Patents

Literature

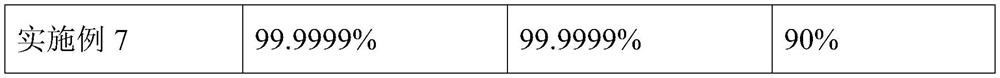

37results about How to "Realize online production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-radiation self-cleaning composite function glass and producing method

This invention relates to a low radiation self-cleaning complex function glass. This glass has trilamellar membrane structure, membranous layer from glass outward in turns is : SiO2 transition layer, ion adulterated SnO2 layer, ion adulterated SiO2 - TiO2 layer. The on-line preparation method is sol-gel method, combine with atomizing sedimentation, utilize thermal decomposition and coagulation process of collosol at 450 to 550 deg to proceed heat sedimentation, in turns form membranous layer on the on-line glass plate surface. This invention through controlling the coating material concentration, dopant ion variety, thermal decomposition temperature and membranous layer thickness bring low radiation to the glass coated this membrane, execute stable uniwafer low emissivity glass, reduce cost, and realize reprocessing treatment of low radiation steeling and hot bending. This invention applies to common building and shield glass.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

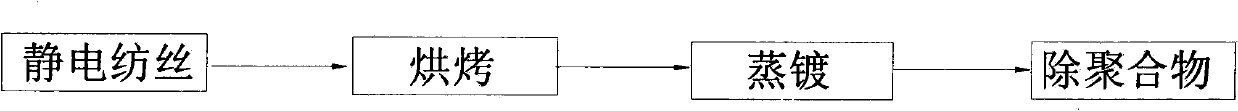

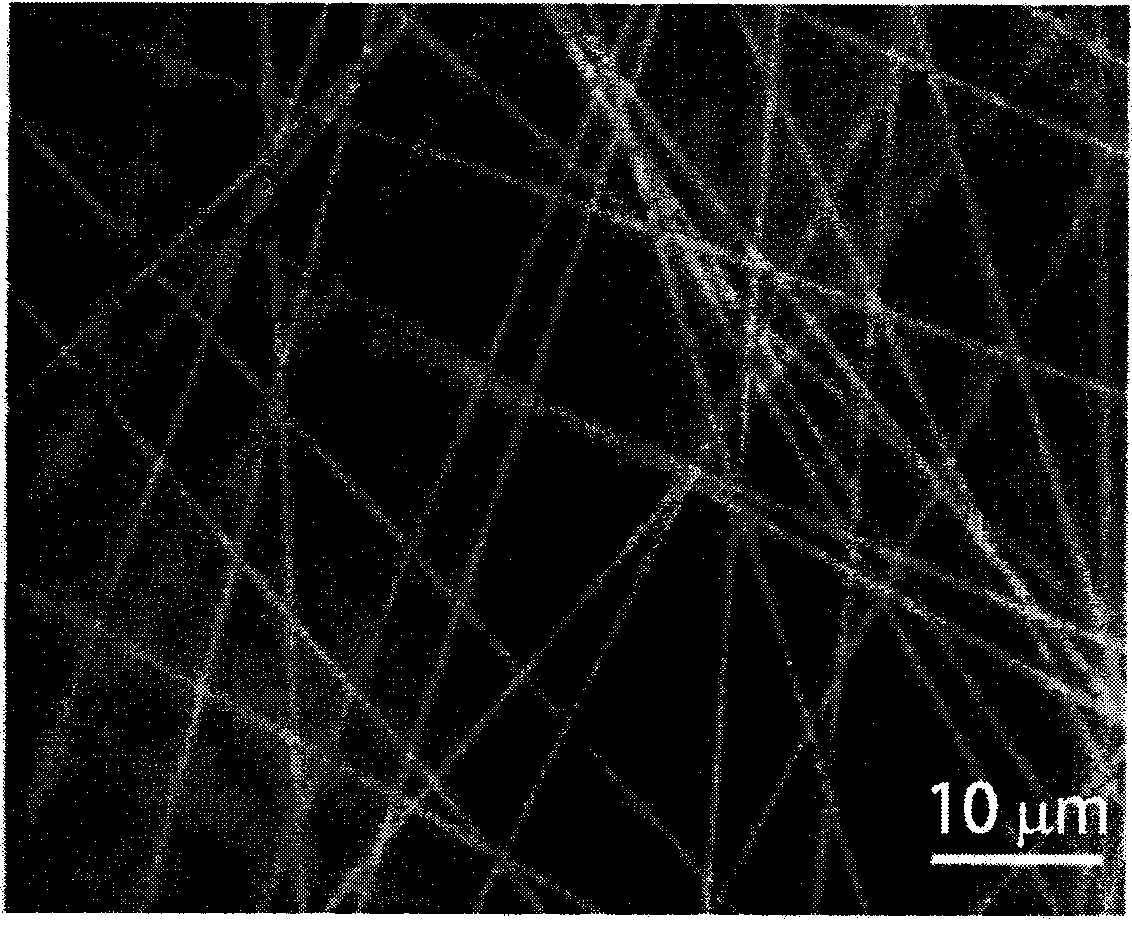

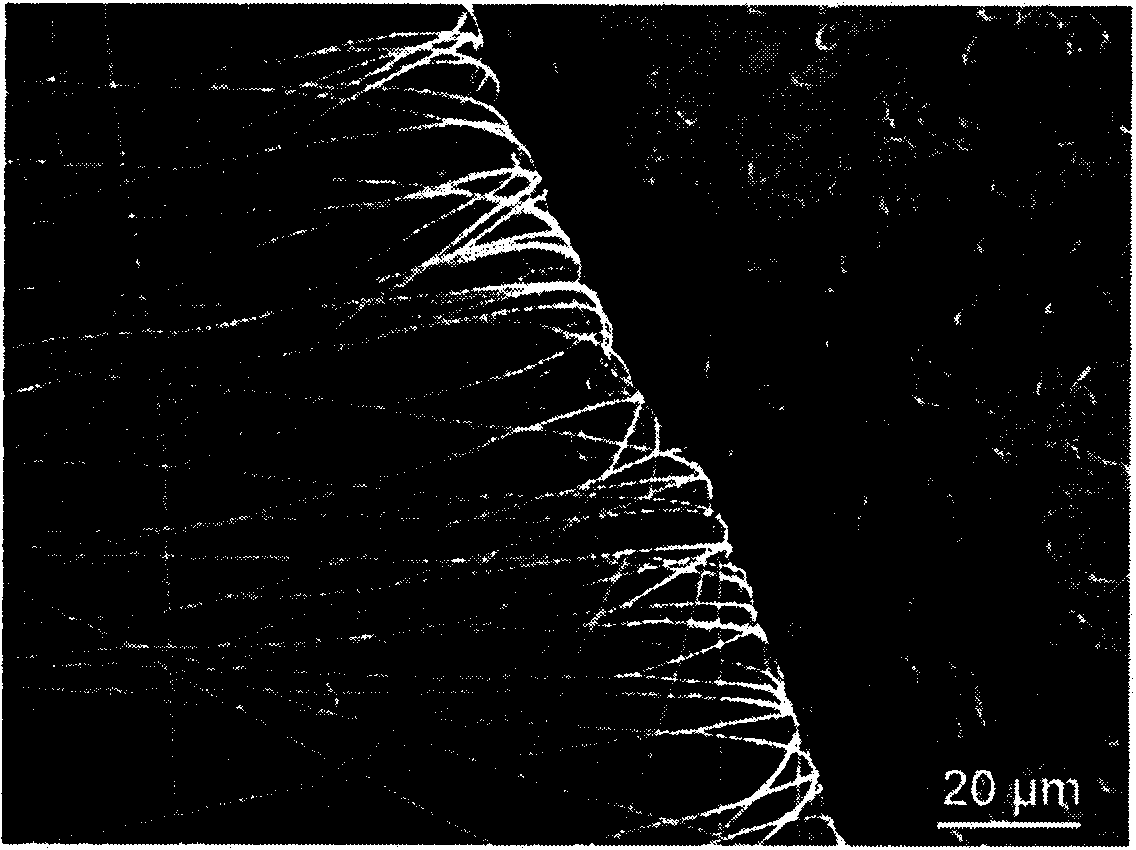

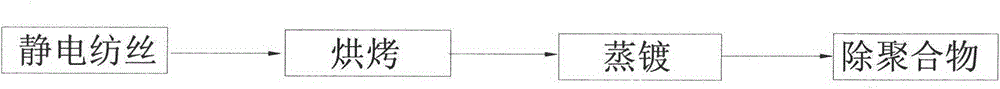

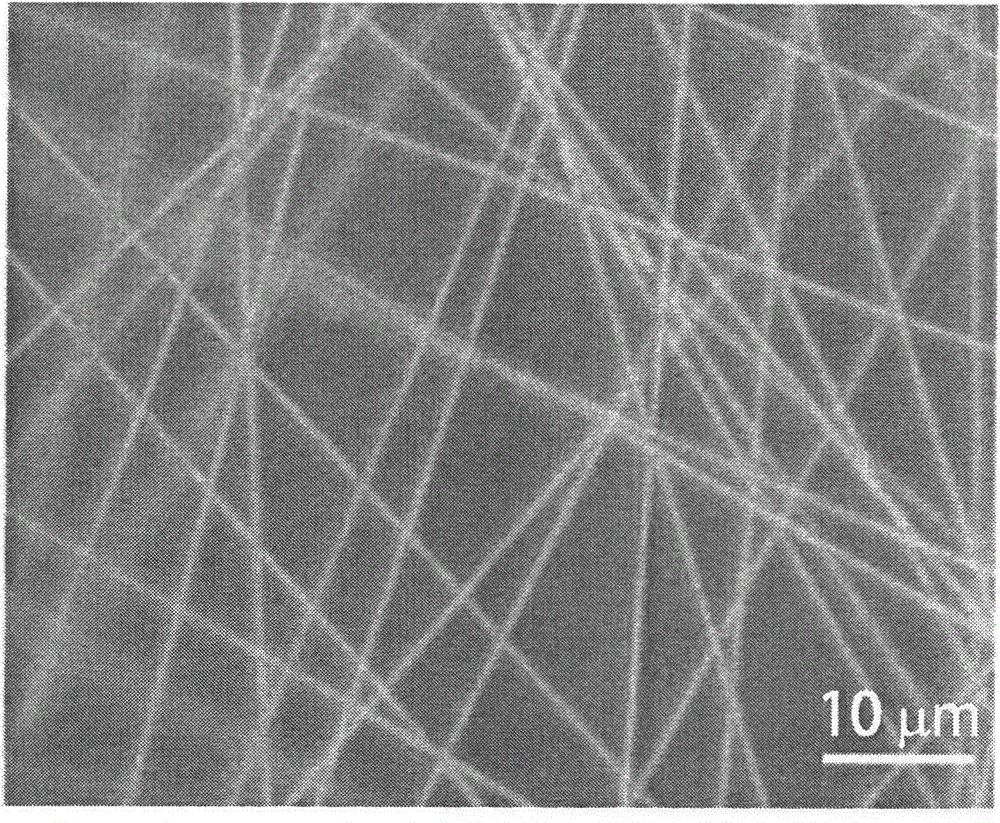

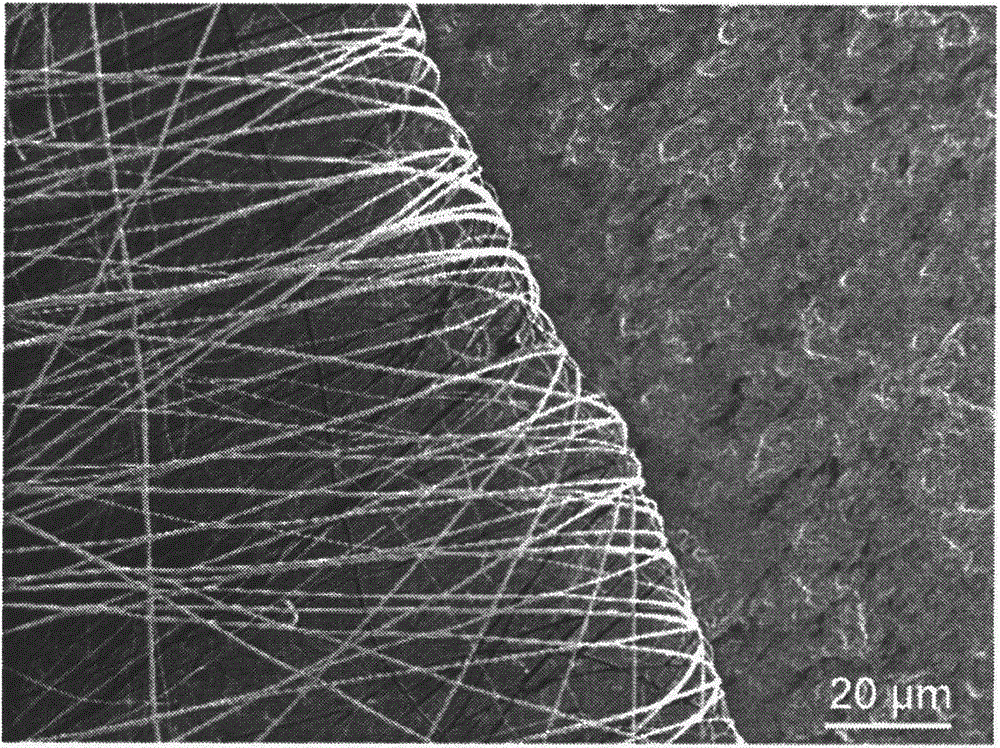

Preparation method for transparent conductive metal network

ActiveCN103628028AAchieve productionReduce energy consumptionVacuum evaporation coatingFilament/thread formingEtchingElectrospinning

The invention discloses a preparation method for a transparent conductive metal network. The preparation method comprises the following steps: a) preparing a nanofiber network through electrospinning; b) evaporating a metal layer on the nanofiber network so as to obtain a metal-polymer network complex; and c) removing a metal in the metal-polymer network complex so as to obtain the transparent conductive metal network. The invention has the following beneficial effects: downstream tedious etching and patterning processes are avoided in preparation of a conductive film prepared from the flexible transparent metal network, demands of touch screens and display panels for patterning can be directly met, and online production can be realized.

