Patents

Literature

118results about How to "Great benefit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

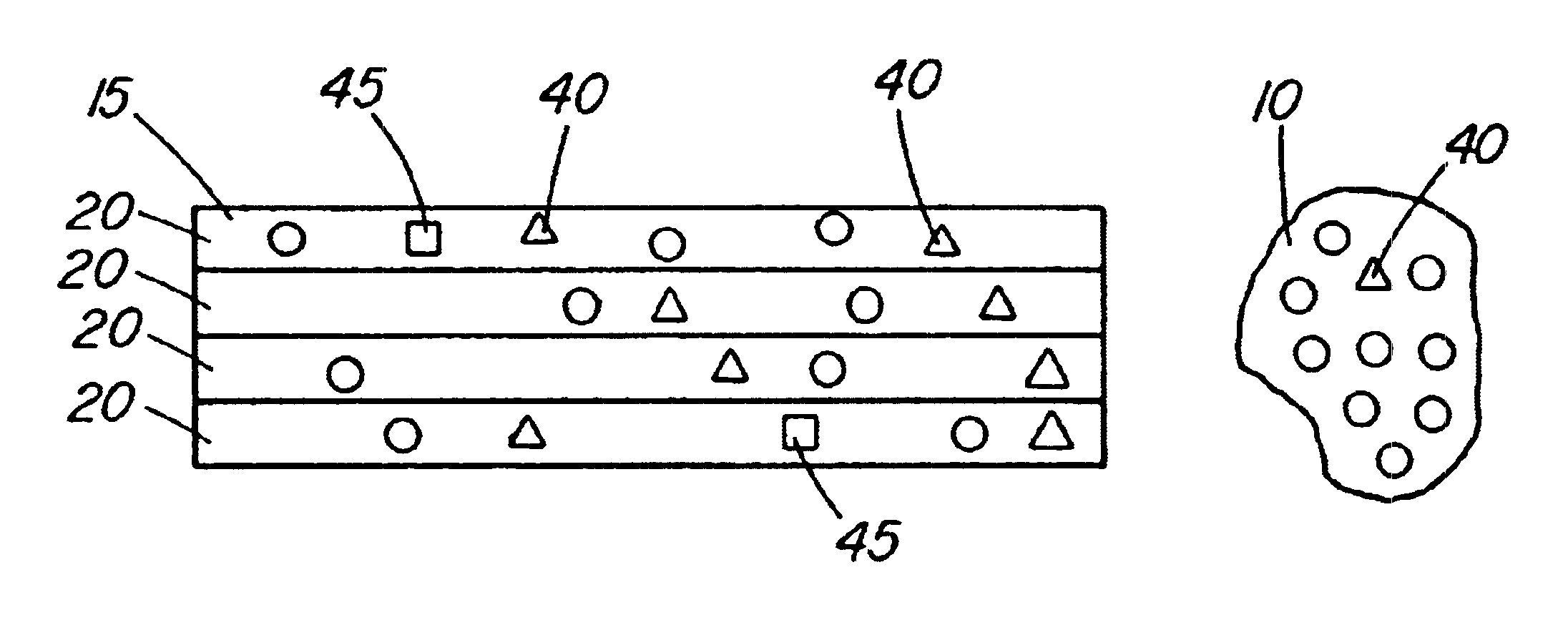

Multi-formed collagenous biomaterial medical device

InactiveUS6666892B2Great benefitFavorable immune responseStentsSurgical adhesivesBiomedical engineeringMedical device

Owner:COOK BIOTECH

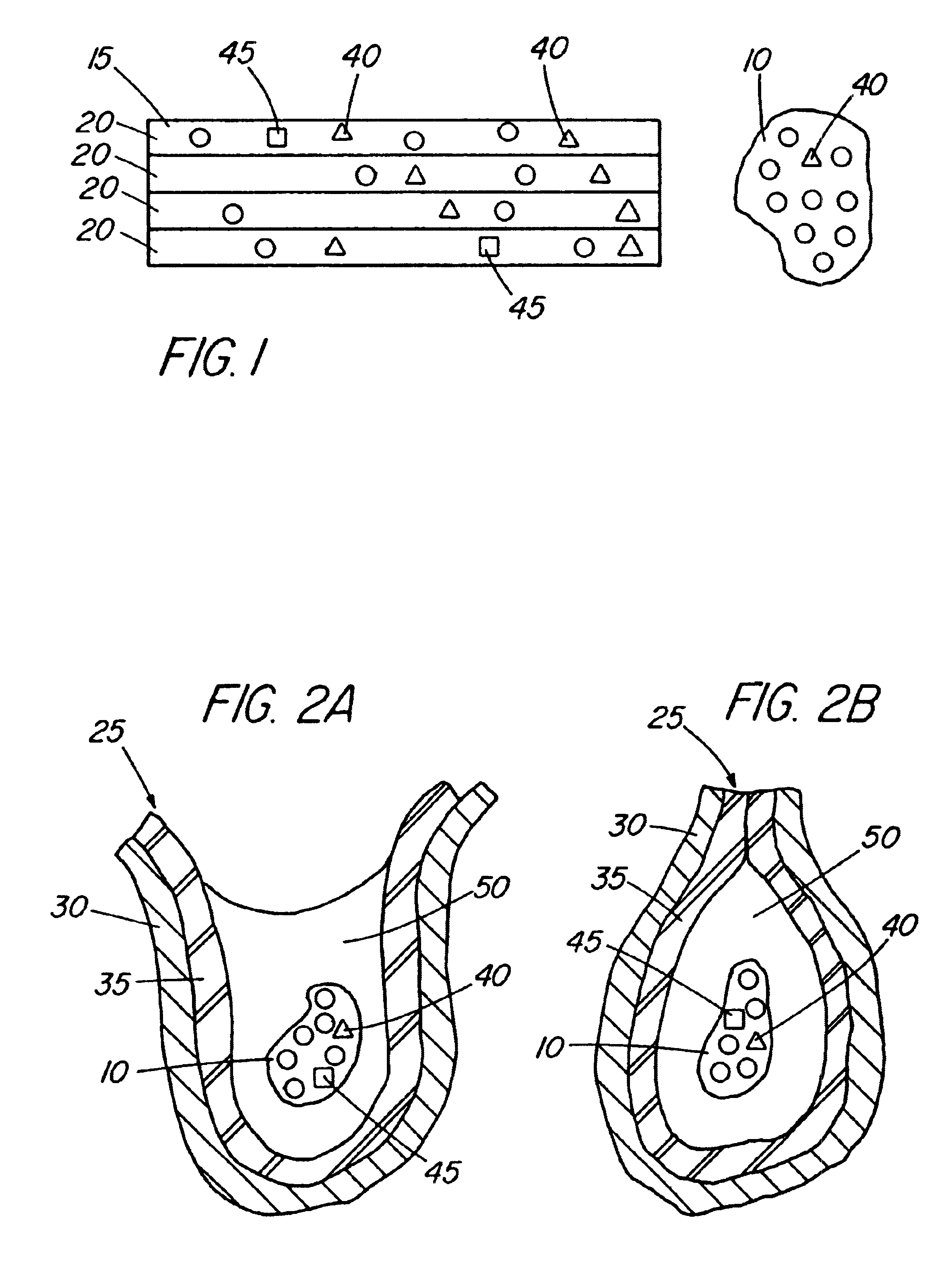

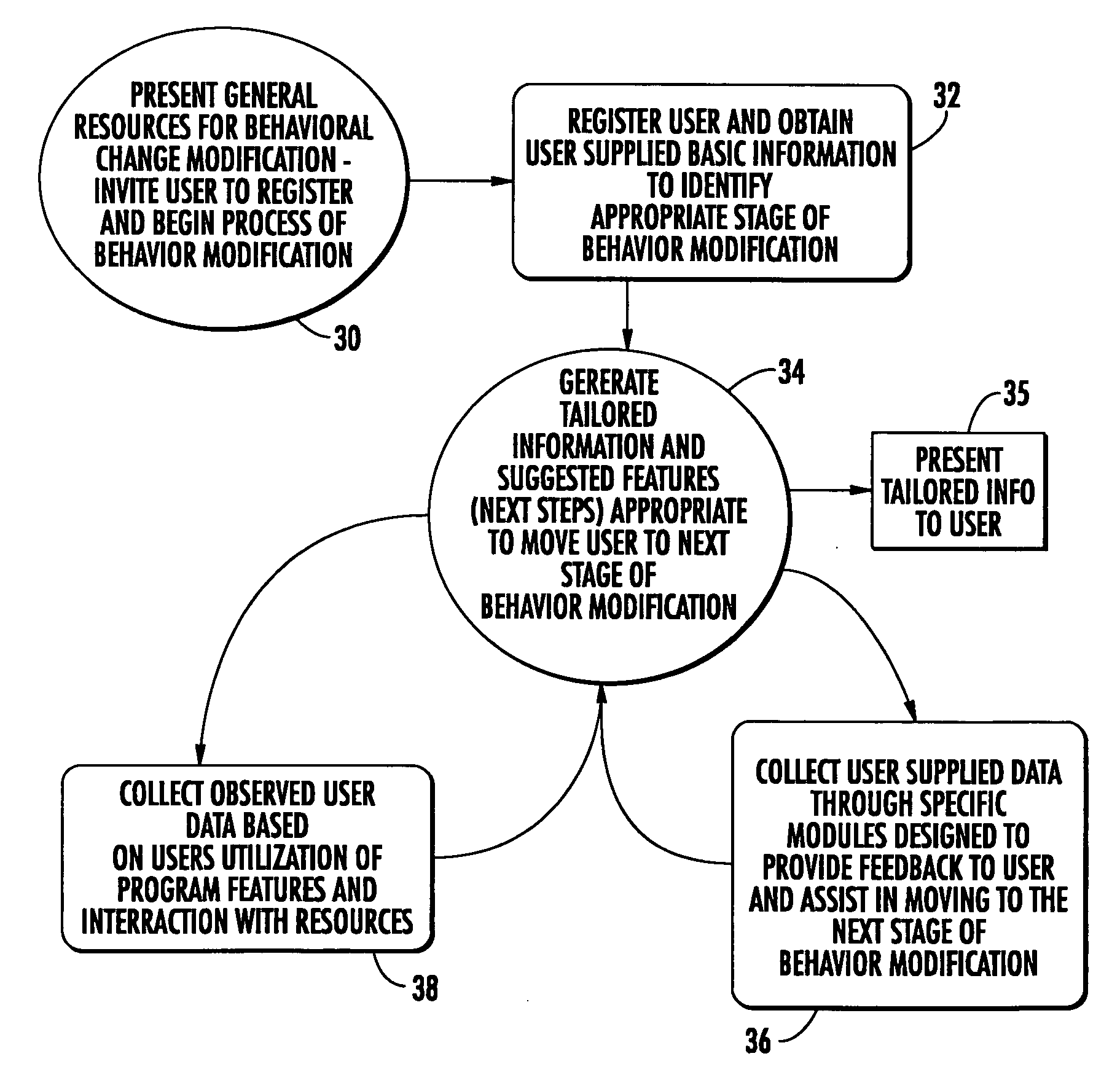

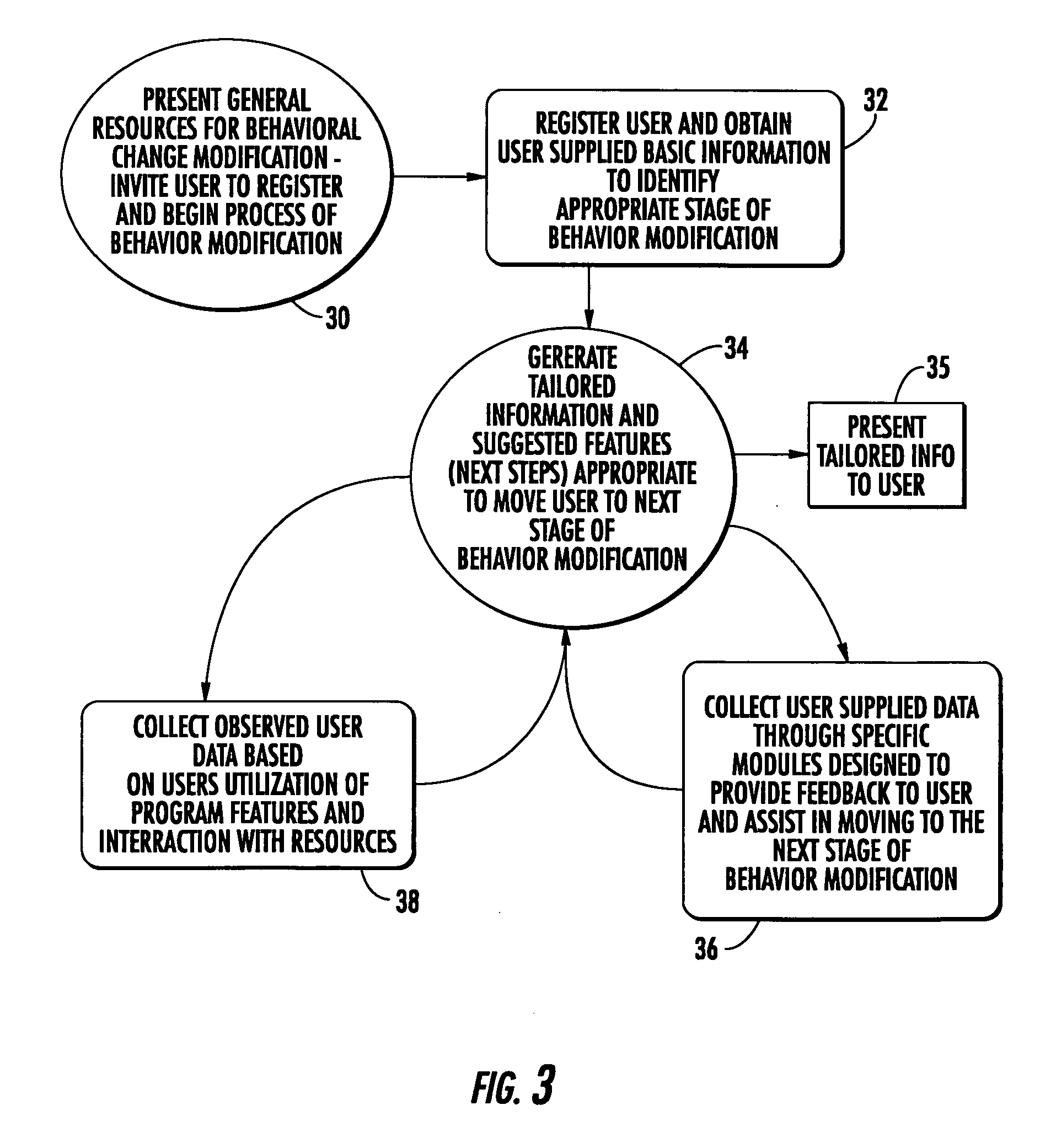

Method and system for delivering behavior modification information over a network

InactiveUS20070168501A1Great benefitEfficient combinationDrug and medicationsDigital computer detailsInformation deliveryBehavior modification

This invention features a method of delivering information over one or more information delivery networks, the method including: monitoring the actions of a user on the one or more networks to obtain observed user data relating to a desired behavior modification; obtaining user supplied data relating to the desired behavior modification; evaluating the observed user data and the use supplied data to generate tailored information for progressing a user towards the desired behavior modification; presenting the tailored information to the user over at least one of the networks; and repeating steps a), b), c) and d) until the desired behavior modification is achieved. The user is continually provided with re-tailored information resulting from an iterative process of obtaining and evaluating data that progresses the user towards a desired behavior modification. The desired behavior modification can be, for example, the cessation of smoking.

