Patents

Literature

66results about How to "Eliminate malfunctions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

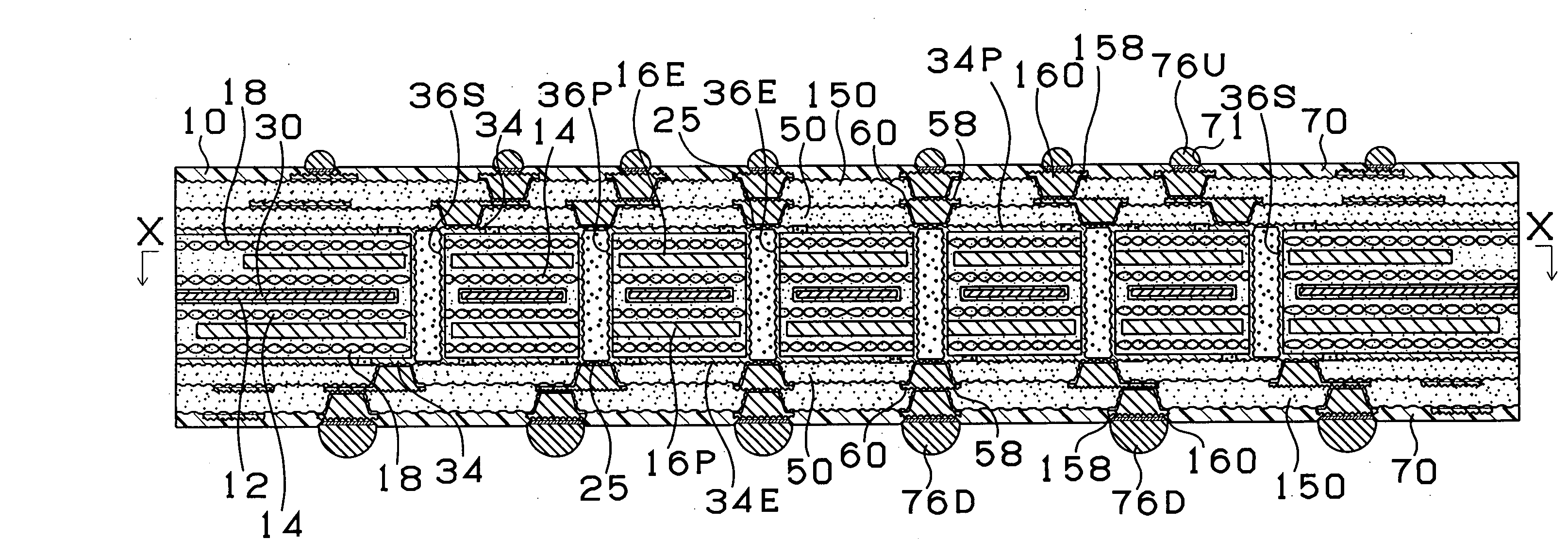

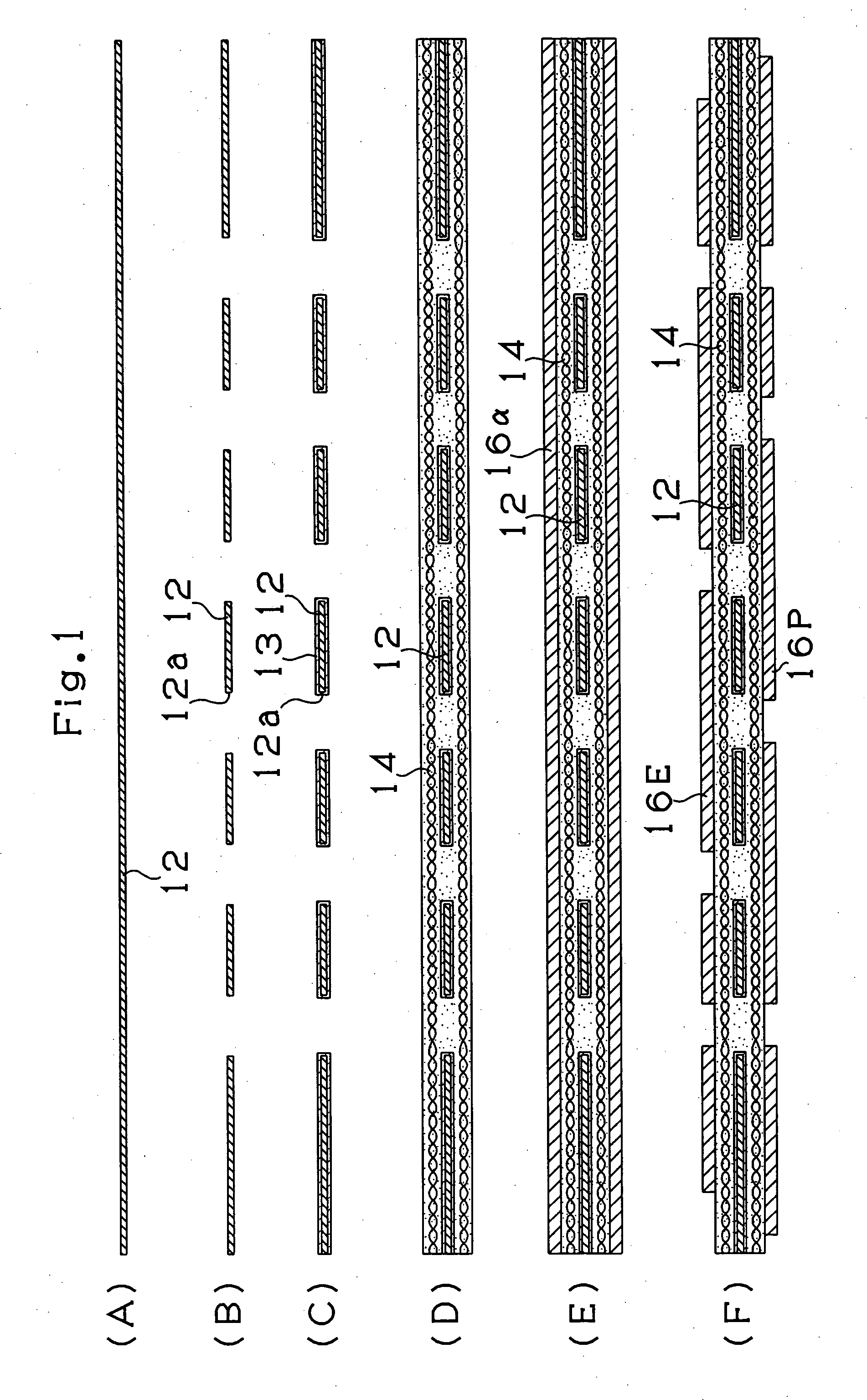

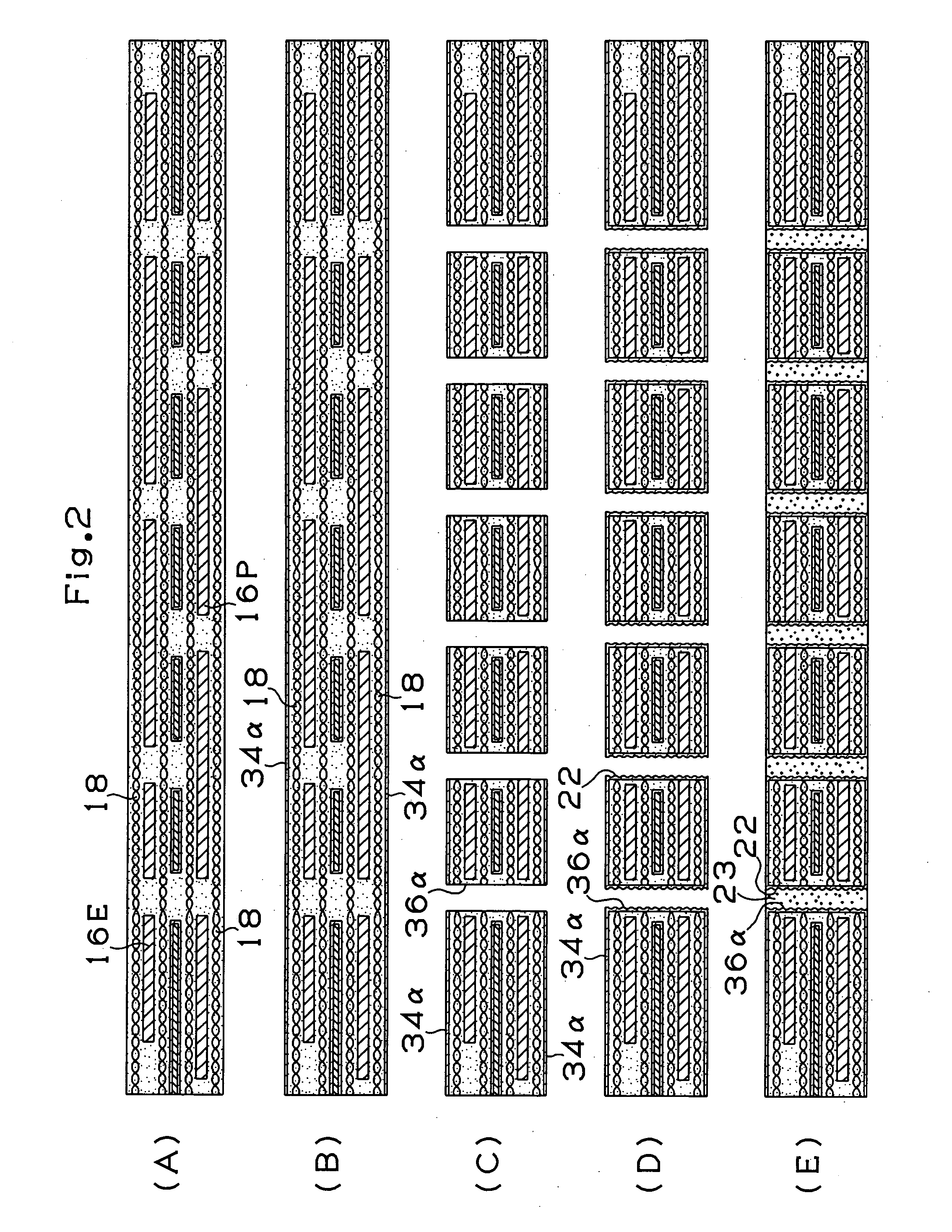

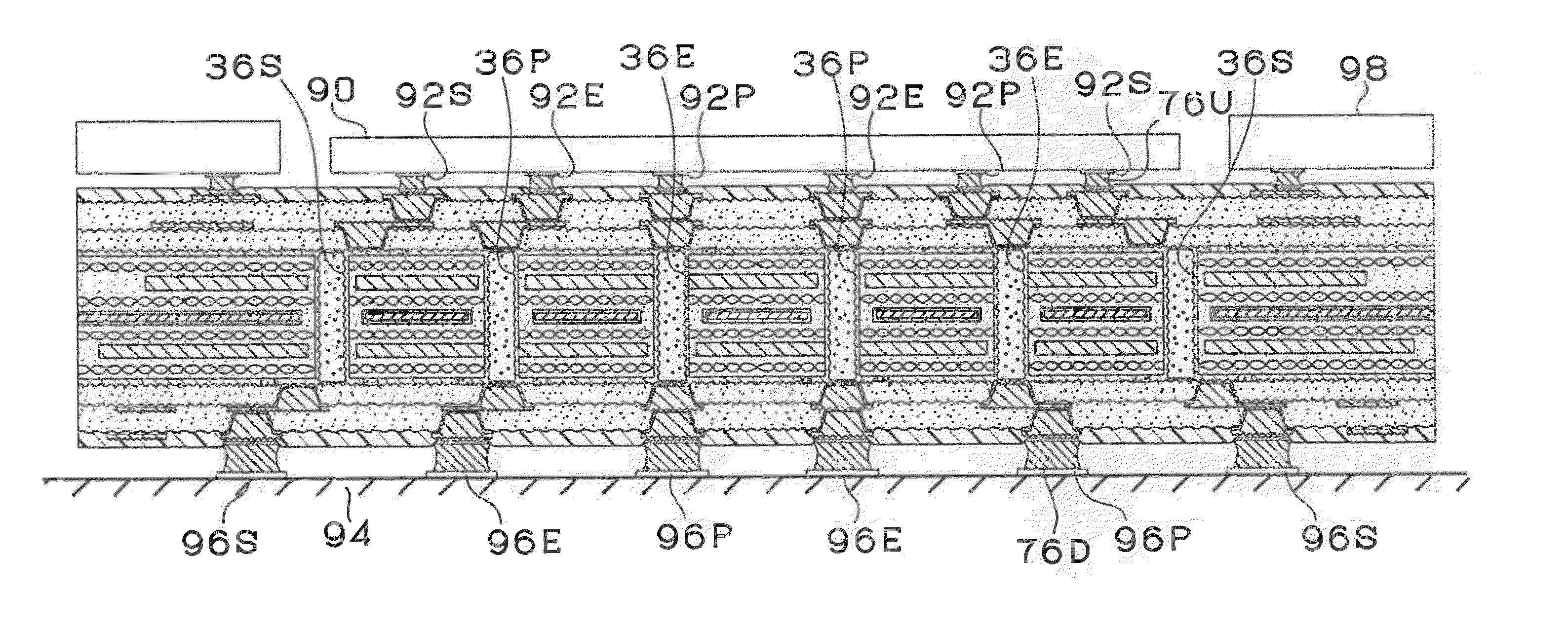

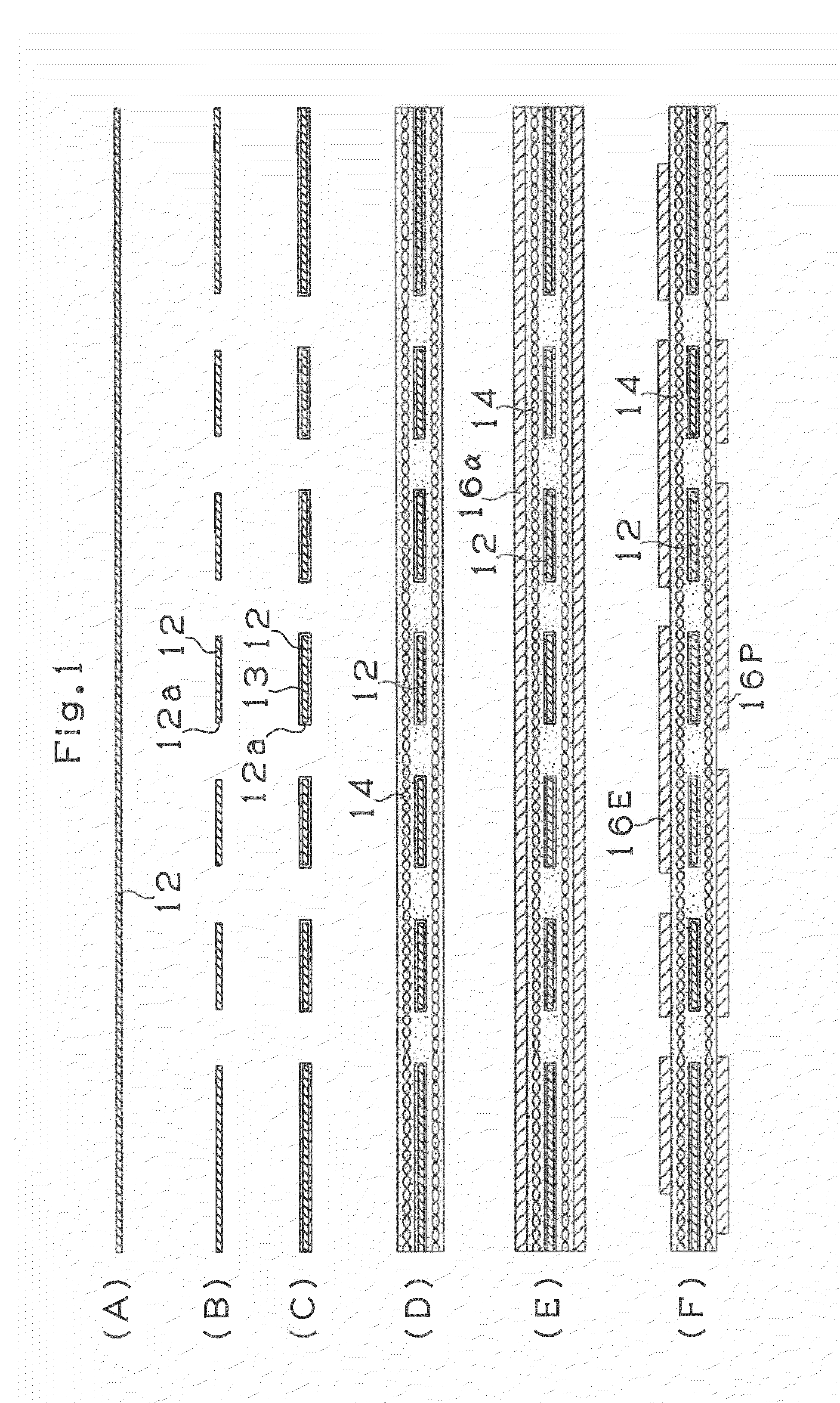

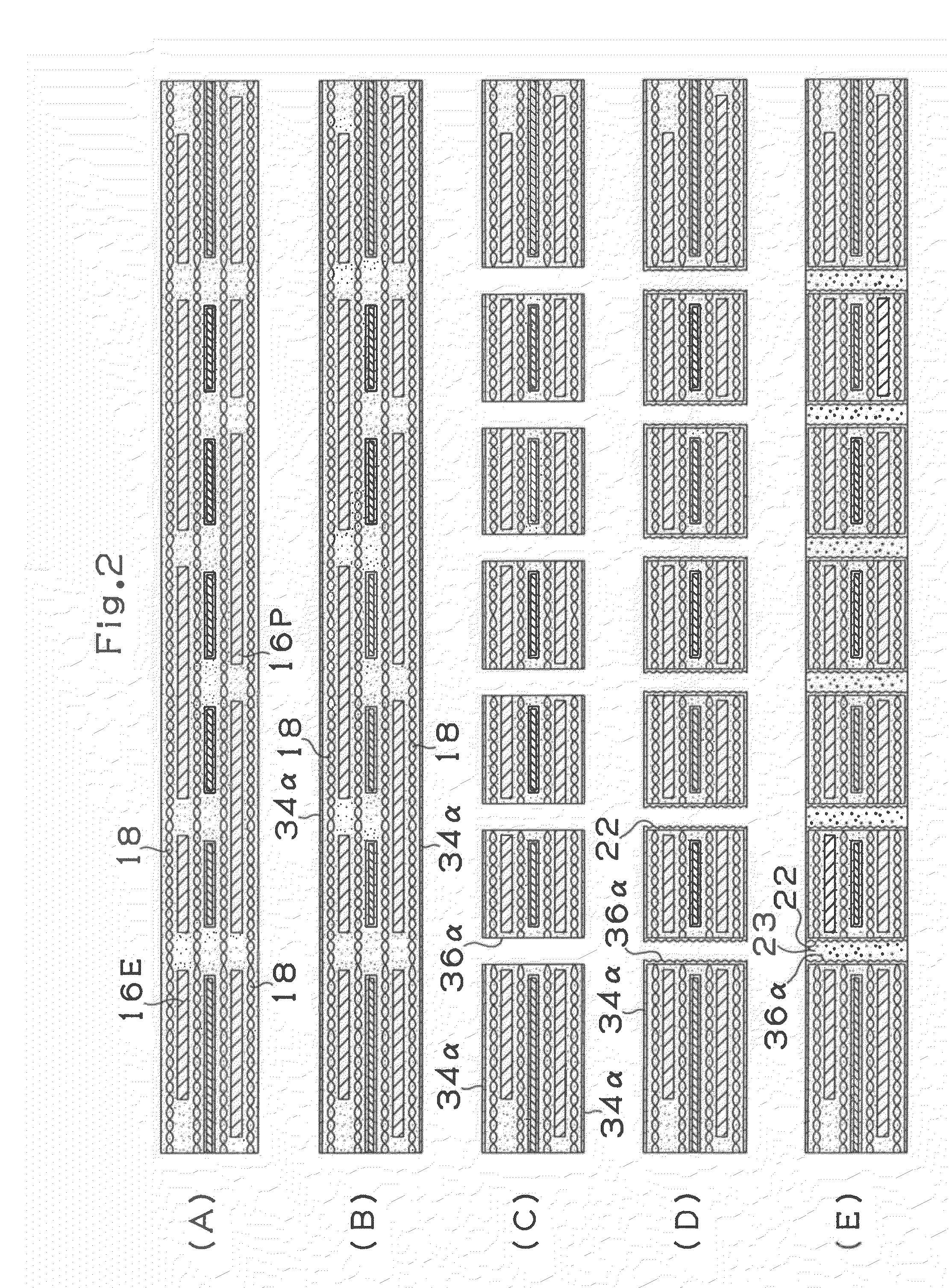

Multilayer printed wiring board

ActiveUS20070029106A1Improve matchExcellent electrical propertiesSemiconductor/solid-state device detailsPrinted electric component incorporationEngineeringElectromotive force

In a core substrate 30, a ground through hole 36E and a power through hole 36P are disposed in the grid formation, so that electromotive force induced in X direction and Y direction cancel out each other. As a result, even if mutual inductance is reduced and a high frequency IC chip is loaded, electric characteristic and reliability can be improved without generating malfunction or error.

Owner:IBIDEN CO LTD

Normal brake system used for airplane and having take-off line brake capability

InactiveCN104787310AReduce workloadEliminate malfunctionsAircraft braking arrangementsEngineering principlesElectro hydraulic

The invention discloses a normal brake system used for an airplane and having take-off line brake capability. The normal brake system comprises a hydraulic brake valve, an electric valve, an electro-hydraulic servo valve, an anti-slip control box, a hydraulic switch and a speed sensor, wherein the hydraulic brake valve is mounted near a pedal mechanism under a bottom plate of a cockpit, controlled by operation of stepping on a brake pedal by a pilot and used for outputting a required brake pressure; the electric valve is mounted on a hydraulic pipeline at the downstream part of the hydraulic brake valve; the electro-hydraulic servo valve is mounted on a hydraulic pipeline at the downstream part of the electric valve; the anti-slip control box is mounted in a main landing gear cabin and powered by a power supply on the airplane; the hydraulic switch is mounted on a hydraulic pipeline between the hydraulic brake valve and a first oil inlet of the electric valve. The normal brake system can meet a braking demand of an existing normal brake system of the airplane on a take-off line, is reasonable in structure, simple, convenient, feasible, consistent with a man-machine engineering principle and favorable for reducing the burden of the pilot, and eliminates accident potentials caused by false operation of switching on a take-off line brake switch.