Owner:苏州冷石纳米材料科技有限公司

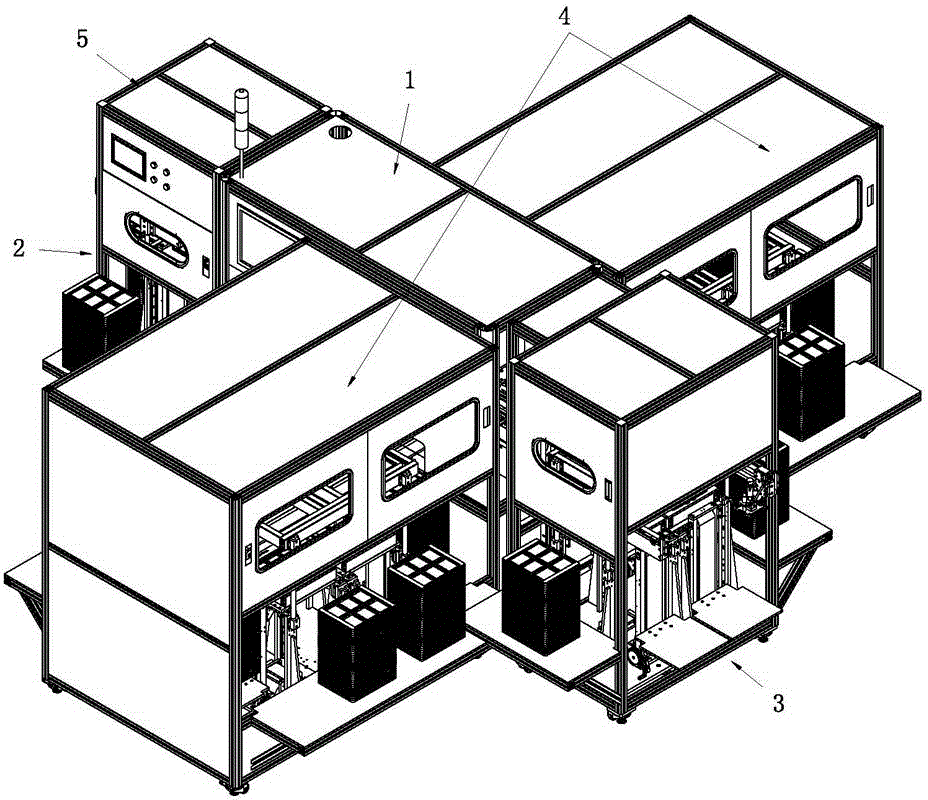

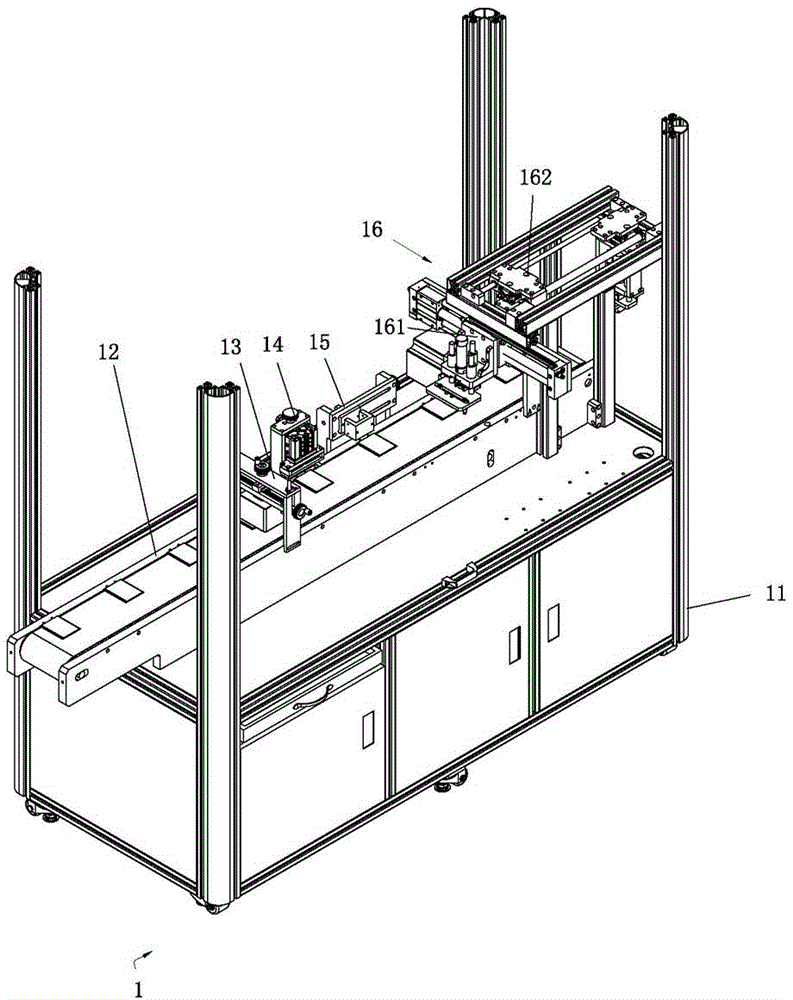

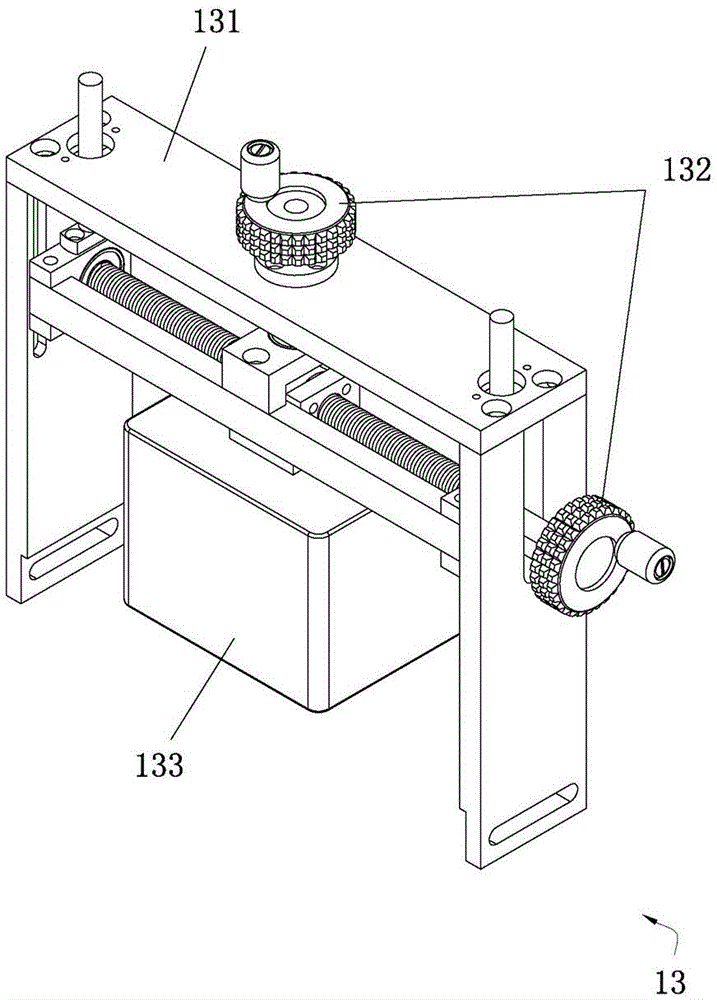

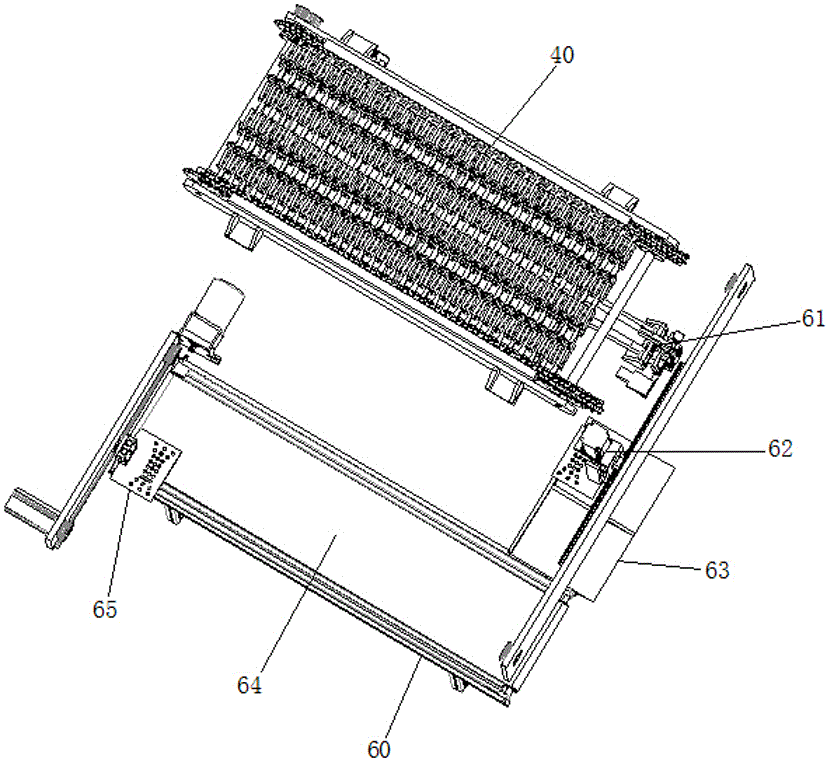

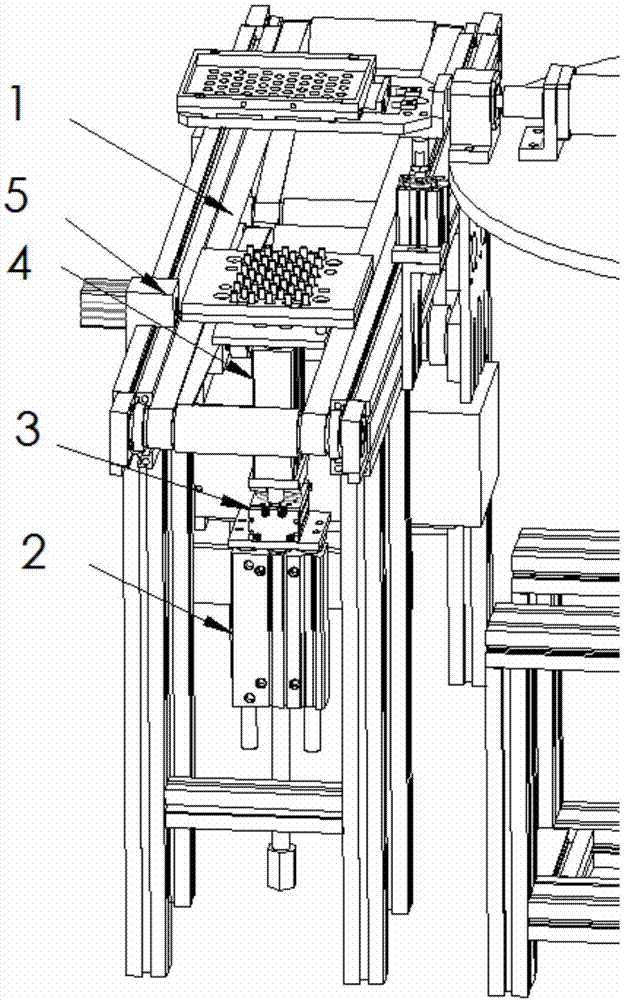

Fully automatic battery code spaying grouping device

ActiveCN104802535AFully automaticRealize automatic feeding processTypewritersProduction lineHigh rate

The invention discloses a fully automatic battery code spaying grouping device for solving the problems of high labor intensity, low efficiency, high rate of defective products and the like in processes of code scanning, testing, code spaying as well as sorting and collection of semi-finished batteries. Compared to the prior art, the fully automatic battery code spaying grouping device achieves the online production of the processes of feeding, code scanning, testing, code spaying as well as sorting and collection of the semi-finished batteries to achieve automation, is high in efficiency to facilitate the maintenance of the consistency of product quality, integrates multiple processes needing to be completed by multiple workers with multiple devices previously into a single device to greatly save labors, most importantly, improves production efficiency and yield, is small in size and occupation area, avoids the occupation of workshop space by semi-finished batteries due to the fact that the processes of feeding, code scanning, testing, code spaying as well as sorting and collection of the semi-finished batteries are completed at one time, and can be combined with a battery production line to achieve the on-line production from battery raw materials to finished battery products.

Owner:东莞德方智能装备中心(有限合伙)

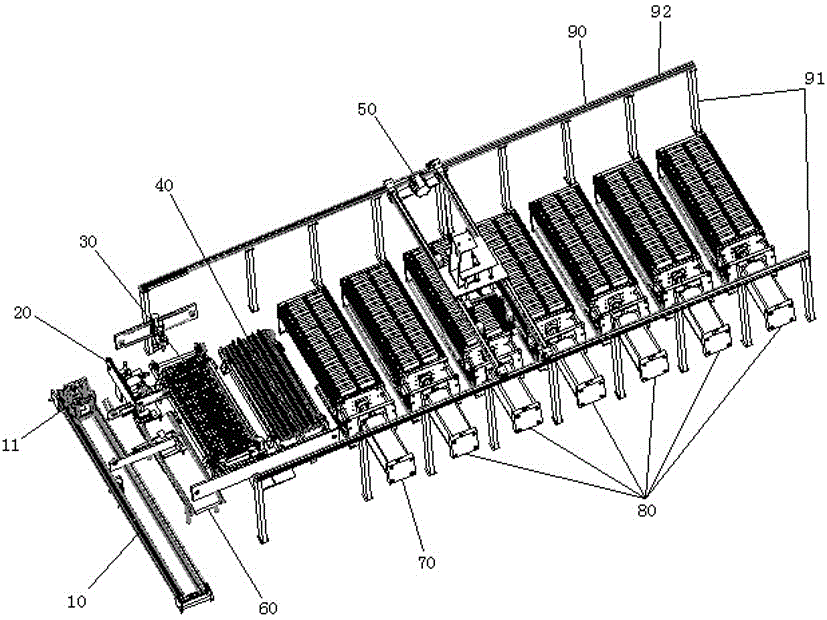

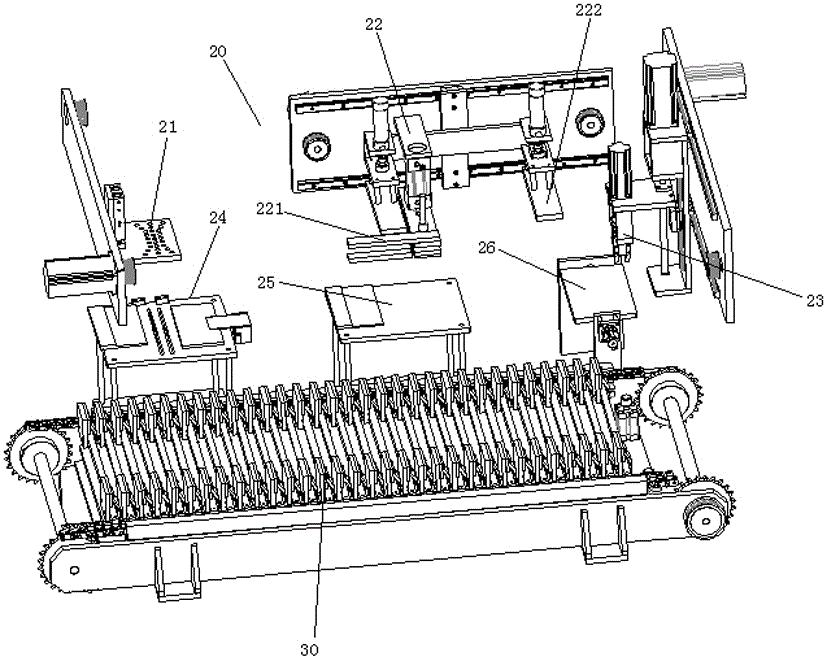

All-in-one machine for polymer lithium battery with functions of formation and capacity grading

PendingCN106129449AGood process continuityGood effectAssembling battery machinesFinal product manufactureCell assemblyManipulator

The invention discloses an all-in-one machine for a polymer lithium battery with functions of formation and capacity grading. The all-in-one machine comprises a cell assembly line, wherein a cell elastic clamp which is fully loaded with cells; a formation and capacity-grading apparatus is arranged on one side of the cell assembly line; the formation and capacity-grading apparatus comprises a material-feeding mechanical arm bracket and a material-discharging mechanical arm bracket; a material-feeding material-waiting frame, a material-discharging material-waiting frame, a group of formation clamps and multiple capacity-grading clamps are arranged in the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket; the material-feeding material-waiting frame, the material-discharging material-waiting frame, the group of formation clamps and the multiple capacity-grading clamps are arranged in sequence from one side to the other side; a material-feeding mechanism and a material-discharging mechanism are arranged between the material-feeding material-waiting frame and the cell assembly line; the material-feeding mechanism and the material-discharging mechanism are positioned on the front and back sides respectively; and material-moving mechanical arms are arranged on the material-feeding mechanical arm bracket and the material-discharging mechanical arm bracket. The all-in-one machine for the polymer lithium battery with the functions of formation and capacity grading has the advantages of high continuity of capacity-grading processes, high degree of automation, high efficiency, good formation effect, high product quality and the like.

Owner:东莞德方智能装备中心(有限合伙)

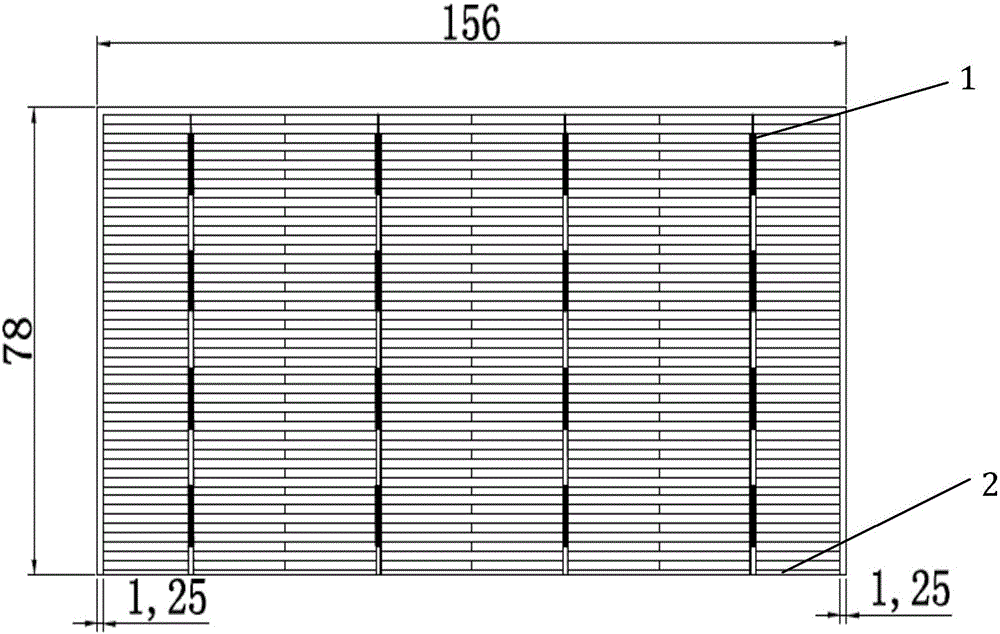

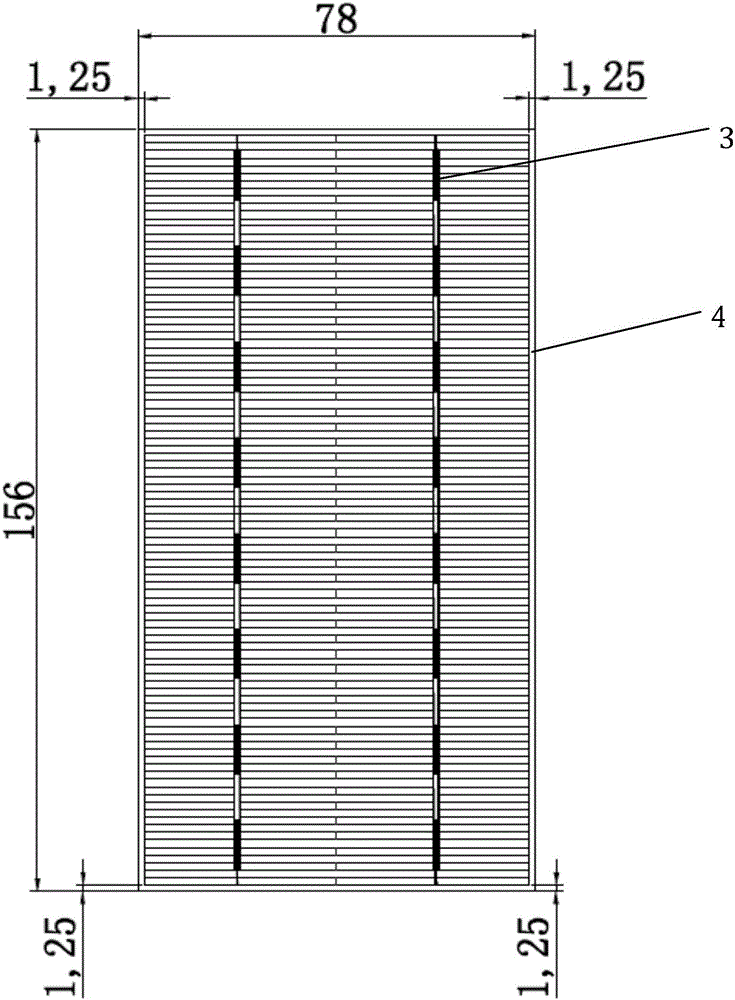

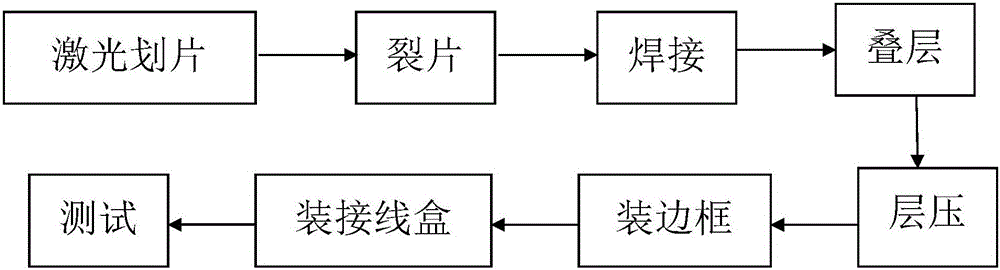

Photovoltaic module and manufacturing process thereof

InactiveCN106169517ARealize online productionOvercoming technical bottlenecksFinal product manufacturePhotovoltaic energy generationSolar fieldLaser scribing

The invention discloses a photovoltaic module which comprises a plurality of solar battery piece slices, wherein the solar battery piece slices are formed by cutting a solar battery piece along a direction parallel to a main grid line. Meanwhile, the invention further discloses a manufacturing process of the photovoltaic module. The manufacturing process comprises the following steps: welding the solar battery piece, performing laser scribing along the direction parallel to the main grid line of the solar battery piece to form a cutting channel, and slicing the solar battery piece according to the cutting channel; and performing stacking, lamination, framing, wiring box arrangement and test. The photovoltaic module overcomes the technical bottleneck and the bias in the conventional solar field; the solar slicing direction is creatively designed to be parallel to the main grid line, so that on-line production of a slice assembly can be realized, and fragments are reduced; and compared with the yield of a conventional half battery module, the yield of the photovoltaic module is greatly increased.

Owner:CECEP SOLAR ENERGY TECH (ZHENJIANG) CO LTD

Rapid curing process of battery plate

ActiveCN107342396ARealize online productionIncrease capacityLead-acid accumulator electrodesMetallurgyMaterials science

The invention discloses a rapid curing process of a battery plate. The rapid curing process comprises the following steps: stage 1: the temperature is 60 to 65 DEG C, the humidity is 95% to 100%, and the time is 0.5h to 1.0h; stage 2: the temperature is 60 to 65 DEG C, the humidity is 90% to 95%, and the time is 0.5h to 1.0h; stage 3: temperature is 70 to 75 DEG C, the humidity is 85% to 90%, and the time is 0.5h to 1.0h; stage 4: the temperature is 80 to 85 DEG C, the humidity is 80% to 85%, and the time is 1.0h to 2.5h; stage 5: the temperature is 70 to 75 DEG C, the humidity is 85% to 90%, and the time is 0.5h to 1.0h; and a drying stage: the temperature is 80 to 85 DEG C, the humidity is 0%, and the time is 1.0h to 4.0h. The scheme of the invention greatly improves the production efficiency of plate curing and drying, realizes the continuous production of lead-acid battery plates and assembly, and the manufactured lead-acid batteries have good capacity and cycle life.

