Patents

Literature

329 results about "Lepidolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

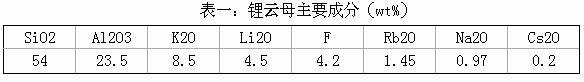

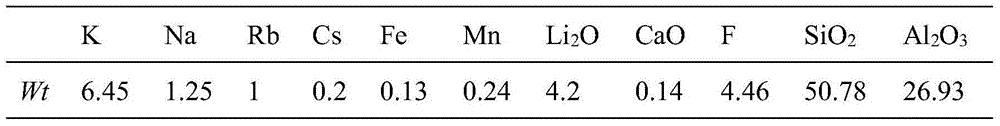

Lepidolite is a lilac-gray or rose-colored member of the mica group of minerals with formula K(Li,Al,Rb)₂(Al,Si)₄O₁₀(F,OH)₂. It is the most abundant lithium-bearing mineral and is a secondary source of this metal. It is a phyllosilicate mineral and a member of the polylithionite-trilithionite series.

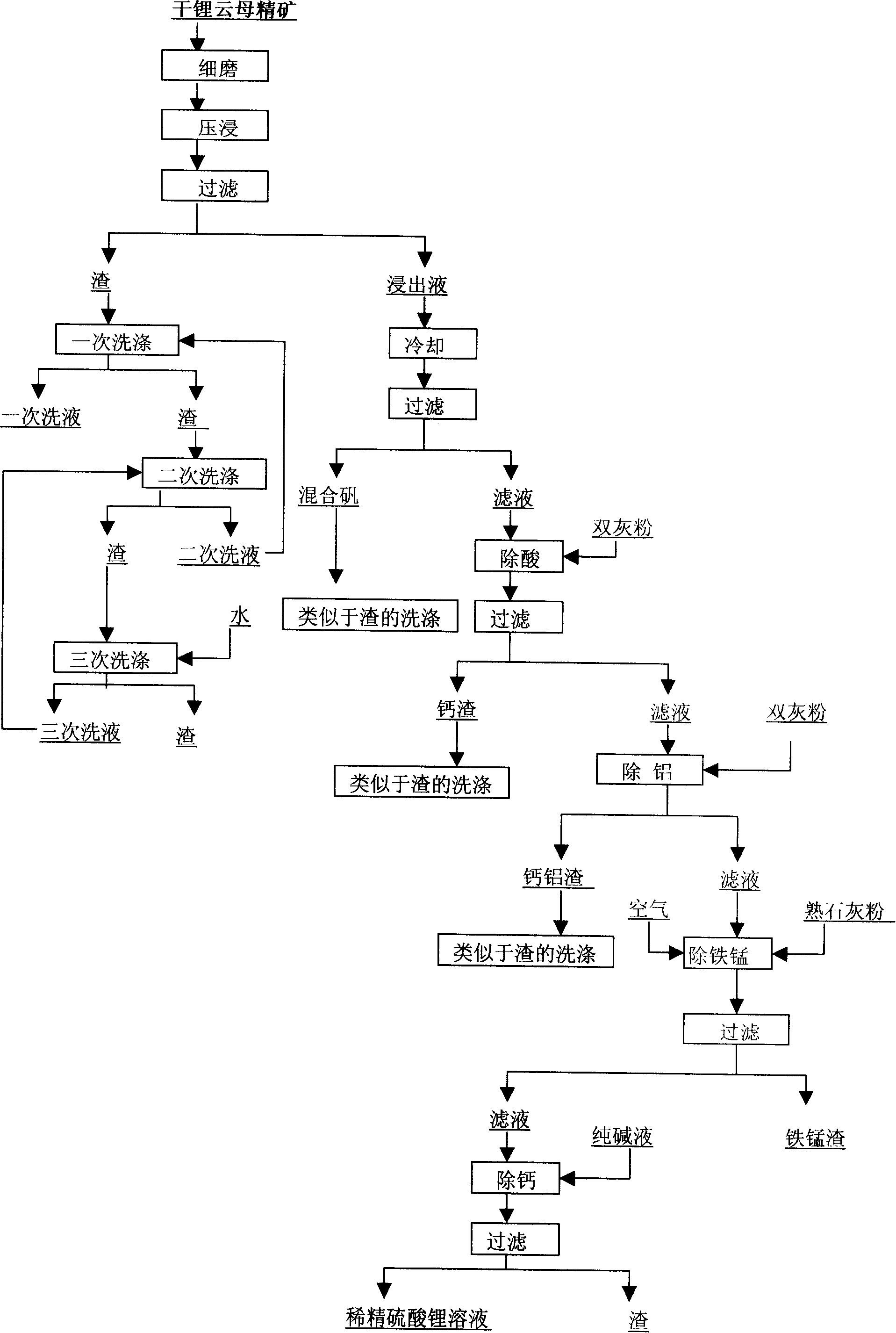

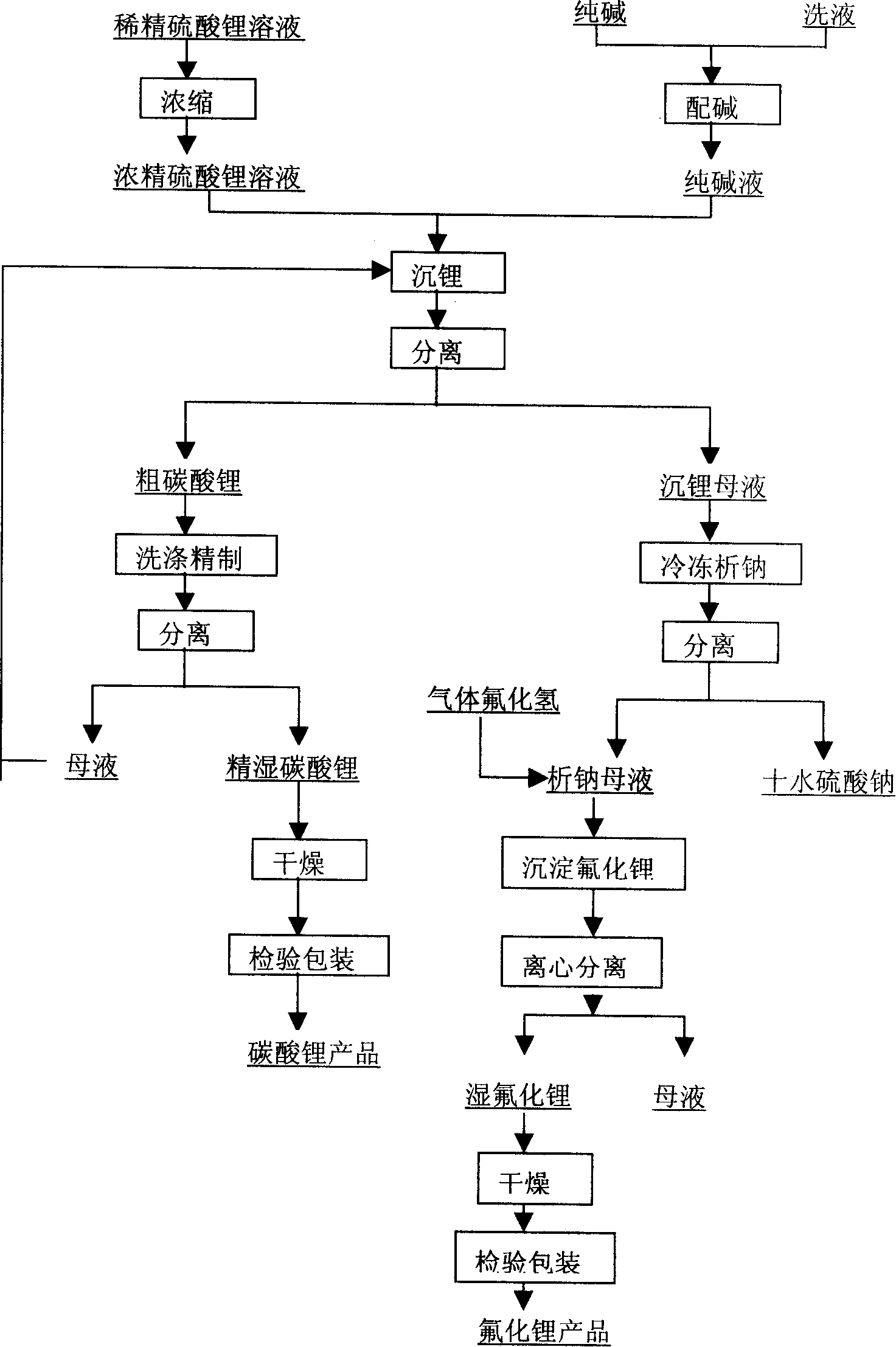

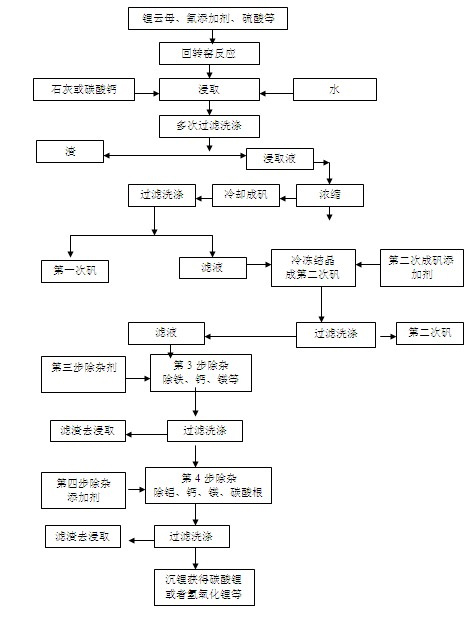

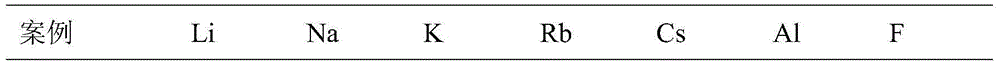

Method for producing refined lithium sulfate solution used in lepidolite lithium-extracting technique by sulfuric acid process

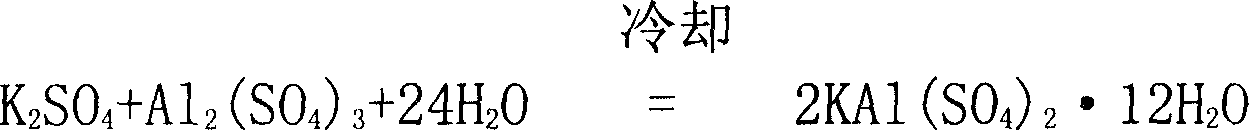

Provided is a process for producing refined lithium sulfate solution of lepidolite lithium extracting technology with sulfuric acid process, which takes lepidolite clean ore as raw material and sequentially includes the following steps, including leaching, alum cooling and decanting, acid removing, aluminum removing, decontaminating and deliming, thereby achieving refined lithium sulfate solution. The alum cooling and decanting process of the invention can precipitate kalium, rubidium and caesium in alum form, thereby the separation of lithium and kalium, rubidium and caesium is easily achieved, and the achieved alum dregs of kalium, rubidium and caesium are blend alum with high purity, which creates perfect condition for comprehensive utilization and simultaneously reduces the burdens of the separation of lithium and aluminum. The aluminum removing process can easily achieve the separation of lithium and aluminum. The process of the invention has the advantages that the energy consumption is relatively low, and the lithium yield is relatively high, most of the residues can be used and the process is favorable for comprehensive utilization. The invention further provides a process for producing lithium carbonate and lithium fluoride with the achieved refined lithium sulfate solution.

