Automatic plate reversing-sawing device and sawing method thereof

A sawing device and fully automatic technology, applied in sawing components, sawing equipment, feeding devices, etc., can solve the problems of increasing manual workload, difficult to complete complex cutting, and high difficulty in operation, and achieve the improvement of automation level and production. Efficiency, large market space and economic benefits, the effect of solving the low degree of numerical control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further understand the features, technical means, specific objectives and functions achieved by the present invention, and to analyze the advantages and spirit of the present invention, a further understanding of the present invention can be obtained through the following detailed description of the present invention in conjunction with the accompanying drawings and specific embodiments.

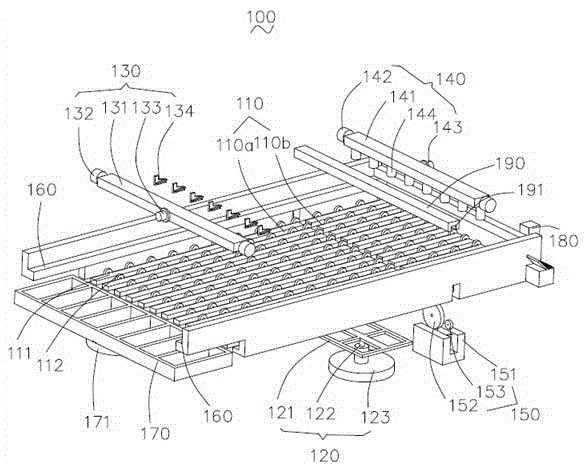

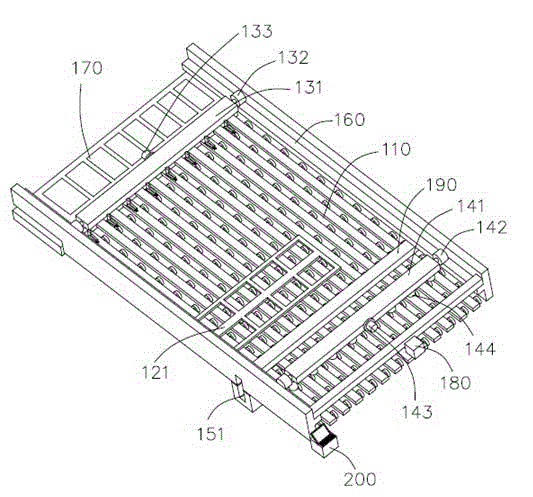

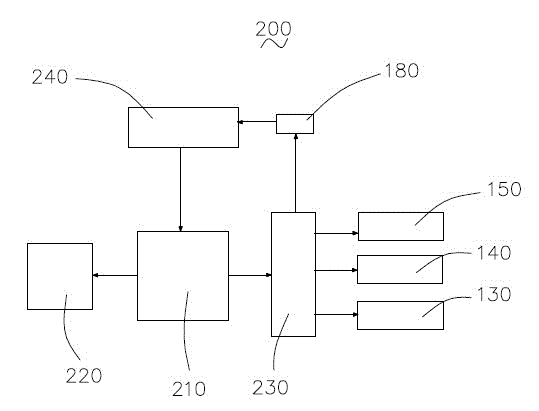

[0038] As shown in the drawings of the specification, a full-automatic board reversing sawing device includes a sawing device body 100 and a control system 200 arranged on the sawing device body 100 . The sawing device body 100 includes a bracket 110 , a reversing mechanism 120 , a pinching mechanism 130 , a pushing mechanism 140 and a sawing mechanism 150 . The bracket 110 is used to support the board, the reversing mechanism 120 is used to change the arrangement direction of the board according to the cutting needs, and the pinch mechanism 130 is used to pinch the board t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com