Owner:SHENZHEN CENT POWER TECH +1

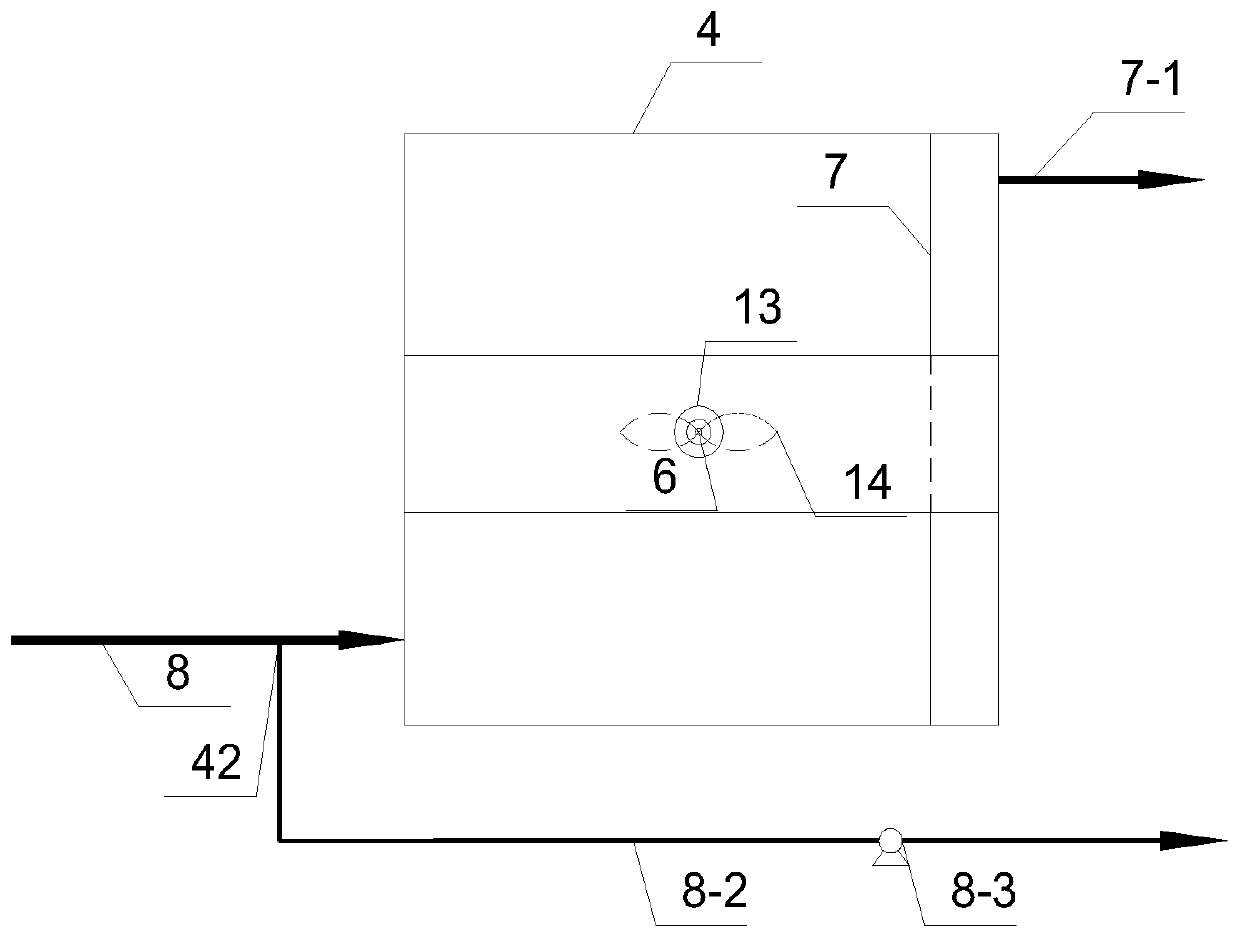

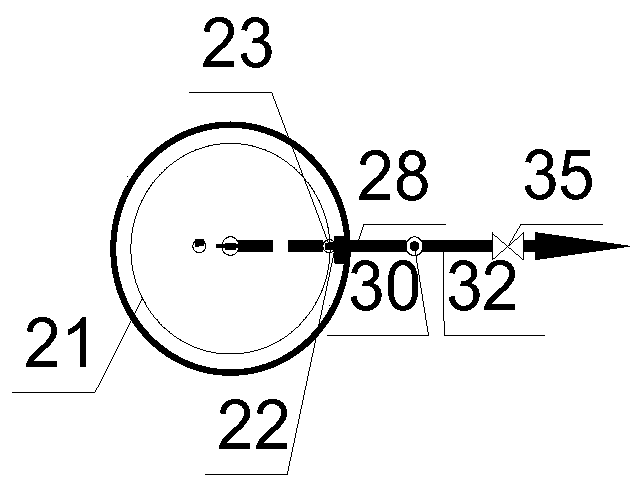

Labeling device

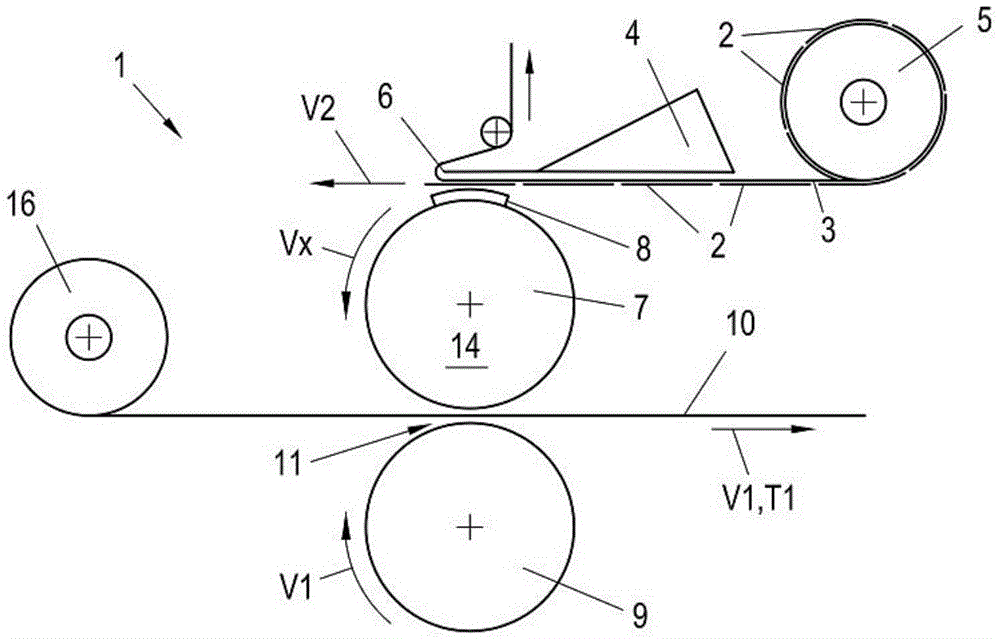

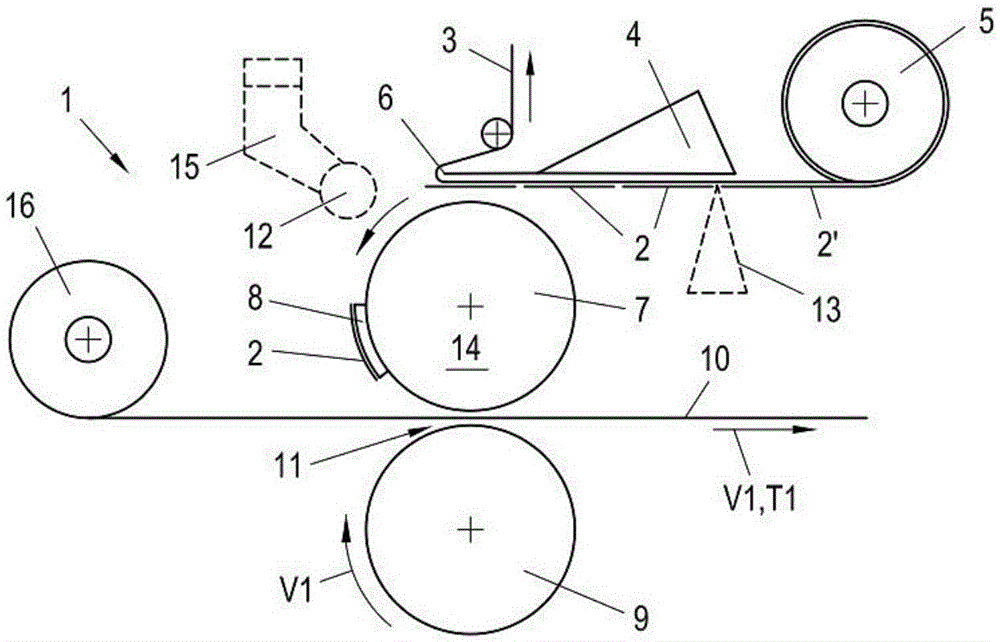

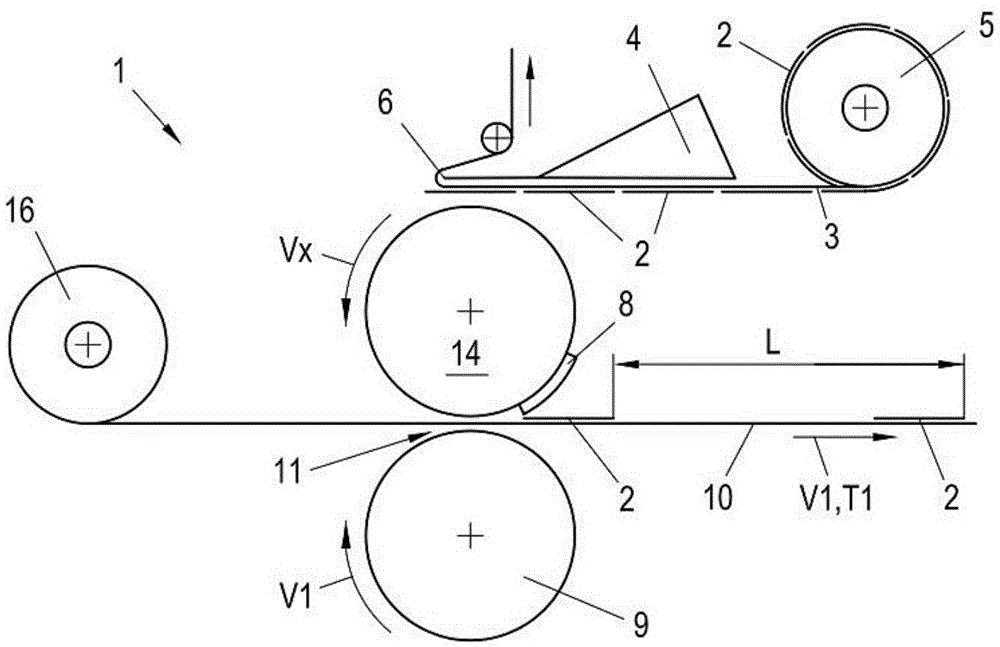

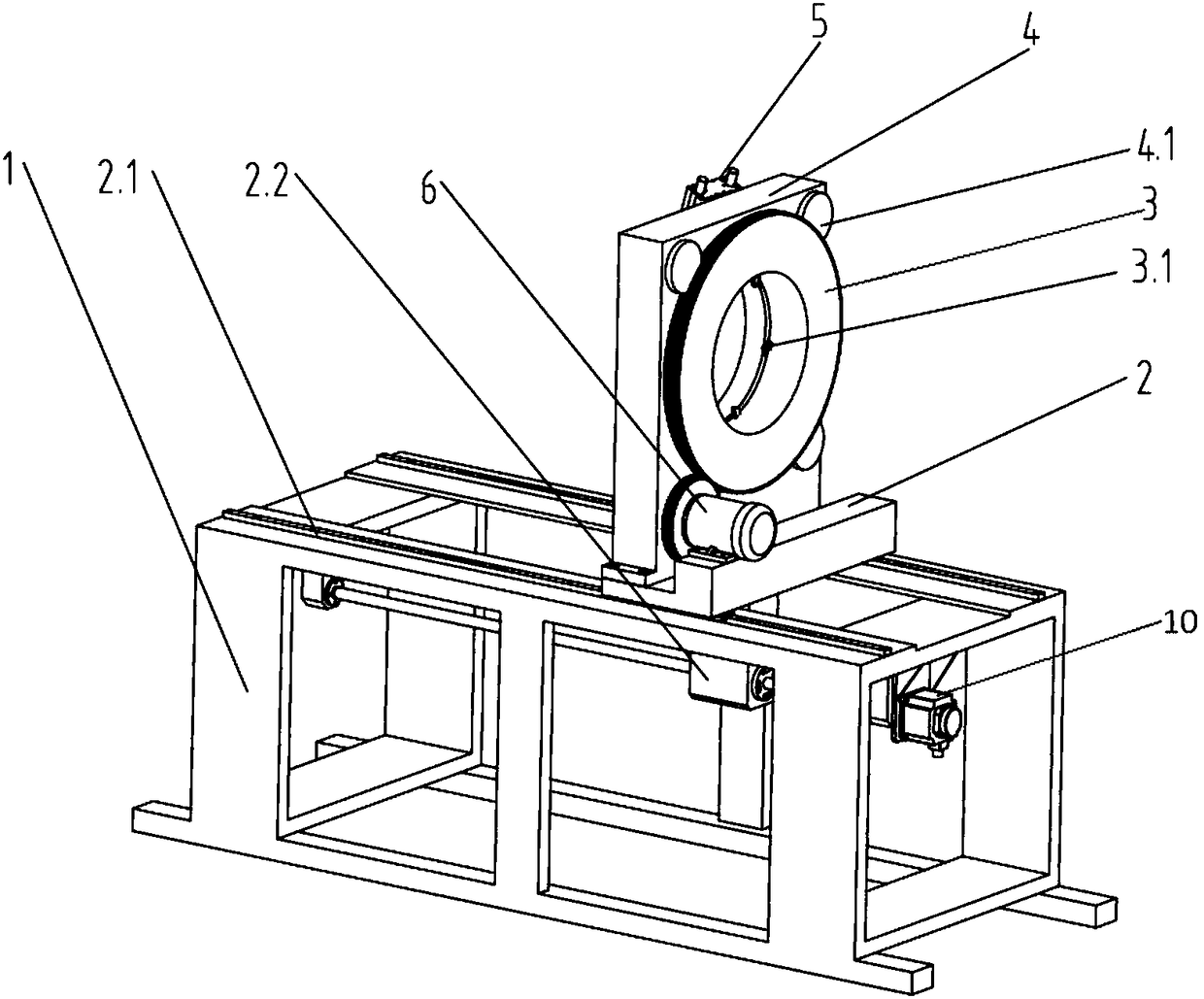

ActiveCN105636871AFast and reliable controllable operationTransfer is simple but reliableLabelling machinesEngineeringMechanical engineering

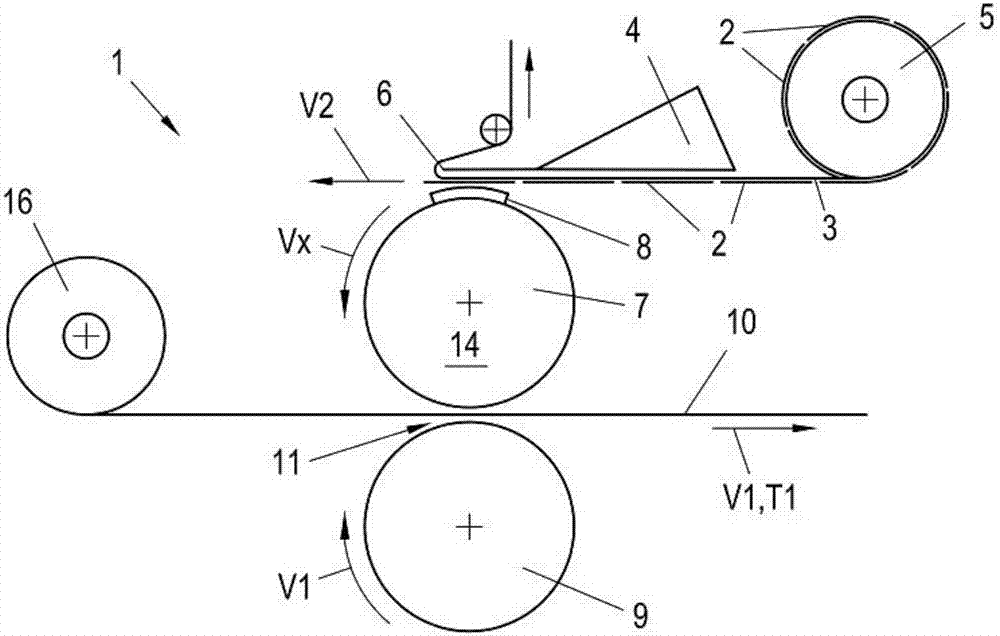

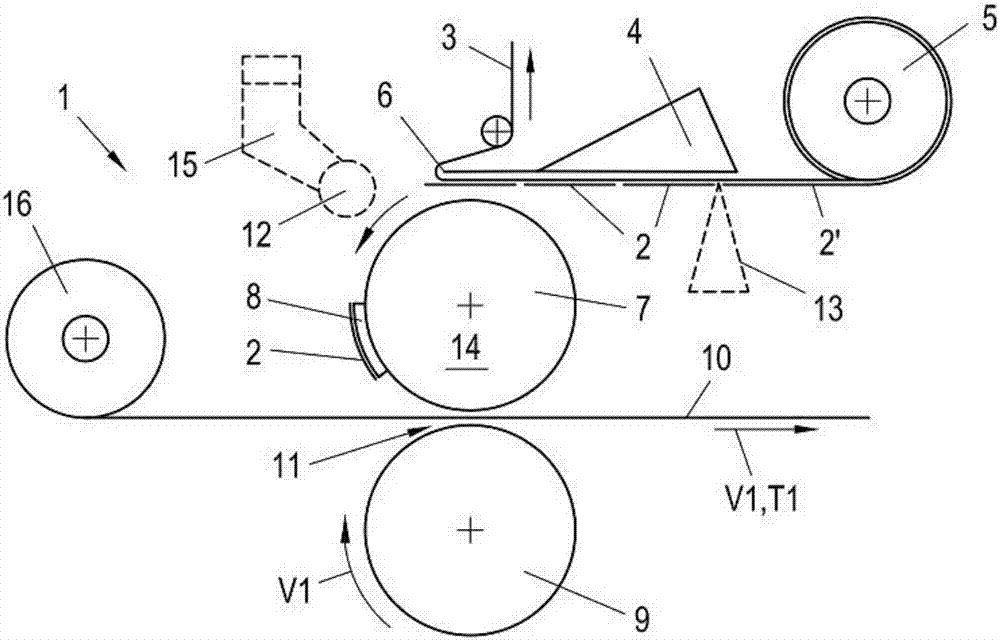

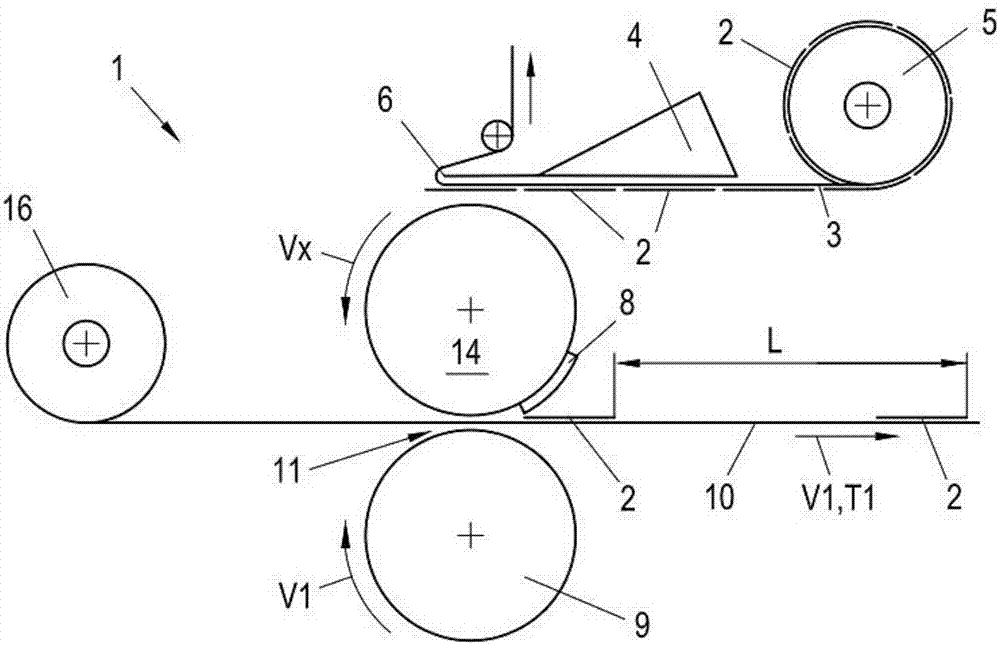

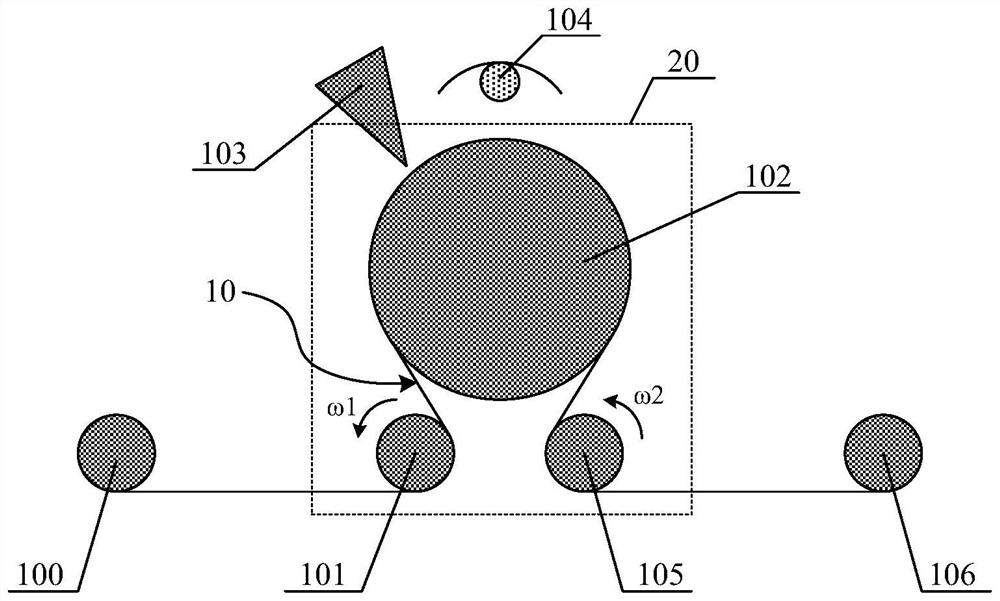

The invention relates to a labeling device (1) for applying labels (2) onto a material web (10) which is moved in a transport direction (T1) at a web speed (V1), comprising a label dispenser (4) and a transferring device (7) which transfers the labels (2) from the label dispenser (4) towards the material web (10) by means of holding means (8) and applies the labels onto the material web (10) at a transfer location (11). The holding means (8) of the transferring device (7) can be moved in the transport direction (T1) and opposite the transport direction in a circulating path at a variable circulating speed (Vx), said holding means (8) moving in the transport direction (T1) at the web speed (V1) when the holding means are located at the transfer location (11).

