Patents

Literature

532results about How to "Eliminate Bubble Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

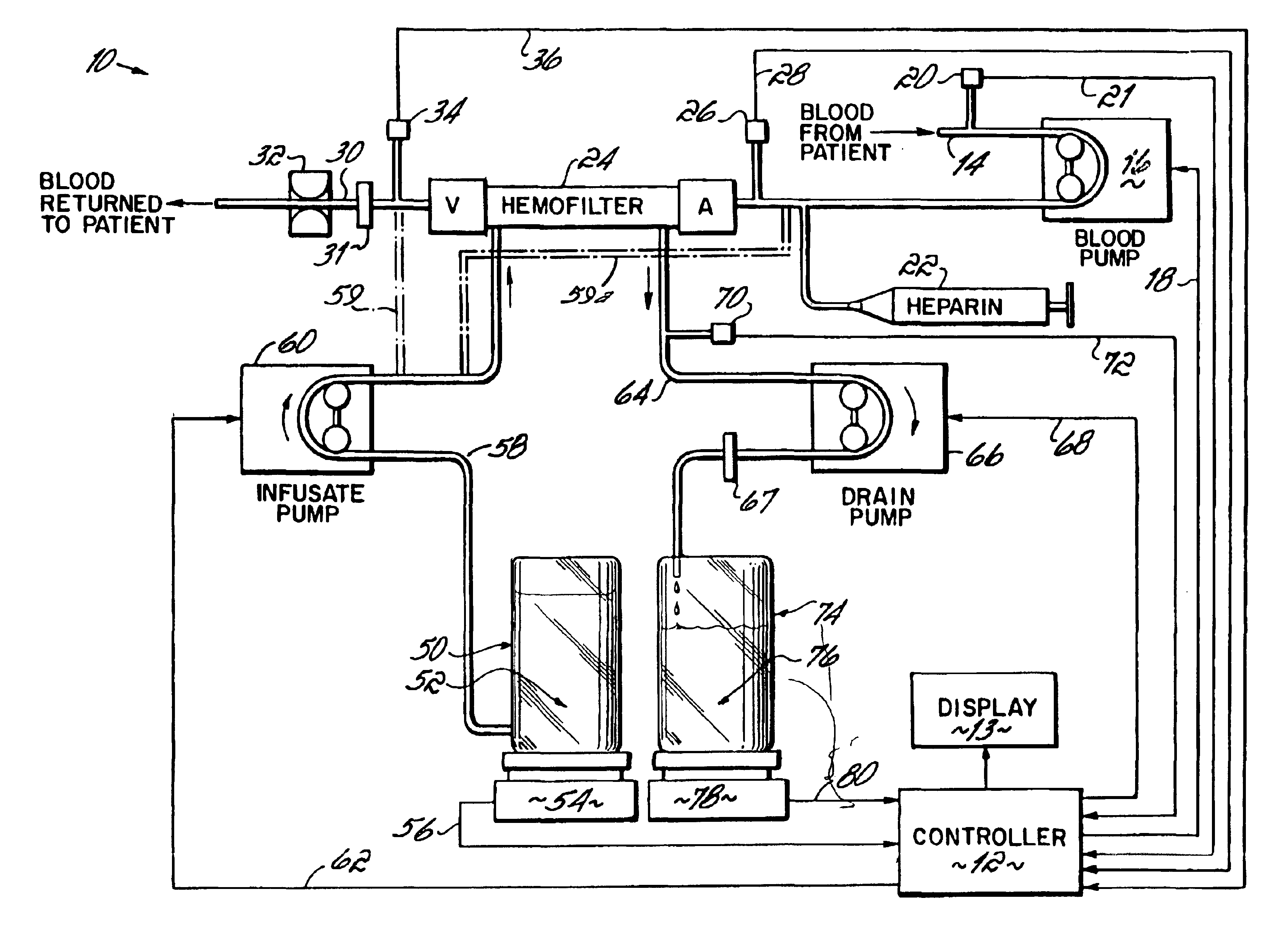

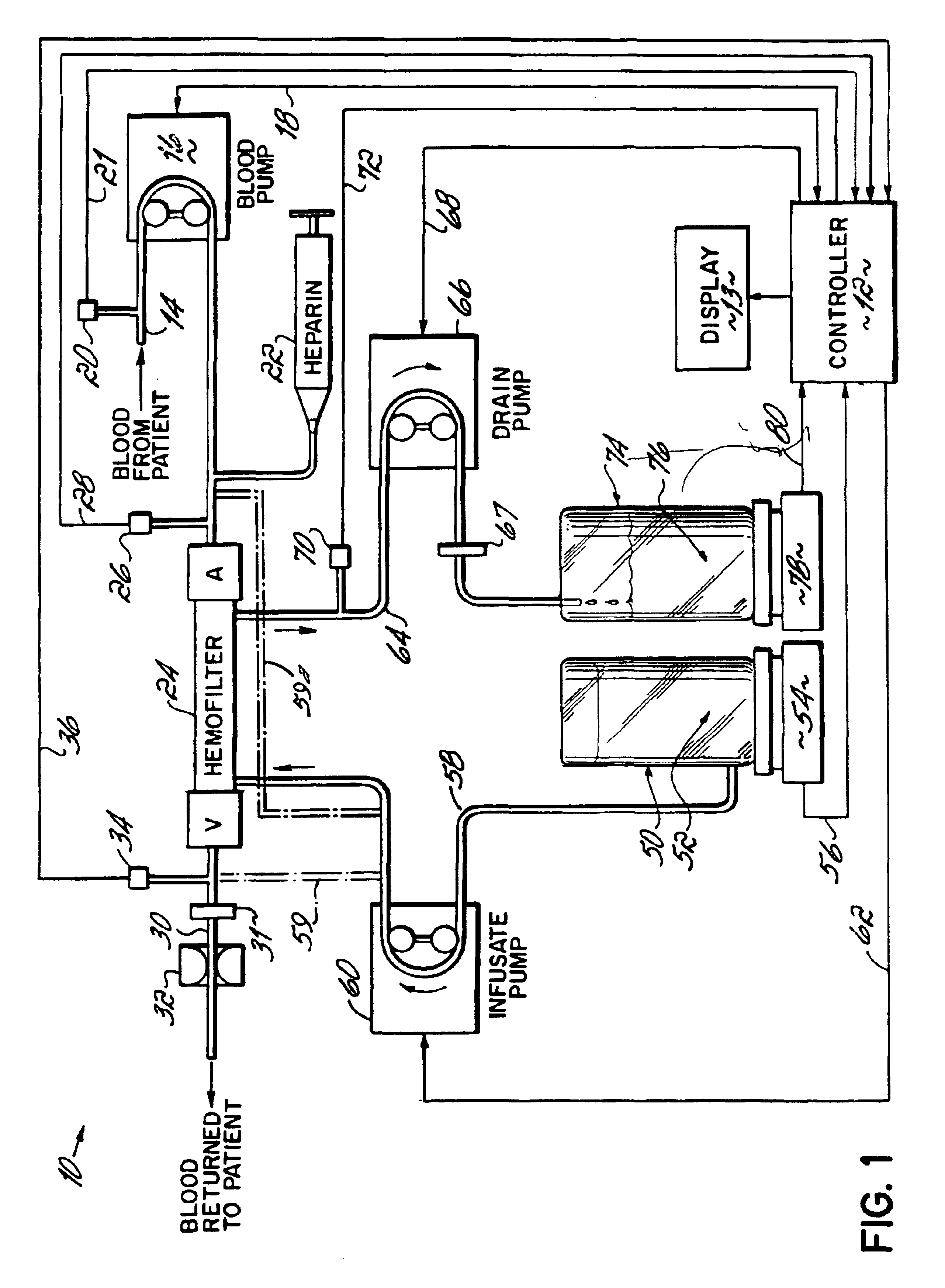

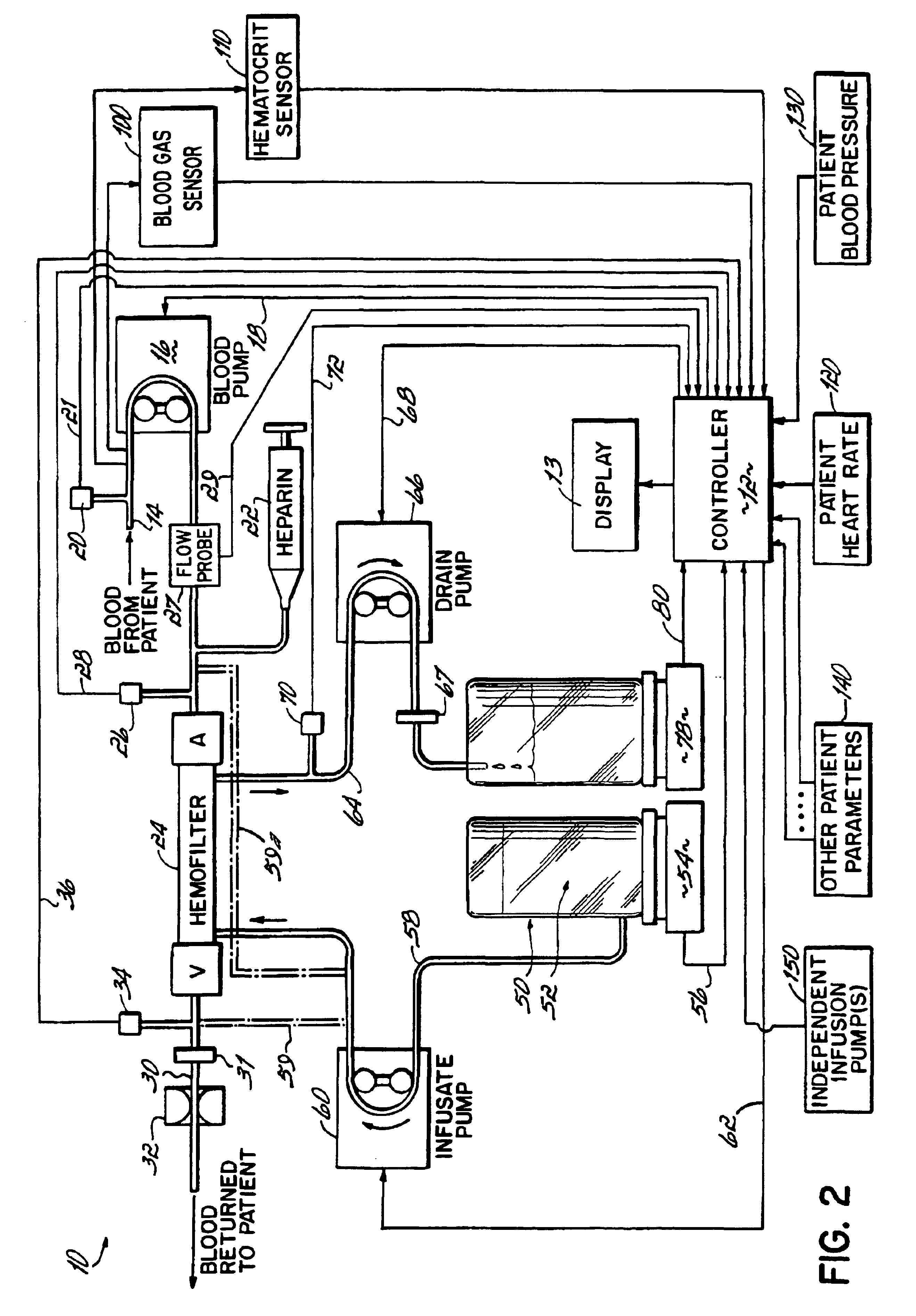

Hemofiltration system

InactiveUS6780322B1Reliable and long-term operationImprove accuracySolvent extractionUltrafiltrationMedicineTime changes

A multipurpose hemofiltration system (10) and method are disclosed for the removal of fluid and / or soluble waste from the blood of a patient. The system (10) continuously monitors the flow rates of drained fluid, blood, and infusate. When necessary, the pumping rates of the infusate, drained fluid and blood are adjusted to remove a preselected amount of fluid from the blood in a preselected time period. A supervisory controller (160) can monitor patient parameters, such as heart rate (120) and blood pressure (130), and adjust the pumping rates accordingly. The supervisory controller (160) uses fuzzy logic to make expert decisions, based upon a set of supervisory rules, to control each pumping rate to achieve a desired flow rate and to respond to fault conditions. An adaptive controller (162) corrects temporal variations in the flow rate based upon an adaptive law and a control law.

Owner:CHILDRENS HOSPITAL MEDICAL CENT CINCINNATI

Preparation method of scratch-resistant polyurethane matt black finish for woodware

ActiveCN103013325AEliminate Bubble ProblemsNo surface foggingPolyurea/polyurethane coatingsLacquerSolvent

The invention relates to a preparation method of a scratch-resistant polyurethane matt black finish for woodware. The scratch-resistant polyurethane matt black finish comprises a resin paint component A and a curing agent component B in the weight ratio of 1: 0.5, wherein the resin paint component A comprises alkyd resin, extinction powder, a dispersing agent, carbon black paste, a modifying flatting agent, an antifoaming agent, an anti-settling agent and a solvent; and the curing agent component B comprises a TDI-HDI (Toluene Diisocynate-Hexamethylene Diisocyanate) mixed tripolymer or a TDI / TMP (Trimethylolpropane) affixture, an HDI tripolymer and a solvent. The scratch-resistant double-component polyurethane matt black finish for woodware, prepared by the preparation method provided by the invention, brings no precipitate during being stored, is high in solidity, low in viscosity and excellent in leveling property; and the filming can be realized at one time, and the film is thick, free from sagging, and soft, full, fine, smooth, slippery in hand feel, shows alternate kindness with severity, is given the effect of full decoration like a mirror plane, brings a graceful and comfortable feel, and is adapted to modern aesthetic view and widely popular with the market and customers. The scratch-resistant polyurethane matt black finish is widely applied to protective decoration of surfaces of products such as the woodware, metals and plastics.