Owner:XIAN AVIATION BRAKE TECH

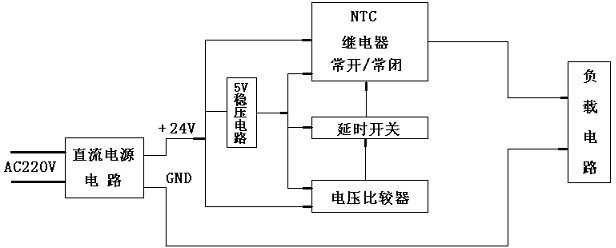

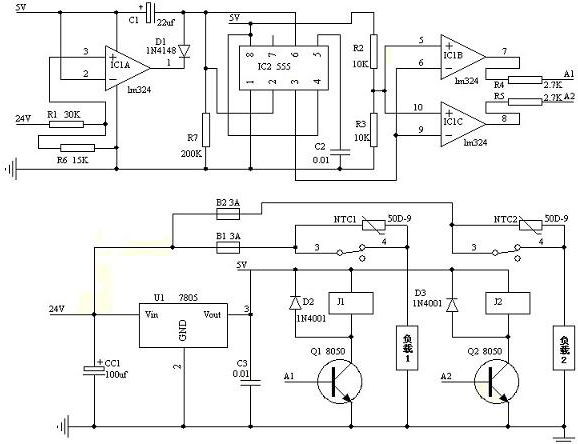

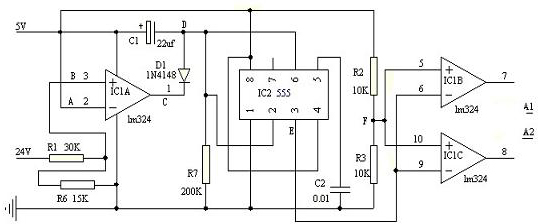

Novel surge control circuit

InactiveCN102354965ANo lossNo self-heating phenomenonEmergency protective arrangements for limiting excess voltage/currentLoad circuitTime delays

The invention relates to a novel surge control circuit and belongs to the technical field of electronic circuits. A relay rapidly works and is closed at the moment of powering-on. A power supply supplies power to a load through a thermistor NTC. Because of the characteristics of the thermistor NTC, supply current is kept in a stable and constant current state. When a capacitor in a load circuit is charged and works stably, the relay is opened, the power supply supplies power to the load through the normally-closed contact of the relay. Since the thermistor NTC and the normally-closed contact of the relay are connected in parallel, the thermistor NTC is disconnected and stops working. By detecting input voltage through an instantaneous comparison amplifier, when the power supply is turned off and is turned on again, the instantaneous comparison amplifier can output a resetting signal to reset a time-delay switching circuit, so as to ensure that the switching time of a time-delay switch is stable and the misoperation is eliminated when the time-delay switch is turned on or off at each time. Therefore, the requirement on the instantaneous power of the power supply is reduced, the damage rate of the thermistor NTC is greatly decreased, the power supply cost is reduced, the power consumption is extremely low because the novel surge control circuit is in a static state after surge control work is completed, and the common practicability and the good economic and technical efficiency are realized.

Owner:江苏普明光电科技有限公司

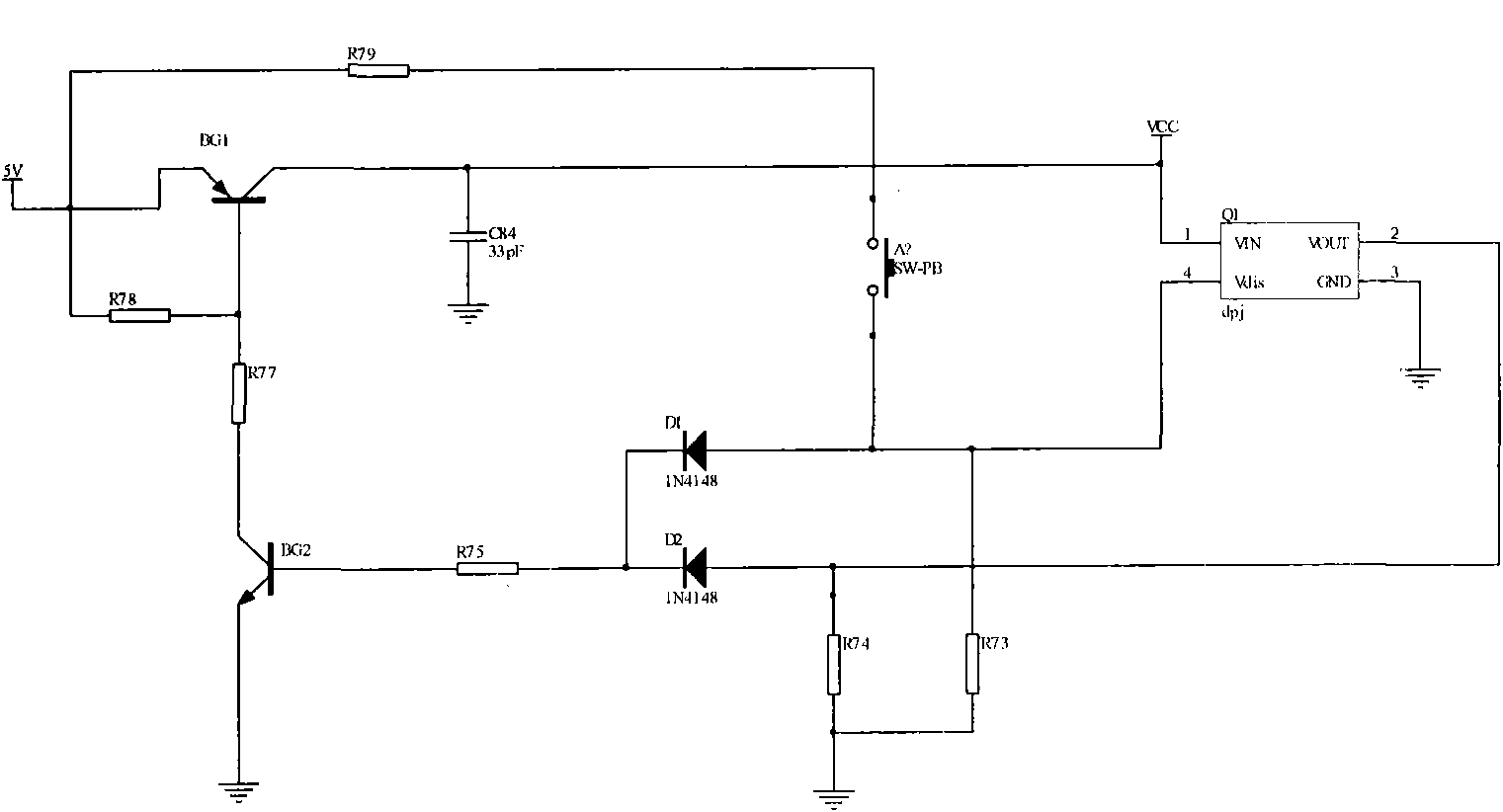

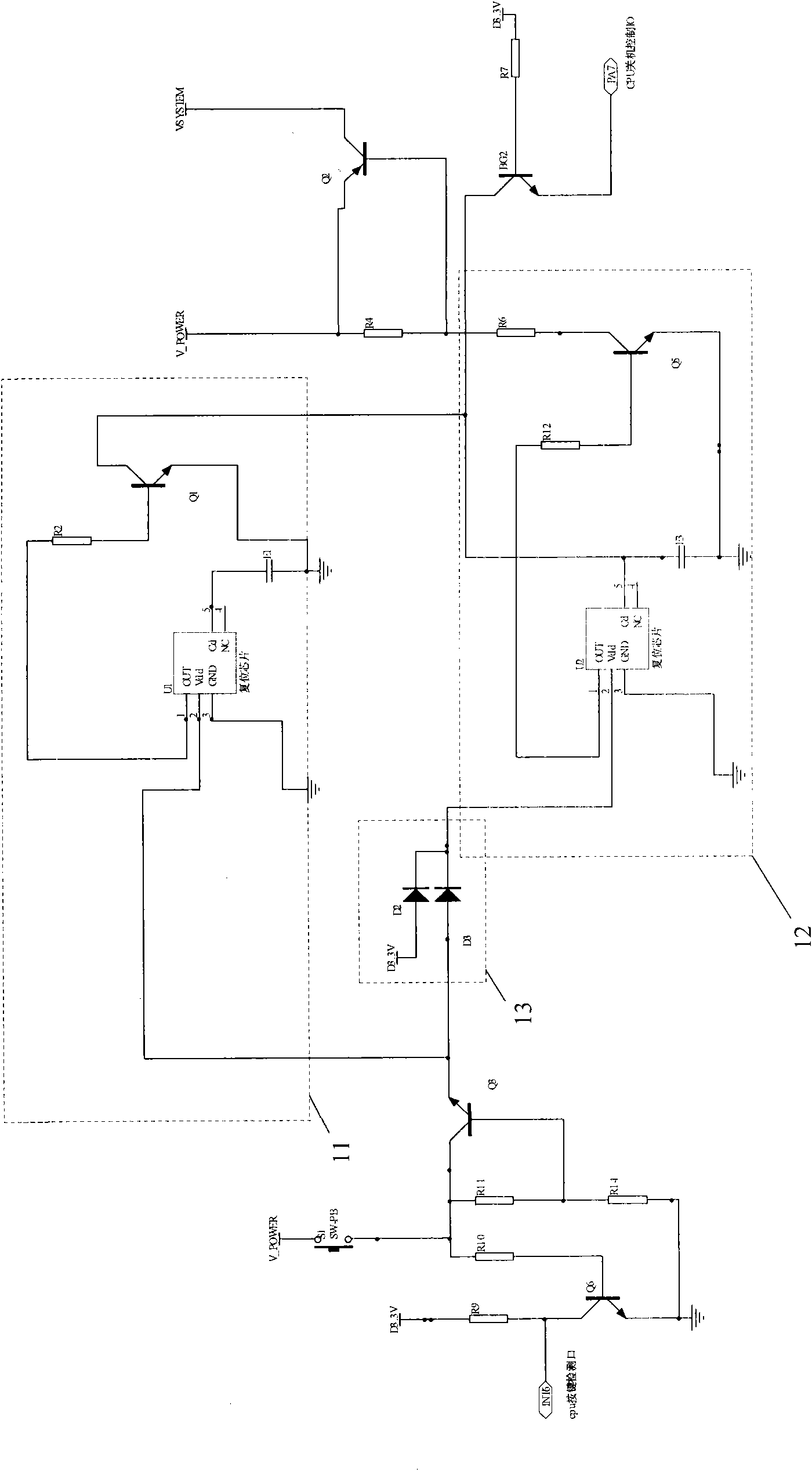

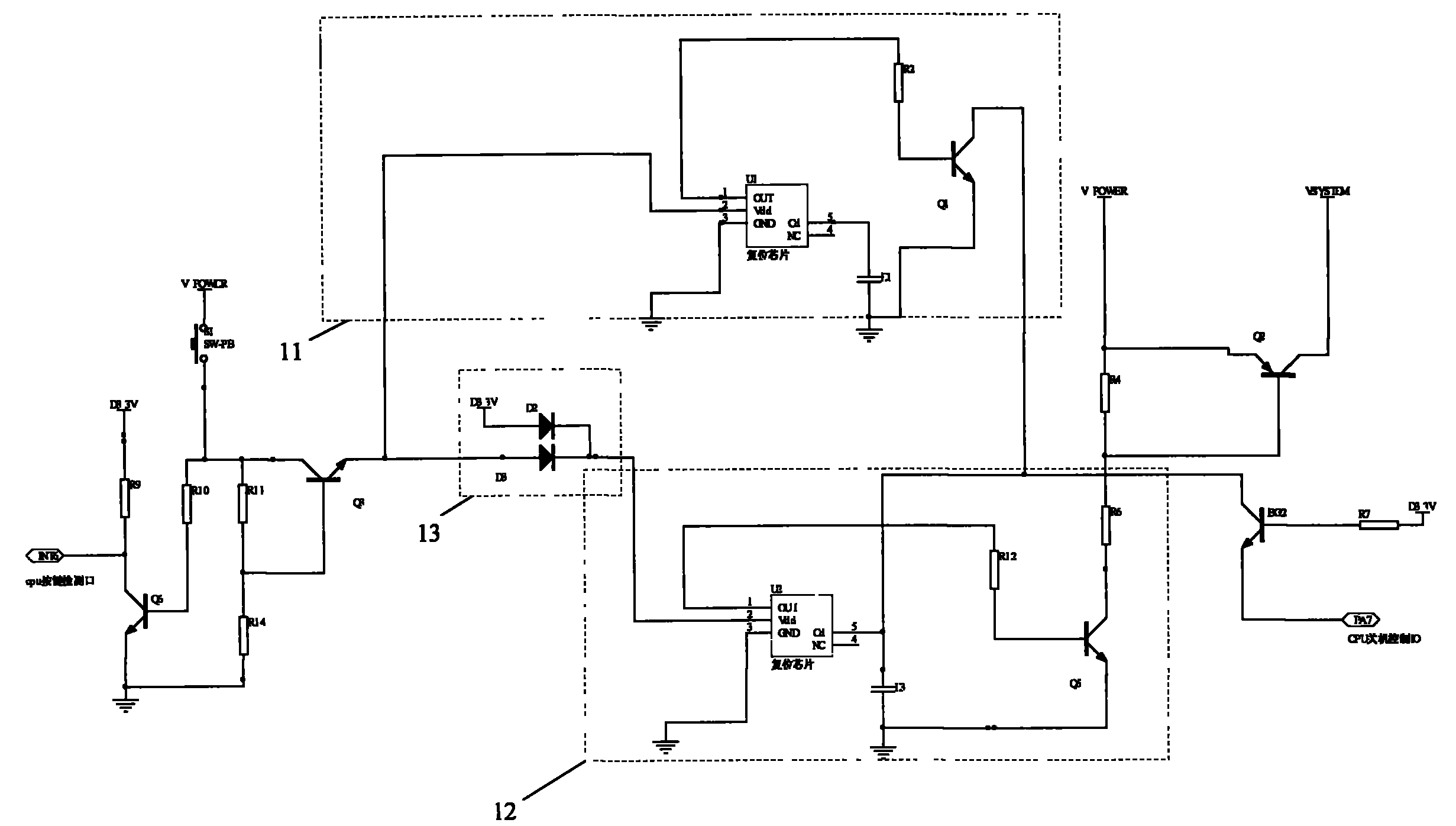

Controllable on/off circuit

InactiveCN101783663ALow costEliminate hardware jitter and human errorElectronic switchingHardware circuitsEngineering