Owner:STARLINGER & CO GMBH

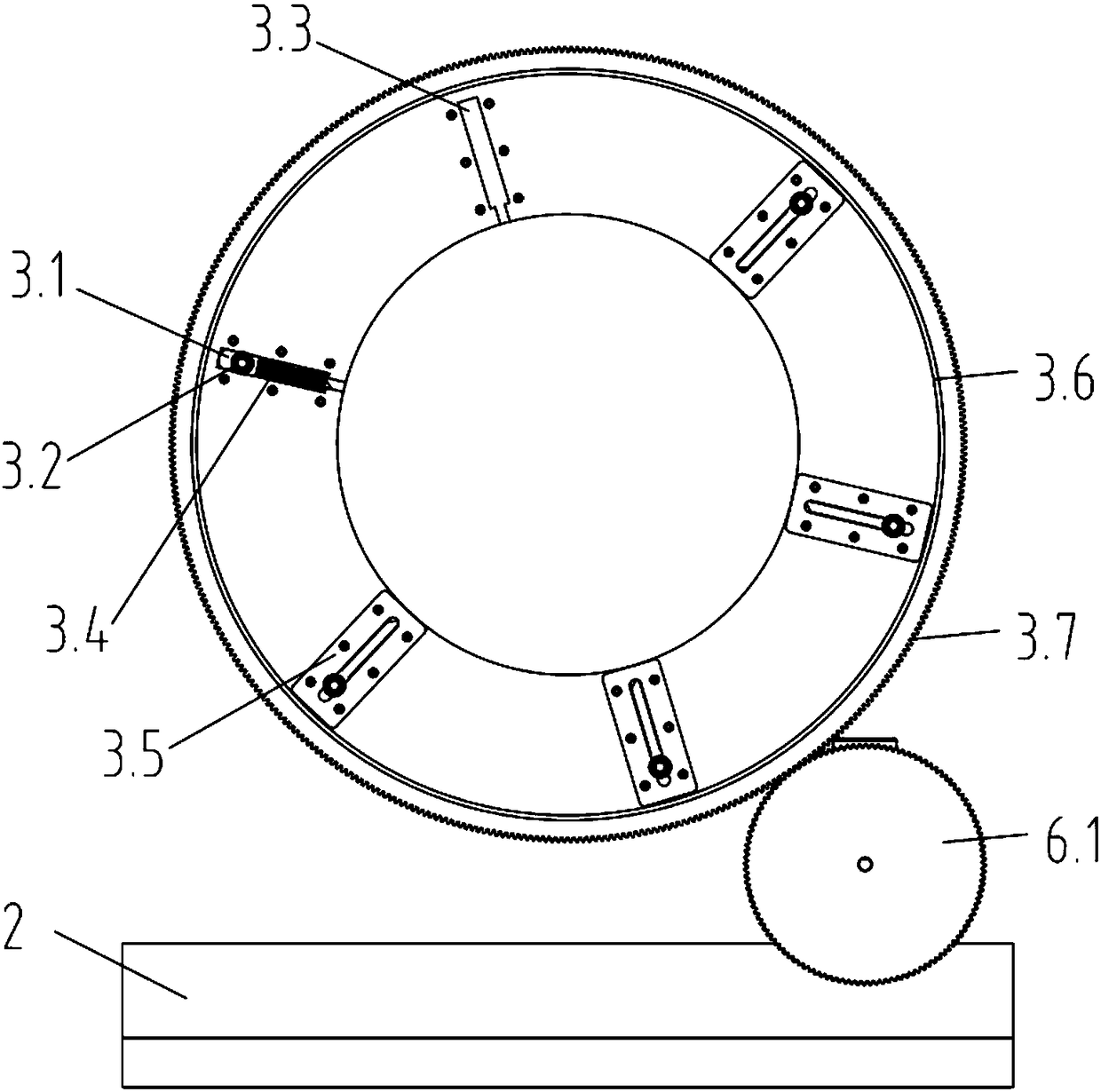

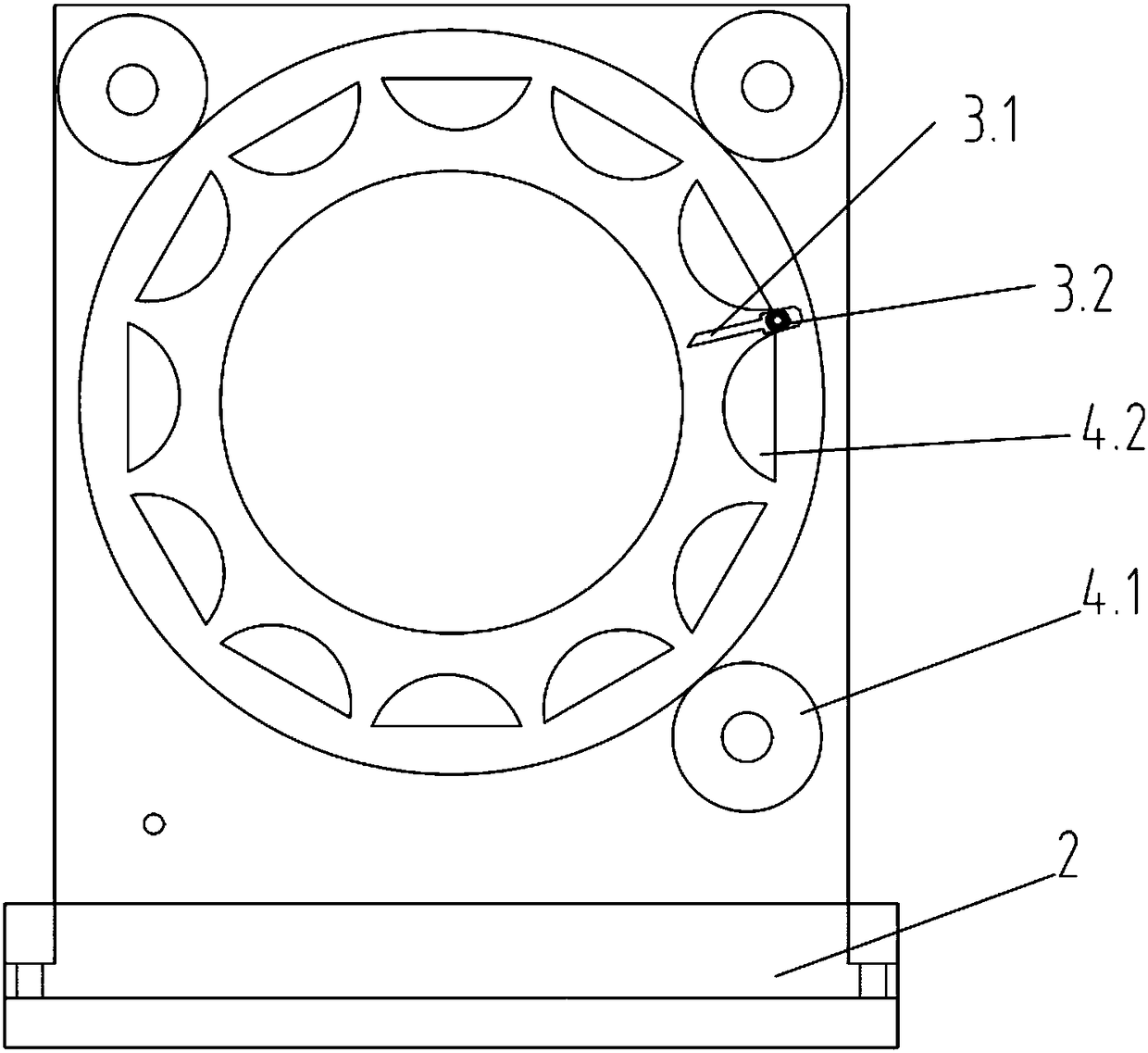

Efficient grooving device for PE corrugated pipe

The invention discloses an efficient grooving device for a PE corrugated pipe, relates to the field of PE corrugated pipes for flood systems, and specifically relates to grooving of a PE corrugated leaking pipe. The device comprises a rack, a synchronous sliding table, a rotary cutter plate and a fitting cam rack, wherein the rotary cutter plate and a cam plate are mounted on the synchronous sliding table; the rotary cutter plate is driven through a servo motor, and thus a cutter in the rotary cutter plate can move along a track of the cam plate to perform grooving. The device is arranged on acorrugated pipe production line to realize the effective grooving of the PE corrugated pipe; the device is simple in structure, convenient to operate and repair, and applicable to online processing of a PE corrugated pipe product.