Owner:UNION FOSHAN CHEM +1

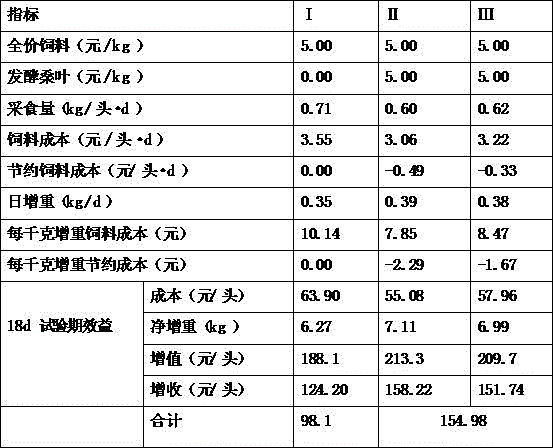

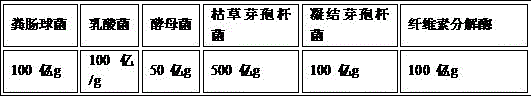

Compound biological strain for feed and preparation method of fermented feed

InactiveCN105483040AInhibition of reproductionEliminate odorFungiBacteriaBiotechnologyBacterial counts

The invention provides a compound biological strain for feed. The compound biological strain comprises enterococcus faecalis, lactobacilli, saccharomycetes, bacillus subtilis and bacillus coagulans, wherein the bacterial count ratio of the enterococcus faecalis to the lactobacilli to the saccharomycetes to the bacillus subtilis to the bacillus coagulans is (0.5 to 1.5):(0.5 to 1.5):(0.1 to 0.5):(4 to 6):(0.5 to 1.5). The compound biological strain for feed and a preparation method of fermented feed provided by the invention have the advantages that the release of crude protein and amino acid in coarse feed can be promoted, and the animal absorption is facilitated.

Owner:河南世纪天缘生态科技有限公司

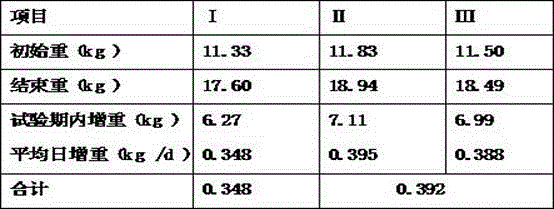

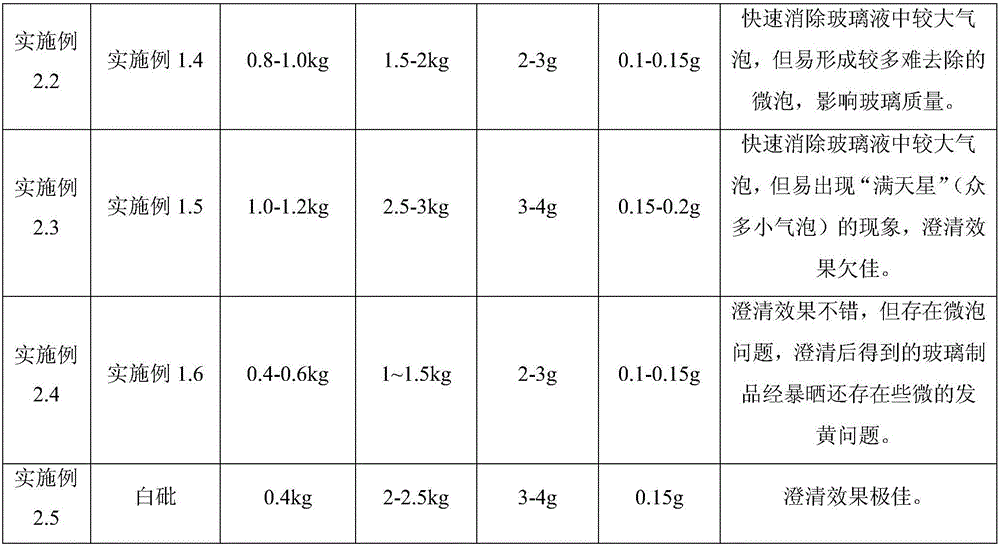

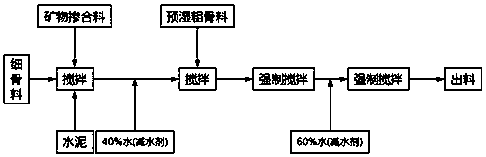

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

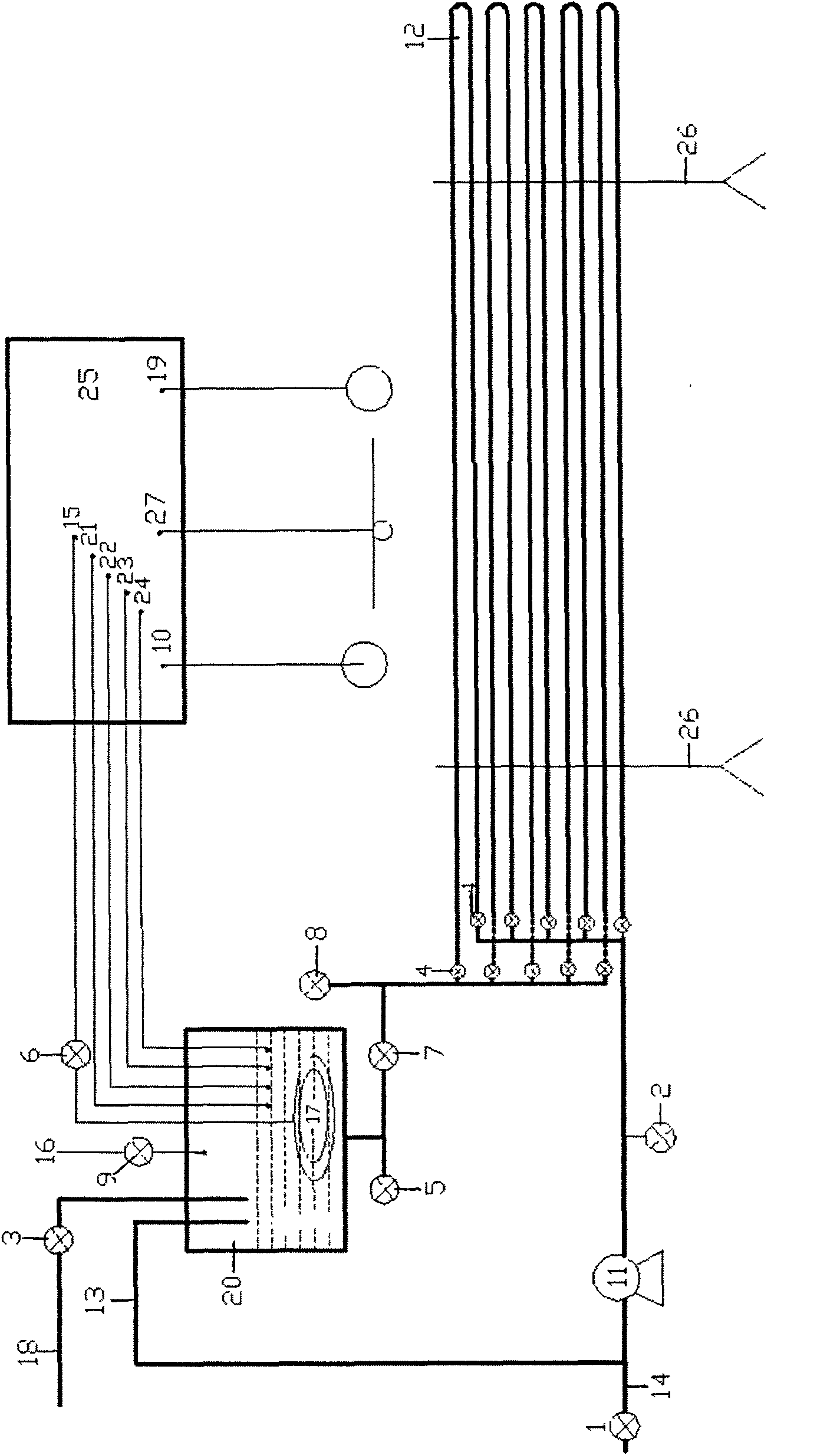

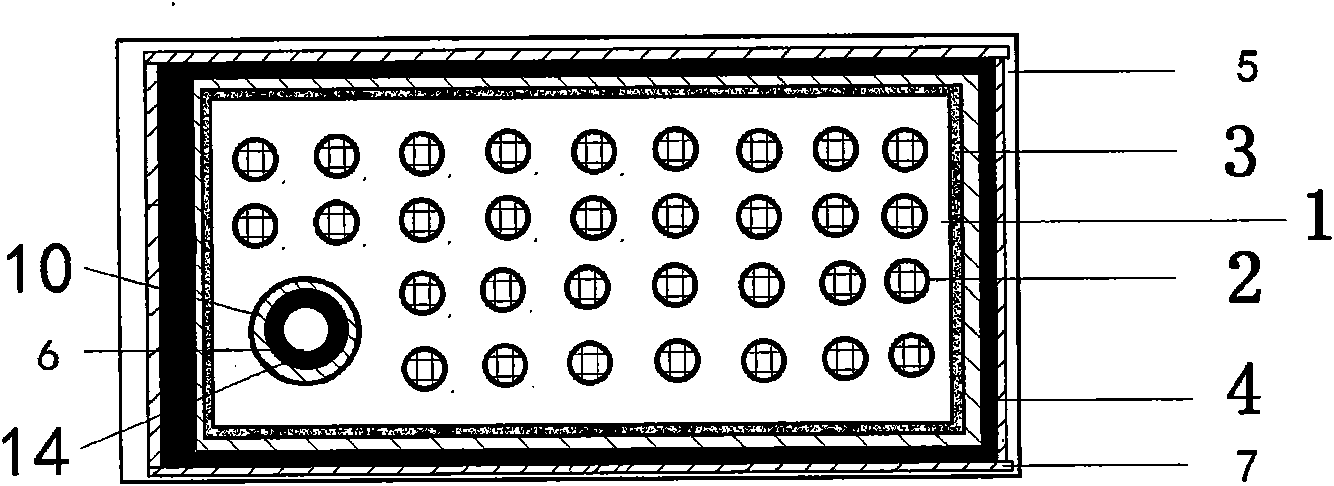

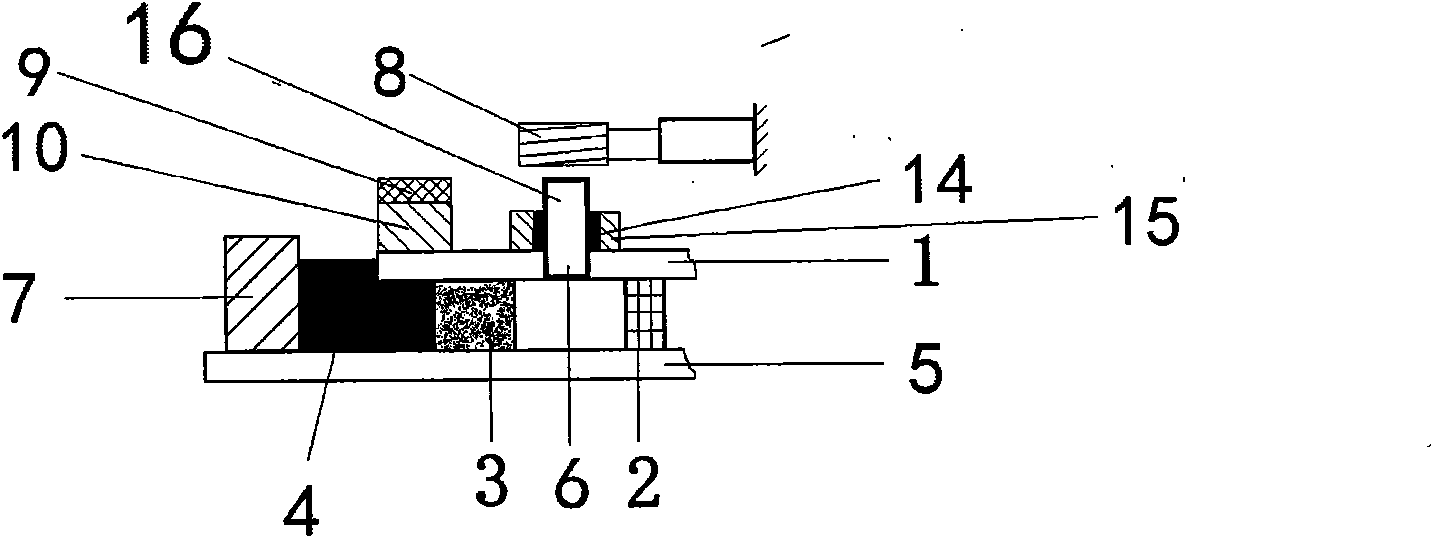

Light bioreactor for culturing microalgae systematically

ActiveCN101654653ARelieve pressureAvoid breakingBioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselSprayer

The invention relates to a light bioreactor for culturing microalgae systematically, which comprises an in-parallel pipe group, a control valve, a pH value sensor, a temperature sensor, a light sensor, a water mist sprayer, a liquid level alarm, a pipe pump, an air inlet pipe, an exhaust pipe, a feed pipe, a discharge pipe, a microporous pipe, a liquid storage tank, a cool and heat exchanger, a control panel, a bracket, a lighting facility and the like, wherein the pipe group and the valve are effectively connected in a close way, specific surface area is enlarged simultaneously when the volume of microalgae is enlarged during culturing, and the invention has small ground occupation, effectively uses stereo space and has sufficient air exchange, and utilization rate is increased; during culturing, the invention monitors parameters such as temperature, pH value, concentration of a culture medium, lighting intensity, and the like in real time, provides the best condition for microalgae growth and metabolism, effectively reduces culturing time, avoids danger of outside harmful creatures, and decreases production cost. The bioreactor can be used for culturing microalgae cells in a continuous or semi-continuous way and producing microalgae protein, biodiesel or aquatic baits and other products.