Owner:GANFENG LITHIUM CO LTD

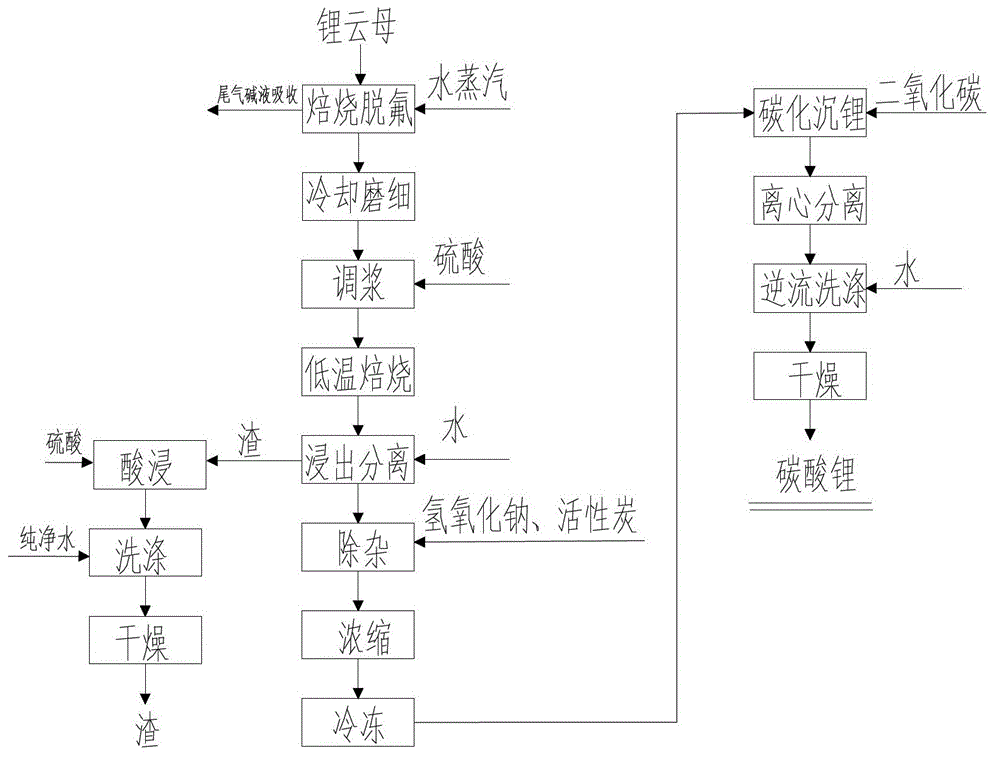

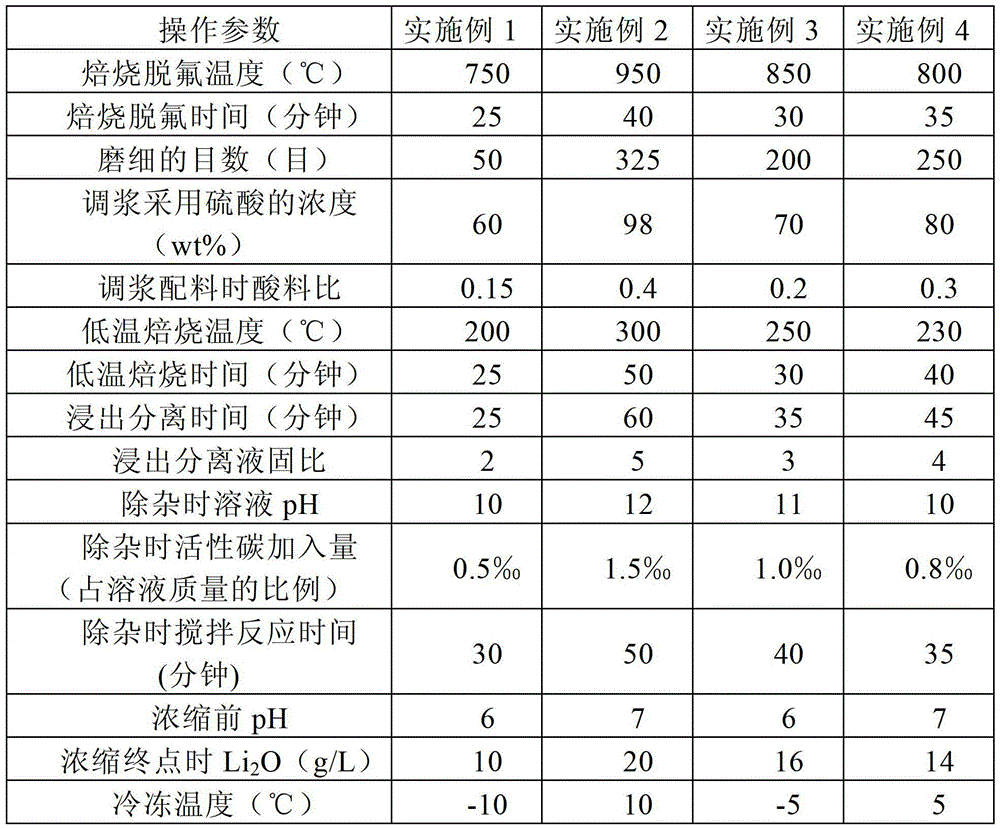

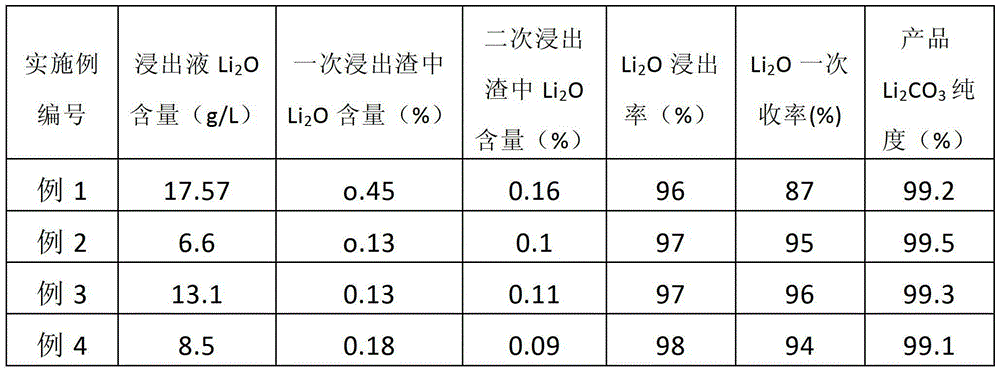

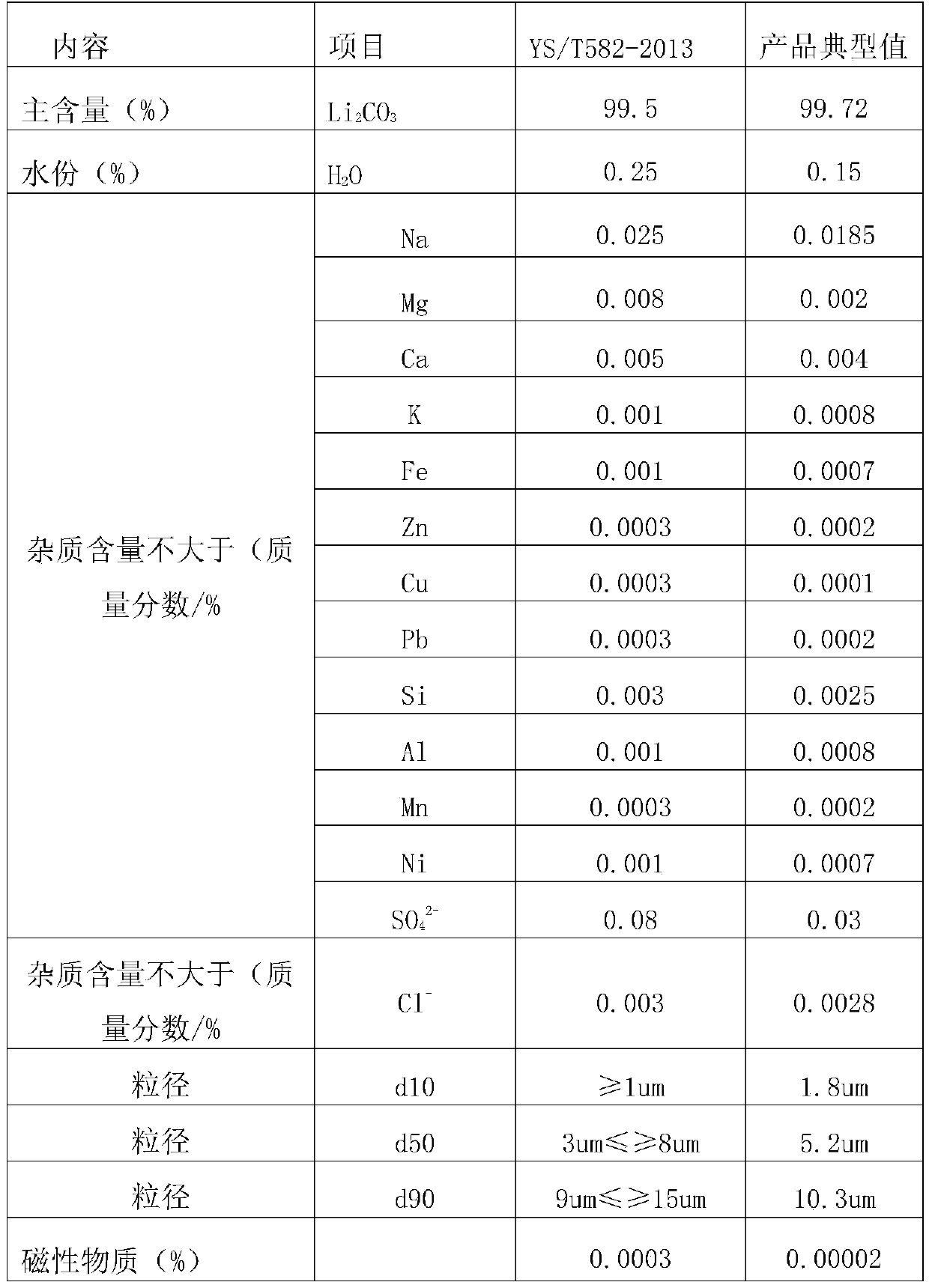

Method for preparing lithium carbonate from lepidolite through sulfuric acid roasting method

ActiveCN103145158AReduce dosageSimple cleaning processLithium carbonates/bicarbonatesResource utilizationLithium carbonate

The invention discloses a method for preparing lithium carbonate from lepidolite through a sulfuric acid roasting method, which comprises the following process steps: (1) roasting, and defluorinating; (2) cooling, and grinding; (3) pulping; (4) roasting at low temperature; (5) leaching, and separating; (6) removing impurities; (7) concentrating; (8) freezing; and (9) performing carbonization lithium precipitation to obtain the lithium carbonate product. The method for preparing lithium carbonate from lepidolite through a sulfuric acid roasting method is simple in process, low in sulfuric acid consumption, low in energy consumption and high in resource utilization rate, and causes less environment pollution.

Owner:GANFENG LITHIUM CO LTD

Method for preparing lithium carbonate by extracting lithium from lepidolite

ActiveCN101302018AImprove leaching rateIncrease concentrationLithium carbonates/bicarbonatesCarbonizationIon exchange