Owner:WUHAN KINGBULL ECONOMIC DEV

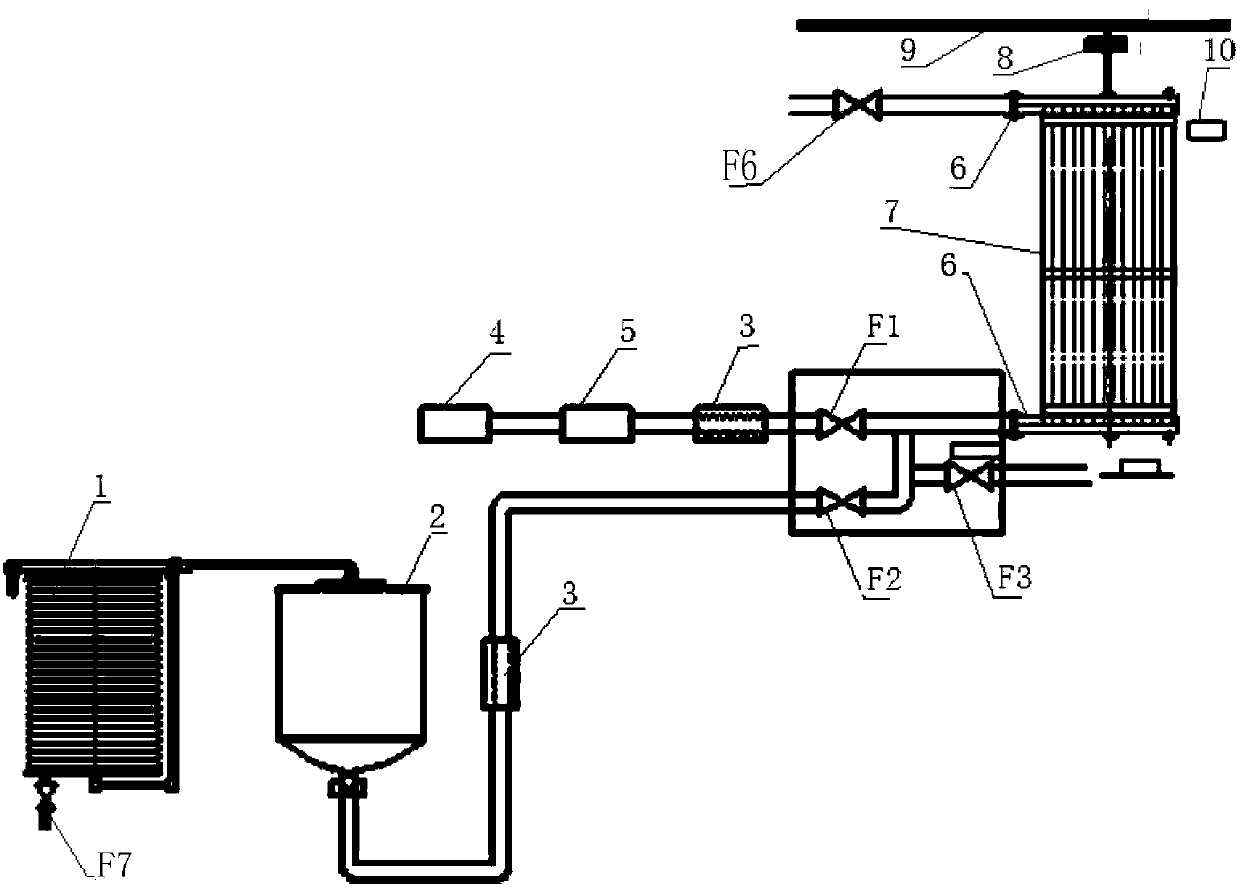

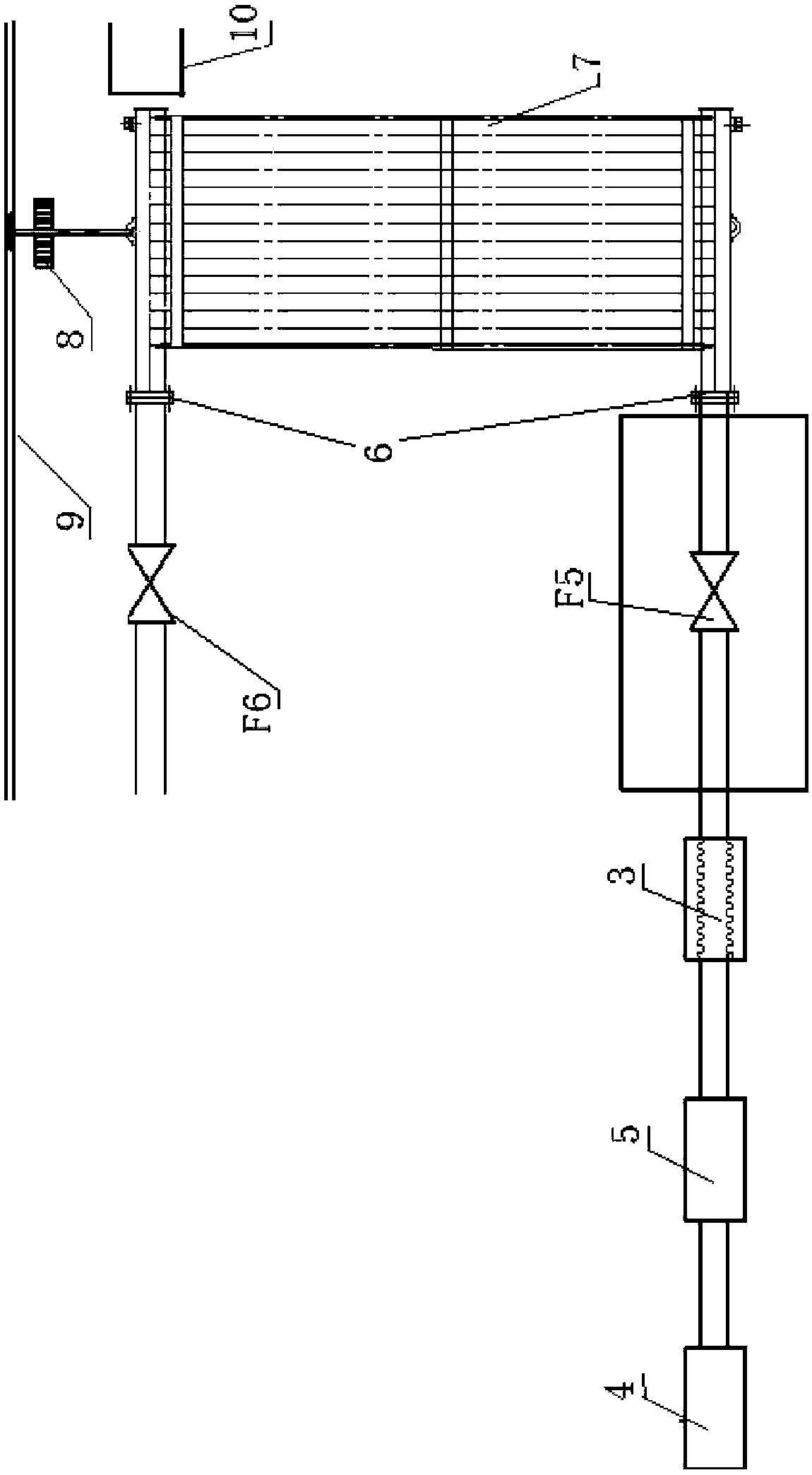

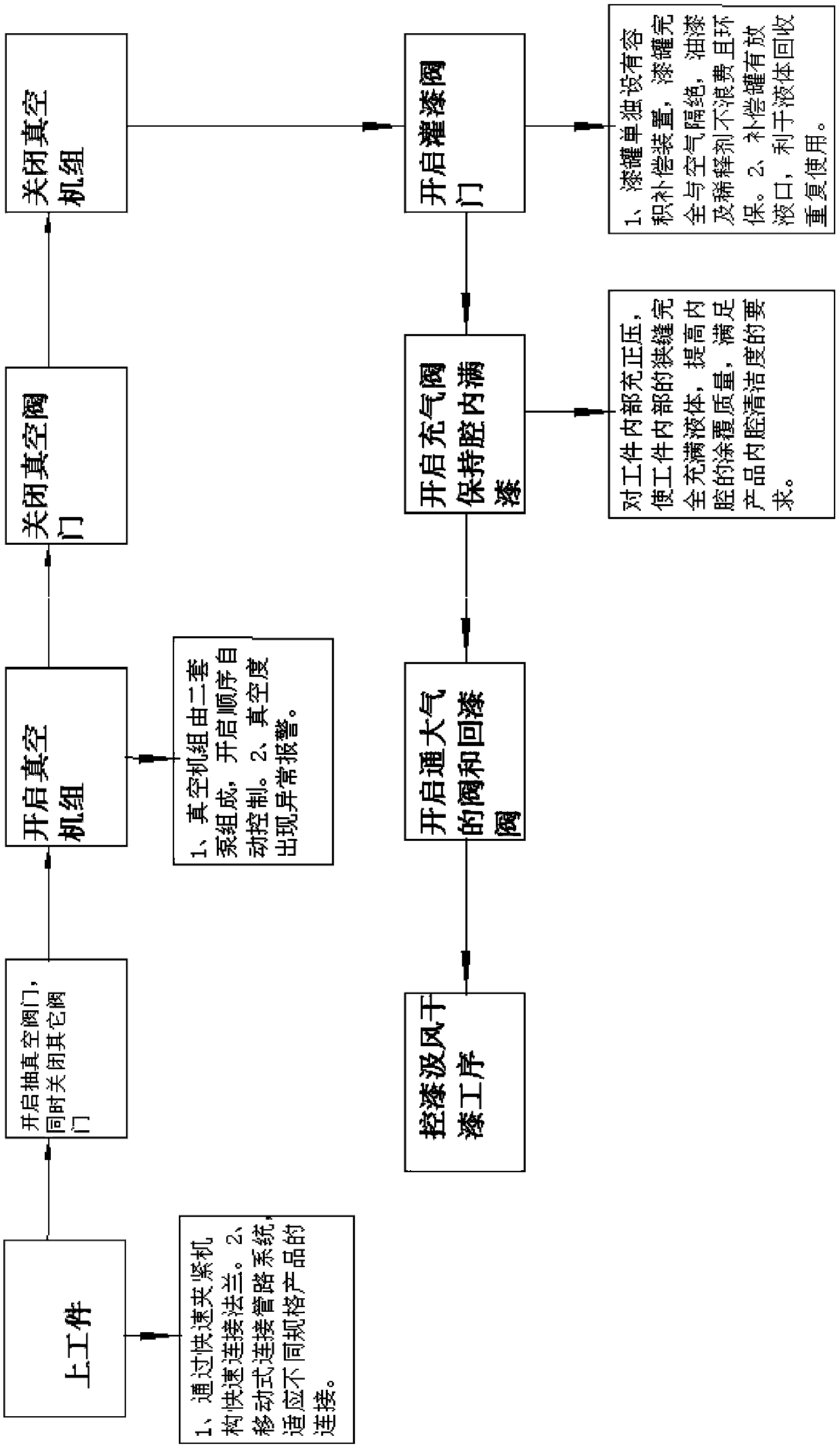

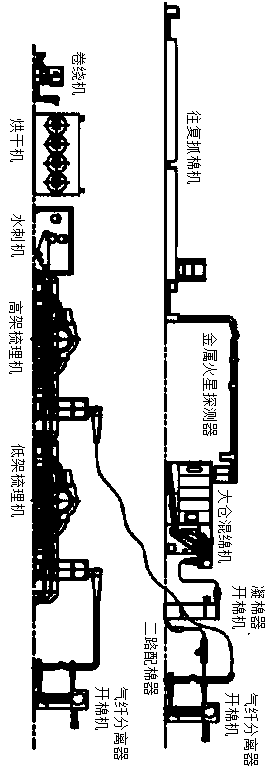

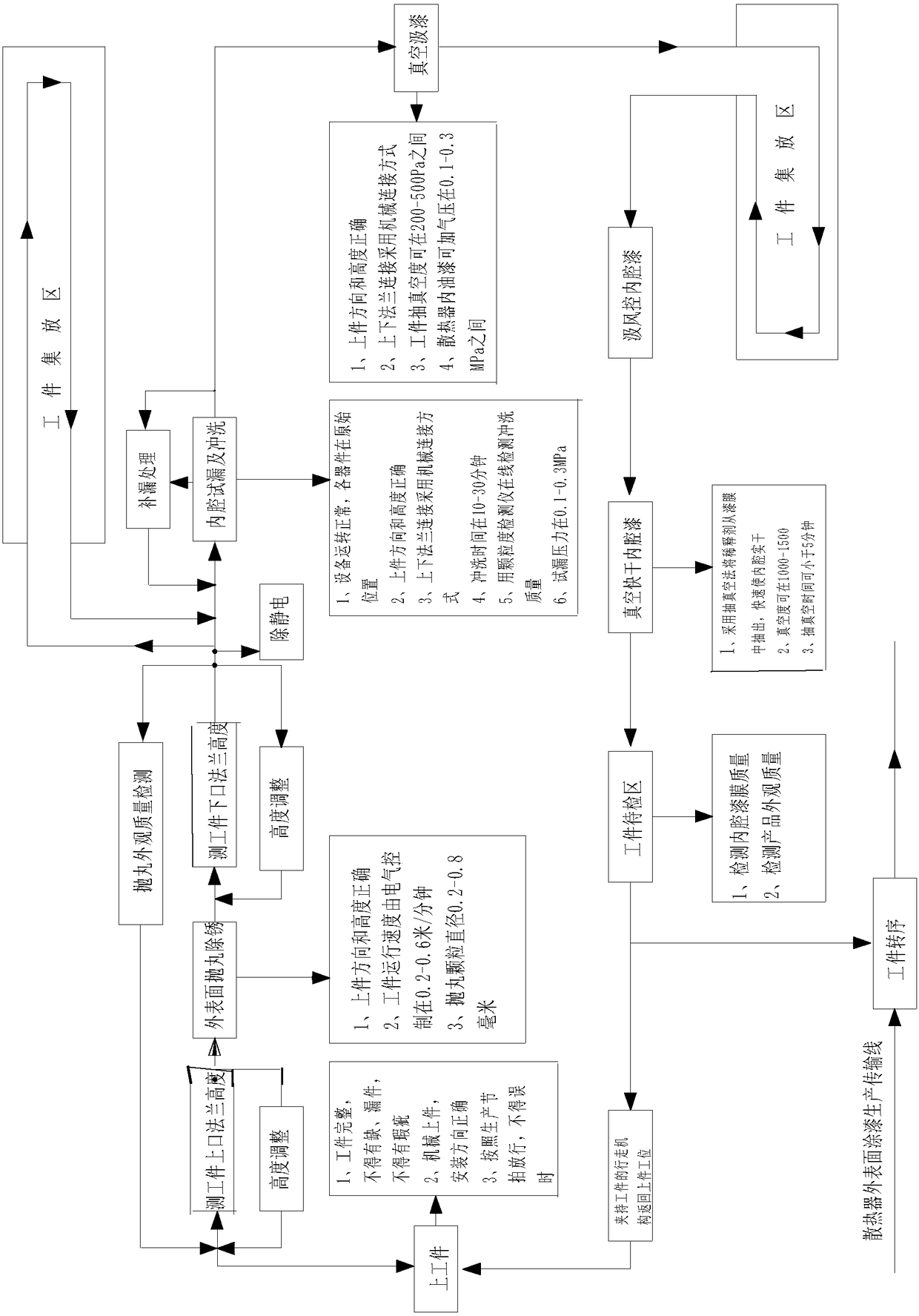

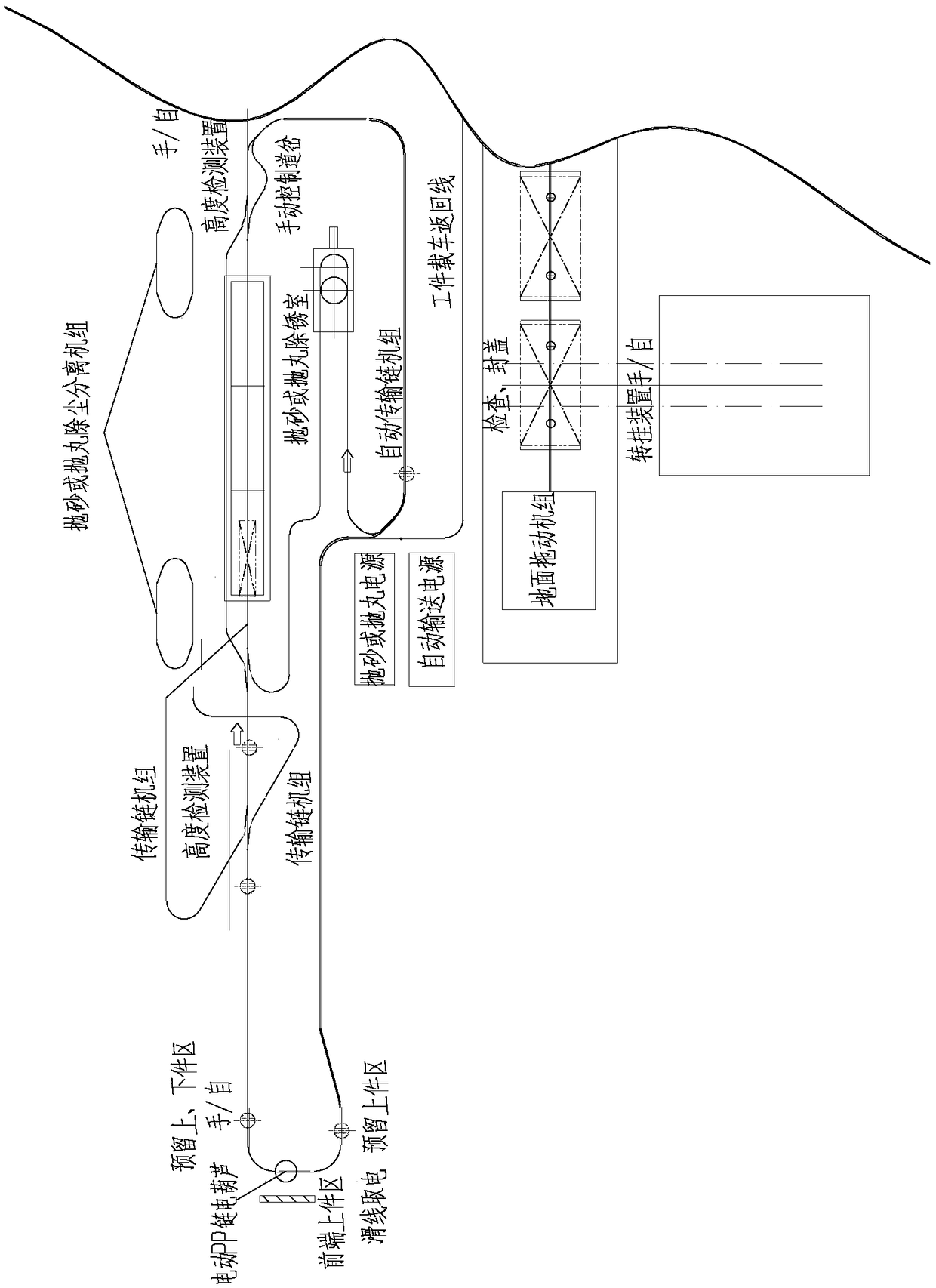

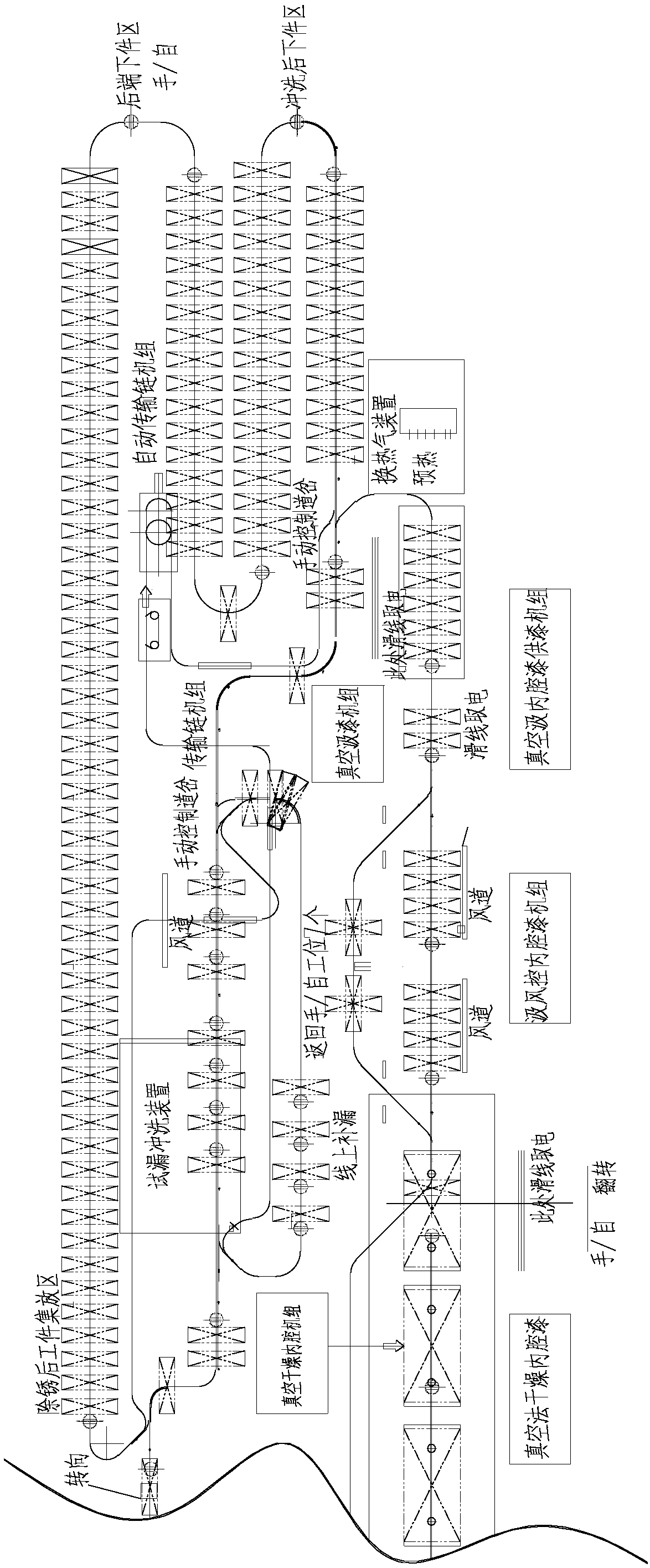

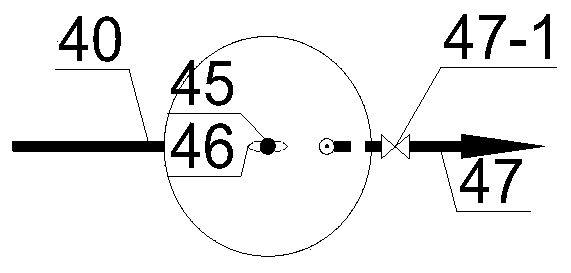

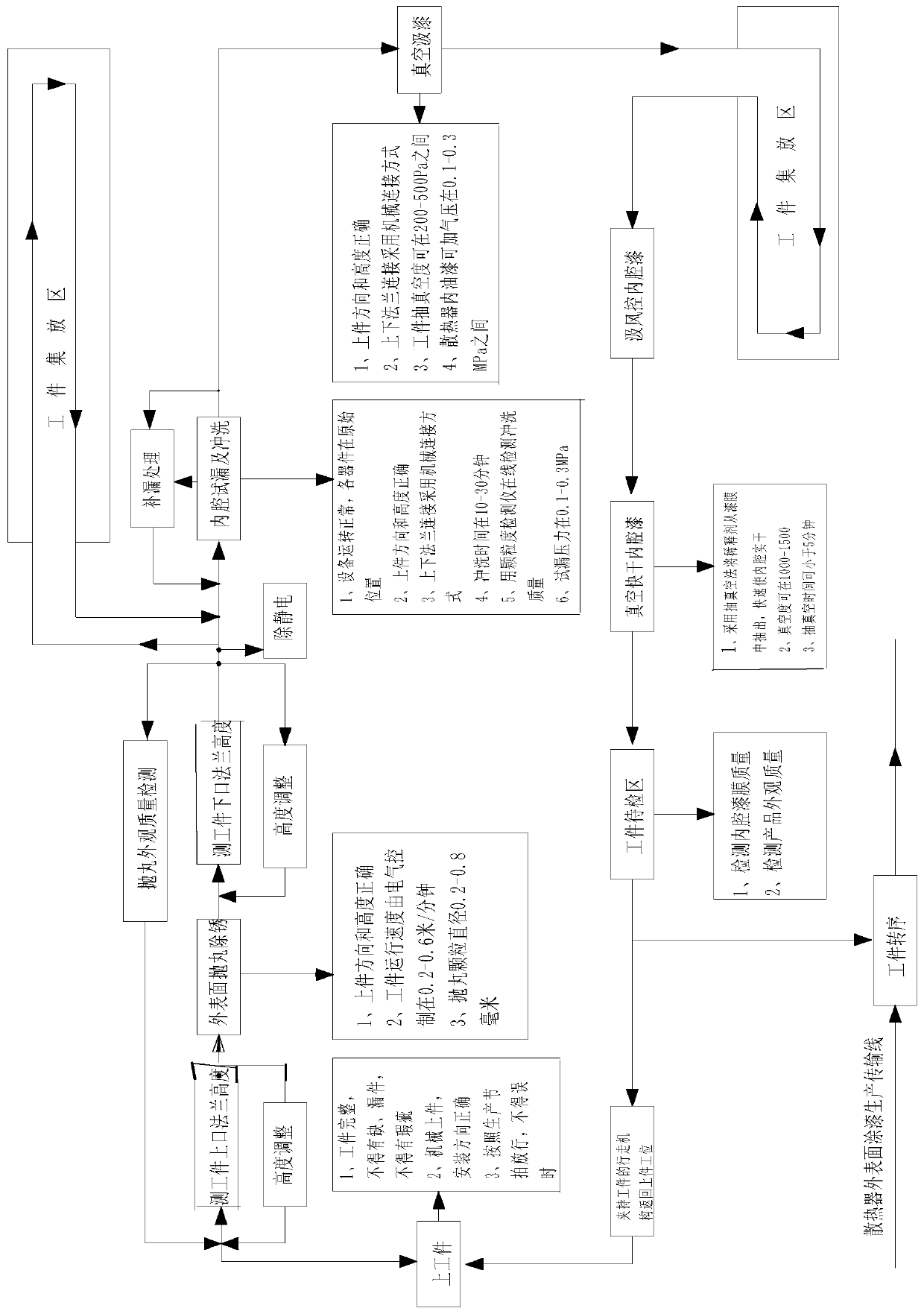

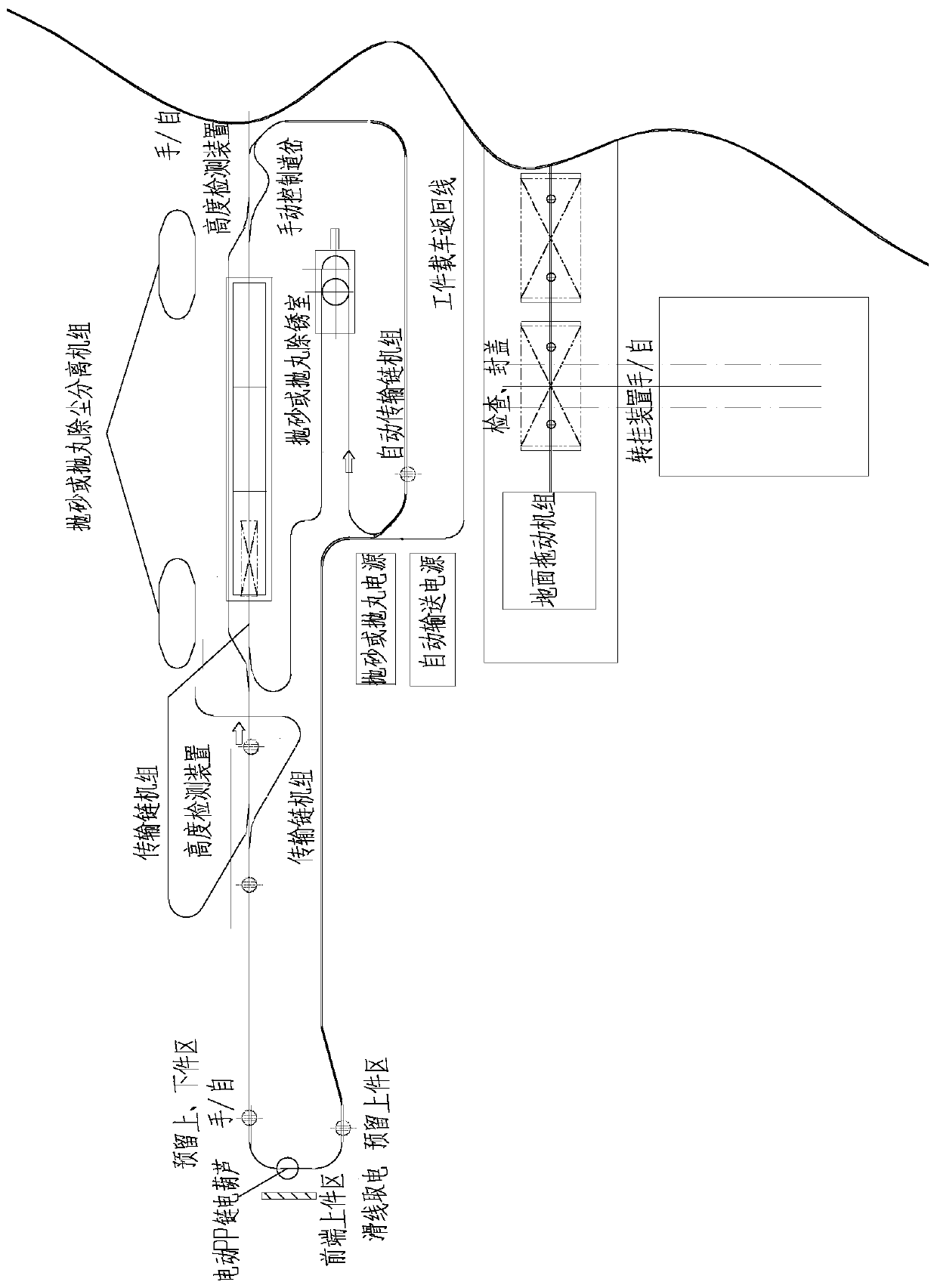

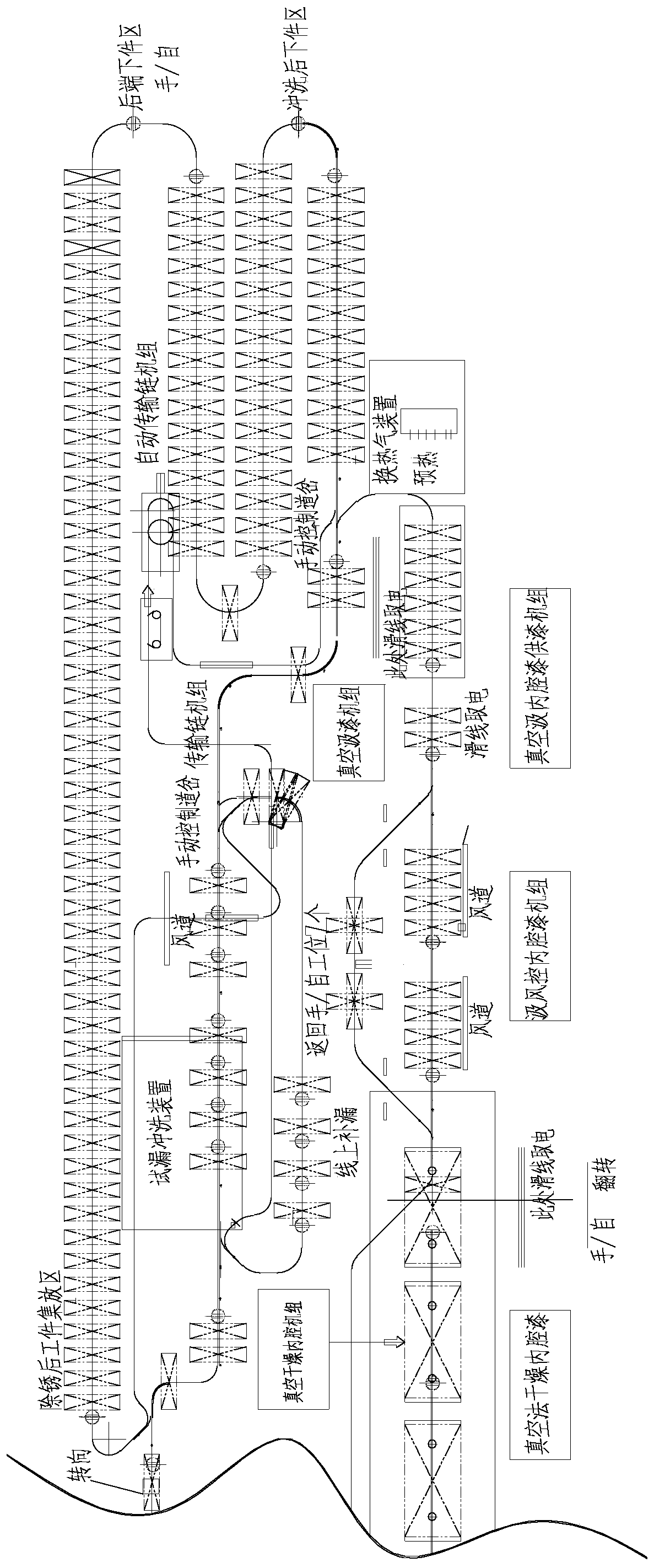

Vacuum paint drawing and vacuum fast drying paint device and process for inner cavity of cooler for transformer

ActiveCN107837989ANo smellProtect healthPretreated surfacesCoatingsProcess engineeringPumping vacuum

The invention discloses a vacuum paint drawing and vacuum fast drying paint device and process for an inner cavity of a cooler for a transformer. The device is characterized in that the device comprises a vacuum unit, a paint drawing device, an air draft unit, a continuous vacuum unit, a fast drying paint process device are arranged along a conveying line and are communicated with a tail gas recycling treatment system through air ducts; vacuum method paint drawing, air drawing of the air draft unit and the vacuum method fast drying paint are all in online continuous operation; a program controls a conveying chain to run according to CNC in an ID code of a workpiece, the takt interval of the machining time duration is 5-8 min, and the conveying speed is 8-12 m / min; a vacuumizing valve is opened, other valves are closed, a vacuum unit is started, and the sequence of two vacuum pumps is automatically controlled; after the vacuum degree is achieved, paint drawing is performed to automatically control the relevant functionality, and paint drawing is performed on the workpiece; and after paint drawing is full, a compressed air valve is started after a paint drawing valve is closed, pressure is 0.1-0.2 MPa, after pressurizing is completed, a valve communicated with the atmosphere and a paint returning valve are opened, paint in the workpiece flows back to a paint storing tank, and procedure conversion is performed.

Owner:SHENYANG TIANTONG ELECTRICITY

Control process for producing non-woven fabric

InactiveCN110396767AImprove the mixing effectSimple structureDrying solid materials with heatFibre mixingWoven fabricWinding machine

The invention relates to the technical field of spunlace non-woven devices, in particular to a control process for producing a non-woven fabric. The control process is characterized by including the following steps of firstly, grabbing; secondly, pre-loosening; thirdly, mixing; fourthly, fine-loosening; fifthly, processing by a final hopper; sixthly, processing by a pneumatic hopper; seventhly, spunlacing; eighthly, drying; ninthly, winding. An automatic winding machine has a quite high automation level and can realize continuous online production of automatic repiecing, lap changing and lap falling.