Owner:云南爱尔发生物技术股份有限公司

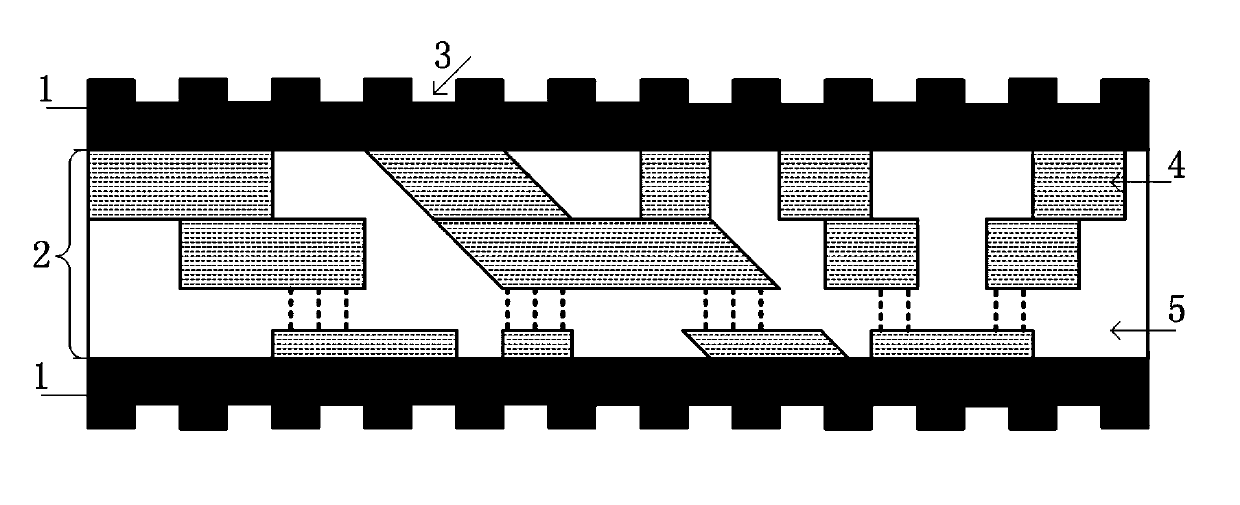

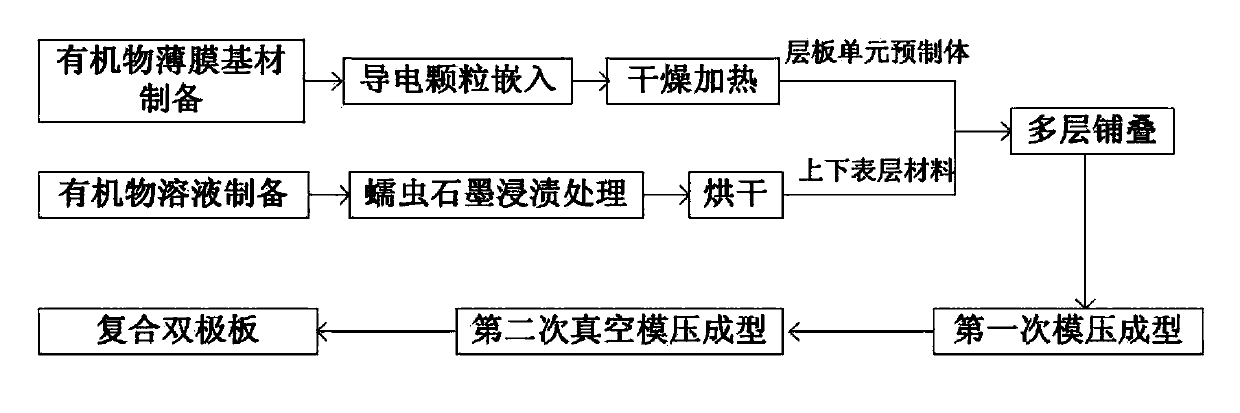

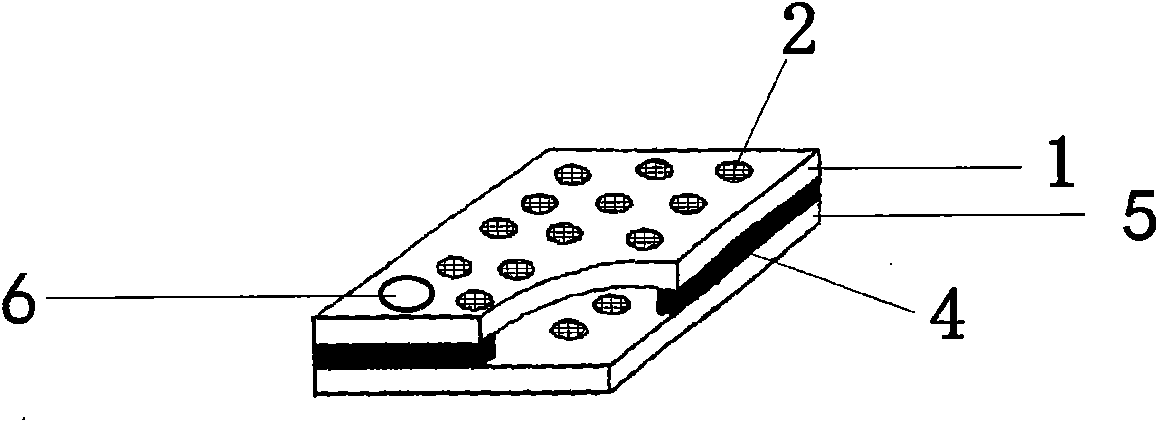

Composite bipolar plate for PEM (proton exchange membrane) fuel battery and preparation method thereof

ActiveCN103746131AGood effectImprove air tightnessFinal product manufactureCell electrodesSurface layerProton

The invention discloses a composite bipolar plate for a PEM (proton exchange membrane) fuel battery and a preparation method thereof. The bipolar plate comprises an upper and lower surface layers prepared by using vermicular graphite as a base material, and a plurality of laminated plate unit preforms prepared by embedding conductive particles in organic substance films, wherein every two adjacent laminated plate unit preforms are provided with one or a plurality of conductive particle overlay areas to form one or a plurality of zigzag conductive paths. The preparation method comprises the following steps: sequentially laying the lower surface layer material, the laminated plate unit preforms and the lower surface layer material in a die, and carrying out die pressing twice to obtain the bipolar plate for a PEM fuel battery. The method enhances the production efficiency of the composite bipolar plate for a PEM fuel battery, and lowers the manufacturing cost; and the composite bipolar plate has the advantages of high bending strength, favorable conductivity and favorable air tightness.

Owner:CHINA THREE GORGES UNIV

Composite fire-resistant glass combination liquid and preparation method thereof as well as composite fire-resistant glass

ActiveCN103317783AEliminate Bubble ProblemsExtended fire protection timeGlass/slag layered productsPlasticizerPotassium

The invention relates to composite fire-resistant glass combination liquid and a preparation method thereof as well as composite fire-resistant glass and belongs to the field of safety glass. The composite fire-resistant glass combination liquid comprises the following materials in parts by weight: 25-150 parts of potash water glass, 100 parts of deionized water, 0.2-1 parts of char forming agent, 0.1-0.5 parts of char forming additive, 0.01-0.05 parts of defoaming agent, 0.1-0.2 parts of plasticizer, 0.1-0.2 parts of flattening agent and 0.1-0.5 parts of cross-linking agent. The composite fire-resistant glass combination liquid has the advantages that the synergistic effect is generated among the components of the combination liquid by improving the formula of the combination liquid, bubbles in the interlayers of the composite fire-resistant glass are eliminated, and the high-performance non-microbubble composite fire-resistant glass with the transmittance of 82%-83% and the fire-resistance time up to 95 minutes is prepared.

Owner:CHINA BUILDING MATERIALS ACAD +1

Supercapacitor sizing manufacturing method

InactiveCN103730265AIncrease energy densityImprove cycle performanceHybrid/EDL manufactureAdhesiveSupercapacitor

The invention relates to a supercapacitor sizing manufacturing method, and belongs to the field of supercapacitors. According to the method, materials are mixed and combined through a high-shear dispersing emulsifying machine and vacuum stirring. The supercapacitor sizing manufacturing method includes the steps that an adhesive and a solution are placed into a mixing tank, and vacuum stirring is carried out for 10-30 minutes; a conductive additive is added during mixing, and vacuum stirring is carried out for another 10-30 minutes; the high-shear dispersing emulsifying machine is used for shearing and dispersing for 2-10 minutes; an active material is added during mixing, and vacuum stirring is carried out for 10-30 minutes; the high-shear dispersing emulsifying machine is used for shearing and dispersing for 5-10 minutes, vacuum stirring is carried out for 20-40 minutes, and accordingly a sizing is obtained. According to the method, dispersion uniformity of matter in the sizing is improved, sizing dispersing time is short, coatability of the prepared sizing is good, and improvement of energy density, cycle performance and uniformity of a supercapacitor is facilitated.

Owner:718TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Magnesium oxychloride fiber light wallboard

InactiveCN103979921AAvoid the phenomenon of moisture absorption and return to halogenHigh strengthSolid waste managementCompressive resistanceSlag

The invention provides a magnesium oxychloride fiber light wallboard, and relates to the wallboard field in the construction materials. The wallboard is composed of the following components in parts by weight: 40 to 60 parts of magnesium chloride water solution, 20 to 30 parts of magnesium oxide, 0.1 part of fly ash, 0.2 part of slag, 0.5 part of construction waste, 0.1 part of waste ceramic, 2 parts of short glass fiber, 2 parts of straw, 2 parts of saw dust, 3 parts of perlite, and 0 to 2 parts of modifier. The formula of the wallboard comprises industrial and agricultural wastes such as fly ash, slag, mineral slag, construction wastes, broken ceramics, straws, and saw dust, thus the wastes are fully recycled and reutilized, and moreover the using amount of sands and stones is reduced, so the destroy on mountain and river bed is avoided, resources are saved, and environment is protected. The prepared magnesium oxychloride fiber light wallboard has the advantages of good water resisting property, high compressive strength, good freeze resisting performance, good acid / alkali resistant property, no halogen appearance, no scumming, and no deformation.