Owner:GANFENG LITHIUM CO LTD

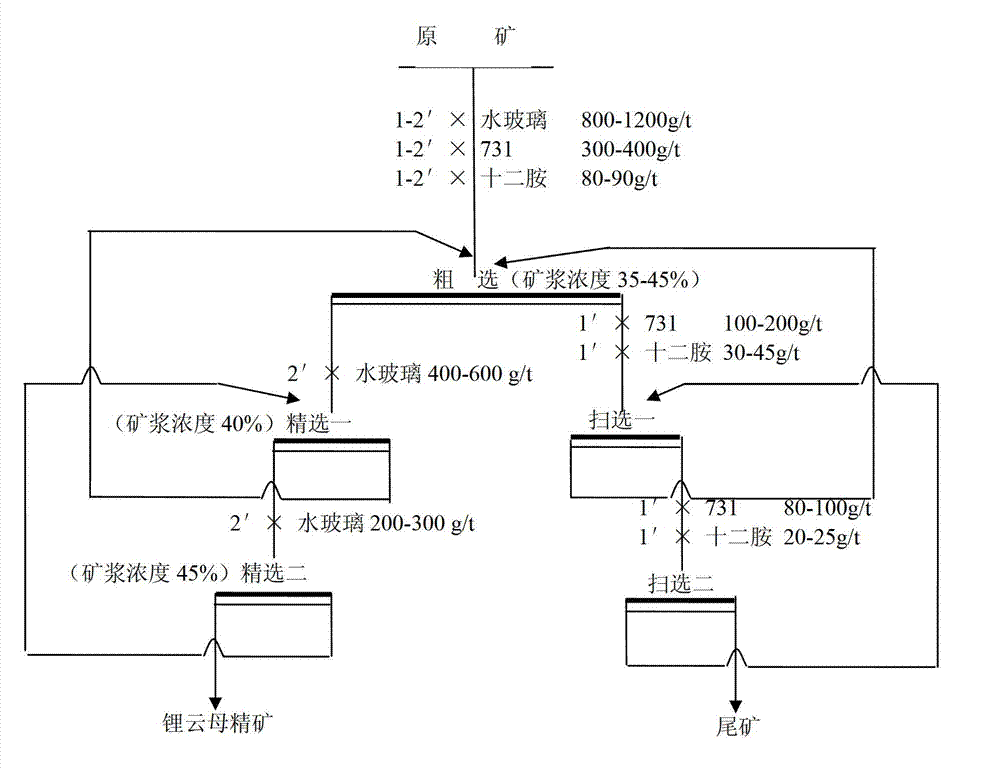

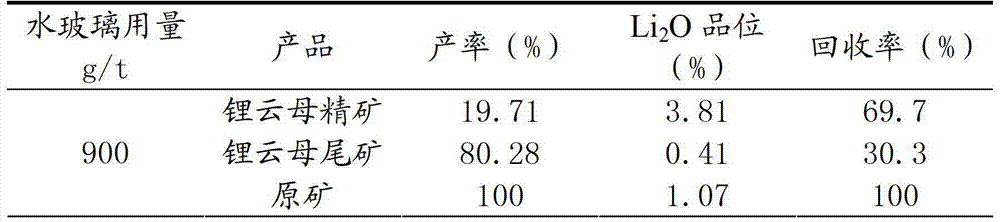

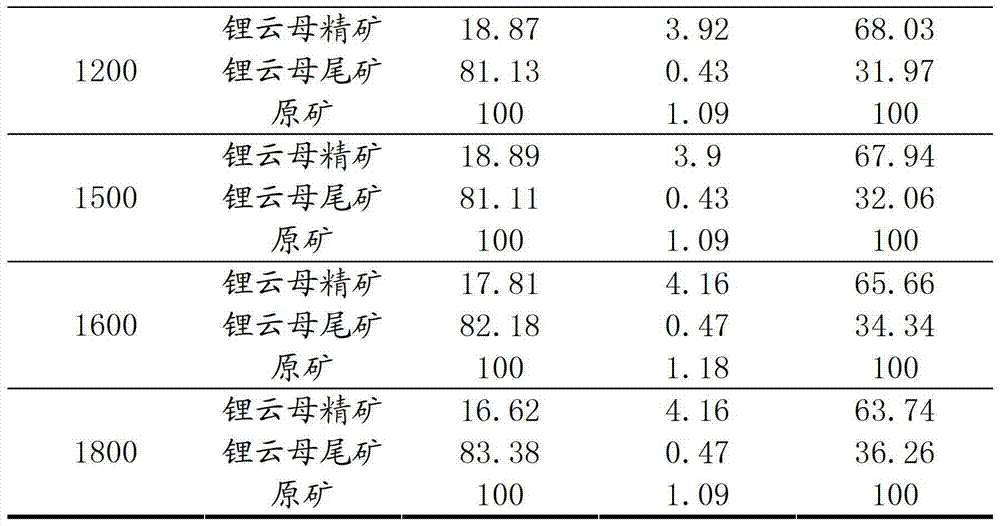

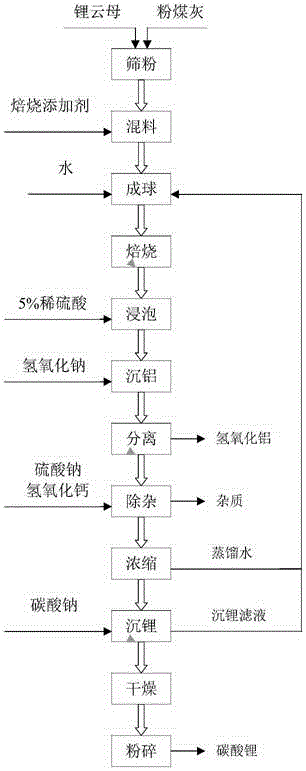

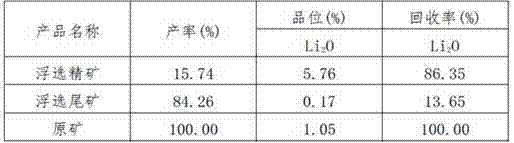

Novel lepidolite flotation method

InactiveCN103240185AEfficient separationLarge adsorption capacityFlotationCoconut oilCharge compensation

The invention discloses a novel lepidolite flotation method including primary rough selection, secondary fine selection and secondary scavenging. During the flotation, sodium silicate is added as an inhibitor with the amount ranging from 1400g / t to 1900g / t; an anionic collector is sodium oleate or oxyparaffin soap 731 with the amount ranging from 480g / t to 700g / t; and a cationic collector is dodecylamine or coconut oil amine with the amount ranging from 130g / t to 160g / t. The adding sequence of collectors is the anionic collector first and the cationic collector second, or the anionic collector and the cationic collector are added together. By the method, the lepidolite is selected through the combination of the anionic and the cationic, good flotation effect can be realized, flotation efficiency is high, and meanwhile, the synergistic effect is generated between the anionic collector and the cationic collector, and results from joint action of three mechanisms of coadsorption, charge compensation and function complementation.

Owner:JIANGXI UNIV OF SCI & TECH

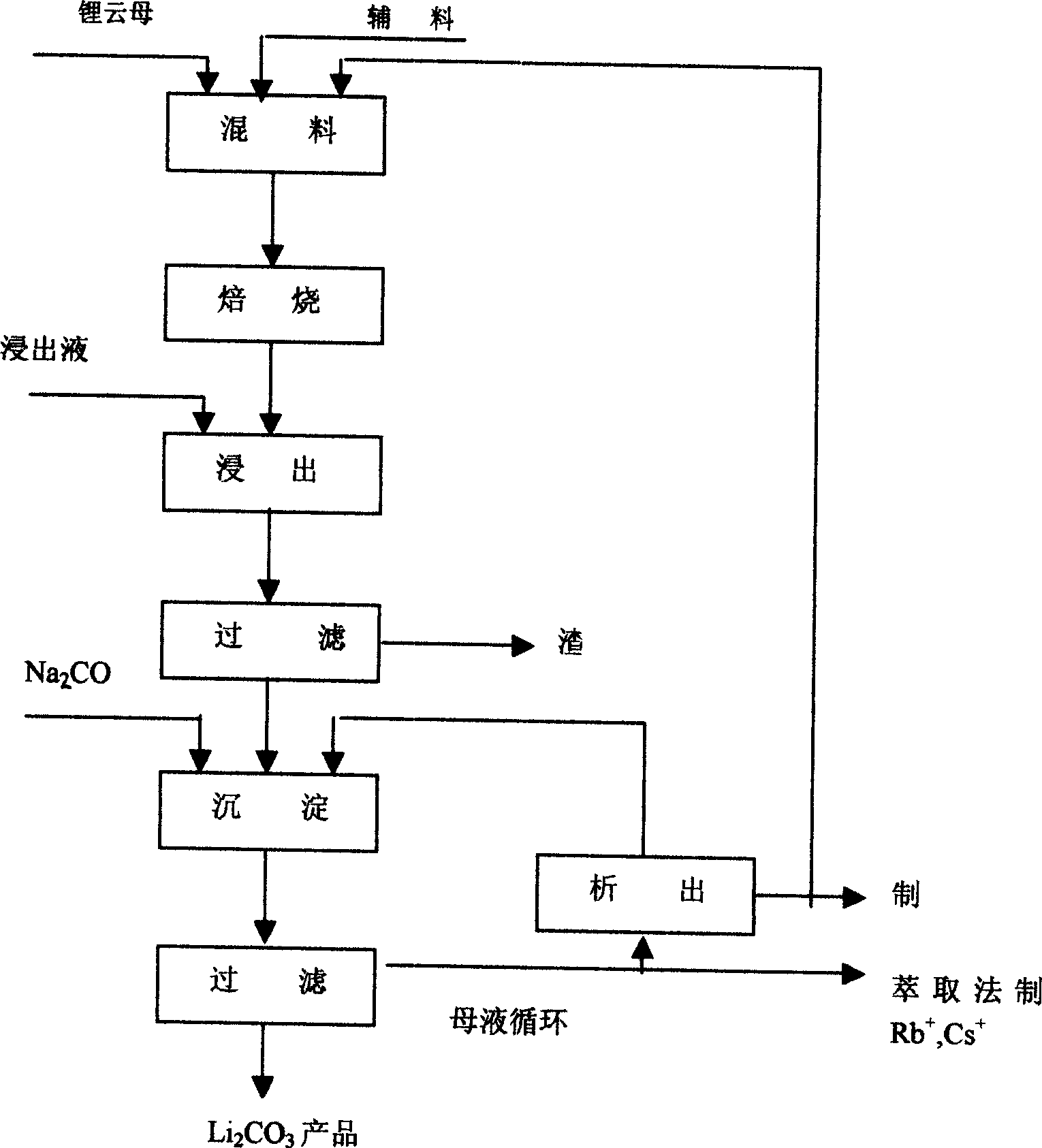

Process for preparing lithium chlorate by lithium extracted from lepidolite

InactiveCN1827527AReduce energy consumptionReduce investmentLithium carbonates/bicarbonatesLithium carbonateSulfate

The invention relates to a method for preparation of lithium carbonate extracting lithium from lithionite. The invention consists of milling, leaching and filtering after modifying by broasting lithonite ore together with the additive findings such as calcium fluoride, calcium sulfate and sodium sulfate at a certain temperature, adding sodium carbonate into the leachate to deposite lithium ion forming the deposition of lithium carbonate, and washing and drying the solid gained by filtering to get the product of lithium carbonate. The filtered mother liquid returns to the circulation to deposit lithium ion. After secondary circulation, we get the mixed salts of potassium sulfate and sodium sulfate as the educts by washing and drying the aforementioned filtered mother liquid. Some of the mixed salts return as findings roasted with lithonite ore for circulation use, while others can be used as raw material for preparation of potassium sulfate.