The invention provides a controllable on / off circuit. The controllable on / off circuit comprises a first reset circuit, a second reset circuit and a latching circuit, wherein the second reset circuit comprises a reset chip U2, a regulating capacitor E3 and an NPN triode Q5;The input end of the first reset circuit is connected with a power button S1; the input end of the second reset circuit is connected with the power button S1 through the latching circuit; the output end of the first reset circuit and the Cd end of the reset chip U2 are connected to the positive pole of the regulating capacitor E3; the Vdd end of the reset chip U2 is the input end of the second reset circuit; the OUT end of the reset chip U2 is connected with the base of the triode Q5; the collector of the triode Q5 is connected to a complete machine system power supply VSYSTEM through an MOS tube Q2; and the power button S1 and the collector of the triode Q5 are connected to both ends of the power supply VPOWER in parallel. The invention can switch the on / off state by pressing one button only after treating the hardware circuit, and does not need software programming, thereby having the advantage of low cost.

Owner:FUJIAN XINO COMM TECH

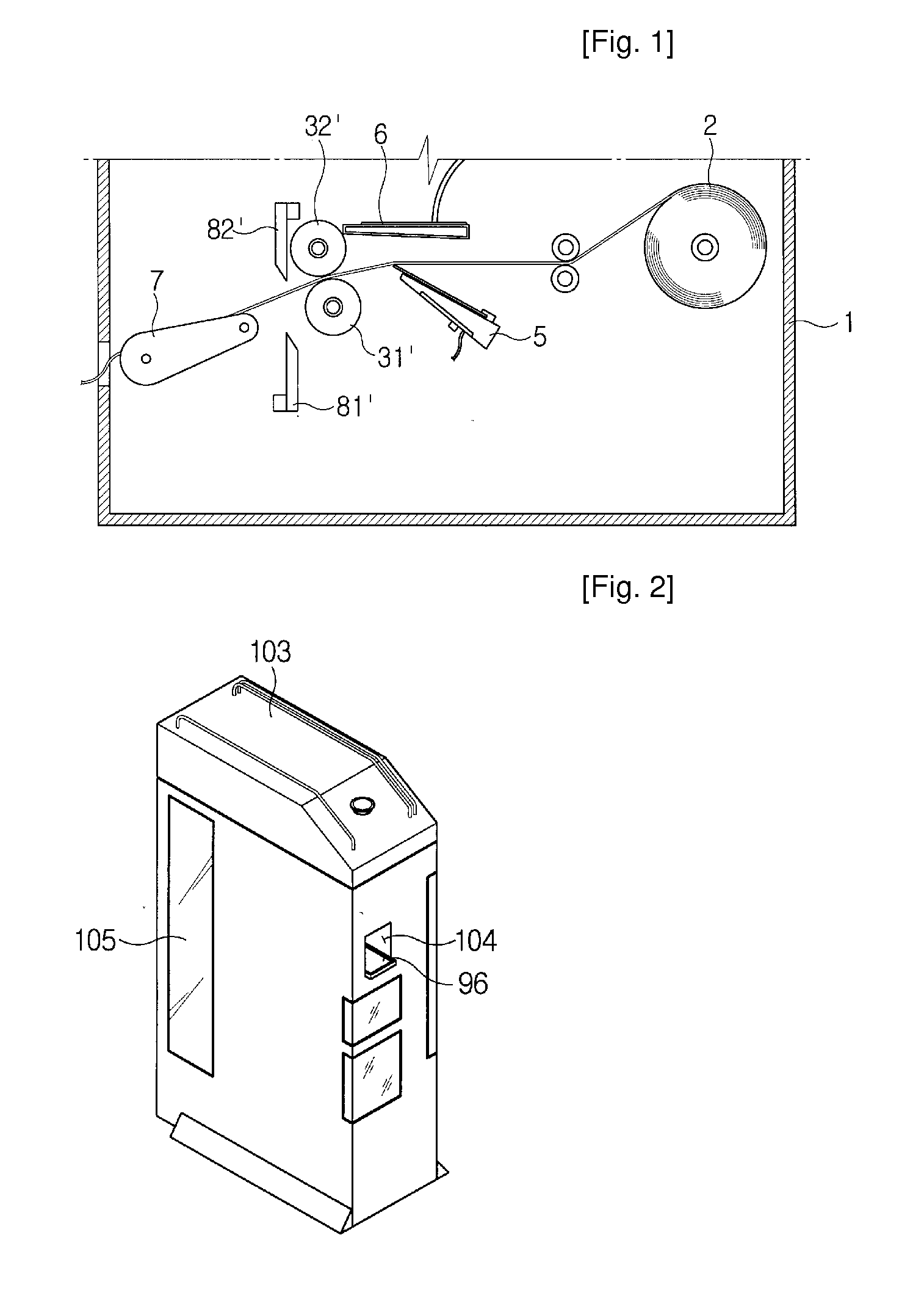

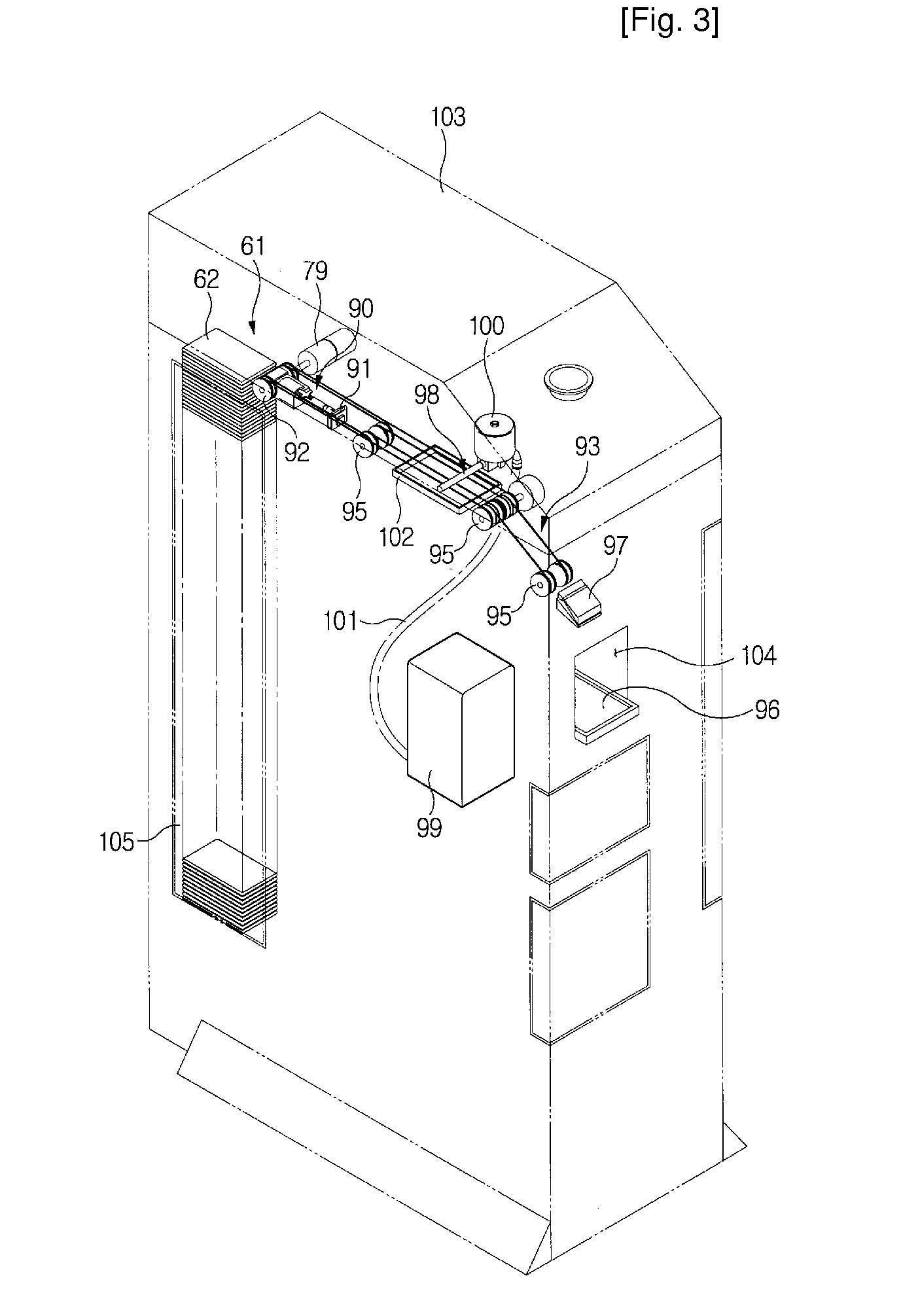

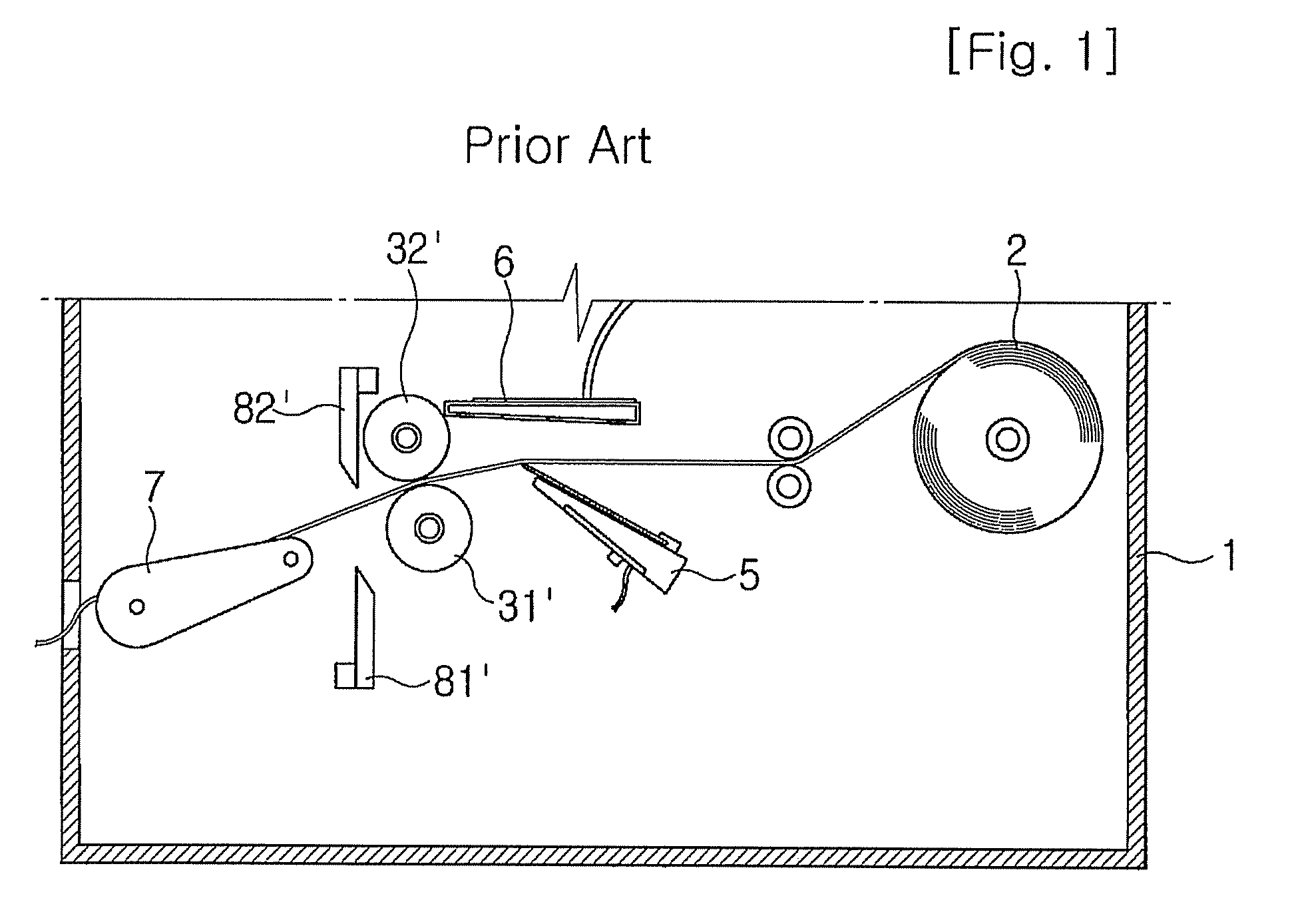

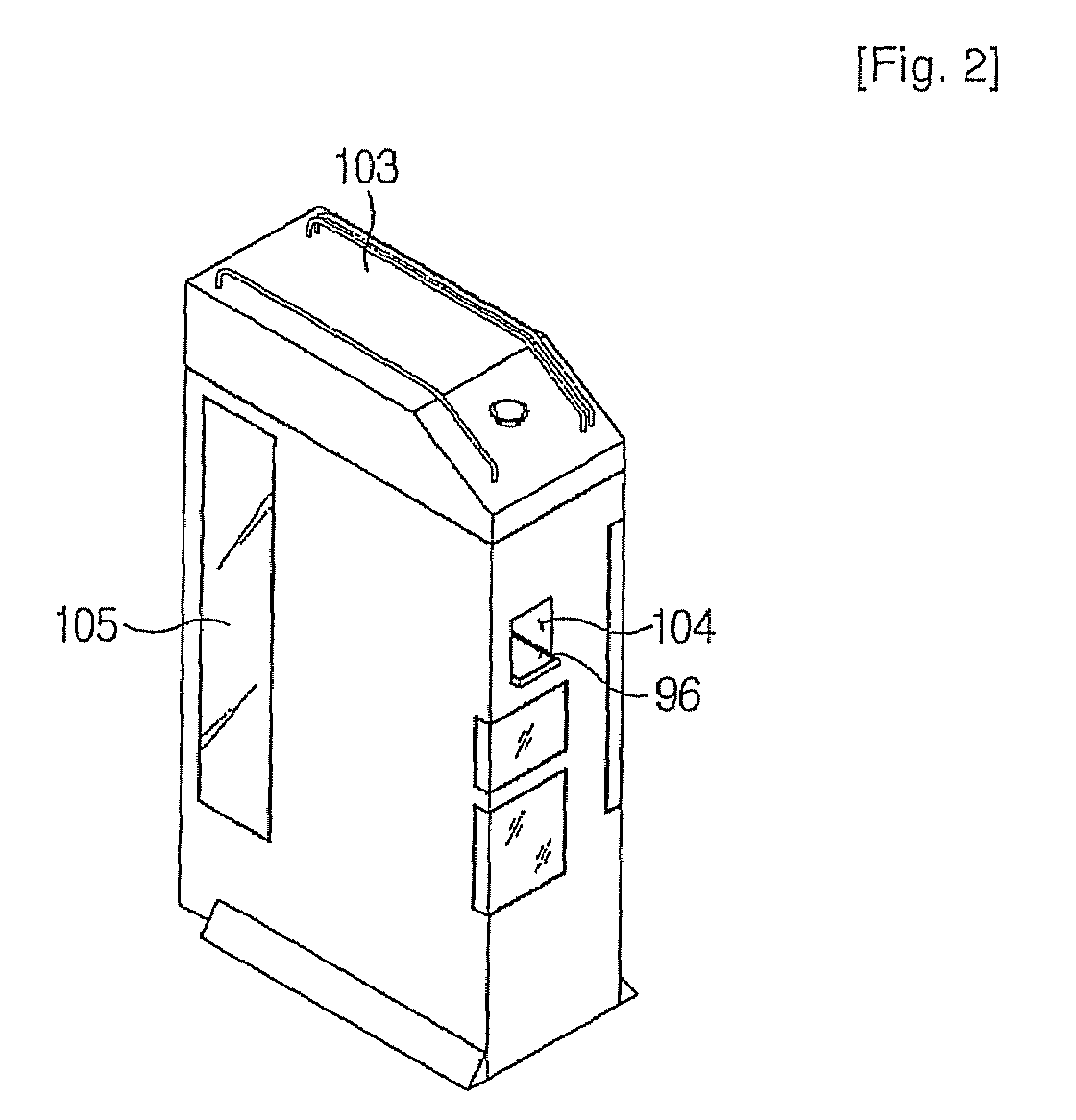

Apparatus for Discharging Tissue

InactiveUS20080135570A1Easily replaceReduce cut effectivenessCoin-freed apparatus detailsDomestic applicationsBiomedical engineering

An apparatus for discharging tissue that is folded several times and stacked is provided. The apparatus includes a cartridge that holds stacked tissue and has a through hole at one end, and a holding member that is disposed adjacent to the through hole of the cartridge and pivots on an axis to grasp and remove tissues one at a time from the top of the stack through an arm. The inventive apparatus allows a user to easily replace tissue and check the amount of tissue used and the amount left to use through visual means. The apparatus virtually eliminates the problem of tissue dispensing failure, and has increased precision and reliability and reduced dispensing time over conventional apparatuses.

