Novel lepidolite flotation method

A lepidolite, a new type of technology, applied in the field of lepidolite flotation, can solve the problems of complex process, difficult to work, and difficult to work in the beneficiation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

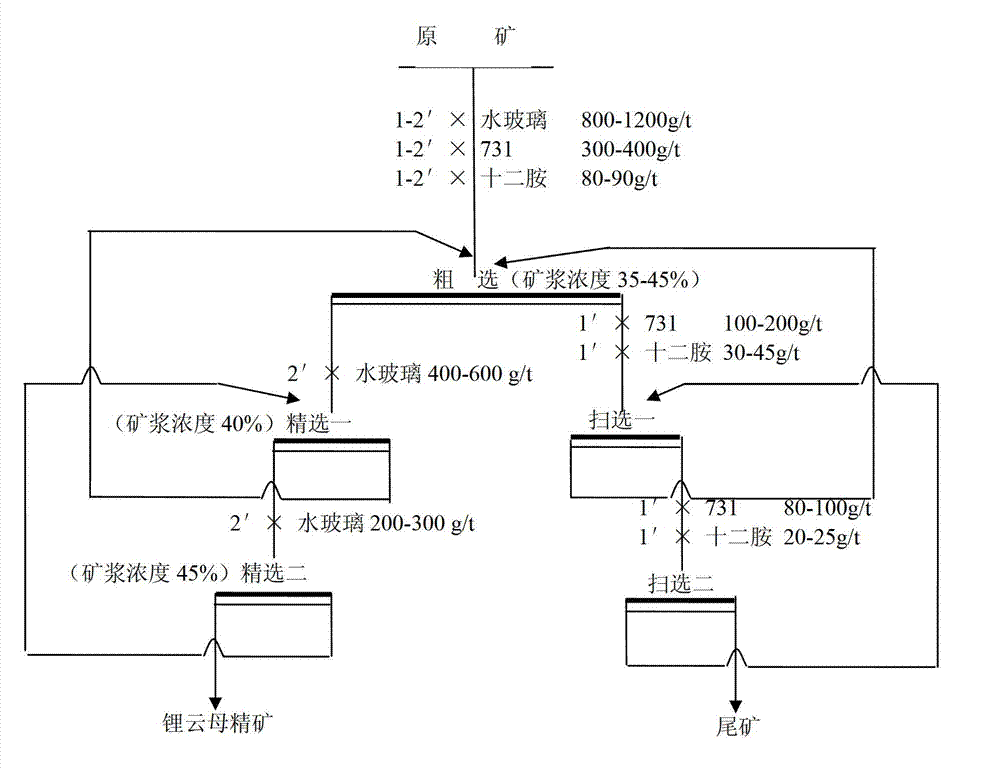

[0023] Such as figure 1 As shown, the novel lepidolite flotation method of the present invention mainly comprises a rough selection, secondary selection and secondary sweeping, specifically as follows:

[0024] 1) A rough selection

[0025] 1.1 Flotate the raw ore with a mechanical flotation machine, add 800-1200g / t of water glass, and stir for 1-2 minutes;

[0026] 1.2 Add 300-400g / t anion collector and stir for 1-2 minutes;

[0027] 1.3 Continue to add 80-90g / t cationic collector and stir for 1-2 minutes;

[0028] 1.4 After stirring fully, start air flotation scraping, and scrape for 2-3 minutes to get lepidolite roughing concentrate, and the product in the tank is the ore of sweeping one;

[0029] 2) Rough selection of lepidolite concentrate

[0030] 2.1 Selection 1: send the roughing concentrate to the selection 1 flotation machine, stir fully, add 400-600g / t water glass and stir for 2 minutes, and perform the first selection to obtain the foam product of selection 1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com