Owner:钟辉

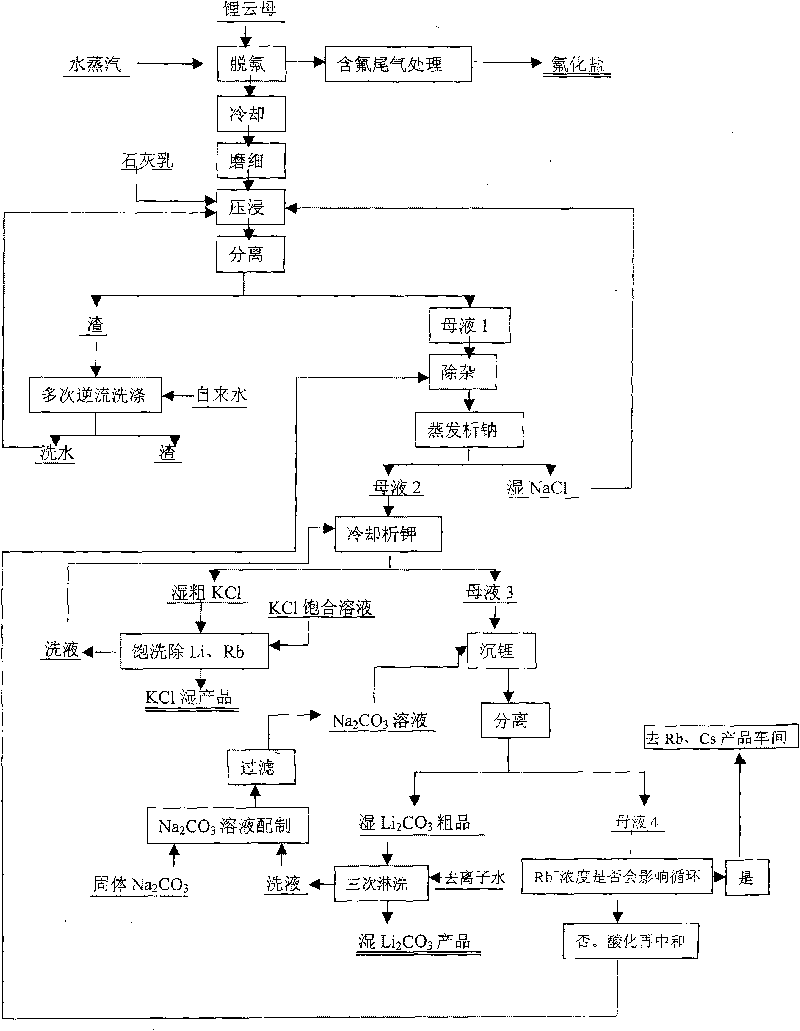

Method for extracting lithium from lepidolite

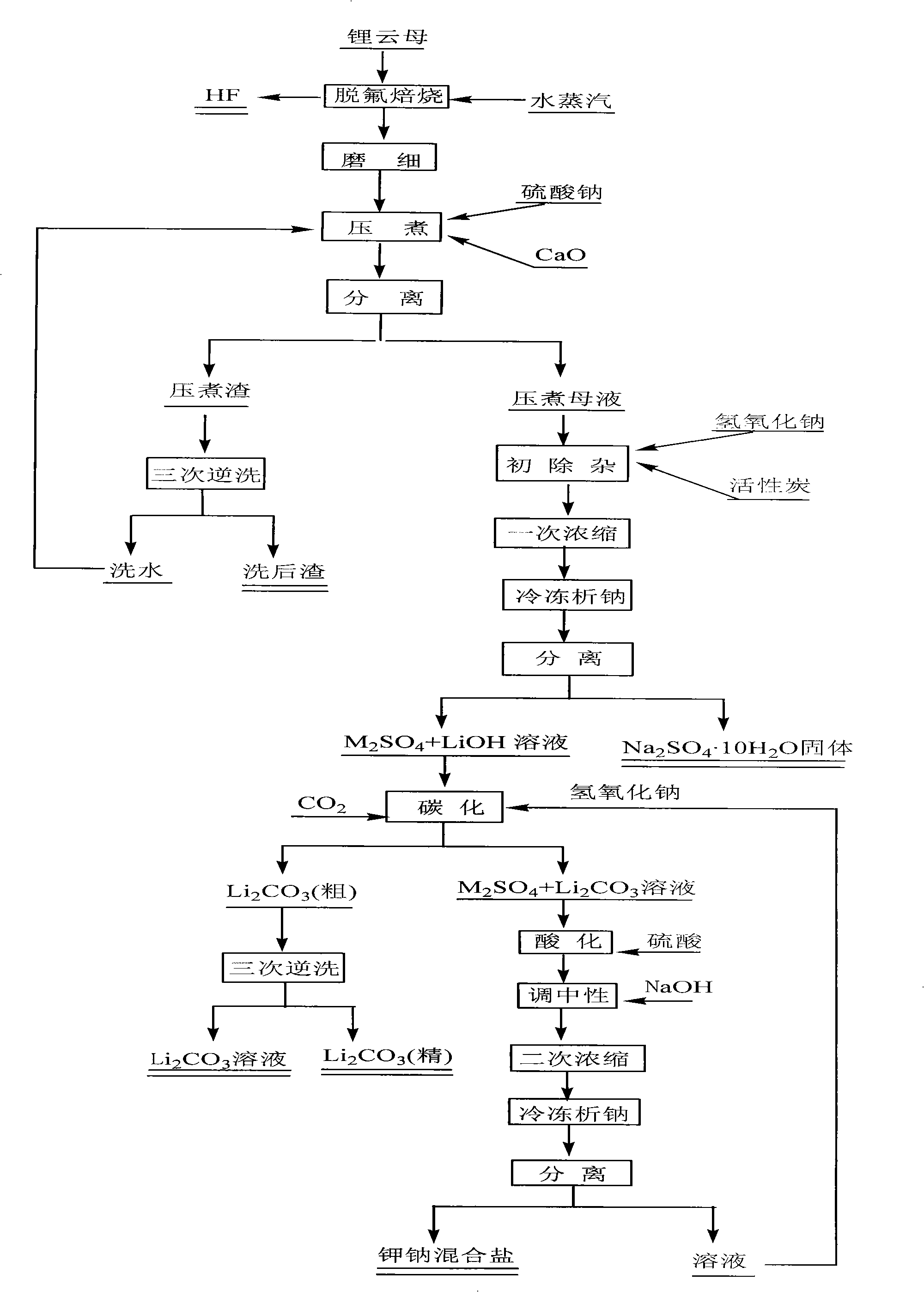

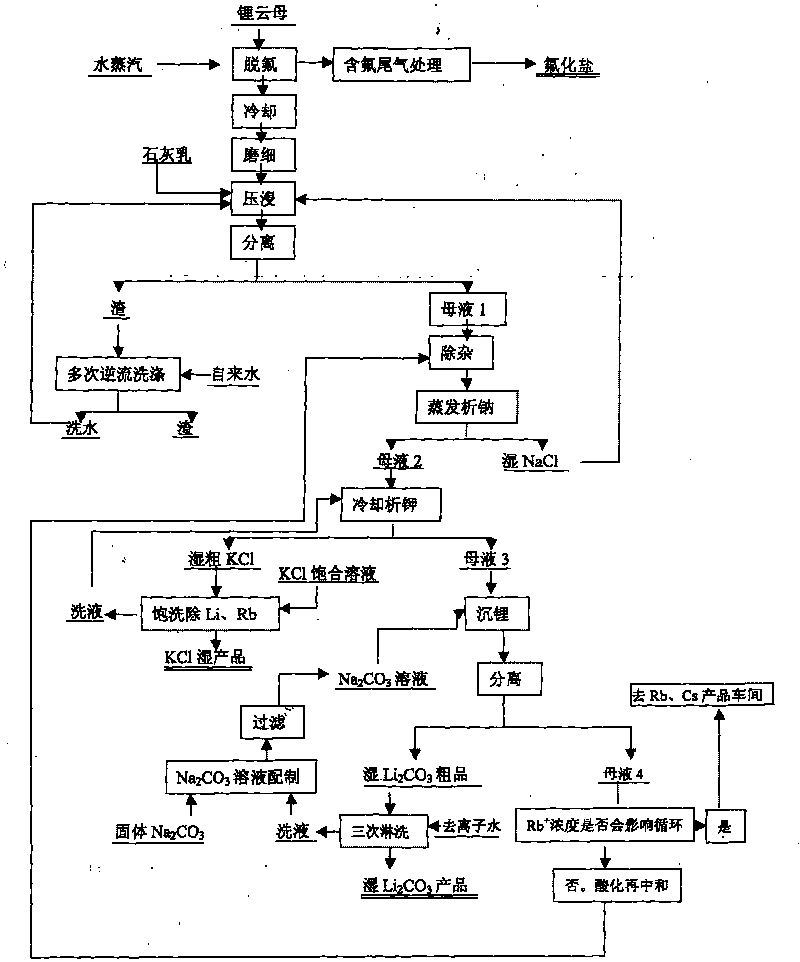

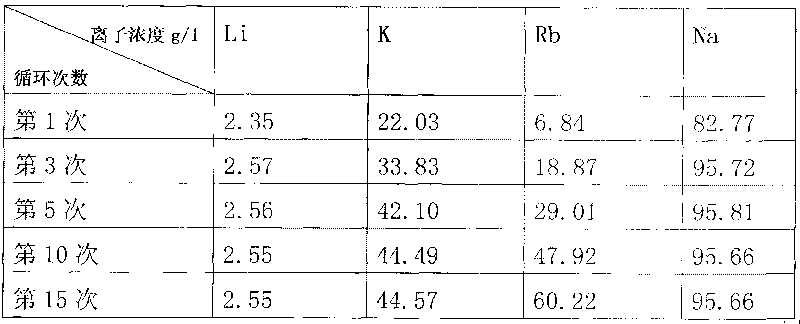

The invention relates to a method for extracting lithium from lepidolite, which comprises the steps of removing fluorine, pressing and soaking, separating, removing impurity, separating out natrium, analyzing kalium, separating, depositing lithium, separating, and separating crude wet lithium carbonate and lithium depositing mother liquid after depositing lithium. The invention is characterized in that the concentration of Rb+ contained by the lithium depositing mother liquid is detected, the circulation trend of the lithium depositing mother liquid is decided by the consistency, when the consistency is low, the product quality is not influenced, the lithium depositing mother liquid which is acidulated returns to the step of removing impurity before analyzing natrium, and when the concentration of the Rb+ is high and influences the product quality, the lithium depositing mother liquid is separated in an Rb and Cs product manufacturing procedure. The invention can avoid increasing the load of a pressing and soaking kettle when the lithium depositing mother liquid returns to the pressing and soaking step, and the content of natrium and kalium in the lithium depositing mother liquid which is finally educed is reduced to enable the subsequent separation of Rb and Cs to be easier, thereby the cost of whole technique comprising the processing cost of lithium carbonate, rubidium and cesium is greatly reduced.

Owner:GANFENG LITHIUM CO LTD

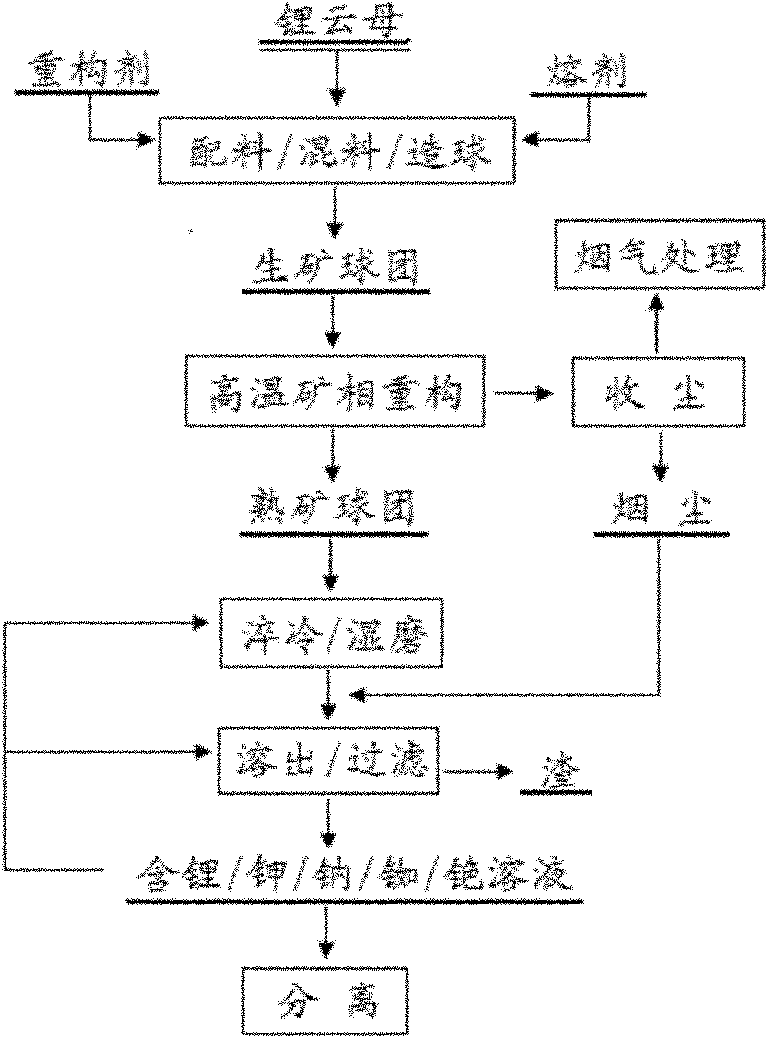

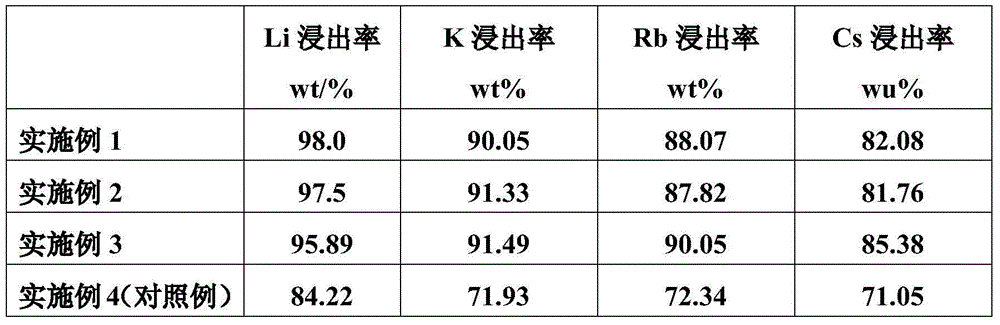

Method for extracting lithium and other alkali metal elements from lepidolite mineral

InactiveCN101974678AEfficient extractionEasy to optimizeProcess efficiency improvementRubidiumPotassium

The invention discloses a high-temperature mineral phase reconstruction method for extracting lithium and other alkali metal elements from lepidolite mineral, comprising the following steps: mixing raw materials, pelletizing, calcining at high temperature, water quenching, ball milling, dissolving out, producing compounds and the like. The invention teaks raw mineral component composition to design target reconstruction mineral and composition to obtain the purpose of optimizing processes, lowering energy consumption and cost of treatment process and efficiently extracting lithium, potassium, rubidium, caesium and the like. Silicon and aluminum in lepidolite can enter anorthite type mineral phase (CaO.Al2O3.2SiO2, (Ca, Na)O. (Al, Si)2O3.2SiO2) and calcium ash quarry phase (CaO.SiO2) after mineral phase reconstruction, and do not dissolve in water and aqueous solution. After mineral phase reconstruction reaction, fluorine in lepidolite enters calcium fluoride mineral phase and does not dissolve in water and aqueous solution. Lithium and other alkali metal elements in lepidolite enter salt (chloride, sulfate) or alkali (hydroxide) phase of lithium and other alkali metal elements after mineral phase reconstruction reaction and can be dissolved in water and aqueous solution.

Owner:CENT SOUTH UNIV

Process for removing impurities from lepidolite leaching solution

The invention relates to a process for removing impurities from a lepidolite leaching solution. The process is completed by carrying out impurity removal on alumina twice and adjusting pH values for twice. Lithium salt precipitation products are obtained by adding additives to a lithium sulfate solution after impurity removal, and corresponding refined lithium salts can be prepared as required. The process has the advantages that the cost of impurity removal is low, by-products with high added values can be obtained, the extraction rate of lithium is high, various useful components of lepidolite ores can also be fully utilized when lithium salts are produced, and the recycling of resources is realized.

Owner:江西海汇龙洲锂业有限公司

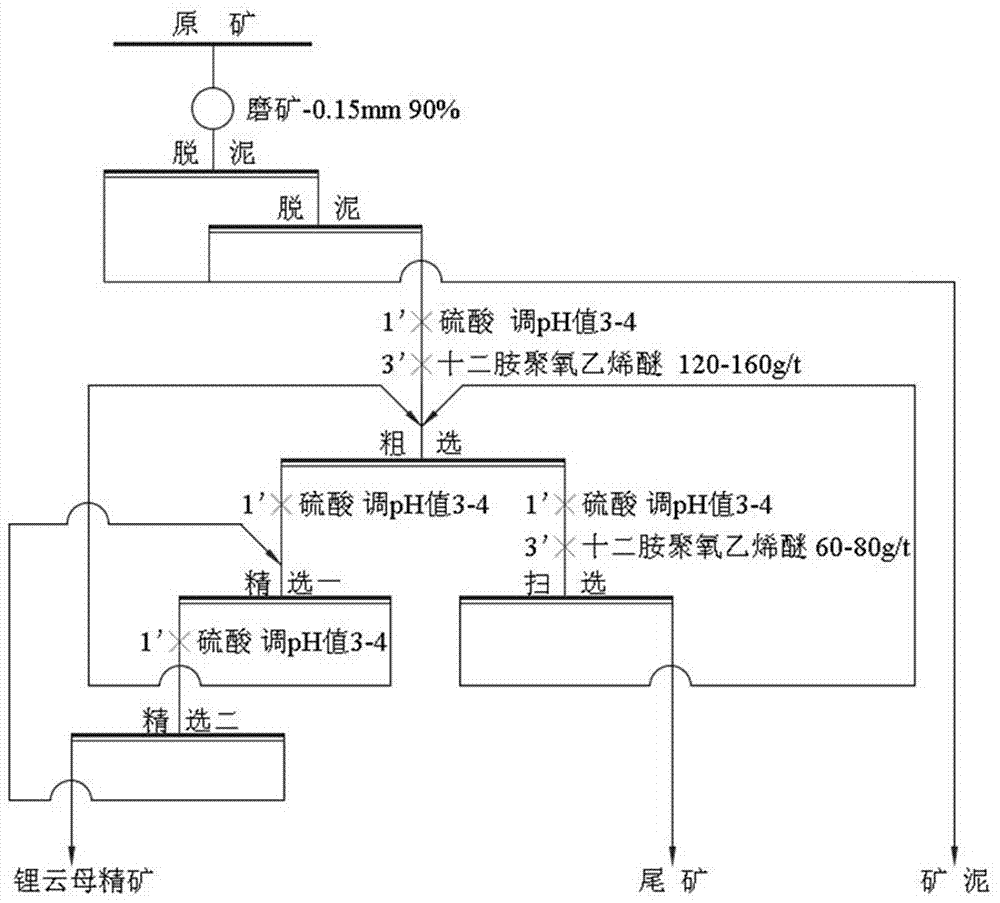

Lepidolite floatation method

ActiveCN107008567AImprove adaptabilityEasy to makeFlotationWet separationConcentration ratioLepidolite

The invention discloses a lepidolite floatation method. The lepidolite floatation method comprises the steps that raw ore is subjected to wet ball milling after being crushed to obtain ore pulp; and the ore pulp is subjected to floatation separation with a lauryl amine polyoxyethylene ether solution serving as a collecting agent and with sulfuric acid serving as a regulating agent to obtain high-quality lepidolite concentrate. The lepidolite floatation method has the characteristics of being simple in process, low in agent consumption and production cost and good in adaptability to slime, the recovery rate of the lepidolite concentrate reaches 66.38% relative to Li2O in the raw ore, the content of lepidolite concentrate grade Li2O reaches 3.17%, the concentration ratio reaches 4.80, comprehensive utilization value of lepidolite resources is remarkably improved, and the floatation method is environmentally friendly and has sustainable-development long-term and practical significance.

