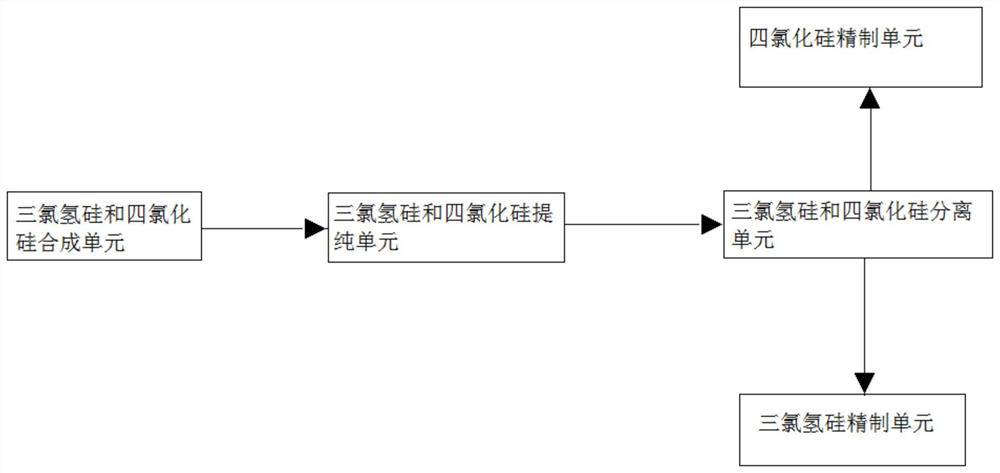

Device and process for producing high-purity trichlorosilane and silicon tetrachloride

A technology of silicon tetrachloride and trichlorosilane, which is applied in the chemical industry, silicon compounds, silicon halide compounds, etc., can solve the problems of affecting the operation cycle of the device, short operation cycle, and post-system blockage, so as to ensure long-term stable operation , Eliminate micro-silica fume clogging, and realize the effect of waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