Owner:四川雅丽兴科技有限公司 +1

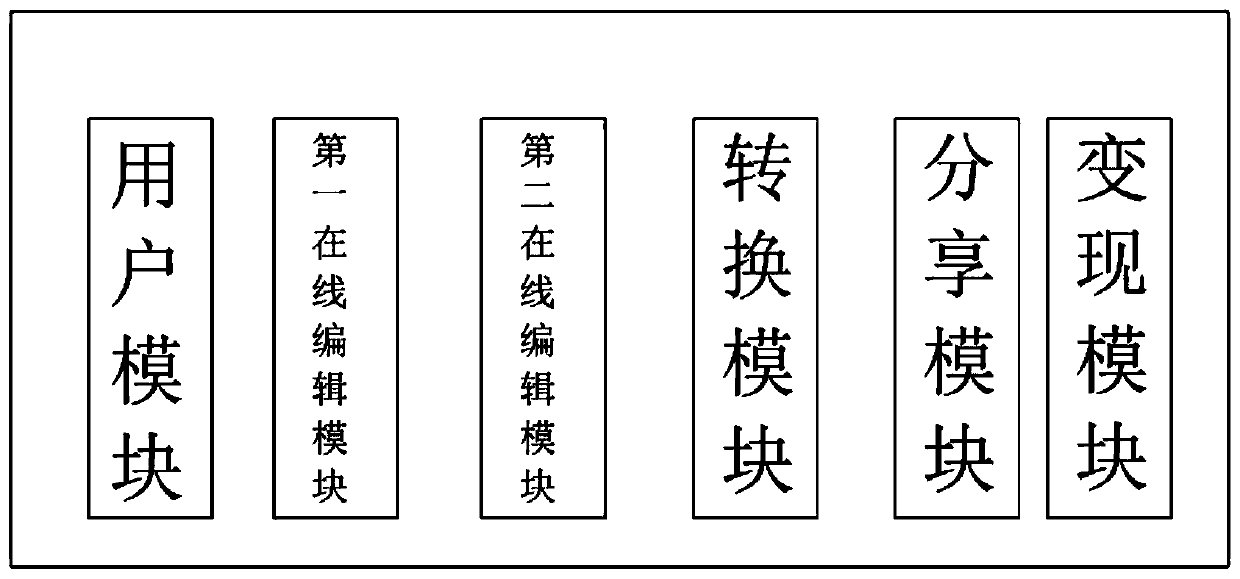

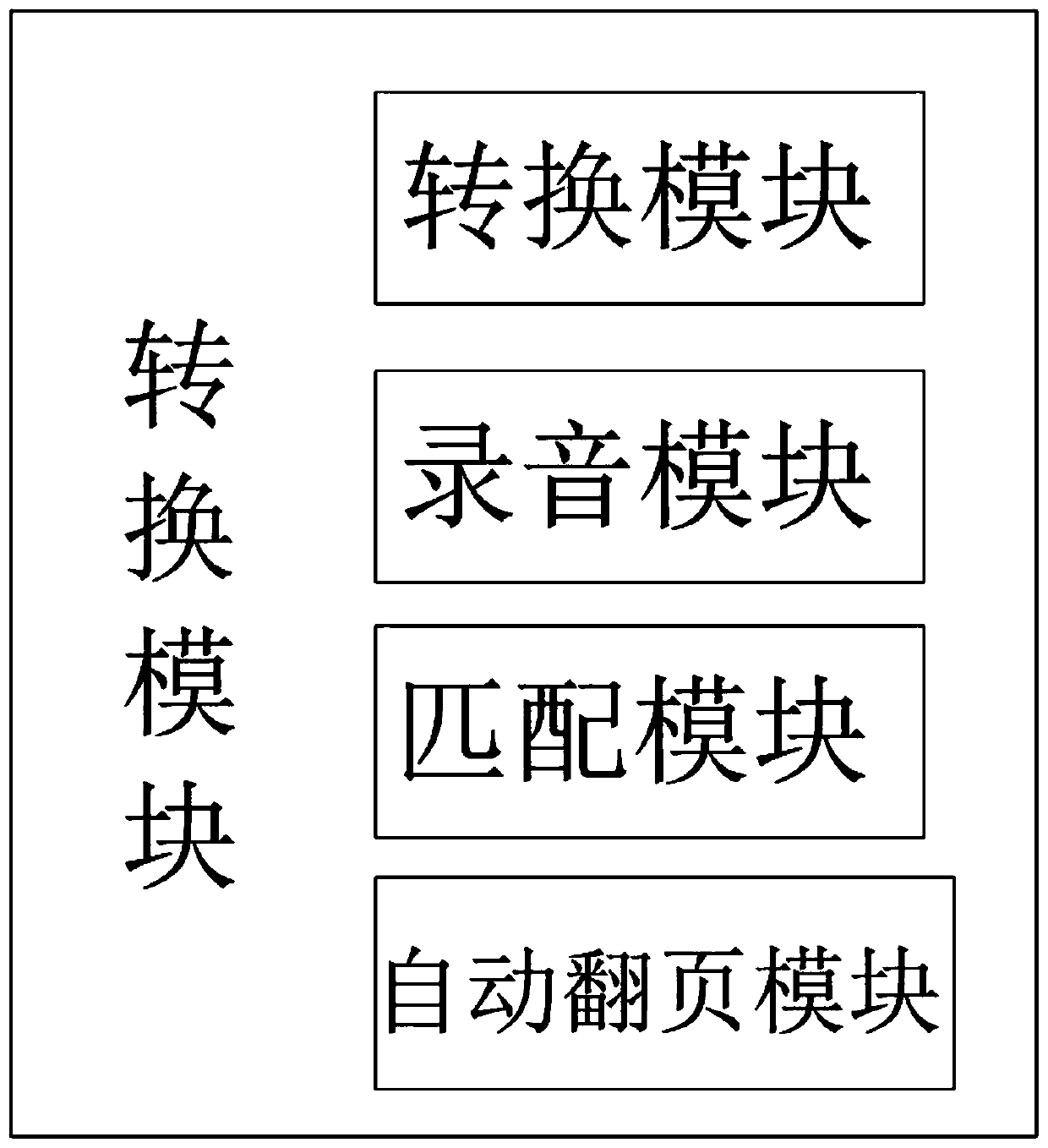

Online courseware editing system

InactiveCN110688604ARealize online productionRealize editingData processing applicationsWebsite content managementEngineeringWorld Wide Web

The invention relates to the technical field of teaching, in particular to an online courseware editing system which comprises a user module, a first online editing module, a second online editing module, a conversion module and a sharing module. The first online editing module is used for enabling a user to edit courseware through the PC terminal. The second online editing module is used for enabling the user to edit courseware through the mobile terminal. The conversion module is used for converting the courseware from a PPT format to an H5 format and storing the courseware. The sharing module is used for sharing the courseware edited by the first online editing module or the second online editing module or the conversion module. According to the invention, online courseware making and editing can be realized, existing courseware is converted from a PPT format to an H5 format, and sharing information is generated through the sharing module after courseware making or conversion is completed, so that students can directly obtain the courseware through the sharing information, and the courseware is convenient to publish and propagate.

Owner:广东力拓网络科技有限公司

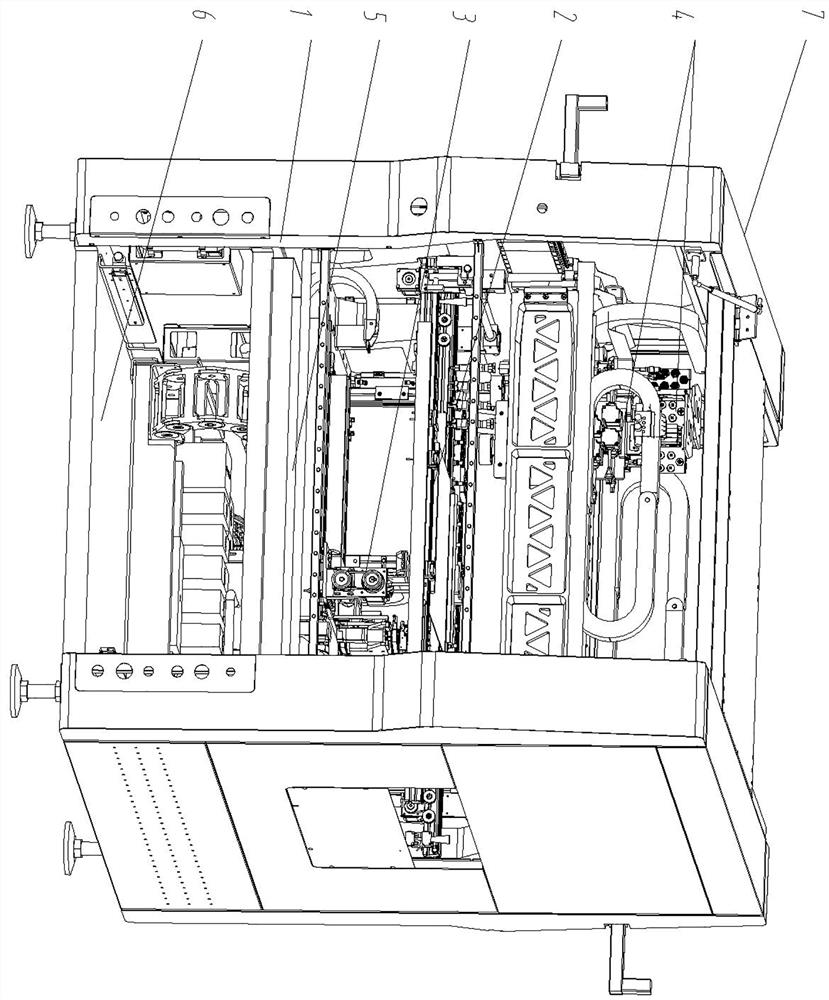

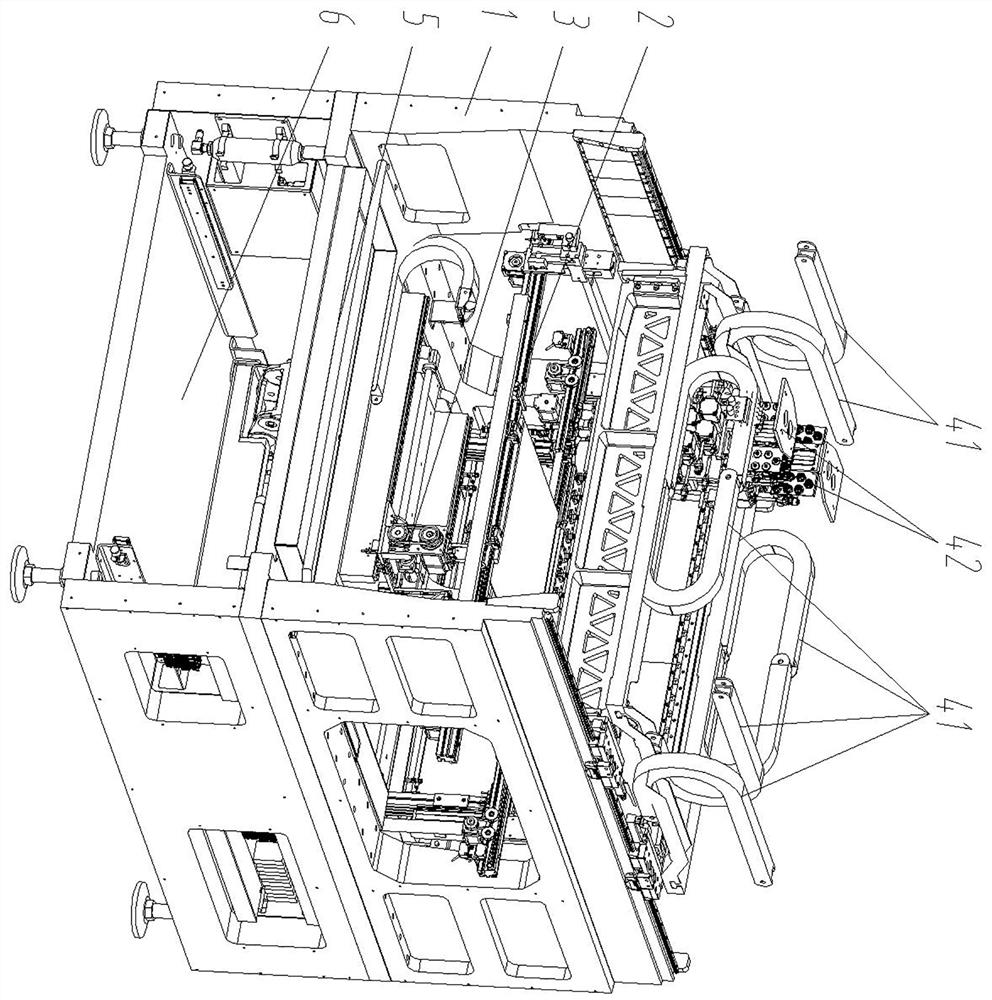

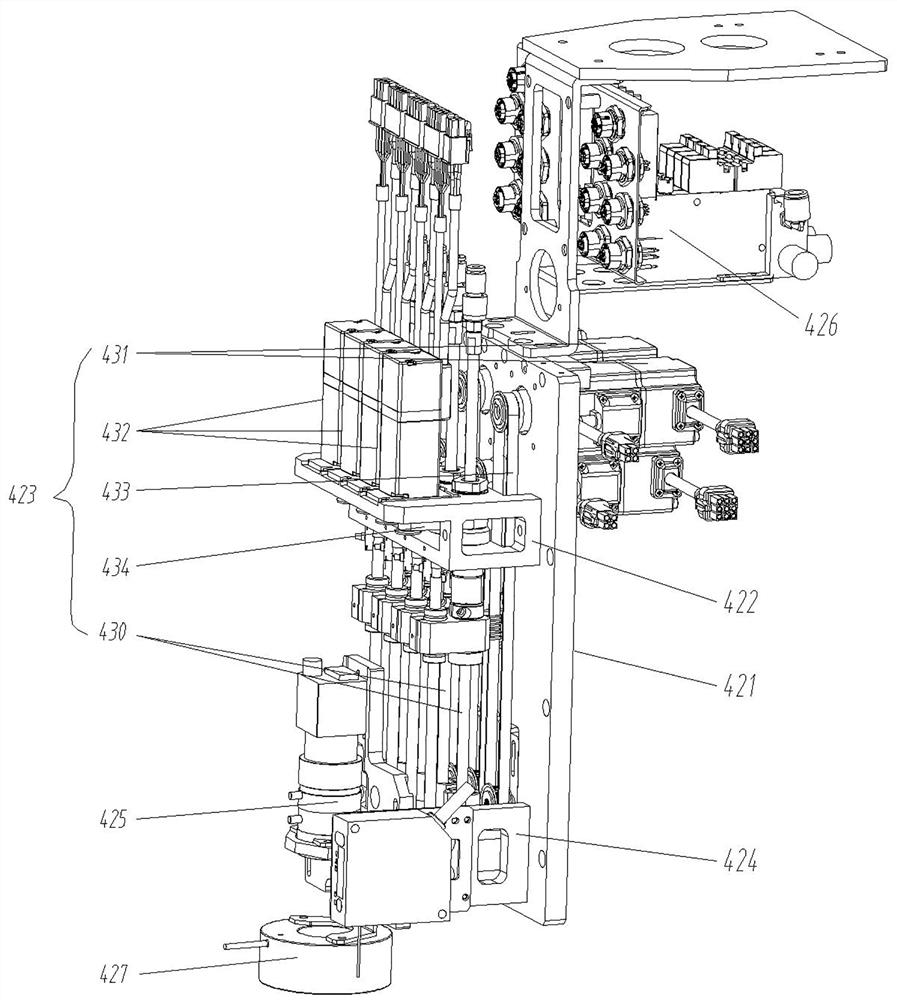

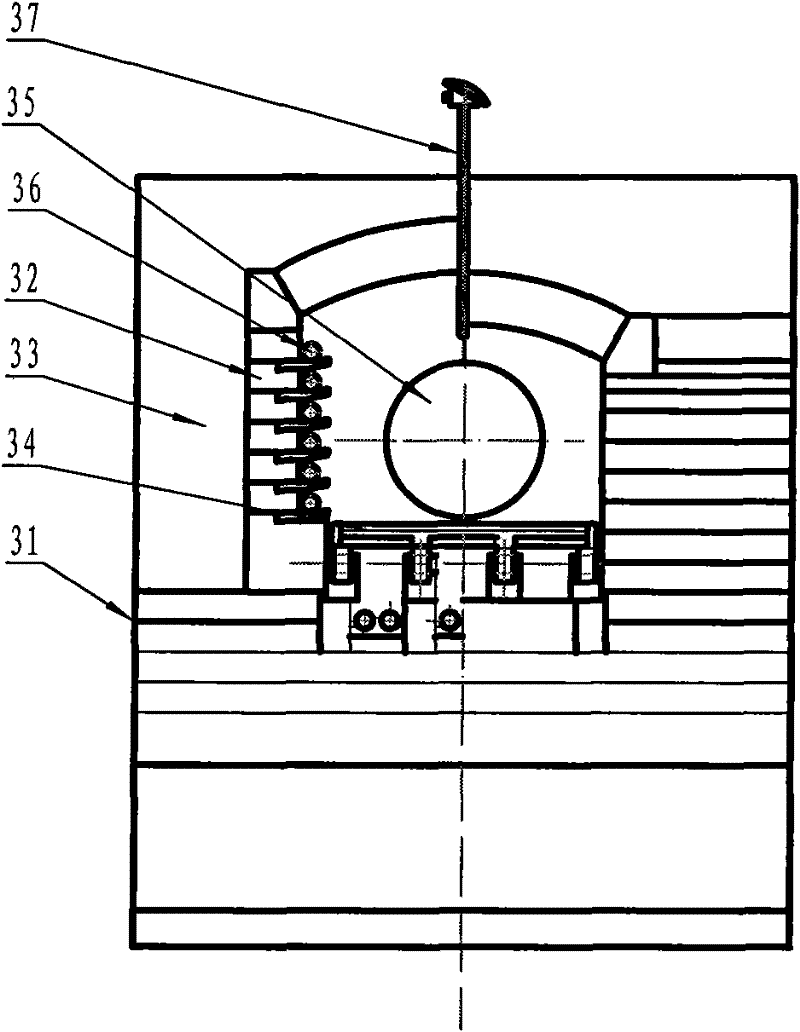

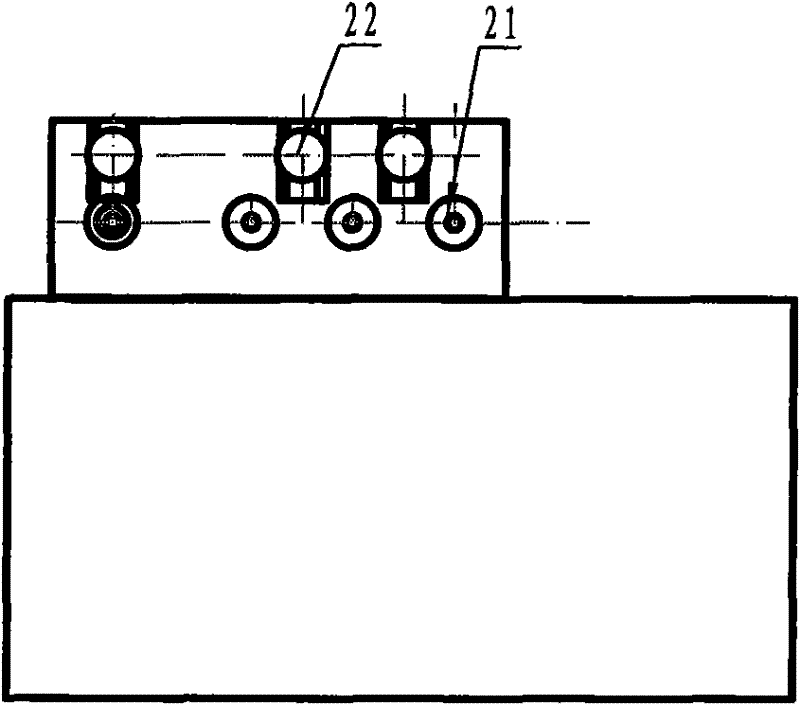

Novel multi-station automatic component inserter

PendingCN111818788ARealize online productionImprove work efficiencyElectrical componentsProduction lineEconomic benefits

The invention aims to provide the novel multi-station component inserter which is reasonable in design, high in automation degree, high in working efficiency and capable of improving economic benefits. The inserter comprises a cabinet (1), a PCB conveying module (2), a pin bending module (3) and two plug-in modules (4) are arranged in the cabinet (1). The PCB conveying module (2) penetrates through the cabinet (1), is connected with a production line and is used for conveying PCB products; the pin bending module (3) is located under the PCB conveying module (2) and used for bending pins on PCBproducts, and the two plug-in modules (4) are both located over the PCB conveying module (2) and used for conducting plug-in on the PCB products on the PCB conveying module (2). The inserter can be applied to the technical field of automation equipment.

Owner:珠海市运泰利自动化设备有限公司

Online treatment method and equipment for manufacturing inner cavity of radiator for high-voltage transformer

ActiveCN108063041AEliminate handling stackingMeet individual process requirementsLiquid surface applicatorsTransformers/inductances coolingDiluentEngineering

The invention discloses an online treatment method and equipment for manufacturing an inner cavity of a radiator for a high-voltage transformer. The online treatment method is characterized in that anID code and CNC information are added to a workpiece online; a program controls each processing time interval to be 5-8min and the transmission speed to be 8-12m / min; the surface is subjected to descaling and shot blasting, the workpiece enters a station of air-free full-hydraulic flow inner cavity flushing equipment, a flushing fluid is kept and a leakage test is carried out in a pressurizing manner; hot air is drawn into the workpiece and enters an inner cavity to draw paint; when the vacuum degree is 200-500Pa, a vacuum valve is automatically closed and a paint pipe valve of a lower-opening flange of the workpiece is opened and stands for 1-3min; a vacuum relief valve of an upper flange opening is automatically opened and the paint in the inner cavity returns to a paint can; the air isdrawn, the paint in the inner cavity is dried through a vacuum method under 1,000Pa; a diluent in a paint film in the inner cavity is quickly separated out of the surface by using negative pressure;and a gaseous diluent is drawn into a recovery filter device to recover the diluent. Linear continuous production is kept and the problem of production of the existing radiator industry is relativelywell solved.