Owner:COBB NATHAN KNIGHT +5

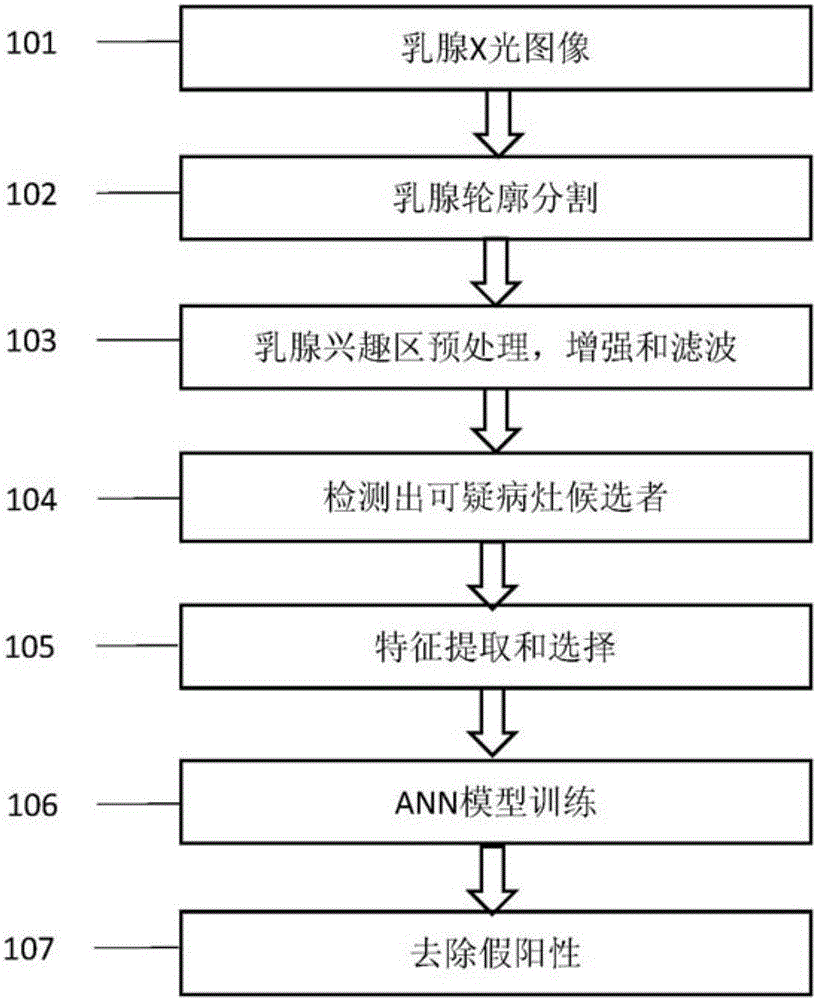

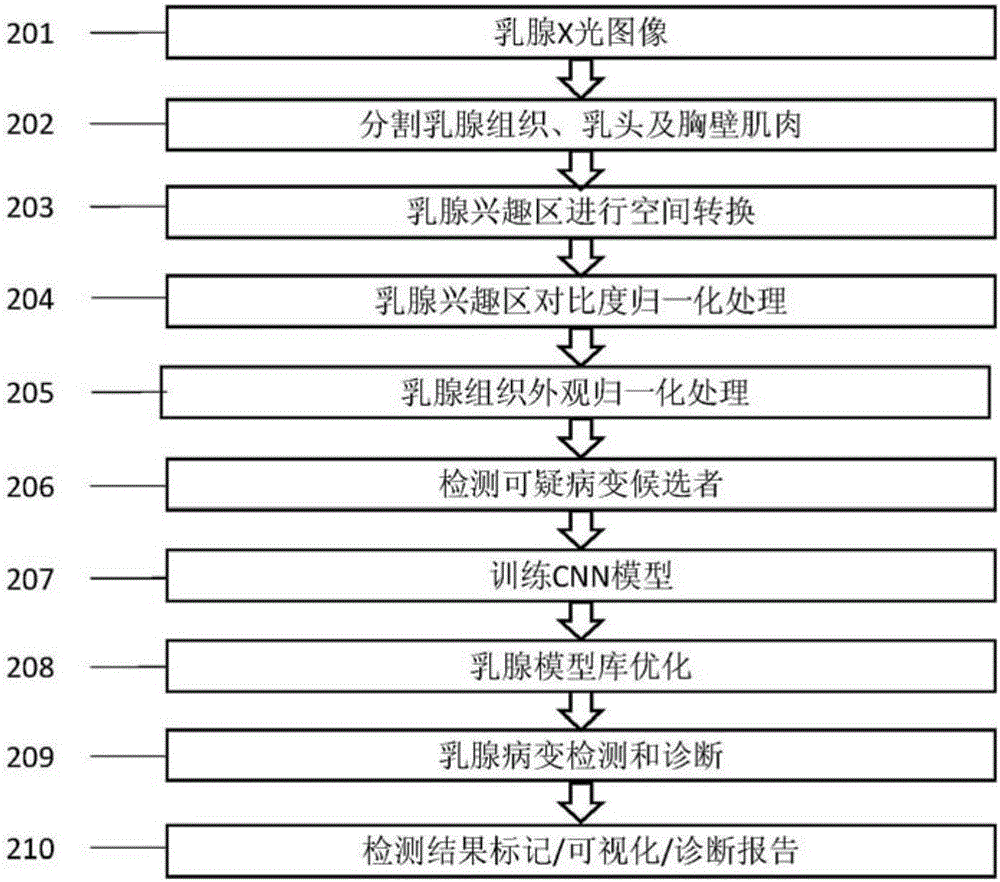

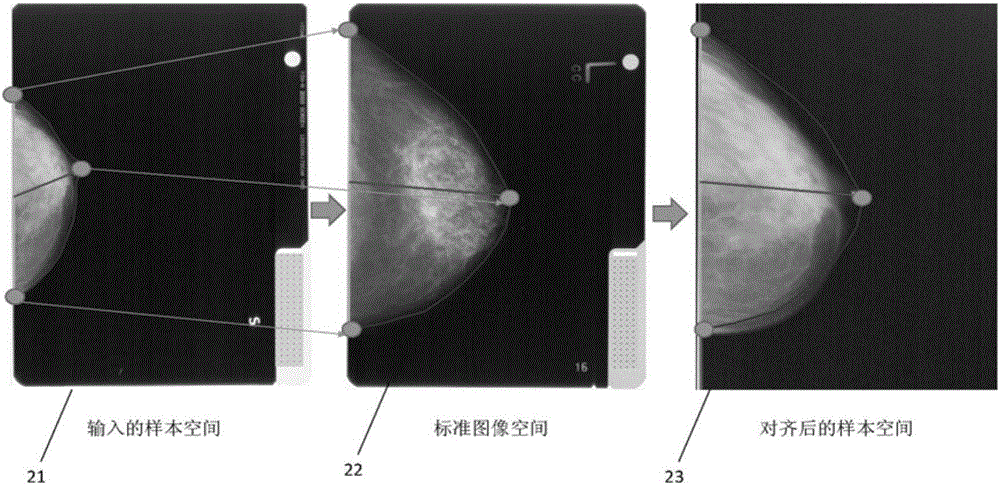

System and method for automatically detecting lesions in medical image through multi-model fusion

ActiveCN106682435AReduce false positivesImprove performanceMedical data miningMedical automated diagnosisPattern recognitionX ray image

The invention discloses a system and method for automatically detecting lesions in a medical image through multi-model fusion; the method comprises using single or fused detection models including deep learning technology to analyze and detect suspicious lesions in the medical image, such as a breast X-ray image. By using the system and method, lesion characteristics can be automatically extracted; the system and method are suitable for detecting or marking one or more types of lesions.

Owner:周明

Chinese medicinal herb additive for promoting the growth of piglet and application thereof

InactiveCN101579043AImprove disease resistanceDisease resistance shortenedFood processingAnimal feeding stuffDiseaseSide effect

The invention discloses a Chinese medicinal herb additive for promoting the growth of a piglet and the application thereof; wherein the additive comprises the following components: officinal magnolia bark, bitter orange, Chinese pulsatilla root, medicated leaven, rhizoma discoreae, sepium, dangshen, polygonummultiflorum thunb, hawthorn, rhizoma atractylodis, dried orange peel, milk veteh, malt, the rhizome of large-headed atractylodes, and wild jujube. According to the physiological function of the piglet, all components with the pertinence are compatible with each other, make good for deficiency, are cooperated with each other and mixed in a matching way. Proved by experiments, the additive has the functions of invigorating the stomach, helping digestion, promoting blood circulation, removing blood stasis, calming the nerves, tranquilizing, and increasing immunity, can prevent disease, treat an illness, help the growth, increase the disease resistance of the piglet, does not have any side effect and harmful substance to be remained; only about 20% of dosage of the additive can play greater function; the additive does not harm the digestive system of the piglet and other physiological functions and is beneficial for the growth of the piglet and the strengthen of disease-resistance capability.

Owner:邹振可

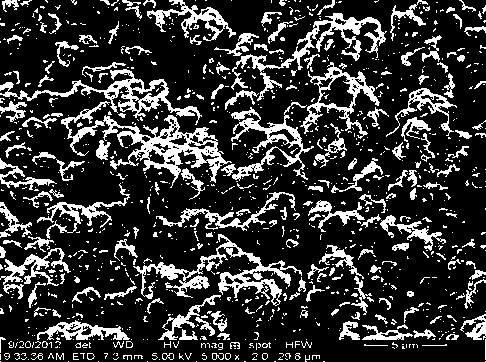

Method for recycling vanadium and molybdenum from waste petroleum catalyst

InactiveCN105274344AReduce pollutionAchieve recyclingProcess efficiency improvementPtru catalystPorphyrin

The invention relates to a method for recycling vanadium and molybdenum from a waste petroleum catalyst, and belongs to the technical field of petrochemical industry. The method comprises air-burning and ball-removing, ball-milling, soda roasting-water leaching, aluminum removing, molybdenum precipitating and enriching molybdenum by ion exchange. The method specifically comprises the following steps: firstly, igniting sticky oil in the waste catalyst in air to burn carbon and oils in the waste catalyst; then, oxidizing the vanadium and nickel in the forms of porphyrin compounds in the waste catalyst into vanadium oxide and nickel oxide, converting most of the molybdenum into molybdenum oxide, wherein the waste catalyst subjected to air-burning and oil-removing is more beneficial for crushing, and the crushed waste catalyst and a certain proportion of sodium carbonate are mixed, and are roasted at a high temperature; leaching roasted materials by hot water, dissolving sodium salts of the vanadium and the molybdenum into water to obtain a solution, filtering the solution, introducing the filtered solution into a leaching solution, introducing a little aluminum into the leaching solution, regulating the pH value of the solution to remove aluminum; regulating the pH value of the solution to 8-9, adding ammonium chloride, precipitating and separating out the vanadium in the form of ammonium vanadate; and concentrating vanadium-precipitated solution by adopting an ion exchange process and enriching an ammonium molybdate solution.

Owner:刘楚玲

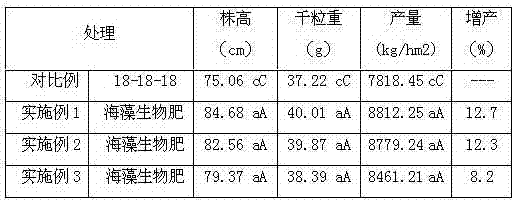

Efficient multifunctional seaweed biological fertilizer

The invention discloses an efficient multifunctional seaweed biological fertilizer and relates to the technical field of compound fertilizers. The raw materials include 10-80 parts of seaweed fermentation liquor, 5-30 parts of humic acid, 5-30 parts of urea, 5-20 parts of monoammonium phosphate, 5-20 parts of potassium sulfate and 2-10 parts of trace elements, and all the raw materials are mixed, concentrated and dried at low temperature to obtain the efficient multifunctional seaweed biological fertilizer. The efficient multifunctional seaweed biological fertilizer can quicken photosynthesis of crops, enhance disease resistance and drought resistance, improve crop yield and improve soil structure and soil water and nutrient retention capability, and is worth popularizing energetically.

Owner:STANLEY AGRI GRP CO LTD

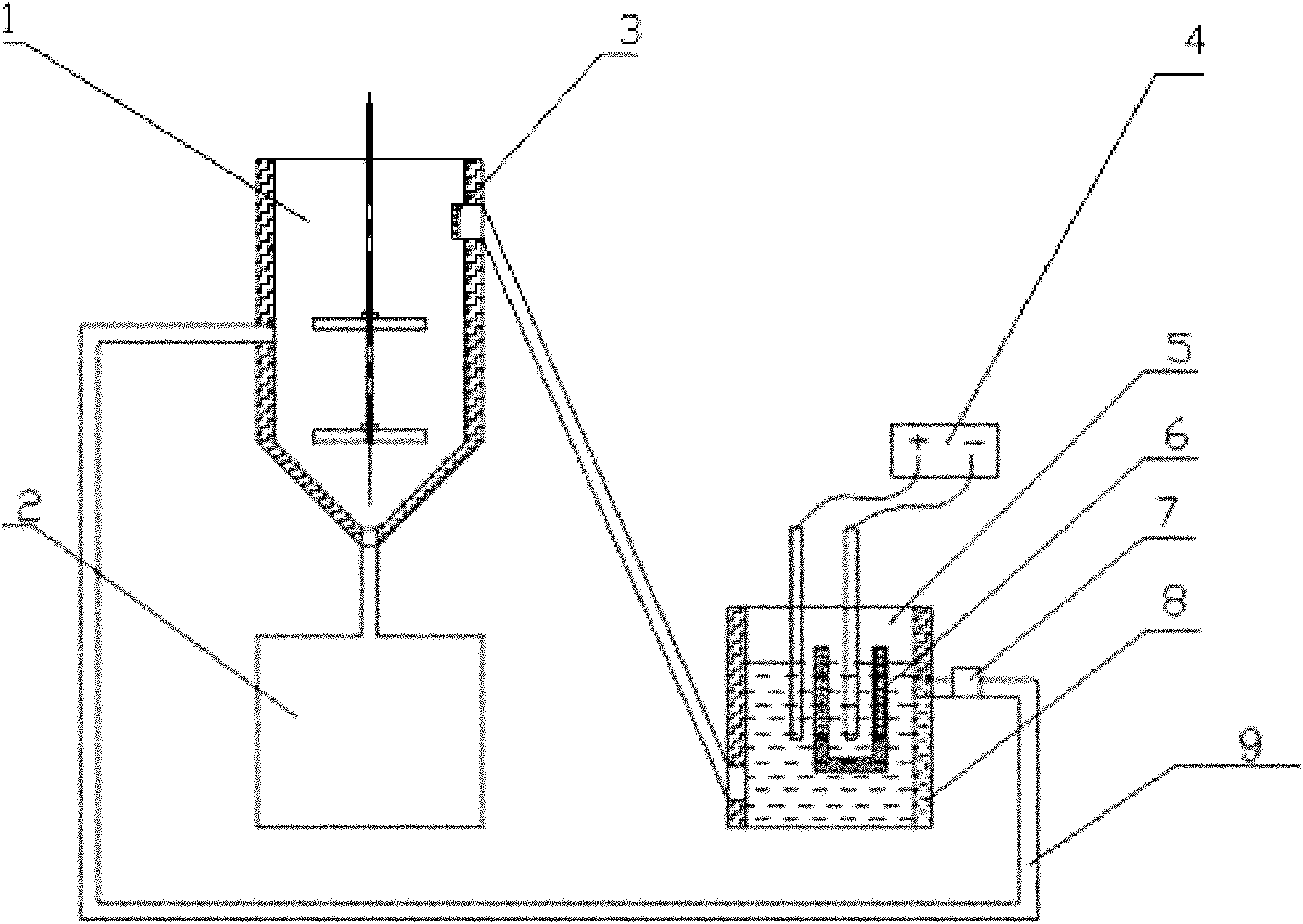

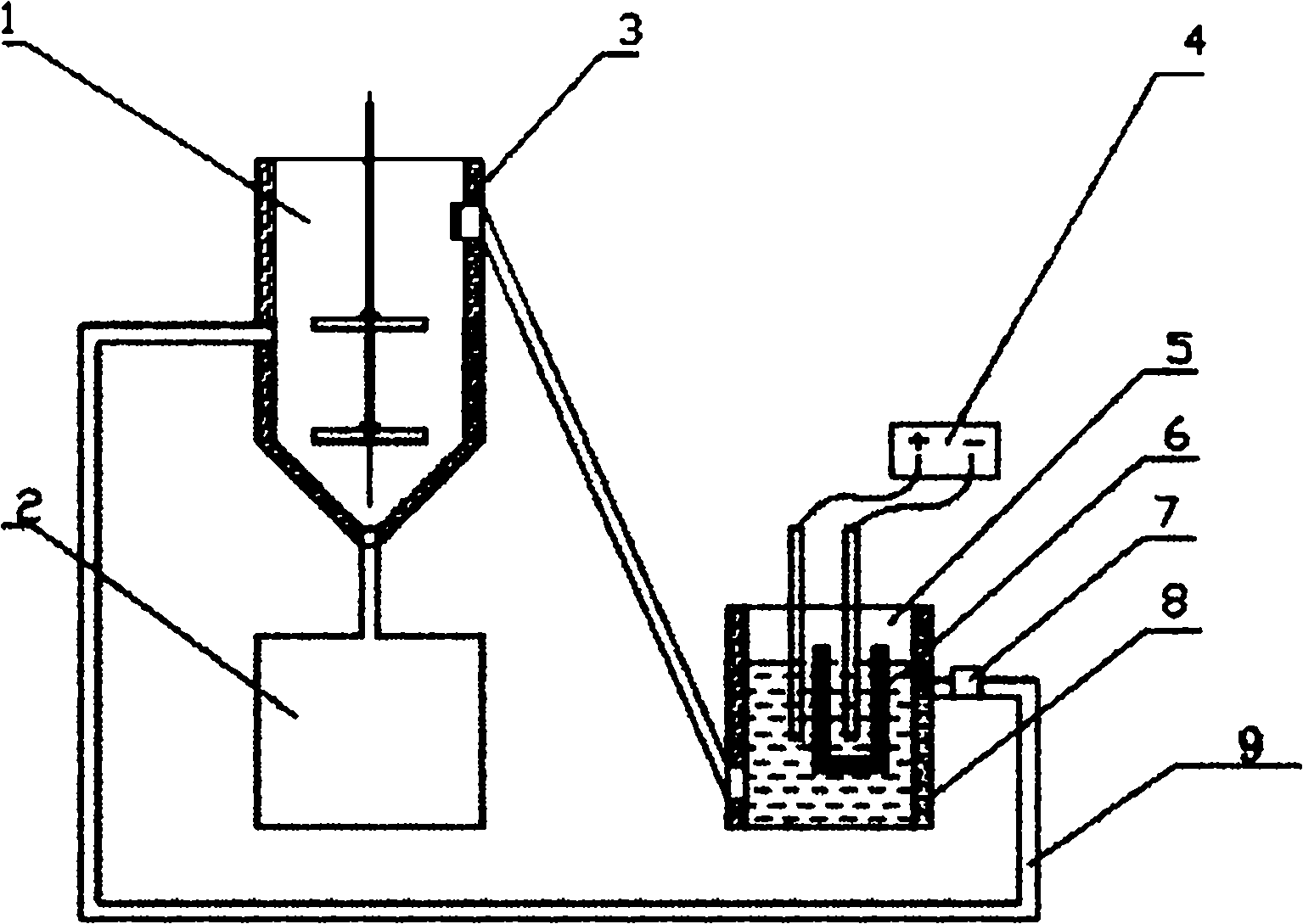

Method and device for recovering metallic lead from lead plaster of waste lead-acid storage battery

ActiveCN102031380AHigh concentrationConcentration unchangedPhotography auxillary processesProcess efficiency improvementLead dioxideSlag

The invention belongs to recovery treatment on lead plaster of a waste lead-acid storage battery. The method comprises the following steps of: mixing the lead plaster of the waste lead-acid storage battery with waste sulfuric acid in the waste lead-acid storage battery according to the design requirement and roasting; adding roasting sand in a stirring kettle; adding tap water to a water level line of the device and stirring the roasting sand; adding a proper amount of calcium acetate, acetic acid and nitric acid; starting a solution circulating system pump, leaching out the roasting sand and maintaining the concentration of lead acetate to be saturated; adding a proper amount of bone glue and beta-naphthol, electrolyzing immersion liquid, recovering the metallic lead at the cathode and recovering lead dioxide at the anode; press filtering residues to obtain lead-off slag and filtrate; and adding calcium carbonate in the filtrate and recycling. The device mainly comprises a leaching part, a press filtration part, a circulating part and an electrolysis part, and concretely includes eight key components of the stirring kettle, a press filter, an overflow port, an electrolysis direct current power supply, an electrolytic cell, a cathode titanium basket, a corrosion resistant pump and a heating element.

