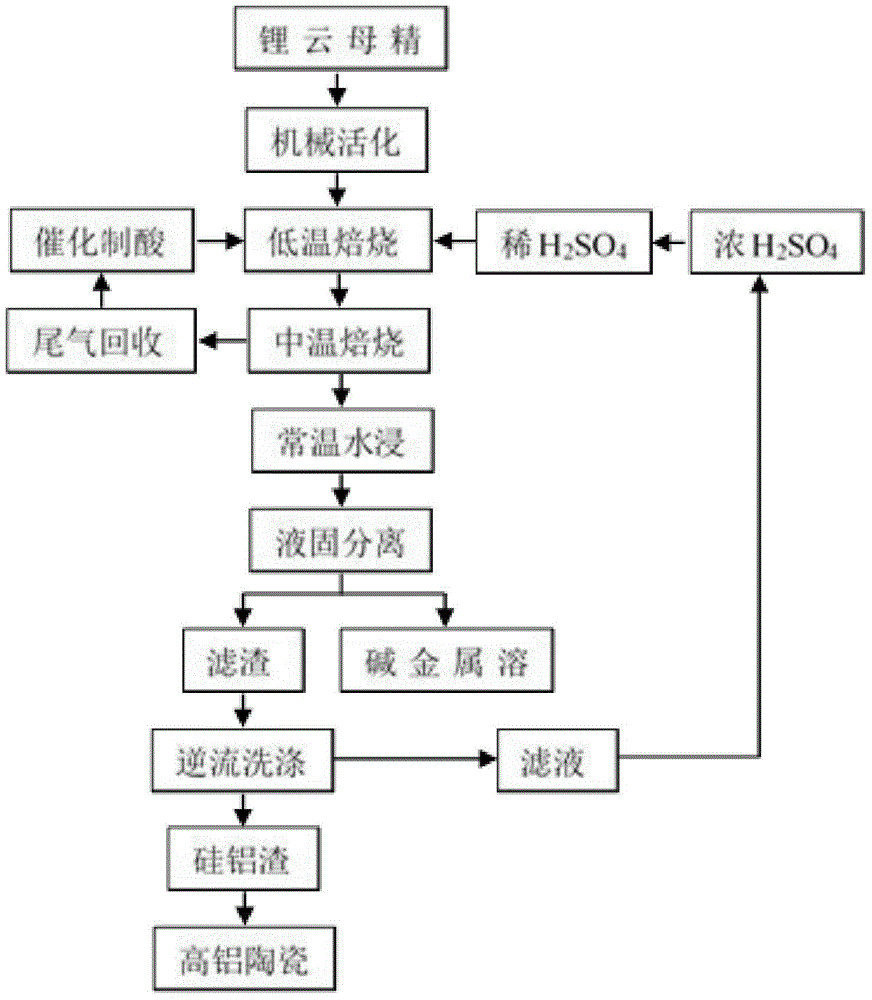

Method for extraction of lithium and removal of aluminum by vitriolization of lepidolite

A technology of sulfuric acid treatment and lepidolite, which is applied in the direction of alumina/aluminum hydroxide, lithium carbonate; Fully utilized, low extraction rate of alkali metals, etc., to achieve high extraction efficiency of alkali metals, realize zero pollution tail gas emissions, and simplify the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

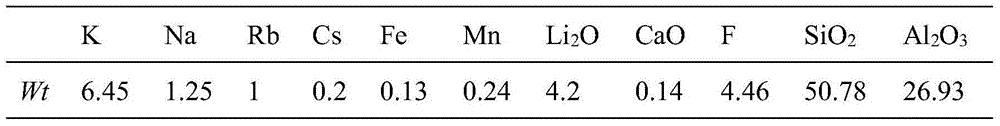

[0032] The raw material lepidolite concentrate used in the present invention is dried by a spiral dryer, the heat source is provided by the residual heat attached to the tail gas of the medium-temperature sintering process section, and the lepidolite powder is mechanically activated until the particle size of the lepidolite powder is below 300 mesh. Then mix with dilute sulfuric acid solution to granulate, control the concentration of sulfuric acid to 60wt.%, control dilute sulfuric acid and lepidolite to mix at a mass ratio of 2:1, and continuously treat in a roller kiln at 250°C for 30min. After the reaction is complete, the temperature is gradually raised to 900°C for 30 minutes, and the tail gas is recovered during the heat treatment to prepare sulfuric acid. The obtained clinker is leached with lithium sinking mother liquor, the liquid-solid ratio is controlled to be 2:1, and the reaction is carried out at 25°C for 30 minutes. The slurry is filtered by belt, which integrat...

specific Embodiment 2

[0033]The raw material lepidolite concentrate used in the present invention is dried by a spiral dryer, the heat source is provided by the residual heat attached to the tail gas of the medium-temperature sintering process section, and the lepidolite powder is mechanically activated until the particle size of the lepidolite powder is below 300 mesh. Then mix it with dilute sulfuric acid solution to granulate, control the concentration of sulfuric acid to 65wt.%, control dilute sulfuric acid and lepidolite to mix at a mass ratio of 2.5:1, and continue to treat it in a roller kiln at 200°C for 20min. After the reaction is complete, the temperature is gradually raised to 900°C for 60 minutes, and the tail gas is recovered during the heat treatment to prepare sulfuric acid. The obtained clinker is leached with lithium sinking mother liquor, the liquid-solid ratio is controlled at 2.5:1, and the reaction is carried out at 75°C for 30 minutes. The slurry is filtered by a belt, which i...

specific Embodiment 3

[0034] The raw material lepidolite concentrate used in the present invention is dried by a spiral dryer, the heat source is provided by the residual heat attached to the tail gas of the medium-temperature sintering process section, and the lepidolite powder is mechanically activated until the particle size of the lepidolite powder is below 300 mesh. Then mix with dilute sulfuric acid solution to granulate, control the concentration of sulfuric acid to 60wt.%, control dilute sulfuric acid: mix according to the mass of 2.5:1, and continuously treat in the roller kiln at 220°C for 20min. After the reaction is complete, the temperature is gradually raised to 800°C and the reducing gas CO is introduced to promote the decomposition of aluminum sulfate into Al 2 o 3 , keep the temperature for 30 minutes, and recover the tail gas to prepare sulfuric acid during the heat treatment process. The obtained clinker is leached with lithium sinking mother liquor, the liquid-solid ratio is co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com