Owner:ELIX CO LTD

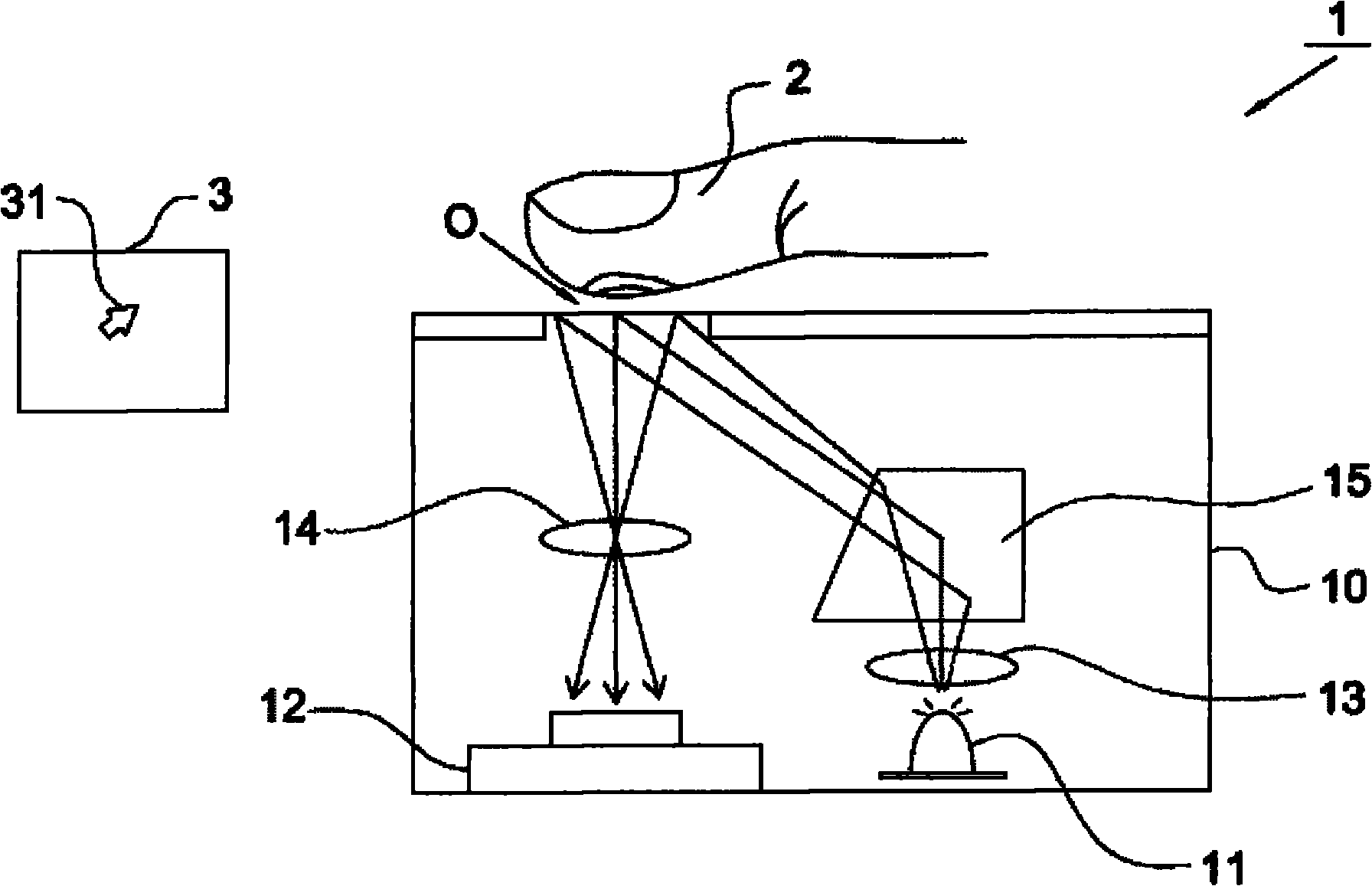

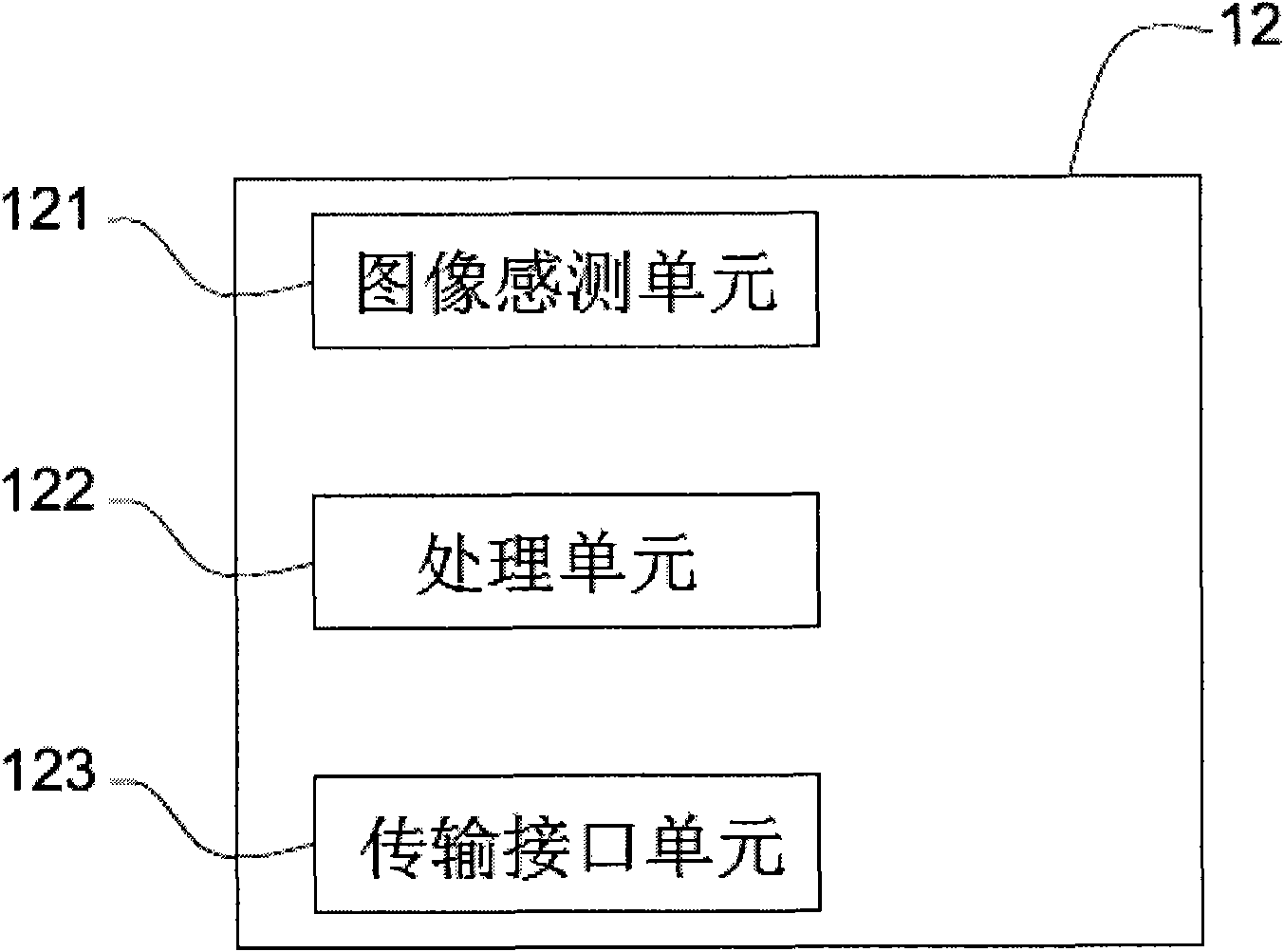

Optical displacement detection device and operation method thereof

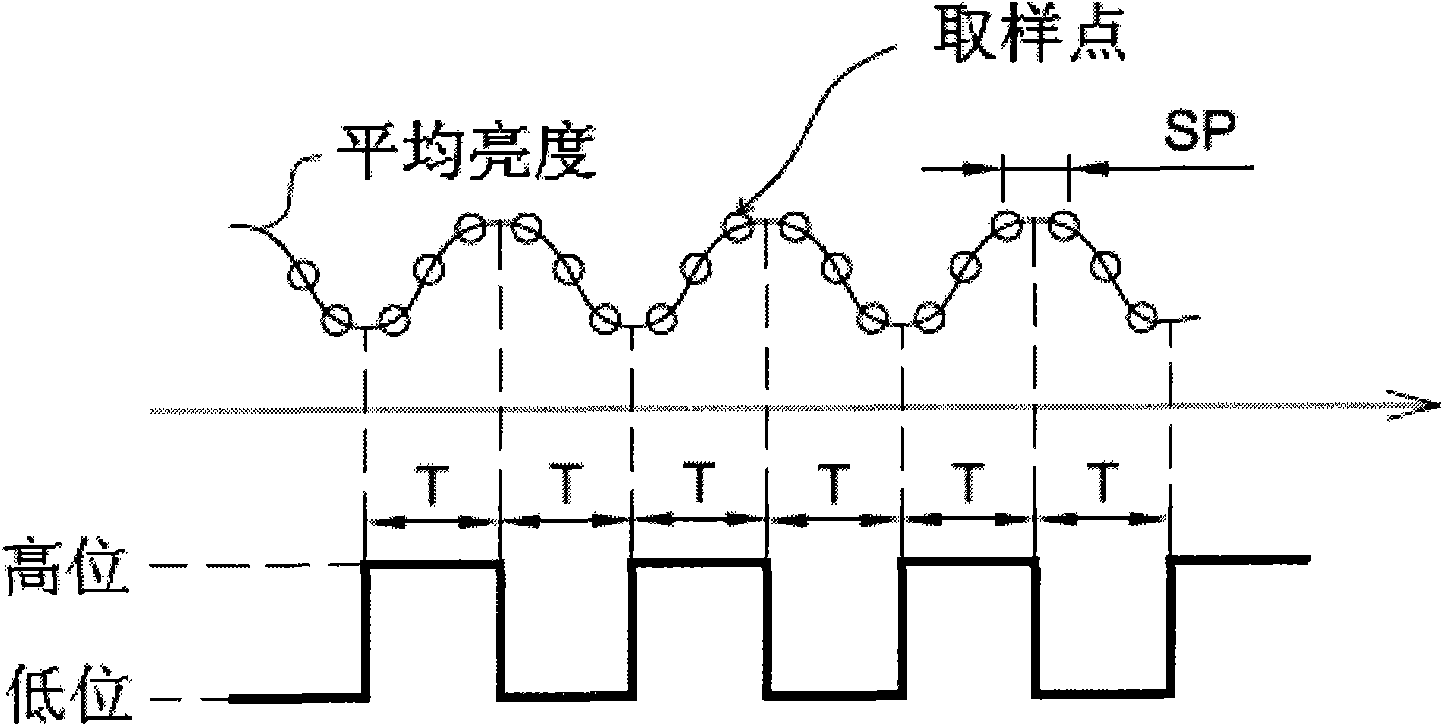

InactiveCN101853091AEliminate malfunctionsInput/output processes for data processingComputer science

