Glass clarifying agent and preparation method thereof

A clarifying agent and glass technology, which is applied in the field of preparation of the glass clarifying agent, can solve the problems of solubility gradient disorder and micro-bubbles on the surface of the glass plate, and achieve the effects of simple preparation method, elimination of bubbles, and excellent clarification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment relates to a group of glass clarifiers and their preparation methods.

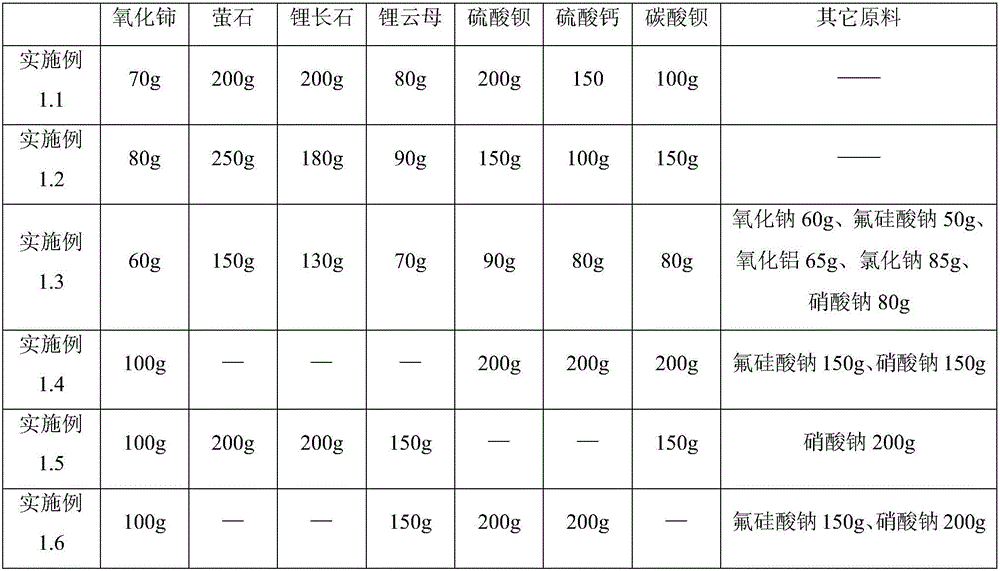

[0020] The raw material composition formula of glass clarifier is shown in the following table:

[0021]

[0022] Examples 1.4-1.6 in the above table are used as comparative examples for comparison with the clarification effect of the glass clarifying agent of the present invention, that is, Examples 1.1-1.3.

[0023] According to the raw material components and consumption shown in the table above, the following preparation method is adopted:

[0024] a. Pulverizing and sieving each raw material component respectively to obtain particles with a particle size of 50-200 microns;

[0025] b. Mix and pulverize the raw material components: first mix fluorite, lithium feldspar, and lepidolite, stir evenly, then add cerium oxide while stirring, after mixing evenly, add barium carbonate, and then add barium sulfate and sulfuric acid Calcium, fully stirred evenly, finally add sodium oxi...

Embodiment 2

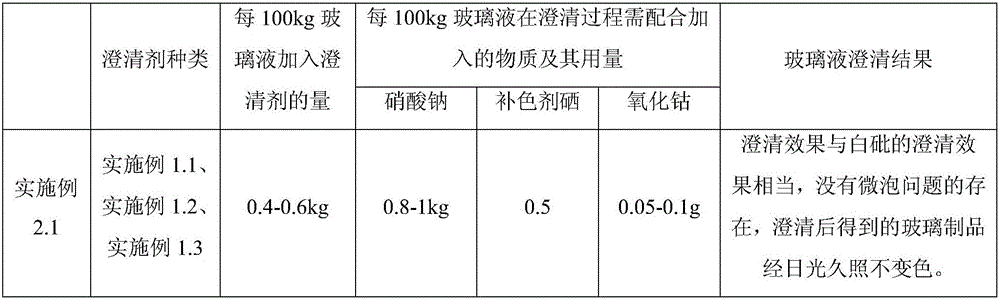

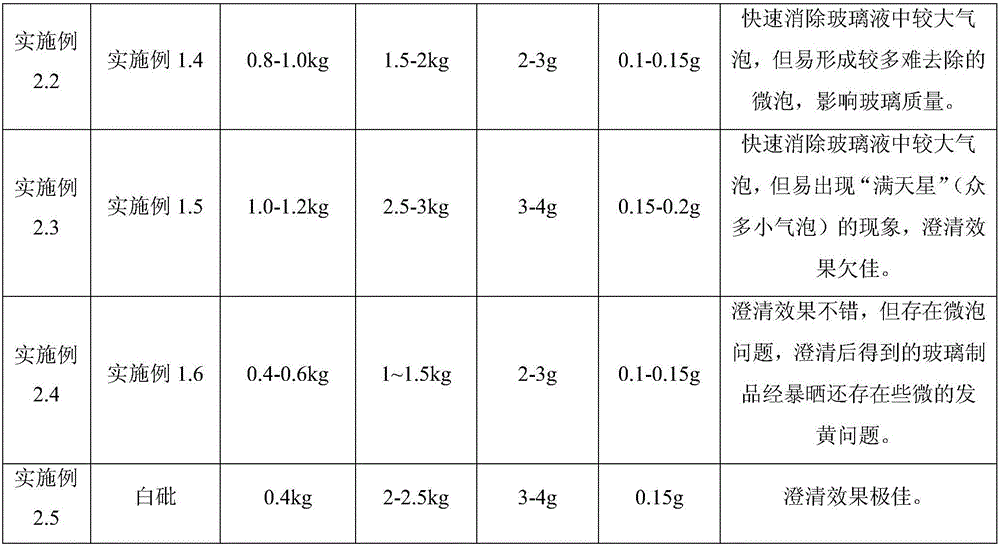

[0028] This example relates to the verification of the use effect of the glass clarifying agent of the present invention.

[0029] The glass clarifying agent of the present invention is suitable for the production process of crucible furnace or pool furnace, and is suitable for the production of plain white material glass. Use the glass clarifier of the present invention, adopt the conventional glass clarification operation process, if the addition of cullet in the glass batch exceeds 30%, it is necessary to increase the amount of soda ash in an appropriate amount to supplement the amount of volatilized sodium oxide, and at the same time appropriately increase the use of glass clarifier If the iron content of the glass (the iron content of the glass and the iron content of the glass batch are two concepts, in glass melting, the iron content of the glass always exceeds the iron content of the glass batch) in When it is less than 0.07%, the amount of sodium nitrate introduced is...

Embodiment 3

[0036] This example relates to the influence of the mixing sequence of the various raw material components on the use effect in the preparation method of the glass clarifying agent of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com