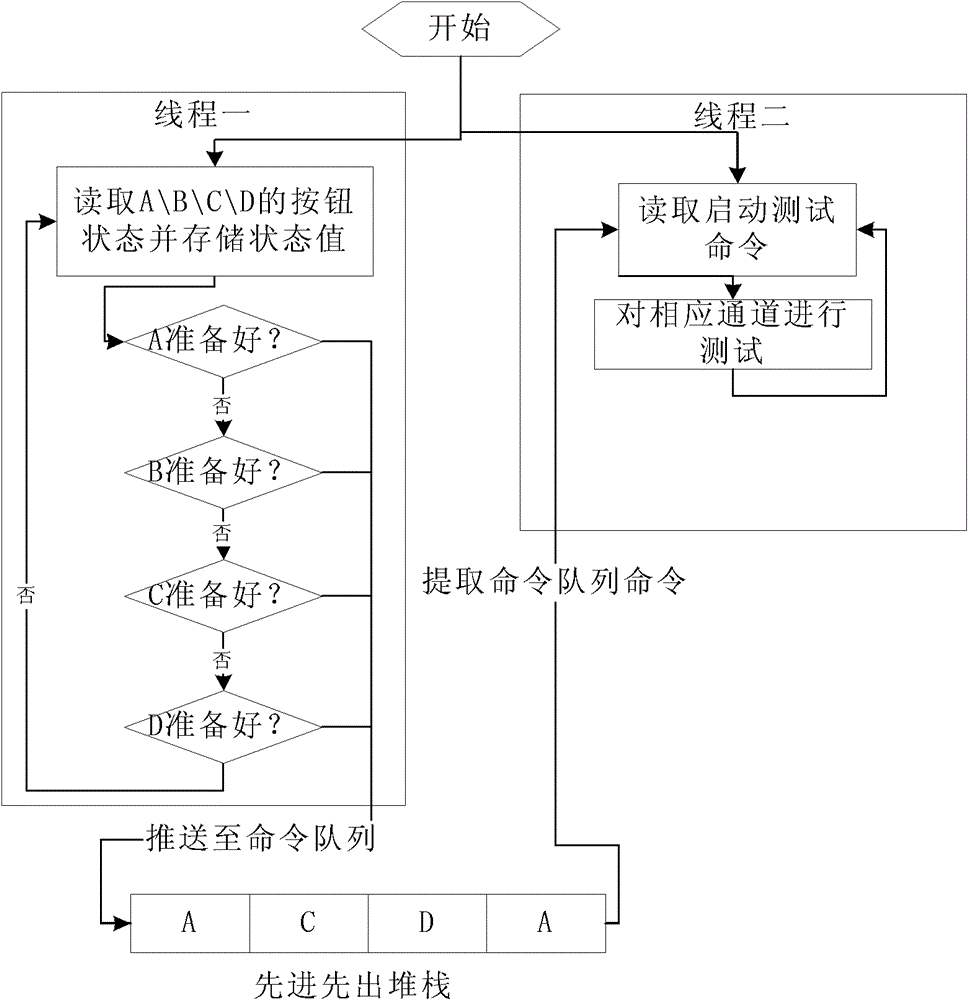

Conversion method of multiple testing channels of testing system

InactiveCN103163407AReduce idle wait timeImprove efficiencyElectrical testingEngineeringInstrumentation

The invention discloses a conversion method of multiple testing channels of a testing system. The conversion method of the multiple testing channels of the testing system includes that a switch used for judging if the testing channels are ready or not is installed at a tail end of each testing channel of the testing system. A queue for starting testing orders and storing all testing channels of the testing system is set up. Firstly, whether each testing channel of the testing system is ready or not is sequentially judged. If yes, orders to start tests of the testing channels which are ready are stored in the queue for starting the testing orders and the process is repeated at intervals. Secondly, an order to start a test is abstracted from the queue for starting the testing orders and a test of a corresponding channel is started. After the test is finished, the next order to start a test is abstracted from the queue for starting the testing orders and the process is repeated in the same way, wherein the first step and the second step work individually. Automatic conversion of the testing systems of the testing system is achieved through data coordination of the queue for stating the testing orders. By means of the conversion method, automatic conversion of multiple testing channels of the testing system of electronic products is achieved and utilization efficiency of testing instruments is improved.

Owner:浙江明凯照明有限公司

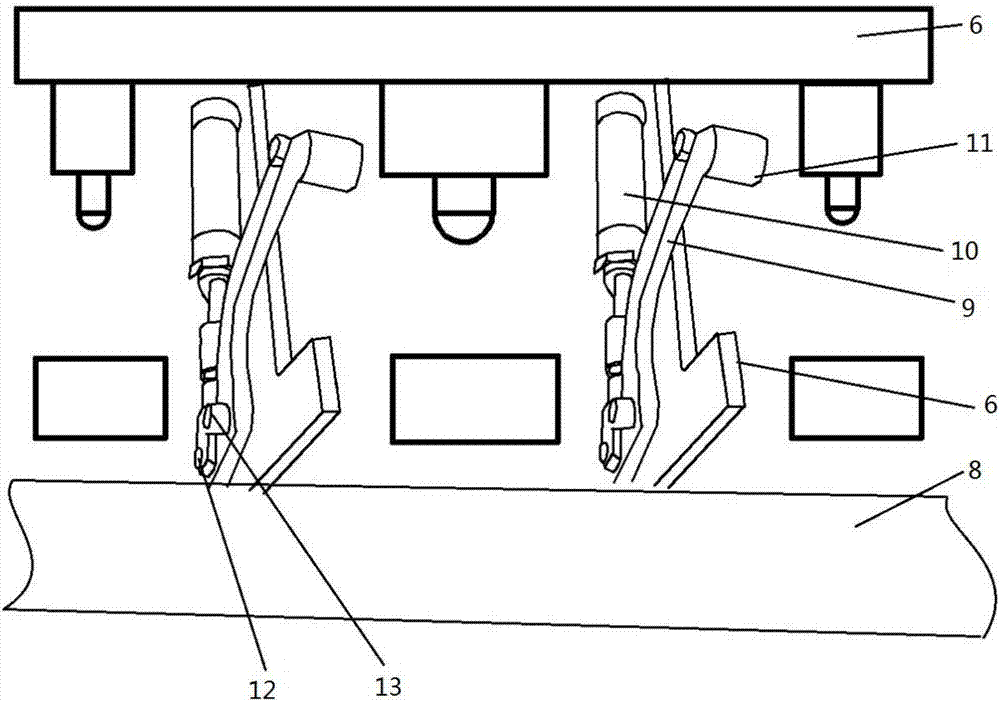

Wood drilling equipment

PendingCN106891389AEasy to operateEasy to installStationary drilling machinesProcess engineeringWoodworking machine

The invention belongs to the technical field of woodworking machines, and particularly relates to wood drilling equipment. The wood drilling equipment is a common tool for woodworking and used for processing raw materials such as planks and square wood, and is mainly composed of a machine frame, a working table and a drilling mechanism, and during use, wood is placed on the working table, and the drilling mechanism is pushed to realize drilling operation. The wood drilling equipment is simple to operate and convenient to install, the drilling operation of the wood can be carried out quickly, the drilling dislocation is avoided, the drilling precision is improved, the defect rate is reduced, the idle waiting time is shortened, the working efficiency is improved, and meanwhile, the unpredictable safety accidents caused by manual feeding, drilling and discharging are avoided.

Owner:青岛吉森木业有限公司

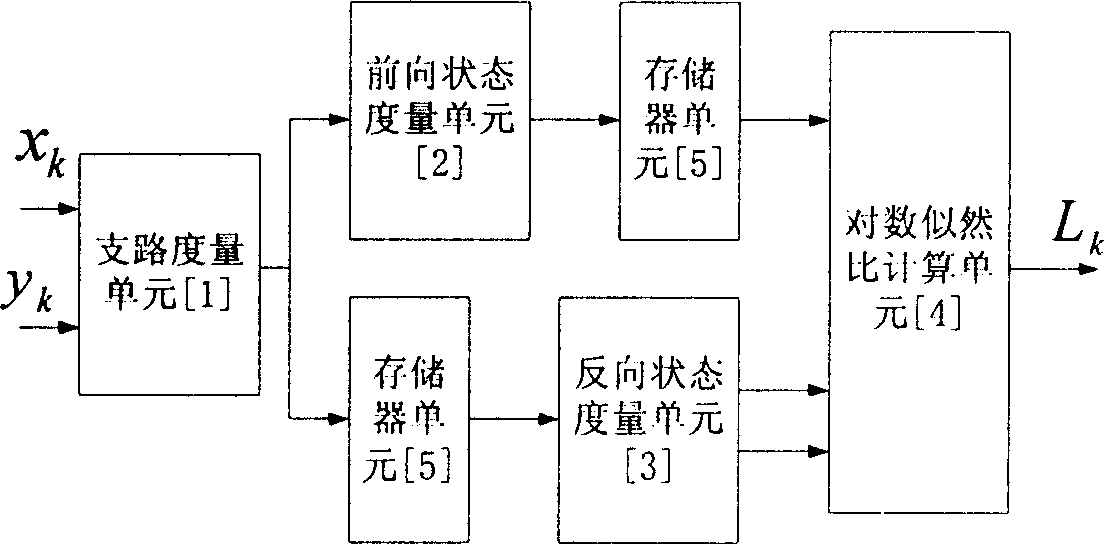

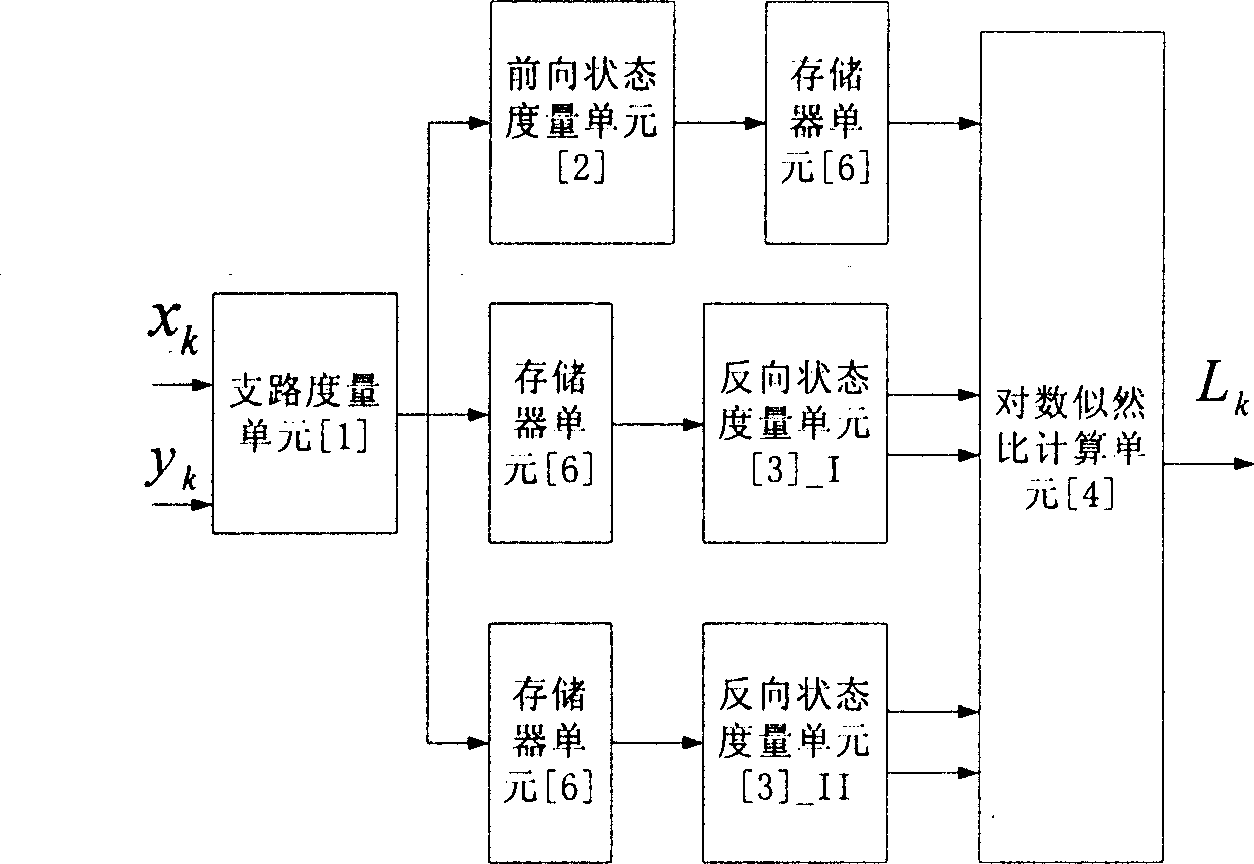

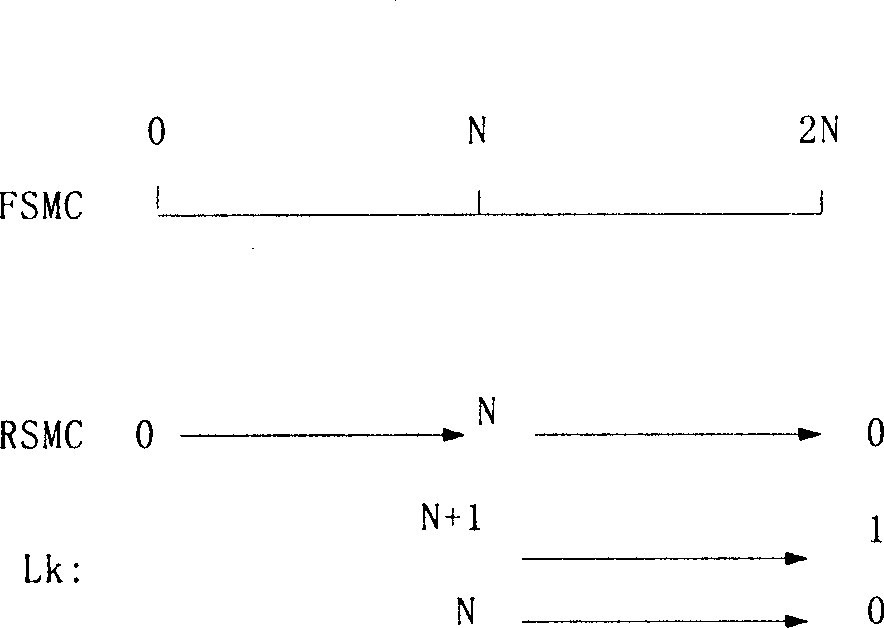

Realising method for parallel cascade convolution code hardware decoder

InactiveCN1378345AReduce idle wait timeReduce data throughputError correction/detection using convolutional codesCode conversionConvolutional codeLogic gate

In order to meet the saving needs required by FAMC and RSMC to the storage, the invented device of the present invention exchanges the increasing use of logic resources with the throughput decreasingof storage data when the use of site programmable logic gate-array is realized. The specific method is to use two sets of RSMC and both of them are working at the same time, and the iteration is started from different initial time to select the correct data output part. Its superority is that the data throughput of storing unit in the course of decoding realization does not rely on quanitity N ofdata which waist for decoding but only depends on the value L which can satisfy the requirement, when L is bigger than 5 times of constrained length of the coder with member's convolution code.

Owner:INST OF TELECOMM TRANSMISSION MINIST OF INFORMATION IND +1

Production method of woodcarving inlaid door panels subjected to film pressing

PendingCN112025903AReduce idle wait timeShorten the timeDecorative surface effectsWood working apparatusPlastic forming machineNumerical control

The invention discloses a production method of woodcarving inlaid door panels subjected to film pressing. The production method of the woodcarving inlaid door panels subjected to film pressing comprises the following steps: (1) carving door panel substrates by means of a numerical control carving machine provided with a rear surface carving machine station and at least two front surface carving machine stations, making the door panel substrates sequentially enter the rear surface carving machine station to complete rear surface carving, then turning over the door panel substrates to front surfaces by an overturning part, conveying the door panel substrates to one spare front surface carving machine station through a conveyor belt for front surface pattern carving at the same time, keepingthe rear surface carving time of the door panel substrates short, and carving corresponding inlaid core panels; (2) conducting surface polishing on the carved door panel substrates and inlaid core panels; (3) conducting glue-spraying and airing on the door panel substrates and the inlaid core panels which are subjected to surface polishing; (4) conducting PVC high-temperature coating on the aireddoor panel substrates and inlaid core panels by means of a plastic forming machine; and (5) bonding the inlaid core panels and inlaid grooves of the door panel substrates by means of glue, and conducting pressing and fixing. The production method of the woodcarving inlaid door panels subjected to film pressing is simple in process, the production efficiency of the door panels can be improved, andthe production cost is reduced.