Owner:北京绿色引领环保科技研究院有限公司

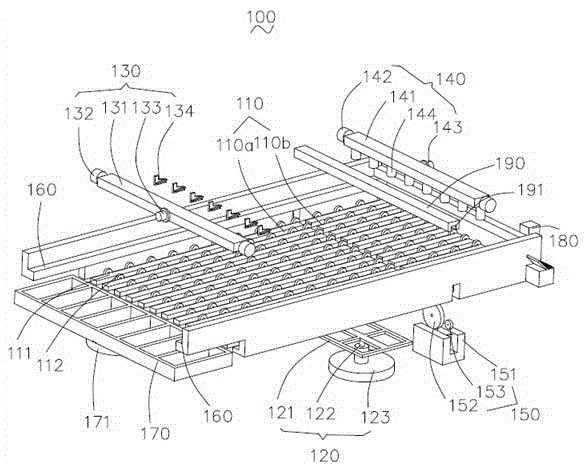

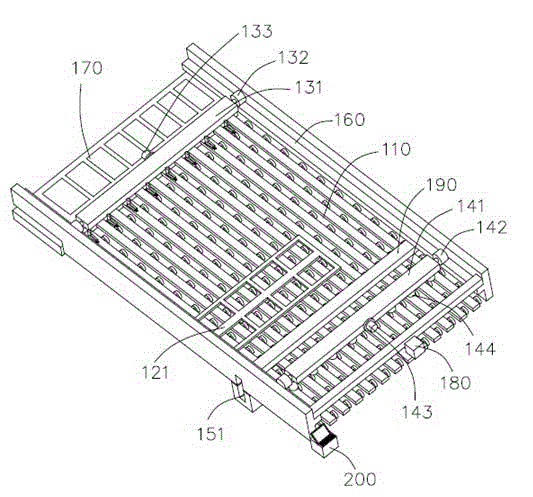

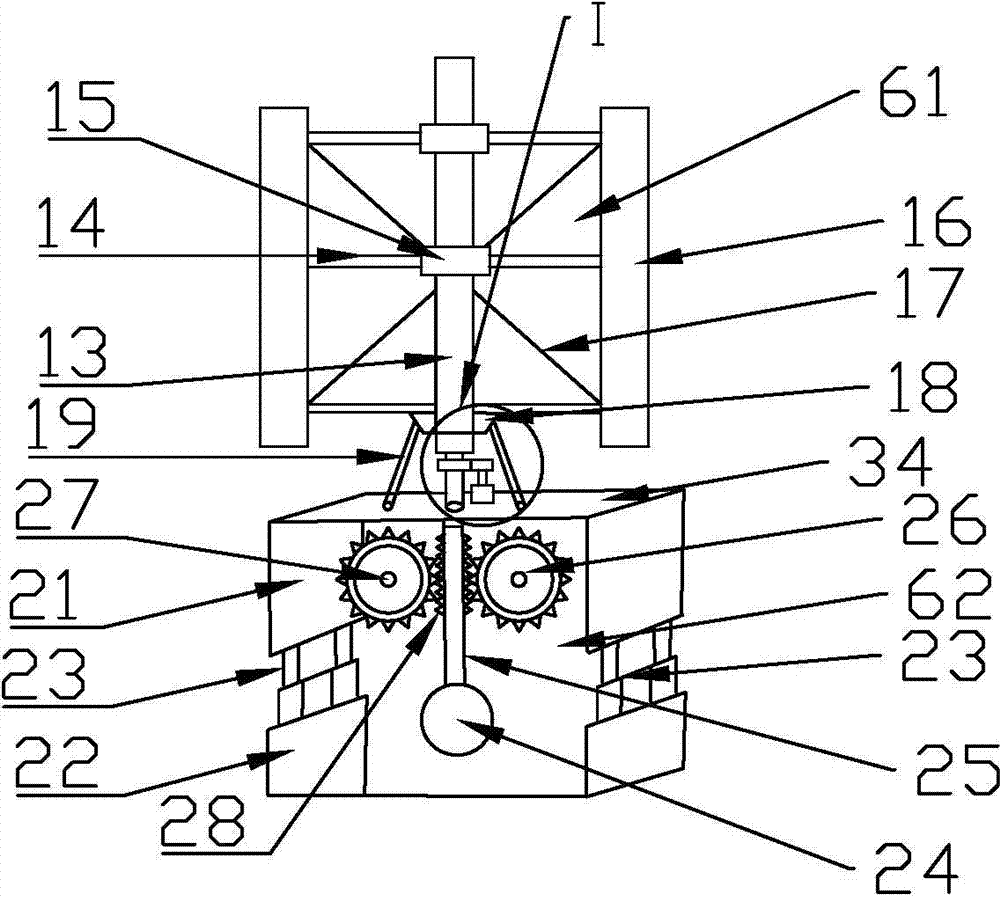

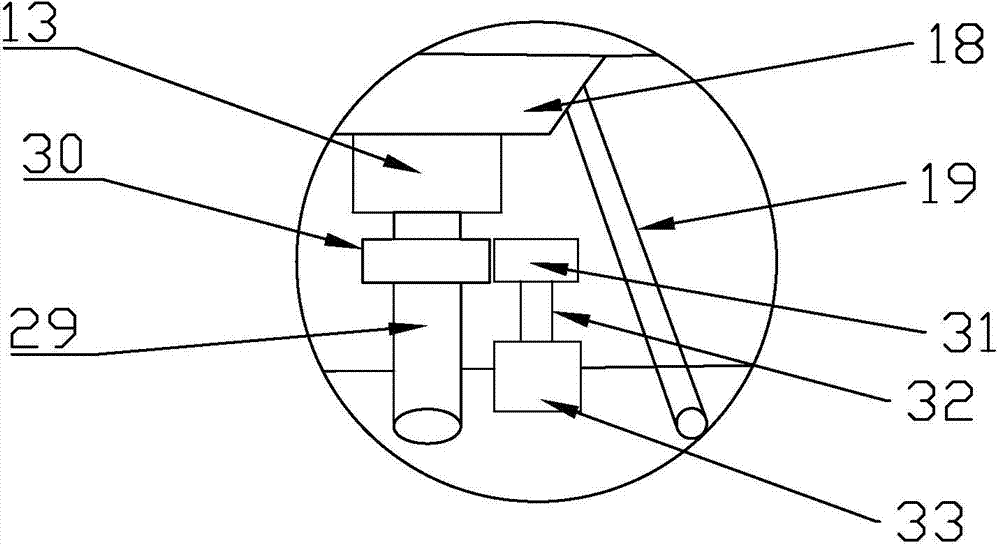

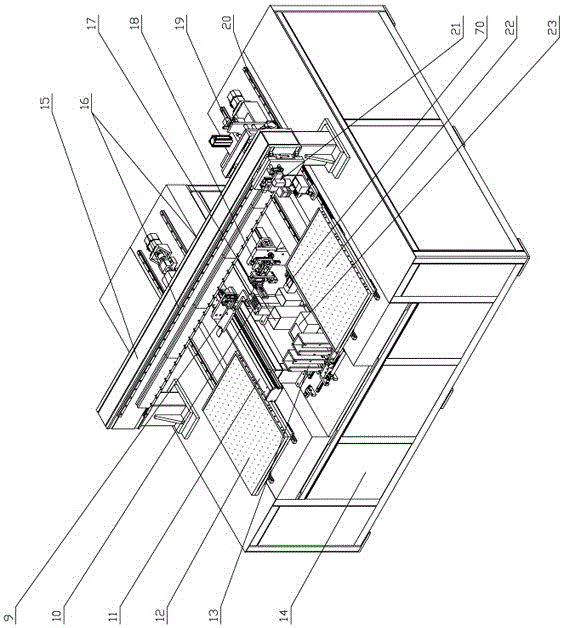

Automatic plate reversing-sawing device and sawing method thereof

InactiveCN102909754AIncrease the level of automationIncrease productivityFeeding devicesCircular sawsControl systemEngineering

The invention discloses an automatic plate reversing-sawing device and a sawing method thereof. The automatic plate reversing-sawing device comprises a sawing device body. The sawing device body comprises a tray, a reversing mechanism, a clamp-conveying mechanism, a push mechanism and a sawing mechanism. Slide rails are disposed on the sides of the tray. The tray comprises a first tray and a second tray. The reversing mechanism is embedded in the first tray. The clamp-conveying mechanism is disposed above the first tray. The push mechanism is disposed above the second tray. The sawing mechanism is disposed between the first tray and the second tray. A bearing rack is disposed at the end of the first tray. An automatic labeling mechanism is disposed at the end of the second tray. The sawing device body is provided with a control system electrically connected with a display screen. The automatic plate reversing-sawing device is simple and reasonable in design, full-automatically controllable, convenient to operate, high in safety and high in yield. The sawing method is novel. With intelligent stock layout and the automatic labeling mechanism, the production process is informationized and intelligent.

Owner:东莞华信智能技术有限公司

Production method of soy preserved ginger

The invention discloses a production method of soy preserved ginger, comprising: selecting first-class fresh ginger, processing by the steps of cleaning, peeling, pickling, dewatering, insolation and the like; dipping with sugar and vinegar liquid; carrying out secondary insolation and dewatering; then, selecting first-class broad bean sauce, and adding spices (sesame oil, hot pepper, garlic and the like); and closing a cylinder and pickling dewatered sugar and vinegar ginger for one month. The prepared soy preserved ginger does not contain any additive and is a pure natural green food; the soy preserved ginger is naturally sour and sweet, is fragrant and delicious, and leads eaters to endless aftertastes; the soy preserved ginger has the effect of tonifying spleen, appetizing, increasing appetite, aiding digestion, inviting body fluid, promoting urination, eliminating blood stasis, removing food retention, performing health care, beautifying, preventing and curing diseases and prolonging life.

Owner:TONGLING TIANPINGSHAN FLAVORING FACTORY

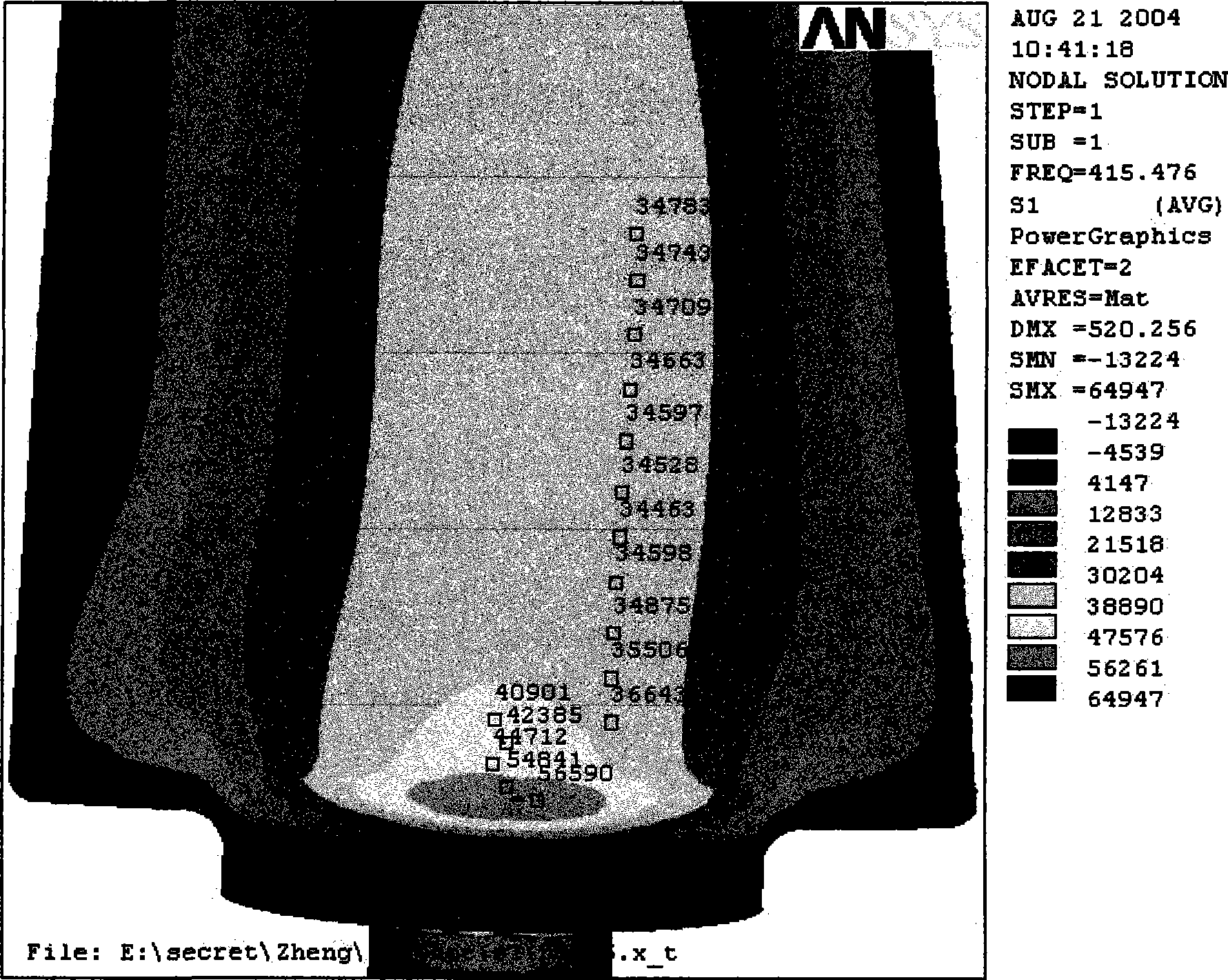

Method for measuring fatigue test maximum stress of single-journal vane

InactiveCN101419114AGuaranteed reliabilityBig societyForce measurementVibration testingSocial benefitsStress distribution

The invention relates to a method for measuring the maximum stress of a fatigue test leaf lamina of a single-journal leaf blade, which comprises the following steps: firstly, the method of electrical measurement of a stress gauge is adopted for measuring stress distribution on the surface of the leaf lamina of the leaf blade and initially determining an area with large blade vibration stress; and secondly, the measuring method of sequential approximation is adopted for moving the stress gauge in the vertical or / and horizontal direction according to the small dimension of between 0.01 and 1 millimeter each time in the area with large blade vibration stress, performing repeated measurement, and finally finding out a coordinate of a point with the maximum stress on the leaf blade. The method is particularly suitable to be applied to a fatigue test of the single-journal leaf blade, can be well applied to a fatigue test assessment item in the field of national defense, solves the technical problem of related tests, and has large potential social benefit and military benefit.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Cup milky tea containing fruit and vegetable juice bag

InactiveCN103960367AFull of nutritionGreat market potentialMilk preparationPre-extraction tea treatmentFood additiveAdditive ingredient

The invention discloses cup milky tea containing a fruit and vegetable juice bag. The cup milky tea is characterized by containing a milky tea powder bag and the fruit and vegetable juice bag. The invention relates to the field of production of food beverages and particularly relates to the cup milky tea containing the fruit and vegetable juice bag. The milky tea powder bag contains one or more than one milk powder or a milk product, non-dairy creamer or acid-resisting non-dairy creamer. Ingredients, a condiment, a food additive and the like are added in a step of preparing materials; the milky tea powder bag is prepared by the procedures of blending, mixing, filling, sterilizing and the like; when a product is packaged, the fruit and vegetable juice bags with different flavors are selected and added according to requirements of the product and secondary packaging is carried out so that the disadvantages that the milky tea has no nutrition and the taste is single are overcome and multiple types of cup milky tea with different flavors can be formed.

Owner:宋信宇

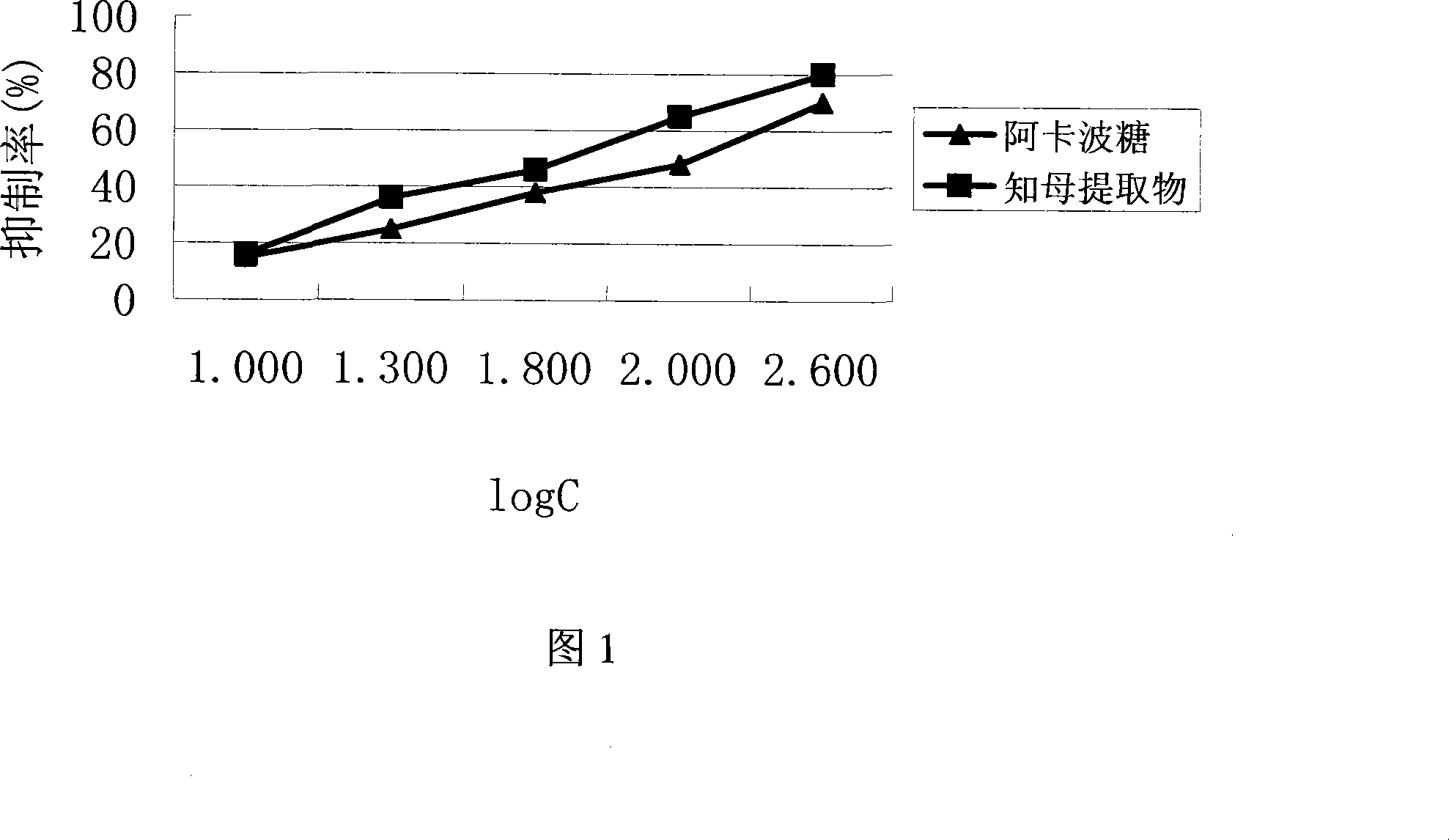

Rhizoma anemarrhenae extrac and applications as type 2 diabetes-curing medicine thereof

InactiveCN101229316AIncrease the number of receptorsReduce resistanceMetabolism disorderPlant ingredientsSeparation technologyKetone

The invention discloses an anemarrhenae extract and the application as a medicine treating type II diabetes thereof. The invention uses membrane separation technology, macropore to absorb resin separation and refines anemarrhenae extract after extracting the hizome anemarrhenae by water and ethanol with water. The main activities of the anemarrhenae extract of the invention are three kinds or any two kinds among anemarrhenae saponins, anemarrhenae polysaccharides and double benzene pyrrole ketones, and the total content of the main active components is up to more than 50 percent. The pharmacological experiment of the anemarrhenae extract of the invention proves that the medicine has a big medical value and economic benefit as the medicine for treating or preventing type II diabetes and the complications thereof.