Owner:SHENYANG TIANTONG ELECTRICITY

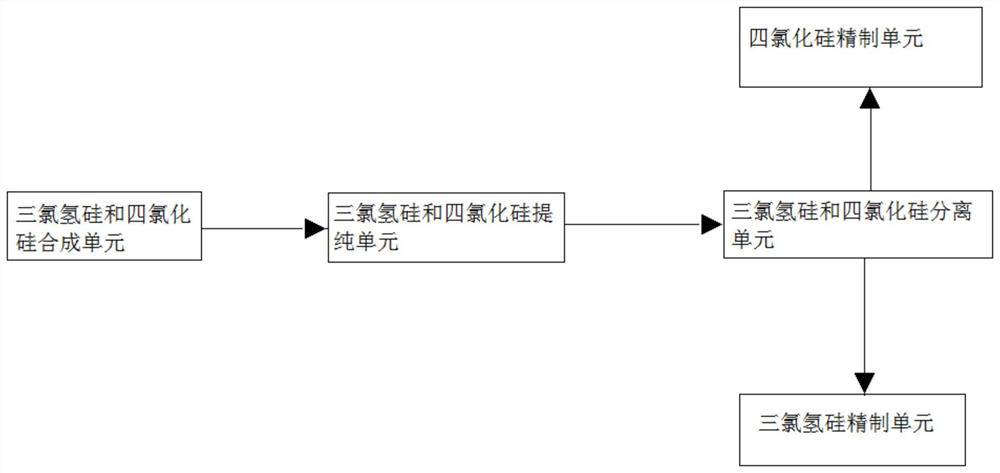

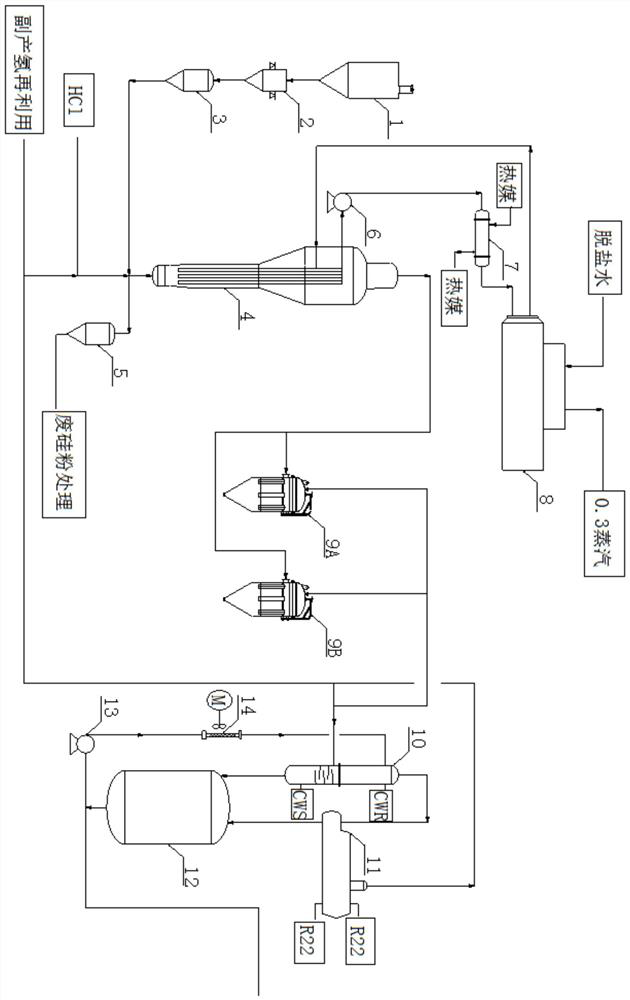

Device and process for producing high-purity trichlorosilane and silicon tetrachloride

InactiveCN112209384AEliminate entryRealize online productionEnergy inputHalogenated silanesPhysical chemistryCryogenic treatment

The invention relates to a device and a process for producing high-purity trichlorosilane and silicon tetrachloride. The device comprises a trichlorosilane and silicon tetrachloride synthesis unit, atrichlorosilane and silicon tetrachloride purification unit and a trichlorosilane and silicon tetrachloride separation unit which are connected in sequence, and a trichlorosilane refining unit and a silicon tetrachloride refining unit are respectively connected with the trichlorosilane and silicon tetrachloride separation unit. By adopting the device provided by the invention, HCl completely reacts in the synthesis process, a hydrogen chloride recovery device and a byproduct hydrogen water washing treatment device of a later system are not needed, direct recycling of hydrogen after cryogenic treatment is realized, online production is realized, unreacted silica fume of the system can be discharged without stopping the device, long-term stable operation of the device is ensured, and waste heat recovery of the device can be ralized. The dry dust remover is added in the device so that the dry dust removal of the trichlorosilane device is realized, the silica fume is prevented from entering a subsequent washing tower device, the blockage of the subsequent system due to the silica fume is eliminated, and the long-term stable operation of the device is ensured.

Owner:郑州格矽科技发展有限公司

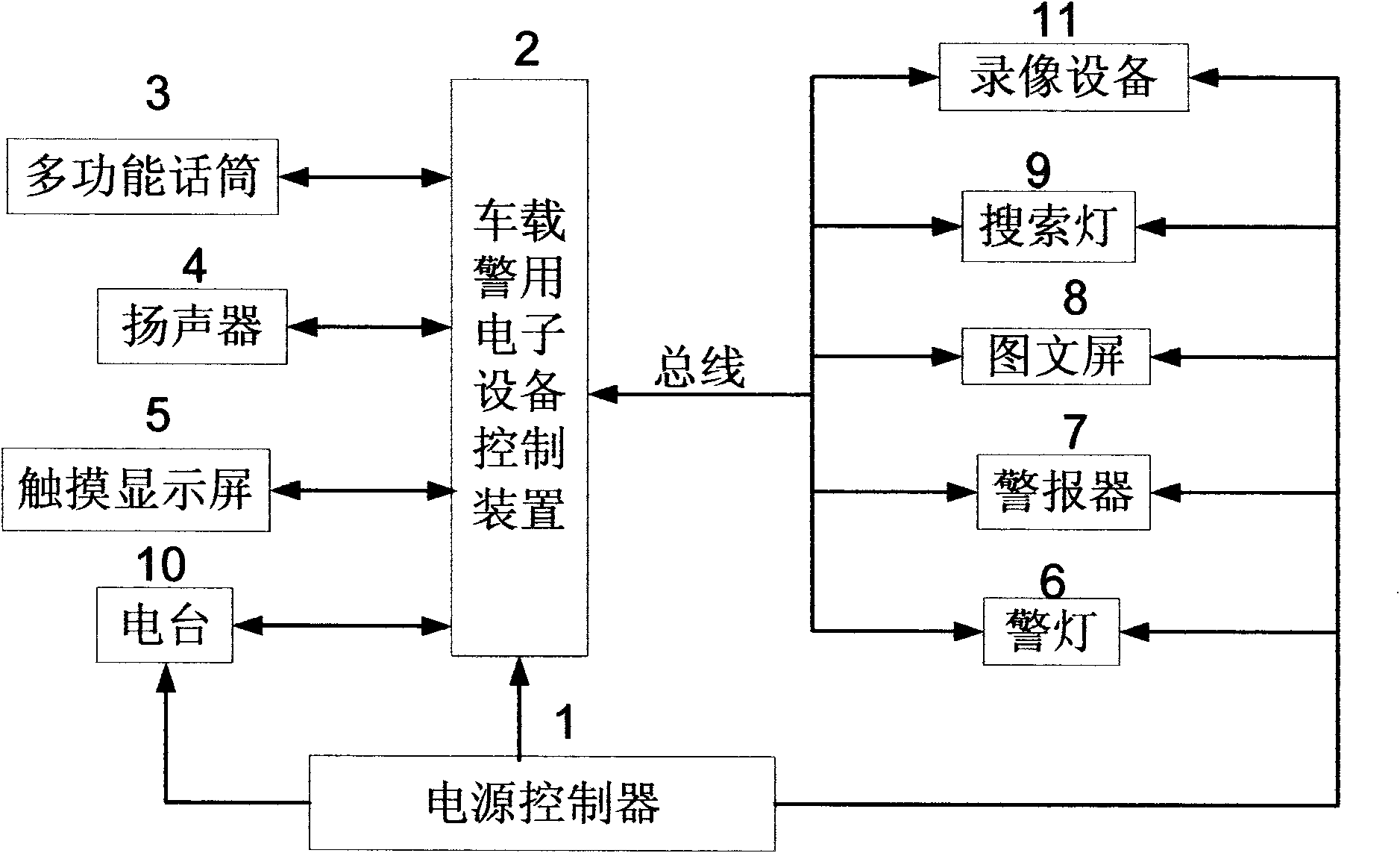

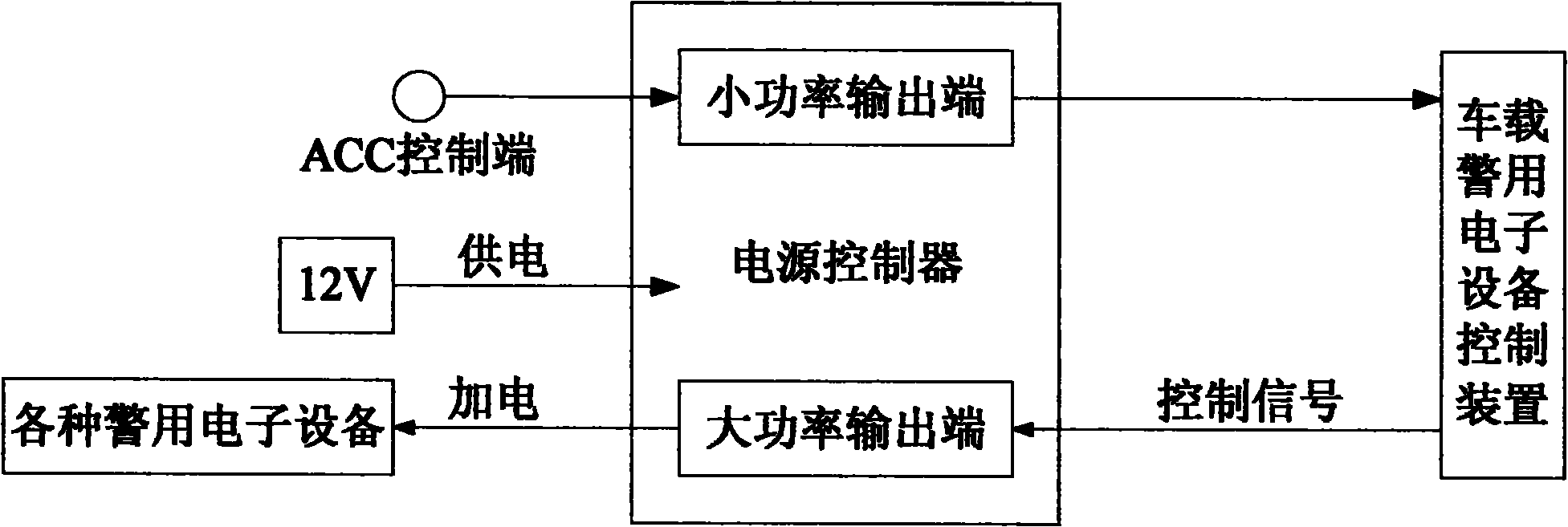

Central control system of police vehicle-mounted electronic equipment

InactiveCN102039858AImprove efficiencyRealize intelligent controlDashboard fitting arrangementsElectric/fluid circuitControl systemPolice vehicle

The invention relates to a central control system of police vehicle-mounted electronic equipment. A multifunctional microphone, a loudspeaker, a radio station and a touch display screen are connected to a vehicle-mounted police electronic equipment control device; the vehicle-mounted police electronic equipment control device is connected with a police vehicle-mounted equipment alarm lamp, an alarm, an image-text screen, a search lamp and video equipment in a bus manner; and a user interface with interaction of the vehicle-mounted police electronic equipment control device and the police vehicle-mounted equipment is displayed on the touch display screen. By utilizing an electronic technology and a communication technology, the central control system provided by the invention controls various police vehicle-mounted equipment according to the communication between the vehicle-mounted police electronic equipment control device and the police vehicle-mounted equipment, thereby unifying the operation of a plurality of police vehicle-mounted equipment, solving the control problem of different police vehicle-mounted equipment, realizing the intelligent control of the vehicle-mounted police electronic equipment control device to the police vehicle-mounted equipment and improving the using efficiency of the police vehicle-mounted equipment and the reliability of police vehicles and police affairs.

Owner:河北普华科技有限公司

Classic espresso coffee formula and production technology thereof

InactiveCN109170071AKeep the aromaMellow tasteClimate change adaptationGreen coffee treatmentSterile environmentShielding gas

The present invention discloses a classic espresso coffee formula and a production technology thereof. The classic espresso coffee formula is prepared from coffee beans, lemon peel powder, cassia barkpowder, grapefruit sauce, citrus sinensis cv. Liu Cheng powder, vitamin B12, mint and borneol as raw materials; proportion of the components is strictly controlled; a traditional neutralization preparation formula is changed; an obtained mixture is placed in a container to be put still; a vacuuming device is used to conduct a vacuuming treatment of the container; vacuum low-temperature environment inside a fine grinding device is kept; a grinding degree is controlled to be three-degree; original quality and aroma of coffee beans are better preserved; the coffee beans are mellow in mouthfeel;after grinding, the desired espresso coffee is obtained; the quality of the classic coffee is strictly ensured; a quantitative sealed packaging method is used; and packaging bags are filled with a sufficient amount of inert gas as protection gas to limitedly prevent the classic coffee to be oxidized; the classic coffee is long in shelf life; the entire packaging process is conducted in a sterile environment; the manufacture process is simple; an online production can be achieved; and the production efficiency is high.

Owner:安徽咖力士咖啡食品有限公司

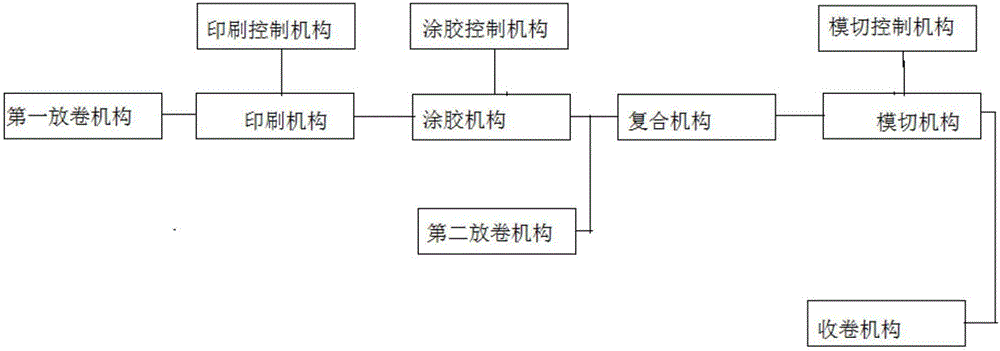

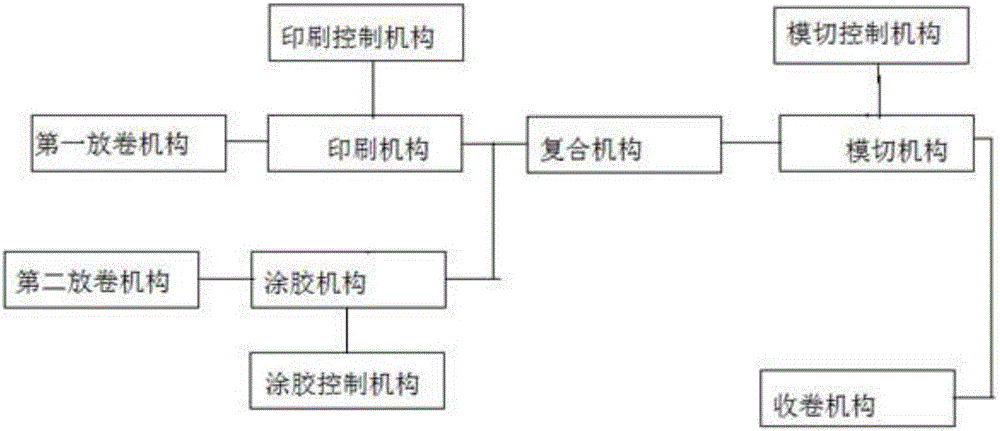

Processing device of tags for two-layer logistics

InactiveCN106042464ARealize online productionMeet the need to preserve original documentsStampsLamination ancillary operationsLogistics managementEngineering

The invention provides a label processing equipment for two-layer logistics, including a first unwinding mechanism, a printing mechanism, a glue coating mechanism, a second unwinding mechanism, a composite mechanism, a die-cutting mechanism and a winding mechanism, the first The unwinding mechanism, the printing mechanism and the gluing mechanism are sequentially arranged according to the flow direction of the first layer of the material layer to be processed, and the output ends of the second unwinding mechanism and the gluing mechanism are sequentially arranged with a composite mechanism, a die-cutting mechanism and a winding mechanism; The gluing mechanism is a partial gluing mechanism. The invention realizes the online production of two-layer logistics labels, the matching of printing, partial gluing and die-cutting processes, and realizes partial gluing through the gluing mechanism, which can meet the needs of logistics companies to preserve original documents, and at the same time save a layer of paper and Its processing procedure reduces waste paper pollution, saves resources, and reduces costs by about 30%.

Owner:天津中天盛通科技有限公司

Method for producing transparent conducting film glass

The invention discloses a method for producing transparent conducting film glass. The method comprises the following steps: (1) introducing a gaseous-state shielding layer precursor containing silane and an oxygen source to the glass surface at a temperature ranging from 460 to 480 DEG C by taking an inert gas as a carrier in an annealing kiln, carrying out photodissociation of the gaseous-state shielding layer precursor by use of a parallel incident laser beam and thus carrying out a chemical vapor reaction to form a shielding layer which is 50-90nm thick on the glass surface; (2) in the annealing kiln and in the glass temperature range of 435-455 DEG C, introducing a gaseous-state conducting layer precursor containing pre-gasified zinc and aluminum sources and the oxygen source to the glass surface on which the shielding layer is already deposited by taking the inert gas as the carrier, and causing the photodissociation of the gaseous-state conducting layer by use of the parallel incident laser beam and thus carrying out the chemical vapor reaction to form a conducting layer which is 250-400nm thick on the glass surface. The method has the advantages that the temperatures of the coating reactions are effectively reduced so that the quality of the film can be improved, and the utilization rate of the precursor gases is increased so that the working conditions of a float line can be kept stable.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD +1

H5 technology-based APP virtual prototype making platform, making method and simulation method

InactiveCN108804090ARealize online productionSimple interfaceProgramming languages/paradigmsProcess systemsSimulation

The invention relates to H5 technology-based APP operation simulation, in particular to an H5 technology-based APP virtual prototype making platform, making method and simulation method. APP operationis simulated on line by utilizing an H5 page; an H5 technology-based pseudo APP concept is proposed; a pseudo APP platform is built and is different from a traditional H5 template platform; the platform can simulate an APP by using the H5 page; the jump of the H5 page is realized by clicking a previously preset button identifier; and a use scene of the APP is simulated. The key step of making a virtual prototype is introduced into a development process system of the APP, so that the contradiction between the huge number of potential demanders and the high development cost faced by the APP development is solved; and the platform mainly aims at startup teams needed to provide novel concept display in financing roadshow, dual-creative competitions, crowd-funding display, advertising, marketassessment and market survey, and groups needed to develop APPs.

Owner:张弢 +4

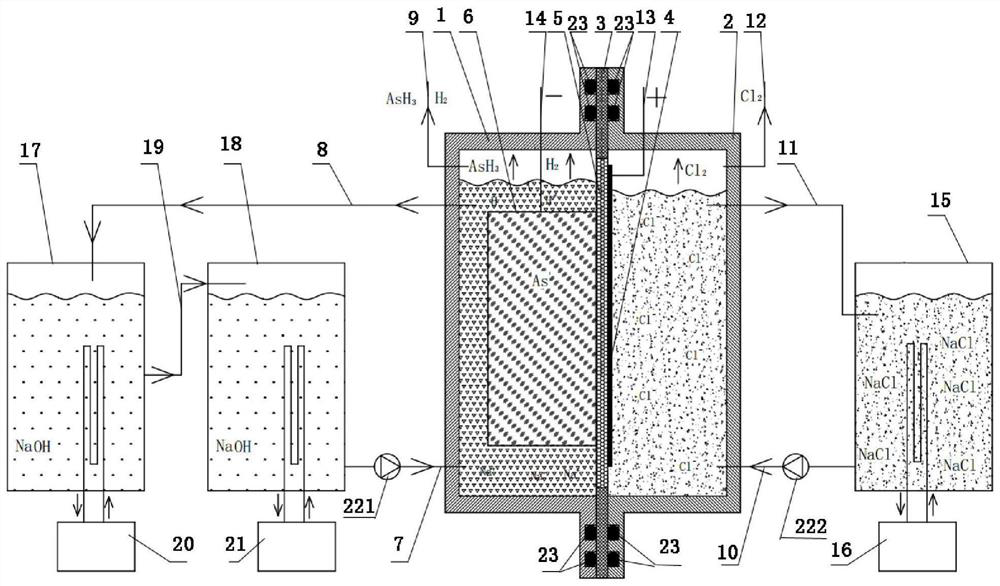

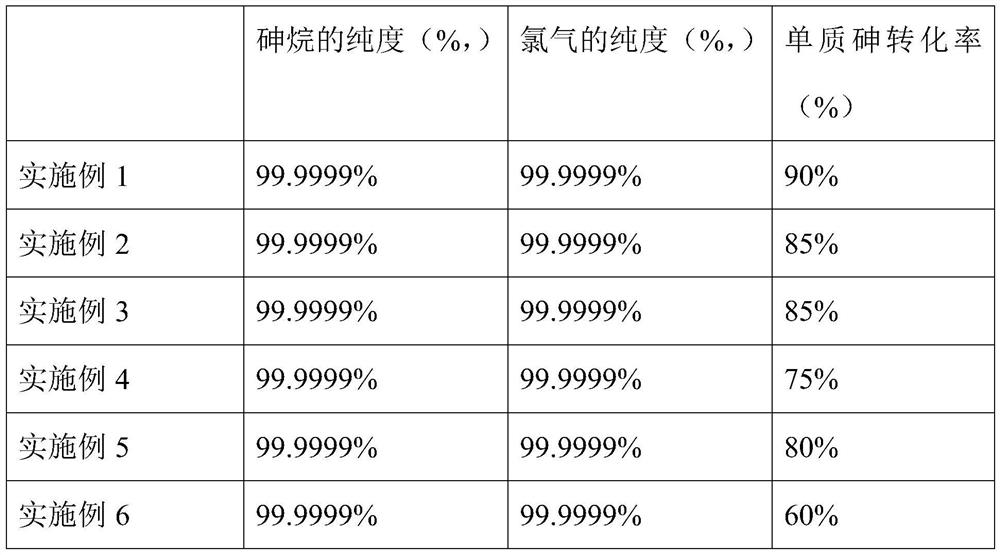

Arsine and chlorine combined electrolysis device and arsine and chlorine combined electrolysis method using same

PendingCN112301367AImprove safe operation reliabilityMaximize the benefitsCellsElectrode shape/formsArsineElectrolytic cell

The invention provides an arsine and chlorine combined electrolysis device and an arsine and chlorine combined electrolysis method using the same. The device comprises an electrolytic cell, a cation semipermeable membrane is arranged in the electrolytic cell, the electrolytic cell is divided into an anode electrolytic cell and a cathode electrolytic cell by the cation semipermeable membrane, an anode membrane electrode is arranged in the anode electrolytic cell, and the anode electrolytic cell is communicated with an anode electrolyte feeding pipe, an anode electrolyte discharging pipe and a chlorine discharging pipe; an arsenic cathode is arranged in the cathode electrolytic cell, and the cathode electrolytic cell is communicated with a catholyte feeding pipe, a catholyte discharging pipeand an arsine discharging pipe. The method comprises the following steps: electrolyzing an anolyte containing chlorine salt by using the anode membrane electrode in the anode electrolytic cell to obtain chlorine gas, and enabling the cations in the chlorine salt to enter the cathode electrolytic cell through the cation semipermeable membrane; meanwhile, electrolyzing water in the catholyte by using the arsenic cathode in the cathode electrolytic cell to obtain arsine. The device provided by the invention realizes simultaneous production of high-purity arsine and high-purity chlorine.

