Novel multi-station automatic component inserter

An automatic plug-in machine and multi-station technology, applied in the direction of electrical components, electrical components, etc., can solve problems such as complex structure, reduced economic benefits, and low degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

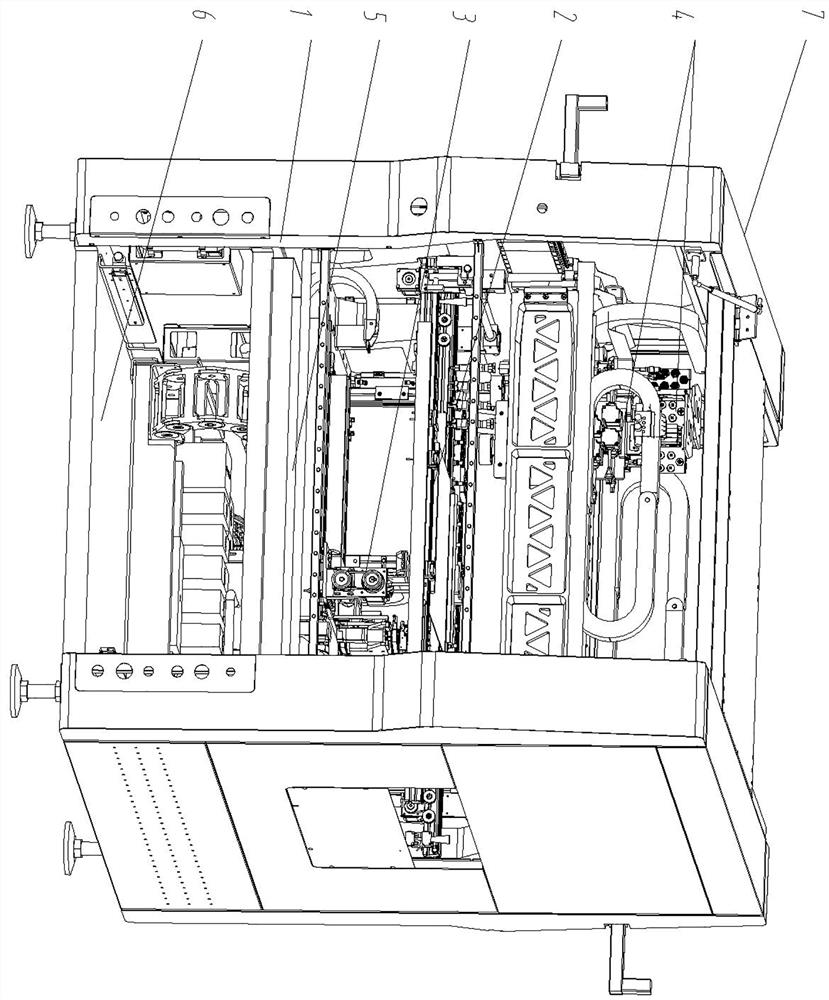

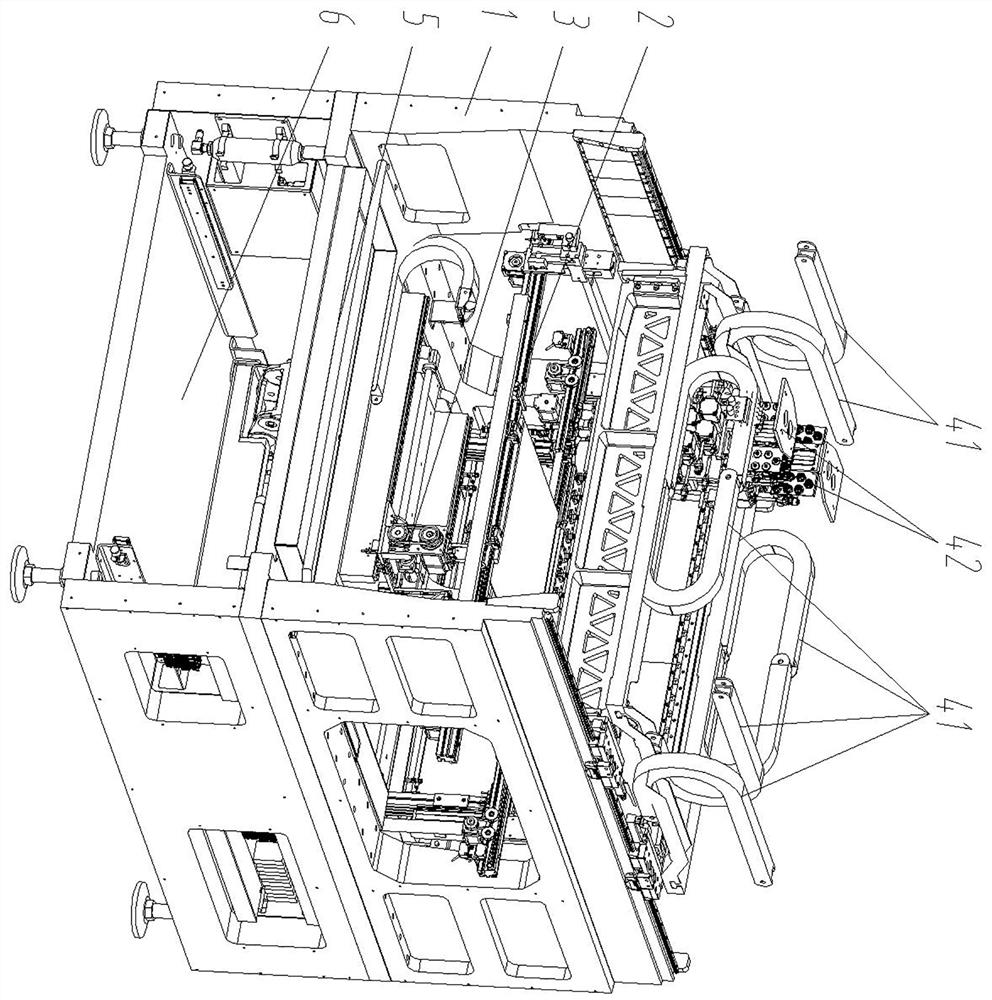

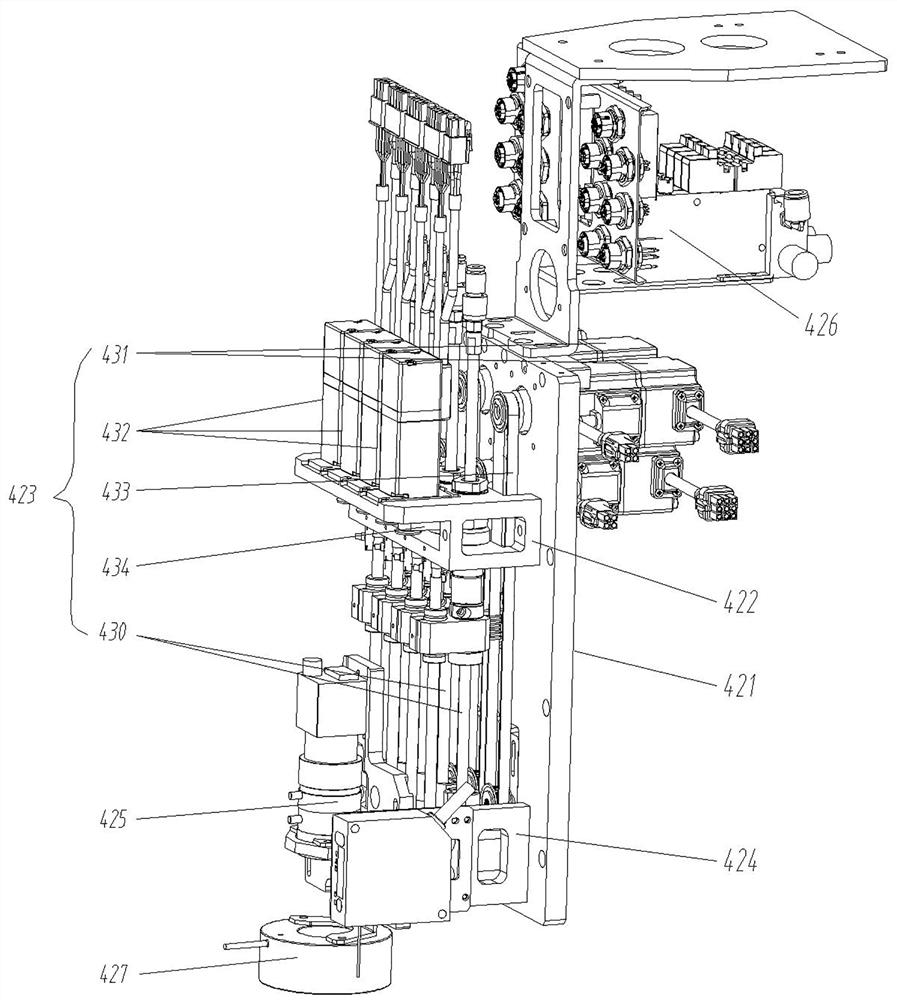

[0025] Such as Figure 1 to Figure 9 As shown, in this embodiment, the present invention includes a cabinet 1, and the cabinet 1 is provided with a PCB conveying module 2, a bent foot module 3 and two sets of plug-in modules 4, and the PCB conveying module 2 runs through all The cabinet 1 is connected with the production line for conveying PCB products, and the bending foot module 3 is located below the PCB conveying module 2 for bending the pins on the PCB products. The two groups of plug-in modules 4 are located above the PCB conveying module 2 for inserting the PCB products on the PCB conveying module 2. The cabinet 1 is used for accommodating various modules and integrating each module into one space, and the PCB conveying module 2 is used for conveying PCB products, and its two ends pass through channels opened on both sides of the cabinet 1 The mouth is connected with an external production line or assembly line, which can realize online production; the bending foot mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com