Owner:上海速居科技集团有限公司

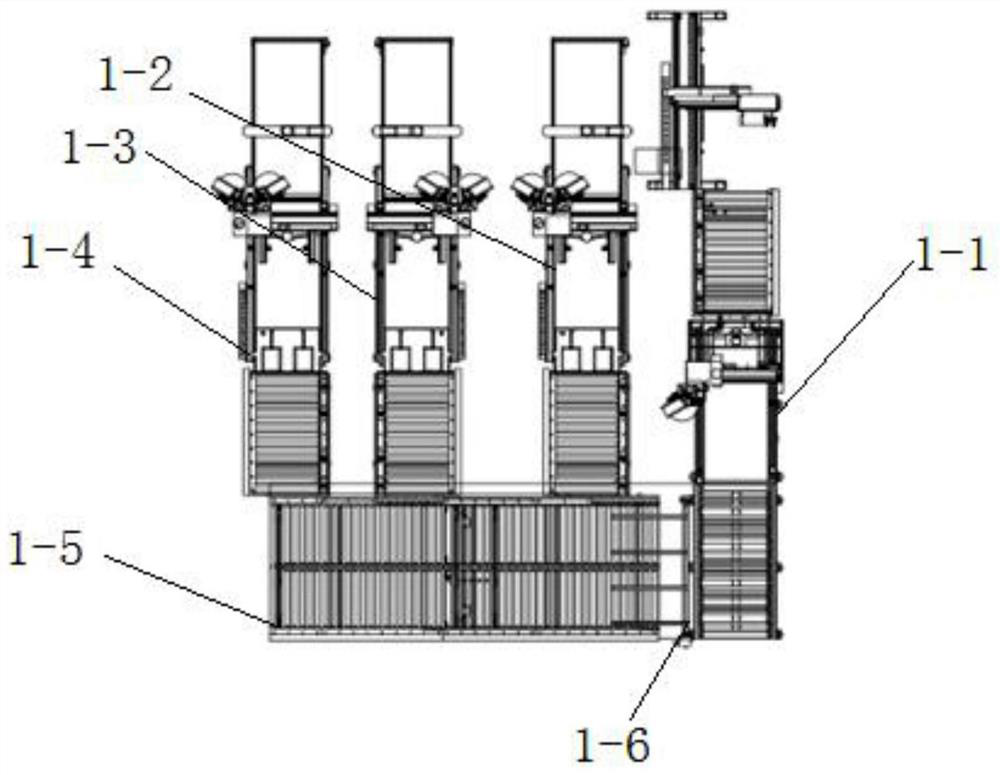

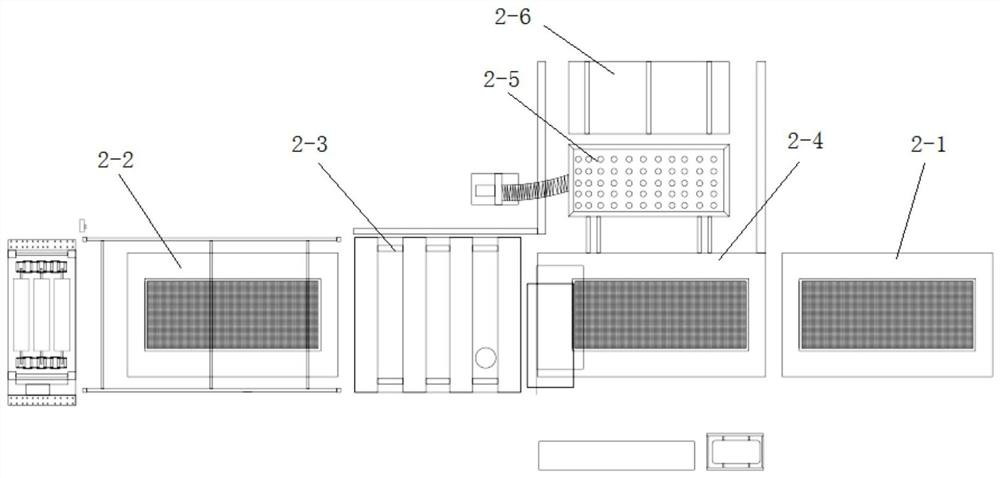

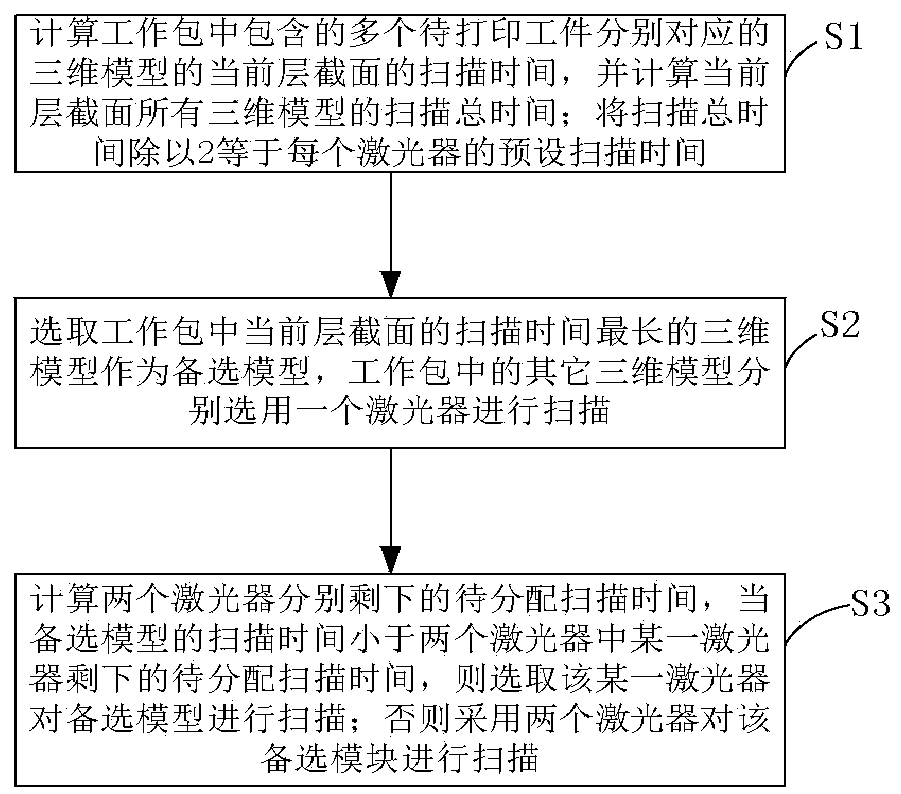

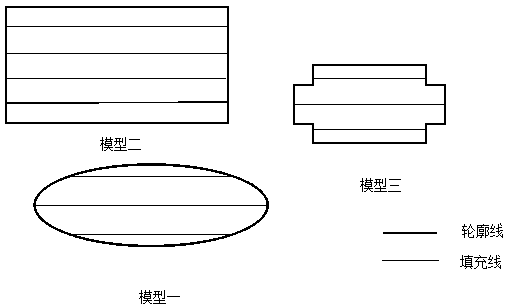

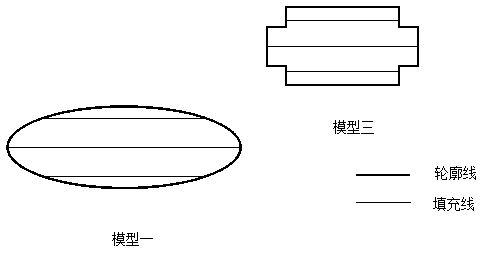

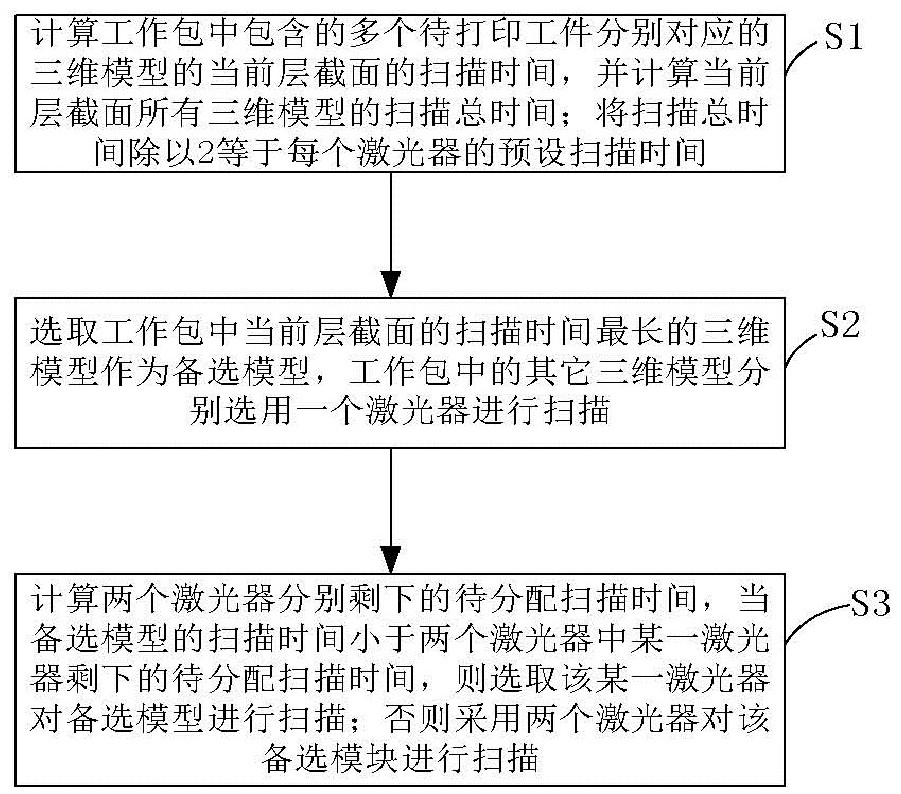

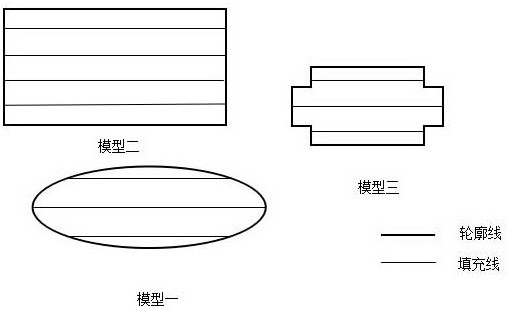

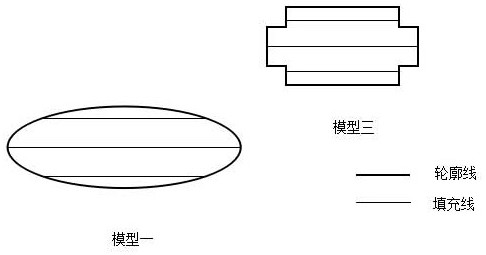

Scanning path planning method and device based on double lasers and three-dimensional object manufacturing equipment

ActiveCN110524883AReduce interactionReduce idle wait timeAdditive manufacturing apparatus3D object support structuresPlanning methodComputer science

The invention discloses a scanning path planning method and device based on double lasers and three-dimensional object manufacturing equipment. The method comprises the following steps: at most one to-be-printed workpiece in the current layer section of a working package is scanned by two lasers; other workpieces to be printed in the current layer section of the work package are scanned by only one laser, wherein the to-be-printed workpiece scanned by the two lasers belongs to contours, and the areas filled with the upper surface and the lower surface are scanned by the same laser. According to the scanning path planning method and device based on the double lasers and the three-dimensional object manufacturing equipment, by estimating the scanning time of the current layer section and reasonably allocating the scanning time of each laser, the idle waiting time of the lasers is shortened, that is to say, the scanning waiting time of the lasers is shortened as much as possible on the premise of ensuring the scanning quality.