Owner:GUANGDONG PHARMA UNIV

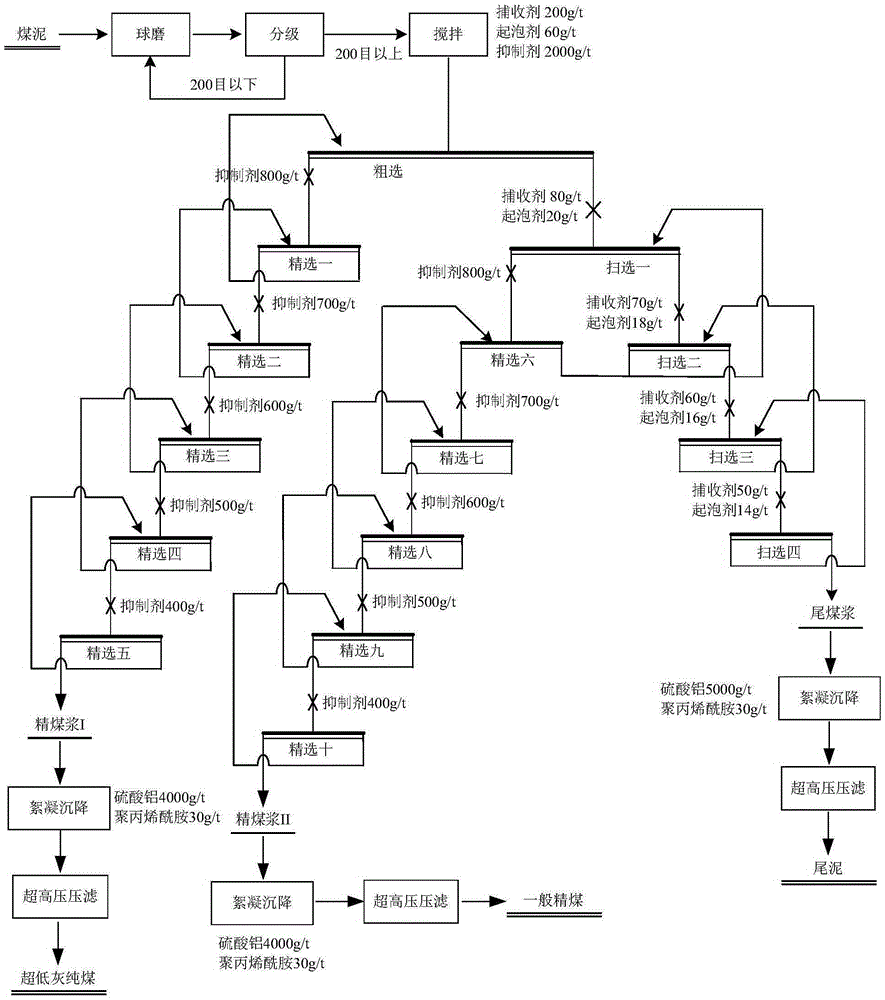

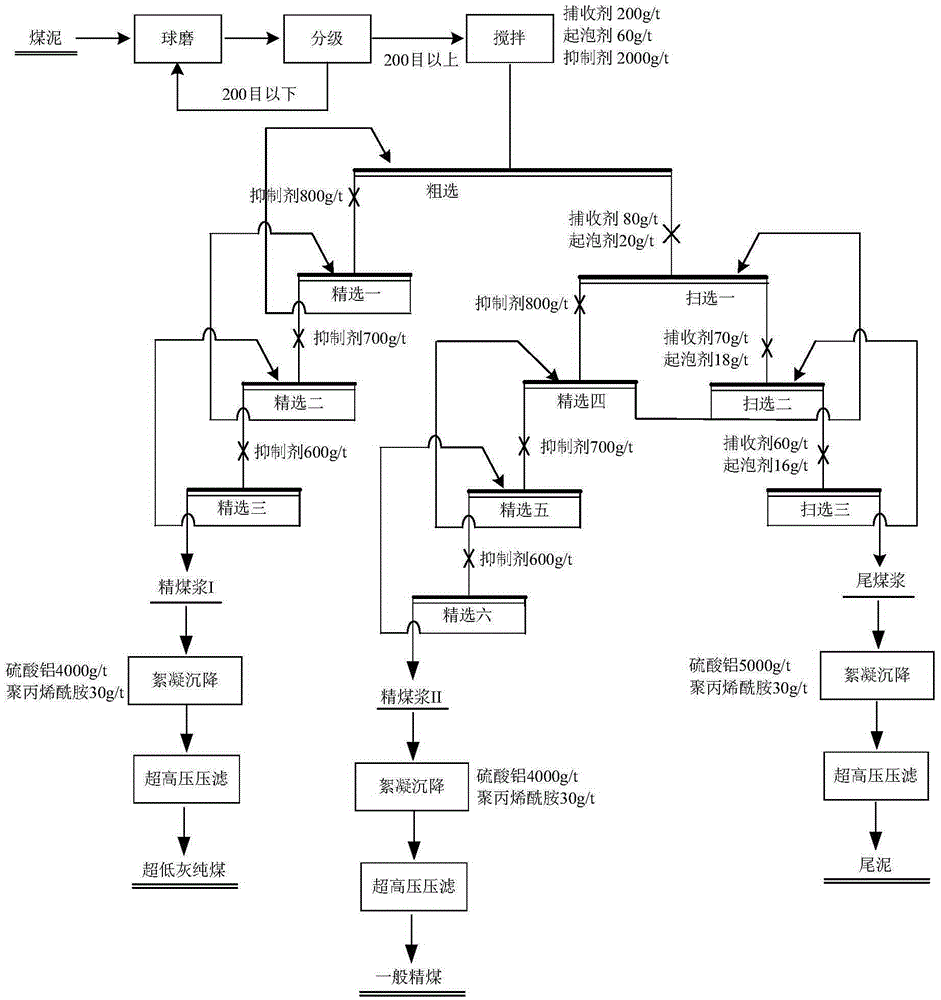

Method for extracting ultra-low-ash-content pure coal from coal slime

InactiveCN105396684ALow recovery rateGood technical effectDifferential sedimentationFlotationFlocculationFoaming agent

The invention discloses a method for extracting ultra-low-ash-content pure coal from coal slime. The method comprises the following steps: ball-milling slurrying, specifically, milling coal slime until particles with less than 200 meshes occupy more than 90%, and controlling the mass percent concentration of the coal slime slurry to be 10-35%; grading, specifically, conveying the particles with less than 200 meshes to a flotation step; flotation, specifically, adding a collecting agent, a foaming agent and an inhibitor in the obtained coal slime slurry, uniformly mixing, and carrying out one-time rough flotation, two sections of three-to-six-time fine flotation and one section of three-to-six-time scavenging to obtain refined coal slurry I, refined coal slurry II and tailing coal slurry respectively; and dehydration, specifically, adding a flocculant in the refined coal slurry I, the refined coal slurry II and the tailing coal slurry which are obtained through the flotation, carrying out flocculation settling, then dehydrating by virtue of an ultrahigh-pressure pressure filter, and controlling a pressure filter pressure to be 4.5-5.5Mpa, thus obtaining ultra-low-ash-content pure coal products, common refined coal products and tailing coal products. The method disclosed by the invention is simple in process flow, and capable of efficiently extracting the ultra-low-ash-content pure coal products from the coal slime; and moreover, the water contents of the obtained coal products are low and can achieve less than 15%, thus the coal products have remarkable economic benefits and environmental protection value.

Owner:SHENZHEN RUICHENG SHIDAI IND CO LTD

High-gloss transparent glaze formula for daily-use ceramics, as well as preparation method and using method of high-gloss transparent glaze formula

The invention belongs to the field of manufacturing of ceramics and specifically relates to a high-gloss transparent glaze formula for daily-use ceramics, as well as a preparation method and a using method of the high-gloss transparent glaze formula. The high-gloss transparent glaze formula for the daily-use ceramics provided by the invention is prepared by taking feldspar powder, heavy calcium carbonate, limestone, talcum, dolomite, kaolin, silicon oxide, zinc oxide, barium carbonate and water as raw materials and performing a production process with reasonable formula and appropriate control. A ceramic device produced by a transparent glaze is detected to have high gloss and low dissolution of lead and cadmium, is suitable for production of the daily-use ceramics, such as bowls, spoons, basins and the like, has the characteristics of aesthetic shape, health, environmental friendliness and the like, and has great popularization value and social and economic benefits.

Owner:福建省德化县宏达陶瓷有限公司

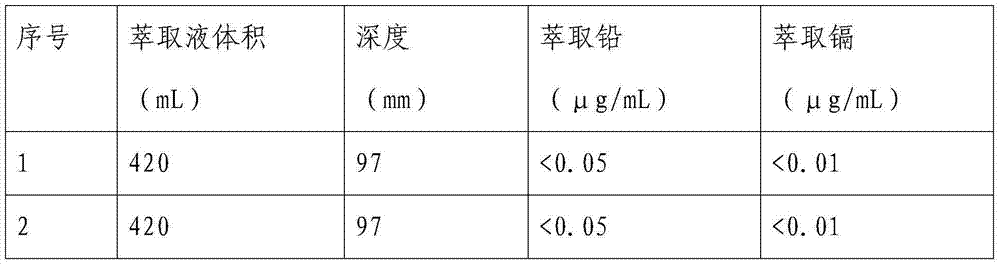

Process for recovering triphenyl phosphine oxide and 2-mercaptobenzothiazole from production waste liquid of cephalothin active ester

The invention discloses a method for recycling triphenyl phosphine oxide and 2-mercaptobenzothiazole from the production waste liquid of cephalosporin active ester, which includes the following steps: 1 to 10 percent sodium hydroxide solution is added drop by drop into the production waste liquid of the cephalosporin active ester under 0 to 80 DEG C; the pH value of the system is adjusted to be 10 to 12, and then the waste liquid is mixed fully for 0.5 to 6 hours, standing still and layering; an organic layer is decompressed to recycle an organic solvent; the solid waste slag is recrystallized directly to obtain the triphenyl phosphine oxide; the 2-mercaptobenzothiazole is extracted and obtained from water layer by a using acid neutralization method. The recycling method of the invention has the advantages of the simple operation, the high recycling rate, the good product purity, the good atom economy, etc., which effectively solves the problems existing in the prior art, such as the complicated operation, the high energy consumption, the low yield rate, the serious environment pollution, etc., thus having a wide implementary value and potential social economic benefits.

Owner:ZHEJIANG UNIV OF TECH +2

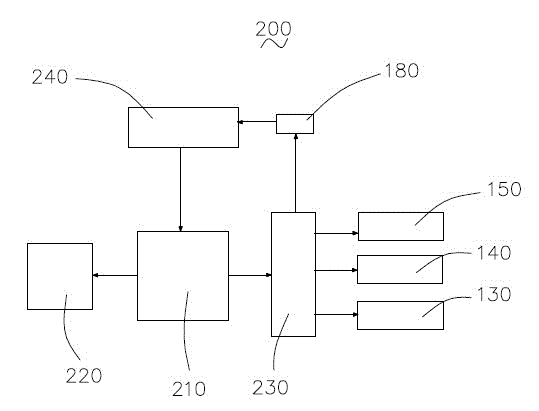

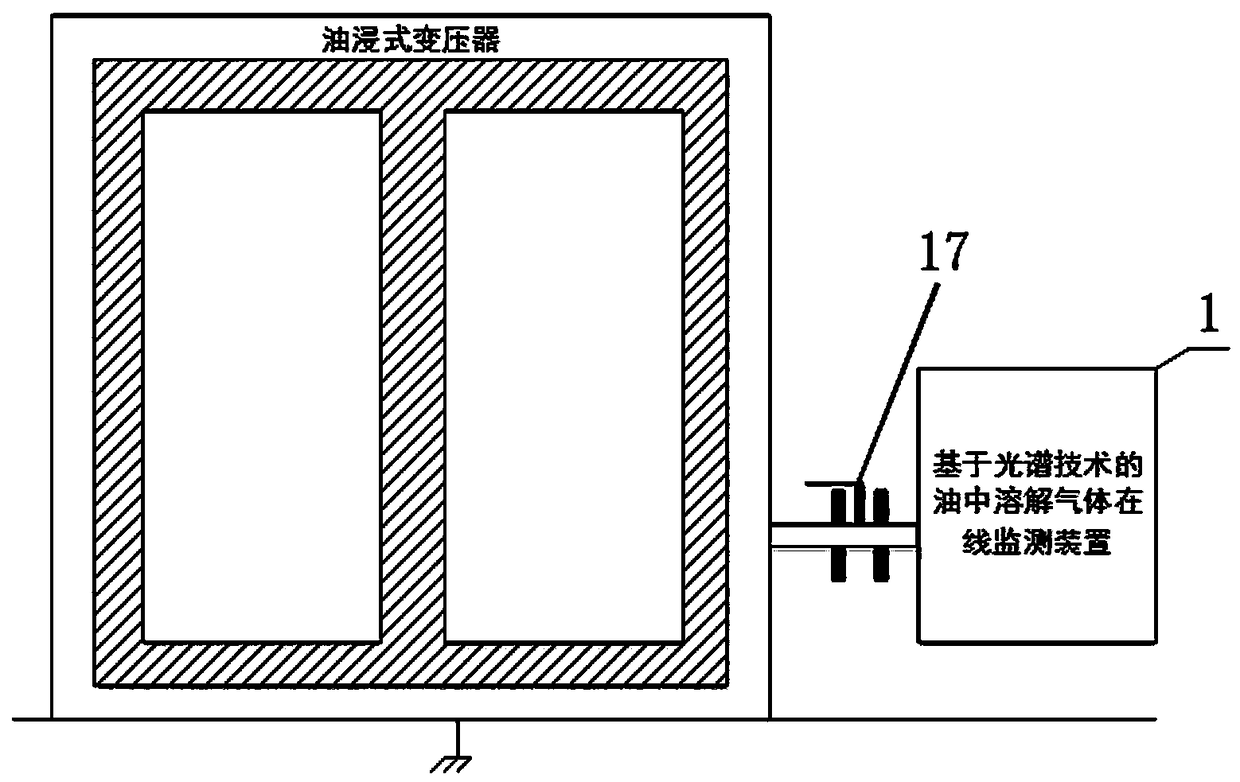

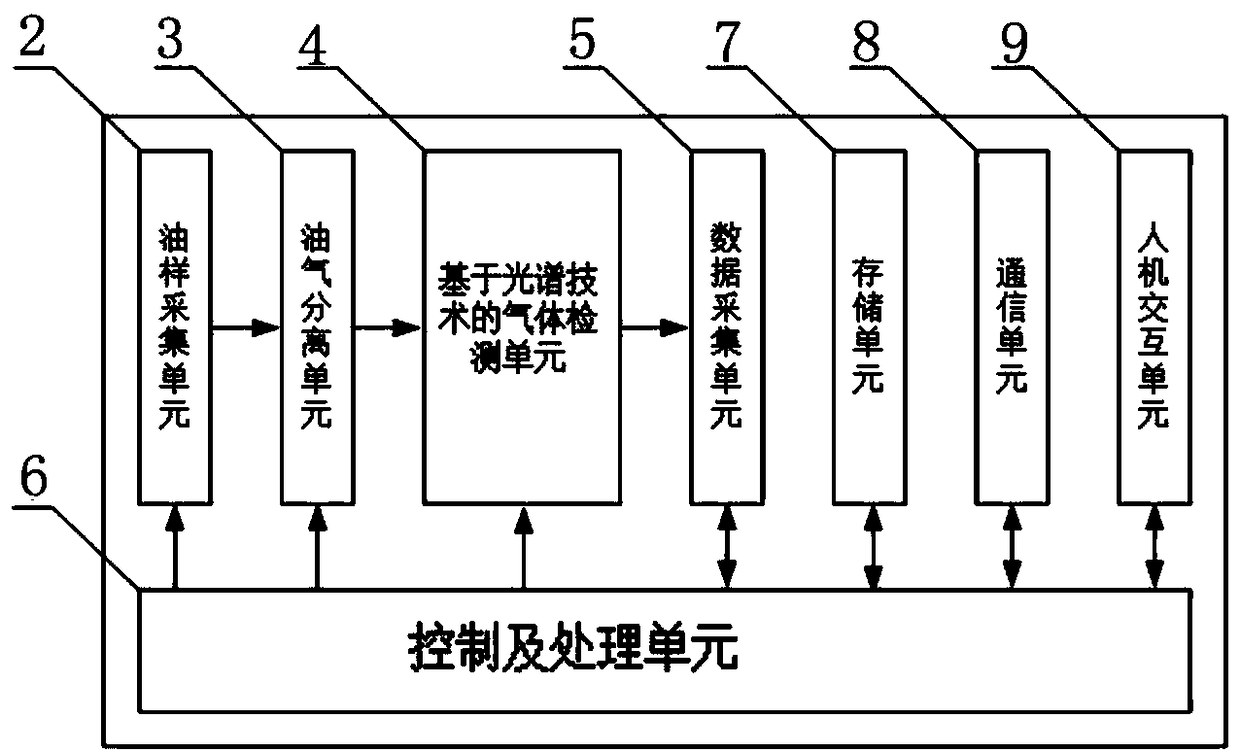

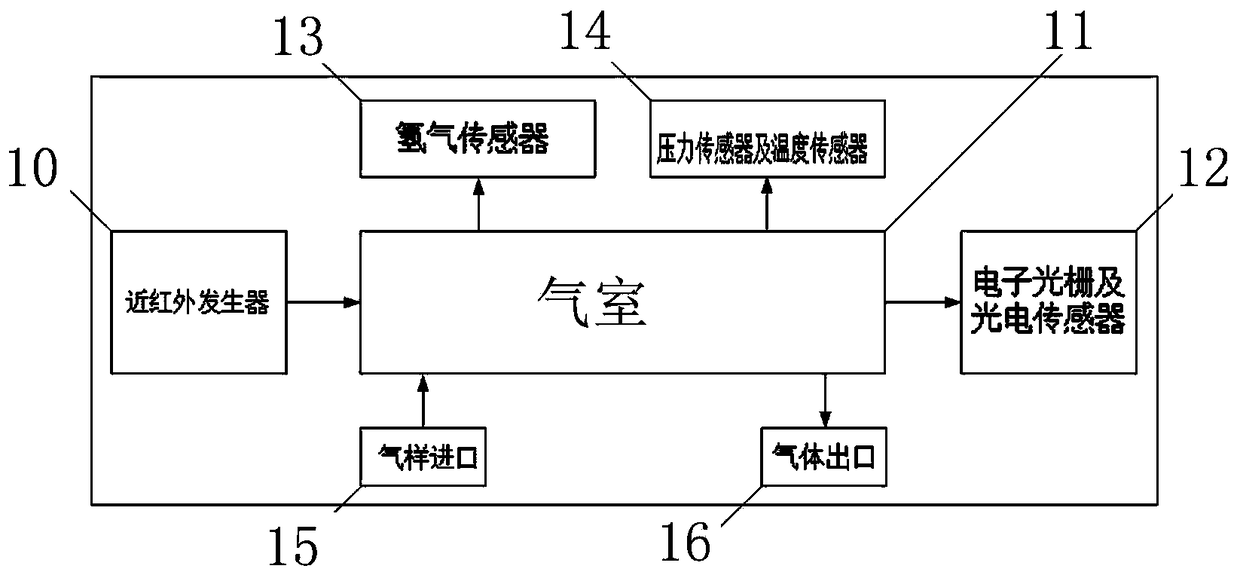

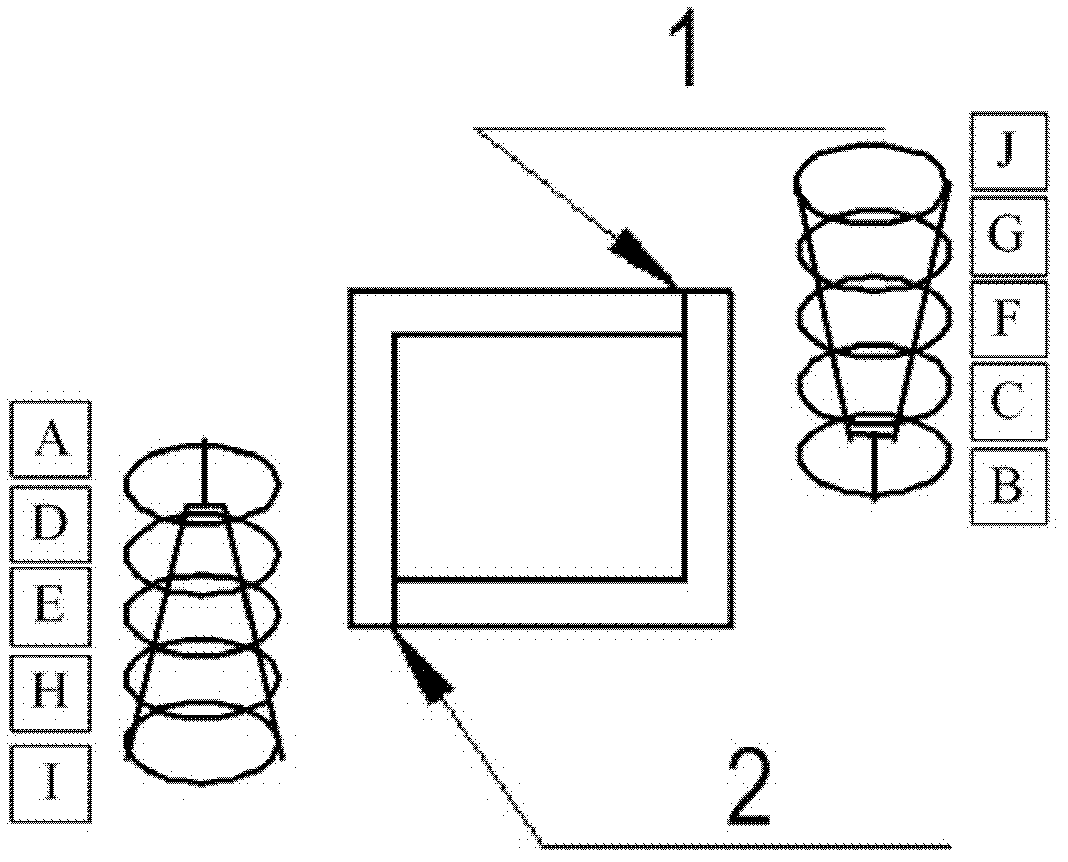

Device and method for online monitoring dissolved gas in transformer oil based on spectrum technology

PendingCN108918459ANo consumables requiredImprove stabilityMaterial analysis by optical meansCommunication unitProduct gas

The invention belongs to the technical field of online monitoring of transformers, and in particular relates to a device and method for online monitoring dissolved gas in transformer oil based on a spectrum technology. An oil sample acquisition unit is connected with an oil-gas separation unit; the oil-gas separation unit is connected with a gas detection unit based on the spectrum technology; thegas detection unit based on the spectrum technology is connected with a data acquisition unit; the data acquisition unit is connected with a control and processing unit; and the control and processing unit is separately connected with the oil sample acquisition unit, the oil-gas separation unit, the gas detection unit based on the spectrum technology, a storage unit, a communication unit and a human-computer interaction unit. The device in the invention is good in stability, high in reliability and free from carrier gas, consumable and maintenance, and is not influenced by noise and mechanical vibration; the field installation workload is low; installation and disassembly are easy; the application prospect of the device is wide; and, once being implemented, the device has greater economicbenefit and social meaning.

