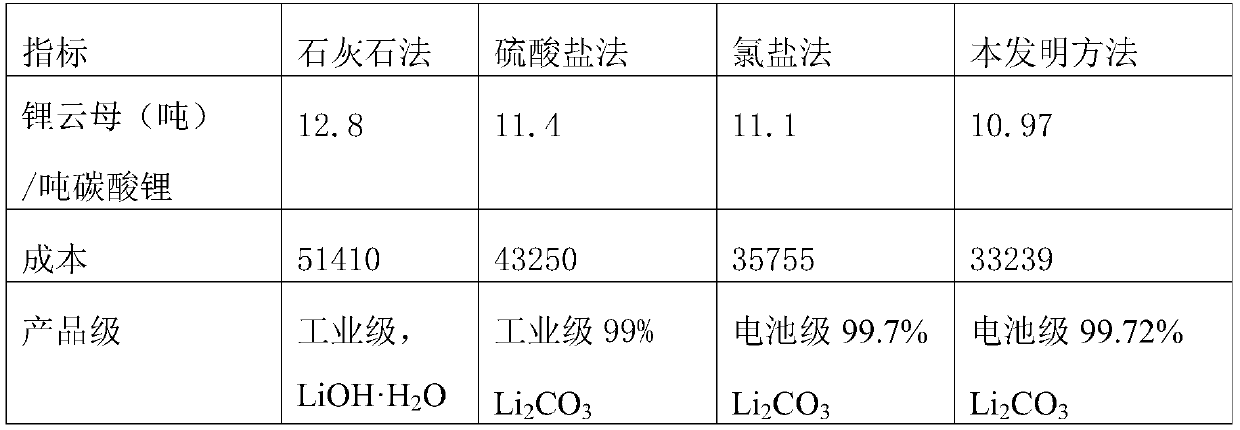

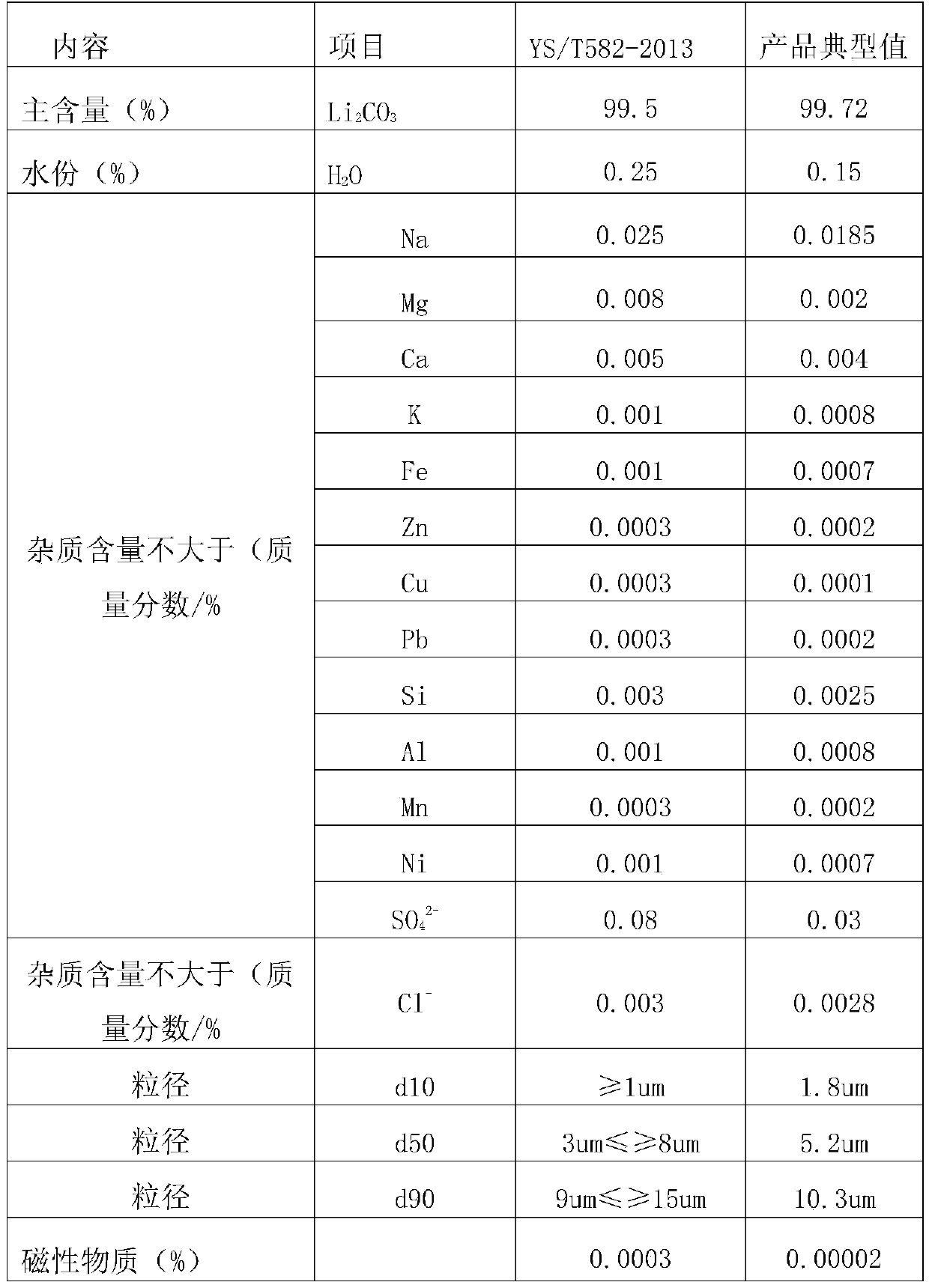

Method for one-step preparation of battery-grade lithium carbonate from lepidolite

A lepidolite, battery-grade technology, applied in the direction of lithium carbonate;/acid carbonate, etc., to achieve the effect of low production cost, stable process and improved recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Get its main chemical composition of the lepidolite raw material that Yichun tantalum niobium lithium ore produces as following table (wt%) surplus is fluorine,

[0043] Li 2 o

K 2 o

Na 2 o

AL 2 o 3

SiO 2

Fe 2 o 3

Rb 2 o

Cs 2 o

4.32 7.51 0.46 23.8 54.32% 0.38 1.66 0.28

[0044] 1) To make lepidolite concentrate powder by crushing, crush the above-mentioned lepidolite raw materials through a crushing device, then pass through a high-gradient magnetic separator to remove weak magnetic iron minerals, and pass through a sieve of more than 100 mesh to obtain lepidolite concentrate pink;

[0045] 2), mix the ingredients, fully mix the lepidolite concentrate powder and compound salt potassium sulfate and sodium sulfate, control the addition of potassium sulfate and sodium sulfate to be 45% of the lepidolite concentrate powder quality, the ratio of potassium sulfate and sodium sulfate is different Accou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com