Circular acid leaching extraction process for lepidolite

An extraction process, lepidolite technology, applied in the direction of improving process efficiency, etc., can solve the problems of cumbersome operation steps, many external materials, and many by-products, and achieve the goal of improving ion exchange efficiency, improving leaching efficiency, and improving utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

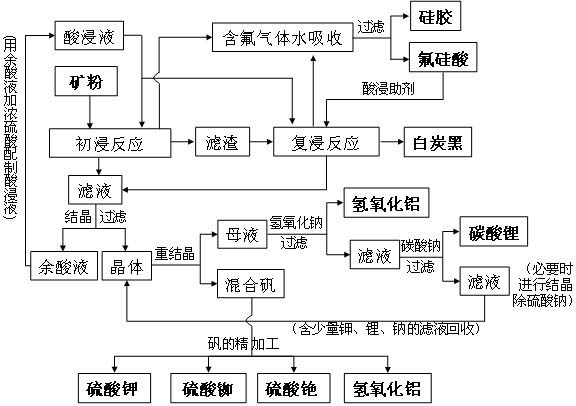

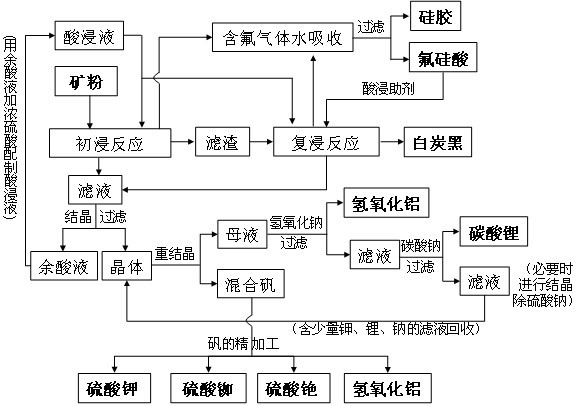

Method used

Image

Examples

Embodiment 1

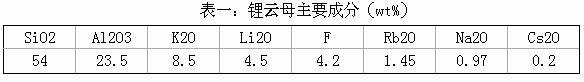

[0037] Primary leaching process: first add lepidolite ore powder with a particle size of 150 mesh into the acid leaching solution under stirring, and the mass ratio of lepidolite ore powder and acid leaching solution is 1:5. The acid leaching solution contains 30% (mass percentage concentration, the same below) sulfuric acid, which is prepared from the crystallized residual acid solution of the previous round of acid leaching, sulfuric acid with a mass percentage concentration of 98% and the initial washing liquid of the releaching filter residue washing operation. become. Then stir the reaction under normal pressure for 4 hours to carry out the initial immersion reaction, the reaction temperature is 120°C, and the fluorine-containing gas generated during the reaction is exported and absorbed by water. After the reaction is finished, the reaction solution is filtered and separated to obtain primary leaching residue and primary leaching filtrate, and then the primary leaching f...

Embodiment 2

[0042] Primary leaching process: first add lepidolite ore powder with a particle size of 200 mesh into the acid leaching solution under stirring, the mass ratio of lepidolite ore powder and acid leaching solution is 1:4. The acid leaching solution contains 40% sulfuric acid, which is prepared from the crystallized residual acid solution of the previous round of acid leaching, sulfuric acid with a mass percentage concentration of 98% and the initial washing solution of the releaching filter residue water washing operation. Then stir the reaction under normal pressure for 3 hours to carry out the initial immersion reaction, the reaction temperature is 110°C, and the fluorine-containing gas generated during the reaction is exported and absorbed by water. After the reaction is finished, the reaction solution is filtered and separated to obtain primary leaching residue and primary leaching filtrate, and then the primary leaching filtrate is sequentially subjected to cooling crystall...

Embodiment 3

[0047] Primary leaching process: first add lepidolite ore powder with a particle size of 250 mesh into the acid leaching solution under stirring, the mass ratio of lepidolite ore powder and acid leaching solution is 1:3. The acid leaching solution contains 35% sulfuric acid, which is prepared from the crystallized remaining acid solution of the previous round of acid leaching, sulfuric acid with a mass percentage concentration of 98% and the initial washing solution of the releaching filter residue water washing operation. Then stir the reaction under normal pressure for 2 hours to carry out the initial immersion reaction, the reaction temperature is 100°C, and the fluorine-containing gas generated during the reaction is exported and absorbed by water. After the reaction, the reaction solution is filtered and separated to obtain the primary leaching residue and primary leaching filtrate, and then the primary leaching filtrate is sequentially subjected to cooling crystallization...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com