Owner:STATE GRID LIAONING ELECTRIC POWER RES INST +4

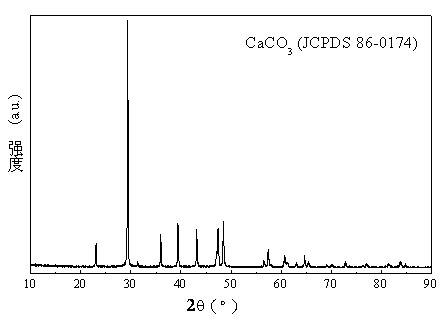

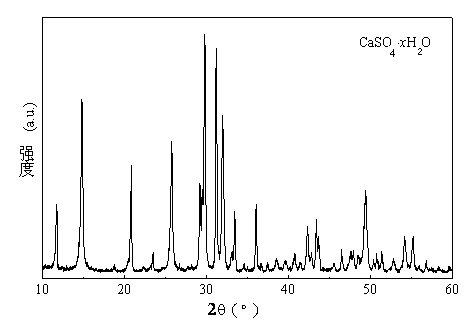

Application of sugar-mill lime sludge in wet flue gas desulfurization

The invention discloses the application of sugar-mill lime sludge in wet flue gas desulfurization. The application of the sugar-mill lime sludge is characterized in that the sugar-mill wet lime sludge is directly mixed with water to prepare slurry liquid, and the slurry liquid serves as an absorbing agent in a limestone-gypsum wet desulfurization method; the desulfurization absorbing agent is the waste lime sludge (namely filter residue or yellow mud) generated by the sugar prepared by a carbonic acid method in a sugar mill, mixed with water to form the slurry liquid with the proportion of 1:10-1:12, and used for absorbing sulfur dioxide (SO2) discharged by a coal burning boiler; and when the calcium-sulfur ratio is 1-1.1, the removal ratio of SO2 is up to more than 95 percent, the national desulfurization standard is met. The application of the sugar-mill lime sludge in the wet flue gas desulfurization adopts the waste residue of enterprises as the desulfuration absorbing agent, so as to be convenient and economic for material taking, simple in processing, and universal with the limestone-gypsum wet desulfurization method in requirements for equipment. The method not only saves the cost of purchasing an desulfurization agent, but also finds a way out for safe disposal of the lime sludge, so as to realize the purposes of treatment of wastes by other wastes, energy conservation and emission reduction, and have larger social environment benefits and economic benefits.

Owner:UNIV OF JINAN

Electric driving membrane treatment process for acid bath wastewater in viscose fiber production

InactiveCN106868635ARealize deep recoveryEnvironmentally friendlySemi-permeable membranesArtificial filament recoveryZinc hydroxideSulfate

The invention provides an electric driving membrane treatment process for acid bath wastewater in viscose fiber production. The electric driving membrane treatment process comprises the following steps: A, pre-treating an acid solution after spinning; B, conveying the pre-treated acid solution after spinning to an electrodialysis membrane module for electrodialysis treatment, and when the contents of sulfuric acid, sodium sulfate and zinc sulfate in a receiving liquid achieves the technical requirements of an acid bath before spinning, performing recovery for spinning; C, performing acid-base neutralization of the raw material liquid subjected to electrodialysis, adjusting the pH value to 8-10 to generate sodium sulfate and zinc hydroxide precipitation, and performing solid-liquid separation to obtain a sodium sulfate solution and a zinc hydroxide solid; and D, conveying the sodium sulfate solution and the acid bath solution after spinning to a bipolar membrane apparatus, performing electrodialysis to recover acid and base, and directly using the acid bath solution and the base solution obtained from electrodialysis to the production system. Deep recovery of sulfuric acid from the acid bath after spinning is achieved, and the acid bath before spinning is directly formed and reused to the production system. According to the process, steam consumption is prevented, and inventory problem of sodium sulfate is solved.

Owner:YIBIN GRACE GROUP CO LTD

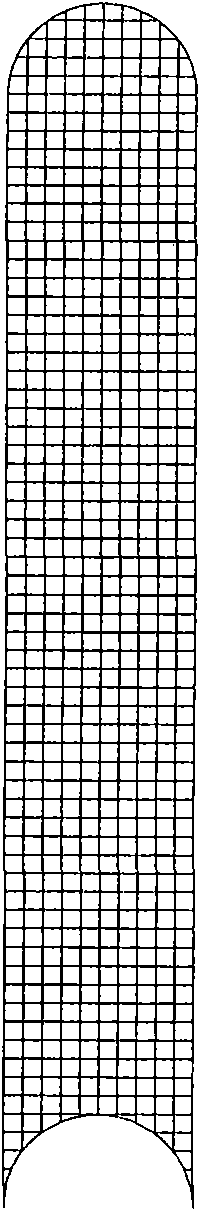

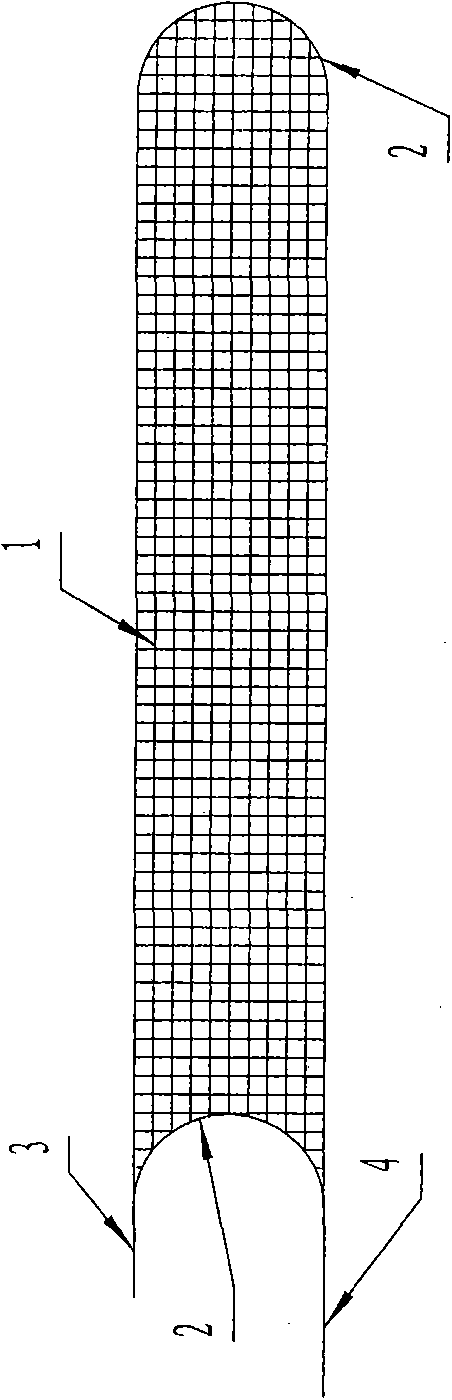

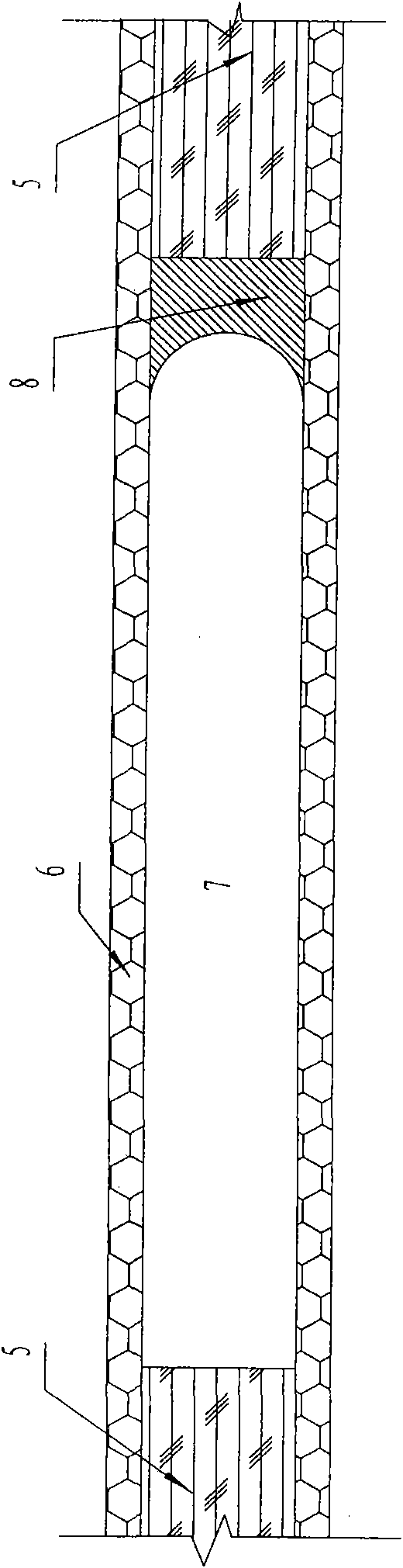

Diaphragm wall seam waterproof method and diaphragm wall construction method based on same

ActiveCN101886402AImprove connection strengthImprove acceleration performanceArtificial islandsUnderwater structuresSlurry wallClassical mechanics

The invention belongs to the technical field of diaphragm wall construction, in particular relates to a diaphragm wall seam waterproof method and a diaphragm wall construction method based on the same, and solves the problem that the conventional seam waterproof method easily causes an engineering accident. The diaphragm wall construction seam waterproof method comprises the following steps of: 1) binding a reinforcement cage, wherein one end face of the reinforcement cage is a concave circular arc surface and the other end face of the reinforcement cage is a convex circular arc surface, and the radius of the concave and convex circular arc surfaces is consistent with that of a joint pipe; and 2) welding iron sheet protective surfaces with the same shape on the concave and convex circular arc surfaces, and welding waterproof plates on inner and outer side surfaces of the reinforcement cage at the end of the concave circular arc surface, wherein the length of the outer side surface waterproof plate beyond the reinforcement cage is greater than that of the inner side surface waterproof plate beyond the reinforcement cage. The diaphragm wall seam waterproof method has the advantages that: the joint waterproof problem is radically solved; the economic effect is obvious; and the pulling of the joint pipe is not limited by time any more and substantially has no disturbance and damage to the diaphragm wall, so the construction quality of the diaphragm wall is guaranteed.

Owner:CHINA RAILWAY NO 3 GRP CO LTD

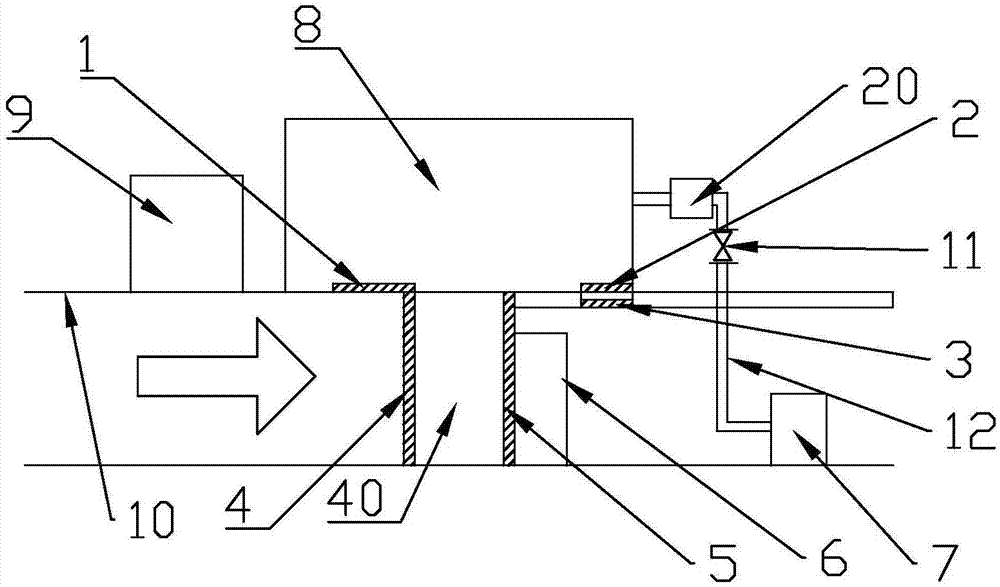

Device and method for disposing river sewage through wind and tidal power generation and water storage drainage

ActiveCN104746475AEasy to implementNo pollution in the processBarrages/weirsEnergy industryTidal waterWater storage

The invention discloses a device and method for disposing river sewage through wind and tidal power generation and water storage drainage. The device comprises water storage gates and a high-position water storage platform. The high-position water storage platform is provided with a high-position water storage pool and a control room. The water storage gates comprise the first water storage gate, the second water storage gate, the third water storage gate, the fourth water storage gate and the fifth water storage gate. The fifth water storage gate is connected with a wind and tidal power generation device. The high-position water storage pool is connected with a water drawing pipe. The water drawing pipe is connected with a tidal water storage unit. The method for disposing river sewage through wind and tidal power generation and water storage drainage includes the procedure of high-position water storage platform and high-position water storage pool construction, water storage gate installation, wind and tidal power generation device and power generator set installation, tidal water storage unit installation, wind and tidal power generation device power generation and energy storage, tidal water storage unit water storage conducted for the high-position water storage pool, river upstream guidance of water in the high-position water storage platform, river floating object disposal, and river suspended object disposal.

Owner:ZHEJIANG UNIV OF WATER RESOURCES & ELECTRIC POWER

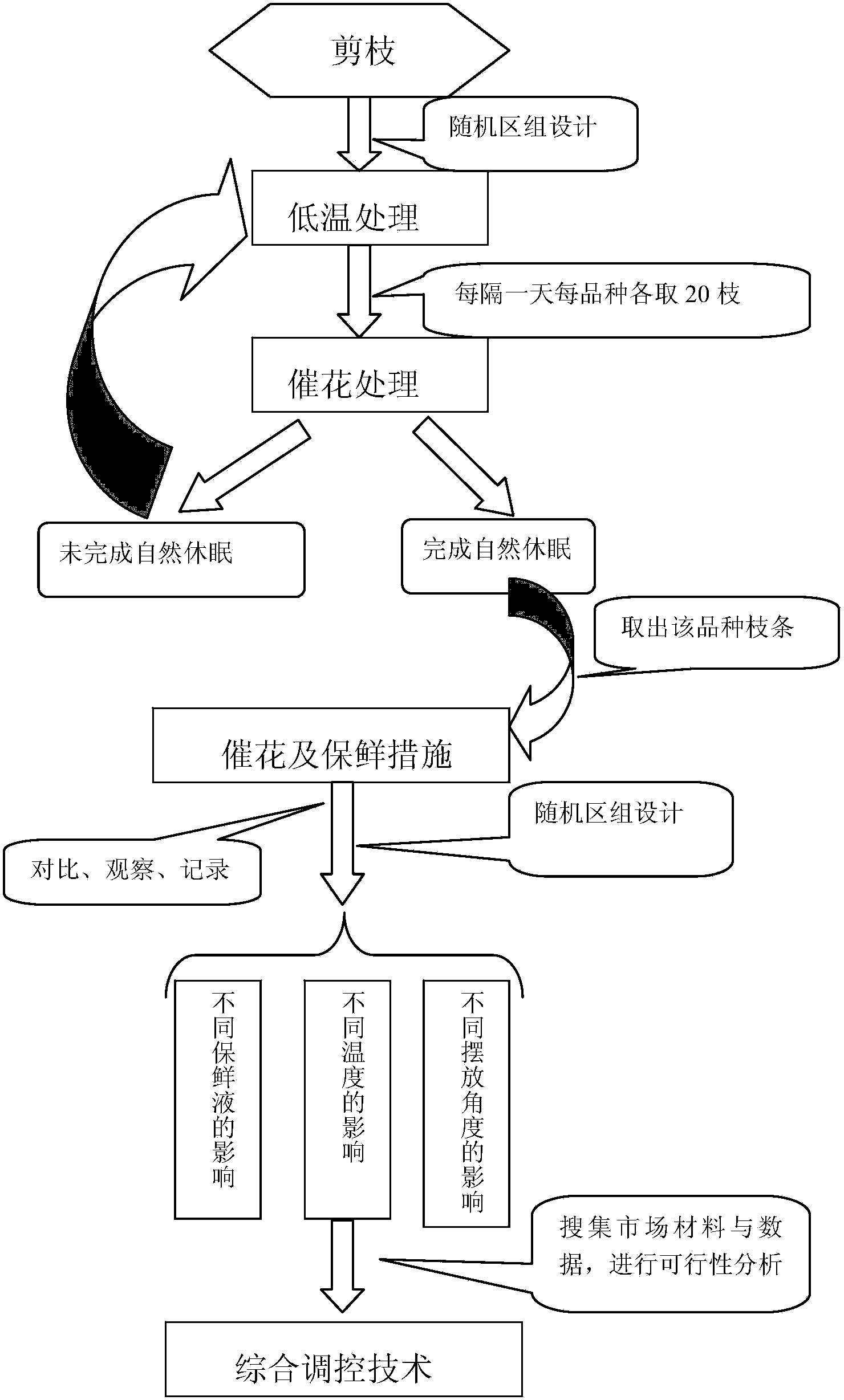

Method for regulating and controlling flowering phase of peach cut-flowers and guaranteeing flowering quality

The invention discloses a method for regulating and controlling a flowering phase of peach cut-flowers and guaranteeing the flowering quality. The method for regulating and controlling the flowering phase of peach cut-flowers and guaranteeing the flowering quality disclosed by the invention comprises the following steps: determining a pickup date of the peach cut-flowers according to the selected optimal ornamental date, performing low-temperature treatment according to the chilling requirement after the peach cut-flowers are picked up at the pickup date, obtaining peach cut-flowers in natural dormancy, performing flower forcing treatment, and obtaining the peach cut-flowers in the optimal ornamental period. According to the method disclosed by the invention, the flowering phase on the specified date can be regulated and controlled by combining environmental control according to different chilling requirements of different peach cut-flower qualities, for example, early-maturing varieties are guided to bloom on Christmas Day, New Year's Day and Spring Festival, and late varieties are guided to be in full bloom on May Day even can bloom on each needed festival. The method has significance in promoting development of sightseeing agriculture and Peach Flower Festival and realizing greater social benefits, landscape benefits and economic benefits.