Owner:PIXART IMAGING INC

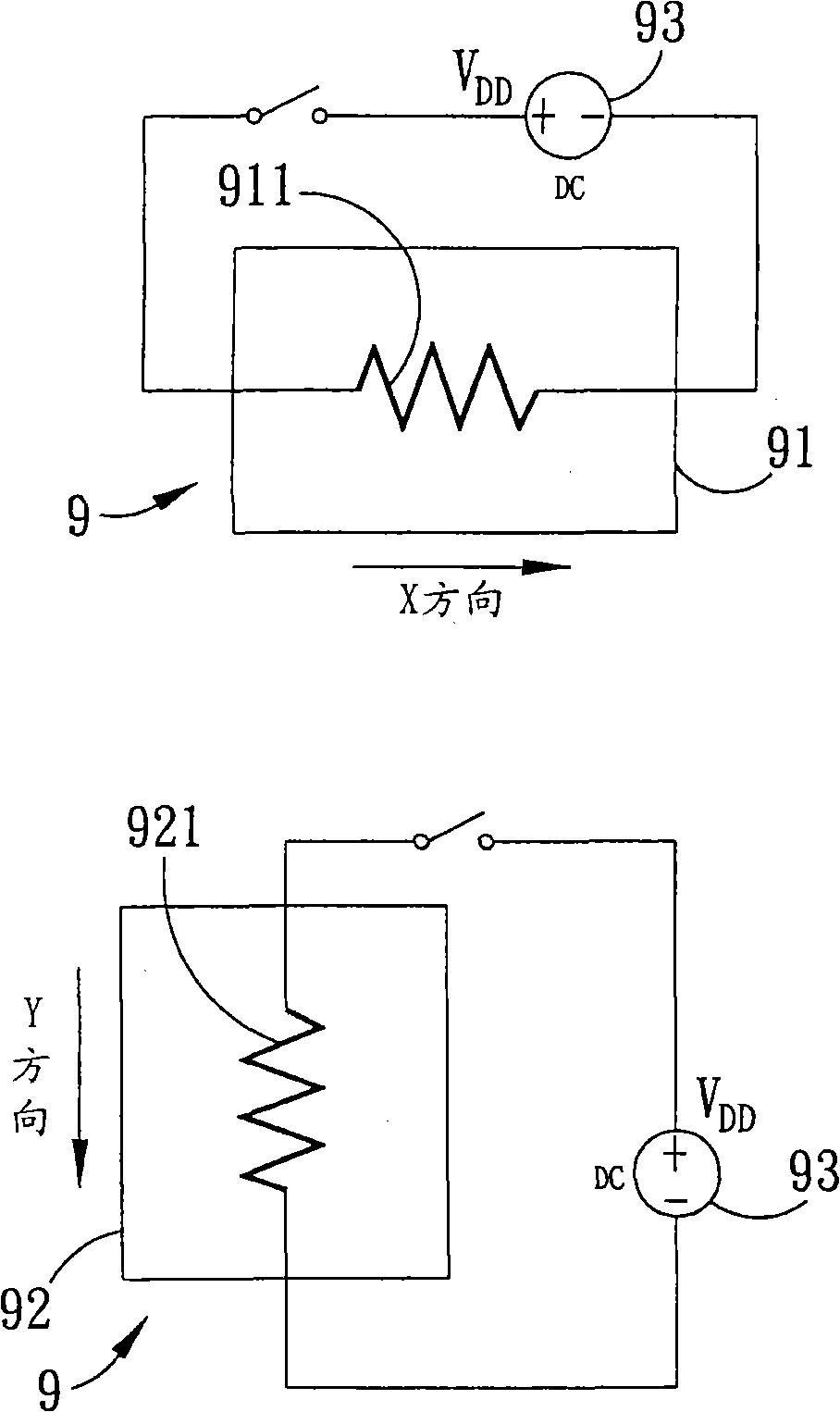

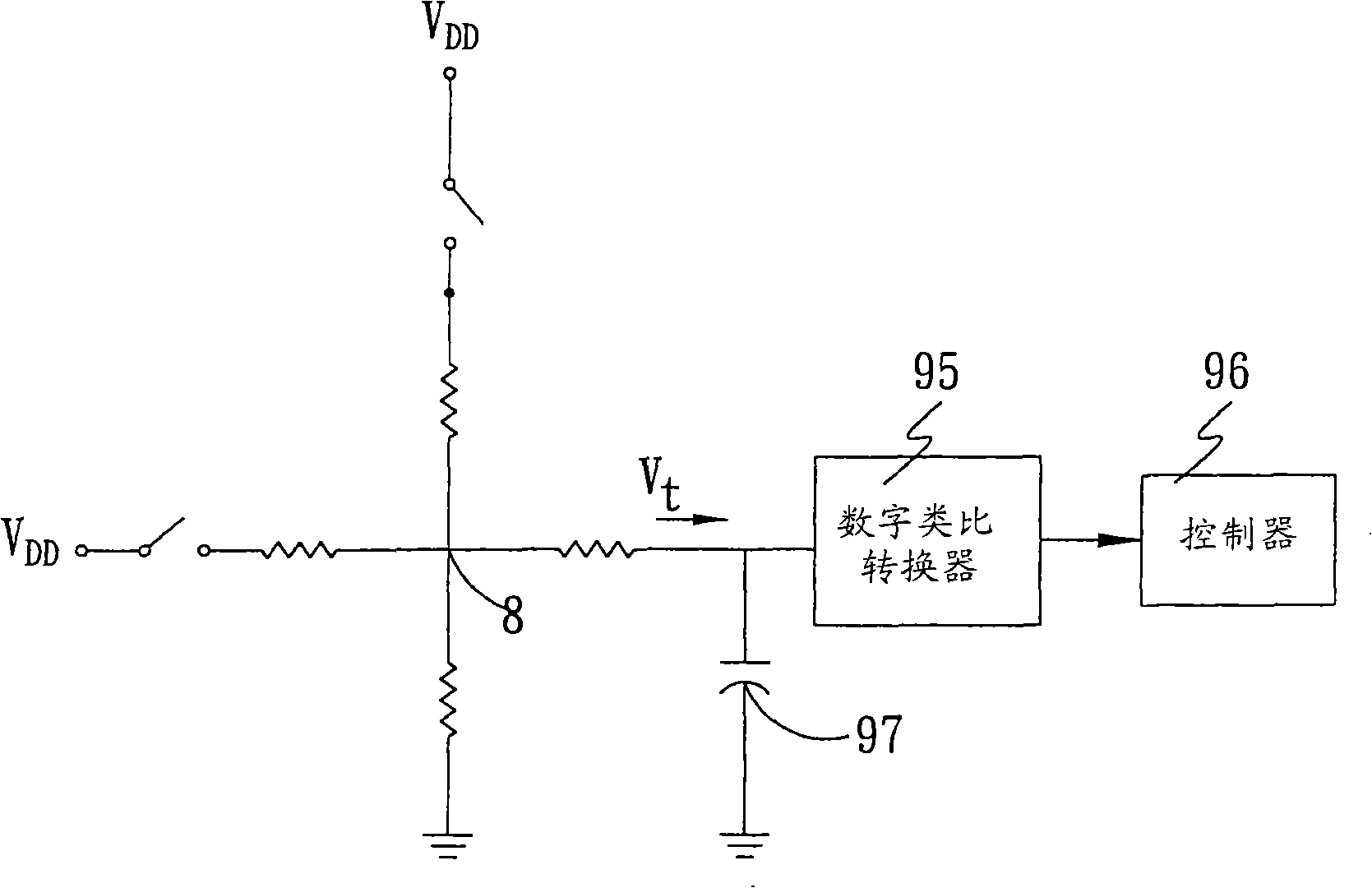

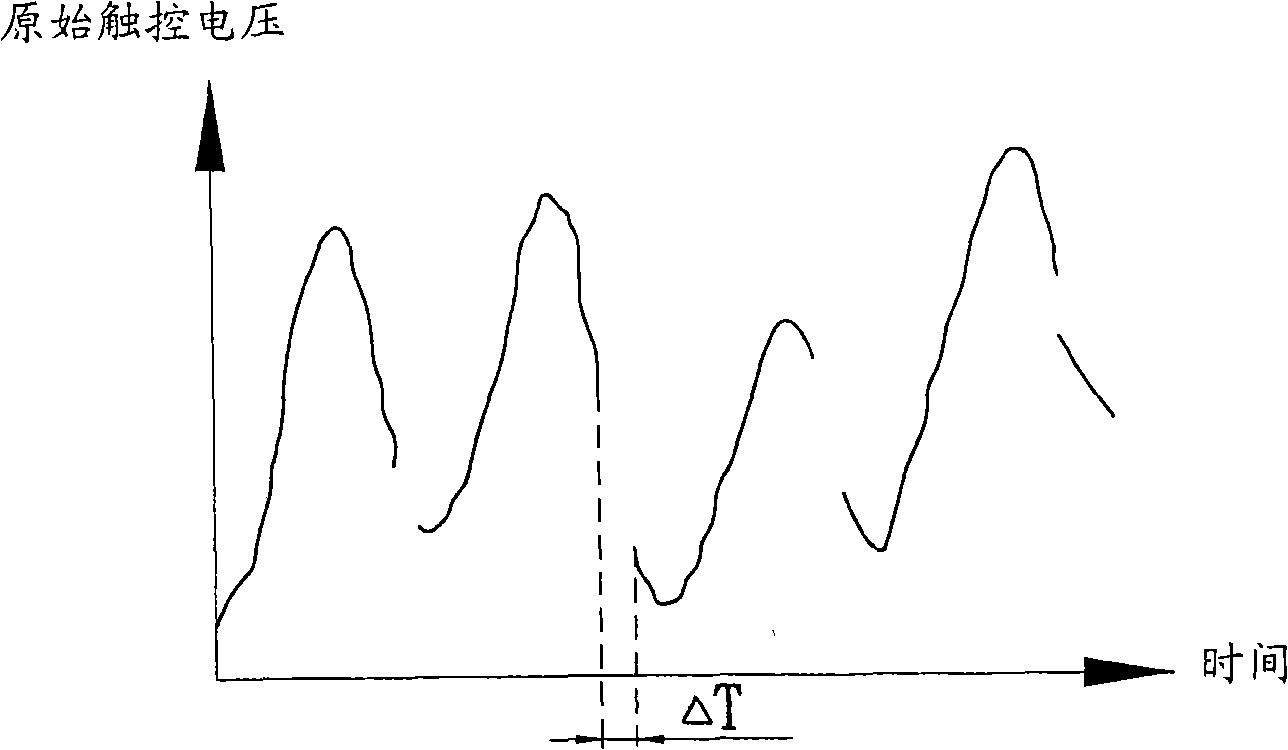

Signal processing method for resistor type touch control plate

InactiveCN101295220AAccurate outputEliminate malfunctionsInput/output processes for data processingPhysical factorSignal processing

The invention provides a signal processing method for a resistance-typed touch control plate, which is characterized in that whether error signals exist or not is found out by comparing the signal change rate of an article on the touch control plate with a general standard rate; if the error signal is generated, the error signal is removed and whether intermission exists or not is further judged; if the intermission exists, whether the intermission is a normal signal intermission caused by no-action of the user or a non-normal signal intermission caused by false actions resulted from physical factors under the situation that the user has actions; if the intermission is the non-normal signal intermission, the signal is re-processed; when the moving of the article on the touch control plate tends to be static or shaking, effective or ineffective moving is judged by the method of signal integer output and remainder accumulation, so as to lead the signal output which has moving tendency to be more precise.