Owner:HUNAN FARSOON HIGH TECH CO LTD

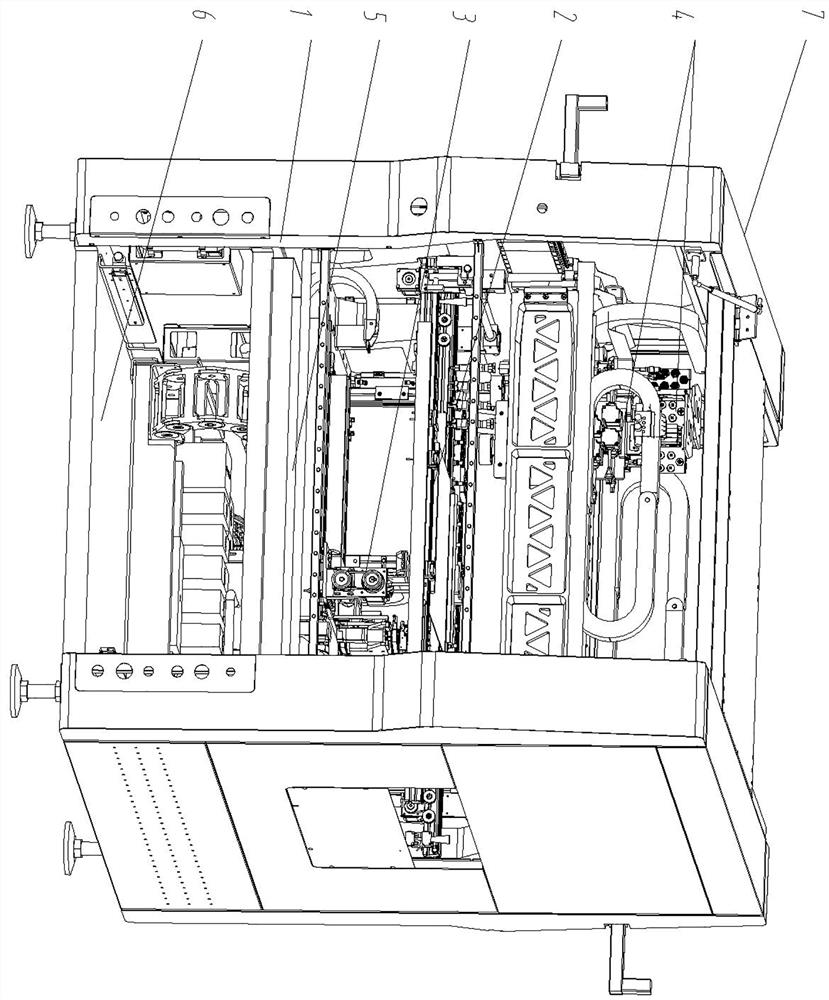

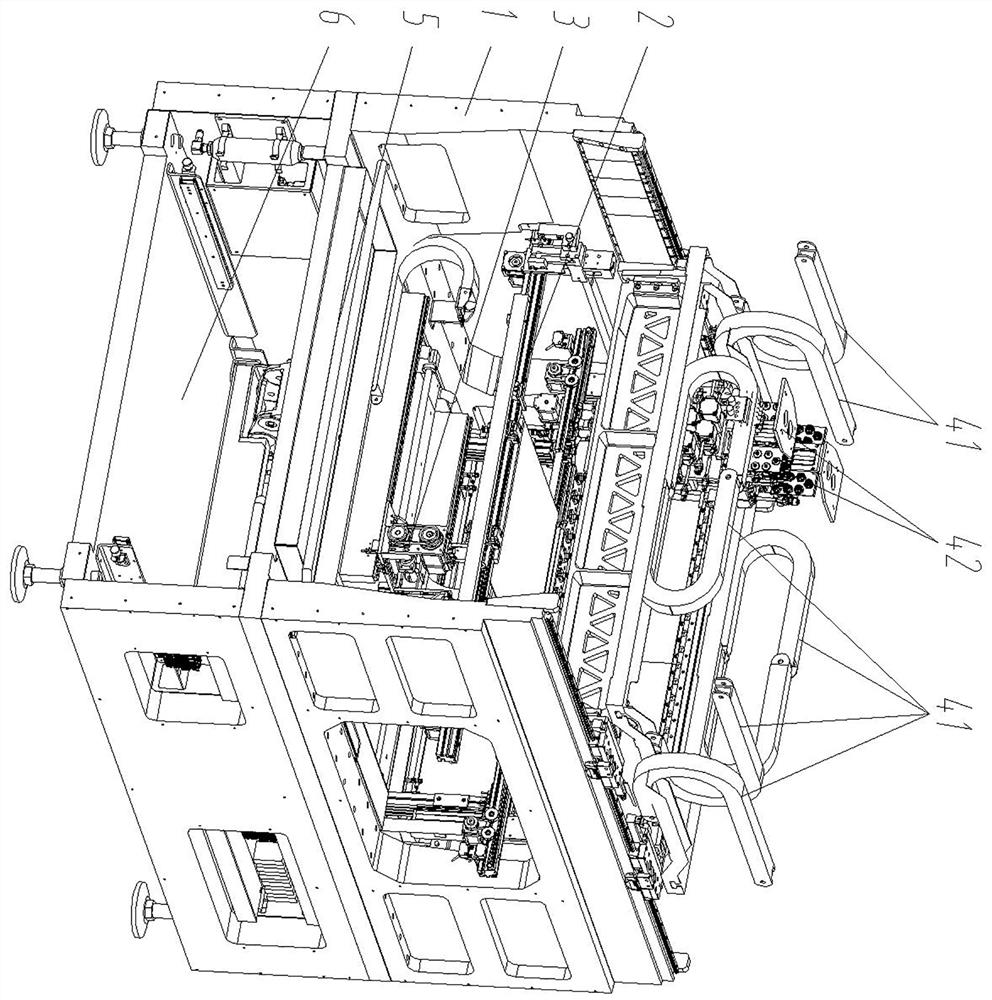

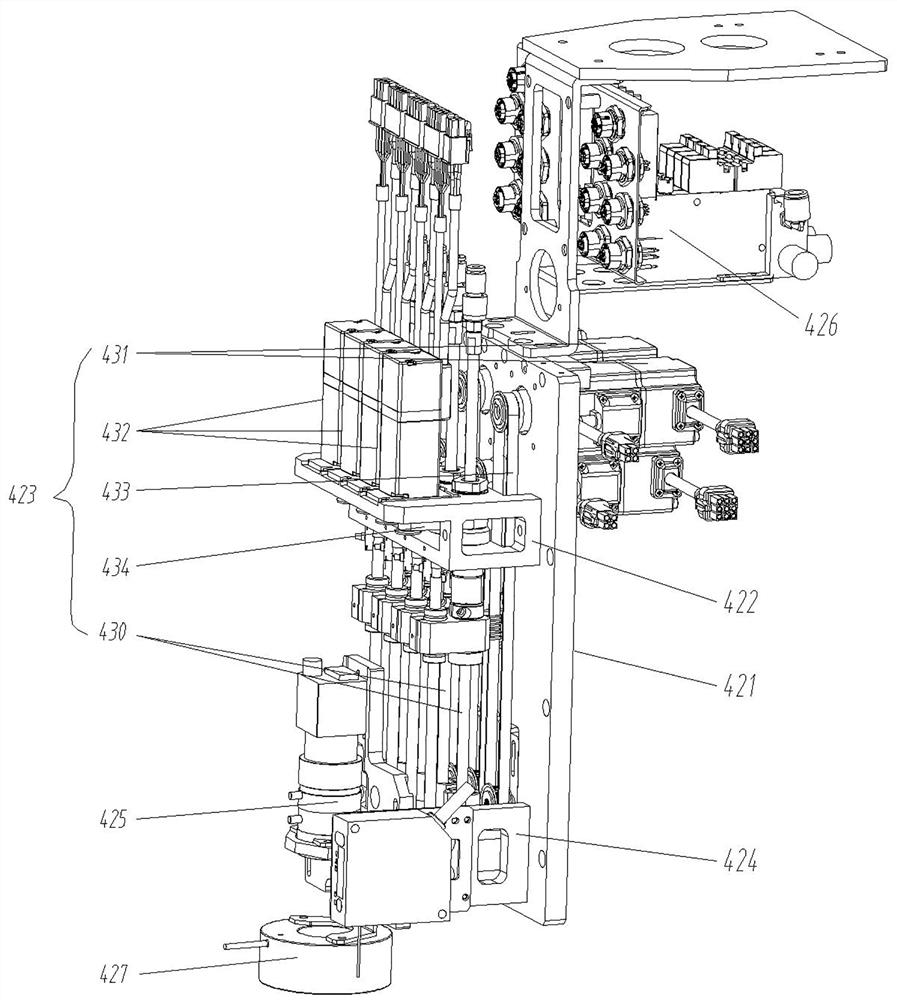

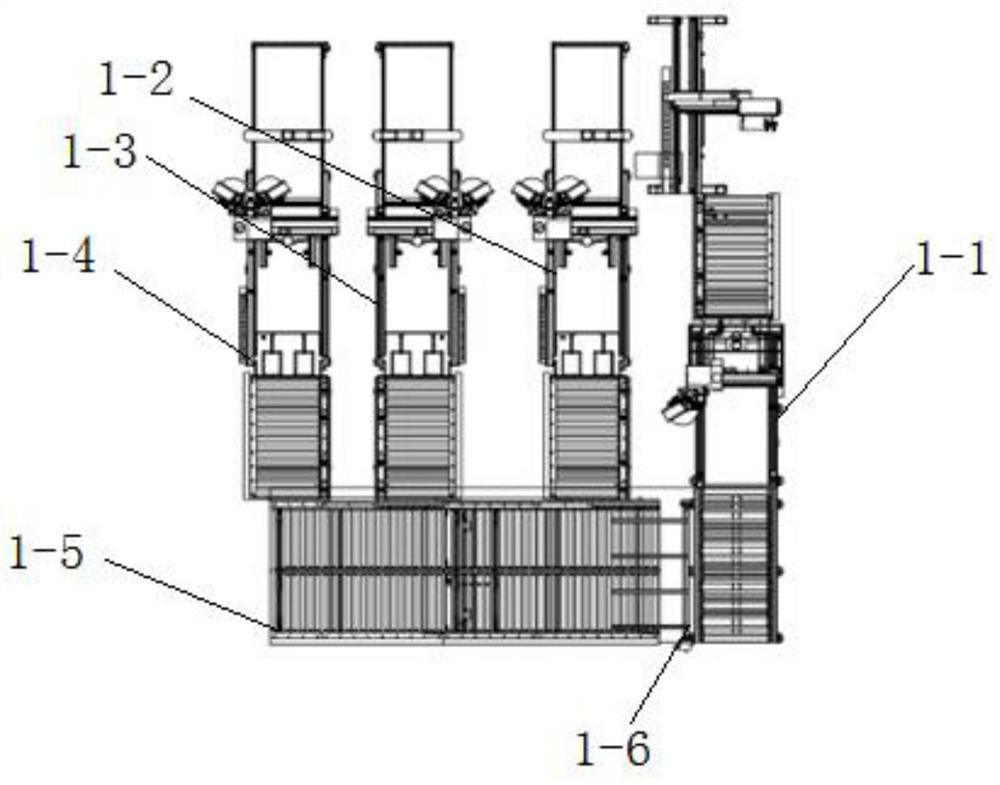

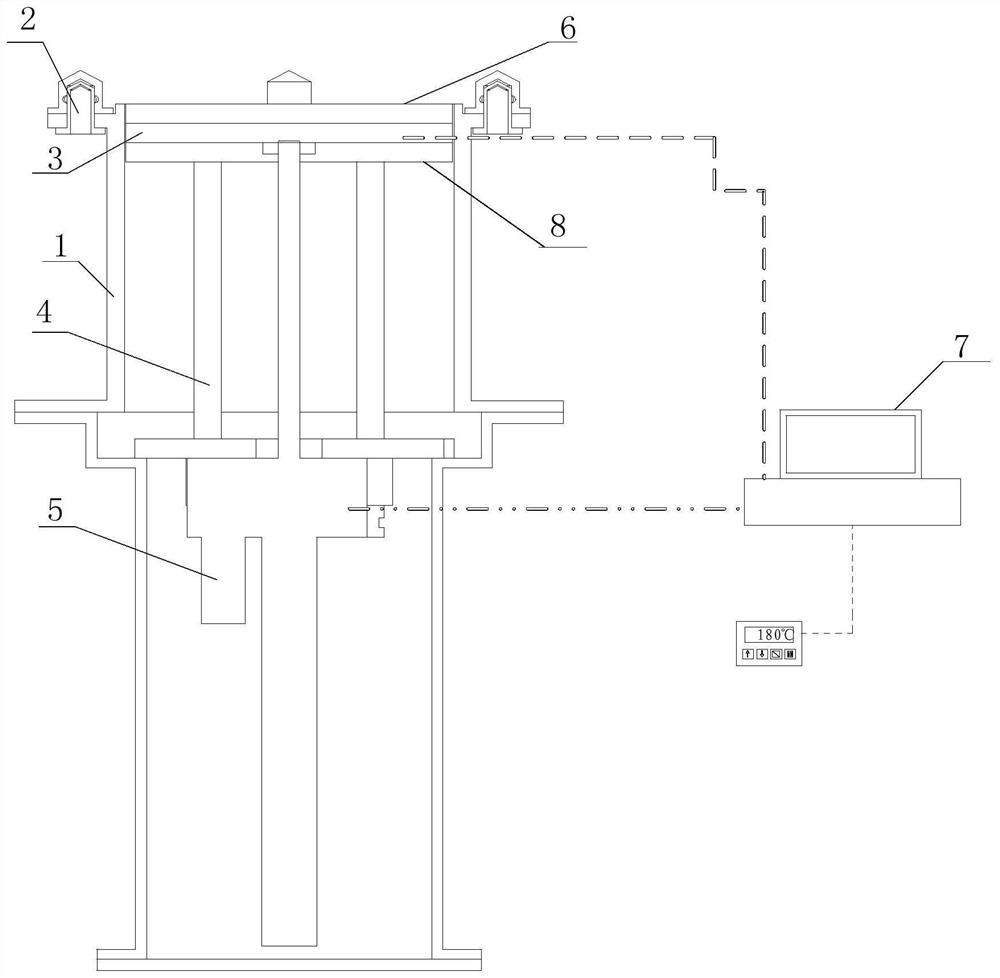

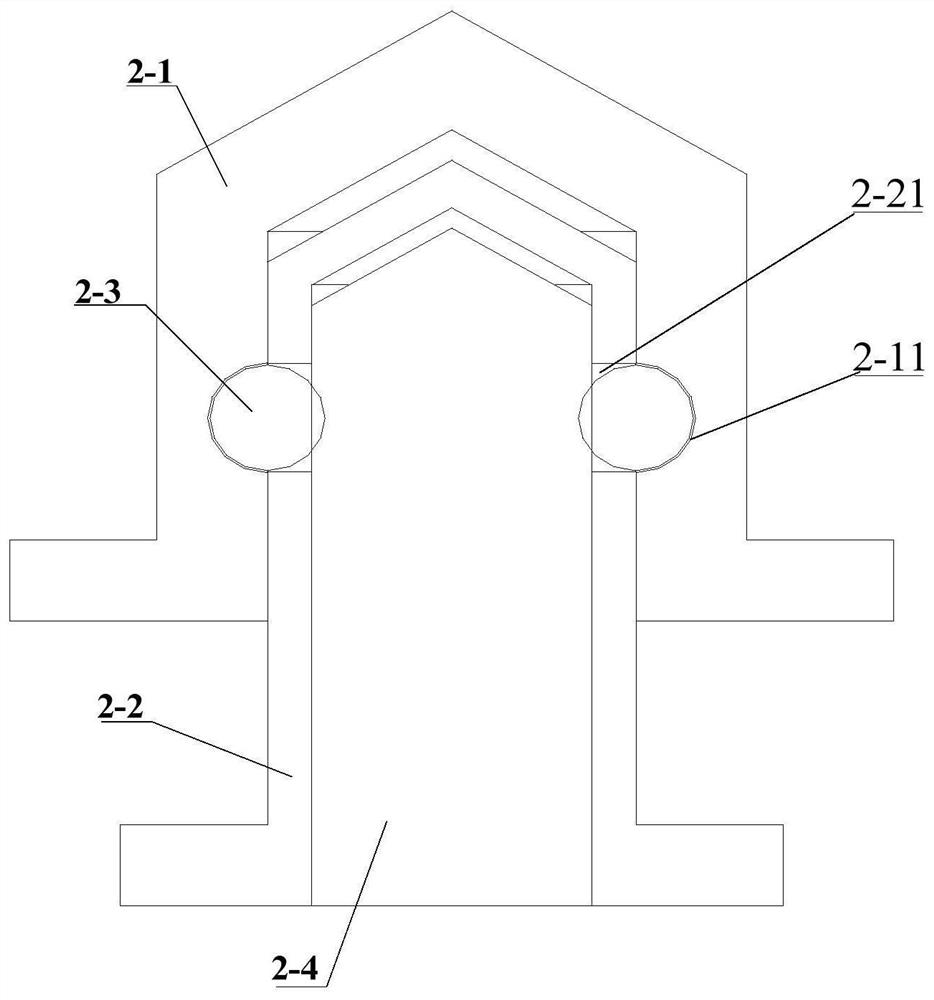

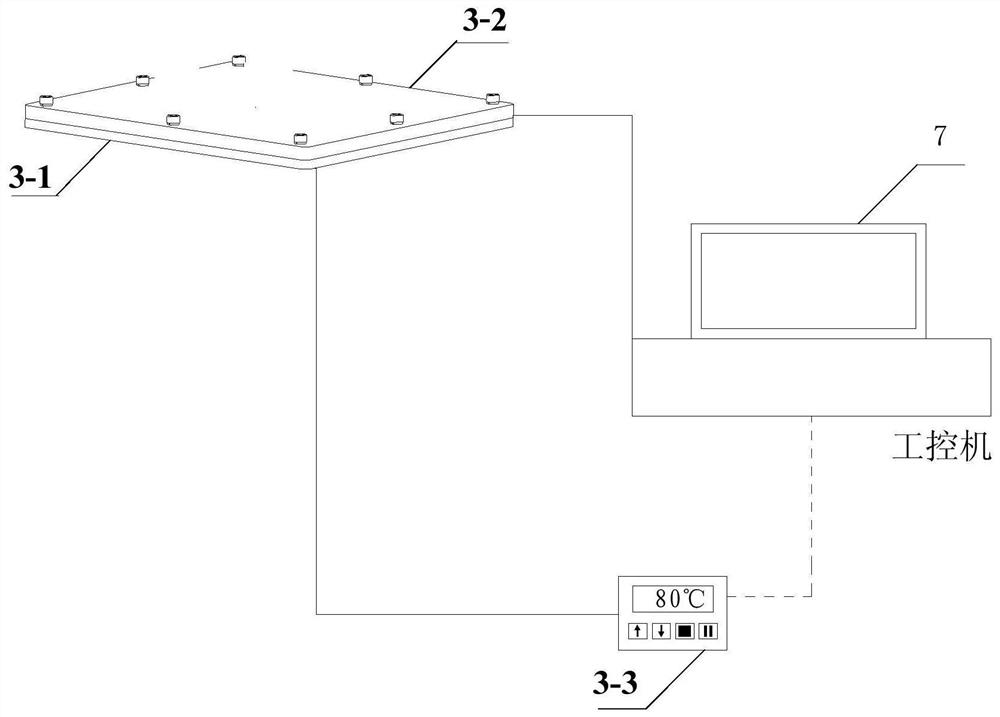

Novel multi-station automatic component inserter

PendingCN111818788ARealize online productionImprove work efficiencyElectrical componentsProduction lineEconomic benefits

The invention aims to provide the novel multi-station component inserter which is reasonable in design, high in automation degree, high in working efficiency and capable of improving economic benefits. The inserter comprises a cabinet (1), a PCB conveying module (2), a pin bending module (3) and two plug-in modules (4) are arranged in the cabinet (1). The PCB conveying module (2) penetrates through the cabinet (1), is connected with a production line and is used for conveying PCB products; the pin bending module (3) is located under the PCB conveying module (2) and used for bending pins on PCBproducts, and the two plug-in modules (4) are both located over the PCB conveying module (2) and used for conducting plug-in on the PCB products on the PCB conveying module (2). The inserter can be applied to the technical field of automation equipment.

