Method and device for preparing composite phosphate fertilizer from wastewater

A phosphate fertilizer and wastewater technology, applied in fertilization equipment, sewage/sludge fertilizer, chemical instruments and methods, etc., can solve the problems of less adsorption, low purity of phosphate fertilizer, harsh conditions, etc., and achieve saving of operating costs and high selective adsorption , good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

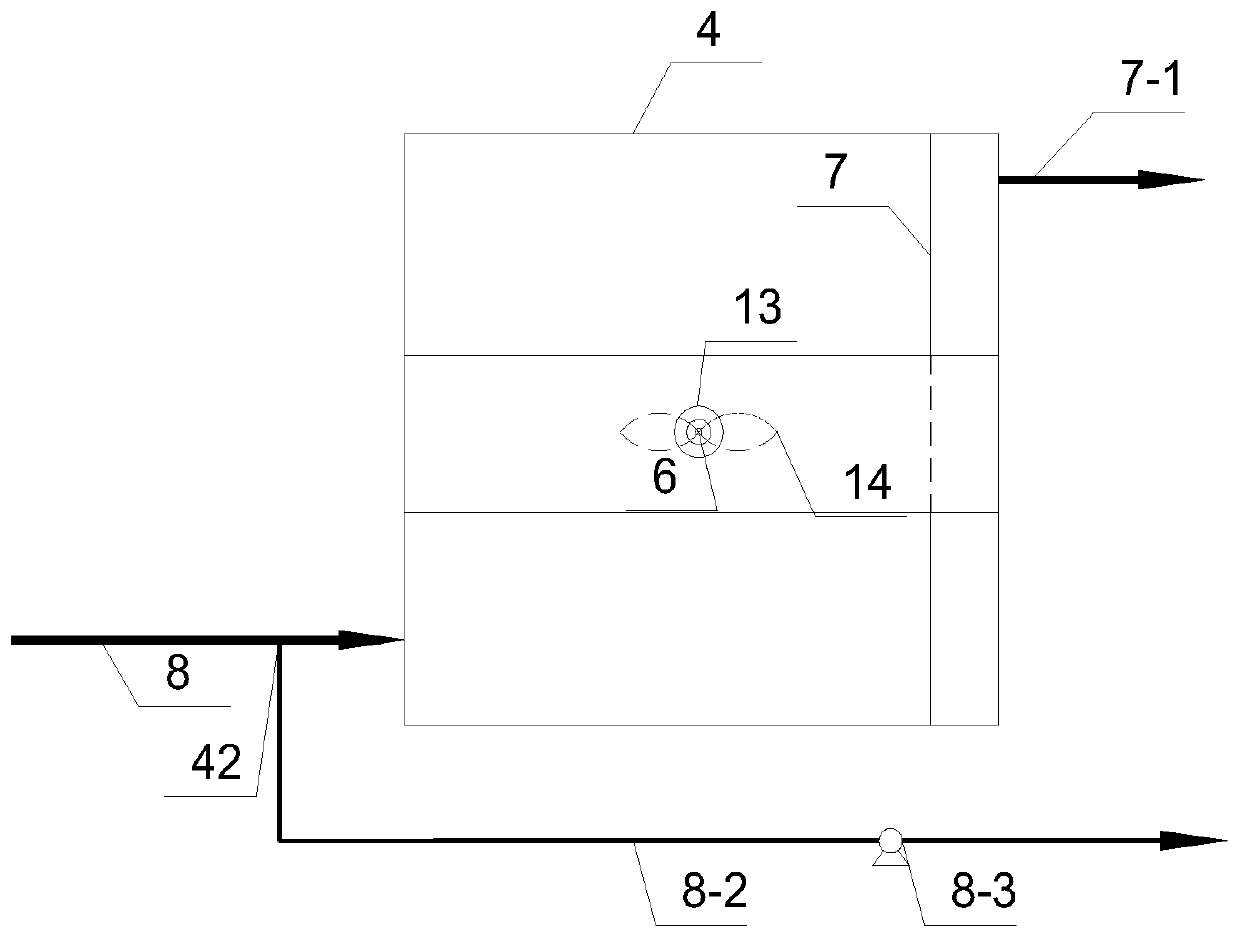

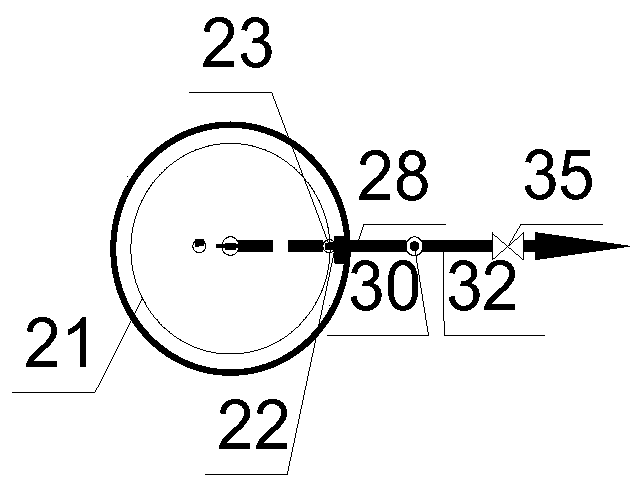

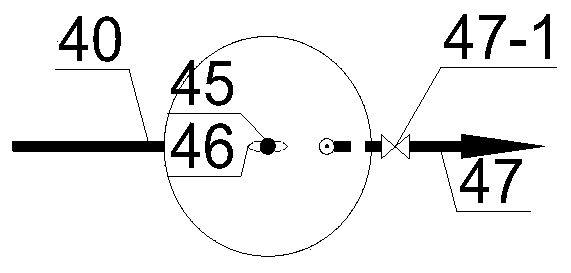

Method used

Image

Examples

Embodiment 1

[0037] Example 1 Preparation of lanthanum-loaded adsorbent

[0038] (1) N 2 Under protection, 0.42mol / L FeCl 3 solution with 0.21mol / L FeCl 2 Solution and 25wt% ammonia monohydrate solution were mixed and stirred according to the volume ratio of 1:1:2, and 0.50mol / L nitric acid was added to adjust the pH to 3 to obtain Fe 3 o 4 Nano magnetic nucleus precursor suspension 66 mL;

[0039] (2) Under the condition of heating in a water bath at 70°C, slowly inject 5mL of an ethanol solution of 10wt% trimethylsiloxysilicate into the suspension prepared in step (1) until the concentration of sodium silicate is 2.5wt%, The precipitate was magnetically separated, washed and dried to obtain SiO 2 wrapped Fe 3 o 4 Granules 5.2g;

[0040] (3) Add 3.65g of magnesium chloride hexahydrate (18 mmol), 0.3176g of aluminum trichloride hexahydrate (3mmol), and 1.11g of lanthanum chloride heptahydrate (3mmol) into 400mL of NaOH solution with a concentration of 1.5mol / L, A magnesium aluminu...

Embodiment 2

[0043] Example 2 Preparation of adsorbent for loading hafnium