Owner:COMPAL ELECTRONICS INC +1

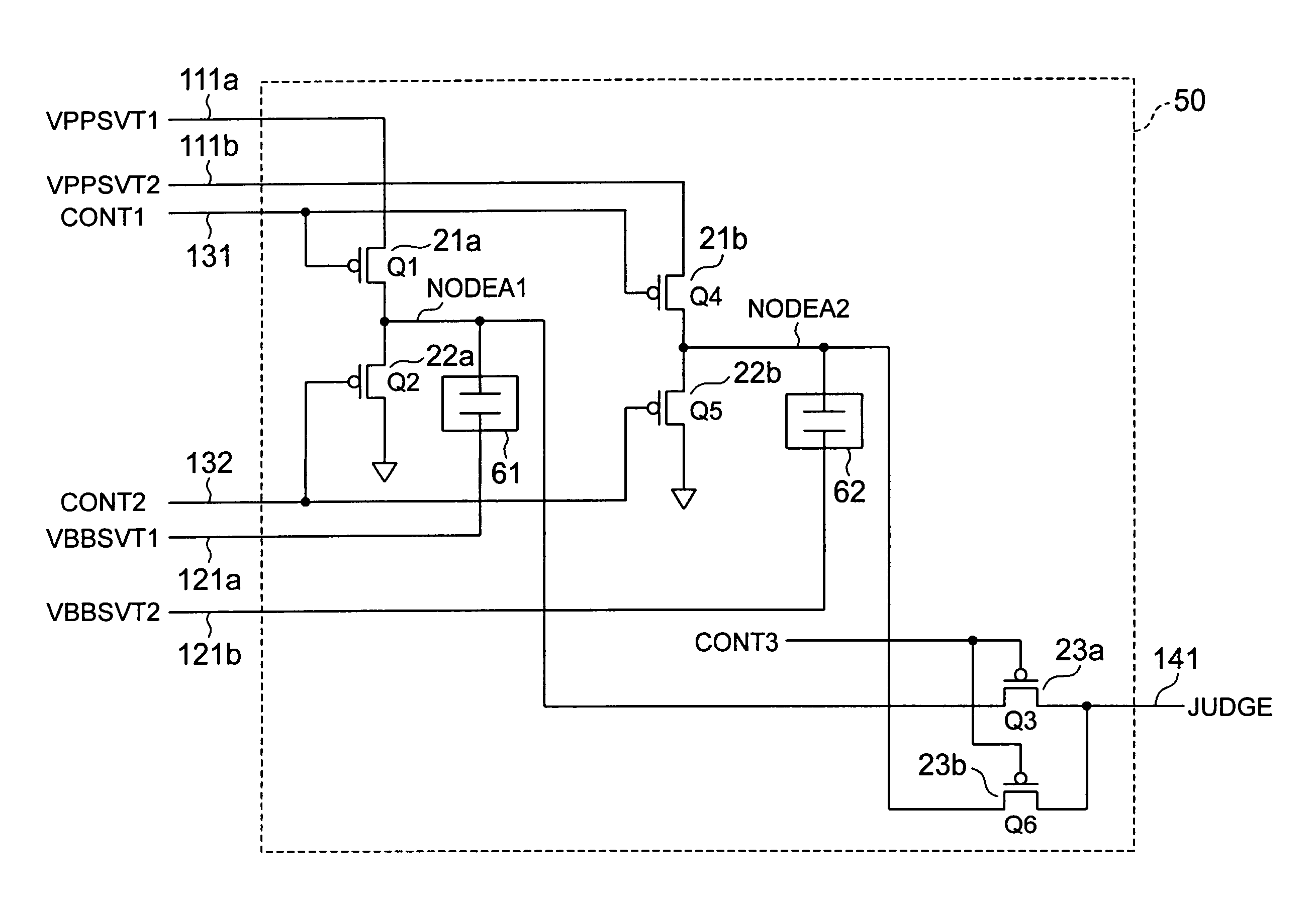

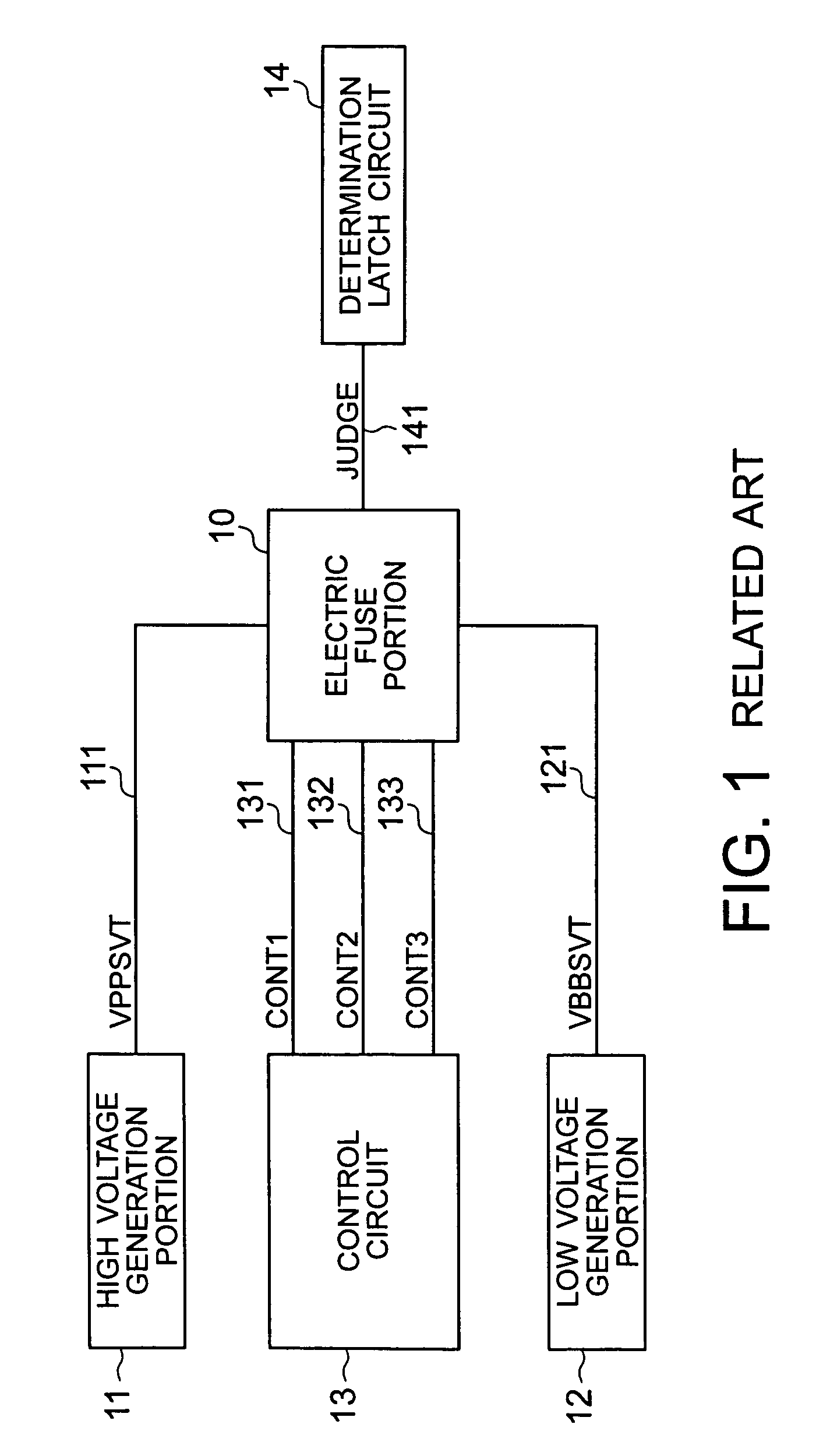

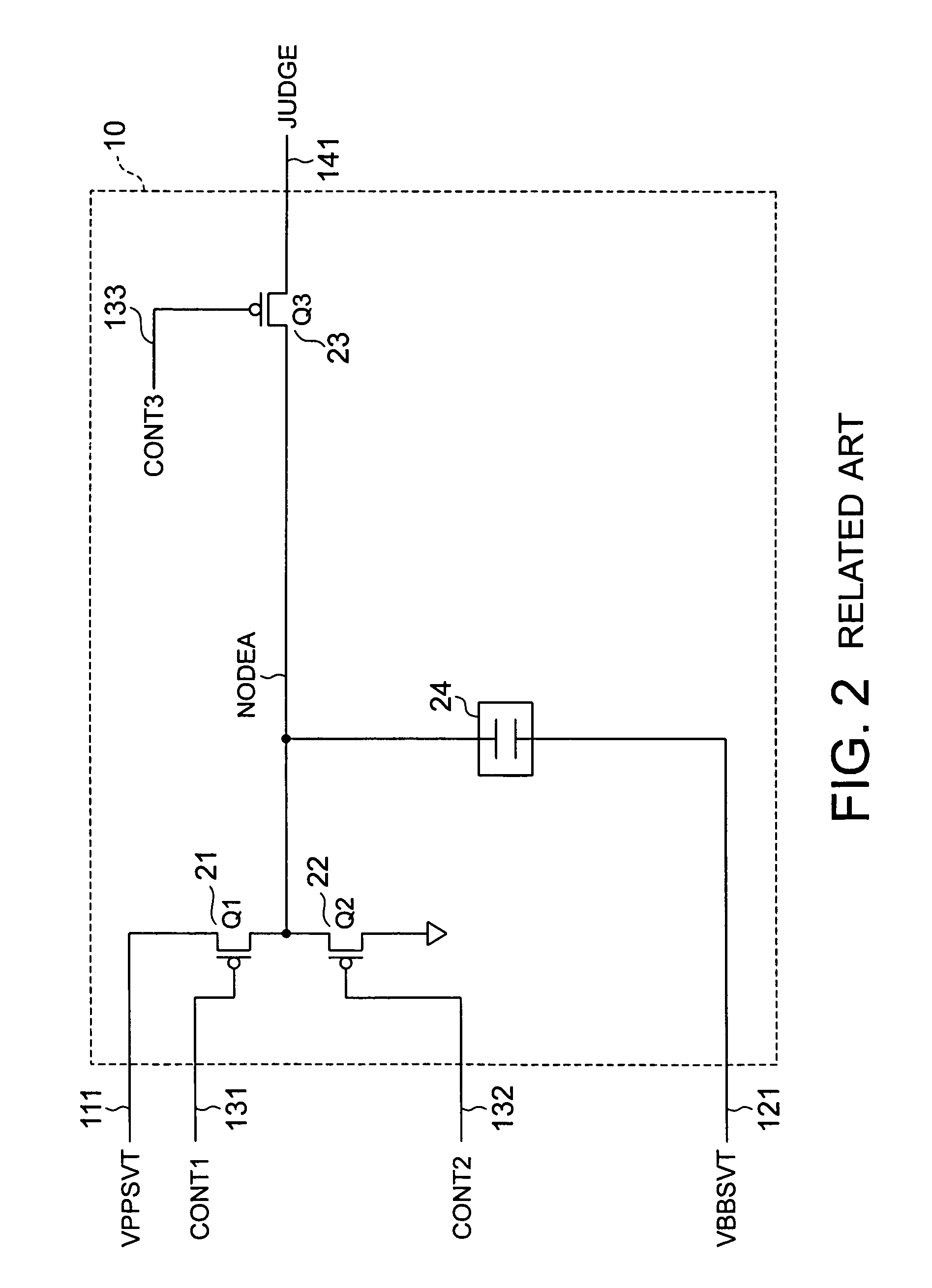

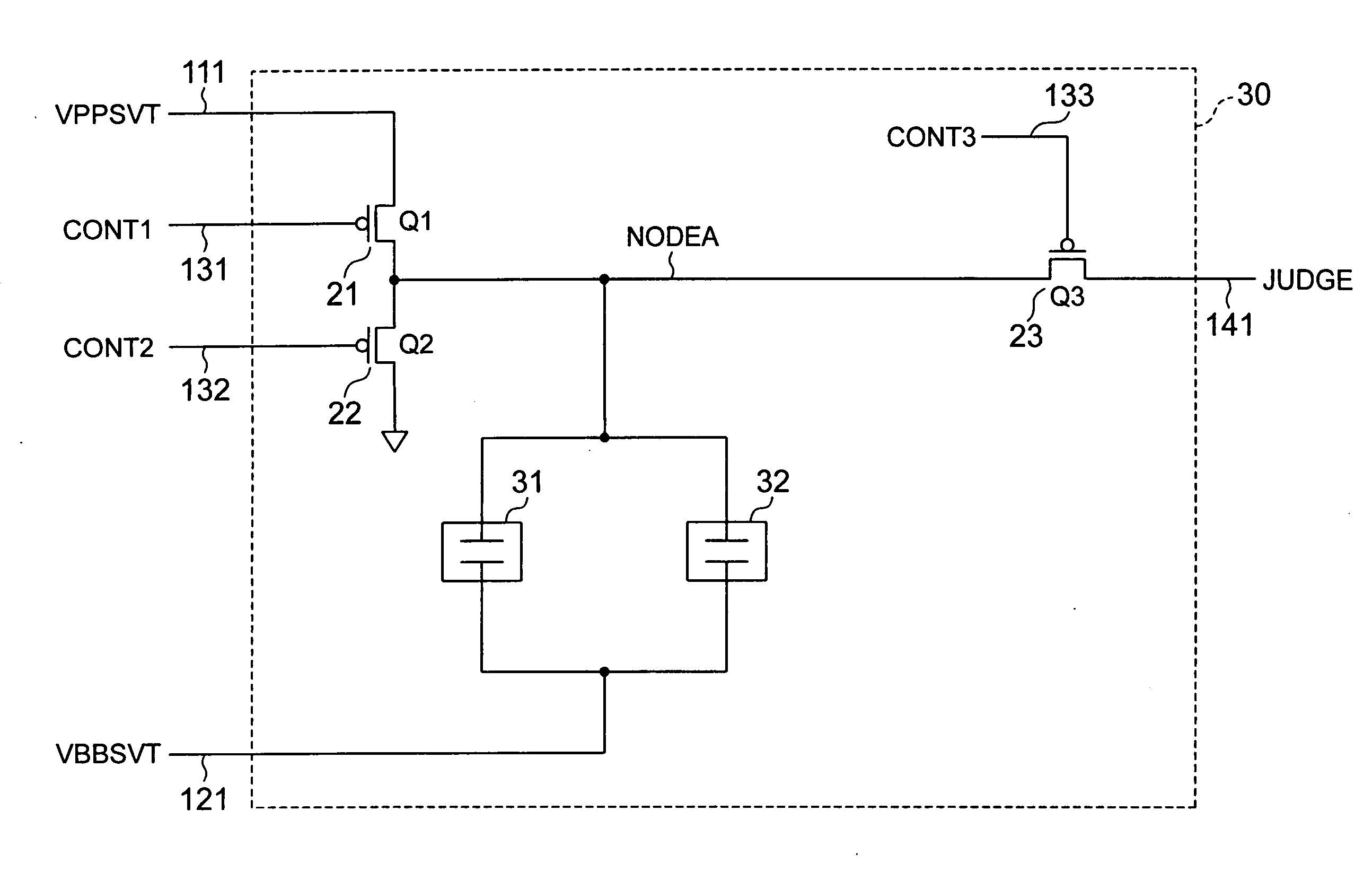

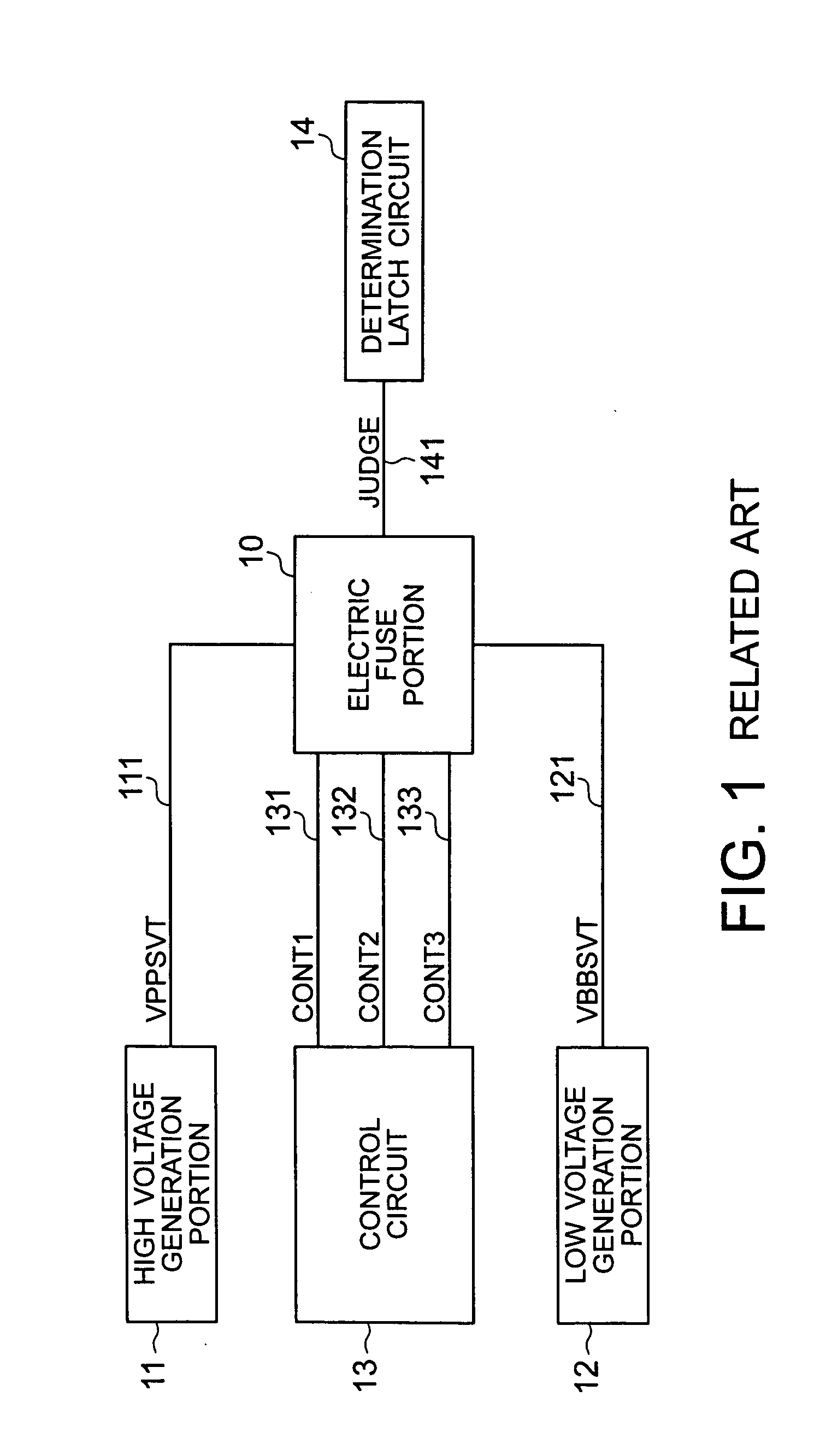

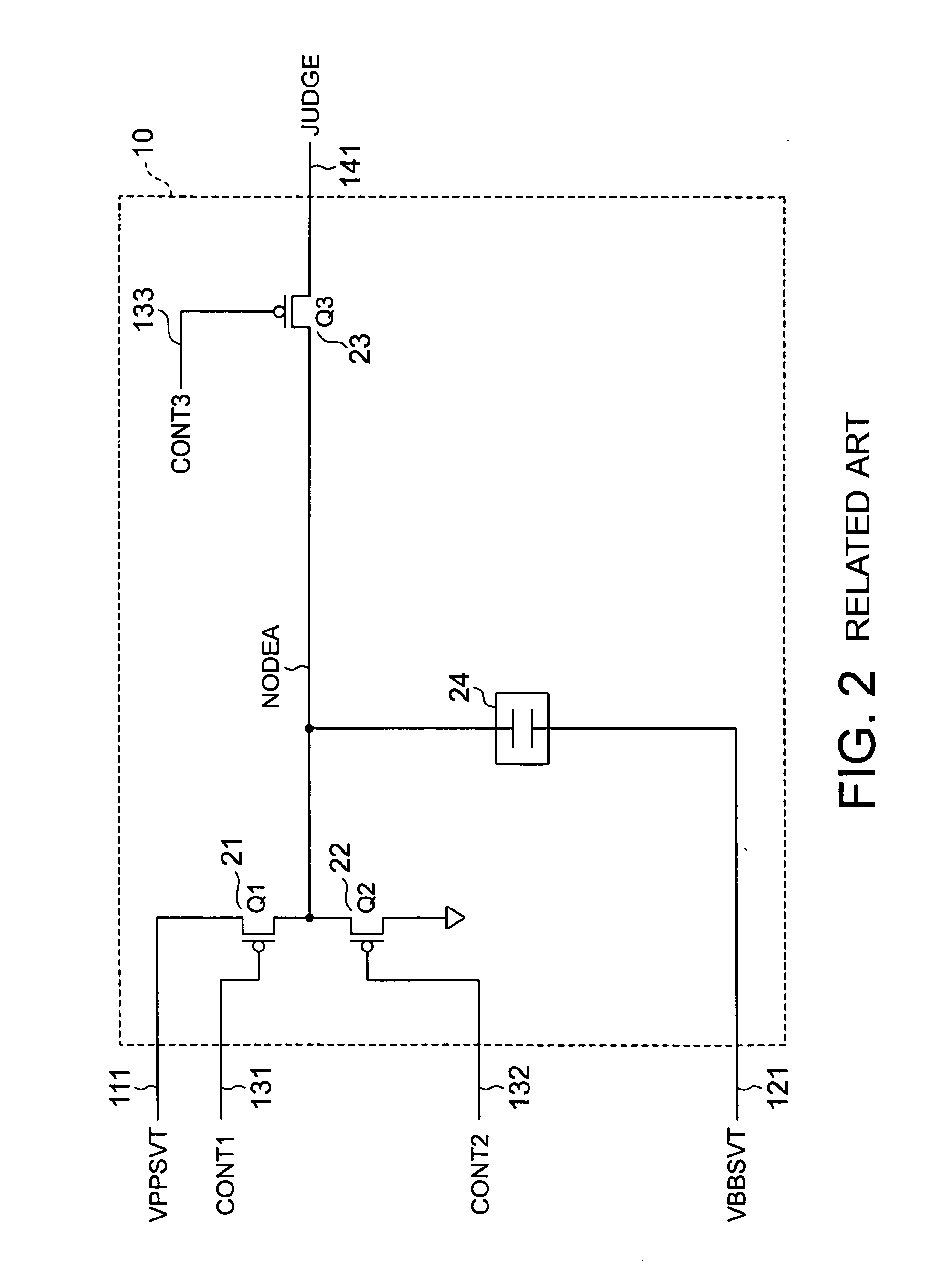

Semiconductor device having two fuses in parallel

InactiveUS7567114B2Eliminate malfunctionsRead-only memoriesHeating/cooling contact switchesElectric fusesP channel

A semiconductor device employs two electric fuses (31, 32) connected in parallel to each other. First terminals of the electric fuses (31, 32) are connected to a junction of first and second P-channel transistors (21, 22), which are connected in series between a high potential application line (111) and a ground, and connected to a third P-channel transistor (23). Second terminals of the electric fuses (31, 32) are connected to a low potential application line (121). When an extra-high voltage is applied between the first and second terminals of the electric fuses (31, 32), a breakdown connection is produced in at least one of the electric fuses (31, 32). Thus, 1-bit information is written into the semiconductor device.