Owner:BEIJING FORESTRY UNIVERSITY

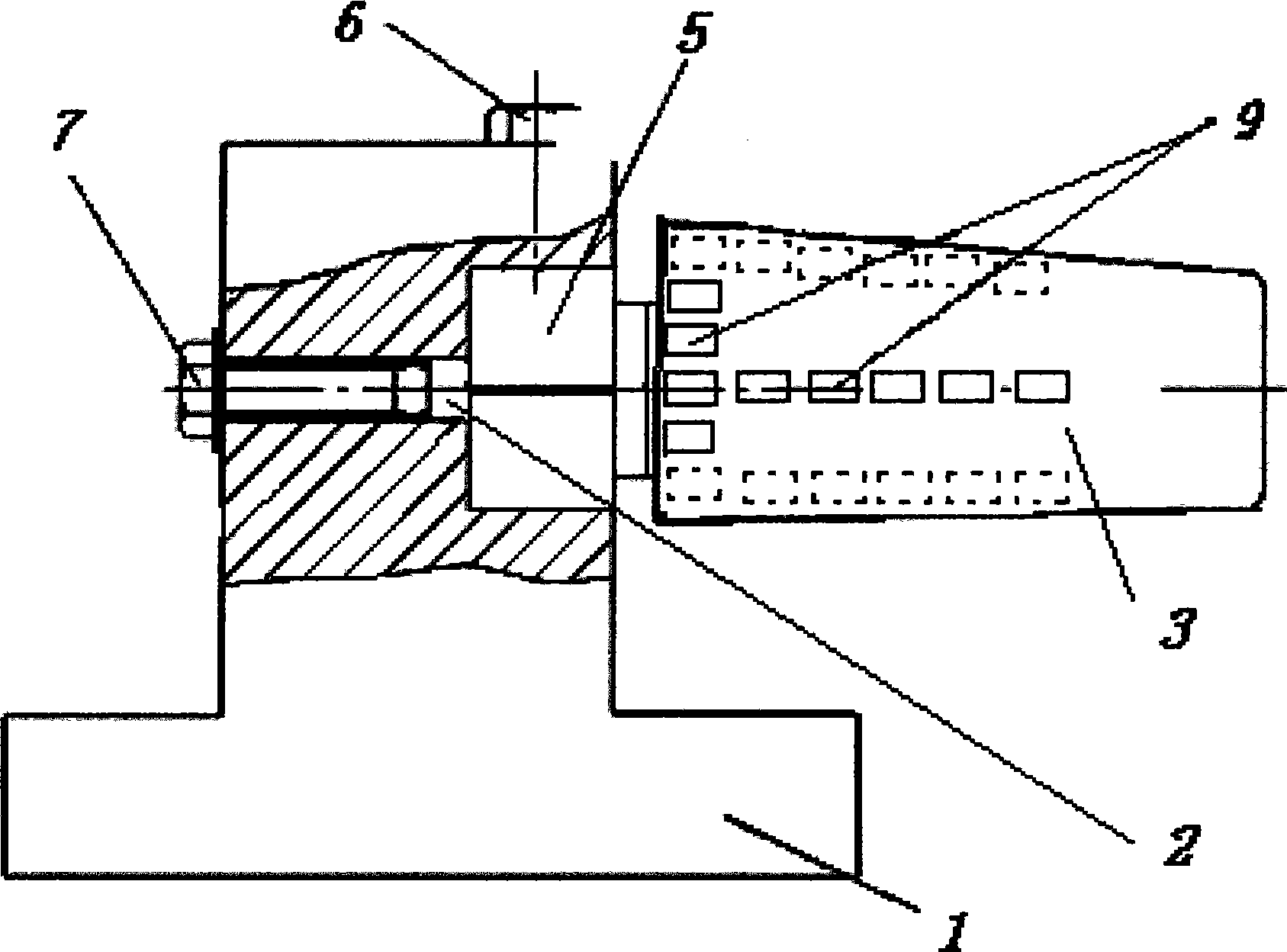

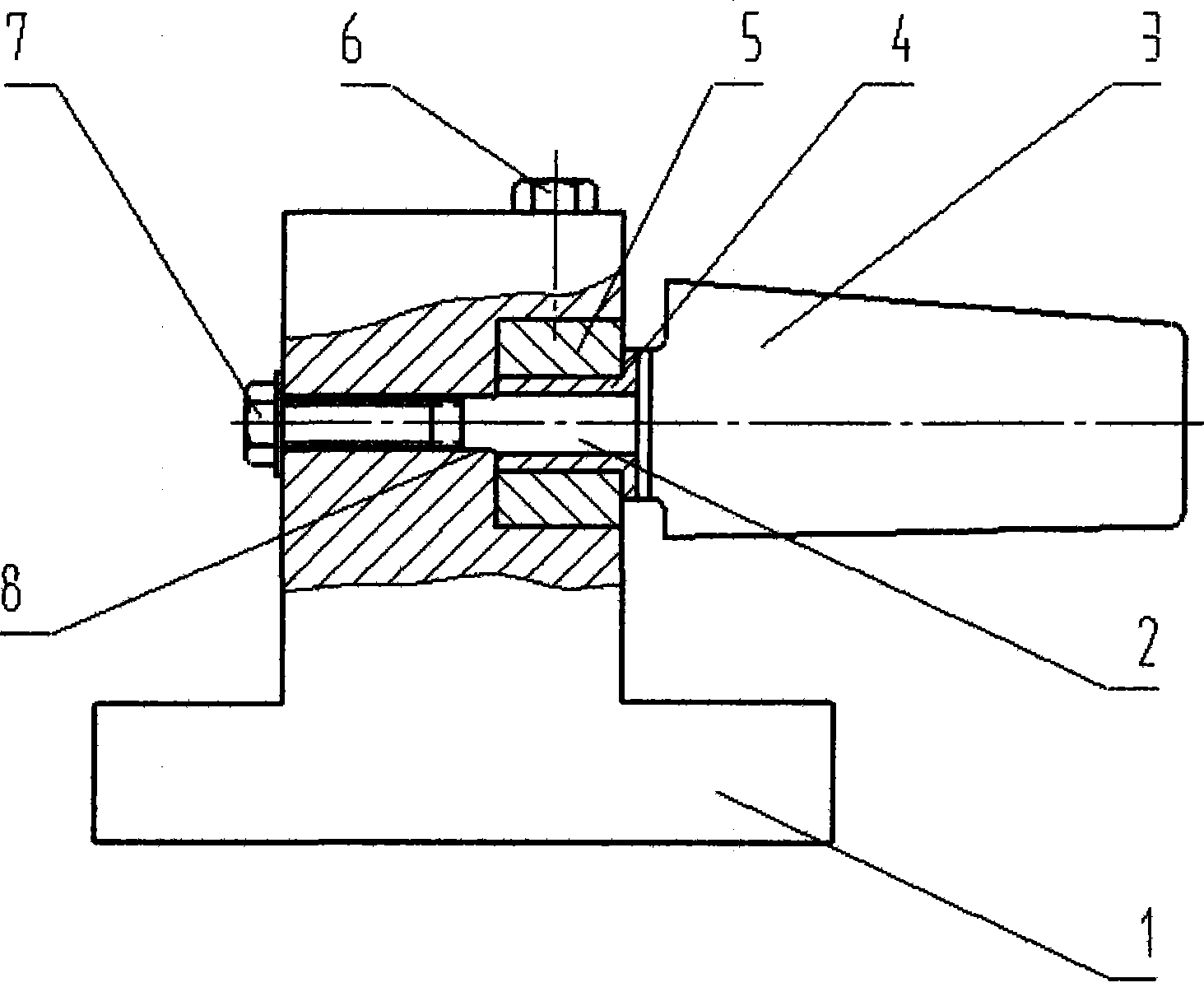

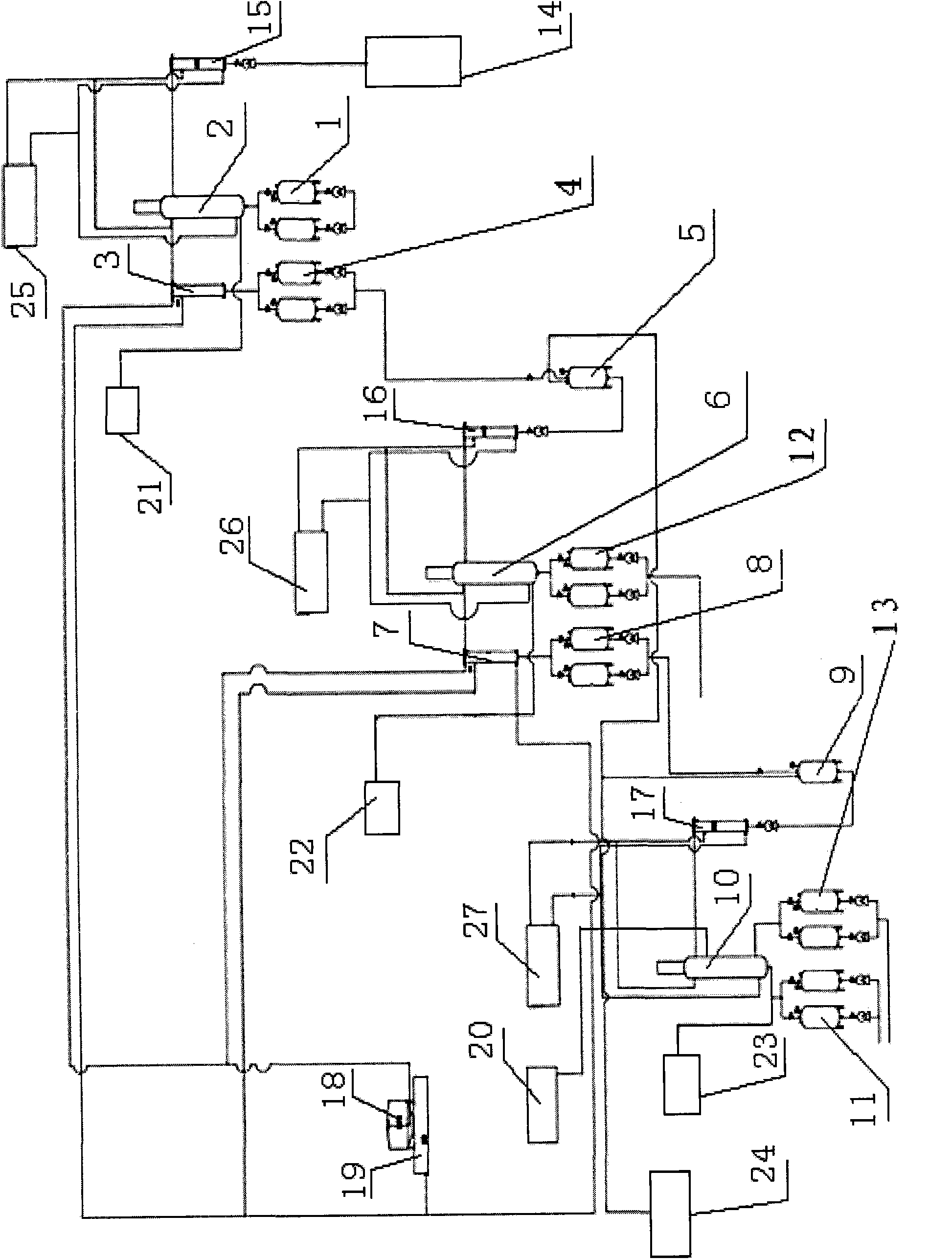

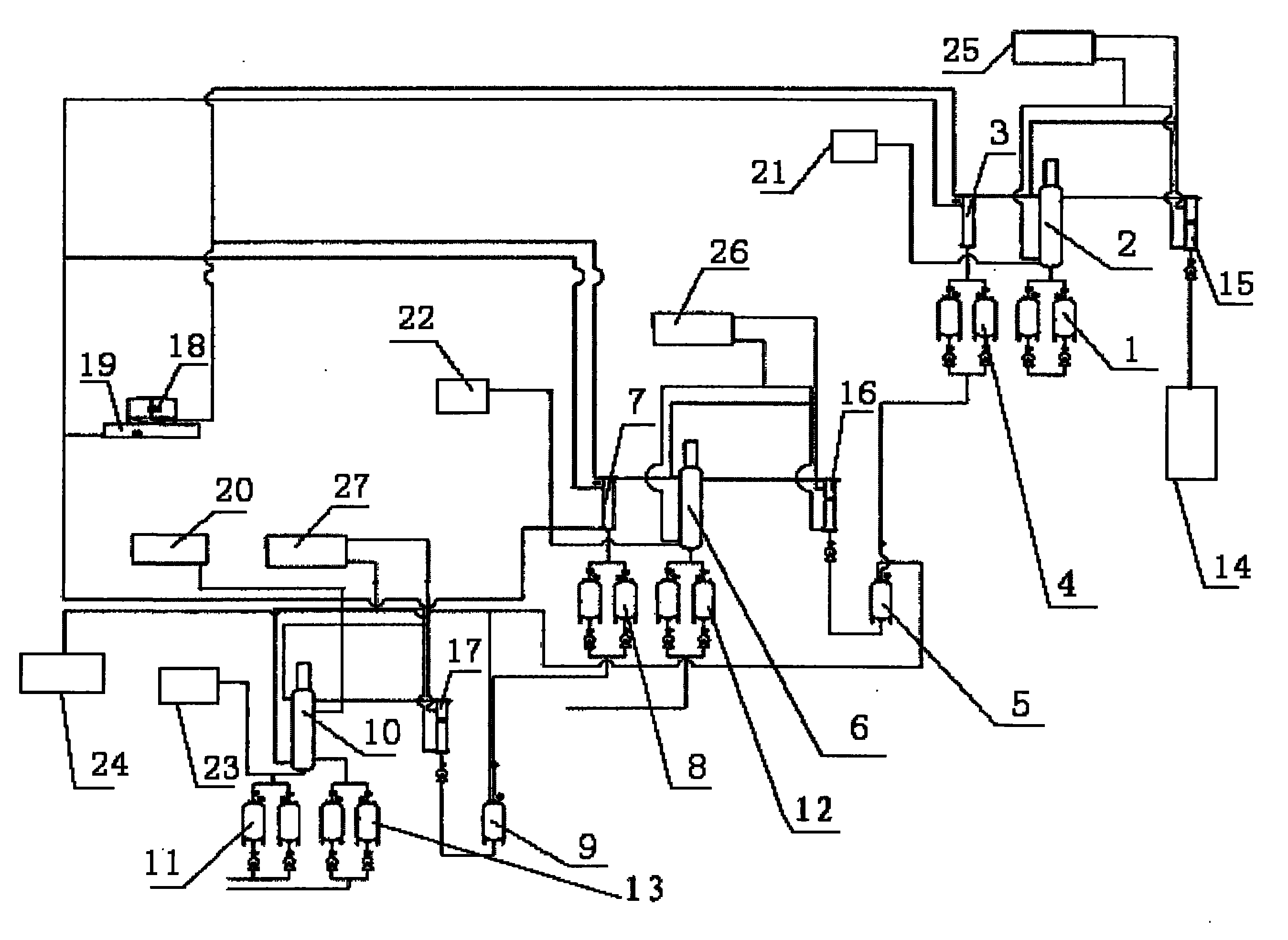

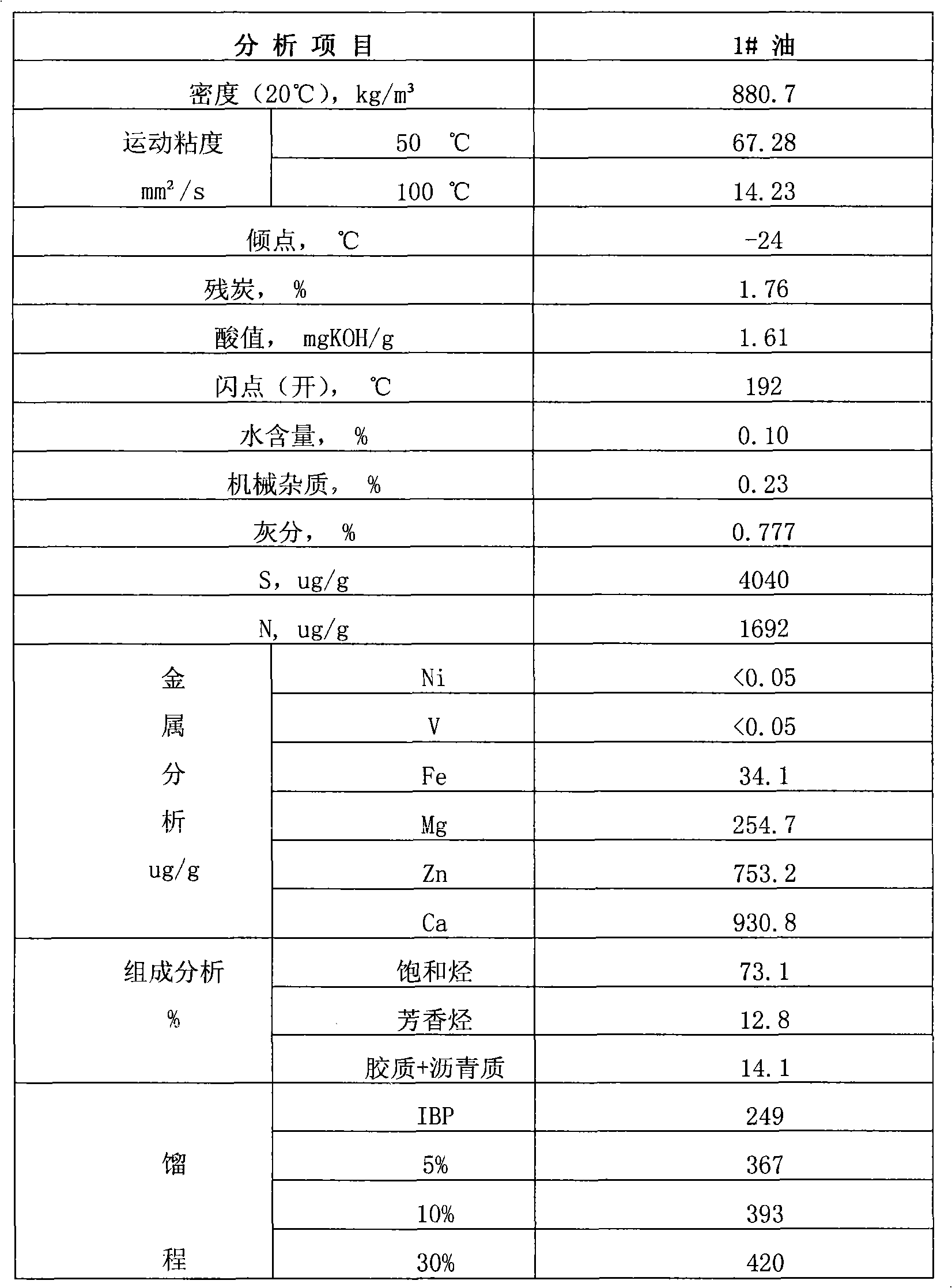

Lubricating oil regeneration device of waste internal-combustion engine

InactiveCN101775329AReasonable structural designGreat benefitMolecular distillationLubricant compositionWaste oilInternal combustion engine

The invention relates to a lubricating oil regeneration device of a waste internal-combustion engine, belonging to the technical field of regeneration device structures. The lubricating oil regeneration device comprises a pretreatment tank of raw materials; the pretreatment tank of the raw materials is connected with a first-stage heat exchanger which is connected with a first-stage distiller; the first-stage distiller is connected with a first-stage cooler and a first-stage waste oil tank; the firs-stage cooler is connected with a first-stage finished product oil tank which is connected with a first-stage intermediate oil tank which is connected with a second-stage heat exchanger; the second-stage heat exchanger is connected with a second-stage distiller which is connected with a second-stage cooler and a second-stage waste oil tank; the second-stage cooler is connected with a second-stage finished product oil tank which is connected with a second-stage intermediate tank; the second-stage intermediate tank is connected with a third-stage heat exchanger which is connected with a third-stage distiller; and the third-stage distiller is connected with a third-stage finished product oil tank and a third-stage waste oil tank. The invention has reasonable structural design and can thoroughly separate and purify light and heavy base oil components in the waste lubricating oil.