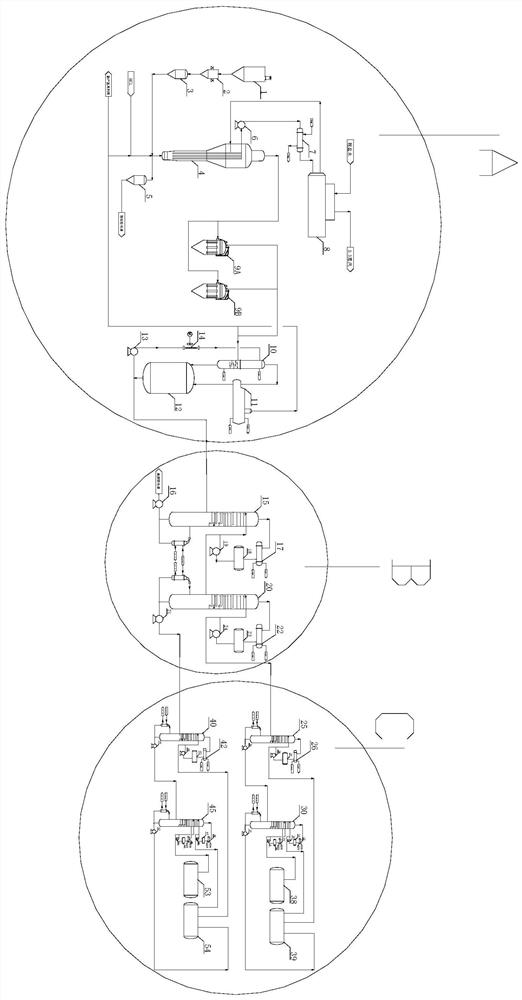

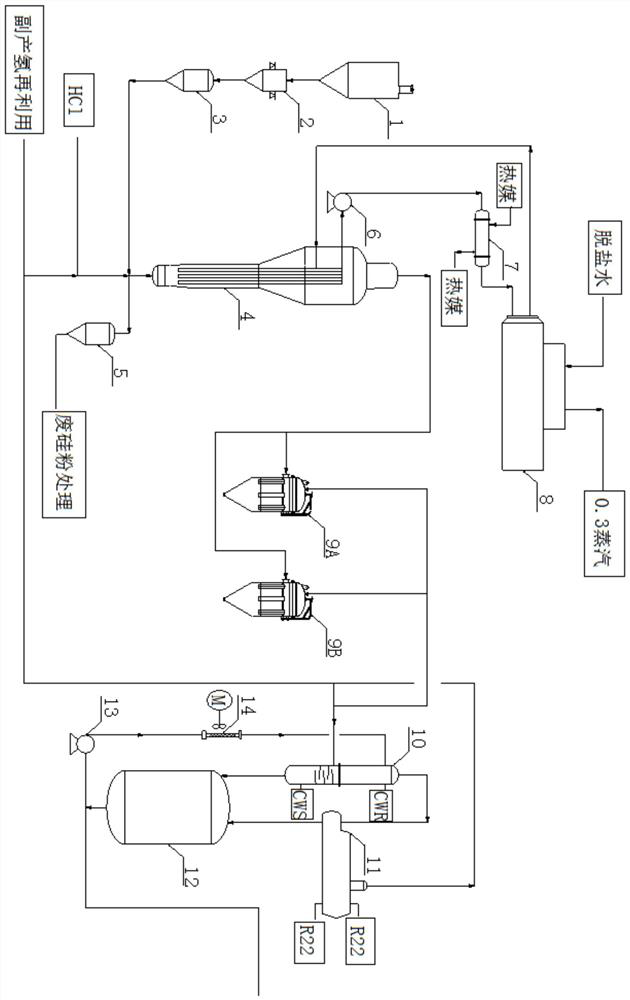

Embodiment 1

[0035] Such as image 3 As shown, the synthesis unit of trichlorosilane and silicon tetrachloride in the present embodiment comprises a silicon powder silo 1, a silicon powder weighing hopper 2, a silicon powder feeding bin 3 and a synthesis furnace 4 connected in sequence, and the silicon powder The feeding bin 3 is also connected with a waste powder tank 5, which processes the waste silicon powder. HCl is also added to the synthesis furnace 4 to react with the silicon powder as a reactant to produce trichlorosilane and silicon tetrachloride. .

[0036] The top of the synthesis furnace 4 is also connected with the heat transfer oil heater 7 through the heat conduction oil circulation pump 6, and the heat transfer oil heater 7 is also connected with a reboil boiler 8, and the reboil boiler 8 is also connected with the synthesis furnace 4 connections. The reaction carried out in the synthesis furnace 4 of trichlorosilane and silicon tetrachloride belongs to exothermic reaction,...

Embodiment 2

[0038] Such as image 3 As shown, the purification unit of trichlorosilane and silicon tetrachloride in this embodiment includes a first dry dust collector 9A, a second dry dust collector 9B, a water-cooled washing tower 10 and a cryogenic condensation tower 11 connected in sequence. The water-cooled washing tower 10 and the cryogenic condensing tower 11 are respectively connected with the chlorosilane buffer tank 12. The trichlorosilane, silicon tetrachloride, and hydrogen generated after the synthesis furnace 4 react pass through the first dry dust collector 9A and the second dry dust collector 9B to remove unreacted silicon powder, and then pass through the water-cooled scrubber 10, deep-cooled The condensing tower 11 obtains chlorosilane liquid. The condensed chlorosilane liquid enters the chlorosilane buffer tank 12, and the water-cooled washing tower circulation pump 13 transports the washing materials to the water-cooled washing tower 10 after being cooled by the air c...

Embodiment 3

[0042] Such as Figure 4 As shown, the separation unit of trichlorosilane and silicon tetrachloride in this embodiment includes a distillation column 15, a distillation condenser 17, a first buffer tank 18, a circulation pump 19, trichlorosilane and silicon tetrachloride connected in sequence Separation tower 20. The top of the trichlorosilane and silicon tetrachloride separation tower 20 is connected with a trichlorosilane first condenser 22 , a second buffer tank 23 , and a trichlorosilane circulating pump 24 in sequence. The mixed solution of trichlorosilane and silicon tetrachloride from the chlorosilane buffer tank 12 enters the distillation tower 15 under the action of the system pressure, and the high boilers discharged from the bottom of the tower are sent to the high-waste treatment device through the circulation pump 16 at the bottom of the distillation tower. deal with. Trichlorosilane circulating pump 24 outputs trichlorosilane, and the purity of trichlorosilane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com