Owner:四川省元程中博能源开发有限公司

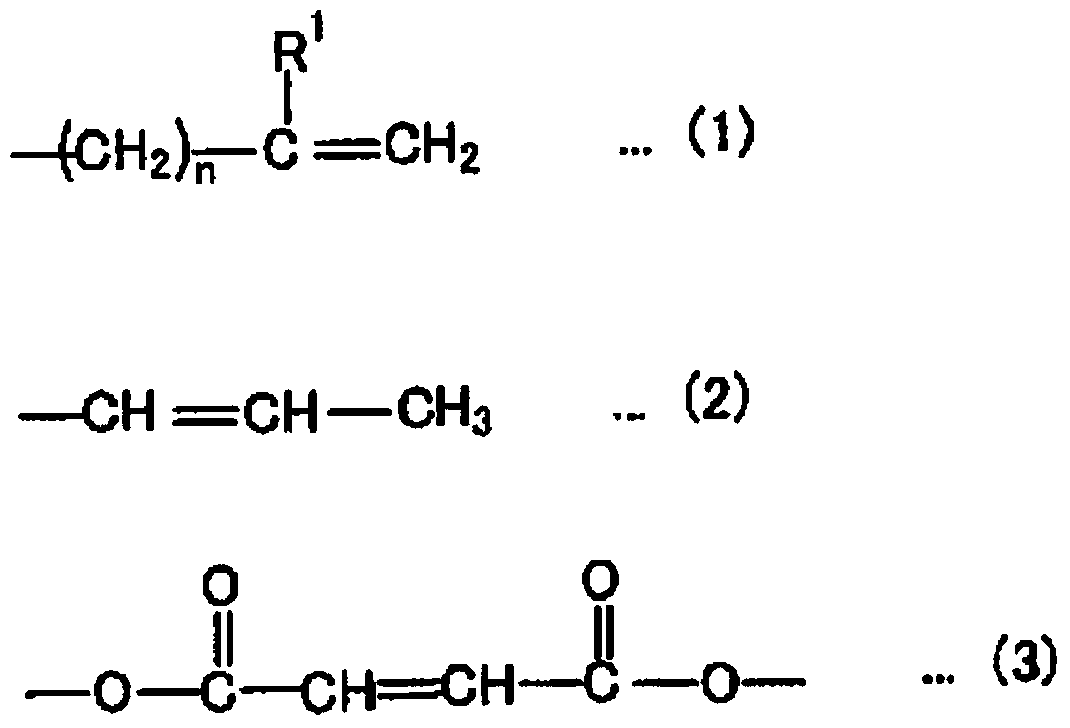

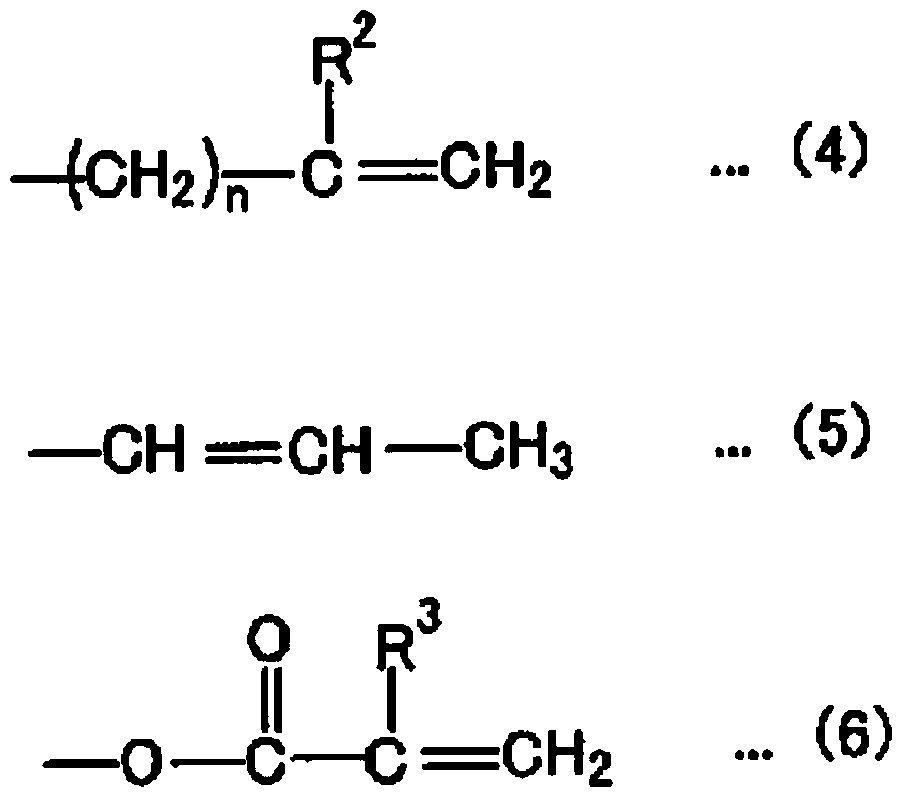

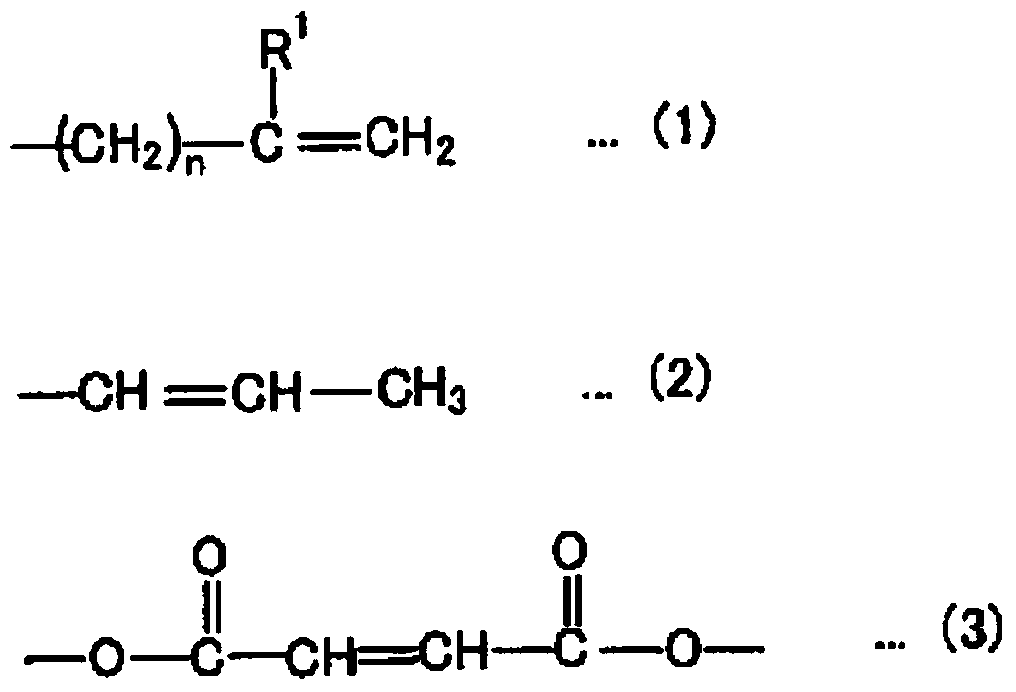

Emulsion polymerization method using reactive emulsifying agent, aqueous polymer dispersion obtained by same, and polymer film

InactiveCN103906768ASolve the problem of adverse effects caused by copolymerizationImprove copolymerization performanceHydrophilic monomerFunctional monomer

Provided is an emulsion polymerization method for carrying out emulsion polymerization of monomers using a reactive emulsifier in an aqueous medium in the presence of a polymerization initiator, the emulsion polymerization method being capable of solving problems such as an enhancement of a rate of copolymerization of the reactive emulsifier with the monomer, dissolution of a bubbling trouble, a more improvement of water resistance of a coating film, etc. The emulsion polymerization is carried out using one or two or more kinds of polymerizable unsaturated monomers X having at least one carbon-carbon double bond in a molecule, one or two or more kinds of reactive emulsifiers Y having at least one polymerizable group in a molecule, and one or two or more kinds of polyfunctional monomers Z1 having two or more polymerizable unsaturated groups in a molecule and having a molecular weight per functional group of less than 150, or one or two or more kinds of hydrophilic monomers Z2 having one polymerizable unsaturated group and a hydrophilic group in a molecule and having an average molecular weight of less than 250, with a proportion of the total use amount of the polyfunctional monomer Z1 or hydrophilic monomer Z2 to the total use amount of the reactive emulsifier Y being in the range of Z1 / Y = 1 / 3 to 1 / 30 or Z2 / Y = 1 / 1 to 1 / 30 in terms of a mass ratio.

Owner:DAI ICHI KOGYO SEIYAKU CO LTD

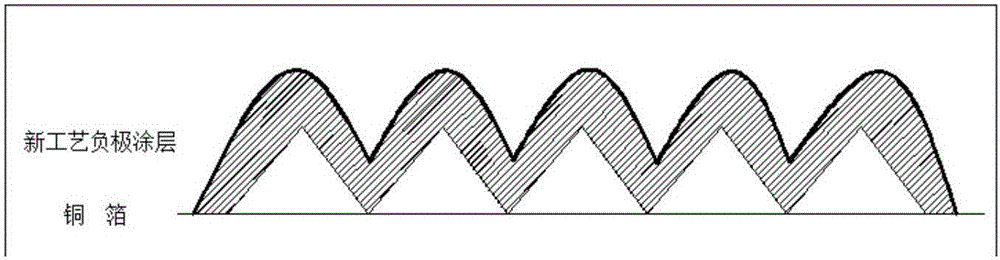

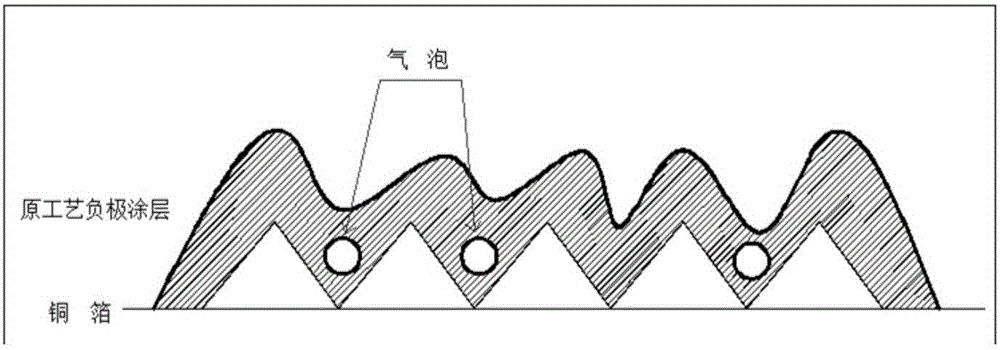

Preparation method of lithium ion power battery cathode

ActiveCN106848205AImproved mixing schemeShorten mixing timeElectrode collector coatingSodium carboxymethylcelluloseButadiene-styrene rubber

The invention relates to the field of power lithium ion batteries, in particular to a preparation method of a lithium ion power battery cathode. The preparation method comprises the following steps: first preparing sodium carboxymethylcellulose glue solution in a number 1 stirring machine, adding conducting carbon black and dry graphite powder in a number 2 stirring machine, uniformly mixing, and then adding the sodium carboxymethylcellulose glue solution in the number 1 stirring machine into the number 2 stirring machine; and adding little alcohol, vacuumizing, defoaming, adding styrene-butadiene latex, mixing, finally vacuum defoaming, and obtaining the lithium ion power battery cathode material. By improving a stirring scheme, the stirring time of the cathode slurry is shortened, the moisturizing coating performance of the cathode slurry is improved, and a bubble-free purpose is achieved.

Owner:HEFEI HENGNENG NEW ENERGY TECH

Waterborne FEVE (chlorotrifluoroethylene copolymer) fluorocarbon coating and preparation method thereof

The invention relates to a waterborne FEVE (chlorotrifluoroethylene copolymer) fluorocarbon coating and a preparation method thereof. The coating is prepared from the following raw materials in percentage by mass: 0.05-0.20% of alkaline pH value regulator, 0.05-0.20% of hydroxyl cellulose, 0.10-0.50% of wetting agent, 0.20-1.00% of dispersing agent, 0.05-0.20% of defoaming agent, 1.00-30.00% of pigment, 0.00-30.00% of filler, 0.10-1.00% of nanometer anatase titanium dioxide, 1.00-3.00% of film-forming additive, 0.20-1.00% of thickening agent, 0.00-1.00% of flatting agent, 45-65% of FEVE fluorocarbon resin emulsion and the balance of water. The preparation method comprises the steps of: color paste preparation, paint mixing and the like. The production time is shortened, and air bubbles in the coating are effectively eliminated by combining the effects of machines and auxiliaries. The coating prepared by the invention is a waterborne single-component normal-temperature cured fluorocarbon coating, has excellent weather resistance, pollution resistance, acid rain resistance and mildew resistance, and has the characteristics of environment friendliness, safety, no toxicity and the like.

Owner:RUYUAN YAO AUTONOMOUS COUNTY DONGYANGGUANG FORMED FOIL CO LTD

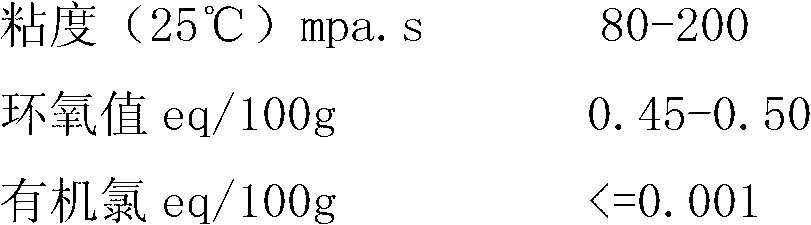

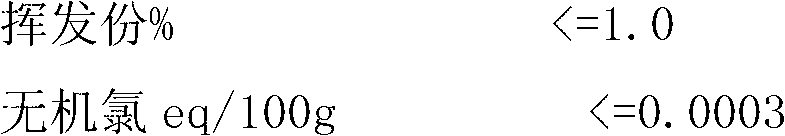

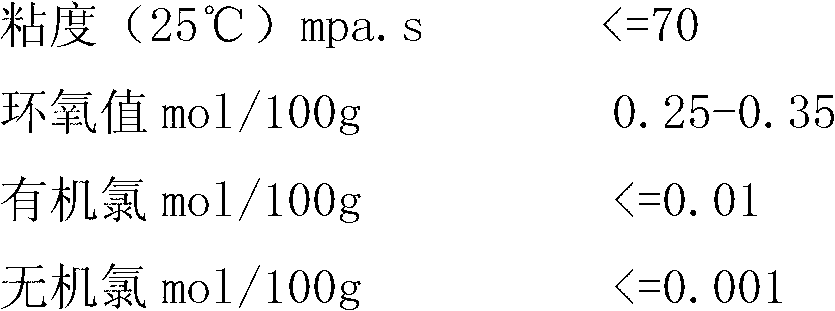

Dry outdoor type electric power complete equipment insulation casting material and preparation method thereof

The present invention discloses a dry outdoor type electric power complete equipment insulation casting material, which comprises the following raw materials, by weight, 100 parts of an EHL-55A modified high purity and flexibility alicyclic epoxy resin, 80-85 parts of an EHLS-60 modified methylhexahydrophthalic anhydride, 17-20 parts of an EHLP-200 reactive toughener, 0.2-0.3 part of a N,N-benzyldimethylamine accelerator, 300-350 parts of EHLA-400 coupling silicon micropowder, and 1-3 parts of an LA epoxy resin colorant. The invention further discloses a preparation method for the dry outdoor type electric power complete equipment insulation casting material. The dry outdoor type electric power complete equipment insulation casting material has characteristics of good outdoor weathering resistance, excellent mechanical performance, excellent dielectric performance and excellent heat resistance, can not deform and crack under high temperature impact and low temperature impact (-40 to 125 DEG C), and has high insulation and mechanical properties.