Owner:王树波 +2

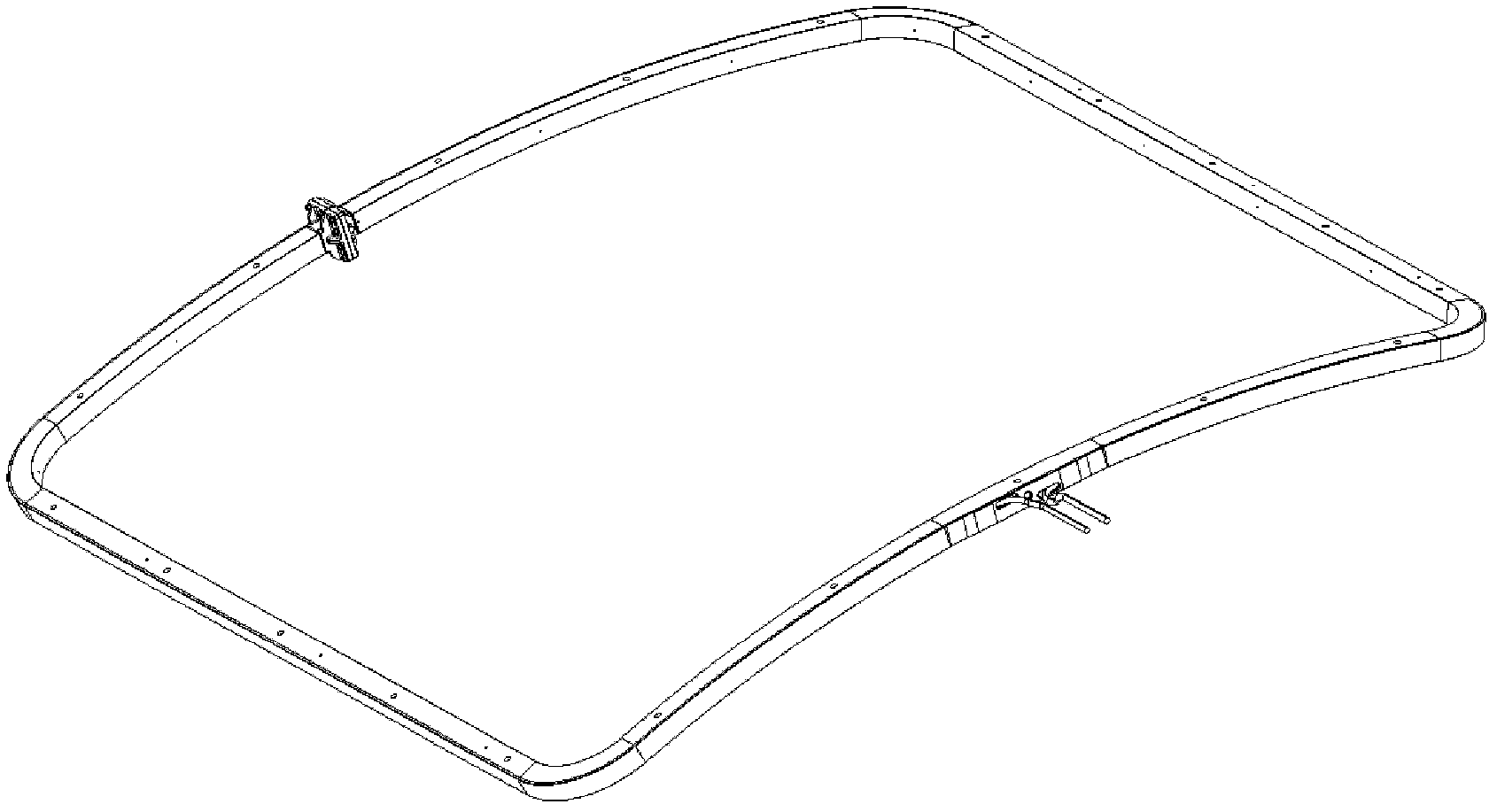

Method for narrow-gap laser welding with filler wires for superconducting coil box

InactiveCN103252578ATo achieve weldingTo meet the welding requirementsLaser beam welding apparatusNuclear fusionSuperconducting Coils

The invention discloses a method for narrow-gap laser welding with filler wires for a superconducting coil box. The method is used for a superconducting coil box of a nuclear fusion reactor, and narrow-gap laser welding with filler wires is performed for a large superconducting coil shell by the aid of laser, so that the whole coil box is sealed. The method includes the steps: firstly, arranging a narrow-gap V-shaped groove on a part to be welded and cleaning weld joints and surfaces by the aid of acetone; secondly, fixedly placing the part to be welded on a bearing fixture and a profiling fixture and continuously welding truncated edges by tack welding and laser through a laser machining head driven by a robot; and finally, performing laser welding with multilayer hot filler wires for groove weld joints to integrally seal the coil box. Layers are welded in a symmetrical and alternant welding sequence. The method solves the sealing problem of a superconducting coil in a first international thermonuclear experimental reactor plan of China, and an effective method for welding an ultra-large structure is provided.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Method for preparing (S)- or (R)-2-aminobutanamide through transaminase biocatalysis

ActiveCN106834372AHigh optical purityReduce manufacturing costFermentationHigh selectivityRaw material

The invention discloses a method for preparing (S)- or (R)-2-aminobutanamide through transaminase biocatalysis. The method comprises the following steps: taking transaminase as a biocatalyst and catalyzing carbonyl on 2-carbonylbutylamide into amino in the presence of an amino donor, thereby obtaining the (S)- or (R)-2-aminobutanamide. The used transaminase refers to any one of Cv-omega-TA WT, Cv-omega-TA W60C, Vf-omega-TA, ATA-117 and ATA S9. According to the method disclosed by the invention, the (S)- or (R)-2-aminobutanamide is prepared by taking the 2-carbonylbutylamide as a raw material through a biocatalysis method. The transaminase is used for catalysis of carbonyl amide substances first, the transaminase with high efficiency and high selectivity can be successfully screened, the reaction selectivity is high, the product yield is 85% or higher, the ee value of the product is more than 99.5% or higher, and the problems in the prior art that the product yield is low and the ee value is not high are completely solved.

Owner:HAINAN UNIVERSITY

Extracting and purifying method of dysprosium oxide

InactiveCN106745171AIncrease loadHigh purityRare earth metal oxides/hydroxidesSolid sorbent liquid separationLiquid wasteDysprosium

The invention discloses an extracting and purifying method of dysprosium oxide. Existing roughly machined collected low-purity dysprosium oxide is re-purified through the steps of to-be-purified solution preparation, intermediate agent preparation, separation column preparation, elution column transformation, adsorption operation, eluent ion exchange operation, sampling analysis according to a collected solution in volume, sediment concentration, merging and collection, liquid waste treatment and the like, so that the purity of the dysprosium oxide is up to 99.998 to 99.99999 percent.

Owner:中国稀有稀土股份有限公司 +1

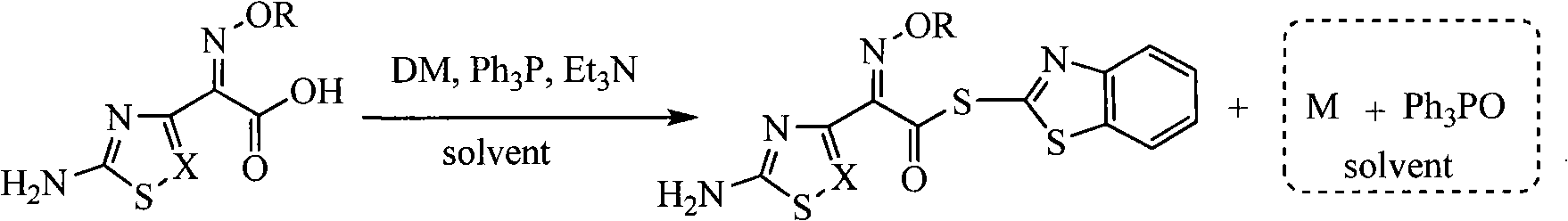

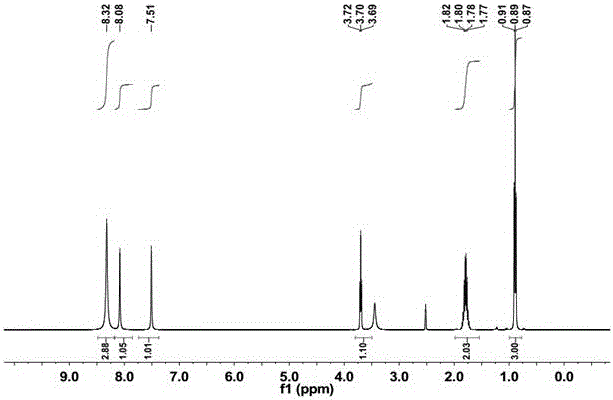

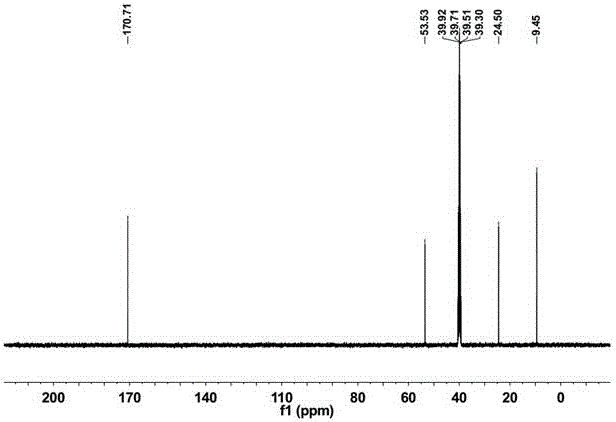

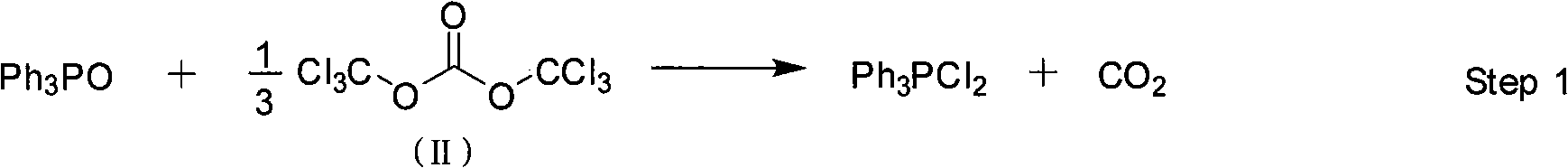

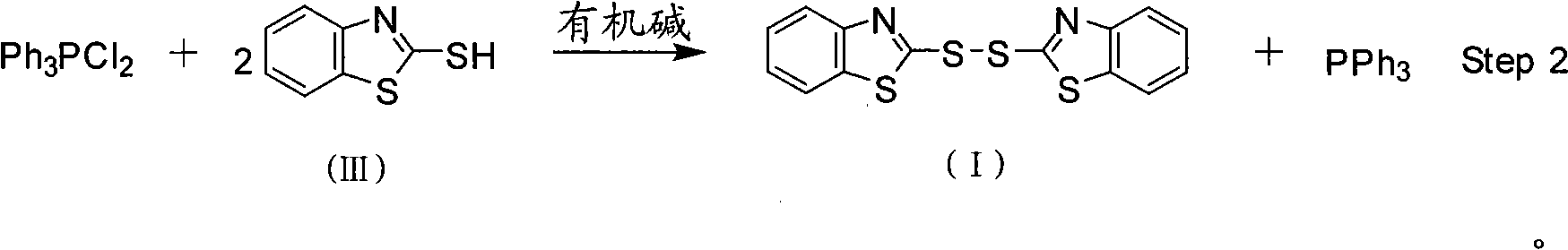

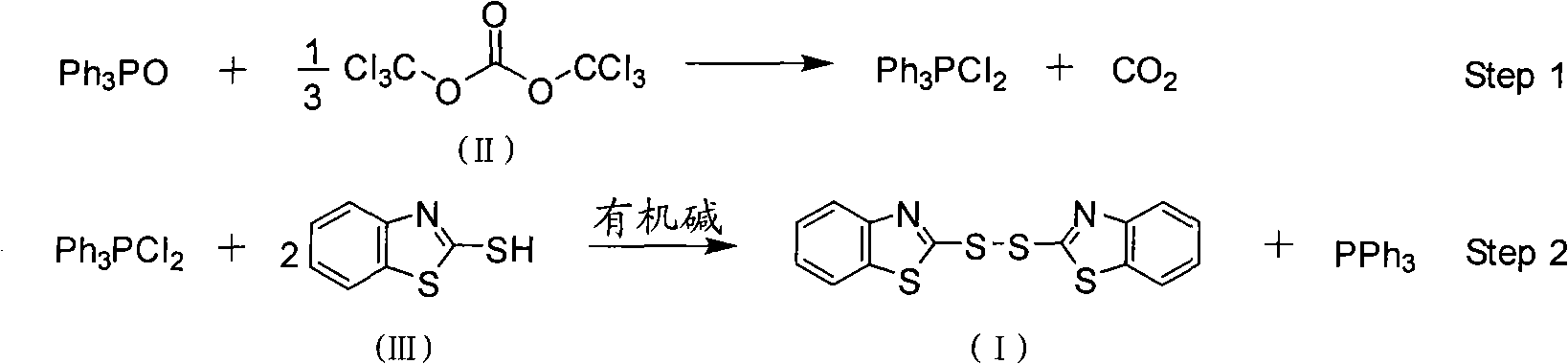

Bisbenzothiazole disulfide and triphenylphosphine preparation by means of one pot

InactiveCN101357908AEasy to separate and purifyHigh yieldGroup 5/15 element organic compoundsOrganic baseBottle

The invention discloses a method for preparing bisbenzothiazole disulfide (DM) and triphenylphosphine (TPP) by a pot method, comprising the following processes: an organic solvent A, bis (trichloromethyl) carbonate shown in formula (II) and triphenyl phosphine oxide are sequentially added to a reaction bottle, and the insulating reaction is carried out for 0.5 to 10 hours at the temperature of minus 30 DEG C to 90 DEG C; the reaction solution is added with mixed solution of 2-sulfhydryl benzothiazole and organic base which are dissolved by an organic solvent B shown in formula (III), and the mixture reaction is carried out for 0.5 to 10 hours at the temperature of -30 DEG C to 90 DEG C; after the reaction is completed, drawing and filtering are carried out, the filter cake is dried and then the bisbenzothiazole disulfide is obtained, the organic solvent in the filter solution is recycled to obtain crude products, the crude products are re-crystallized to obtain the triphenylphosphine. The method has the advantages of simple operation, high reaction yield, high product purity and good atom economy, thus solving the problem that by-products can cause environment pollution, and the like, owning to difficult recovery and utilization in the process of producing cephalothin active ester, and the method has great implement value and potential social and economic benefits.

