A sealing seat device for roll boxes of high-line finishing mills

A technology for sealing seats and finishing mills, which is applied to the sealing of engines, metal rolling mill stands, metal rolling stands, etc., which can solve the problems of increasing maintenance costs, increasing wear of double lip seals and oil flingers, and polluting lubricating oil System and other issues, to achieve the effect of increasing service life, reducing processing difficulty, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

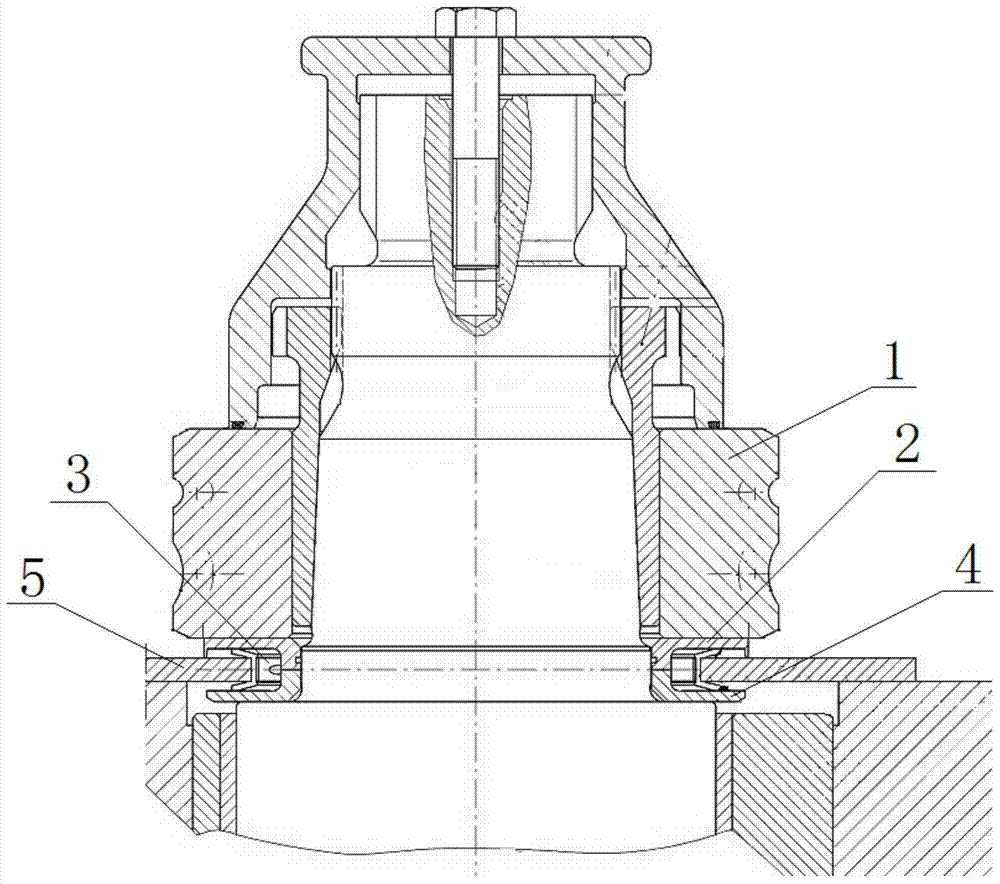

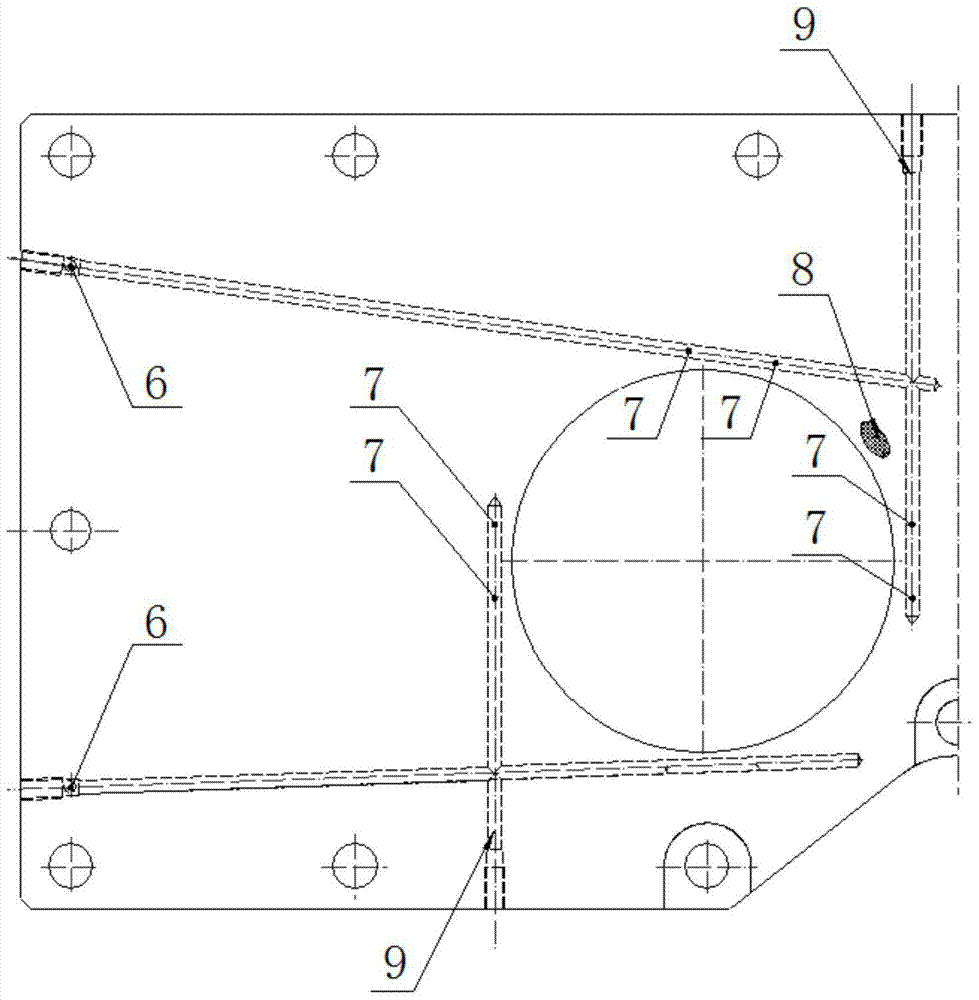

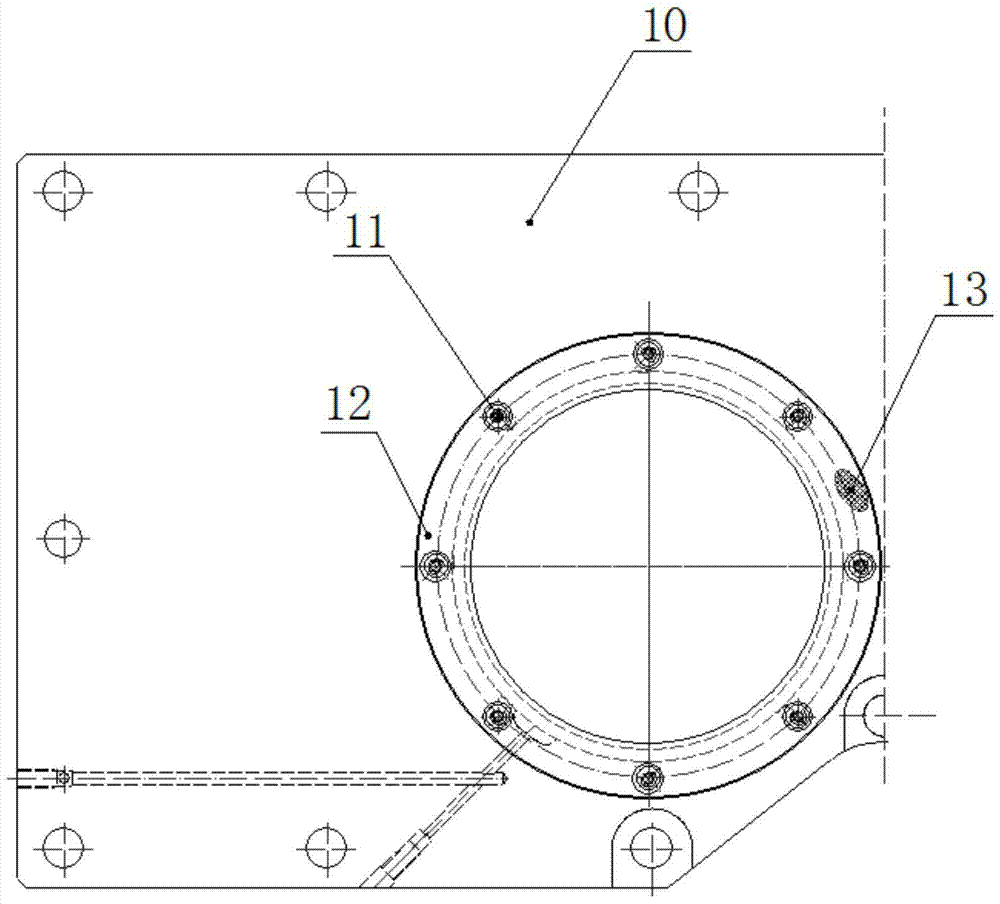

[0019] figure 1 It is a schematic diagram of the assembly of the roll box and roll shaft of the finishing mill. The double-lip seal 3 is installed on the seal seat 5, and the upper and lower lips of the double-lip seal 3 are axially compressed with the upper oil flinger 2 and the lower oil flinger 4 to form an interference to realize the sealing effect. figure 2 It is a structural schematic diagram of the roll box seal seat of the finishing mill in the prior art. The roll box seal seat 5 of the finishing mill in the prior art is a whole, and the shaft seal water has four seal seat shaft seal water inlet holes 6 input, and by adding four Shaft seal water process holes 9 form a total of eight channels inside to transport the shaft seal water to 16 seal seat shaft seal water outlet holes 7 . The inner hole of the double lip seal of the sealing seat 5 is worn, the waterway of the shaft seal is blocked, or a pit 8 is formed on the surface. Only by replacing the assembly of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com