Owner:CENT SOUTH UNIV

Preparation method of metal-imitation glaze

The invention provides a production method for a colorful, color-stable imitated metallic luster glaze which can meet the requirements of low-temperature rapid firing process. The method includes: (1) first making the following raw materials into a frit by weight percentage of 10-20 per cent quartz, 40-60 per cent lepidolite, 10-20 per cent boric acid, 2-6 per cent barium carbonate, 3-10 per cent limestone, 3-12 per cent metal oxide and then evenly mixing the raw materials after melting at 1200-1350 DEG C and obtaining a color frit by water quenching. (2) making the glaze with the following materials by weight of 75-90 per cent color frit, 0-20 per cent high boron frit and 5-10 per cent kaolinite. The metallic luster glaze products is colorful and low in sintering temperature and is suitable for the characteristics and style of interior wall glazed tiles of twice low-temperature rapid firing and the frit is produced by sintering metal oxides, therefore the color is very stable.

Owner:冼金源 +1

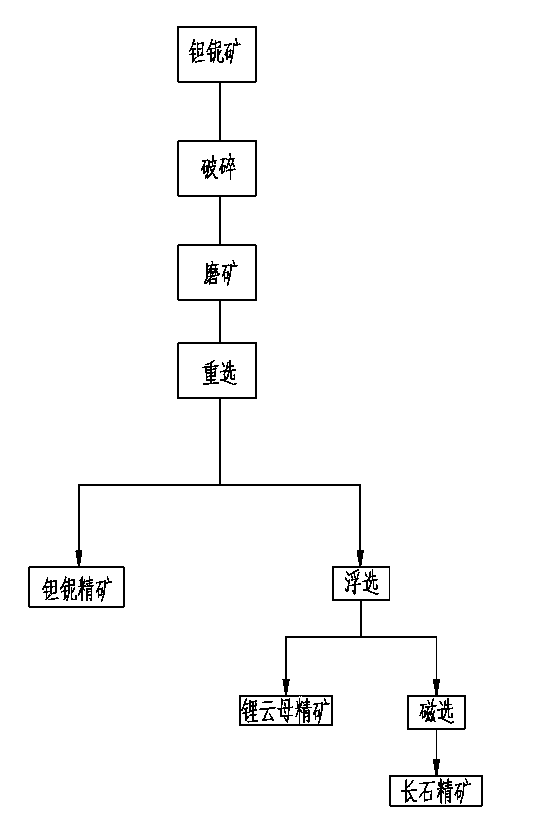

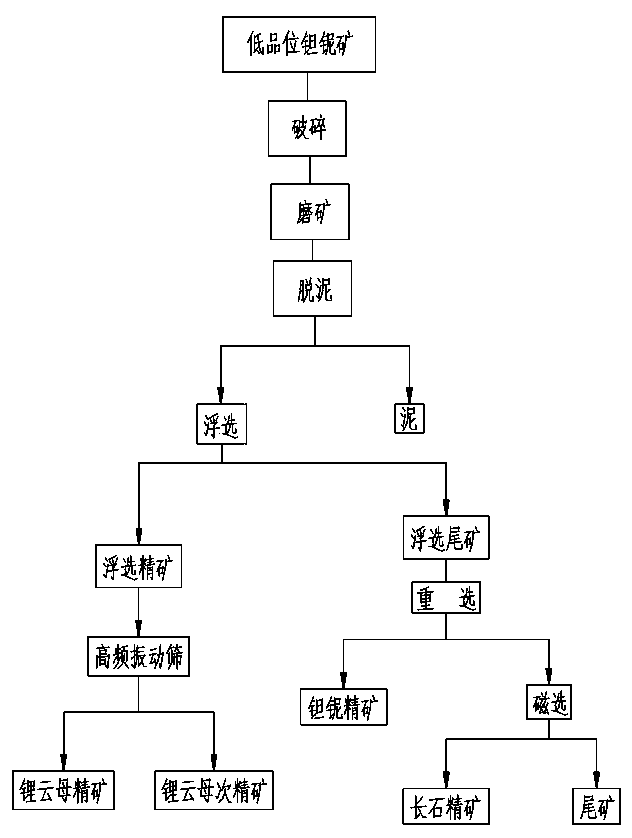

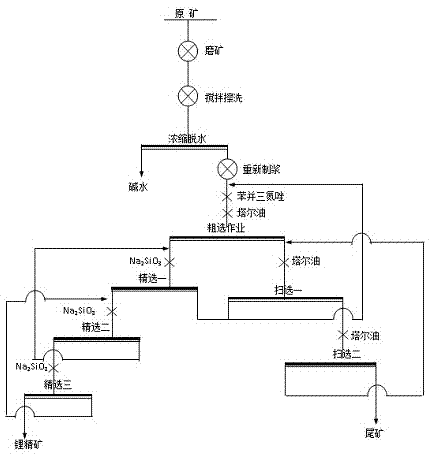

Production method for preferably selecting lepidolite from tantalum and niobium ores

The invention relates to the technical field of mineral processing, in particular to a production method for preferably selecting lepidolite from tantalum and niobium ores. The technological process comprises crushing, ore grinding, desliming and floation, the flotation concentrate is filtered by a high-frequency vibrating screen to obtain lepidolite concentrate and secondary lepidolite concentrate, the flotation tailings are re-elected to obtain tantalum and niobium concentrate, and the re-elected tailings are magnetically separated to obtain feldspar concentrate. The comprehensive recovery rate of lepidolite in the tantalum and niobium ores is greater than 70%, so that the economic efficiency of tantalum and niobium ores is greatly improved. The production method provided by the invention is particularly suitable for preferably selecting the lepidolite from the low-grade tantalum and niobium ores.

Owner:HUBEI XINYING ENVIRONMENTAL TECH

Refining process for lepidolite in tantalum-niobium ore waste rocks

ActiveCN105251606ASolve the way outHigh Lithium Oxide ContentHigh gradient magnetic separatorsFlotationNiobiumIron removal

The invention relates to a refining process for lepidolite in tantalum-niobium ore waste rocks. A combined method with magnetic separation, high gradient magnetic separation, dense medium separation and flotation is adopted. The flotation adopts the process of rough flotation, dual fine flotations and sweeping. The process for refining the lepidolite from the granite-type tantalum-niobium ore waste rocks is provided. The tantalum-niobium ore waste rocks are crushed, screened, ground and subjected to high-frequency screening, spiral grading, permanent magnet magnetic separation for iron removal, high gradient magnetic separation, dense medium separation and flotation, so that lepidolite concentrates are obtained. By means of the method, the lepidolite concentrates are separated from the tantalum-niobium ore waste rocks. The lepidolite concentrates contain at least 4.5% of Li2O, at least 8.0% of K2O and Na2O and at most 0.10% of TiO2 and Fe2O3, the recovery rate of the lepidolite concentrates is larger than 80%, the qualities of the lepidolite concentrates meet the requirement of national standards, and the recovery rate of the lepidolite concentrates exceeds the industry level.

Owner:江西金辉再生资源股份有限公司

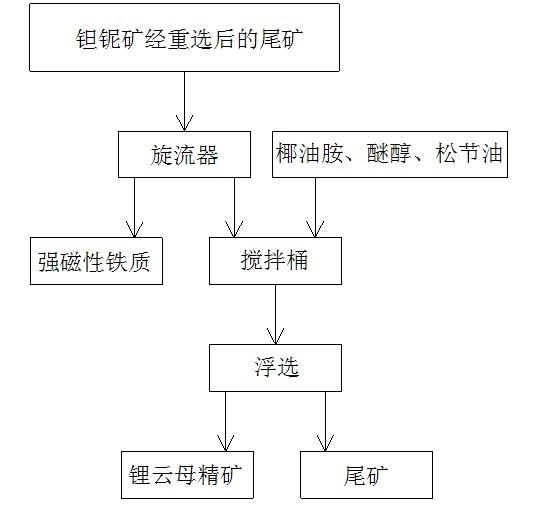

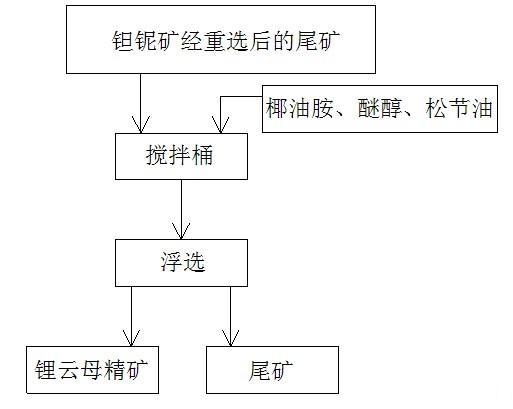

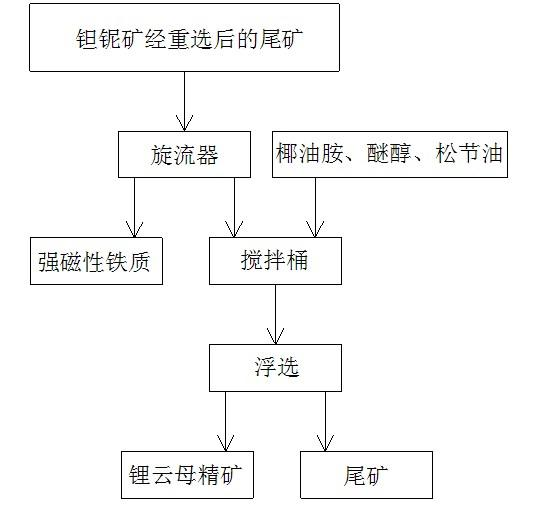

A kind of flotation lepidolite process method

The invention discloses a process method for flotation lepidolite, specifically: the tailings of tantalum-niobium ore after re-election are deslimed and then enter the flotation process, or directly enter the flotation process, add flotation agents, and perform flotation Obtain high-quality lepidolite concentrate. The invention recovers lepidolite by flotation in neutral pulp, and has the advantages of simple process, low chemical consumption, high efficiency, safety and environmental protection of flotation chemical, and the like.

Owner:JIANGXI UNIV OF SCI & TECH +1

Method of extracting lithium salt from lepidolite

InactiveCN104313349AAvoid generatingReduce pollutionProcess efficiency improvementLithium soapRubidium

The invention discloses a method of extracting a lithium salt from lepidolite. The method comprises the following steps: roasting lepidolite mineral aggregates with CaO and Ca(CH3COO)2 in a plasma generator after ball-milling and mixing; reacting roasted materials with a dilute sulfuric acid solution and (NH4)2SO4 under a pressurized state, controlling an acid leaching temperature to 85-100 DEG C to obtain a solid-liquid mixture, cooling and freezing the solid-liquid mixture to separate potassium, rubidium, cesium and alum, filtering, adding alkali and removing impurities and depositing lithium to prepare the lithium salt. The method disclosed by the invention is capable of completely removing fluorine in the raw materials, reducing the equipment damages and environmental pollution caused by fluorine gas generation in a raw material roasting stage, improving the extraction and utilization efficiency of rare metal raw materials in the lepidolite raw material, lowering the energy consumption, shortening the reaction time and reducing the consumption of acid-base raw materials. The method disclosed by the invention is mild in condition, stable in operation process, short in production period, high in equipment efficiency, capable of realizing comprehensive utilization of resources, low in production cost and beneficial to realizing industrial production of extracting the lithium salt from the lepidolite.