Owner:ZHEJIANG UNIV OF TECH +2

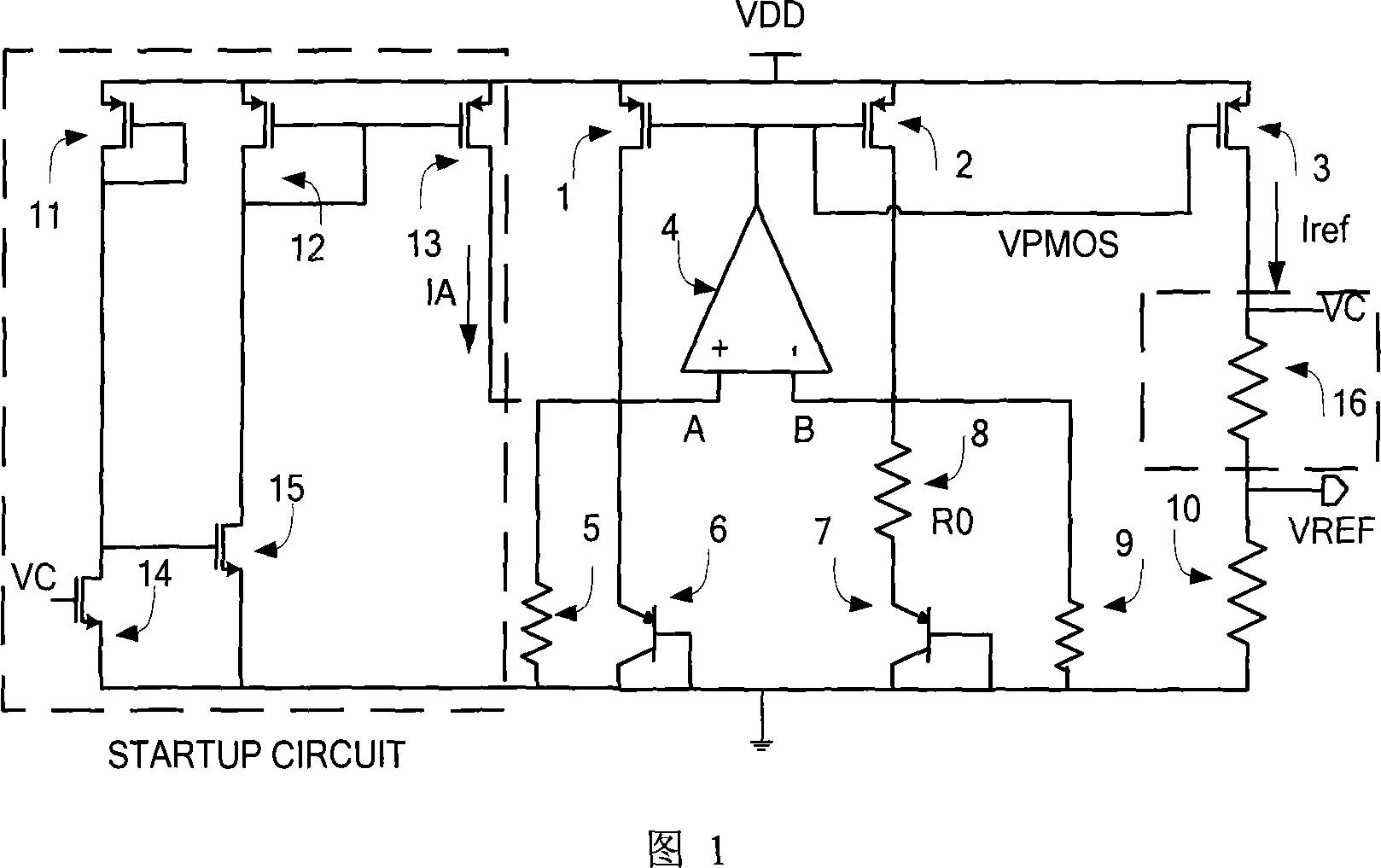

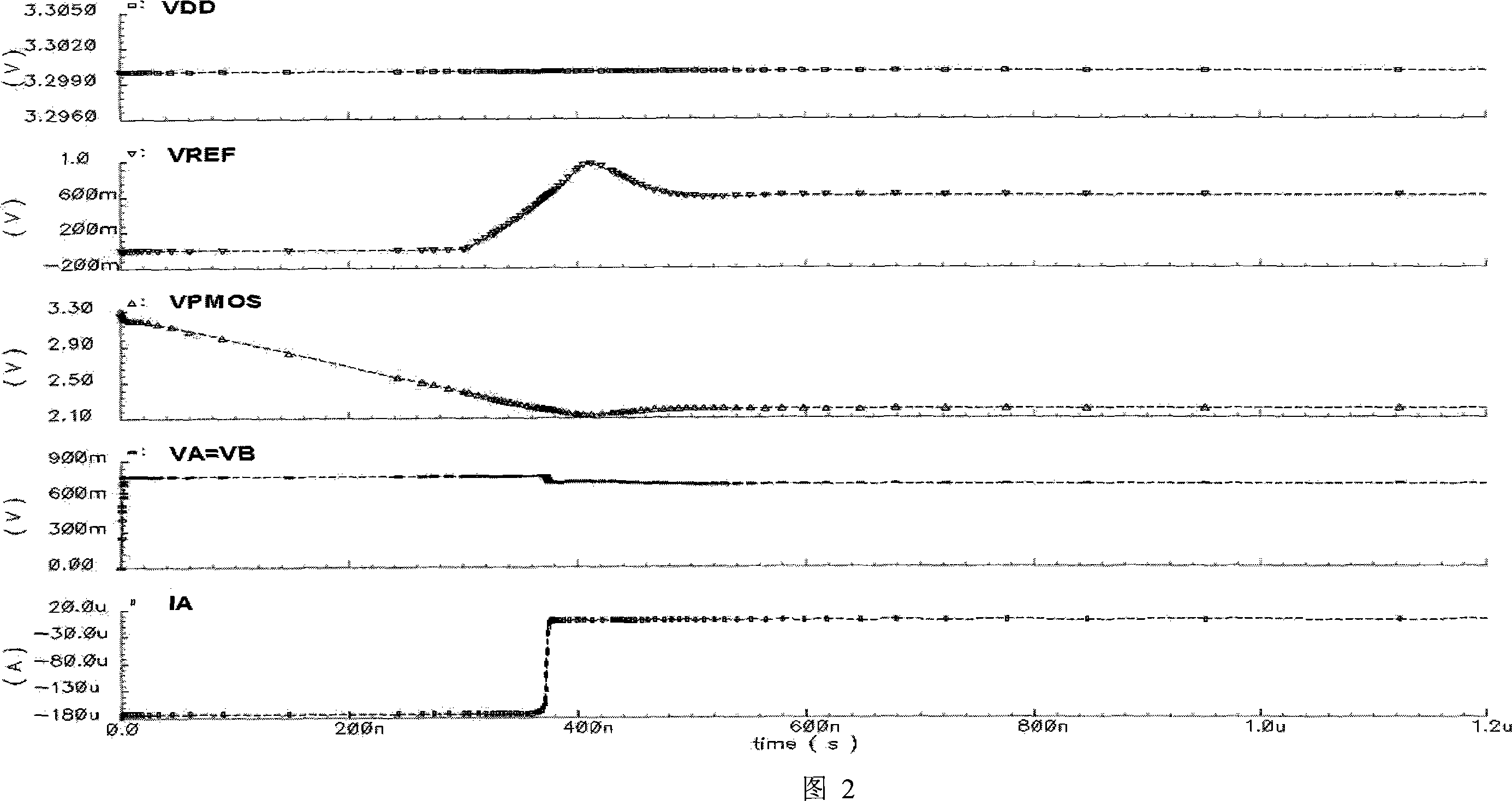

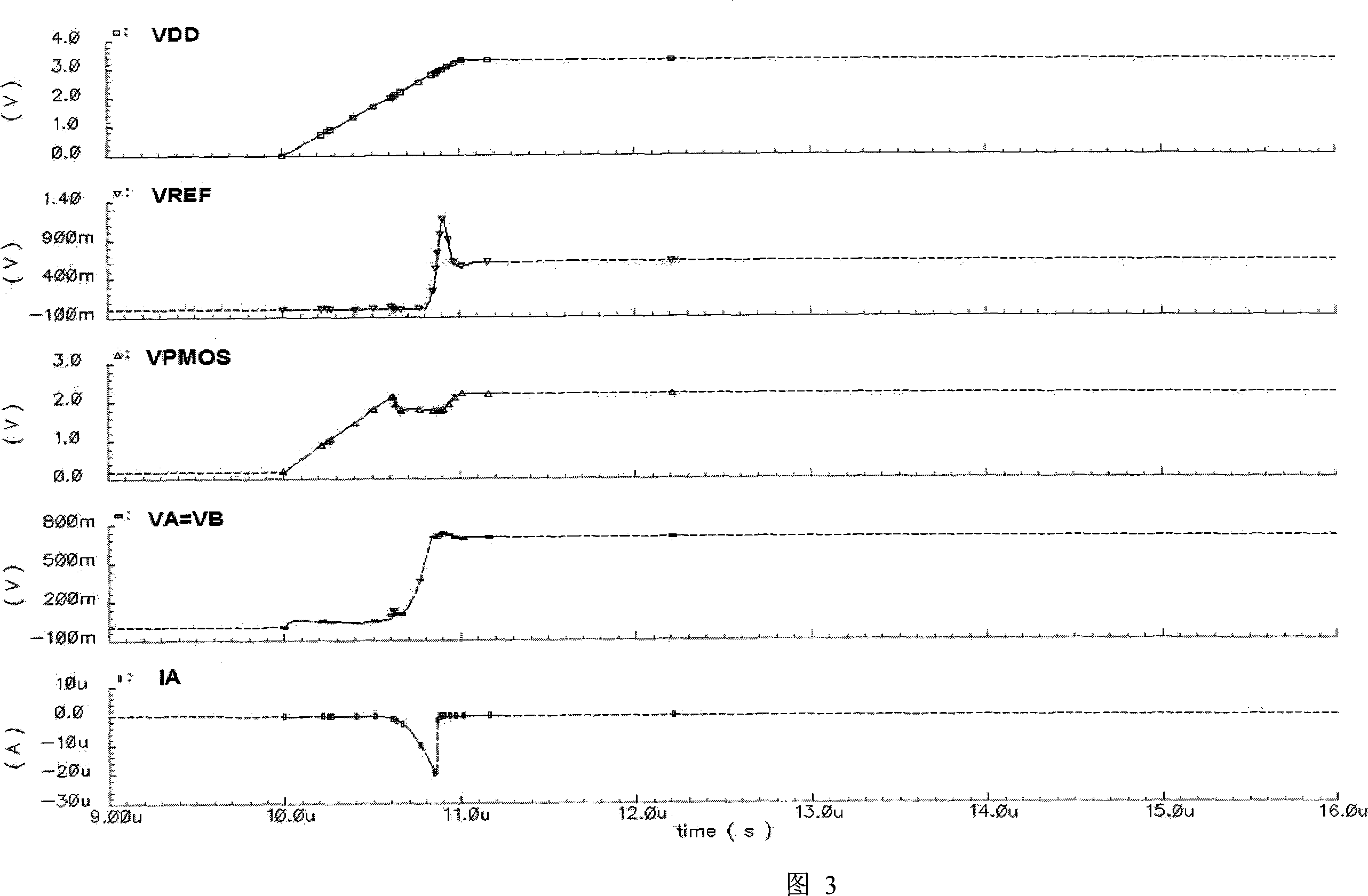

Start circuit for mass production of reference voltage source suitable for Sub1V current mode

InactiveCN101196757AEliminate malfunctionsEasy to implementElectric variable regulationElectrical resistance and conductanceVoltage source

The invention belongs to the technology field of a reference source analog integrated circuit, in particular to a starting circuit being suitable for a reference voltage source capacity with Sbu1V current mode. The circuit is composed of three PMOS pipes, two NMOS pipes and a resistance mutually connected through a circuit. A reference voltage part is composed of three PMOS pipes, an operational amplifier, three triodes and a plurality of resistances mutually connected through a circuit. The starting circuit of the invention can avoid the aftereffect of abnormal working the operational amplifier maladjustment voltage Vos brings to chips and release zero state. The starting circuit has simple structure and easy realization, and is able to be applied in traditional reference voltage source.

Owner:FUDAN UNIV

Control method and control device of oxygen production and assisted respiration integration

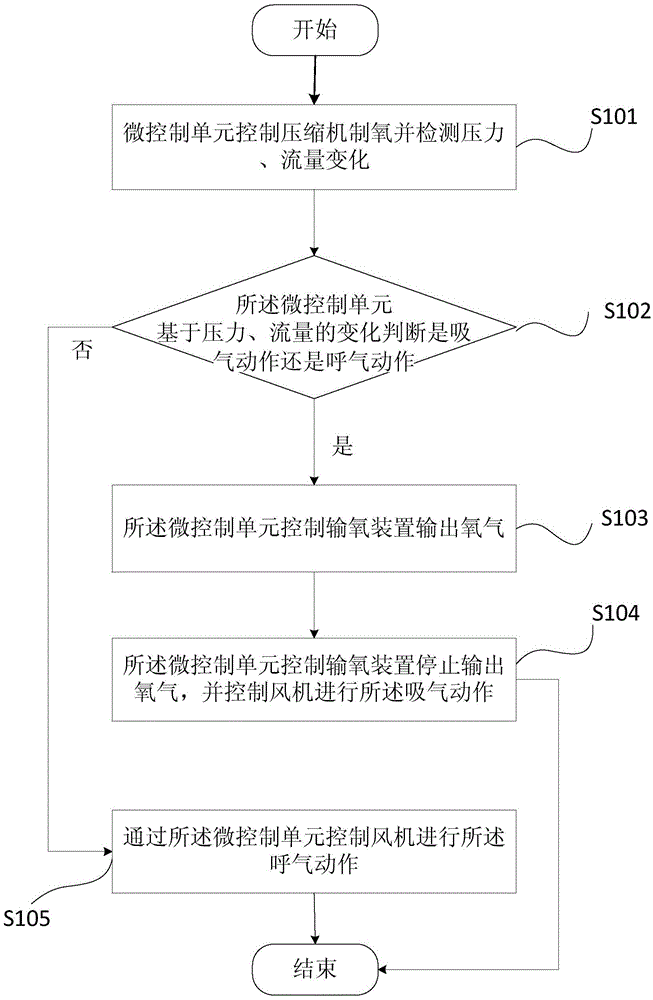

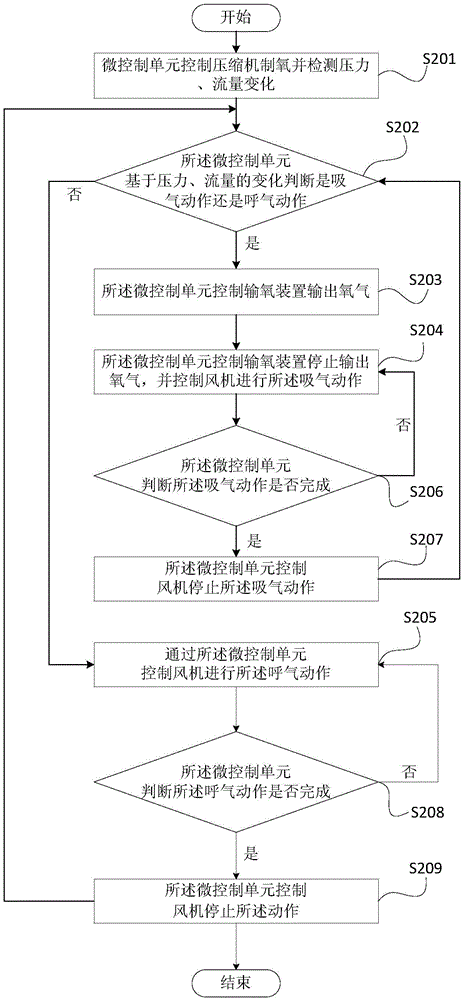

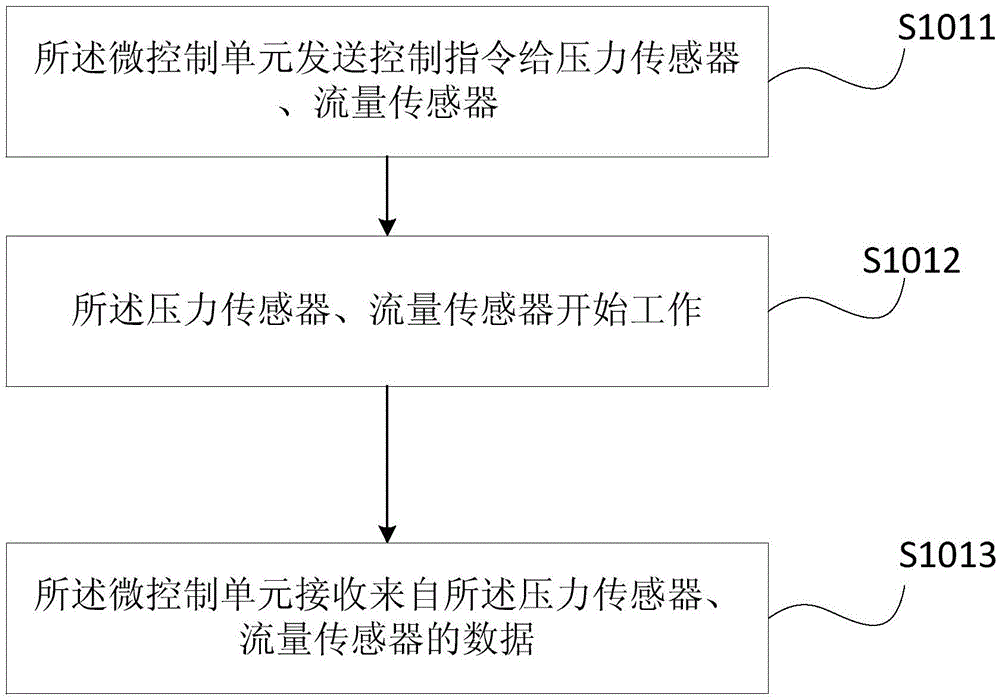

InactiveCN105664319ASolve the disadvantages of non-invasive ventilation but not oxygen productionReduce use costRespiratorsMedical devicesNoninvasive ventilationEngineering

The present invention provides a control method integrating oxygen production and assisted respiration, which is used to produce oxygen and provide non-invasive ventilation, comprising the following steps: a. A micro-control unit controls the compressor to produce oxygen and detects changes in pressure and flow; b. The micro-control unit The control unit judges whether it is an inhalation action or an exhalation action based on the change of pressure and flow rate. If it is an inhalation action, then execute step c and step d. If it is an exhalation action, then execute step e; c, the micro control unit controls The oxygen delivery device outputs oxygen; d, the micro control unit controls the oxygen delivery device to stop outputting oxygen, and controls the fan to perform the inhalation action; e, the micro control unit controls the fan to perform the exhalation action. The invention can realize the integrated process of oxygen production and assisted respiration.

Owner:SHENYANG RMS MEDICAL TECH

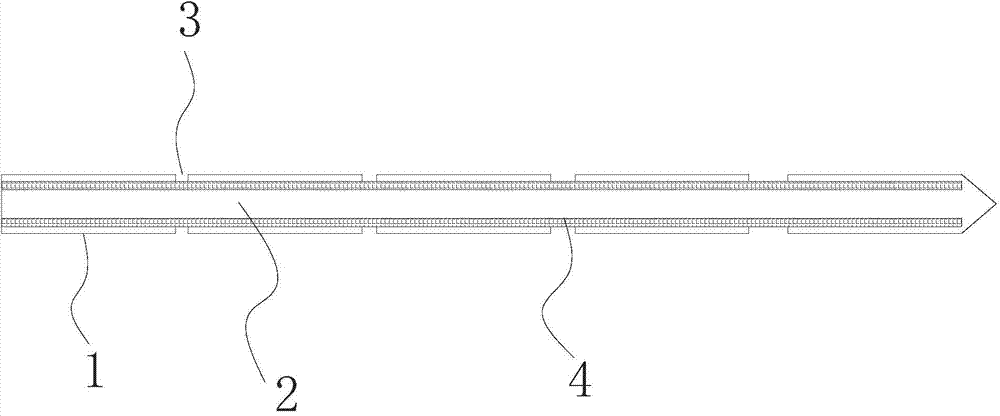

Multi-gap electromagnetic ablation cutter

ActiveCN104490470AIncrease working sizeShorten operation timeSurgical instrument detailsElectrical conductorMultiple point

The invention discloses a multi-gap electromagnetic ablation cutter. The multi-gap electromagnetic ablation cutter is of a coaxial cylinder shape, wherein an inner layer and an outer layer of the ablation cutter are metal conductors; an insulation medium is filled between the metal conductors in the inner layer and the outer layer; at least two radial gaps are formed in the metal conductors in the outer layer at an equal interval. The multi-gap electromagnetic ablation cutter is capable of burning the precutting surface of a liver by electromagnetic wave at multiple points for a single time; an integral bleeding-stopping surface can be built at a time, so that the operation time is shortened while the operation bleeding is remarkably reduced.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Three-dimensional metal label pressing and attaching technique method

ActiveCN105775286AExquisite structure designAdvanced technologyLabelling machinesMetalMaterials science

The invention relates to a three-dimensional metal label pressing and attaching technique method. The three-dimensional metal label pressing and attaching technique method comprises the following steps of: step one. preparing three-dimensional metal labels; step two. preparing a set of three-dimensional metal label pressing and attaching device; step three. pressing and attaching the three-dimensional metal labels to a right label bearing plate B; step four. tearing and stripping top transparent films of the three-dimensional metal labels on the label bearing plate B; step five. repeating the step three and the step four, continuously pressing and attaching the three-dimensional metal labels to a label bearing plate A, and tearing and stripping top transparent films till the pressing and attaching of the three-dimensional metal labels on the label bearing plates A are completed; and step six. changing the label bearing plates into other label bearing objects after completing the whole set of pressing and attaching work on the label bearing plate A and the label bearing plate B ,and continuously repeating the step three, the step four and the step five so as to realize continuous automatic production. The three-dimensional metal label pressing and attaching technique method is advanced in technique, high in pressing and attaching accuracy, low in defective rate, high in working efficiency and large in yield, replaces manual film tearing operation very well, avoids existing problems and has very high actual use value and economic benefits.

Owner:GIESECKE & DEVRIENT (CHINA) INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com