Owner:TAICANG LIANAN NEW INSULATION MATERIAL MFG WORKS

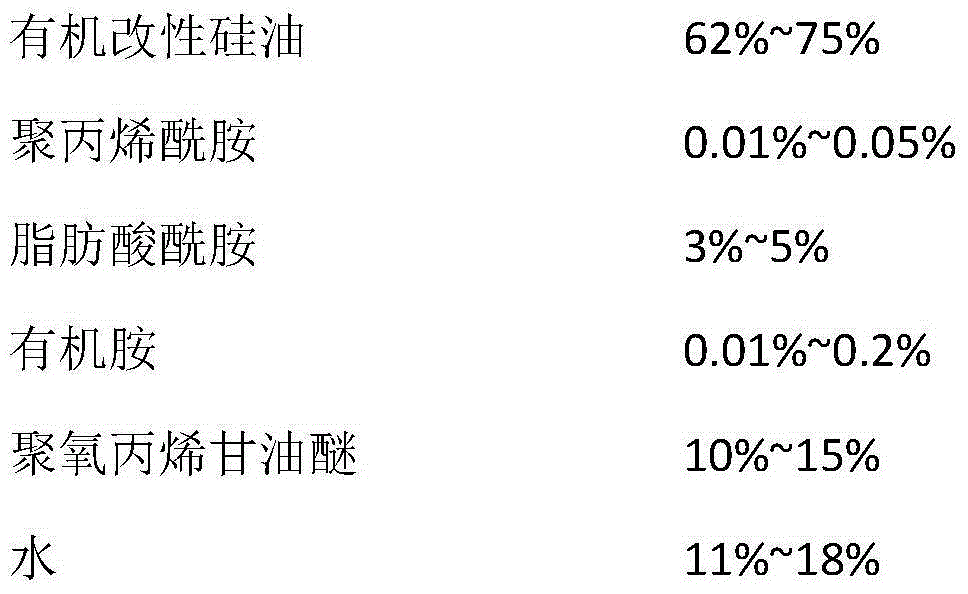

Releasing agent special for bare concrete and preparation method thereof

ActiveCN105001965AGood water solubilityEliminate Bubble ProblemsLubricant compositionSilicone oilPolyacrylamide

The invention relates to a releasing agent special for bare concrete and a preparation method thereof. The releasing agent special for the bare concrete is a water dispersion solution and comprises raw materials including organic modified silicone oil accounting for 62%-75% of the total mass of the raw materials, polyacrylamide accounting for 0.01%-0.05% of the total mass of the raw materials, fatty acid amide accounting for 3%-5% of the total mass of the raw materials, organic amine accounting for 0.01%-0.2% of the total mass of the raw materials, polyoxypropylene glycerol ether accounting for 10%-15% of the total mass of the raw materials and water accounting for 11%-18% of the total mass of the raw materials. The polyacrylamide is firstly solved in the water, the temperature is improved to be 35-55 DEG C, other components are added after even stirring, natural cooling is performed after re-stirring to obtain the releasing agent special for the bare concrete. The appearance effect of a bare concrete cement product can be improved, the surface of the bare concrete cement product can be smooth and free of air bubbles, the releasing agent special for the bare concrete is environmentally friendly, free of pollution and low in cost, 1-7.5 times of water can be added for dilution when the releasing agent is used, 3-4 times of continuous releasing can be performed through one-time spraying, and performance is stable.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

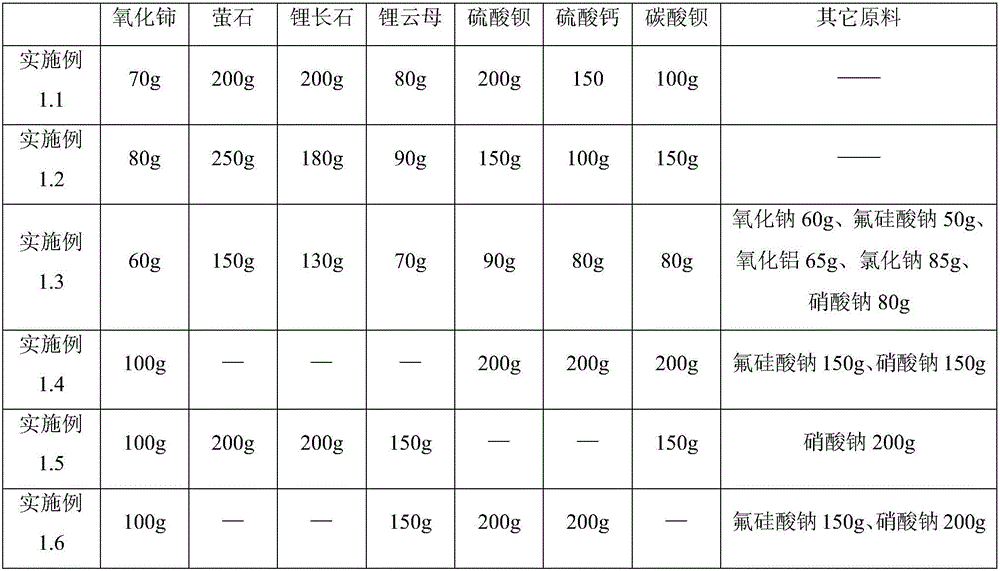

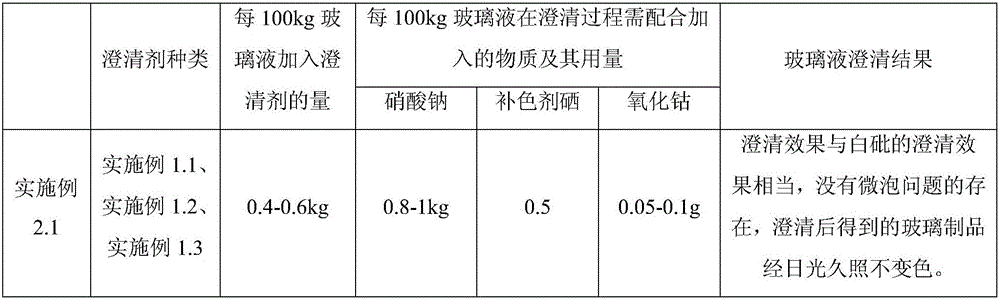

Glass clarifying agent and preparation method thereof

The invention provides a glass clarifying agent. The glass clarifying agent is prepared from components of raw materials in parts by weight as follows: 5-10 parts of cerium oxide, 10-25 parts of fluorite, 10-25 parts of lithium feldspar, 5-10 parts of lepidolite, 5-20 parts of barium sulfate, 5-15 parts of calcium sulfate and 5-15 parts of barium carbonate. The glass clarifying agent has excellent clarifying effect, can realize the clarifying effect the same as that of arsenic trioxide, can also remarkably reduce the use quantity of production raw materials introduced through matching with the clarifying agent and reduces the production cost of glass, and the comprehensive effect is better than that of arsenic trioxide; besides, the problem of glass defects caused by high probability of microbubbles on a glass panel with the adoption of a cerium oxide and sulfate composited clarifying agent is solved by means of the glass clarifying agent. The preparation method of the glass clarifying agent is simple, realizes safe production, prevents environmental pollution and is applicable to large-scale production.

Owner:郑国利

Solder-reflow soldering method

InactiveCN101396751AReduces the chance of forming solder voidsEliminate Bubble ProblemsSoldering apparatusReflow ovenTin can

The invention is applicable to the field of reflow soldering, which provides a reflow soldering method comprising the following steps: a workpiece to be soldered is arranged into a reflow brazier, and processes are carried out in a preheating region, a reacting region, a reflow region and a cooling region of the reflow brazier in sequence. The ultrasonic wave is applied on the workpiece to be soldered in the reflow region to cause the workpiece to vibrate while being processed. As soldering tin in the reflow region is easy to generate bubbles and form voidages and the ultrasonic wave is applied in the reflow region to cause the workpiece to vibrate, a majority of bubbles generated by the soldering tin are eliminated, thereby effectively reducing the probability of forming soldering voidages at the soldering part, and the surface of the soldering tin can be cleaned so as to ensure that the soldering voidage ratio can be effectively controlled and the soldering performance can be improved.

Owner:BYD CO LTD

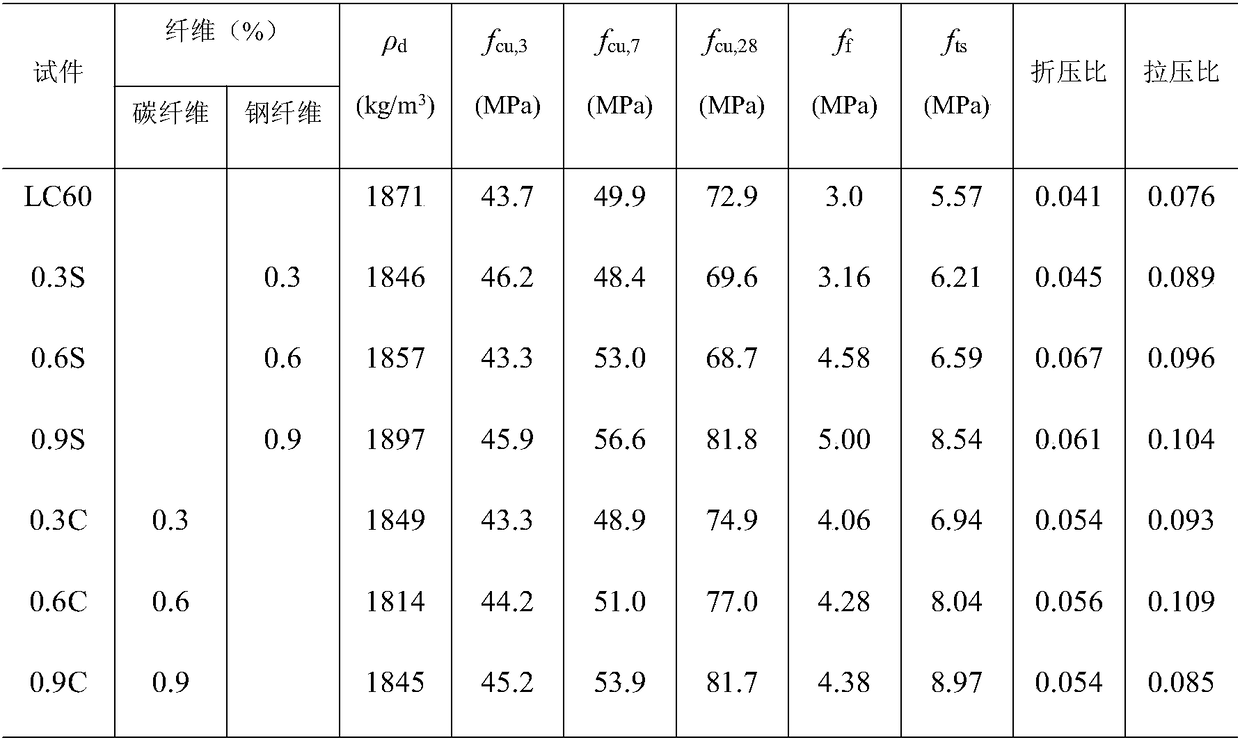

Mixing proportion and preparation method of high-performance light-weight aggregate concrete

The invention relates to a mixing proportion and a preparation method of high-performance light-weight aggregate concrete. A cementing material for preparation of high-strength light-weight aggregateconcrete adopts a composite cementing material and is characterized by being prepared from raw materials in percentage by mass as follows: 80% of Portland cement, 12% of fly ash and 8% of silica fumein a certain proportion. The fiber doping amount of the fiber modified light-weight aggregate concrete is 0.9% of the volume of coarse aggregate. In the preparation process, firstly, fiber is uniformly dispersed in water by use of a dispersing agent and a defoaming agent to be in a monofilament state, and waves and bubbles on the surface of the fiber are eliminated. The high-performance light-weight aggregate concrete adopting the preparation method and the mixing proportion has remarkable functions on improving the crack resistance of the light-weight aggregate concrete and reduce the brittleness coefficient of the light-weight aggregate concrete.