Owner:李宇龙 +1

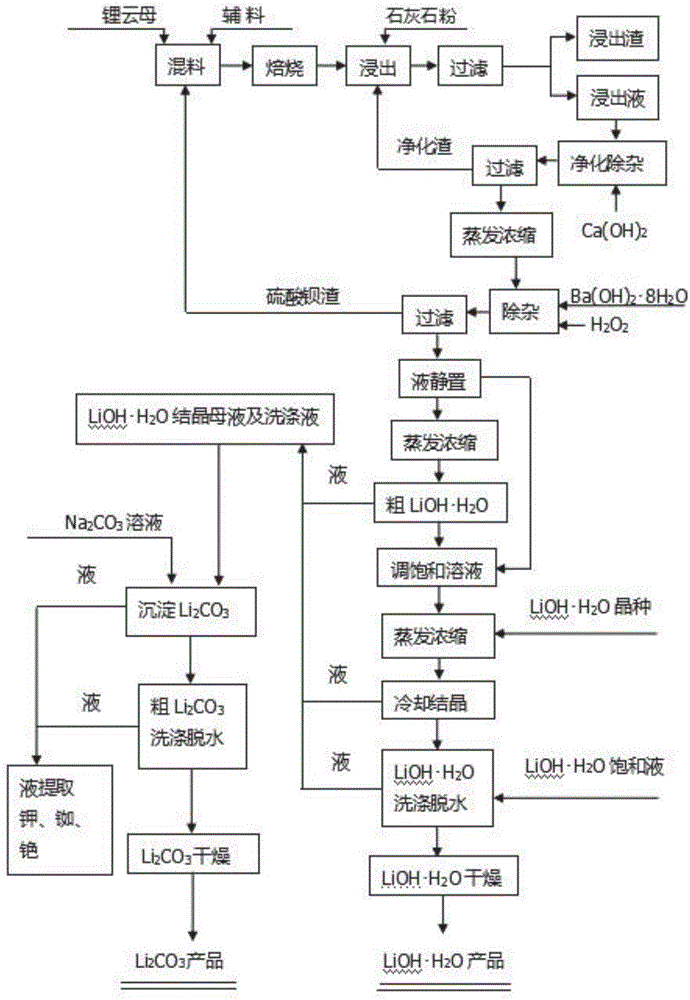

Method for extracting lithium from lepidolite concentrate

ActiveCN106745097AEasy to controlStable productionLithium oxides/hydroxidesLithium carbonates/bicarbonatesResource utilizationLithium hydroxide

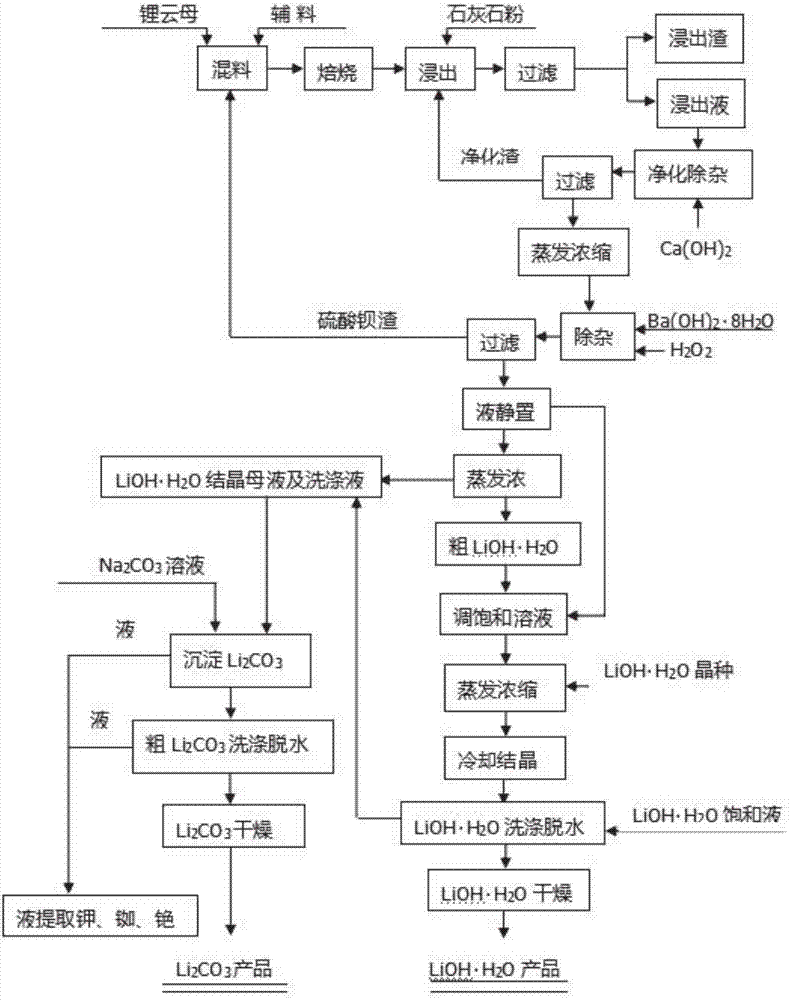

The invention discloses a process for extracting lithium hydrate monohydrate and lithium carbonate by performing active roasting and sulfuric acid leaching on lepidolite concentrate. The method comprises the following steps: adding water into the lepidolite concentrate, calcium sulfate, barite powder or barium sulfate return slag and mixing; performing roasting in a preferable roasting furnace at a proper temperature for proper time; grinding and performing sulfuric acid leaching on a roasted material; performing primary purification, concentration and secondary purification on a leaching agent to obtain LiOH finished liquid; performing secondary crystallization and primary saturated liquid washing on the finished liquid to obtain a lithium hydrate monohydrate product; adding sodium carbonate for precipitating the lithium hydrate monohydrate crystallization mother liquor and washing liquid to obtain a lithium carbonate product. By adopting the process, lithium can be separated effectively from the lepidolite concentrate, and qualified lithium hydrate monohydrate and lithium carbonate products are produced. The process has the advantages of low energy consumption, less material flow, low production cost, low discharge capacity, high environmental friendliness, efficient realization of resource utilization, and capability of meeting industrial production.

Owner:谭春波

Circular acid leaching extraction process for lepidolite

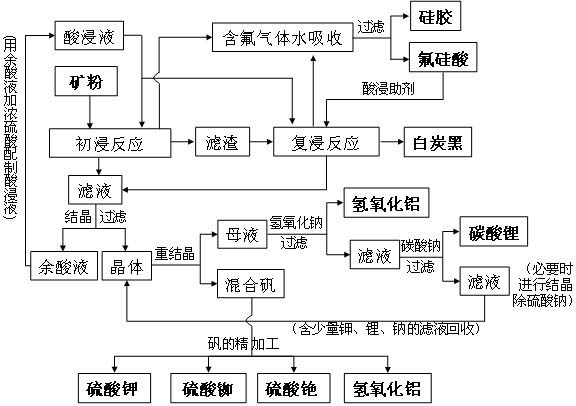

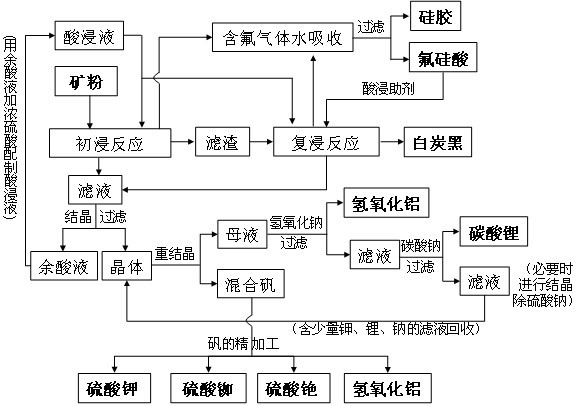

InactiveCN102649996APromote dissolutionReduce ion concentrationProcess efficiency improvementAluminium hydroxideLithium carbonate

The invention relates to a circular acid leaching extraction process for lepidolite, which comprises the following steps of: firstly, adding lepidolite mineral powder to acid leaching liquid to react; then, performing filtering separation on reaction liquid to obtain preliminarily-leached filter residues and preliminarily-leached filtrate, cooling to crystallize the preliminarily-leached filtrate, and performing the filtering separation to obtain preliminarily-leached crystals and preliminarily-leached crystal spent acid liquid; adding the preliminarily-leached filter residues to the acid leaching liquid, and then, adding a fluosilicic acid solution to react; performing the filtering separation on the reaction liquid to obtain re-leached filter residues and re-leached filtrate; cooling to crystallize the re-leached filtrate, and performing the filtering separation to obtain re-leached crystals and re-leached crystal spent acid liquid; washing the re-leached filter residues, and drying to obtain silicon dioxide of which the purity exceeds 98 percent; mixing the preliminarily-leached crystals with the re-leached crystals, dissolving by water, performing recrystallization and filtering to remove mixed alum to obtain recrystallization mother liquid; and adding sodium hydroxide to the recrystallization mother liquid to regulate the pH value to be 7-10 so as to precipitate aluminum, filtering to remove aluminum hydroxide, adding sodium carbonate to the filtrate, and filtering to obtain lithium carbonate.

Owner:张韵 +2

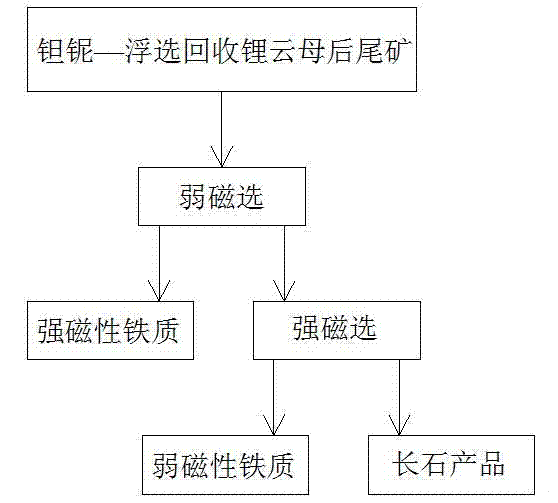

Technical method for producing high-quality feldspar from tantalum-niobium ore tailings

InactiveCN102442674AEfficient removalImprove qualityAluminium silicatesMagnetic separationNiobiumEconomic benefits

The invention discloses a technical method for producing high-quality feldspar from tantalum-niobium ore tailings. The technical method comprises the following steps: removing strong magnetic iron from tailings by performing weak magnetic separation, and then utilizing strong magnetic separation to remove weak magnetic iron, thereby obtaining a high-quality feldspar product. For an accompanying resource, namely, feldspar, in the tantalum-niobium ore, a combined technology of successively performing weak magnetic separation and strong magnetic separation for efficiently removing impurities from the tailings after recycling tantalum, niobium and lepidolite, thereby obtaining the high-quality feldspar product. The technical method has the characteristics of simple process, high environmental benefit, good economic benefit, and the like.

Owner:JIANGXI UNIV OF SCI & TECH +1

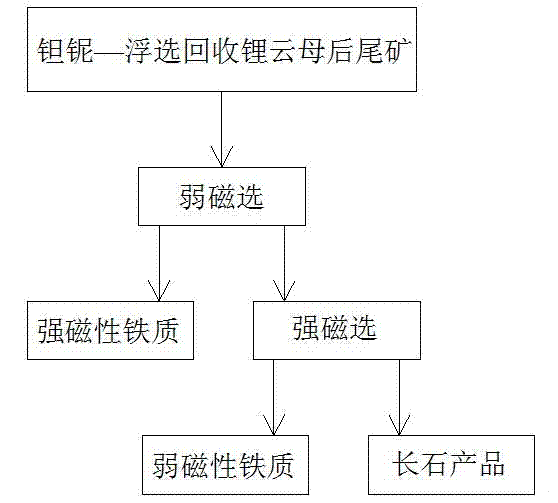

Method for extracting lithium carbonate and aluminum hydroxide through lepidolite and fly ash

ActiveCN106587116AIncrease profitImprove conversion rateAluminium compoundsLithium carbonates/bicarbonatesAluminium hydroxideLithium carbonate

The invention provides a method for extracting lithium carbonate and aluminum hydroxide through lepidolite and fly ash. The method comprises the steps of an extraction process and calcination additive obtaining. The extraction process comprises the substeps of powder sieving, mixing, prilling, calcination, soaking, alumina precipitation, separation, impurity removal, concentration, lithium precipitation, drying, crushing and the like; a calcination additive is composed of active CaCO3, Na2SO4, NaOH, CaO and the like, the calcination conversion ratio and leaching rate of Li and Al can be increased, and the comprehensive utilization rate of lithium carbonate is increased and can reach 85% or above. Accordingly, the production process is simple, free of pollution and high in comprehensive utilization rate, and the method is suitable for large-scale industrial production.

Owner:天津二八科技股份有限公司

Beneficiation method of lithium ore

ActiveCN103934112ASolve the tedious problem of beneficiation processReduce energy consumptionFlotationMining engineeringBenzotriazole

The invention discloses a beneficiation method of lithium ore. In order to resolve the problems of a beneficiation process used for recycling lithium from complex pegmatite lithium ore at present in China, a process of bulk flotation of spodumene and lepidolite is developed, benzotriazole serves as an auxiliary collector, and tall oil serves as a collector. Compared with a common process that flotation of the lepidolite is carried out firstly, and then the spodumene is selected after desliming for flotation of the complex pegmatite lithium ore at present, the beneficiation method of the lithium ore has the advantages of being simple in process, low in processing cost, high in adaptability to raw ore, more stable and controllable in process and the like, and provides a more efficient process used for recycling lithium resources from the complex pegmatite lithium ore.