Owner:珠海市运泰利自动化设备有限公司

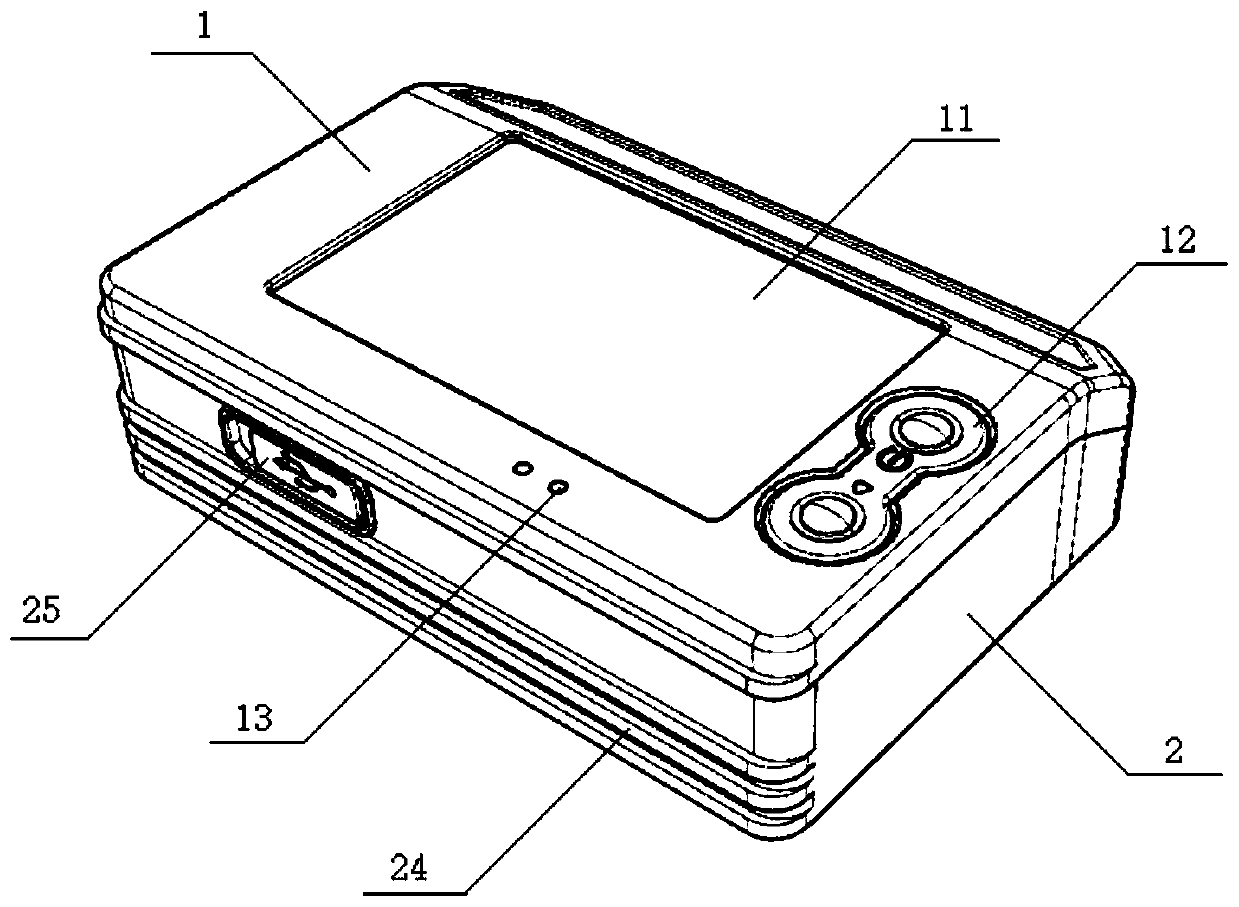

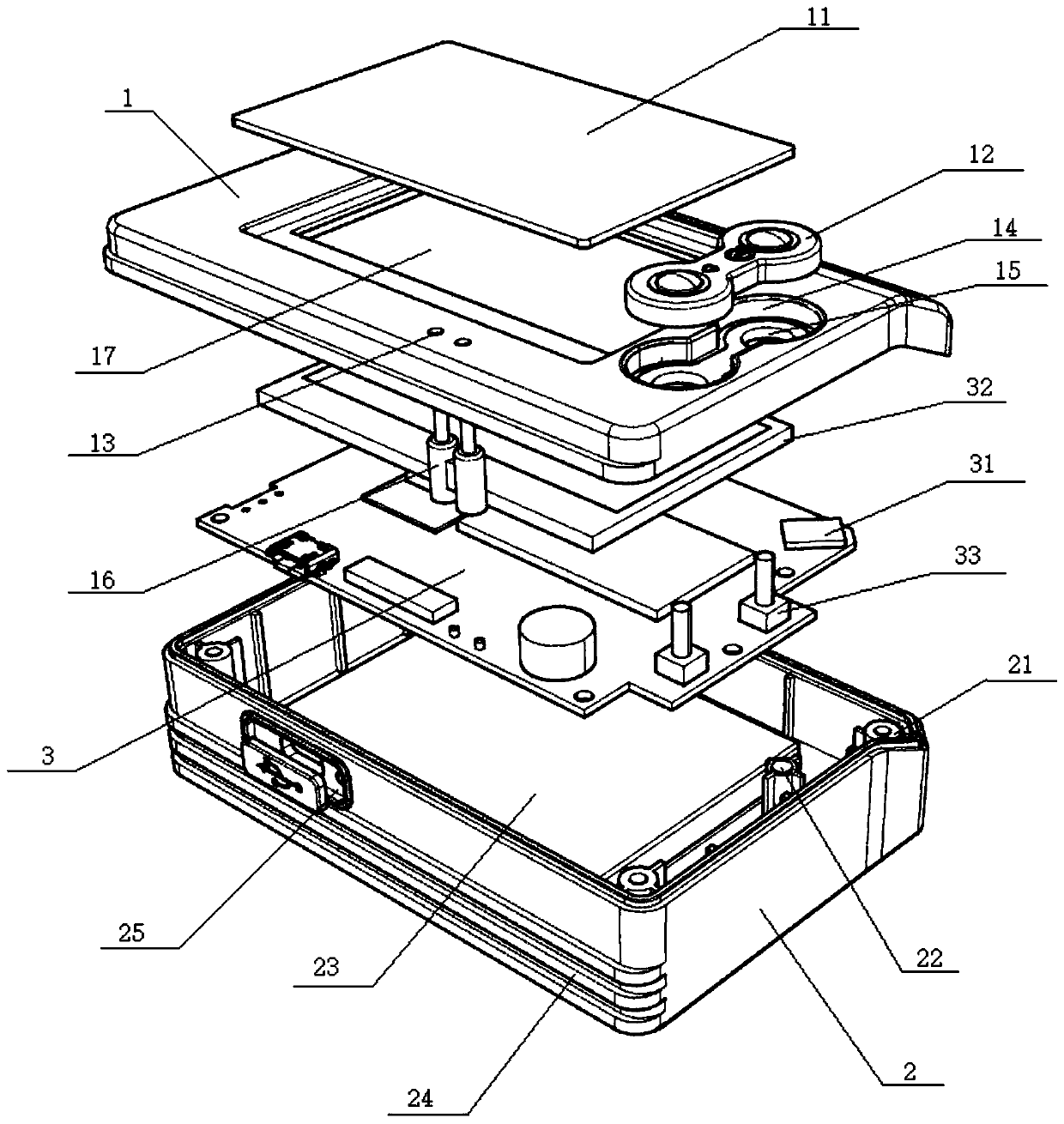

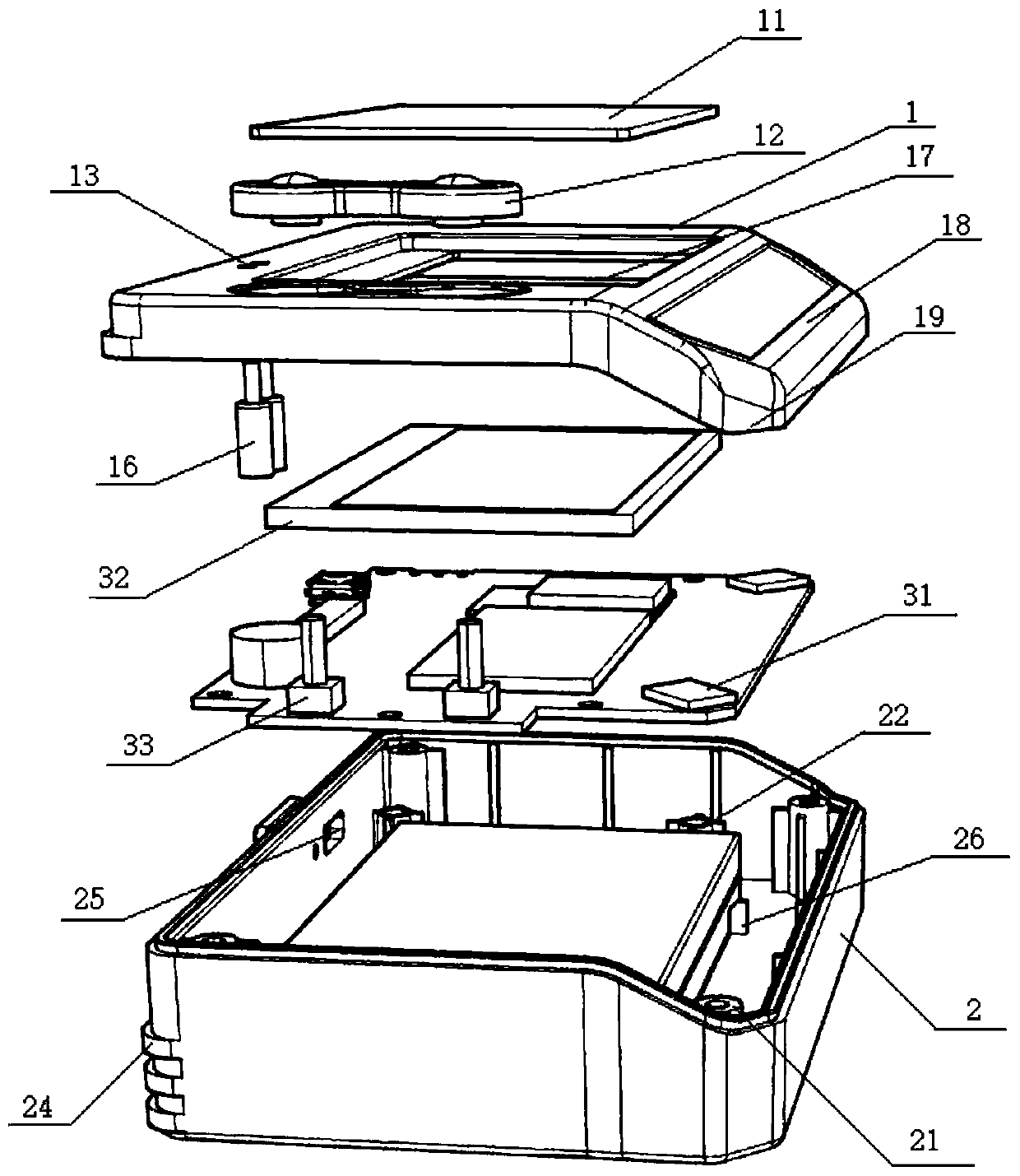

Real-time distance measuring device, system and method for high-grade leveling

PendingCN111090091AImprove stabilityReduce congestionHeight/levelling measurementRadio wave reradiation/reflectionMeasuring instrumentControl engineering

The invention discloses a real-time distance measuring device, system and method for high-grade leveling, and belongs to the field of horizontal distance measurement. In order to solve the problems that in the prior art, the sight distance error is large before and after level gauge measurement, the consumed time of a distance measuring instrument is long, and power consumption is high, the invention provides a real-time distance measuring device, system and method for high-grade leveling; the device comprises an upper shell and a lower shell, circuit boards are arranged in the upper shell andthe lower shell, and antennas are installed on the circuit boards; each circuit board further comprises a man-machine module, a control module, a sensing module, a monitoring module and a power supply module, when the device measures the distance, the antenna with the optimal signal is calculated through an antenna switching algorithm, the long distance measuring time due to bad single antenna signal is avoided, the distance measuring result can be obtained more accurately and rapidly, meanwhile, the power consumption of the device is reduced, and installation is convenient; and the device can be installed on a level gauge for common movement.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD

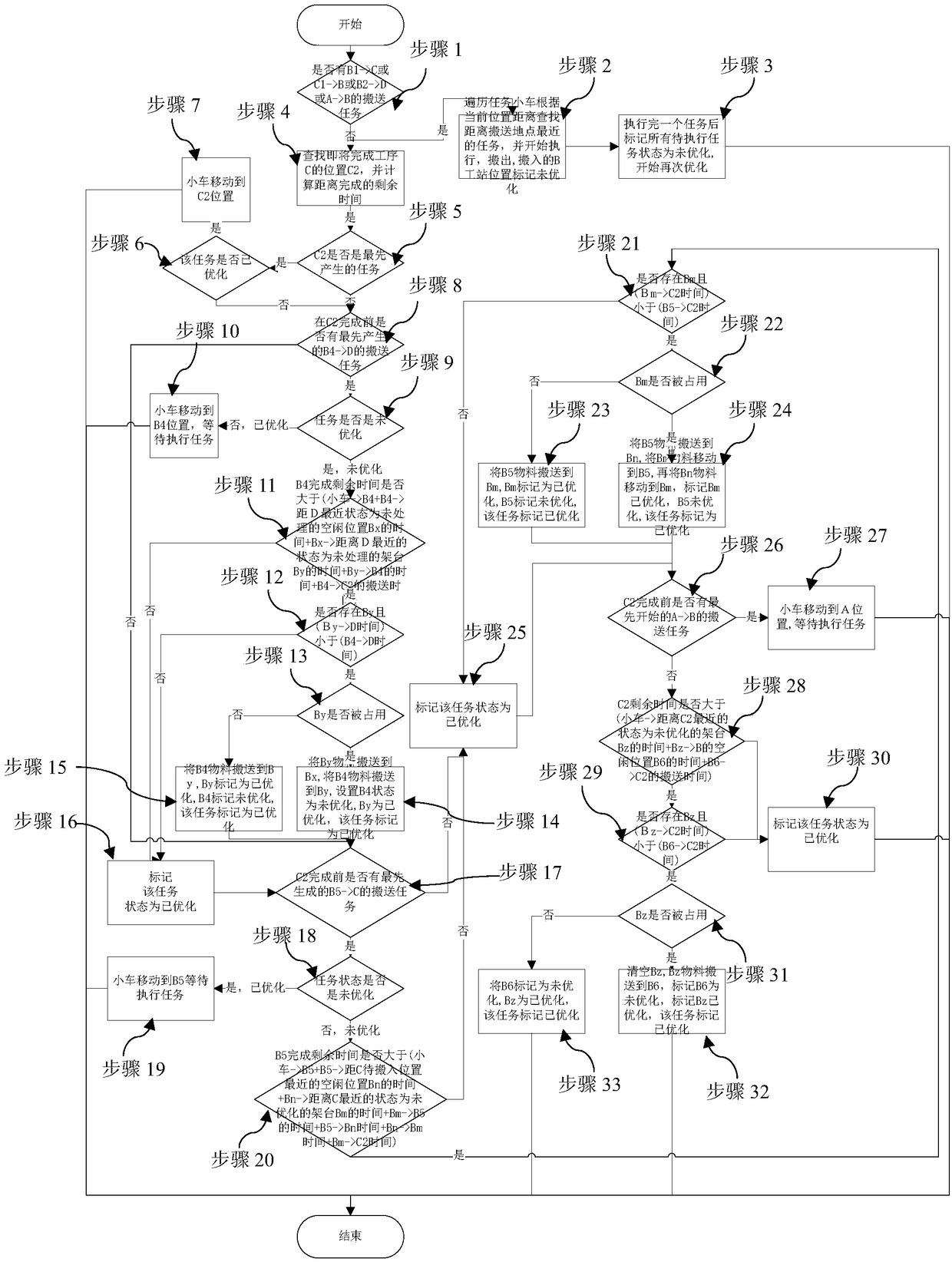

Lithium ion battery production process optimization method

ActiveCN108280555AGuaranteed timely feedingReduce idle wait timeForecastingManufacturing computing systemsProcess optimizationLithium-ion battery

The invention relates to a lithium ion battery production process optimization method, and aims to improve equipment production efficiency. The specific technical scheme includes that the lithium ionbattery production process optimization method includes the steps: 1 judging whether B1-C or C1-B or B2-D or A-B carrying tasks exist or not, turning to step 2 if the carrying tasks exist, otherwise,turning to step 4; 2 searching the task closest to a carrying site, and starting execution; 3 marking the state of all tasks to be executed as 'non-execution' after executing one task, returning to the step 2 and performing optimization again until finishing; 4 searching the position C2 of a working procedure C nearing completion and calculating remaining time of completion. Compared with the prior art, the lithium ion battery production process optimization method has the advantages that an independent carrying task selection sequence is innovatively added to execute carrying and forecasted carrying tasks, carrying routes are optimized in advance, and the waiting time of production equipment is shortened by the two functions.