Owner:CHANGAN UNIV

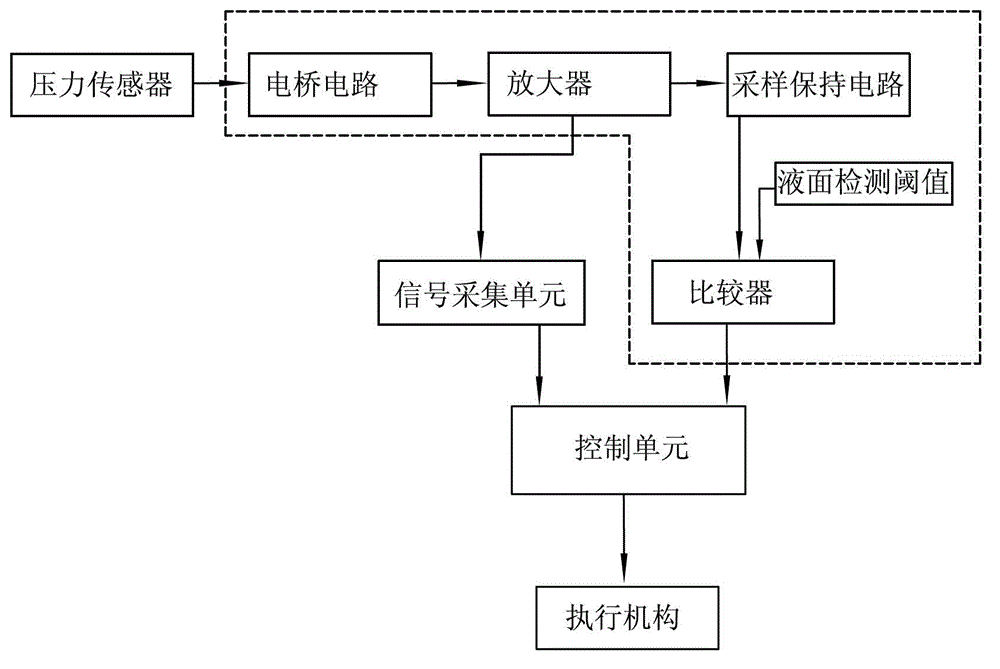

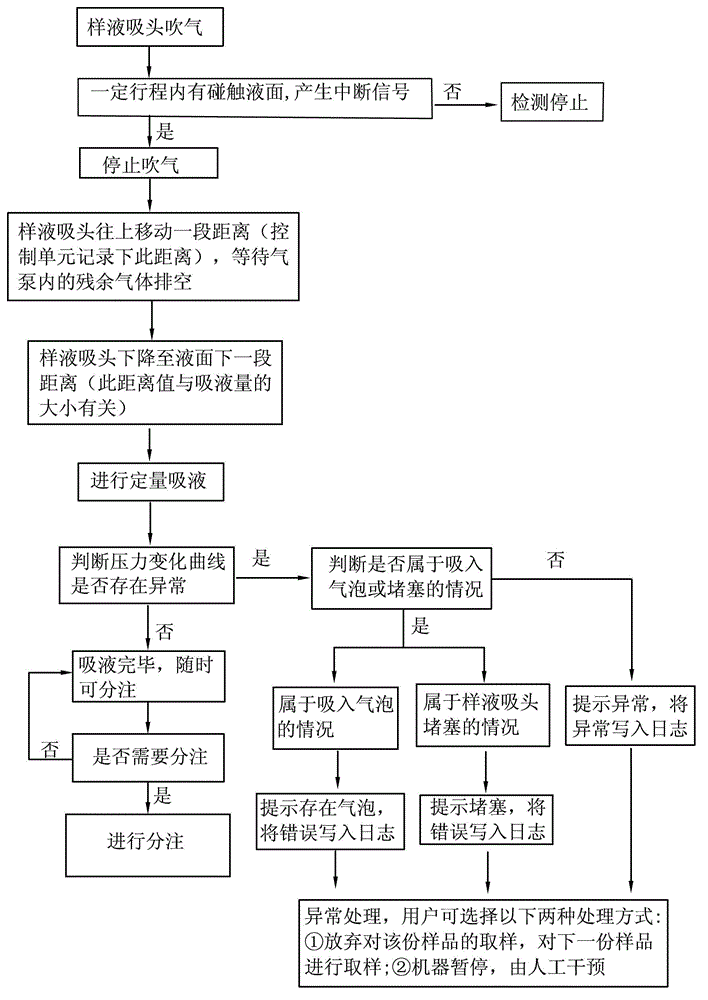

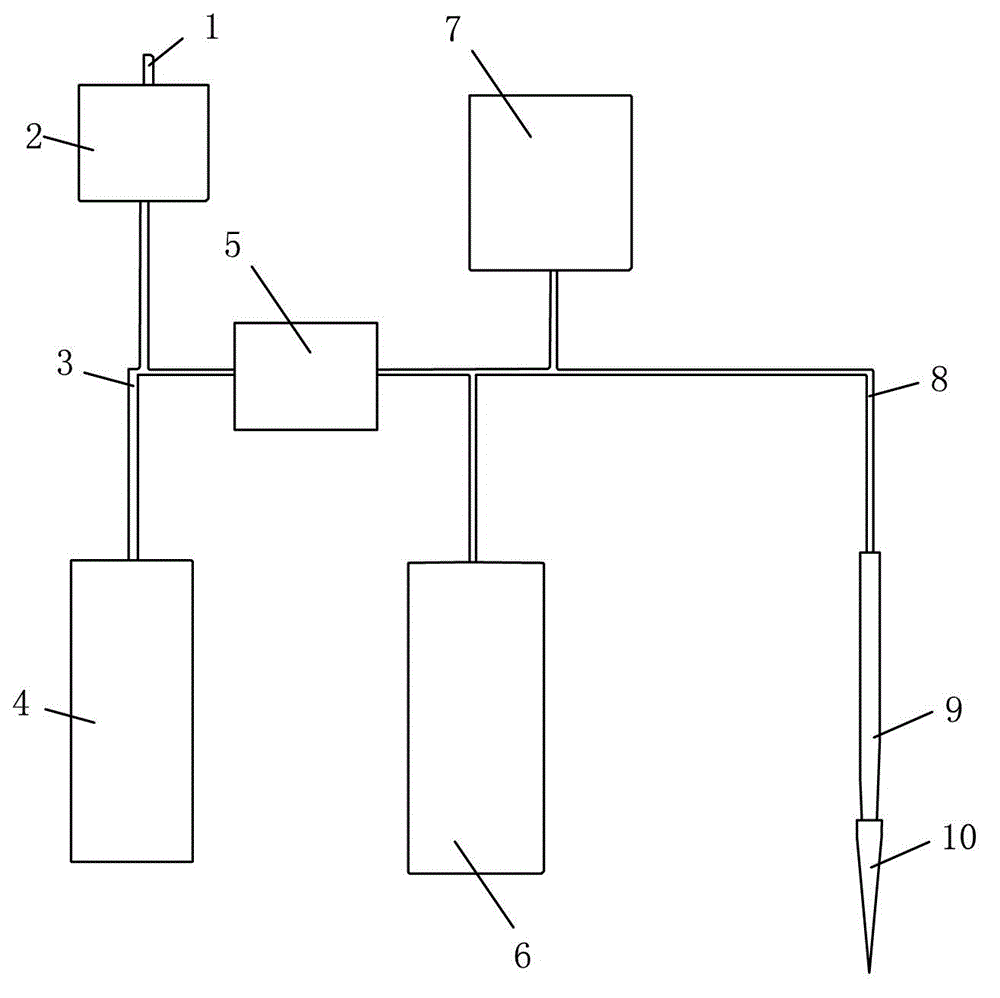

Liquid loading device and control method thereof

ActiveCN103185622AAchieve precisionRealize quantitative monitoring of sample additionMachines/enginesLubrication indication devicesEngineeringPressure sensor

The invention discloses a liquid loading device and a control method thereof. The device comprises at least one hollow sample needle; the tail end of the sample needle is connected with a first valve by a pipeline; the pipeline between the sample needle and the first valve is also connected with a pressure sensor and a sample injector; a pipeline passing through the first valve is divided into two paths by a three-way pipe; one path of the pipeline is connected with a second valve; the other end of the second valve is an open end; and the other path of the pipeline is connected with a pressure injector. The invention further discloses the control method of the liquid loading device. The liquid loading device has the advantages of simple and flexible structure, high accuracy, low cost and the like.

Owner:厦门优迈科医学仪器有限公司

Colored heat insulation anti soak coating material

An insulating color paint resisting water immersion is prepared from white jade powder, nano calcium carbonate, light calcium carbonate, water, talc powder, mica-Ag-Pt powder, water pigment, silicic propylene emulsion, F-C emulsion and assistant through sequentially mixing and reaction. Its advantages are exellent heat insulating and dissipating performance, high resistance to ultravidet ray and dirt, and high weatherability.

Owner:NANXING COATING MATERIAL SCI & TECH GAOMING

Waterborne polyurethane severe corrosion-resisting primer and preparation method thereof

ActiveCN108250927AInhibitionEliminate Bubble ProblemsAnti-corrosive paintsPolyurea/polyurethane coatingsWaxEmulsion

The invention provides a waterborne monocomponent polyurethane severe corrosion-resisting primer and a preparation method thereof. The primer is prepared from waterborne monocomponent polyurethane emulsion, a rust resisting pigment, a coalescing agent, a defoaming agent, a thickening agent, optional wax emulsion, physical filler, a dispersing agent and deionized water. The waterborne corrosion-resisting primer provided by the invention has the advantages of high antirust ability, excellent corrosion resistance, as well as high adhesion and good water resistance of the whole paint film; in addition, the whole paint film has excellent waterproof and antifouling properties and a metal base material is strengthened.