Owner:HUNAN RES INST FOR NONFERROUS METALS

Light floamed ceramic building board and preparation thereof

The invention belongs to the technical field of construction materials and discloses a light foamed ceramic construction board and a production method thereof. The light foamed ceramic construction board comprises the following components according to weight percentage: fly ash: 40 to 60 percent, porcelain clay: 30 to 50 percent, expanded material: 5 to 10 percent, rhombic quartz: 0 to 5 percent, and lepidolite stone: 0 to 1 percent; the board is prepared by carrying out the following procedures to the components: crashing, prilling, pressing and moulding and calcining. The ceramic construction board takes a great amount of the fly ash as raw materials which is low in cost; in the preparation process, the raw material is finely ground and all the components are mixed evenly; then the expanding foam matrix structure is reformed by the technique of prilling with power, thus causing the product to form foam and raise toughness degree; the finished board has ceramic foam structure which is formed by even, independent and closed small holes; the size of the small holes and the density of the product can be adjusted according to special application purpose; and the board can be used in walls and grounds for noise insulation, fire proof and flotation, and the like. The finished products can be cut and processed by a saw and can be taken as a substitute of wood plates.

Owner:RUIJING INVESTMENT HLDG

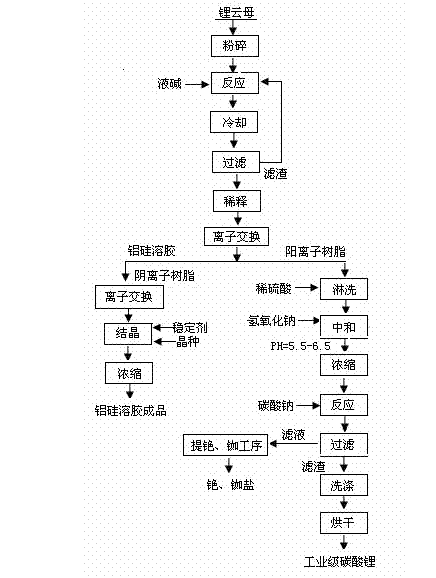

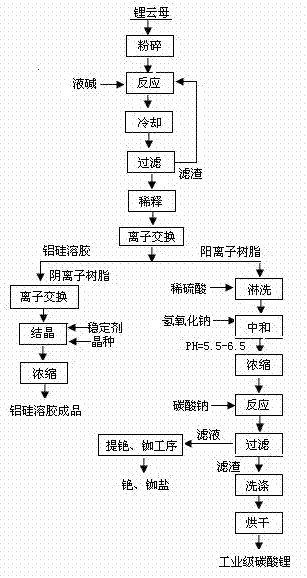

Method for extracting lithium by processing lepidolite through alkali dissolution process

InactiveCN102337399AEasy extractionWide range of usesProcess efficiency improvementPhysical chemistryIon exchange

The invention discloses a method for extracting lithium by processing lepidolite through an alkali dissolution process, which comprises the following steps of: enabling the lepidolite to react with alkali in a liquid environment so as to enable the lithium, sodium, potassium, rubidium and cesium in the lepidolite to enter a solution, diluting lepidolite powder after alkali dissolution, and further performing ion exchange to acquire cations in a system. By adopting the method, 100% of the lithium in the lepidolite can enter the solution, reaction filter slag of the lepidolite returns to the alkali dissolution process step, and the complete alkali dissolution is realized. As sodium ions, potassium ions, lithium ions, cesium ions and rubidium ions in the lepidolite are obtained through ion exchange, and the interference of silicon, aluminum, fluorine and other elements in the system is removed, the lithium ions, the cesium ions and the rubidium ions in the lepidolite are easier to be extracted. According to the method, as the reaction is performed in the alkaline liquid environment, the fluorine in the lepidolite can not generate highly-corrosive hydrofluoric acid capable of corroding equipment. A byproduct generated by the method is aluminum silicon sol with a wide range of applications, and the direct selling of the aluminum silicon sol can greatly lower the cost of lithium extraction reaction.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI

Compound clarifying agent, preparation method thereof and method for preparing E glass fiber by adopting compound clarifying agent

ActiveCN103058513ALess impuritiesExtended clarification timeGlass making apparatusGlass fiberSulfate

The invention discloses compound clarifying agent and a preparation method thereof. The compound clarifying agent is prepared by compounding 10 parts of cerium oxide, 20 parts of antimony oxide, 3 parts of lepidolite and 60 parts of calcium sulfate. The compound clarifying agent is compounded by the cerium oxide, the antimony oxide, the lepidolite and the calcium sulfate, overcomes the difficulty of high cost caused by adopting single cerium oxide, antimony oxide and lepidolite as the clarifying agent, and has low poison and better clarifying effect; the invention further discloses a method for preparing E glass fiber by adopting the compound clarifying agent; and the method uses the gradual clarifying theory of the compound clarifying agent to gradually decompose and clarify when glass is molten, so that the clarifying capacity is always in a vigorous state, and the E glass fiber with few impurities and good quality is obtained.

Owner:NEIJIANG HUAYUAN ELECTRONICS MATERIALS

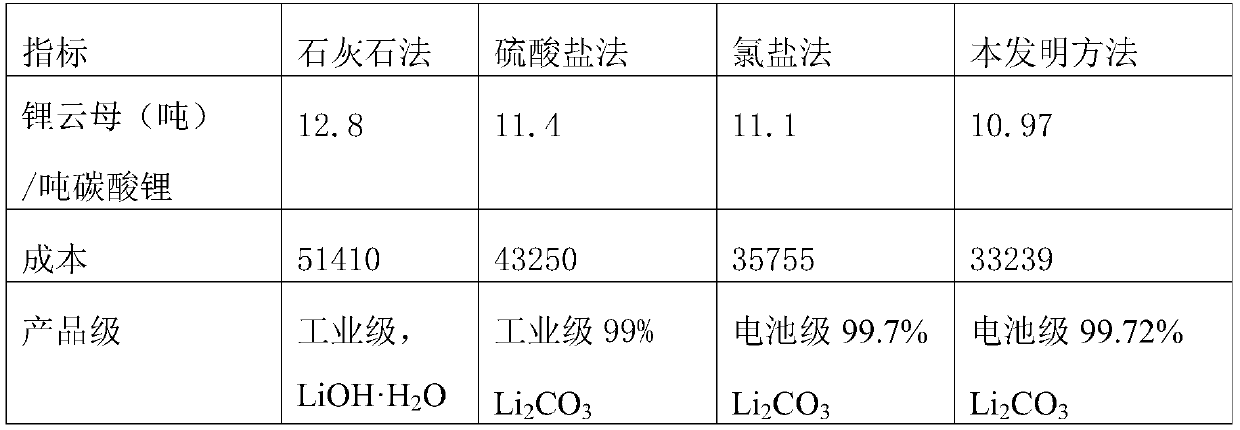

Method for one-step preparation of battery-grade lithium carbonate from lepidolite

InactiveCN110885090AReduce energy consumptionProcess stabilityLithium carbonates/bicarbonatesLithium carbonatePhysical chemistry

The invention provides a method for one-step preparation of battery-grade lithium carbonate from lepidolite. Specifically, lepidolite is adopted as the raw material to mix with auxiliary materials, the mixed raw material and auxiliary materials are subjected to roasting in a rotary kiln device so as to extract lithium, and the process include: crushing of concentrate powder for making lepidolite,mixing, roasting, leaching and extraction of lithium, impurity removal, lithium precipitation for preparation of battery-grade lithium carbonate, etc. The method directly prepares the battery-grade lithium carbonate product by precipitation without the process of producing industrial-grade lithium carbonate. And the method uses the process of extracting lithium by chlorine salt roasting, has smaller influence on the environment, improves the lithium recovery rate, is stable in process and easy to operate, and facilitates industrial production.

Owner:江西南氏锂电新材料有限公司

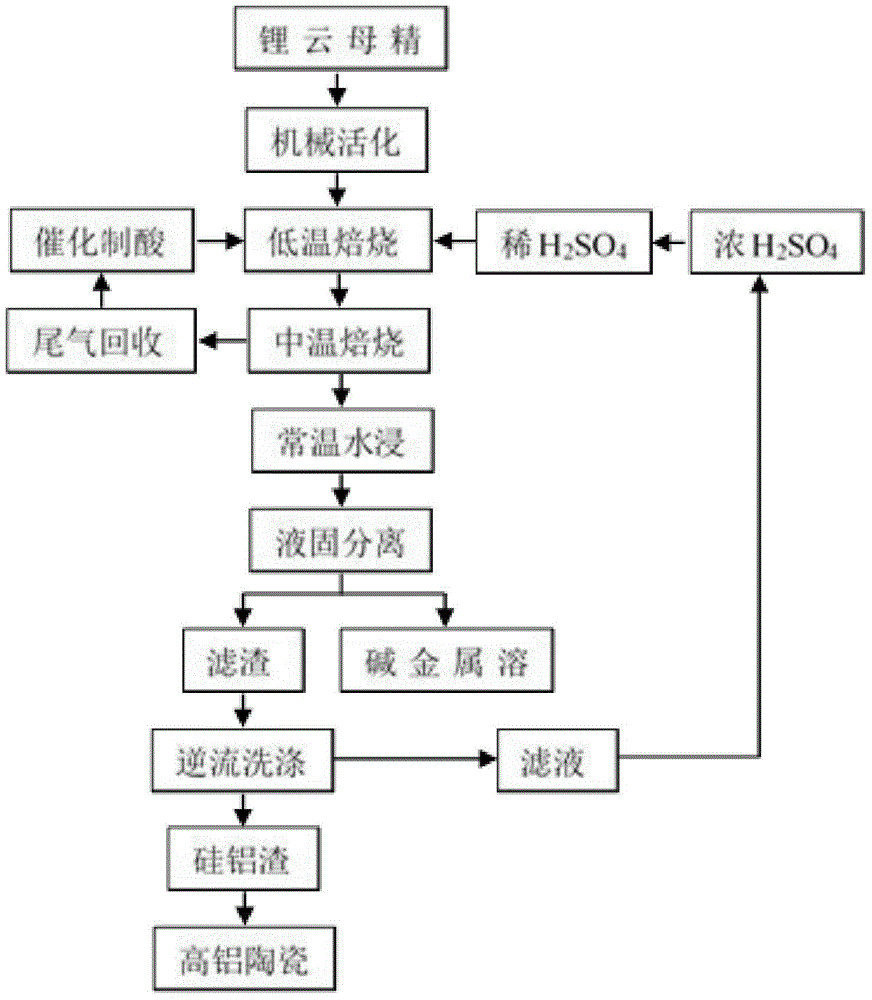

Method for extraction of lithium and removal of aluminum by vitriolization of lepidolite

ActiveCN104876250AEfficient extractionAchieve recyclingLithium carbonates/bicarbonatesAluminium oxides/hydroxidesSlagDecomposition

The invention discloses a method for extraction of lithium and removal of aluminum by vitriolization of lepidolite. The method includes a technical process: 1) mechanical activation of lepidolite; 2) low-temperature vitriolization for extraction of valuable metallic elements; 3) medium-temperature sintering; 4) tail gas recovery; 5) normal-temperature water immersion for extraction of alkali metal sulphates. Alkali metal elements and high-content aluminum in lepidolite are dissolved out and gradually heated until decomposition of aluminum salts, and calcination exhaust is recovered for acid production to realize maximized recycling of leaching agents. Calcination clinkers are subjected to water immersion for extraction of sulfate with the alkali metal elements, and high alkali metal extraction efficiency, technical simplicity, small material flow volume, low energy consumption, maximization in recycling of the leaching agents and the like are realized, so that social benefits of lepidolite are increased. After extraction of the alkali metals, high-aluminum slag can be used for preparation of ceramics, glass, environment-friendly cement, building blocks and the like to realize zero emission of exhaust gas, sewage and waste residues in treatment of lepidolite, and all procedures are in mutual synergy to jointly realize economical and efficient utilization of lepidolite.

Owner:JIANGXI HZONE LITHIUM TECH

Graphene glass and production process thereof

The invention discloses graphene glass and production process thereof. The graphene glass is prepared from the following raw materials in mass part: 100-200 parts of quartz sand, 20-30 parts of calcite, 20-50 parts of sodium carbonate, 10-15 parts of lepidolite, 30-60 parts of graphene, and 40-60 parts of color developing agent. The color developing agent is a kind of metallic oxide, and is one or multiple types from Cu2O, Co2O3, MnO2 and CdO. A finished product is obtained through the procedures of mixing, melting, molding, annealing and the like. As the hardest nano-material in the world at the present, the graphene material is added to the raw materials, so that the strength of the glass is greatly improved, and the prepared glass is harder and more wear-resistant as compared with common glass and has low possibility of breakage.

Owner:HUBEI DINGYU ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

Method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste

InactiveCN108525843AValue cost enhancementGreat benefitWet separationMechanical material recoveryNiobiumSlag

The invention discloses a method for recovering tantalum-niobium, lepidolite and feldspar powder by utilizing difficult-to-treat mine solid waste. The method is characterized in that the difficult-to-treat mine solid waste is taken as a raw material, wherein the difficult-to-treat mine solid waste is a valuable component material containing a trace of (Ta, Nb)2O5, lepidolite and feldspar, and themethod comprises the step of recovering the tantalum-niobium concentrate, the feldspar powder and the lepidolite, recovering of the tantalum-niobium concentrate is achieved though the following steps,the series-connection technology of weak magnetism, medium magnetism and strong magnetism is carried out on the difficult-to-treat mine solid waste raw material for separation of iron slag, magneticminerals and non-magnetic mineral so that the influence of iron minerals on the reselection of the tantalum-niobium ore can be eliminated, a tantalum-niobium ore waste stone raw material is obtained,the tantalum-niobium ore waste stone raw material undergoes classification by adopting a stage grinding-stage separation process method, coarse grains enter a ball mill for ore grinding, a high-frequency vibration fine sieve is adopted for carrying out intensifying classification on the fine fraction, and then the tantalum-niobium concentrate and the feldspar-lepidolite mixture with tailings beingiron-tantalum-niobium contained weak-magnetic impurities are prepared. The method has the advantages that the technology is simple, the efficiency is high, the economic and technical benefits are obvious, and the recovery rate of the tantalum-niobium and other mineral resource products is high.

