Production method for preferably selecting lepidolite from tantalum and niobium ores

A production method and technology of lepidolite, which are applied in flotation, solid separation and other directions, can solve the problems of low recovery rate of lepidolite, affecting the beneficiation benefit, etc., and achieve significant economic and social benefits, easy operation, and unique process effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

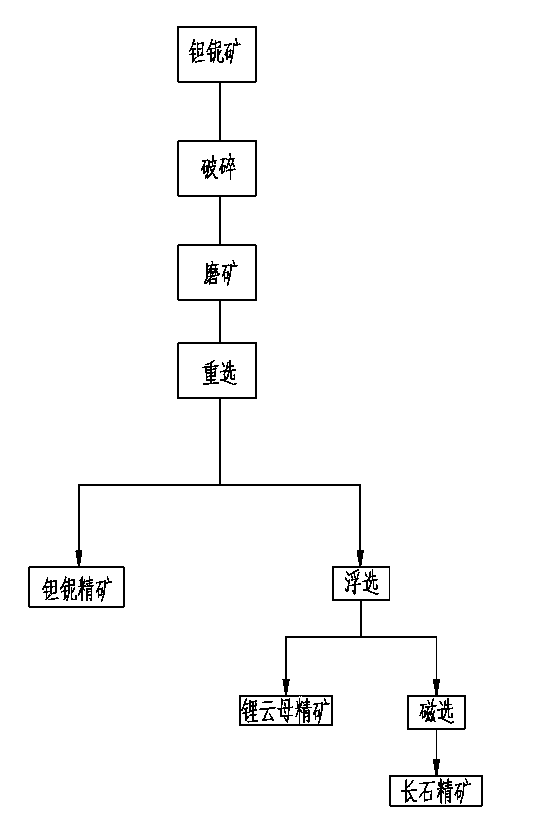

Image

Examples

Embodiment Construction

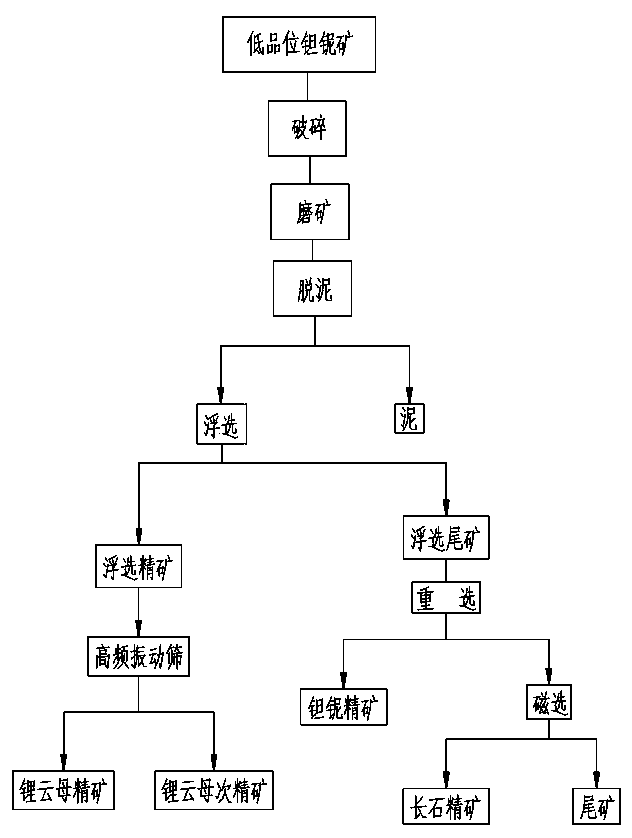

[0017] Apply the present invention to the production method of preferred lepidolite from tantalum-niobium ore in Jinhui mining industry, comprise following processing steps (see figure 2 ): ⑴Crush the tantalum-niobium ore; ⑵Add the crushed ore to the water ball mill, crushed ore: water=65:35, and make the pulp with a fineness of -200 mesh accounting for 50%; ⑶Desliming, using a hydrocyclone, Remove the slime in the pulp; ⑷Flotation; ⑸The flotation concentrate is sent to a high-frequency vibrating screen for screening, and the product on the sieve is lepidolite concentrate, and the product under the sieve is lepidolite secondary concentrate; ⑹Flotation Tailings are re-selected to obtain tantalum-niobium concentrate; (7) Gravity-selected tailings are subjected to magnetic separation to obtain feldspar concentrate.

[0018] The crushing in the above step (1) is to choose a jaw crusher or a roller crusher.

[0019] The above step (4) flotation includes a roughing, a sweeping, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com