Owner:哈尔滨雨阳佳泰环保新材料有限公司

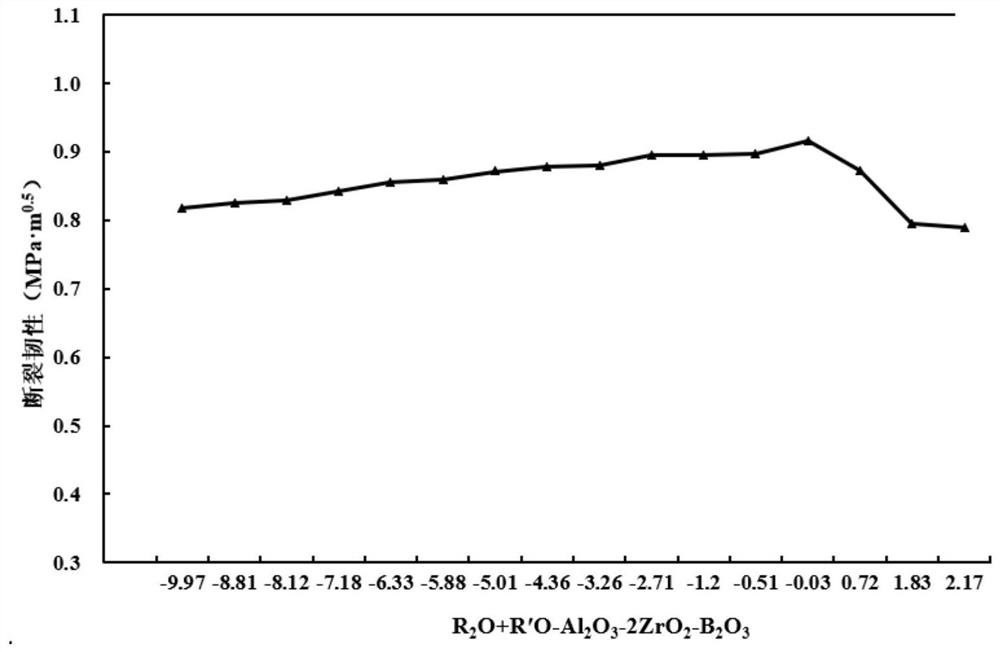

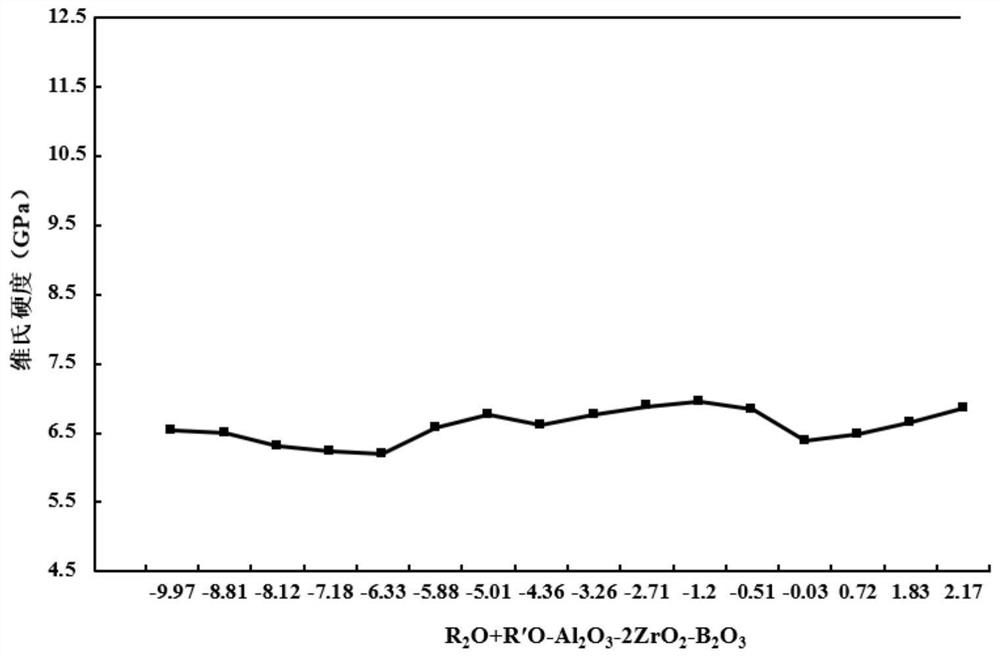

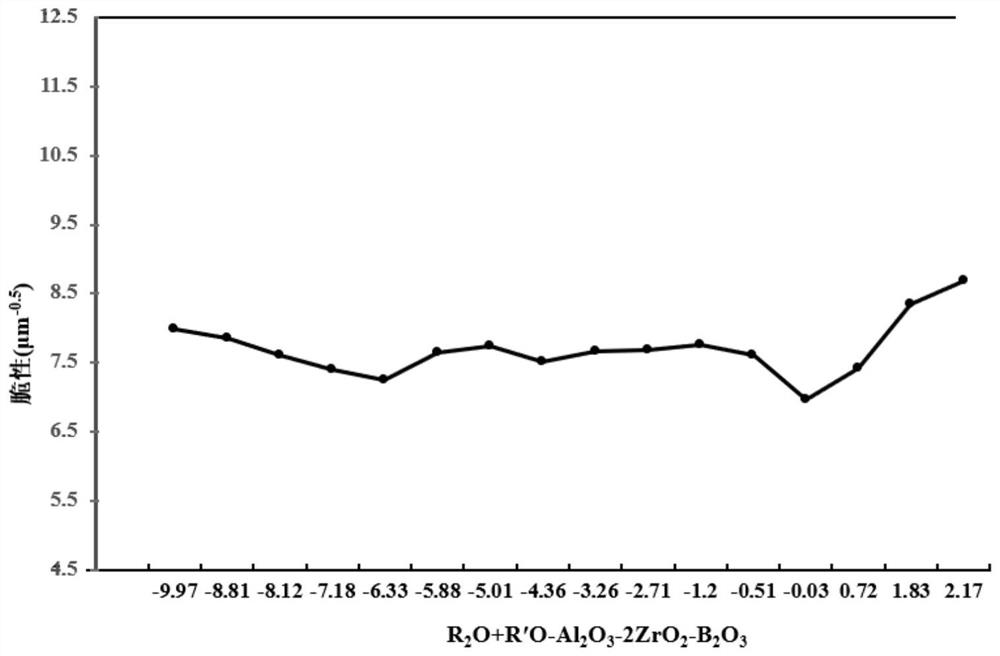

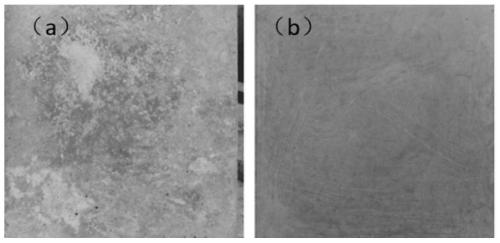

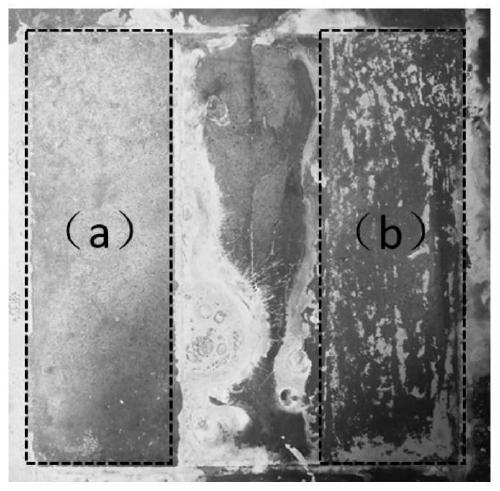

High-strength and low-brittleness aluminosilicate glass as well as strengthening method and application thereof

The invention provides high-strength and low-brittleness aluminosilicate glass as well as a strengthening method and an application thereof. The glass is prepared from the following components in percentage by mole; 56%-70% of SiO2, 8%-25% of Al2O3, 1%-10% of B2O3, 0-15% of Li2O, 6%-20% of Na2O, 0-10% of K2O, 0-5% of MgO, 1%-5% of ZrO2 and 0.1%-1% of SnO2. The strengthening method comprises the following steps: preparing raw materials according to the components of the glass, melting and clarifying the raw materials, and forming the glass; and carrying out ion exchange on the glass in a salt bath of potassium nitrate and sodium nitrate at 360-450 DEG C to obtain the chemically strengthened aluminosilicate glass which can be applied to mobile device protection and fixed device protection.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

Environment-friendly release agent for fair-faced concrete and preparation method thereof

InactiveCN111394165ALow viscosityLow spread uniformityCeramic shaping apparatusLubricant compositionPhysical chemistryEnvironmental engineering

The invention discloses an environment-friendly release agent for fair-faced concrete and a preparation method thereof. The release agent is prepared from the following raw materials in percentage byweight: 35-45% of palm oil, 5-10% of an emulsifier, 0.2% of an antirust agent, 0.1% of a stabilizer, 0-8% of nano titanium dioxide and the balance of water. The preparation method of the release agentcomprises the following steps: 1) respectively mixing and uniformly stirring the emulsifier, the water and the palm oil to obtain two mixed solutions according to the emulsifying property of the emulsifier; and 2) uniformly mixing the two mixed solutions prepared in the step 1), sequentially adding an antirust agent, a stabilizer and nano titanium dioxide, stirring for 40-50 minutes at the temperature of 10-60 DEG C, and cooling to obtain the release agent. The release agent has the properties of low viscosity, good spreading uniformity, isolation lubrication and the like and can effectivelyeliminate bubbles on the surface of fair-faced concrete and stably and effectively ensure the appearance quality of the fair-faced concrete, and the fair-faced concrete after release has the advantages of good apparent quality, smooth appearance, small apparent pore size, small quantity, uniform color and small color difference.

Owner:SOUTHEAST UNIV +2

Scratch resistant polyurethane woodenware glossy black finish paint

ActiveCN103937402AStrong molecular structureGood flexibilityPolyurea/polyurethane coatingsLacquerAcrylic resin

The invention relates to a preparation method of a scratch resistant polyurethane woodenware glossy black finish paint. The finish paint is composed of a resin paint component A and a curing agent component B; wherein the weight ratio of the component A to the component B is 1:0.5; the resin paint component A is composed of alkyd resin, acrylic resin, aldehyde-ketone resin, carbon black color paste, a chelating leveling agent, an antifoaming agent, an anti-settling agent, and a solvent; and the curing agent component B is composed of a TDI-HDI mixed trimer or a TDI / TMP adduct, a HDI trimer, and a solvent. The prepared finish paint has the advantages of high hardness, low viscosity, and good leveling property. The finish paint can form a membrane at a time, the membrane is thick, and no sag is generated. The paint has high gloss and a transparent crystal appearance like a black jade. The paint membrane is like a crystal, is thick and smooth, gives people a high quality sense, has a decoration effect like a mirror, and creates a fresh, grace, concise, and tranquil space. A refreshing unique feeling is created by the finished paint which is accord with the modern aesthetics, so the finish paint is welcomed by market and customers. The finish paint can be used to decorate and protect the surfaces of woodenware, metal products, and plastic products.

Owner:UNION FOSHAN CHEM +1

Nickel anode accumulator anode slurry and method for preparing anode and accumulator using the same

InactiveCN101345310AImprove consistencyImprove electrochemical performanceFinal product manufactureAlkaline accumulator electrodesAlcoholNickel oxide hydroxide

The invention provides an anode slurry used for a nickel anode accumulator. The anode slurry comprises an anode material and a solvent; the anode material comprises NiOH, CoO, a adhesive and a conductive agent; wherein, the anode slurry also comprises an additive which is poly-oxyalkylene and / or polyatomic alcohol. The nickel anode accumulator obtained by the nickel anode prepared by the anode slurry of the invention has excellent consistence of circulation performance; furthermore, the battery has good comprehensive electro-chemical performance simultaneously.

Owner:BYD CO LTD

Manufacturing process of mold for manufacturing carbon fiber box

InactiveCN105500731AHigh thermal deformation coefficientImprove the finishSteel platesHigh intensity

The invention relates to a manufacturing process of a mold for manufacturing a carbon fiber box. In the process, a male mold is used. The manufacturing process comprises the following steps: step 1, spraying a gel coat on the outer surface of the male mold and curing to form a gel coat layer; step 2, coating the gel coat layer with surface felt to form a surface felt layer; step 3, gluing at least three layers of shortly-chopped felt on the surface felt layer to form a shortly-chopped felt layer, and curing the surface felt layer, resin and the shortly-chopped felt layer to form a glass fiber reinforced plastic layer; step 4, sequentially laying the shortly-chopped felt layer, a multi-axial cloth layer and a bordering cloth layer on the glass fiber reinforced plastic layer; step 5, filling in vacuum, namely sequentially laying de-molding cloth, a double-layered flow guide net, a flow guide belt, a flow guide pipe and a double-layered vacuum bag on the layer in the step 4, and after keeping pressure, filling to primarily form a female mold shell plate; step 6, gluing a steel frame and a steel plate; and step 7, after sticking the steel frame and the female mold shell plate for at least 48 hours, taking out the male mold from the female mold shell plate so as to manufacture the mold. The manufacturing process provided by the invention has the characteristics that the high-strength performance of the mold is guaranteed, the durability of the mold is improved, the service life of the mold is prolonged and the like.

Owner:NEWTRY COMPOSITE

Sea tangle vermicelli and method of producing the same

The invention relates to sea kelp vermicelli and a processing method thereof. The sea kelp vermicelli is processed by washing sea kelp, soaking, heating together with table salt, water and soda until pasty, cooking, pulping and milling; weighing a certain amount of thickening starch, mixing with warm water and sea kelp slurry, stirring thoroughly, adding boiling water 7-8 times the weight of starch, and quickly stirring for gelatinization to obtain a paste; adding starch into the paste, repeatedly kneading to make small dough; removing air bubbles from the small dough; molding in a vermicelli-making machine; gelatinating in boiling water; cooling by spraying with tap water and then soaking in cold water; cutting, placing on a rack, curing in a high-humidity dark place indoor, and freezing step by step; defrosting, loosening and drying until the water content is in the range from 10% to 15%. The sea kelp vermicelli retains the nutrients of starch and sea kelp; has no odor or astringent taste; is jade green in color, transparent and lustrous; has good taste; and is chewy after cooking. The processing method has the advantages of reasonable process, easy operation and adaptability to large-scale production.