Owner:江西金辉再生资源股份有限公司

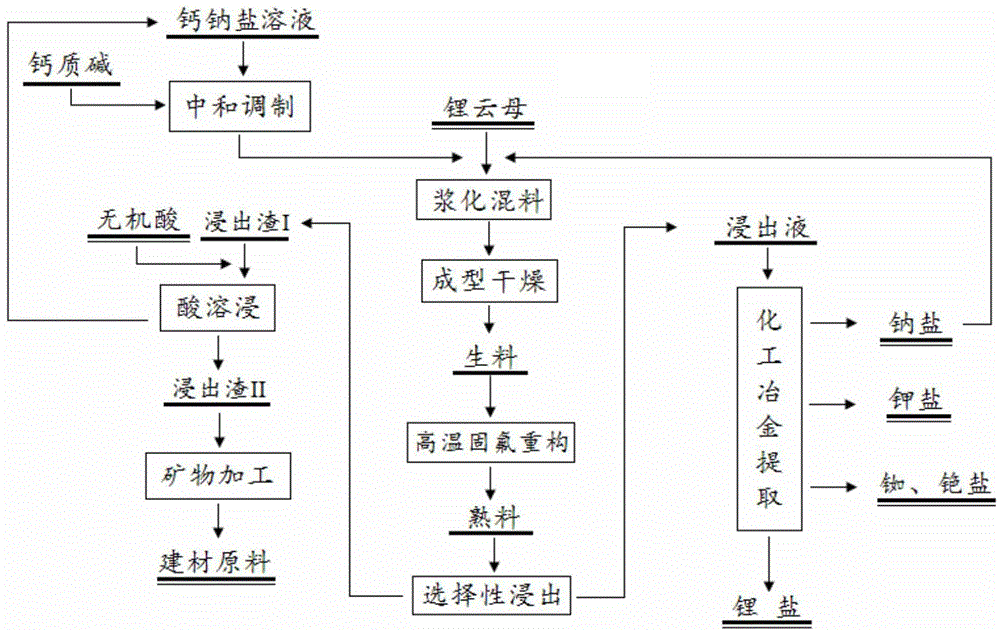

Improved method for extracting alkali metal compound from solid fluorine reconstruction lepidolite

ActiveCN104817099AEliminate the disadvantages of uneven mixingHigh activityAluminium silicatesRubidium/caesium/francium compoundsRubidiumLepidolite

The invention discloses an improved method for extracting an alkali metal compound from solid fluorine reconstruction lepidolite. According to the method, calcium salt and sodium salt liquor or suspension liquid is used as a reconstruction assistant, the assistant and the lepidolite are subjected to high-temperature heat treatment after mixing, pelleting and drying to obtain clinker, the clinker is soaked in water to obtain an alkali metal salt compound, the compound is soaked in acid after residue filtering to recycle a solid fluorine reconstruction reagent, and a high-quality silicate material is produced. The method has the advantages that comprehensive utilization of lepidolite mineral resources is achieved, recovery rate of alkali metal such as lithium, rubidium and cesium is high, cyclic utilization of the solid fluorine reconstruction reagent is achieved, raw material utilization rate is high, production cost is reduced greatly and environment protection is facilitated.

Owner:CENT SOUTH UNIV

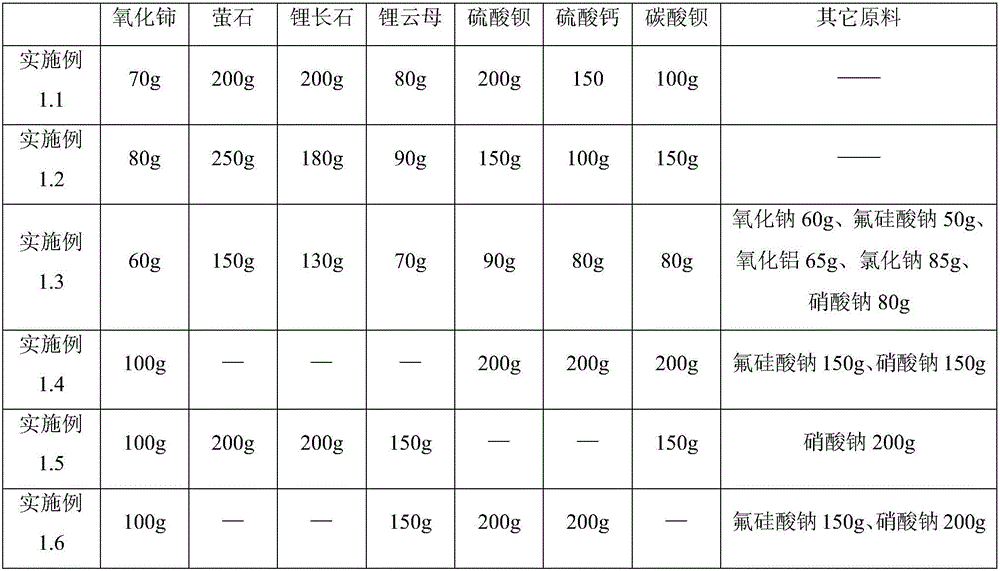

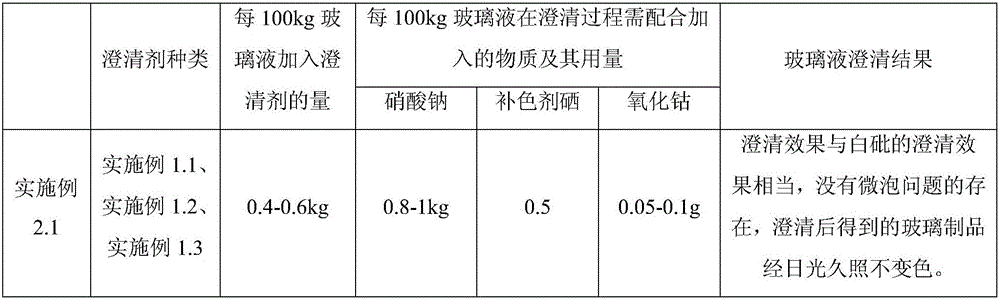

Glass clarifying agent and preparation method thereof

The invention provides a glass clarifying agent. The glass clarifying agent is prepared from components of raw materials in parts by weight as follows: 5-10 parts of cerium oxide, 10-25 parts of fluorite, 10-25 parts of lithium feldspar, 5-10 parts of lepidolite, 5-20 parts of barium sulfate, 5-15 parts of calcium sulfate and 5-15 parts of barium carbonate. The glass clarifying agent has excellent clarifying effect, can realize the clarifying effect the same as that of arsenic trioxide, can also remarkably reduce the use quantity of production raw materials introduced through matching with the clarifying agent and reduces the production cost of glass, and the comprehensive effect is better than that of arsenic trioxide; besides, the problem of glass defects caused by high probability of microbubbles on a glass panel with the adoption of a cerium oxide and sulfate composited clarifying agent is solved by means of the glass clarifying agent. The preparation method of the glass clarifying agent is simple, realizes safe production, prevents environmental pollution and is applicable to large-scale production.

Owner:郑国利

Method for extracting lithium from lepidolite concentrate

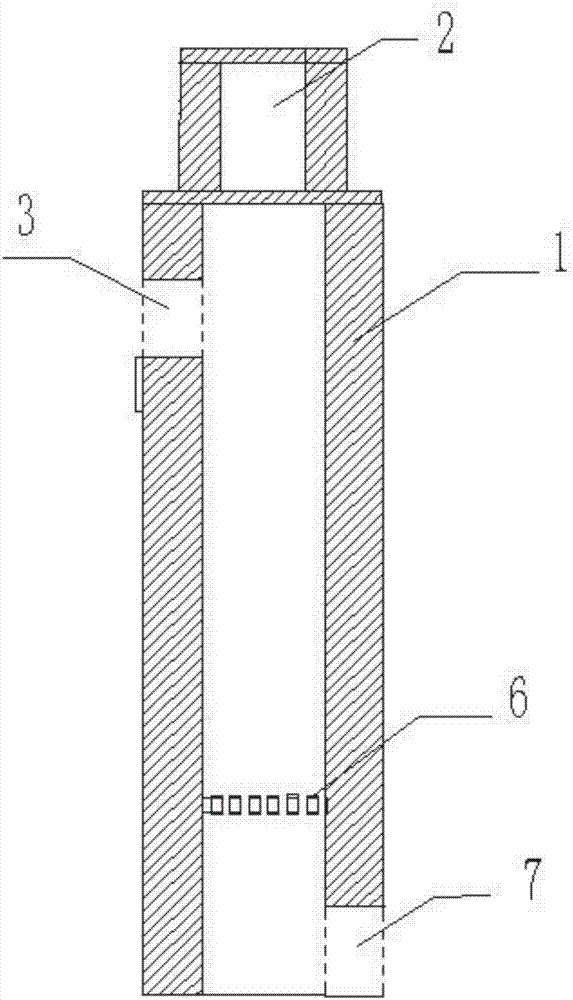

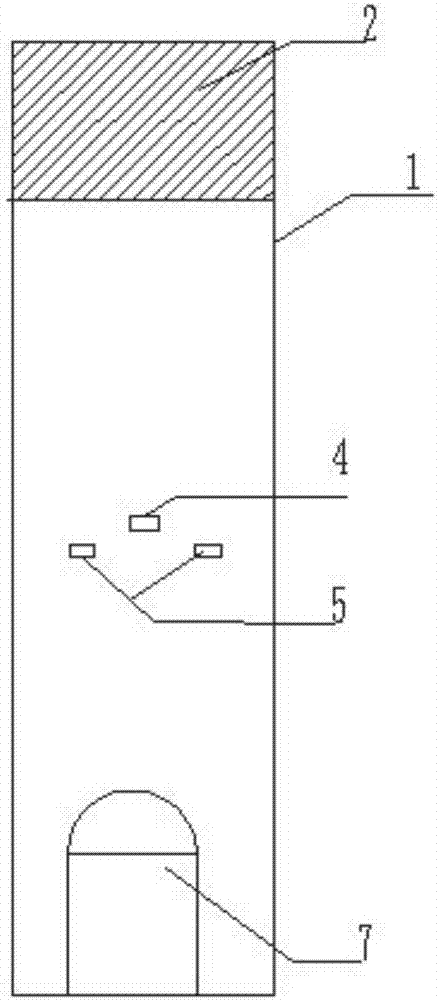

ActiveCN107032372ASolve dust returnSolve technical problems such as melting in the roasting processLithium oxides/hydroxidesLithium carbonates/bicarbonatesSlagLepidolite

The invention discloses a technology for extracting lithium hydroxide monohydrate and lithium carbonate by activating, roasting and leaching lepidolite concentrate with sulfuric acid. The technology comprises the following steps: adding water into lepidolite concentrate and calcium sulfate, barite powder or barium sulfate slag and carbon fuel, pressing and acquiring a green ball; roasting in a shaft kiln under an appropriate temperature and at appropriate time; milling the roasted ball; leaching with sulfuric acid; primarily purifying the leachate, concentrating and secondarily purifying, thereby acquiring a finished LiOH solution; secondarily crystalizing and firstly washing the finished solution with saturated solution, thereby acquiring a lithium hydroxide monohydrate product; adding sodium carbonate into lithium hydroxide monohydrate crystallization mother liquor and scrubbing solution and precipitating, thereby acquiring the lithium carbonate product. According to the technology, the lithium can be effectively separated from the lepidolite concentrate and the qualified lithium hydroxide monohydrate and lithium carbonate products can be produced. The technology has the advantages of less energy consumption, few flowing materials, low production cost, less discharge capacity, environmental protection, capability of efficiently realizing the recycling comprehensive utilization and suitability for industrial production.

Owner:谭春波

Novel method for removing fluorine by lithium carbonate prepared by utilizing tantalum-niobium tailing lepidolite

The invention discloses a novel method for removing fluorine by lithium carbonate prepared by utilizing tantalum-niobium tailing lepidolite, wherein a method for acid leaching and neutralization fluorine removal by adding dilute sulfuric acid solution in lithium carbonate raw material is adopted. The method is characterized by comprising the steps of: crushing lithium mica powder to about 200 meshes; inputting the lithium mica powder and sulfuric acid solution with concentration of 30-70% into a reaction device according to solid-liquid mass ratio of 1: 2-8 so as to carry out acid leaching and fluorine removal reaction for 3-10h at a temperature of 60-200DEG C; vacuumizing to separate generated hydrofluoric acid after the reaction so as to obtain solid-liquid mixed solution; and filtering and removing the slag to obtain mother solution I, wherein the neutralization fluorine removal comprises the step of adding calcium hydroxide after adding water equal to the separated hydrofluoric acid solution in the solid-liquid mixed solution and the pH in the solution is controlled within 9-12.

Owner:YICHUN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com