Lepidolite floatation method

A lepidolite and flotation technology, applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problems of sticky foam, affecting the process, and increasing the cost of chemicals, so that the foam is brittle and does not burst Viscosity, simple reagent preparation, and high flotation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

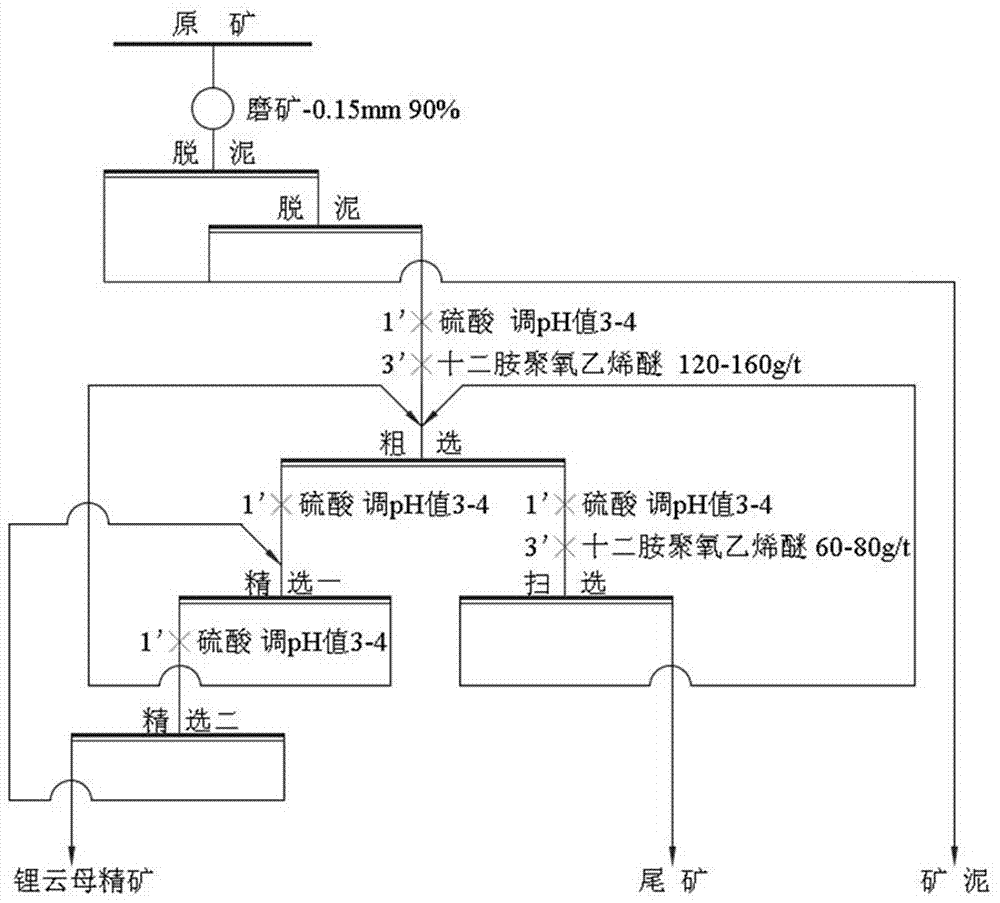

Method used

Image

Examples

Embodiment 1

[0024] According to the above-mentioned lepidolite flotation method of the present invention, it is tried out in Jiangxi Yichun lepidolite ore, the Li of this ore 2 The O content is 0.66%. The sample is first broken-ball milled until 90% of the sample is less than 0.15mm, and then the finely ground slurry is poured into the flotation tank for desliming, and then the flotation test is carried out:

[0025] 1) Second desliming: The raw ore is deslimed for the first time by using a cyclone, and the first deslimed product is deslimed by a hydraulic classifier for the second desliming. After the second desliming, the slime yield reaches 17 -19%, become the ore for roughing;

[0026] 2) Preparation of dodecylamine polyoxyethylene ether solution: Dissolve dodecylamine polyoxyethylene ether with glacial acetic acid and dilute it with water; Amine polyoxyethylene ether accounts for 0.5-2%, glacial acetic acid accounts for 1-3%, and the rest is water. In this embodiment, dodecylamine...

Embodiment 2

[0032] This embodiment is still a test done with the method of the present invention. Compared with Embodiment 1, the process parameters of this embodiment have been adjusted, which is specifically shown in step 3) adjusting the pH of the pulp to 4 in a rough selection to prepare dodecylamine polyoxyethylene The ether solution is prepared by adding 160g / t dodecylamine polyoxyethylene ether per ton of flotation raw ore; the pH of the pulp is adjusted to 4 in step 4); Dodecylamine polyoxyethylene ether solution is prepared by adding 80g / t dodecylamine polyoxyethylene ether per ton of flotation raw ore.

[0033] After the above flotation process was carried out six times, the quality and grade of the flotation concentrate and flotation tailings obtained in each test were basically unchanged, and the stabilized concentrate and tailings were sampled and analyzed. The flotation results show that the Li2O grade in the flotation concentrate is 3.07%, the enrichment ratio is 4.65, the ...

Embodiment 3

[0035] This embodiment is a test of lepidolite ore flotation with the prior art, wherein the collector dodecylamine solution is a collector commonly used in the prior art. After the flotation process was performed six times, the quality and grade of the flotation concentrate and flotation tailings obtained in each test were basically unchanged, and the stabilized concentrate and tailings were sampled and analyzed.

[0036] The flotation results show that the Li2O grade in the flotation concentrate reaches 2.93%, the enrichment ratio reaches 4.44, the concentrate yield is 13.72%, and the recovery rate of Li2O in the raw ore is 60.29%; the Li2O content in the flotation tailings is 0.27% %, the tailings yield was 69.09%, and the lithium recovery rate was 27.98%.

[0037] Compared with the flotation result of prior art embodiment 3, the flotation results of Examples 1 and 2 can be seen: the flotation method of the present invention has high flotation efficiency, and in the obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com