Owner:LONGITUDE SEMICON S A R L

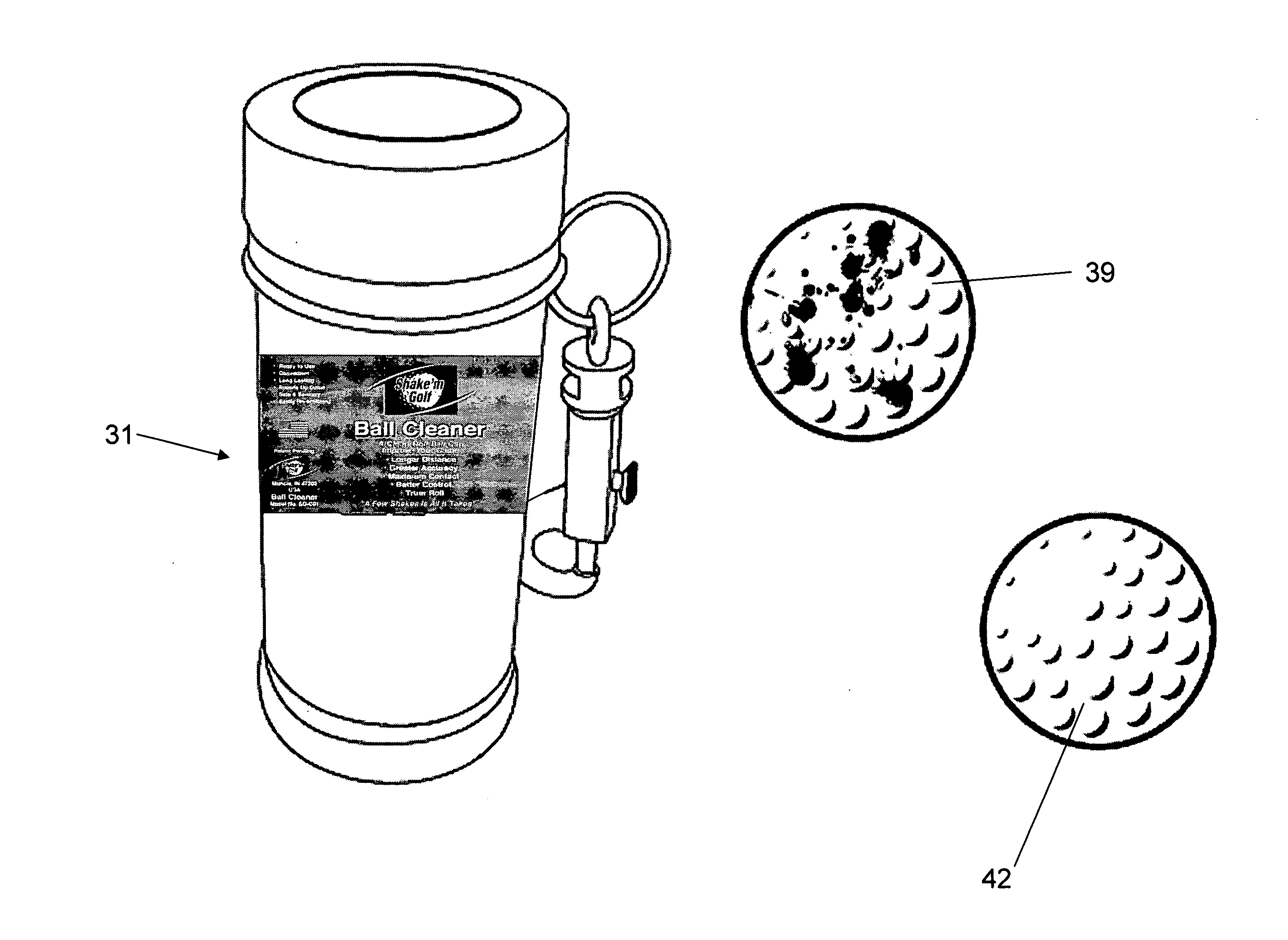

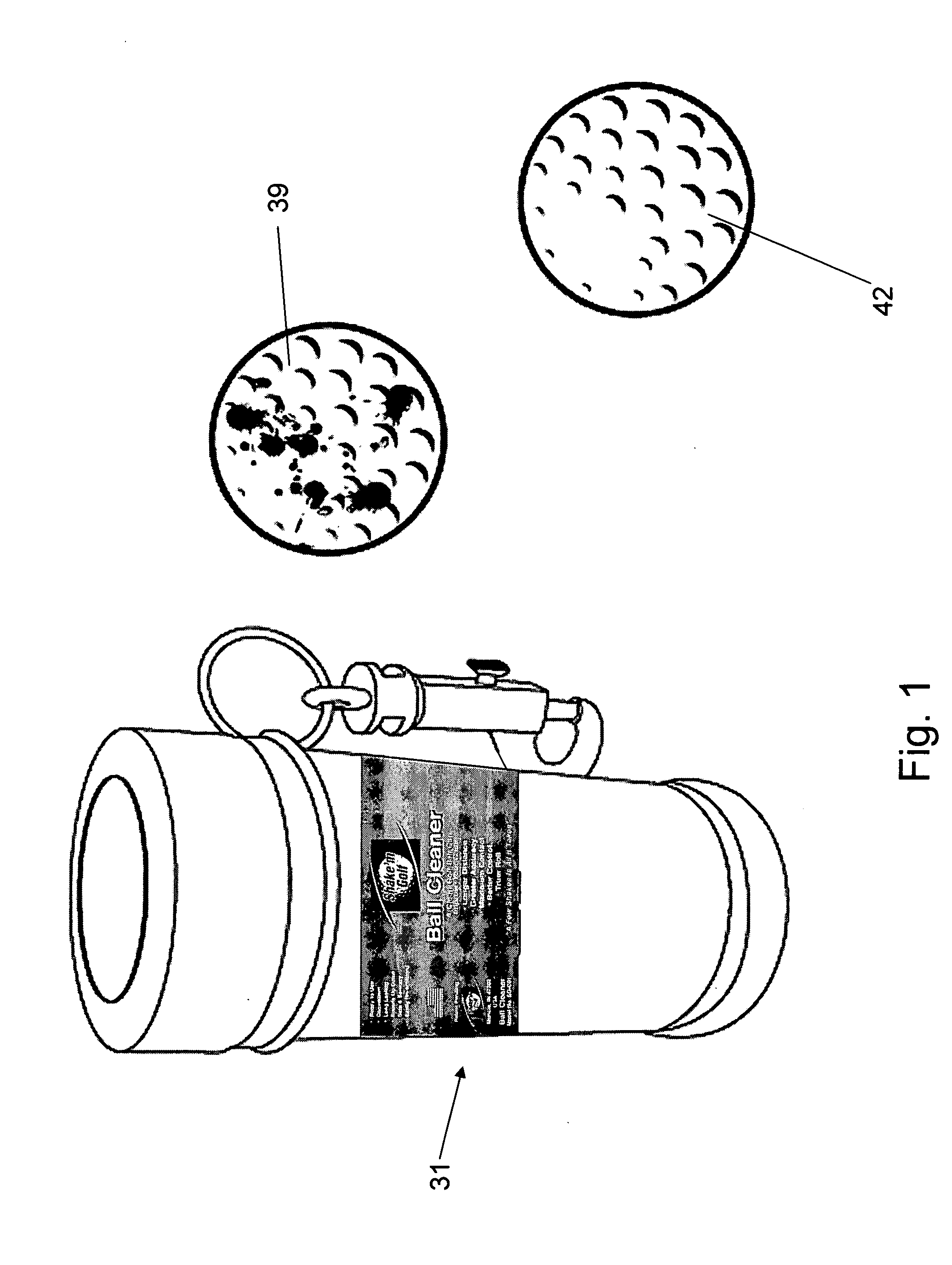

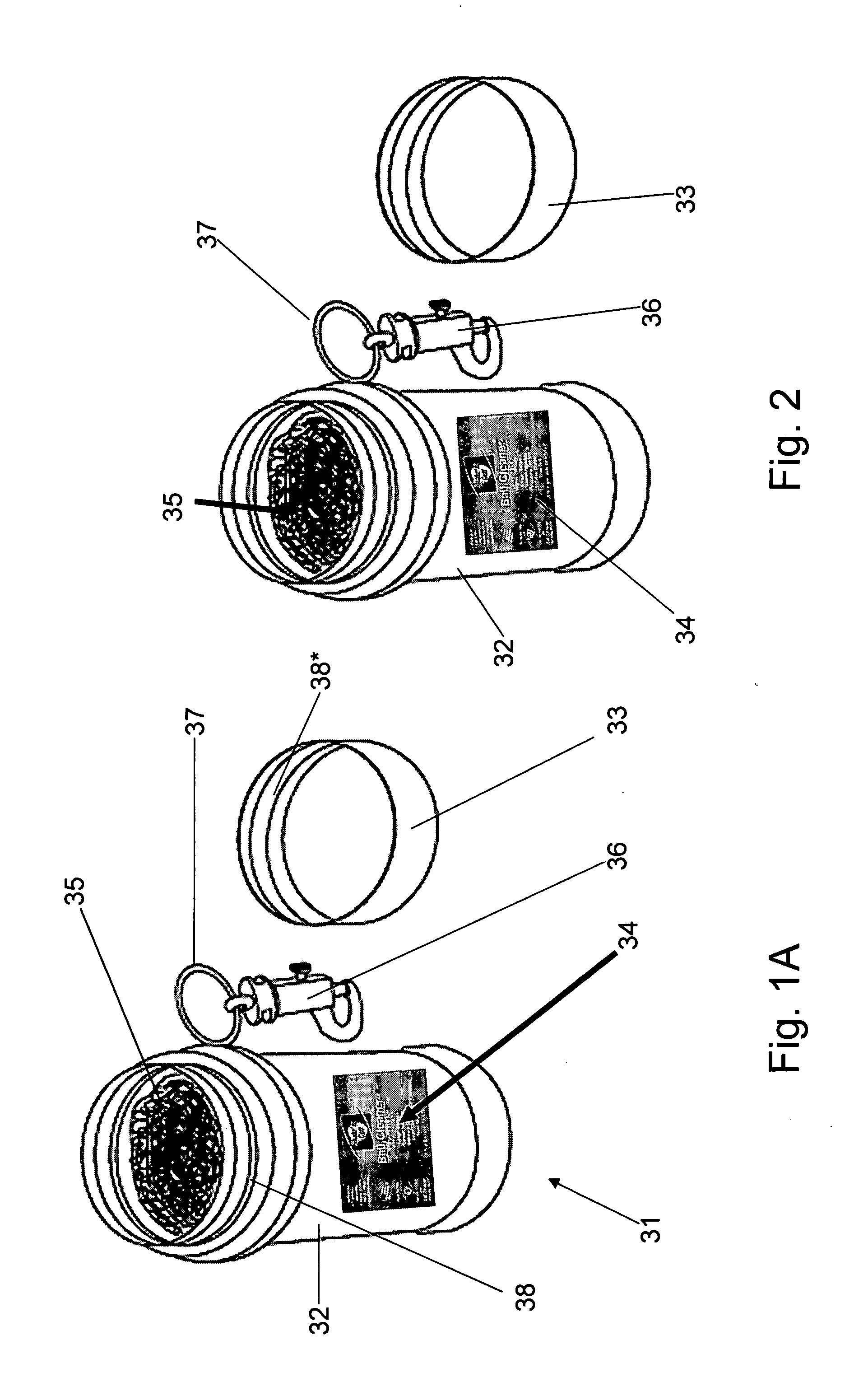

Hand held golf ball cleaner

InactiveUS20050188482A1Easy to useCost-effective manufacturingBowling gamesCarpet cleanersHand heldReturn to play

The HAND HELD GOLF BALL CLEANER is a device that a golfer may use to clean a golf ball. The device is utilized to clean a ball without any other mechanism or assistance. The device is portable and may be carried with the golf bag or cart as desired. The new cleaner device has features to make its use both functional and simple to operate. The golf ball cleaning device has an abrasive membrane which, when a liquid is added before a golf round, may function to clean a ball whenever required during the round. The ball is introduced into the container and shaken, essentially in a vertical direction, for a few times. Any mud, grass or debris is removed by the scrubber membrane attached to the interior of the container. The clean golf ball is then removed from the device and returned to play.

Owner:MATTHEWS MICHAEL DALE

Semiconductor device

InactiveUS20070091662A1Eliminating malfunction of operationEliminate malfunctionsRead-only memoriesHeating/cooling contact switchesDevice materialElectric fuses

A semiconductor device employs two electric fuses (31, 32) connected in parallel to each other. First terminals of the electric fuses (31, 32) are connected to a junction of first and second P-channel transistors (21, 22), which are connected in series between a high potential application line (111) and a ground, and connected to a third P-channel transistor (23). Second terminals of the electric fuses (31, 32) are connected to a low potential application line (121). When an extra-high voltage is applied between the first and second terminals of the electric fuses (31, 32), a breakdown connection is produced in at least one of the electric fuses (31, 32). Thus, 1-bit information is written into the semiconductor device.

Owner:LONGITUDE SEMICON S A R L

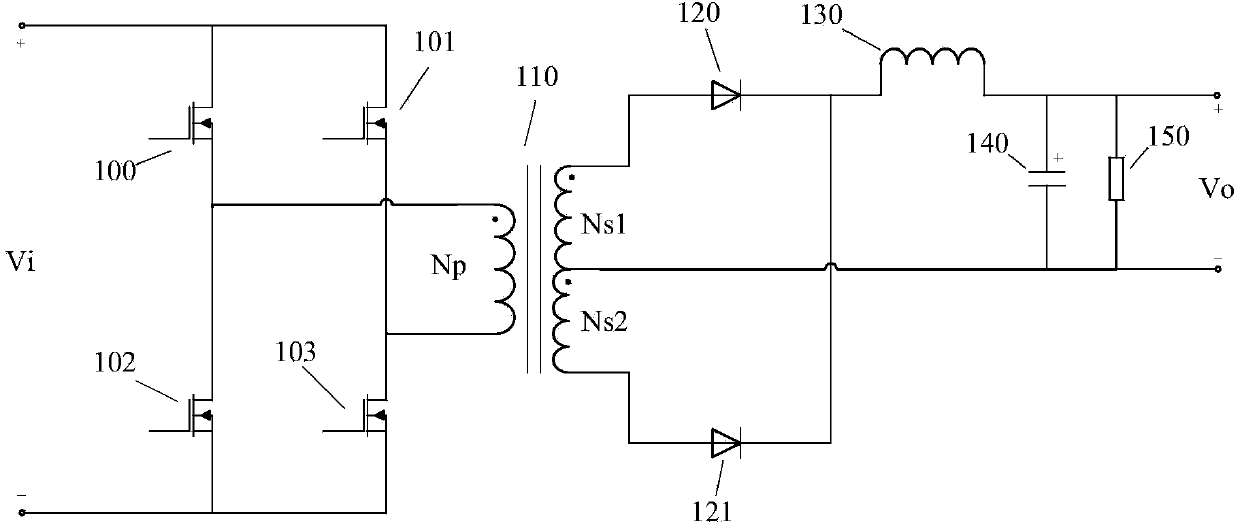

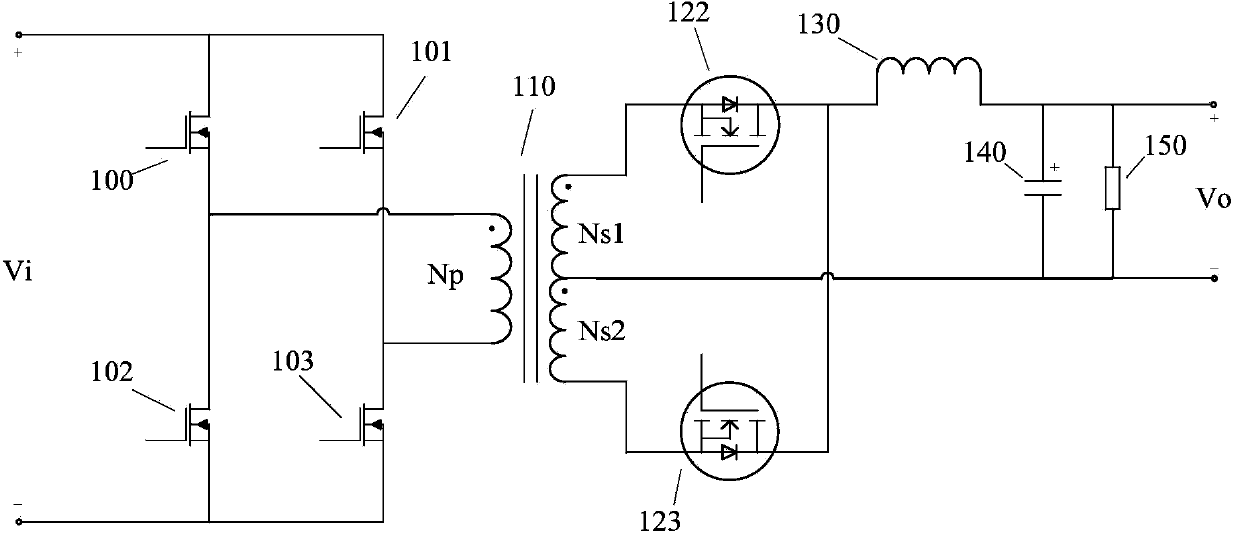

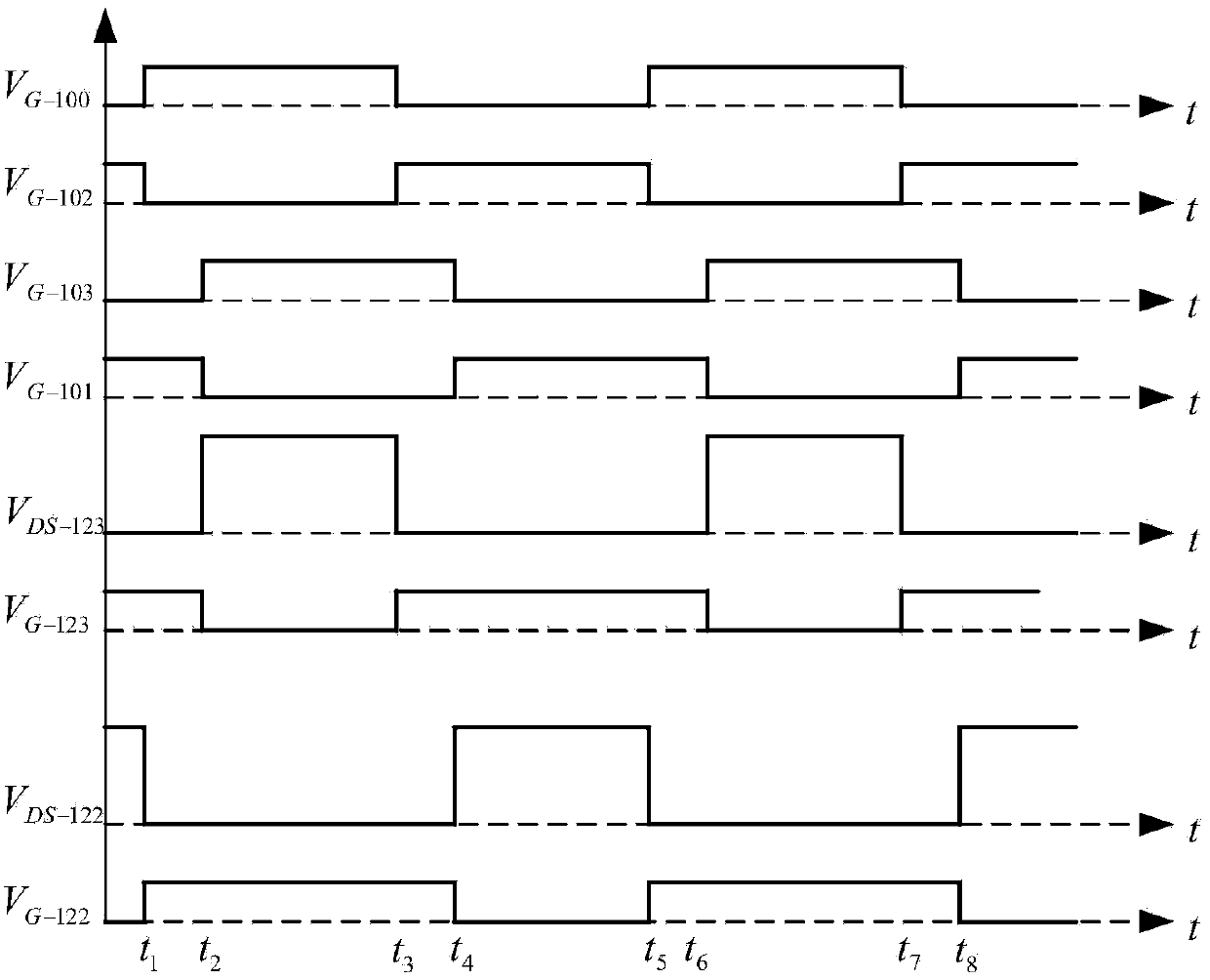

Synchronous rectification driving circuit

ActiveCN103997223AEliminate malfunctionsReduce level fluctuationEfficient power electronics conversionAc-dc conversionInductorCenter tap

The invention discloses a synchronous rectification driving circuit. The synchronous rectification driving circuit comprises four MOS tubes connected to a power source end in parallel. The MOS tube a and the MOS tube b are connected with a power source. The four MOS tubes are connected with the primary level of a transformer, the secondary level dotted terminal of the transformer is connected with a synchronous rectification tube a and is connected with an output filter inductor in series, a secondary center tap of the transformer is connected with a set of output filter capacitors and a load in parallel, or the secondary center tap of the transformer is connected with the output filter inductor in series, and then the secondary center tap of the transformer and the synchronous rectification tube a are connected with the output filter capacitors and the load in parallel. The secondary non-dotted terminal of the transformer and a node between the synchronous rectification tube a and the output filter inductor are connected with the synchronous rectification tube b. An active pole voltage conditioning circuit is connected between the secondary non-dotted terminal of the transformer and the synchronous rectification tube a in parallel. An intelligent synchronous rectification control chip IR1167 is connected between the synchronous rectification tube b and the active pole voltage conditioning circuit in parallel. The combined circuit improves the stability of synchronous rectification driving, and the synchronous rectification tube error movement caused by parasitic oscillation is avoided.