Owner:天津齐物科技有限公司

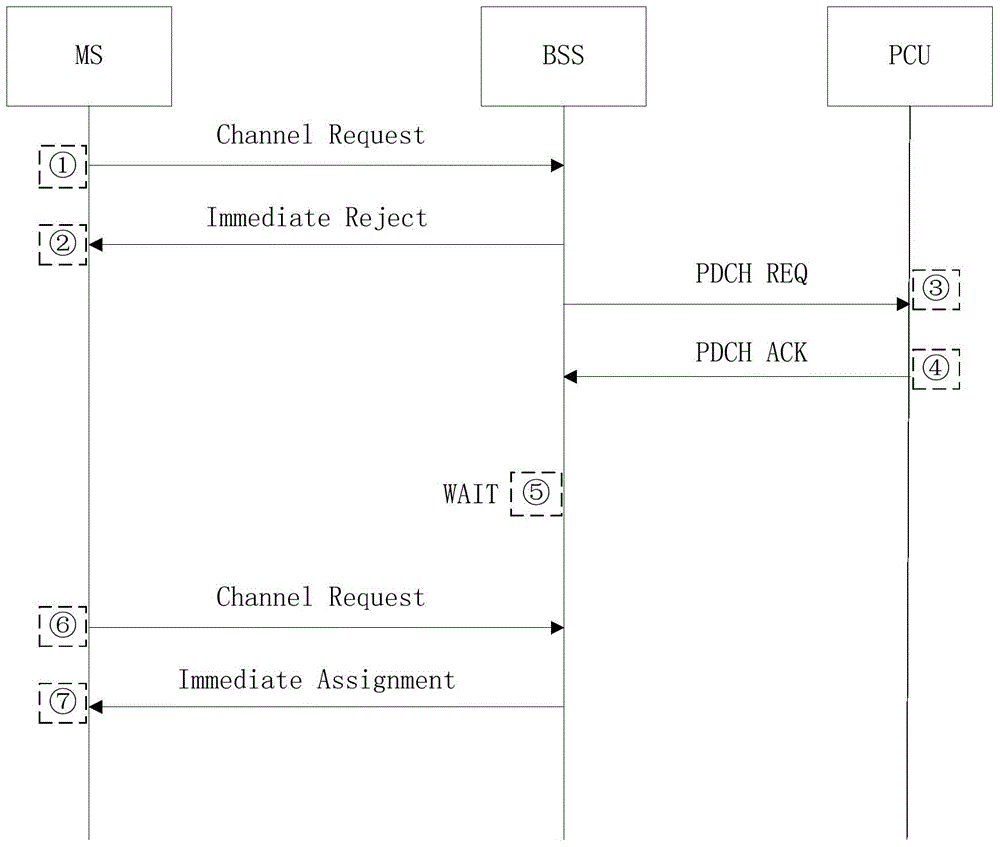

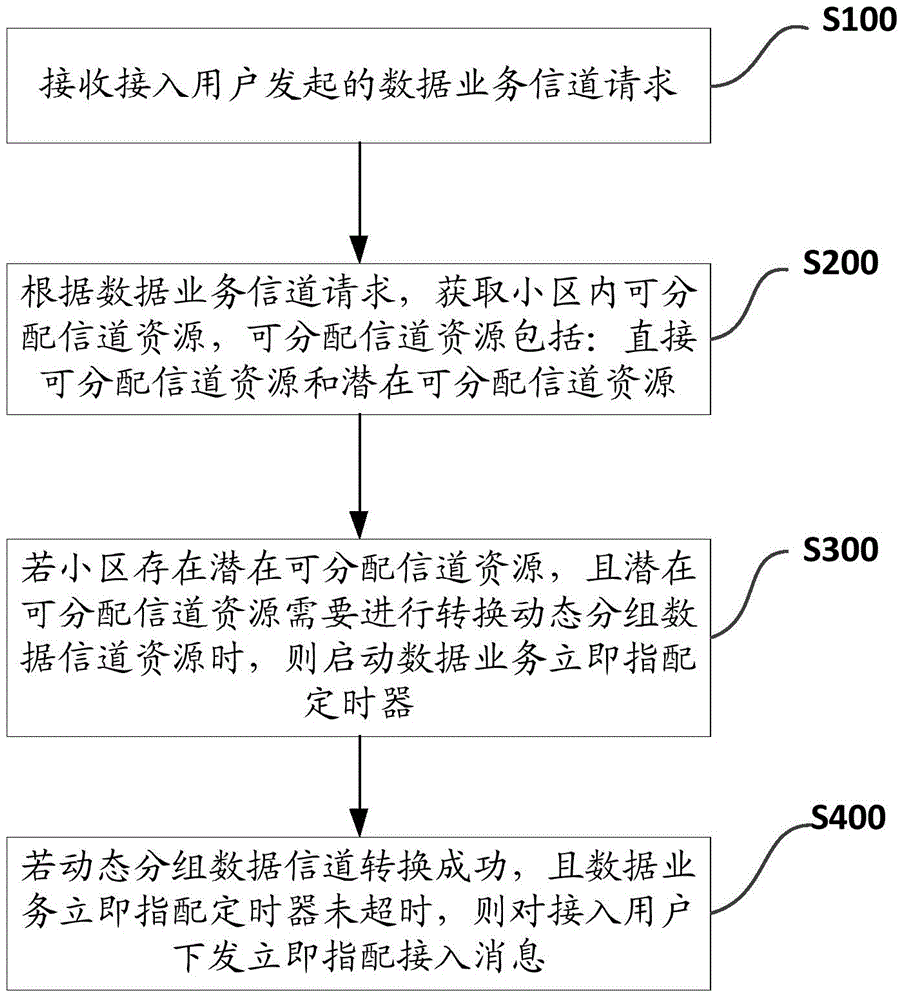

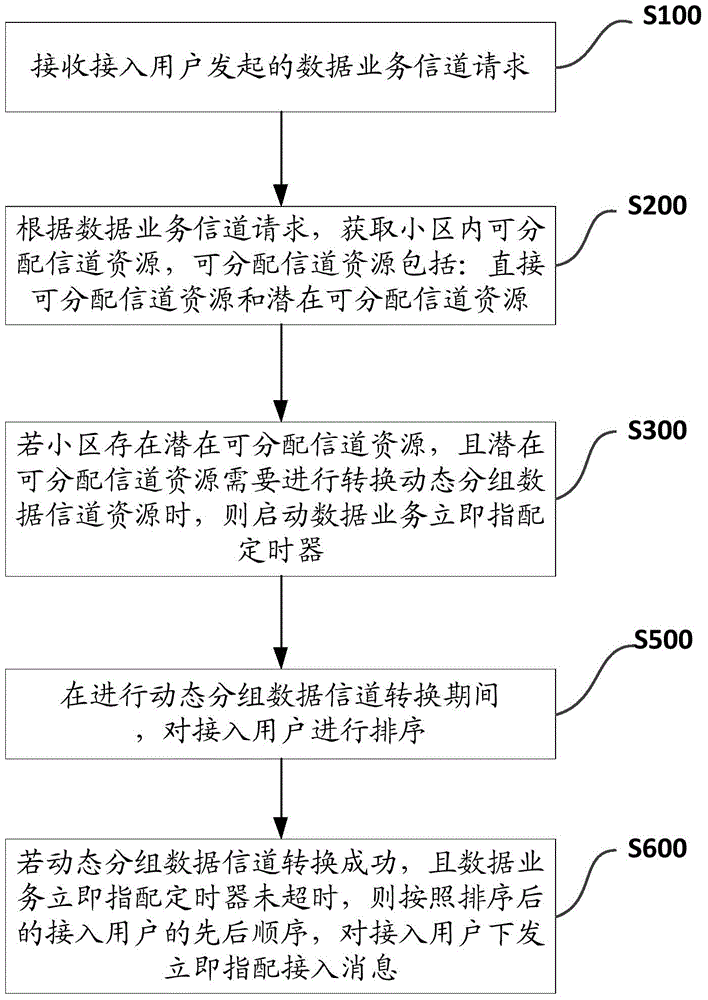

Data service assigning method and device

InactiveCN105578603AReduce access delayReduce the number of complaintsWireless communicationNetwork serviceTimer

The invention provides a data service assigning method and device. The method comprises that a data service channel request initiated by an access user is received; according to the data service channel request, distributable channel resources, including direct distributable channel resources and potential distributable channel resources, in a cell are obtained; if the potential distributable channel resources exist in the cell and the potential distributable channel resources need to be converted into dynamic packet data channel resources, a data service immediate assigning timer is started; and if dynamic packet data channel resource conversion succeeds, and the data service immediate assigning timer is not overtime, an immediate assigning access message is issued to the access user. The method and device of the invention can be used to reduce the time delay of user access, improve the utilization rate of network channels, and further to reduce the complaint amount of the users, and ensure that the users obtain the network service timely.

Owner:CHINA MOBILE GROUP ZHEJIANG

Manufacturing method of wood carving film-pressing door plank

PendingCN112025902AReduce idle wait timeShorten the timeProfiling/shaping machinesWood veneer joiningSanderNumerical control

The invention discloses a manufacturing method of a wood carving film-pressing door plank.The manufacturing method comprises the following steps that step one. a numerical control carving machine comprising a reverse side carving machine position and at least two front side carving machine positions is used for carving a door plank base material, the reverse side carving machine position is used for carving reverse side patterns and hinge holes in the door plank base materials continuously entering in sequence, the door plank base material with the reverse side being carved is turned to the front side by a turning part and is sent to the idle front side carving machine positions by a conveying belt for front side pattern caving, and the time for carving the reverse side of the door plank base material is less than the time for carving the front side of the door plank base material; step two. the door plank base material with the front side and the reverse side being carved is put intoa special-shaped sanding machine to be subjected to surface burr polishing, and surface burrs are removed; step three. surface glue spraying operation is performed on the polished door plank base material, and the polished door plank base material is placed and aired; and step four. the aired door plank base material is fed into a plastic vacuum forming machine to be subjected to PVC (polyvinyl chloride) high-temperature film coating. The manufacturing method can reduce labor cost and improve manufacturing efficiency.

Owner:上海速居科技集团有限公司

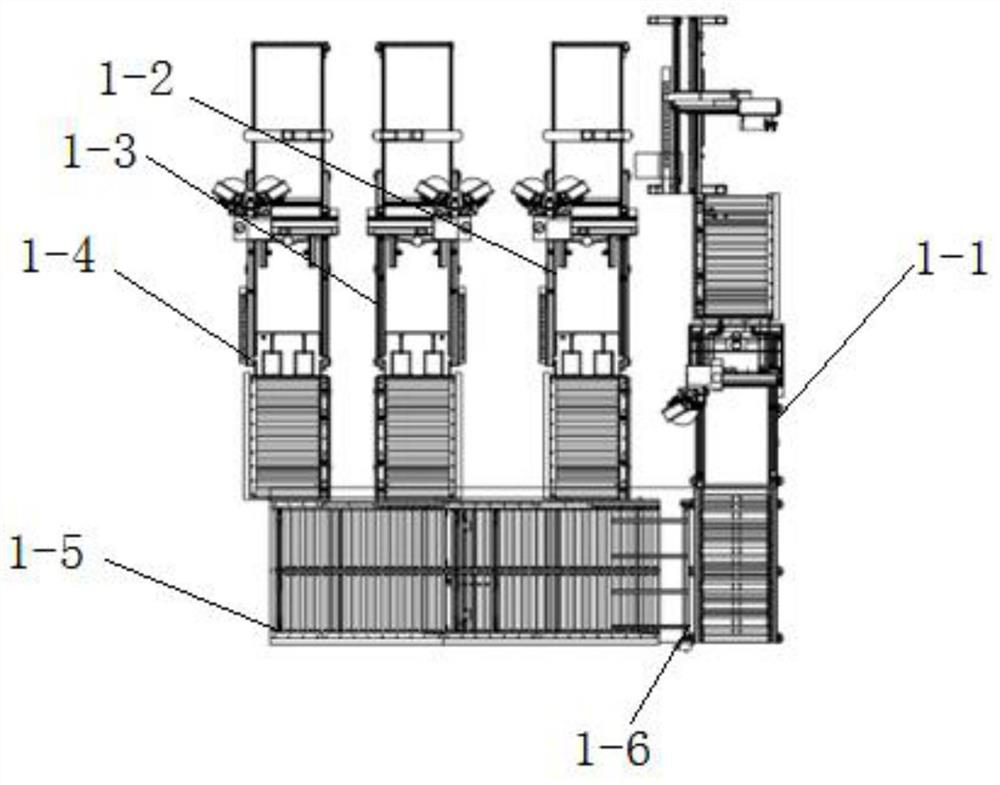

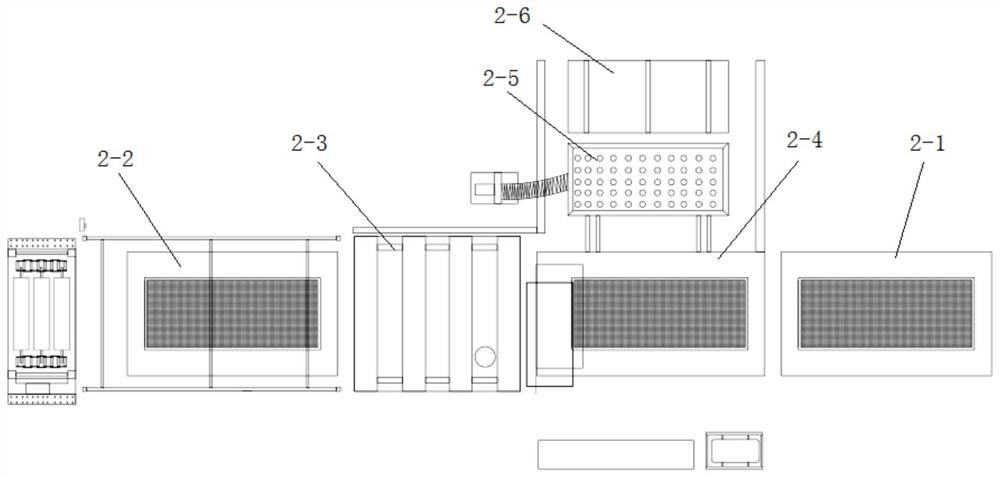

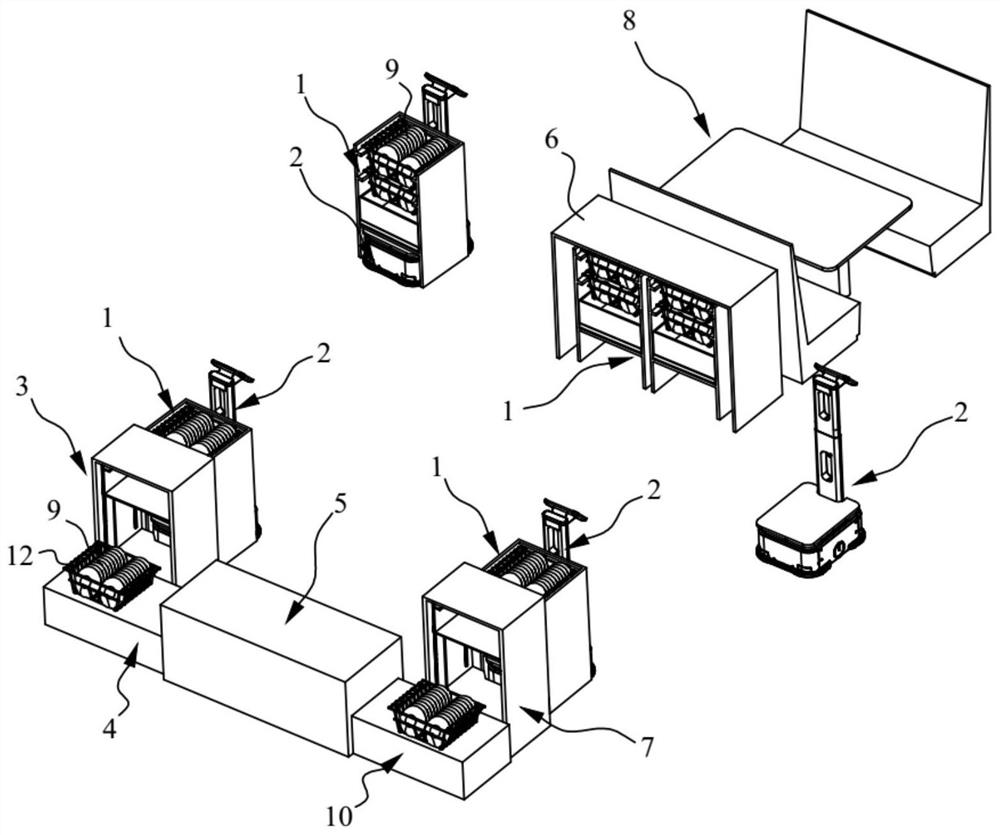

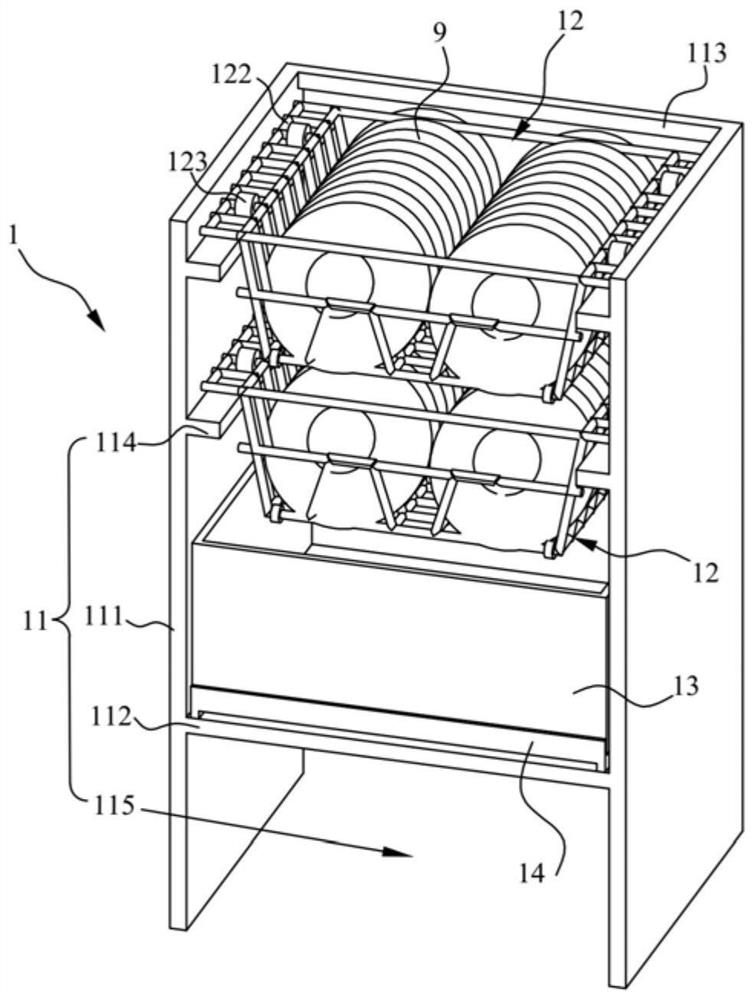

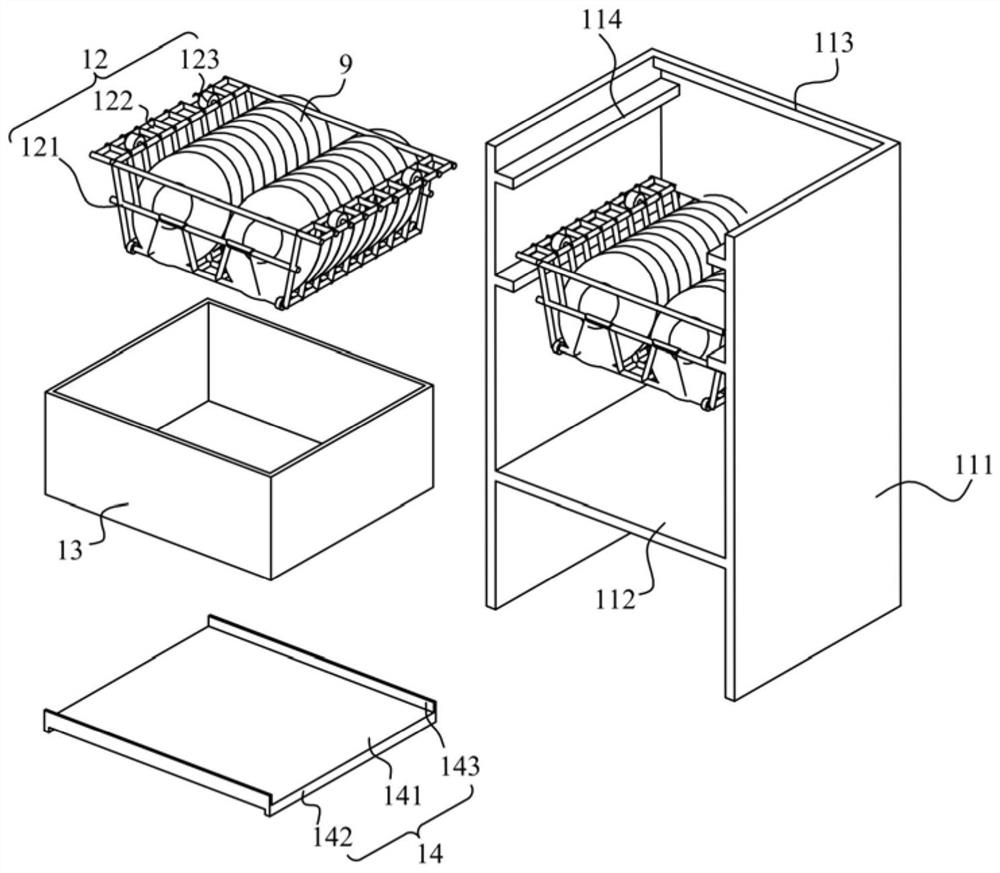

Storage cabinet and tool recovery system

ActiveCN112110116ADegree of reductionHigh degree of automationProgramme-controlled manipulatorStorage devicesSoftware engineeringFuture of robotics

The invention belongs to the technical field of robots, and particularly discloses a storage cabinet and a tool recovery system. A tool containing space used for containing tools is formed in the storage cabinet, and the storage cabinet can be independently arranged and can send an instruction to a conveying robot according to the tool containing state in the tool containing space, so that the conveying robot conveys the storage cabinet to a first preset point. The tool recovery system comprises the storage cabinet capable of being independently placed and provided with a tool containing space, and a conveying robot used for moving the storage cabinet. The storage cabinet can send the instruction to the conveying robot according to the tool containing state in the tool containing space, and the conveying robot can convey the storage cabinet according to the instruction sent by the storage cabinet. According to the storage cabinet and the tool recovery system, the tool recovery automation degree and the tool recovery efficiency can be improved, and the use cost of the tool recovery system is reduced.

