A kind of equipment and method for preparing electrode

A technology for preparing electrodes and equipment, applied in the field of stretchable electrode preparation, can solve the problems of mass production of stretchable electrodes, poor electrical conductivity, and complexity of the manufacturing process, so as to achieve mass production and reduce manufacturing costs. , The process is simple and efficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

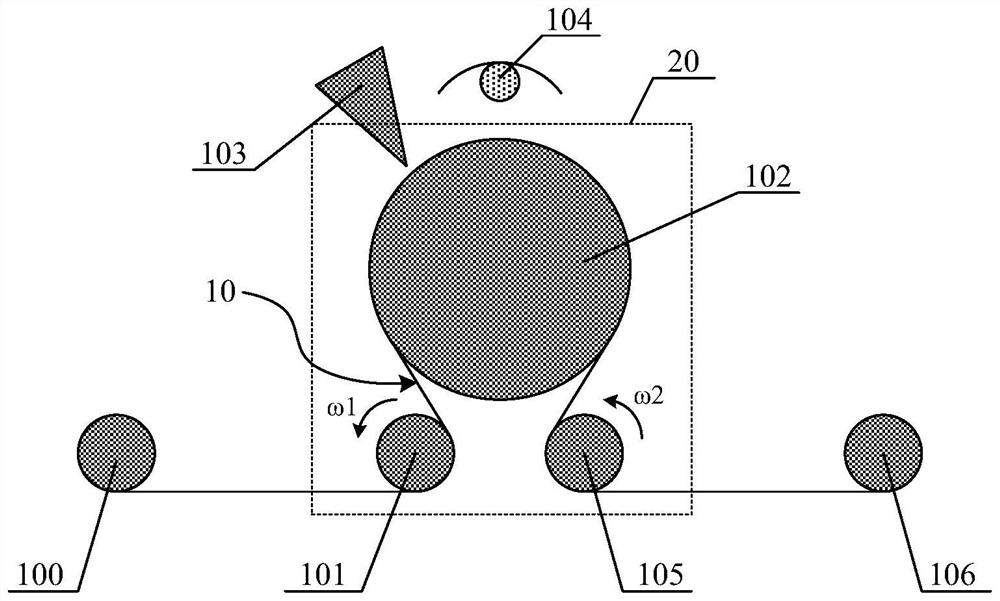

[0046] figure 1 Schematic diagram of the equipment for preparing electrodes according to the first embodiment of the present invention. The equipment for preparing electrodes includes a roll-to-roll device and a coating device 103 . A roll-to-roll apparatus is used to stretch the stretchable substrate. The coating device is used to coat conductive ink on the stretched substrate to form an electrode layer. Thus, a composite electrode with an electrode layer on the substrate is prepared. Since the electrode layer is formed on the substrate when the substrate is in a stretched state, the composite electrode prepared is a stretchable electrode. The stretchable electrode It includes a stretchable substrate and an electrode layer formed on the substrate. In one embodiment, the conductive ink may be a nano-silver solution, and the substrate may be a polydimethylsiloxane (PDMS) elastic substrate.

[0047] The equipment for preparing electrodes proposed in the embodiments of the pr...

no. 2 example

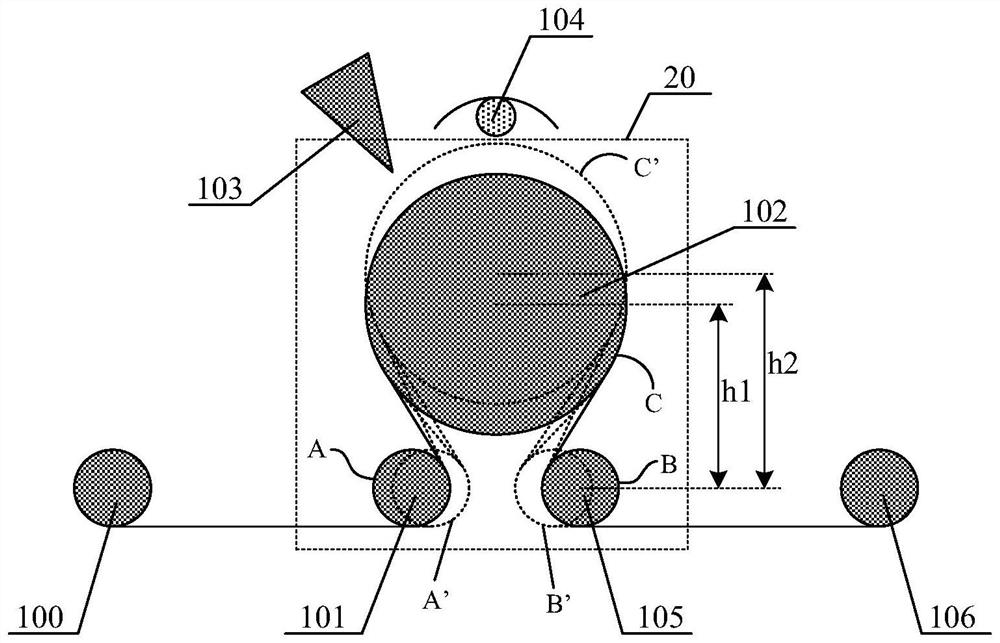

[0067] figure 2 Schematic diagram of the equipment for preparing electrodes according to the second embodiment of the present invention. Different from the first embodiment, the position of the first roller 101 and / or the third roller 105 can be adjusted. For example, the position of the first roller shaft 101 can be adjusted. By adjusting the position of the first roller shaft 101, the winding path length of the substrate 10 from the unwinding device 100 to the second roller shaft 102 can be increased. Tension of the substrate wound on the second roll 102. Similarly, the position of the third roller shaft 105 can be adjusted. By adjusting the third roller shaft 105, the winding path length of the substrate 10 from the second roller shaft 102 to the winding device 106 can be increased. The tension of the substrate wound on the second roll 102.

[0068] In one embodiment, the position of the first roller 101 is adjustable, therefore, the process of stretching the substrate ...

no. 3 example

[0078] Based on the inventive concepts of the above embodiments, the embodiments of the present invention propose a method for preparing an electrode. image 3 It is a schematic diagram of a method for preparing an electrode according to the third embodiment of the present invention. The method for preparing an electrode may include:

[0079] Stretching the stretchable substrate using a roll-to-roll device;

[0080] A coating device is used to coat conductive ink on the stretched substrate to form an electrode layer.

[0081] The method for preparing an electrode proposed in the embodiment of the present invention uses a roll-to-roll device to stretch the stretchable substrate, and then applies the roll-to-roll process to the production equipment of the stretchable electrode, realizing the wire On-board production; using the simple and efficient characteristics of the roll-to-roll process, the production cost of the stretchable electrode is reduced, and the mass production of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com