Releasing agent special for bare concrete and preparation method thereof

A technology of fair-faced concrete and release agent, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as harsh process conditions, unfavorable environmental protection requirements, and difficulty in improving the condition of hornet's nests on the concrete surface, achieving low adhesion and low cost , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

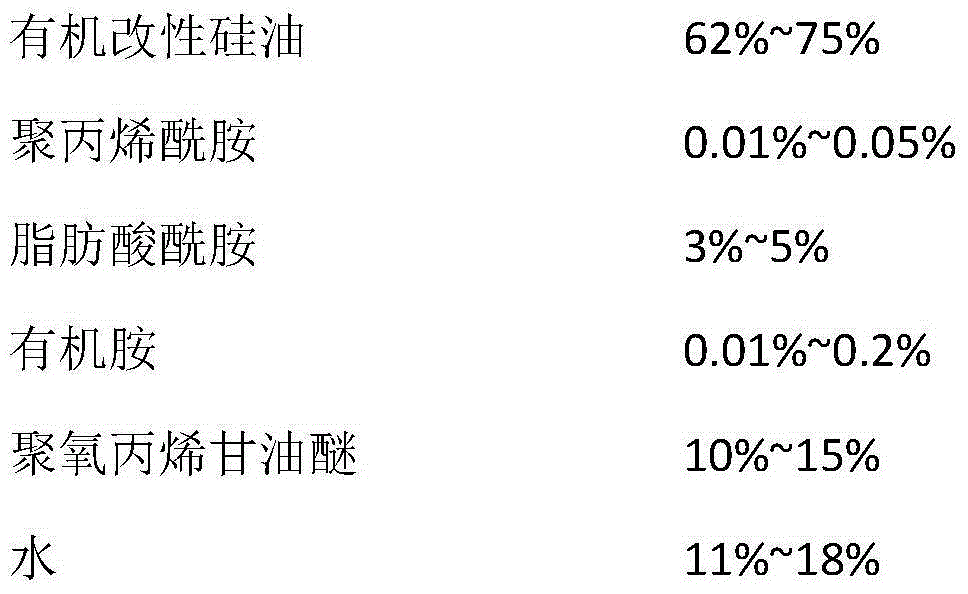

Method used

Image

Examples

example 1

[0017] First, dissolve 0.1g of non-ionic polyacrylamide (molecular weight: 2 million) in 119.8g of water, heat up to 50°C, stir well and add 750g of amodimethicone and 30g of coconut oil fatty acid diethanolamide , 0.1g diethanolamine, 100g polyoxypropylene glyceryl ether, after stirring for 60 minutes, cool naturally to obtain a special release agent for fair-faced concrete.

[0018] The viscosity of the obtained release agent is 79.8mPa.s, diluted with water 3 times, the release performance is tested by the JC / T945-2005 standard, and the concrete adhesion is 1.8g / m3 after continuous release for 3 times 2 , No rust to the steel mold, no change in performance after stable storage at -20°C to 45°C for 30 months.

example 2

[0020] First, dissolve 0.3g of non-ionic polyacrylamide (molecular weight: 8 million) in 178.7g of water, heat up to 55°C, stir well and add 655g of double polyethylene polydimethylsiloxane, 45g of coconut oil fatty acid diethanolamide , 1g N, N-dimethylethanolamine, 120g polyoxypropylene glyceryl ether, after stirring for 120 minutes, cool naturally to obtain a special release agent for fair-faced concrete.

[0021] The viscosity of the obtained release agent is 83.1mPa.s, which is diluted 5 times with water. The release performance is tested according to the JC / T945-2005 standard. After 4 consecutive releases, the concrete adhesion is 2.1g / m 2 , No rust to the steel mold, no change in performance after stable storage at -20°C to 45°C for 30 months.

example 3

[0023] First, dissolve 0.5g of non-ionic polyacrylamide (molecular weight: 12 million) in 177.5g of water, heat up to 35°C, stir well and add 620g of double polyethylene polydimethylsiloxane, 50g of coconut oil fatty acid diethanolamide , 2g ethylenediamine, 150g polyoxypropylene glyceryl ether, after stirring for 30 minutes, cool naturally to obtain a special mold release agent for fair-faced concrete.

[0024] The viscosity of the obtained release agent is 81.2mPa.s, diluted with water 7.5 times, the release performance is tested by the JC / T945-2005 standard, and the concrete adhesion amount is 2.0g / m after continuous release for 3 times 2 , No rust to the steel mold, no change in performance after stable storage at -20°C to 45°C for 30 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com