Owner:KEENON ROBOTICS CO LTD

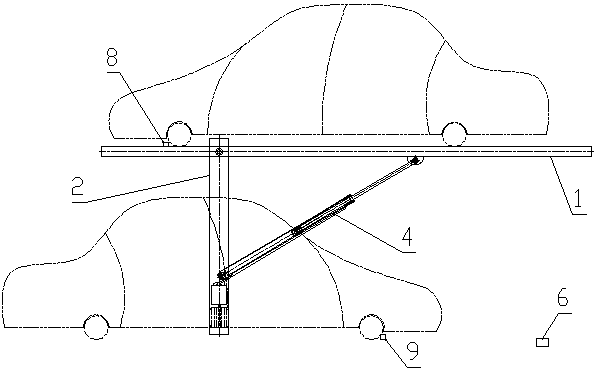

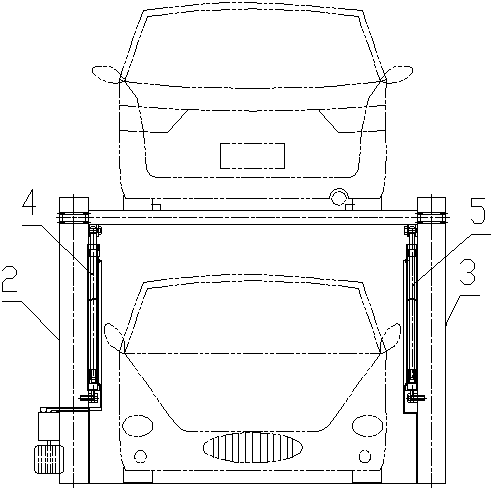

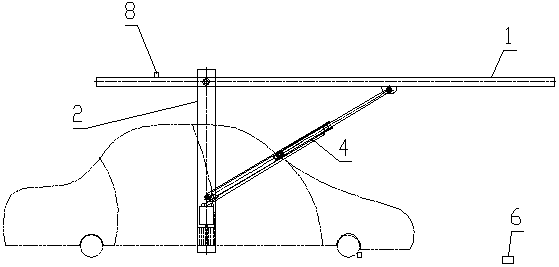

Simple double-layer parking mechanism and vehicle parking and taking method

The invention discloses a simple double-layer parking mechanism, and further discloses a vehicle parking and taking method. The simple double-layer parking mechanism comprises a vehicle standing plate, front stand columns and rear stand columns, and the front stand columns and the rear stand columns are correspondingly arranged at intervals in a front and rear mode. The length of the vehicle standing plate is L meters, the front side of the left part of the vehicle standing plate is hinged to the tops of the front stand columns, and the rear sides of the left part of the vehicle standing plateis hinged to the tops of the rear stand columns; a front hydraulic cylinder is hinged to the lower part of the stand columns, an extending rod of the front hydraulic cylinder is hinged to the front part of the vehicle standing plate, an extending rod of a rear hydraulic cylinder is hinged to the rear part of the vehicle standing plate, and the vehicle standing plate is provided with a parking position and a vehicle taking and placing position under the drive of the front hydraulic cylinder and the rear hydraulic cylinder; and the upper part of the vehicle standing plate is an upper parking space, and the ground on the lower part of the vehicle standing plate is a lower upper parking space. The simple double-layer parking mechanism is simple in structure, low in cost, more convenient to install and use, high in degree of intelligence and high in vehicle parking and taking efficiency, can make full use of corner areas on both sides of urban roads or at residential areas and green spaces, and is very suitable for popularization and application. The floor space is reduced by half due to double-layer parking.

Owner:朱灿灿

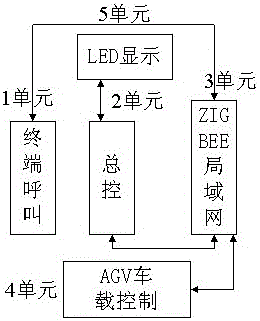

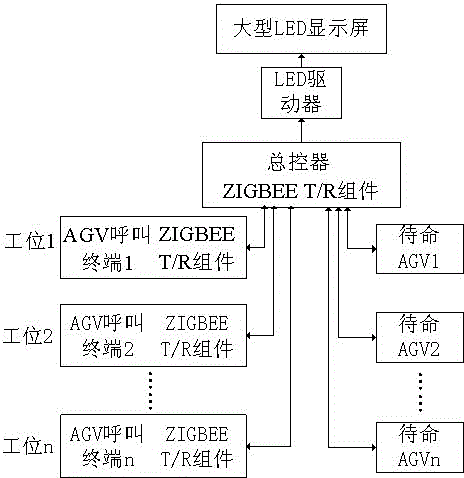

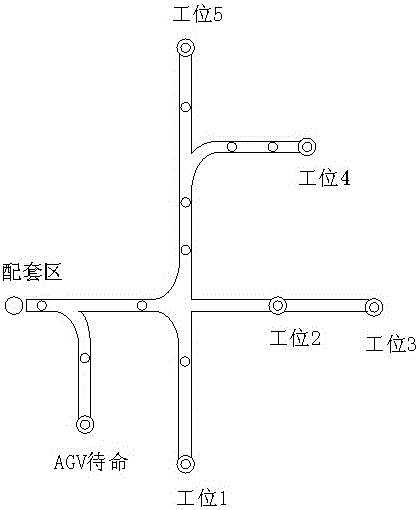

An agv call display and control system based on zigbee LAN

ActiveCN104122879BReduce idle wait timeSave manpower andTransmission systemsNetwork topologiesLED displaySpace environment

The invention discloses an AGV (Automatic Guided Vehicle) calling display control system based on the ZIGBEE local area network. The system comprises a calling terminal module, a master control decision-making module, a ZIGBEE local area network module, an AGV vehicle-mounted control and communication module and an LED display module; the terminal calling module and the AGV vehicle-mounted control and communication module are connected with the master control decision-making module through the ZIGBEE local network area module; the LED display module is connected with a master control module. According to the system, ZIGBEE is utilized to perform wireless transmission, the system controls the AGV, and thus the AGV management labor is decreased, the conflict between management staffs is avoided, the AGV can be dispatched in sequence, the idling and waiting time of the AGV is decreased, and the production of a plant can be matched well; the ZIGBEE local area network applies to a complex electromagnetic space environment of the plant; an LED display screen can be used for displaying the state of the AGV.

Owner:CHENGDU SIWI HIGH TECH IND GARDEN

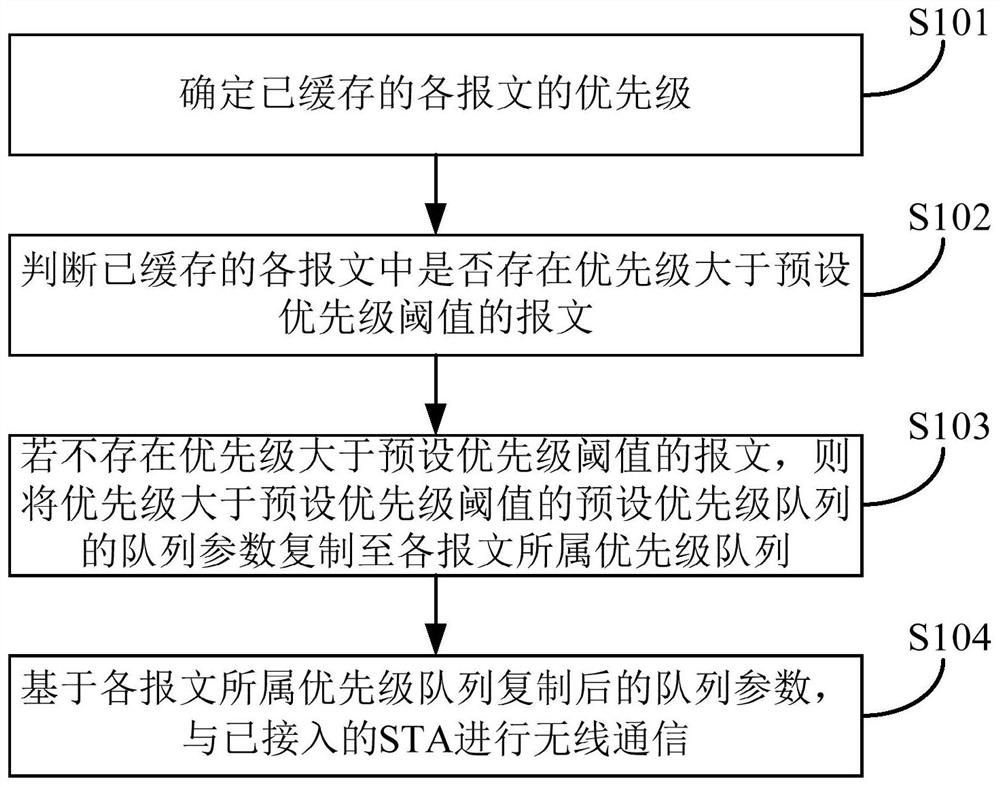

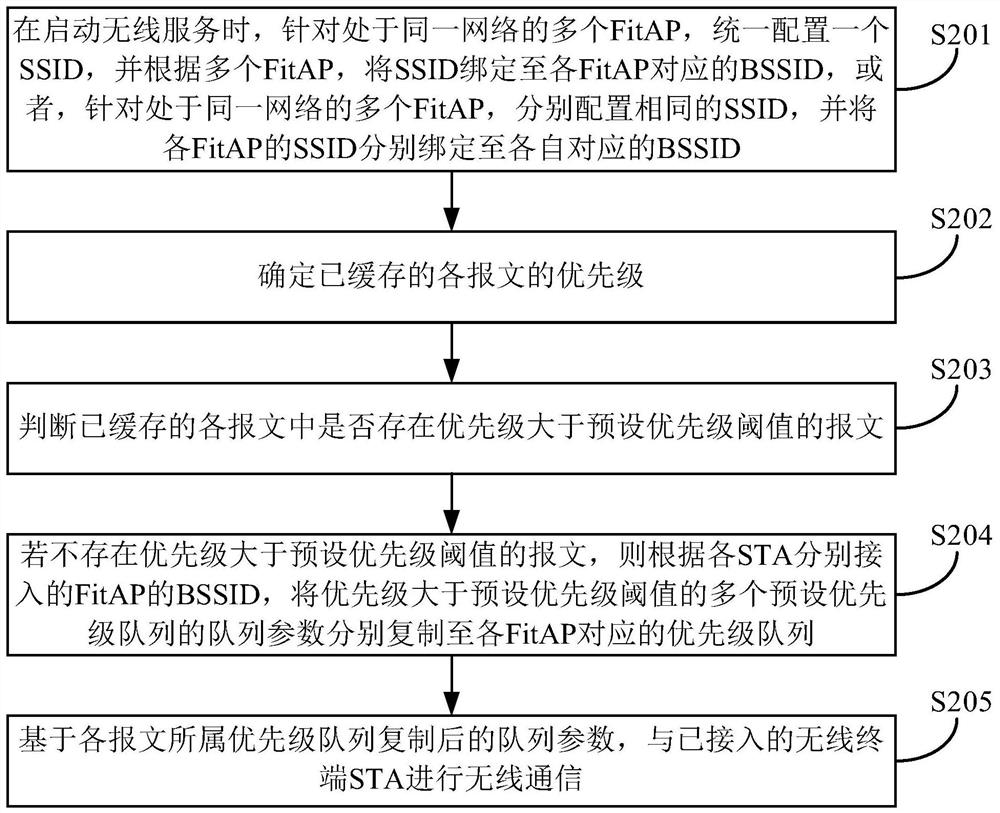

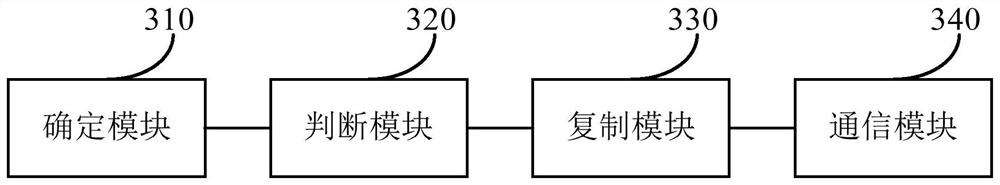

A wireless communication method and device

ActiveCN108933741BImprove transmission efficiencyReduce idle wait timeTransmissionComputer networkTelecommunications

Embodiments of the present invention provide a wireless communication method and device, wherein the wireless communication method is applied to a wireless access device, and the method includes: determining the priority of each cached message; judging whether each cached message is There is a message with a priority greater than the preset priority threshold; if it does not exist, the queue parameters of the preset priority queue with a priority greater than the preset priority threshold are copied to the priority queue to which each message belongs; based on each message The copied queue parameters of the priority queue to which it belongs are used for wireless communication with the connected STA. Through this solution, the message transmission efficiency can be improved.