Owner:紫石能源有限公司

Producing method of low-radiation self-cleaning composite function glass

This invention relates to a manufacture method of a low radiation self-cleaning complex function glass. This glass has trilamellar membrane structure, membranous layer from glass outward in turns is: SiO2 transition layer, ion adulterated SnO2 layer, ion adulterated SiO2 - TiO2 layer. The on-line preparation method is sol-gel method, combine with atomizing sedimentation, utilize thermal decomposition and coagulation process of collosol at 450 DEG C to 550 DEG C to proceed heat sedimentation, in turns form membranous layer on the on-line glass plate surface. This invention through controlling the coating material concentration, dopant ion variety, thermal decomposition temperature and membranous layer thickness bring low radiation to the glass coated this membrane, execute stable uniwafer low emissivity glass, reduce cost, and realize reprocessing treatment of low radiation steeling and hot bending. The membrane layer has photocatalysis performance, realizes the effects of antibiosis and self cleaning, and finally achieves dual function of low radiation and self cleaning of the glass, with controlling the outer layer protective film TiO2 crystal form.

Owner:CHINA LUOYANG FLOAT GLASS GROUP

Production method of pre-hardened high-speed steel products and production device thereof

ActiveCN101691626BRealize online productionDecrease stockIncreasing energy efficiencyFurnace typesQuenchingTractor

The invention discloses a production method of pre-hardened high-speed steel products and a production device thereof. The method is characterized by taking high-speed steel wires as raw materials and comprises the following steps: pre-straightening the raw materials, carrying out quench heating on the pre-straightened raw materials, carrying out small deformation on the high-speed steel wires bya wire-drawing die after quenching, quenching, straightening, tempering in a tempering furnace, straightening, tempering, straightening and cooling, and carrying out cutting-to-length on the productsformed by traction by a tractor. The invention is characterized by combining quenching, tempering and straightening to carry out continuous production, realizing online production of the pre-hardenedhigh-speed steel wires, ensuring identical product organizations and properties, ensuring reliable and stable quality and producing various steel wires with length being more than 2m and with good straightness.

Owner:烟台百特合金材料制造有限公司

Online automatic counterpoint method and device for inner tube transferring mould and delay element screening mould

ActiveCN107118068ASolve the problem of not being able to rotate first and then jack upAvoid issues where itinerary accuracy cannot be guaranteedDetonatorsEngineeringElectrical and Electronics engineering

The invention discloses an online automatic counterpoint method and device for an inner tube transferring mould and a delay element screening mould, designs a combined scheme of a set of rotary air cylinder and two stages of ejection air cylinders and solves the problem that the transferring mould cannot rotate at first and then is ejected out due to reasons of a self structure of a conveyer belt and a designed limiting device. Furthermore, if the transferring mould is ejected to be in place at first, a limiting structure between the two moulds can prevent rotation; thus, the two ejection air cylinders with independent strokes are utilized, and the problem that stroke accuracy of a double-stroke air cylinder cannot be ensured is solved. The online automatic counterpoint method disclosed by the invention not only achieves automatic online production, but also avoids the problem that a plurality of positions of equipment are modified.

Owner:XIANGNAN EXPLOSION APPLIANCES HUNAN PROV

A kind of preparation method of transparent conductive metal network

ActiveCN103628028BAchieve productionReduce energy consumptionVacuum evaporation coatingFilament/thread formingEtchingElectrospinning

The invention discloses a preparation method for a transparent conductive metal network. The preparation method comprises the following steps: a) preparing a nanofiber network through electrospinning; b) evaporating a metal layer on the nanofiber network so as to obtain a metal-polymer network complex; and c) removing a metal in the metal-polymer network complex so as to obtain the transparent conductive metal network. The invention has the following beneficial effects: downstream tedious etching and patterning processes are avoided in preparation of a conductive film prepared from the flexible transparent metal network, demands of touch screens and display panels for patterning can be directly met, and online production can be realized.

Owner:苏州冷石纳米材料科技有限公司

Labeling device

ActiveCN105636871BFast and reliable controllable operationTransfer is simple but reliableLabelling machinesMechanical engineeringEngineering

A labeling device for applying labels onto a material web, which is moved in a transport direction at a web speed, comprises a label dispenser and a transferring device, which takes over the labels from the label dispenser by means of holding means, moves the labels towards the material web and applies the labels onto the material web at a transfer location. The holding means of the transferring device can be moved in the transport direction and opposite the transport direction in a circulating path at a variable circulating speed, said holding means moving in the transport direction at the web speed when the holding means are located at the transfer location.

Owner:STARLINGER & CO GMBH

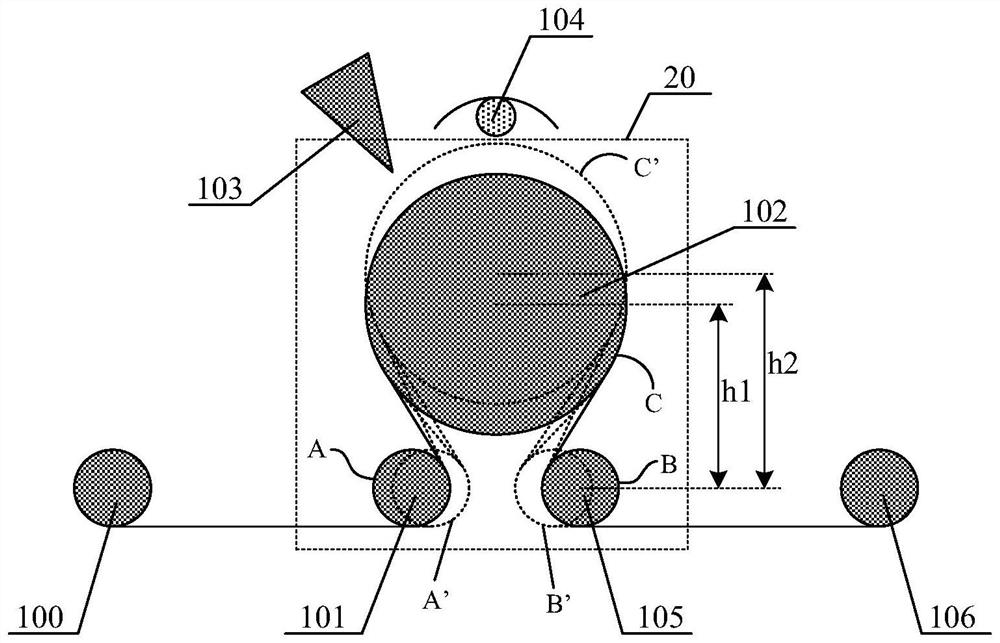

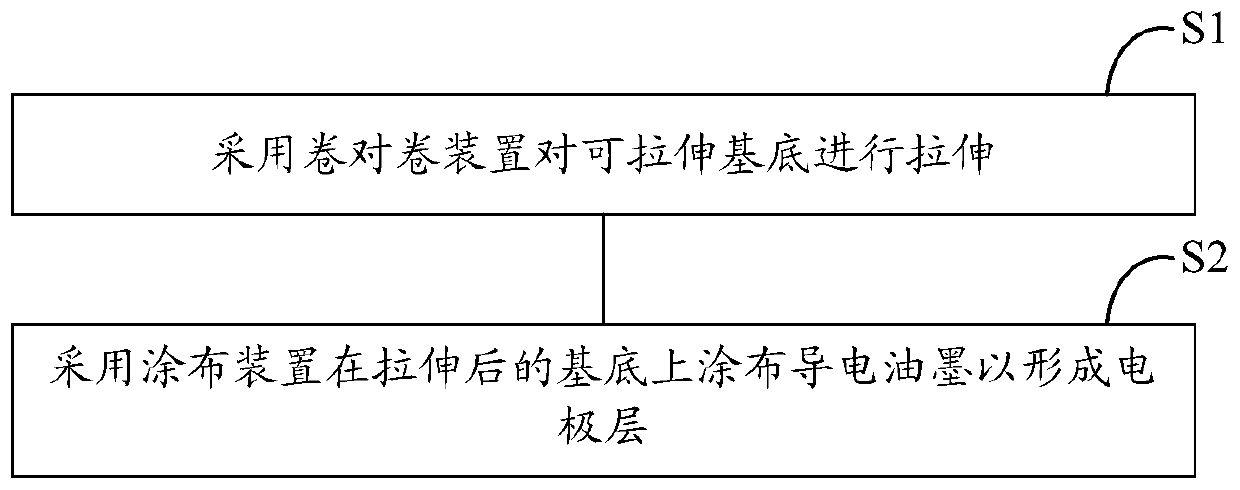

A kind of equipment and method for preparing electrode

ActiveCN110237995BReduce manufacturing costRealize mass productionPretreated surfacesCoatingsHigh volume manufacturingEngineering

The invention discloses a device and a method for preparing an electrode. The equipment for preparing electrodes includes: a roll-to-roll device for stretching a stretchable substrate; a coating device for coating conductive ink on the stretched substrate to form an electrode layer. The equipment for preparing electrodes proposed in the embodiments of the present invention uses a roll-to-roll device to stretch the stretchable substrate, and then applies the roll-to-roll process to the production equipment of the stretchable electrode, realizing the wire-to-stretch electrode. On-board production; using the simple and efficient characteristics of the roll-to-roll process, the production cost of the stretchable electrode is reduced, and the mass production of the stretchable electrode is realized.

Owner:BOE TECH GRP CO LTD

Method and device for preparing composite phosphate fertilizer from wastewater

ActiveCN110877985ARealize online productionImprove adsorption capacityOther chemical processesSpecific water treatment objectivesAmmoniacal nitrogenSorbent

The invention provides a device for preparing a composite phosphate fertilizer from wastewater. The device comprises a mixed adsorption reaction unit, a magnetic separation and regeneration unit and acomposite phosphate fertilizer crystallization unit three units. The invention further provides a method for preparing the phosphate fertilizer by adopting the device. The method can be used for treating wastewater with COD<=2000mg / L, BOD5<=500mg / L, ammonia nitrogen<=500mg / L, phosphate<=80mgP / L and pH value of 6.0-7.0. According to the device disclosed by the invention, an adsorption reactor, a magnetic separation coupling regeneration reactor and a crystallization reactor are organically combined together, the high-purity phosphate fertilizer can be finally prepared, and an adsorption material can be recycled; the crystallization reactor can realize phosphate fertilizer online production, and the final phosphate fertilizer yield can reach 400-500g / t waste liquid. According to the wastewater recycling method disclosed by the invention, efficient and high-selectivity adsorption of phosphate can be realized; one-stop phosphate fertilizer output is achieved, the adding amount of the adsorbent is small, the complex crystallization separation process is avoided, the separation effect is good, and the operation cost is saved.

Owner:SHANDONG JIANZHU UNIV

An online processing method and equipment for manufacturing a radiator inner cavity for a high-voltage transformer

ActiveCN108063041BEliminate handling stackingMeet individual process requirementsLiquid surface applicatorsTransformers/inductances coolingLacquerDiluent

The invention discloses an online treatment method and equipment for manufacturing an inner cavity of a radiator for a high-voltage transformer. The online treatment method is characterized in that anID code and CNC information are added to a workpiece online; a program controls each processing time interval to be 5-8min and the transmission speed to be 8-12m / min; the surface is subjected to descaling and shot blasting, the workpiece enters a station of air-free full-hydraulic flow inner cavity flushing equipment, a flushing fluid is kept and a leakage test is carried out in a pressurizing manner; hot air is drawn into the workpiece and enters an inner cavity to draw paint; when the vacuum degree is 200-500Pa, a vacuum valve is automatically closed and a paint pipe valve of a lower-opening flange of the workpiece is opened and stands for 1-3min; a vacuum relief valve of an upper flange opening is automatically opened and the paint in the inner cavity returns to a paint can; the air isdrawn, the paint in the inner cavity is dried through a vacuum method under 1,000Pa; a diluent in a paint film in the inner cavity is quickly separated out of the surface by using negative pressure;and a gaseous diluent is drawn into a recovery filter device to recover the diluent. Linear continuous production is kept and the problem of production of the existing radiator industry is relativelywell solved.

Owner:SHENYANG TIANTONG ELECTRICITY

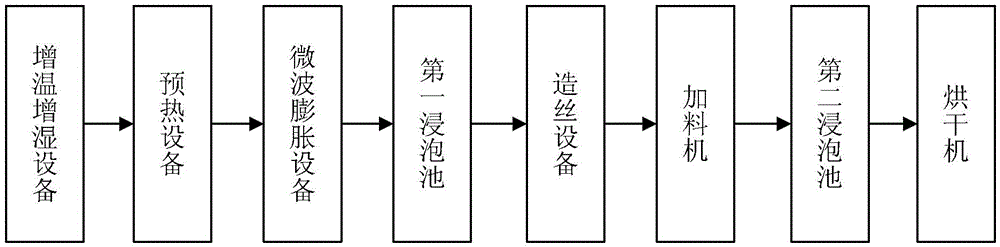

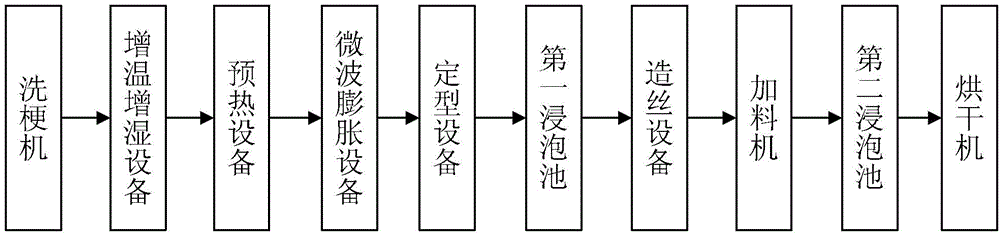

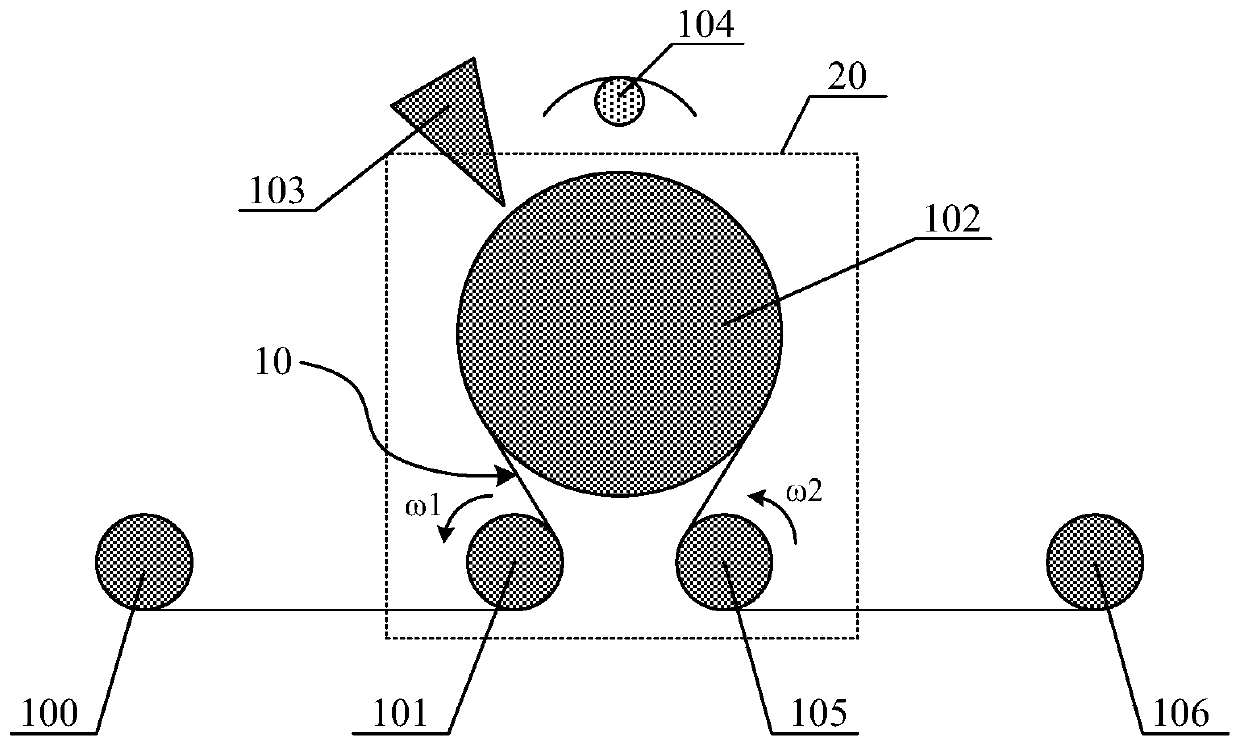

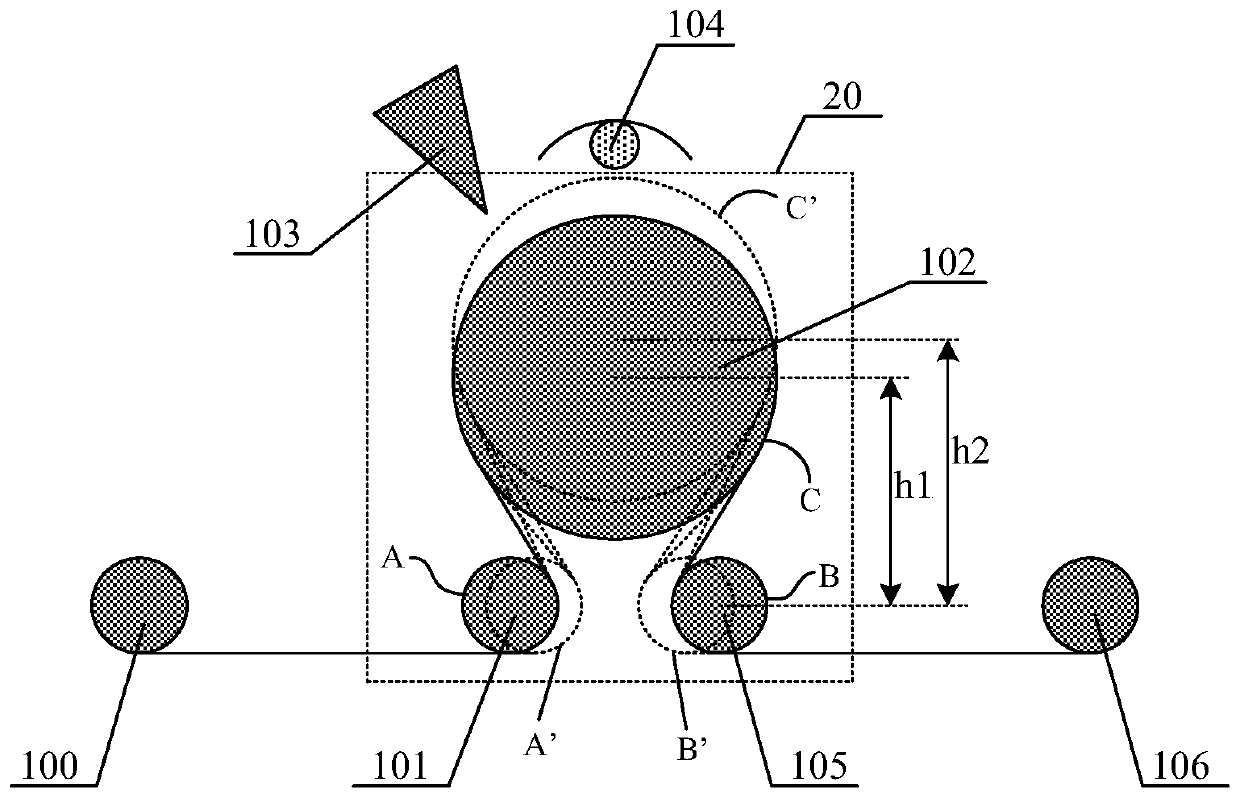

Raw materials for cigarettes, production method and equipment thereof

ActiveCN103169146BSimple production methodReduce water consumptionTobacco preparationTobacco treatmentFiberMicrowave

The invention provides raw materials for cigarettes, a production method of the raw materials for the cigarettes and equipment of the raw materials for the cigarettes. The production method of the raw materials for the cigarettes includes the following steps. Firstly, plant biomass is heated and moistened unit the water content reaches 35 wt% to 40 wt%. Secondly, materials are preheated after being heated and moistened until the water temperature of the materials reaches the boiling point. Thirdly, the preheated materials are expanded with micro waves until the water content reduces to 10 wt% to 20 wt%. Fourthly, water is added to the materials until the water content reaches 30 wt% to 40 wt%. Fifthly, the materials are machined to be fiber shreds. Sixthly, biological enzyme liquid is sprayed onto the fiber shreds, the fiber shreds with the biological enzyme liquid are soaked in water. Seventhly, drying is performed. The raw materials for the cigarettes, the production method of the raw materials for the cigarettes and the equipment of the raw materials for the cigarettes overcome defects in the prior art, have the advantages that water consumption in production is low, crushed raw materials for the cigarettes obtained in production are less, compatibility with tobacco shreds is perfect, woodiness texture is not obvious and can be applied to manufacture of high-grade cigarettes.

Owner:赵鸿

Device and method for preparing electrode

ActiveCN110237995AReduce manufacturing costRealize mass productionPretreated surfacesCoatingsHigh volume manufacturingEngineering

The invention discloses a device and a method for preparing an electrode. The device for preparing the electrode comprises a roll-to-roll device used for stretching a stretchable substrate and a spreading device used for spreading conductive ink on the substrate after being stretched so as to form an electrode layer. The device for preparing the electrode uses the roll-to-roll device for stretching the stretchable substrate, and then applies roll-to-roll technology into production equipment of the stretchable electrode, achieves online production of the stretchable electrode, uses simple, convenient and efficient characteristics of the roll-to-roll technology, reduces manufacture cost of the stretchable electrode, and achieves mass production of the stretchable electrode.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com