Method for extracting lithium carbonate and aluminum hydroxide through lepidolite and fly ash

A technology of fly ash and lepidolite, applied in chemical instruments and methods, lithium carbonate;/acid carbonate, inorganic chemistry, etc., can solve the problems of low yield, waste of mineral resources, secondary pollution, etc. Achieve high comprehensive utilization rate, simple production process, and improve the effect of comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

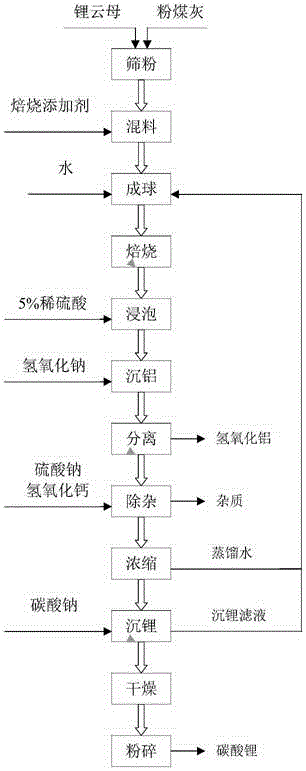

Image

Examples

Embodiment Construction

[0026] The invention can greatly improve the comprehensive extraction rate of lepidolite, which can reach more than 85%, and the product can meet the quality requirement of battery-grade lithium carbonate at one time. The following is illustrated with specific examples:

[0027] 1. Sieve powder: Use 80-mesh iron sieve to sieve lepidolite and fly ash respectively. If there are large particles, crush the large particles and sieve to obtain lepidolite powder and fly ash that meet the requirements.

[0028] 2. Mixing: Mix the sieved lepidolite, fly ash, and roasting additives according to the mass ratio of 1:0.2:0.2, and stir evenly.

[0029] 3. Forming balls: Stir the mixture with water to form balls with a diameter of about 10mm.

[0030] 4. Roasting: put the pellets into a roasting kiln for roasting, the roasting temperature is 920°C, and the roasting time is 30 minutes.

[0031] 5. Soaking: After the roasted ore balls leave the kiln to cool, soak them with 5% sulfuric acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com