Owner:NEW H3C TECH CO LTD

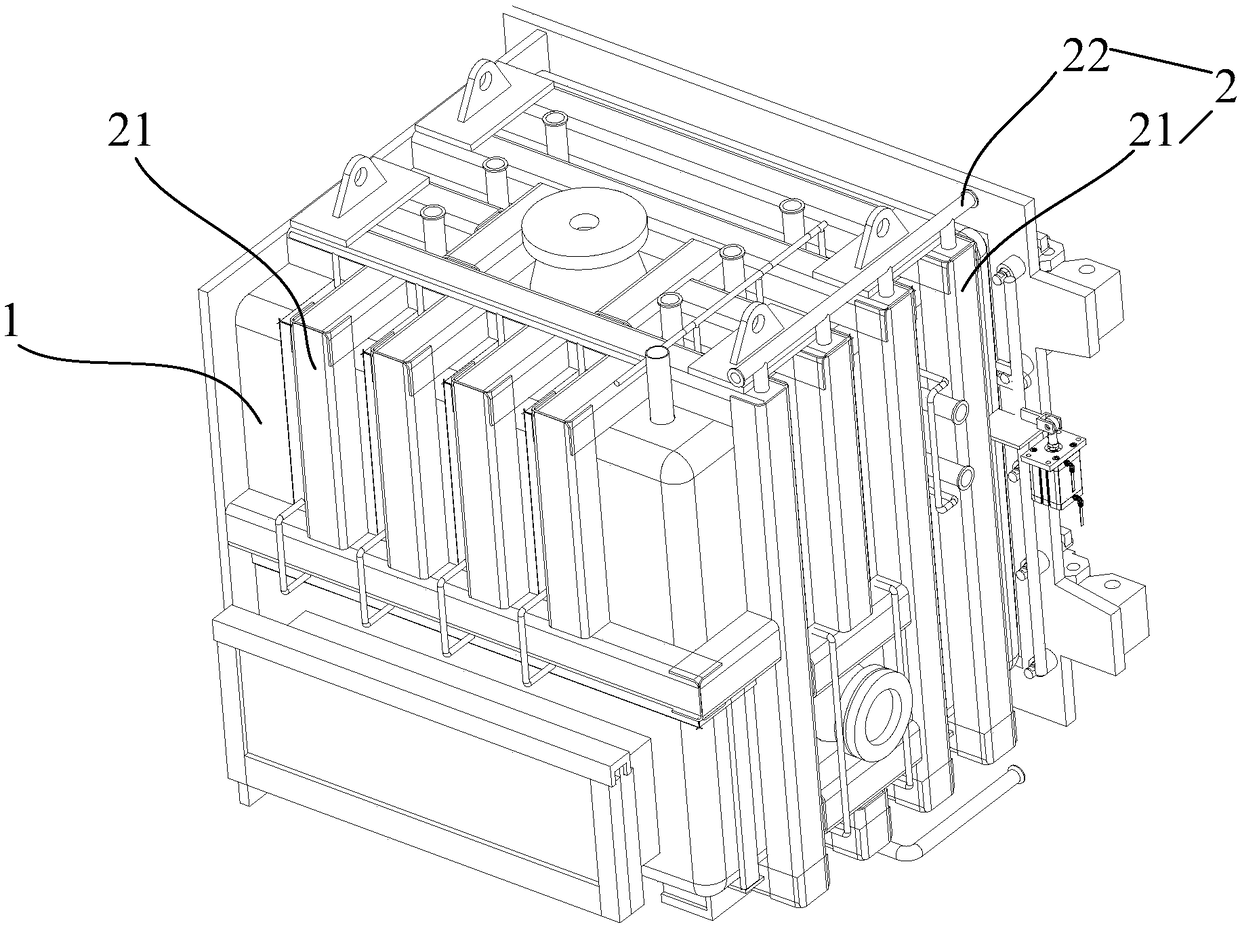

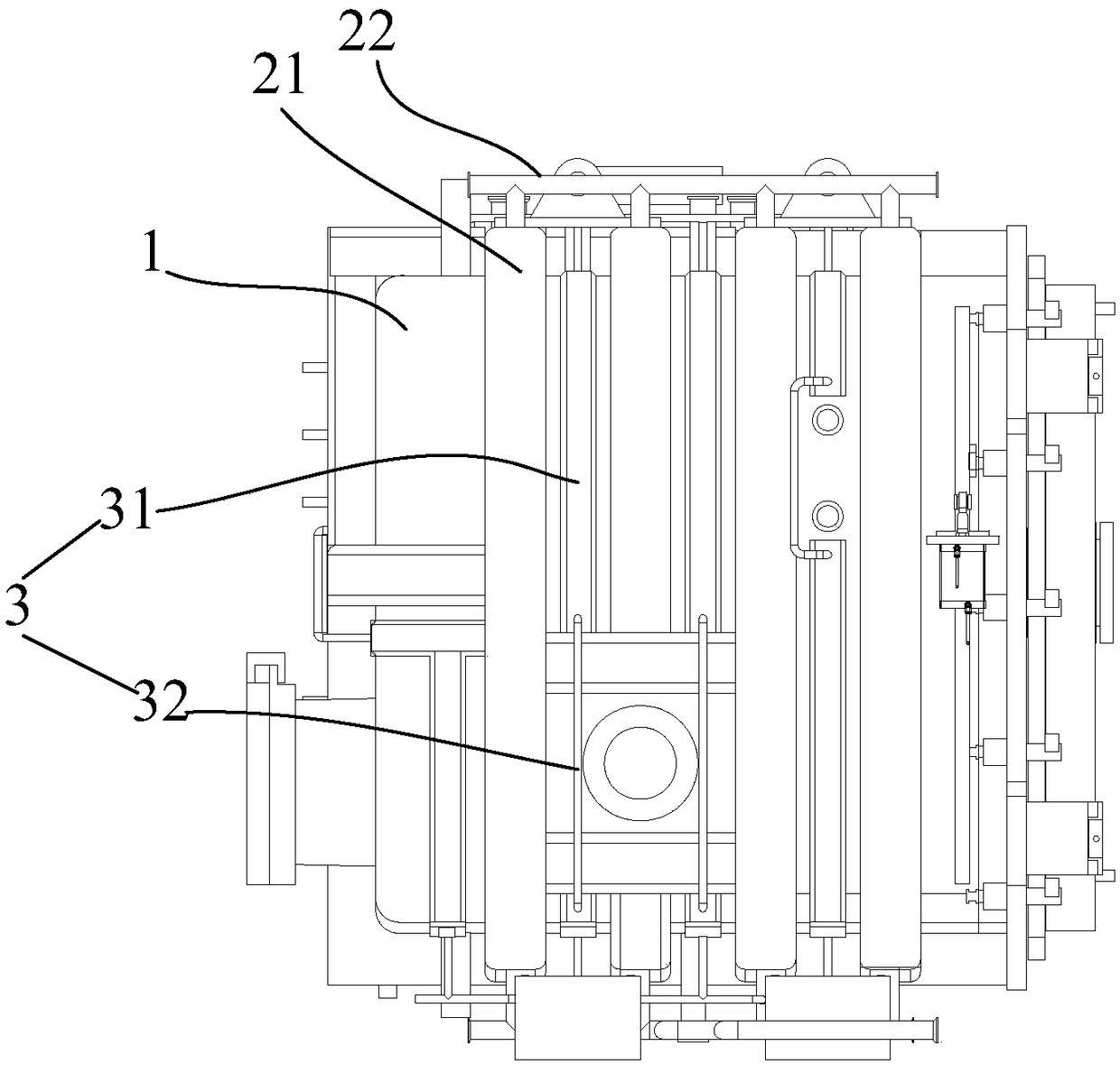

Freeze dryer and box thereof

InactiveCN109140910AReduce dosageFast coolingDrying solid materials without heatHeating timeFreeze-drying

The invention discloses a box of a freeze dryer. The box of the freeze dryer comprises a box inner shell; a freeze drying bin is surrounded by the box inner shell; and the box inner shell is providedwith a pure steam input pipe communicating with the freeze drying bin. The box of the freeze dryer further comprises an auxiliary heating flow path and an auxiliary cooling flow path arranged on the outer side of the box inner shell and contacted with the box inner shell; and the auxiliary heating flow path and the auxiliary cooling flow path are independent two sets of flow paths. The box of thefreeze dryer can quickly increase the sterilization temperature during sterilizing; on the one hand, the consumption of saturated pure steam is reduced, so that the production cost is reduced; and onthe other hand, the heating time is effectively shortened, so that the sterilization efficiency is improved; and after sterilization, the proper temperature can be quickly lowered to, so that the idlewaiting time of the freeze dryer is greatly shortened, and the production efficiency and the equipment utilization rate are improved. The invention further discloses the freeze dryer adopting the box.

Owner:烟台冰轮医药装备有限公司

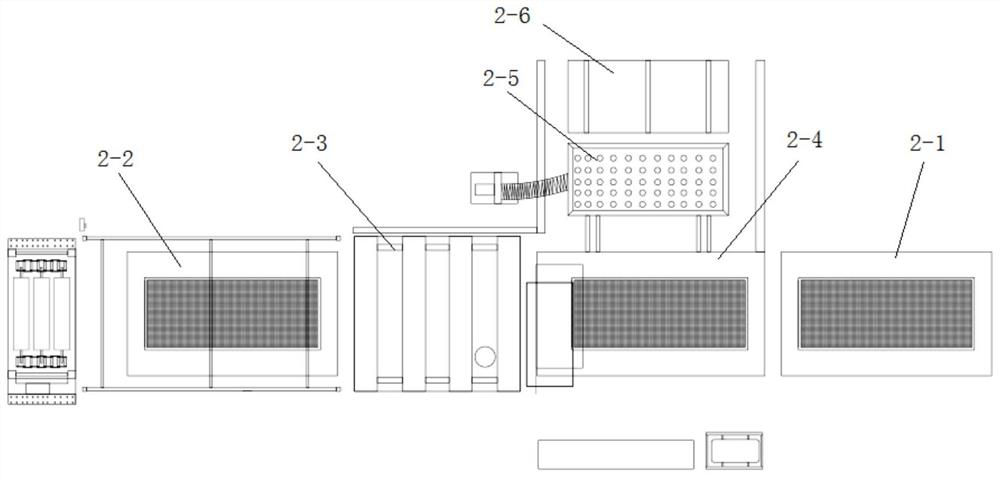

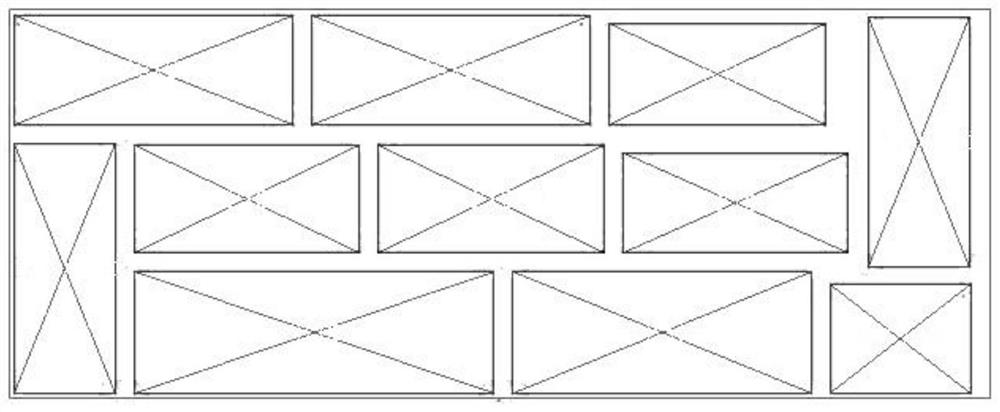

Efficient manufacturing method of wood carving film pressing door plate

PendingCN112008824AEfficient preparation methodReduce idle wait timeDecorative surface effectsLaminationNumerical controlFilm-coated tablet

The invention discloses an efficient manufacturing method of a wood carving film pressing door plate. The efficient manufacturing method comprises the following steps that a numerical control carvingmachine is used for carving the front face and the back face of a door plate base material; surface burr grinding is conducted on the door plate base material with the front face and the back face being carved, and surface burrs are removed; the surface glue spraying operation is conducted on the ground door plate base material, and the placing and airing are conducted; before a plurality of doorplate base materials to be subjected to high-temperature film coating are placed on a film coating workbench of a high-temperature film coating machine, the placing positions of the plurality of aireddoor plate base materials to be subjected to high-temperature film coating on a film coating station are reasonably planned and arranged in advance; according to a pre-planned layout, the door platebase materials to be subjected to high-temperature film coating are placed at designated positions of the film coating workbench; the surfaces of the plurality of door plate base materials are coveredwith a PVC film on the film coating workbench; and the film coating workbench drives the door plate base materials to enter the high-temperature film coating station for PVC high-temperature film coating. According to the efficient manufacturing method, the labor cost can be reduced, and the manufacturing efficiency can be improved.

Owner:上海速居科技集团有限公司

A sealed quick disassembly forming cylinder for 3D printing equipment

ActiveCN109895391BSelf-sealingQuick controlAdditive manufacturing apparatusProcess engineeringIndustrial engineering

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

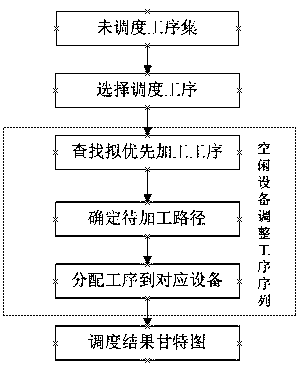

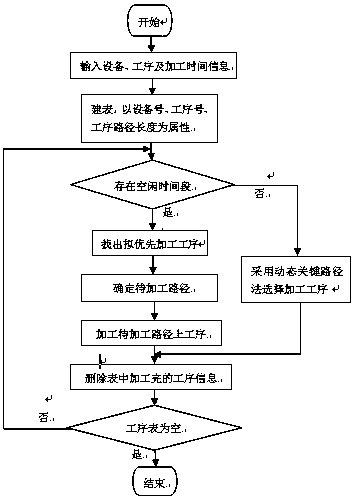

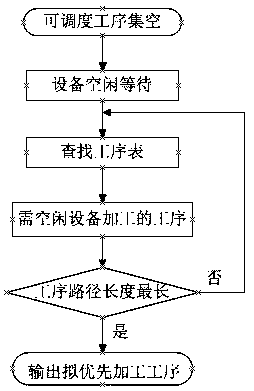

Device driver comprehensive scheduling method for device idle time period adjustment

Disclosed is a device drive integrated dispatching method for adjusting devices during an idle time period. An existing device drive integrated dispatching method does not consider device utilization during the idle time period, and consequently product completion time is influenced. The method comprises the steps that a mode of building a working procedure table is adopted, the device numbers, the working procedure numbers and the working procedure path length are used as three attributes, and descending sorting is carried out according to the working procedure path length; when the devices have the idle time periods, it is indicated that the devices have no working procedures capable of being dispatched, the non-dispatched working procedures needing device processing are found in the table, and the working procedures are used as obtained planned priority processing working procedures; the planned priority processing working procedures are virtualized to root nodes, and a path to the processed is determined; priority dispatching is carried out on working procedures on the path to the processed till processing of the virtual root nodes is completed, and the idle time period of the devices is shortened. The method is used for utilizing the idle time period of part of devices, and therefore the single complex product completion time is shortened.

Owner:HARBIN UNIV OF SCI & TECH

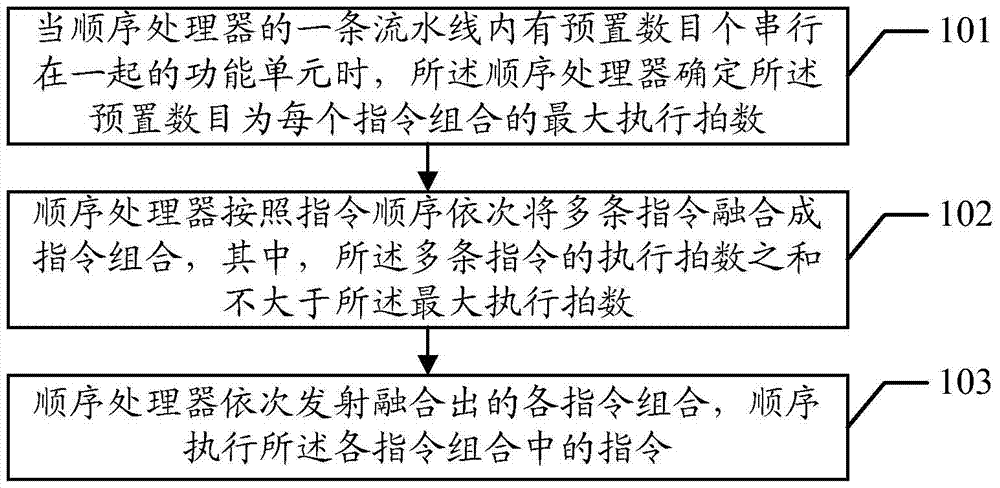

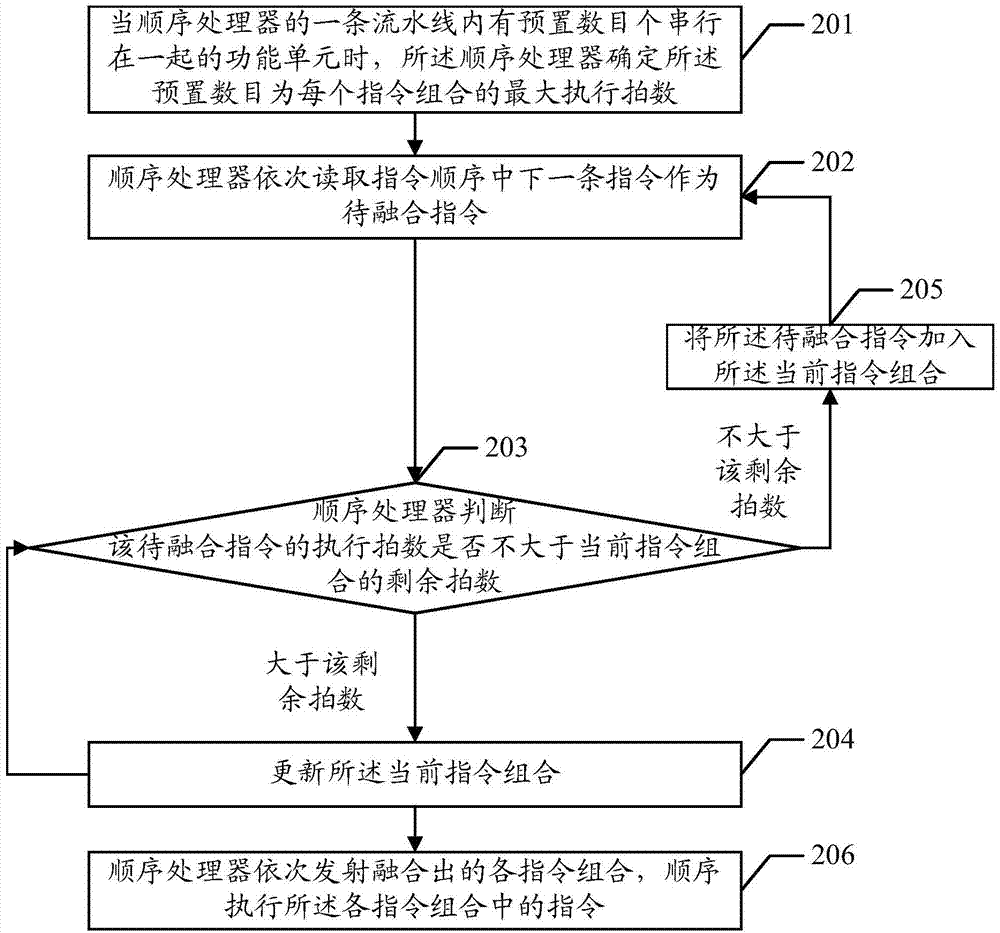

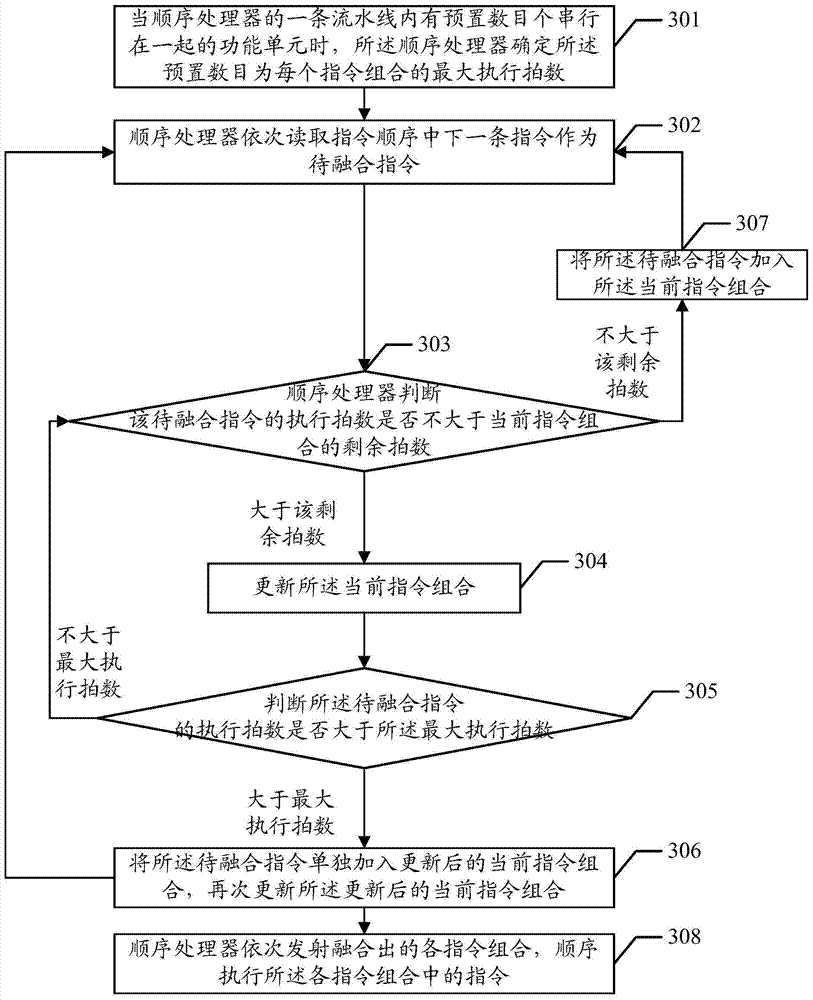

An instruction execution method and sequential processor

ActiveCN105446700BReduce idle wait timePerformanceConcurrent instruction executionParallel computingInstruction sequence

The embodiment of the invention discloses an instruction execution method and a sequential processor, which are used for combining instructions in the sequential processor, reducing idle time, and exerting processor performance to a greater extent. The method in the embodiment of the present invention includes: the sequential processor sequentially fuses multiple instructions into an instruction combination according to the order of instructions, wherein the sum of the execution beats of the multiple instructions is not greater than the maximum execution beats, and then sequentially emits and fuses the instructions into an instruction combination. Each combination of instructions, execute the instructions in each combination of instructions sequentially.