Owner:山东俚岛海洋科技股份有限公司

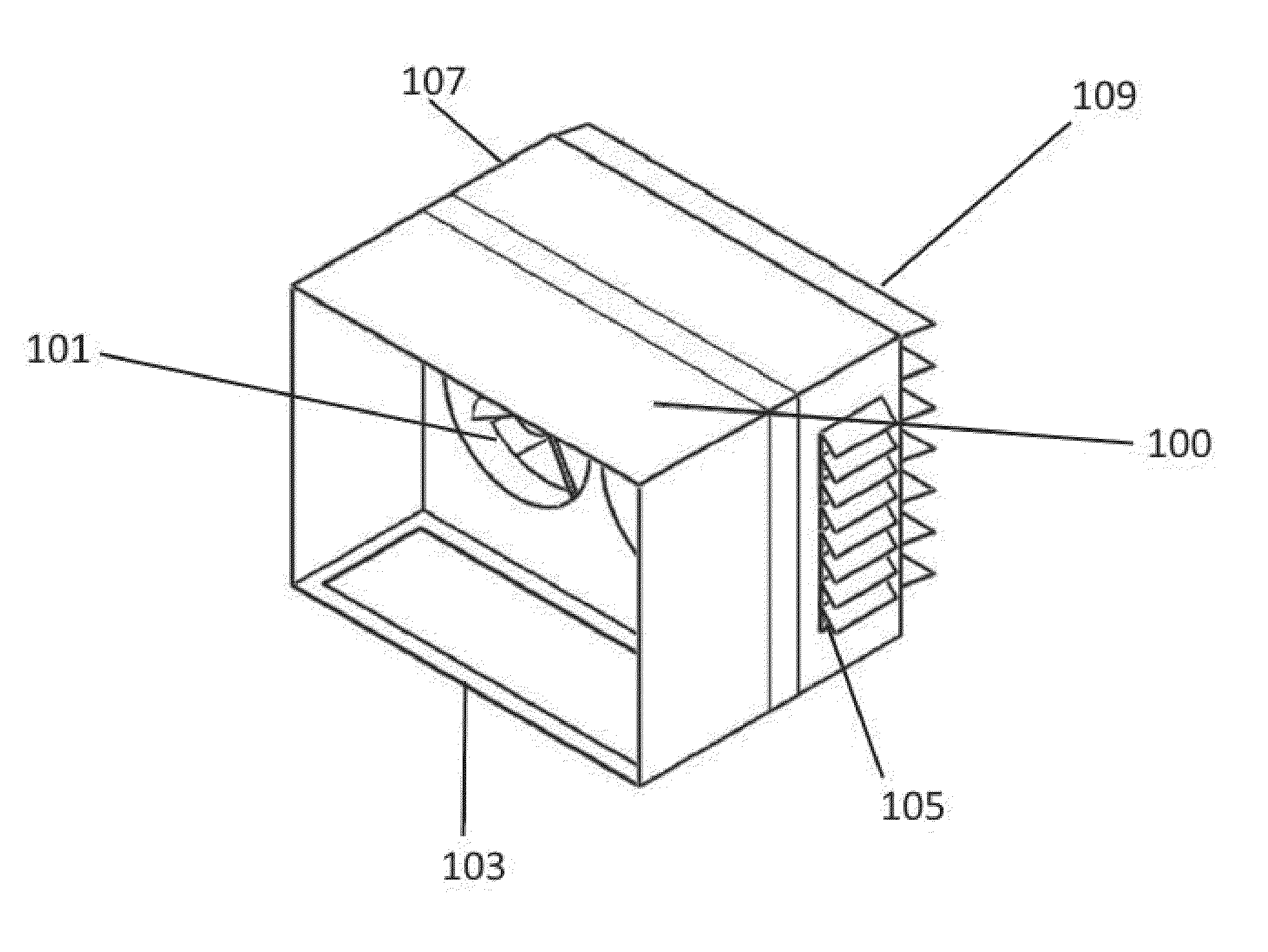

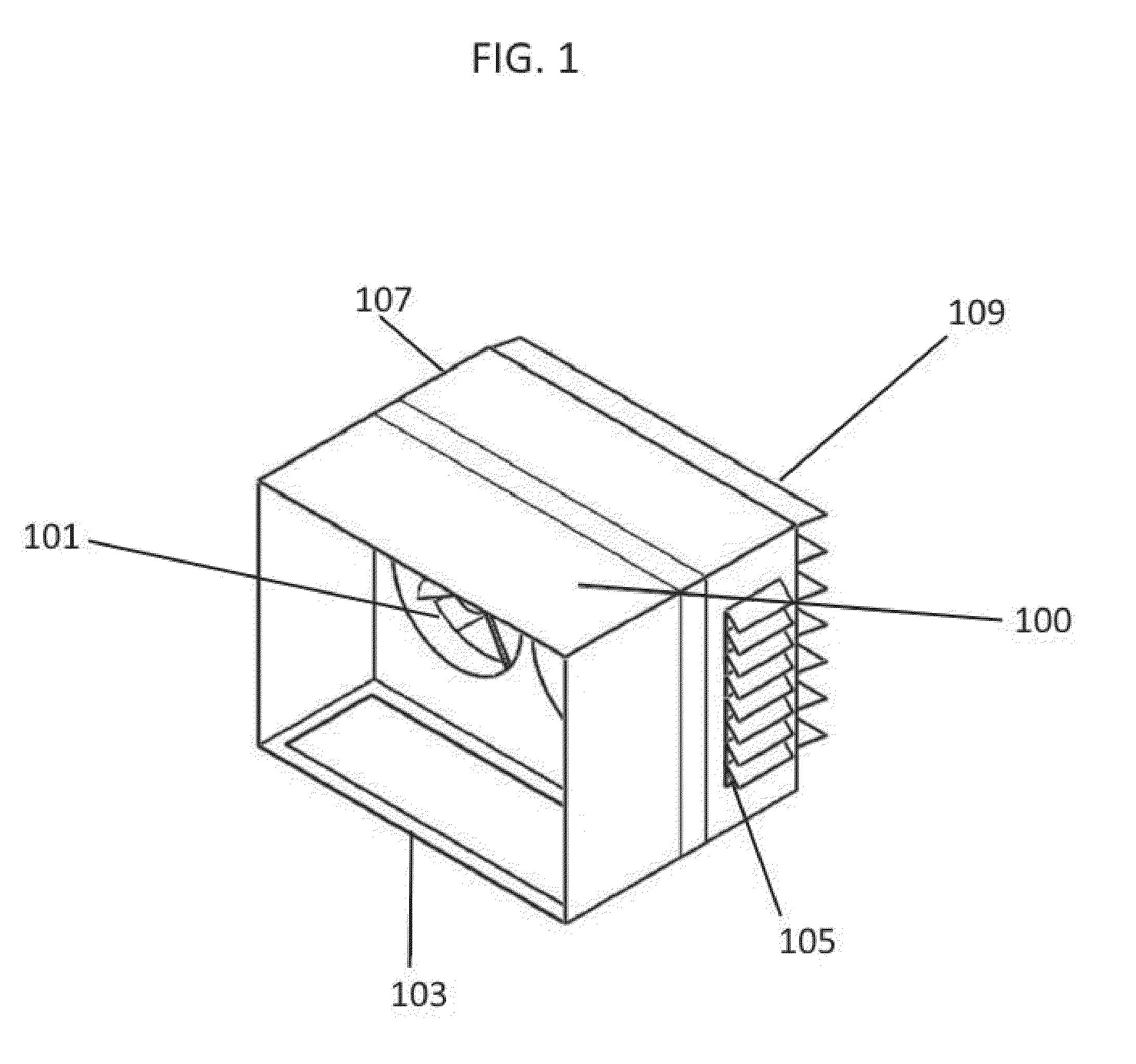

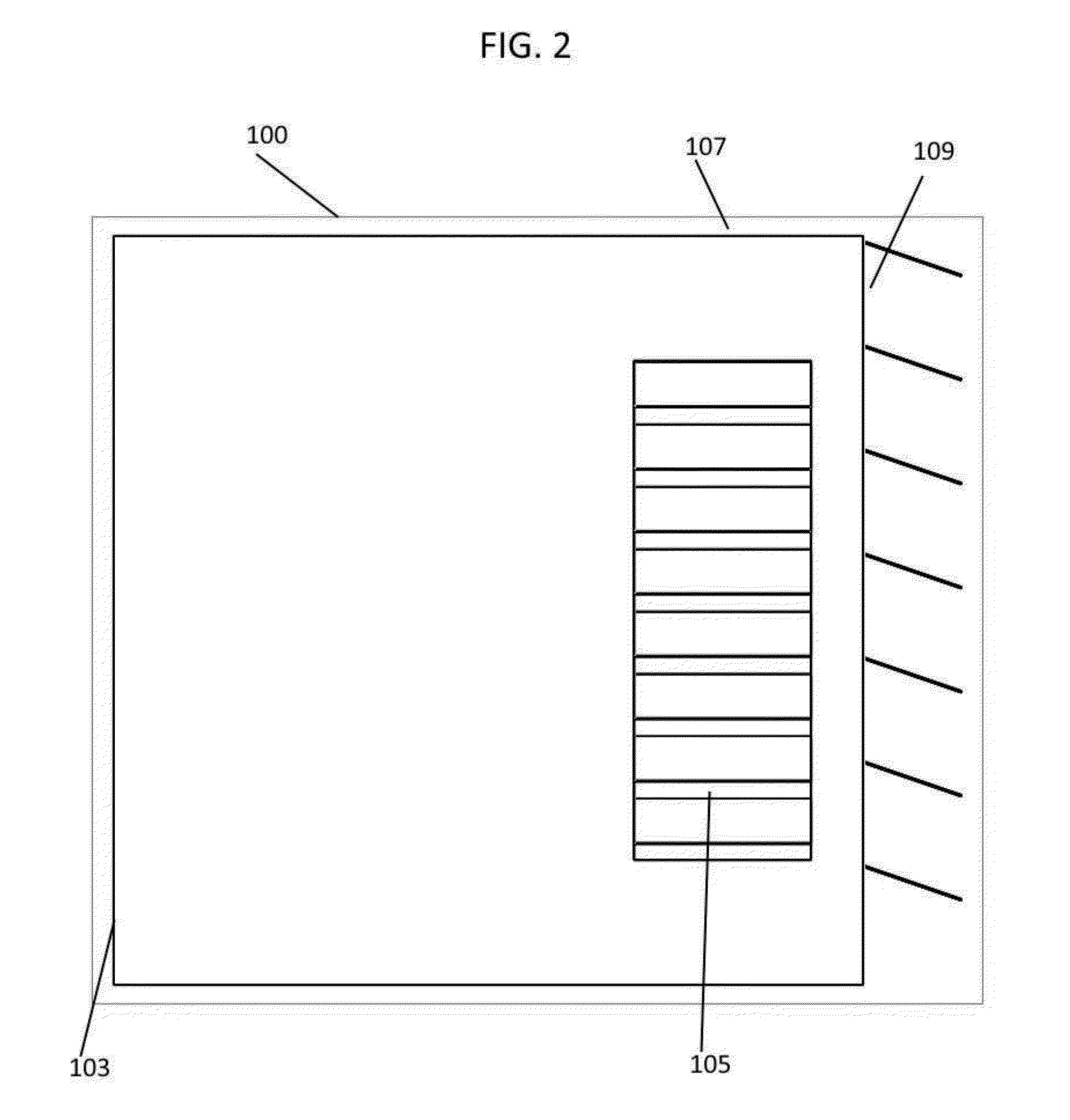

Device and System for Eliminating Air Pockets, Eliminating Air Stratification, Minimizing Inconsistent Temperature, and Increasing Internal Air Turns

InactiveUS20160131156A1Improve facilitiesReduce the amount requiredEngine manufacturePump componentsAerospace engineering

Owner:INTERNAL AIR FLOW DYNAMICS LLC

Vacuum glass sealing method

InactiveCN102863145AFree from pollutionEliminate Bubble ProblemsGlass reforming apparatusSolubilityMetallurgy

The invention relates to a vacuum glass sealing method, which comprises following steps of washing a welding part, placing weld glass powder, heating and melting weld glass and the like, and the method is characterized in that the pressure of the gas surrounding the weld glass powder molten liquid is increased to eliminate the bubbles when the weld glass powder is molten and bubbles are generated. When the pressure of the gas surrounding the weld glass powder molten liquid is increased, the bubbles inside the weld glass powder molten liquid is reduced in a compression way under the effect of the external pressure, the solubility of the bubbles which are dissolved in the weld glass powder molten liquid is increased under the effect of the external pressure, and the bubbles also can be reduced.

Owner:黄家军

A compound suspension of molluscicidal drug niclosamide ethanolamine salt and its preparation method

ActiveCN101006778AGrind evenlyReduce interfacial tensionBiocideMolluscicidesNiclosamideSuspending Agents

The invention discloses a snail control insecticide of compound niclosamide ethanolamine salt suspending agent which comprises the constituents (by weight portion) of niclosamide ethanolamine salt 1-50 parts, methaldehyde 0.01-5 parts, dispersing agent 1-20 parts, wetting agent 0.5-20 parts, and thickening agent 0.05-10 parts, and balancing water. The invention also discloses the process for preparing the suspending agent.

Owner:JIANGSU ESSENCE AGROCHEM

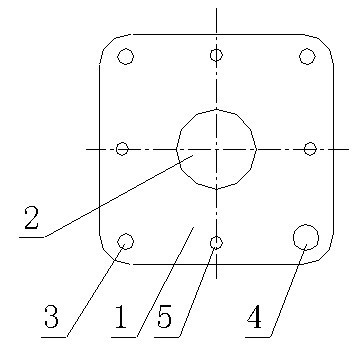

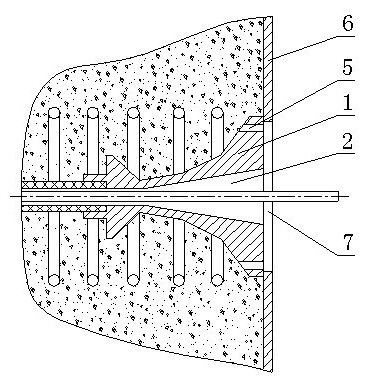

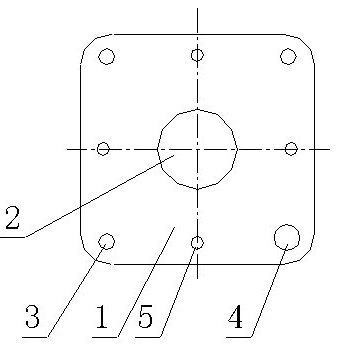

Backing plate under anchorage for post-tensioning method

InactiveCN101899812AAvoid the phenomenon of being crushedAvoid formingBridge structural detailsBuilding reinforcementsSurface finishPre stress

The invention discloses a backing plate under anchorage for a post-tensioning method. The middle of the backing plate under anchorage is provided with a center hole, and an installation fixing hole, a mudjacking hole and an overflow hole are also arranged in the backing plate under anchorage, wherein the distance between the overflow hole and the axis of center hole is less than the radius of a steel strand perforation of a template. By arranging the overflow hole in the backing plate under anchorage, the invention realizes that the vibration compactness of concrete can be judged according to whether concrete grout flows out of the overflow hole after injecting the concrete into a mold cavity at a prestress tensioned hole and vibrating the concrete with a vibrator. If no concrete grout flows out, the result indicates that the concrete is incompact and needs to be further vibrated; and if the concrete grout flows out, the result indicates that the concrete is compact. The backing plate under anchorage is more scientific in structural design, completely avoids the formation of holes behind the backing plate under anchorage, simultaneously prevents the backing plate under anchorage from being broken by pressure in the prestress tensioning process, improves both the quality and the safety of concrete members, and eliminates bubbles on the concrete surface so as to further improve the surface finish after concrete demolding.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com