[0044] (1) N 2 Under protection, 0.42mol / L FeCl 3 solution with 0.21mol / L FeCl 2 Solution and 25wt% ammonia monohydrate solution were mixed and stirred according to the volume ratio of 1:1:2, and 0.50mol / L nitric acid was added to adjust the pH to 3 to obtain Fe 3 o 4 Nano magnetic nucleus precursor suspension 66 mL;

[0045] (2) Under the condition of heating in a water bath at 70°C, slowly inject 5mL of an ethanol solution of 10wt% trimethylsiloxysilicate into the suspension prepared in step (1) until the concentration of sodium silicate is 2.5wt%, The precipitate was magnetically separated, washed and dried to obtain SiO 2 wrapped Fe 3 o 4 Granules 5.2g;

[0046] (3) Add 3.65g of magnesium chloride hexahydrate (18 mmol), 0.3176g of aluminum trichloride hexahydrate (3mmol), and 1.7g of hafnium oxychloride octahydrate (3mmol) into 400mL of NaOH solution with a concentration of 1.5mol / L , to obtain a magn...

Embodiment 3

[0049] Example 3 Preparation of adsorbent for loading cerium

[0050] (1) N 2 Under protection, 0.42mol / L FeCl 3 solution with 0.21mol / L FeCl 2 Solution and 25wt% ammonia monohydrate solution were mixed and stirred according to the volume ratio of 1:1:2, and 0.50mol / L nitric acid was added to adjust the pH to 3 to obtain Fe 3 o 4 Nano magnetic nucleus precursor suspension 66 mL;

[0051] (2) Under the condition of heating in a water bath at 70°C, slowly inject 5mL of an ethanol solution of 10wt% trimethylsiloxysilicate into the suspension prepared in step (1) until the concentration of sodium silicate is 2.5wt%, The precipitate was magnetically separated, washed and dried to obtain SiO 2 wrapped Fe 3 o 4 Granules 5.2g;

[0052] (3) Add 3.65g of magnesium chloride hexahydrate (18 mmol), 0.3176g of aluminum trichloride hexahydrate (3mmol), and 1.8g of cerium chloride hydrate (3mmol) into 400mL of NaOH solution with a concentration of 1.5mol / L to obtain Magnesium aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com