Owner:HUAWEI TECH CO LTD +1

A block chain consensus method, device and electronic equipment for parallel execution

ActiveCN110020859BReduce idle wait timeImprove work efficiencySpecial service provision for substationPayment protocolsComputer architectureIdle time

Owner:杭州秘猿科技有限公司

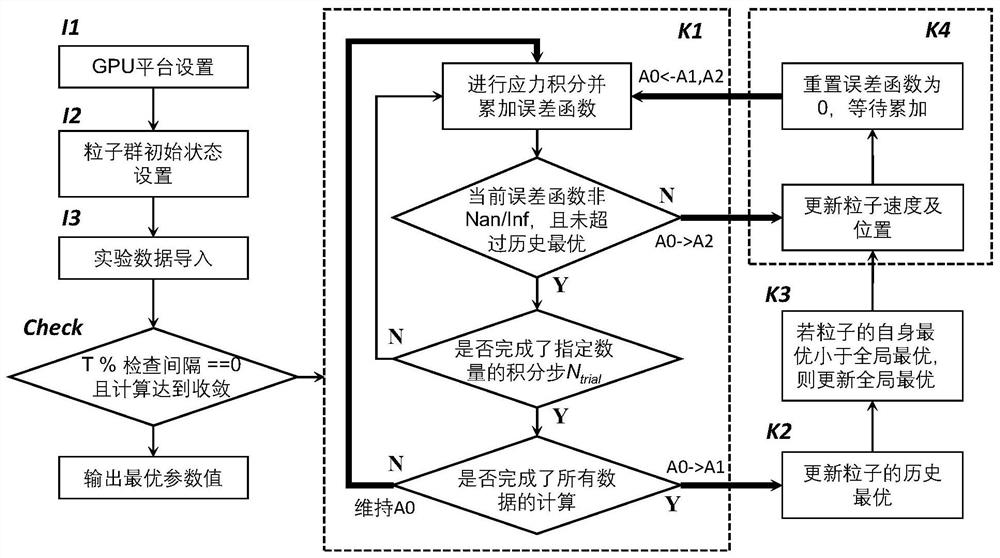

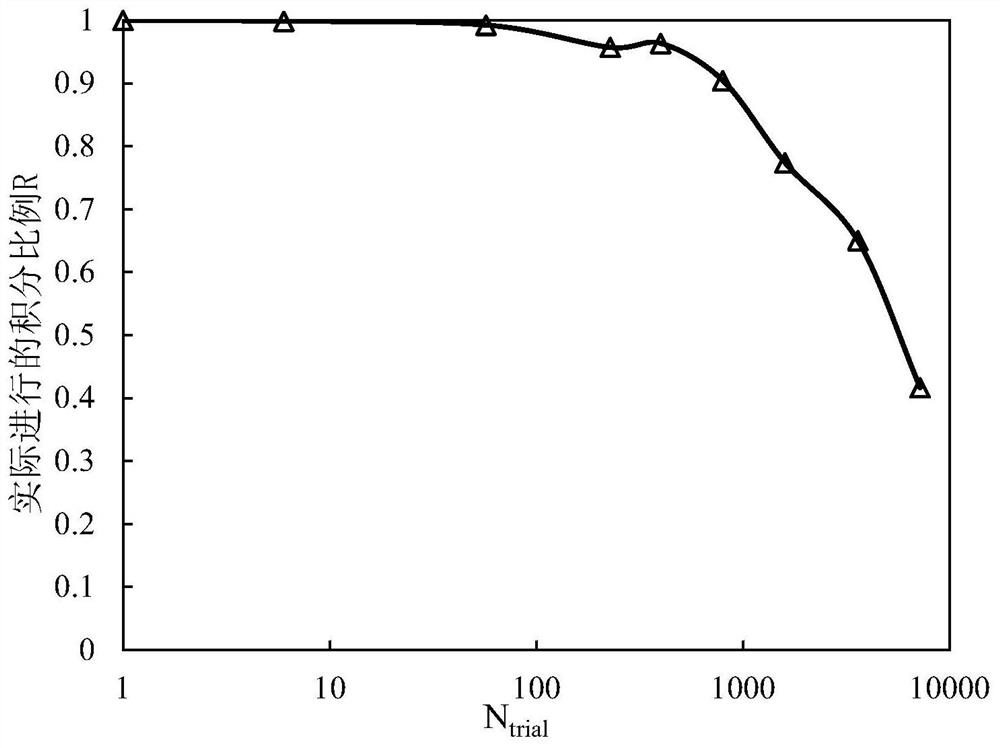

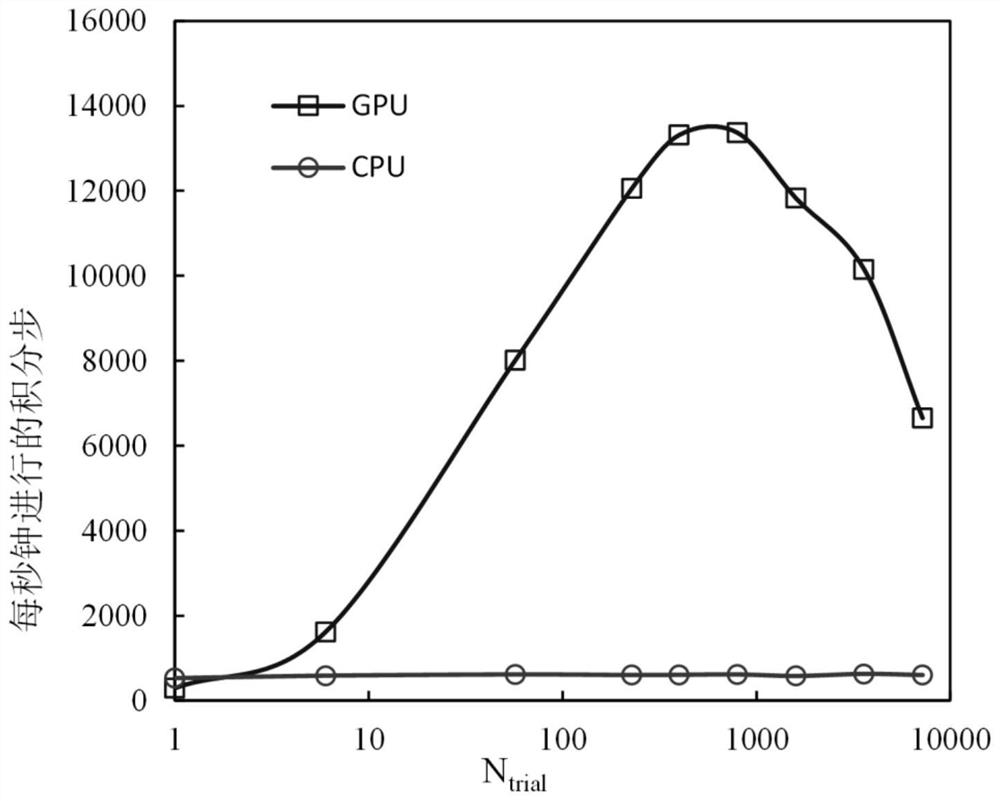

Improved particle swarm method for geotechnical material constitutive model parameter recognition based on GPU acceleration

ActiveCN113239620AReduced stress integration stepReduce computing timeSustainable transportationConcurrent instruction executionComputation processEngineering

The invention discloses an improved particle swarm method for geotechnical material constitutive model parameter recognition based on GPU acceleration, and the method employs a particle swarm algorithm to search for optimal model parameters, and enables the cumulative error of the deviation square of a model calculation value and an experiment value of stress to be minimum. Based on the characteristic that the calculation amount is large in the calculation process, the problem of calculation efficiency is solved from the two aspects of algorithm optimization and high-performance hardware application. On one hand, an early termination mechanism is introduced according to the characteristics of error function accumulation, so that the calculation amount is saved; and on the other hand, the computing equipment applying the GPU makes optimization of a program structure according to the characteristics of an instruction set of the computing equipment. The method has the beneficial effect that the cross-order-of-magnitude calculation efficiency is improved.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

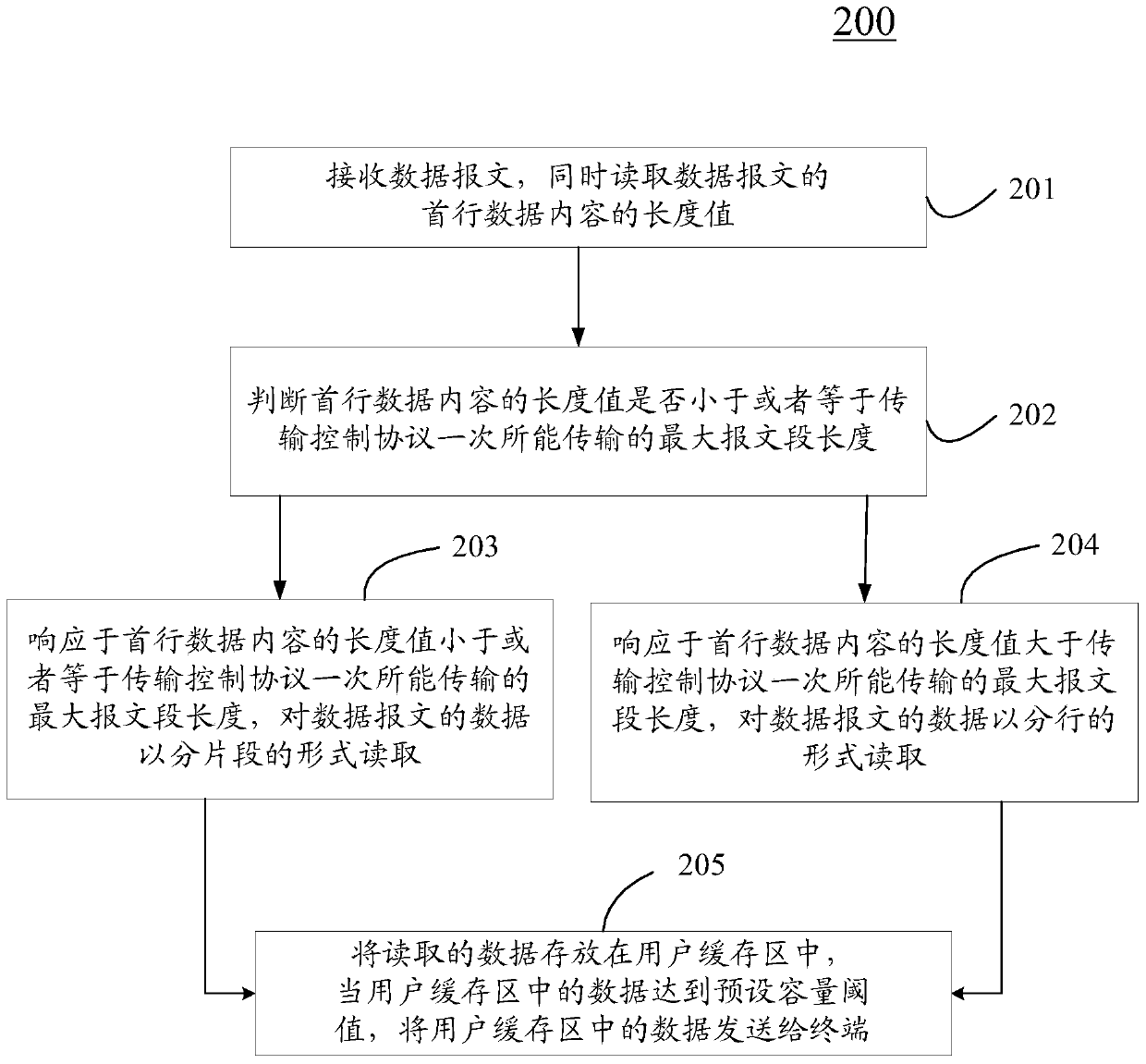

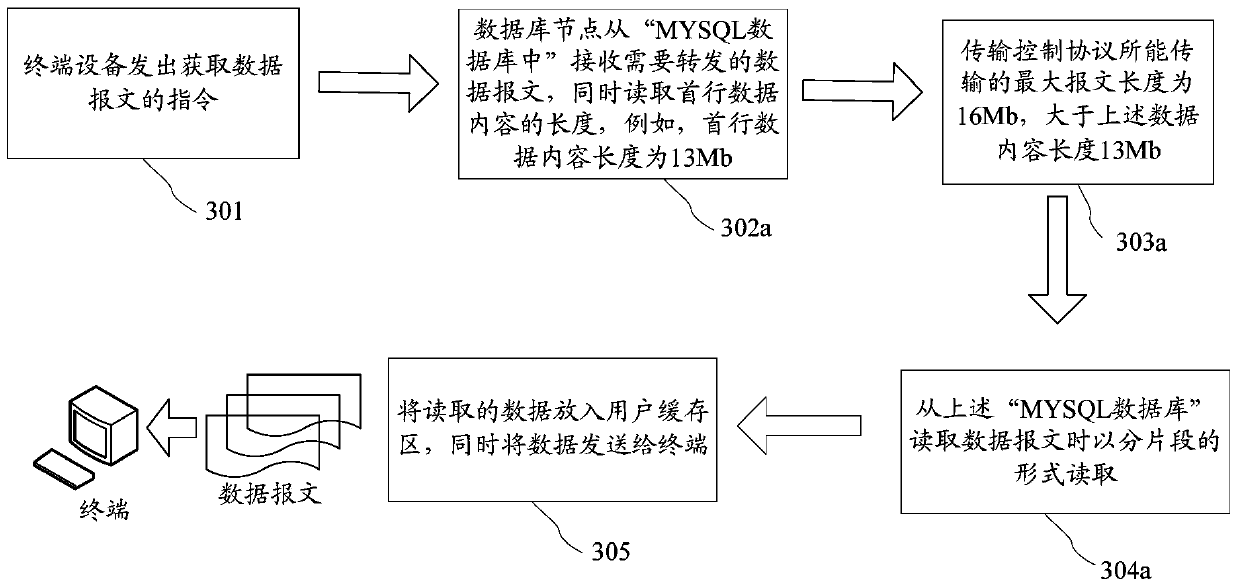

Data message forwarding method and device

ActiveCN106067865BEfficient forwardingReduce idle wait timeData switching networksData contentComputer terminal

The application discloses a data packet forwarding method and device. A specific implementation of the method includes: receiving a data message, and simultaneously reading the length value of the first line of data content in the data message; message segment length; in response to the length value being less than or equal to the maximum message segment length that the transmission control protocol can transmit at one time, the data of the data message is read in the form of fragments; in response to the The length value is greater than the maximum message segment length that the transmission control protocol can transmit at one time, and the data of the data message is read in the form of branches; the read data is stored in the user buffer area, when the user The data in the buffer area reaches the preset capacity threshold, and the data in the user buffer area is sent to the terminal. This embodiment implements fast and efficient forwarding of data packets.

Owner:BEIJING BAIDU NETCOM SCI & TECH CO LTD

A method for converting multiple test channels in a test system

InactiveCN103163407BReduce idle wait timeImprove efficiencyElectrical testingTest channelProduct testing

The invention discloses a conversion method of multiple testing channels of a testing system. The conversion method of the multiple testing channels of the testing system includes that a switch used for judging if the testing channels are ready or not is installed at a tail end of each testing channel of the testing system. A queue for starting testing orders and storing all testing channels of the testing system is set up. Firstly, whether each testing channel of the testing system is ready or not is sequentially judged. If yes, orders to start tests of the testing channels which are ready are stored in the queue for starting the testing orders and the process is repeated at intervals. Secondly, an order to start a test is abstracted from the queue for starting the testing orders and a test of a corresponding channel is started. After the test is finished, the next order to start a test is abstracted from the queue for starting the testing orders and the process is repeated in the same way, wherein the first step and the second step work individually. Automatic conversion of the testing systems of the testing system is achieved through data coordination of the queue for stating the testing orders. By means of the conversion method, automatic conversion of multiple testing channels of the testing system of electronic products is achieved and utilization efficiency of testing instruments is improved.

Owner:浙江明凯照明有限公司

Scanning path planning method, device and three-dimensional object manufacturing equipment based on dual lasers

ActiveCN110524883BReduce interactionReduce idle wait timeAdditive manufacturing apparatus3D object support structuresLaser scanningEngineering

A scanning path planning method and device based on dual lasers, and a three-dimensional object manufacturing device, wherein the method includes: at most one workpiece to be printed in the current layer section of the work package is scanned by two lasers, and the current layer section of the work package is scanned by two lasers. Other workpieces to be printed are scanned by only one laser, and the workpieces to be printed that are scanned by two lasers are contours, and the areas filled on the upper surface and filled on the lower surface are scanned by the same laser. The scanning path planning method and device based on dual lasers and the three-dimensional object manufacturing equipment of the present invention reasonably allocate the scanning time of each laser by estimating the scanning time of the current layer section, reducing the idle waiting time of the lasers, that is, ensuring the scanning quality Under the premise of reducing the laser scanning waiting time as much as possible.

Owner:HUNAN FARSOON HIGH TECH CO LTD

Method and system for quickly starting a TV

ActiveCN103002343BReduce idle wait timeImprove boot speedProgram loading/initiatingSelective content distributionTelevision systemWaiting time

Owner:SHENZHEN TCL NEW-TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com