Owner:西安唯电电气技术有限公司

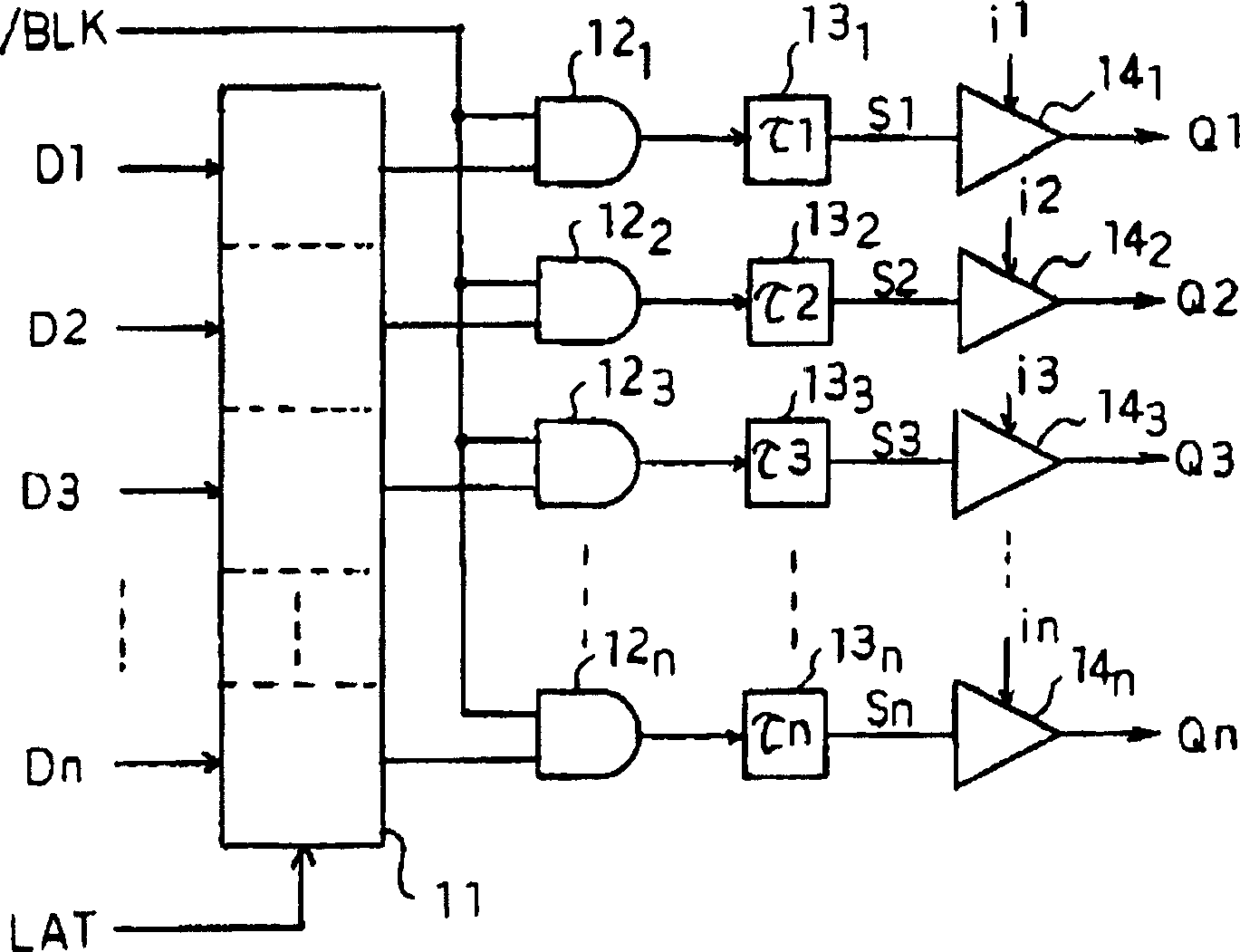

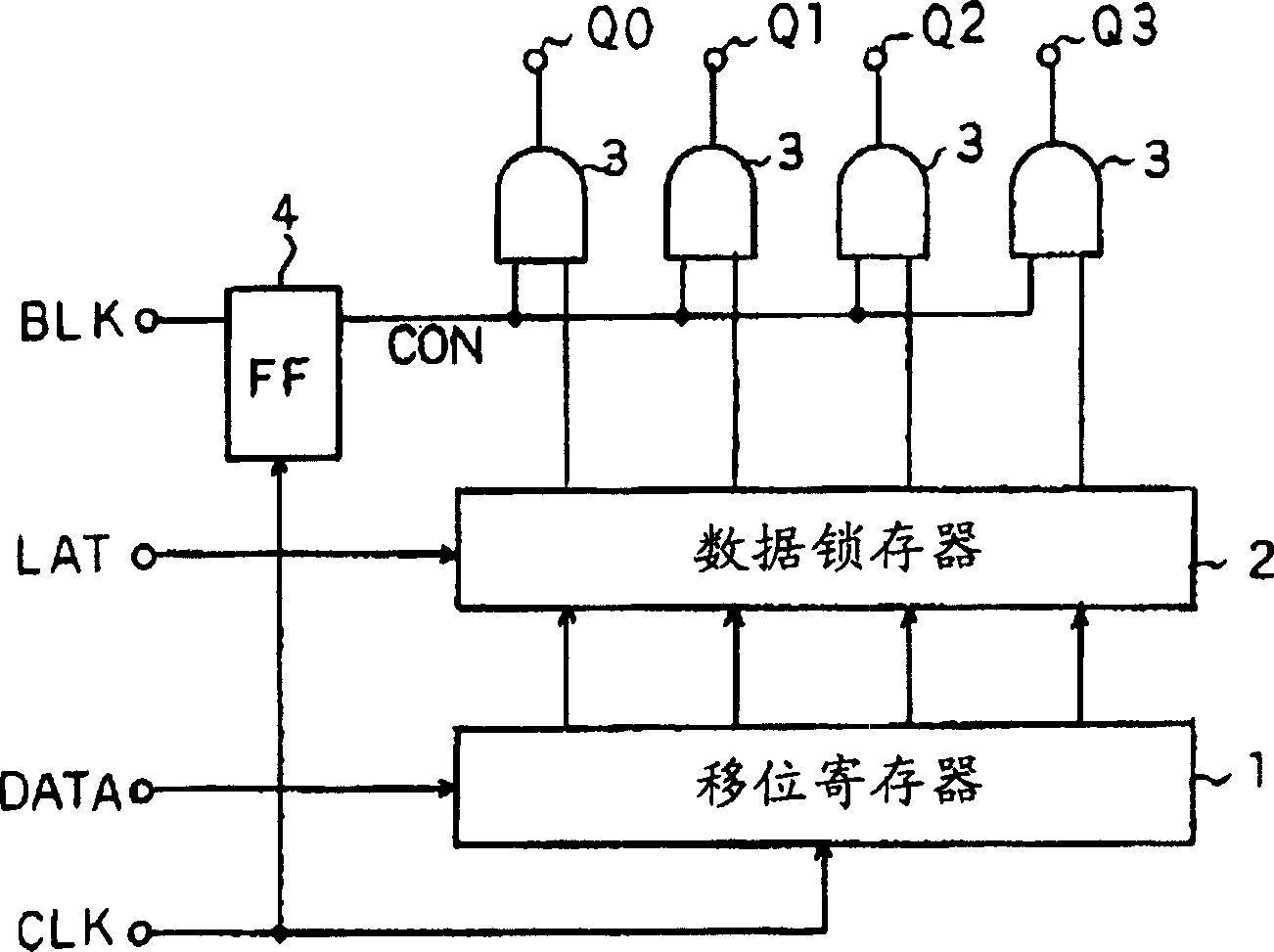

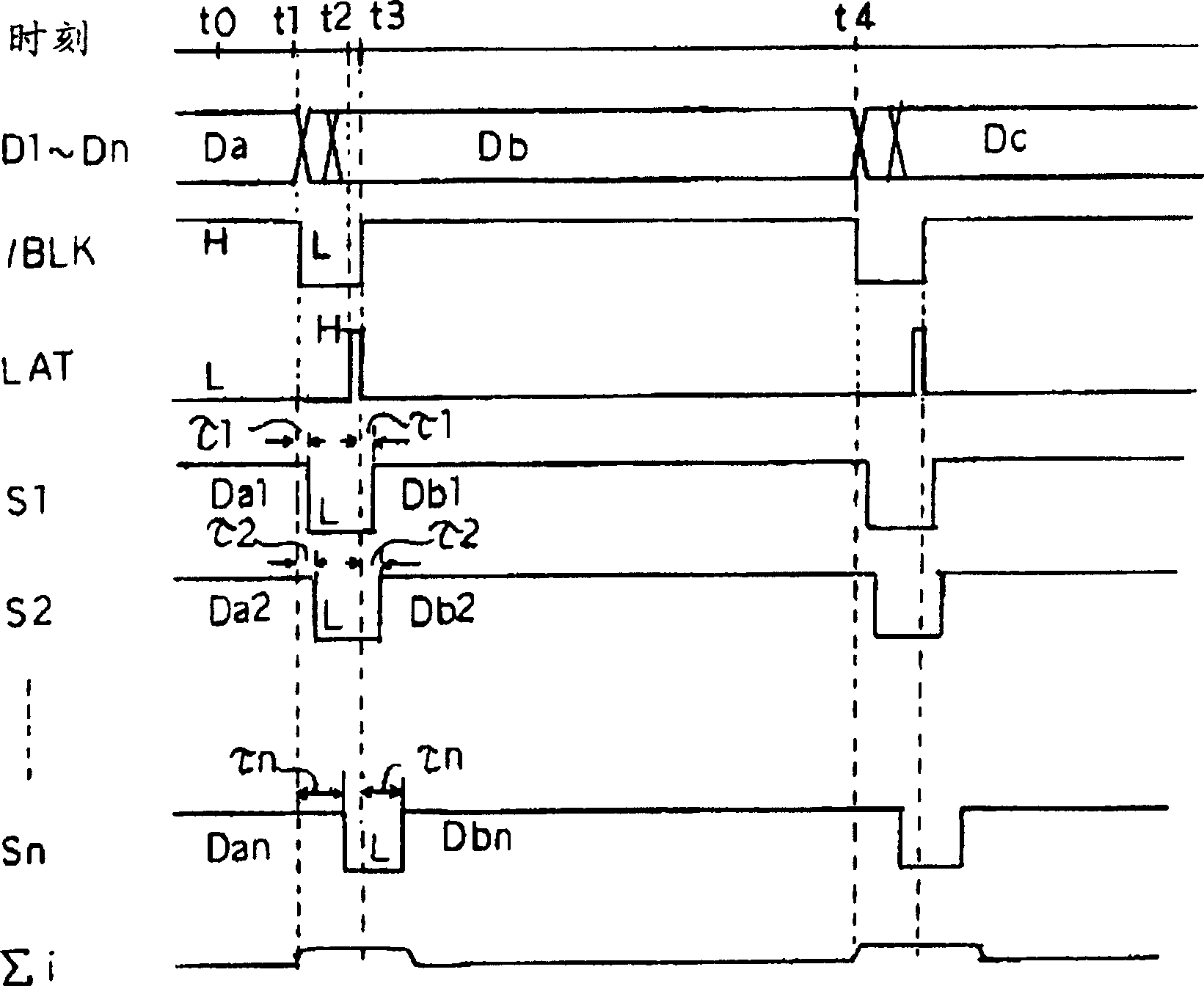

Display driver circuit

ActiveCN1904981ASuppress changesSmooth changeCathode-ray tube indicatorsDigital storageTemporal changeDelayed time

The aim of the invention is to suppress the peak current of a display drive circuit having a blank control function. Pieces of display data (D1-Dn) are latched by a data latch (11) and provided to AND gates (121-12n) to which gate control is performed by a blank signal / BLK. Output signals of the AND gates (121-12n) are provided to drivers (141-14n) after being delayed by delay circuits (131-13n) having mutually different delay time (tau 1-tau n) and supplied to a display unit as drive signals Q1-Qn. Since timing of change of signals S1-Sn provided to each of the drivers 141-14n is distributed by the delay circuits (131-13n), timing of current i 1-i n flowing to the drivers (141-14n) is also distributed and the total sum Sigma 1 of the current i 1-i n shows gently temporal change and a peak current value decreases.

Owner:LAPIS SEMICON CO LTD

Multilayer printed wiring board

InactiveUS20100282502A1Reduce noiseEliminate delaysPrinted electric component incorporationSemiconductor/solid-state device detailsEngineeringElectromotive force

In a core substrate 30, a ground through hole 36E and a power through hole 36P are disposed in the grid formation, so that electromotive force induced in X direction and Y direction cancel out each other. As a result, even if mutual inductance is reduced and a high frequency IC chip is loaded, electric characteristic and reliability can be improved without generating malfunction or error.

Owner:IBIDEN CO LTD

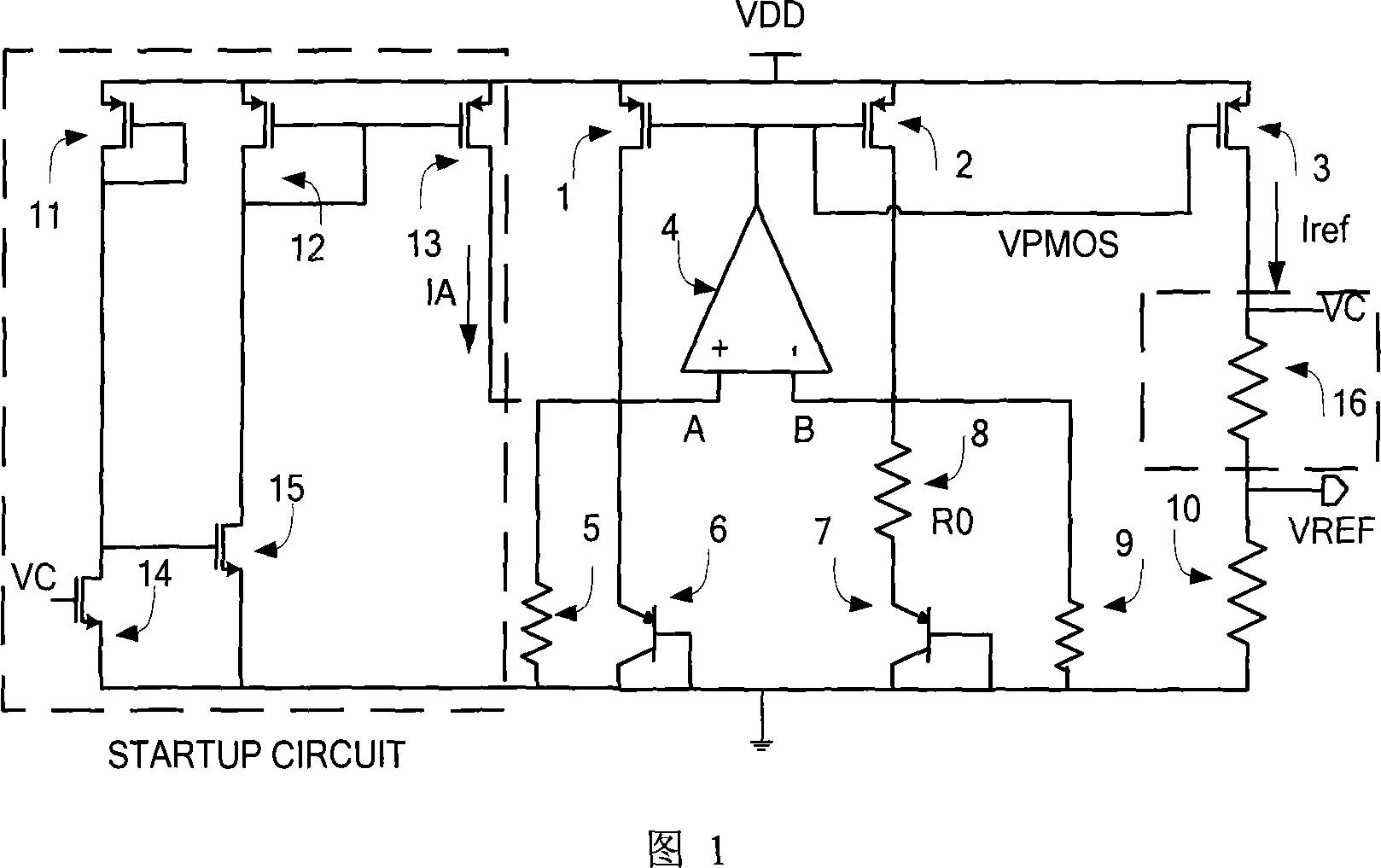

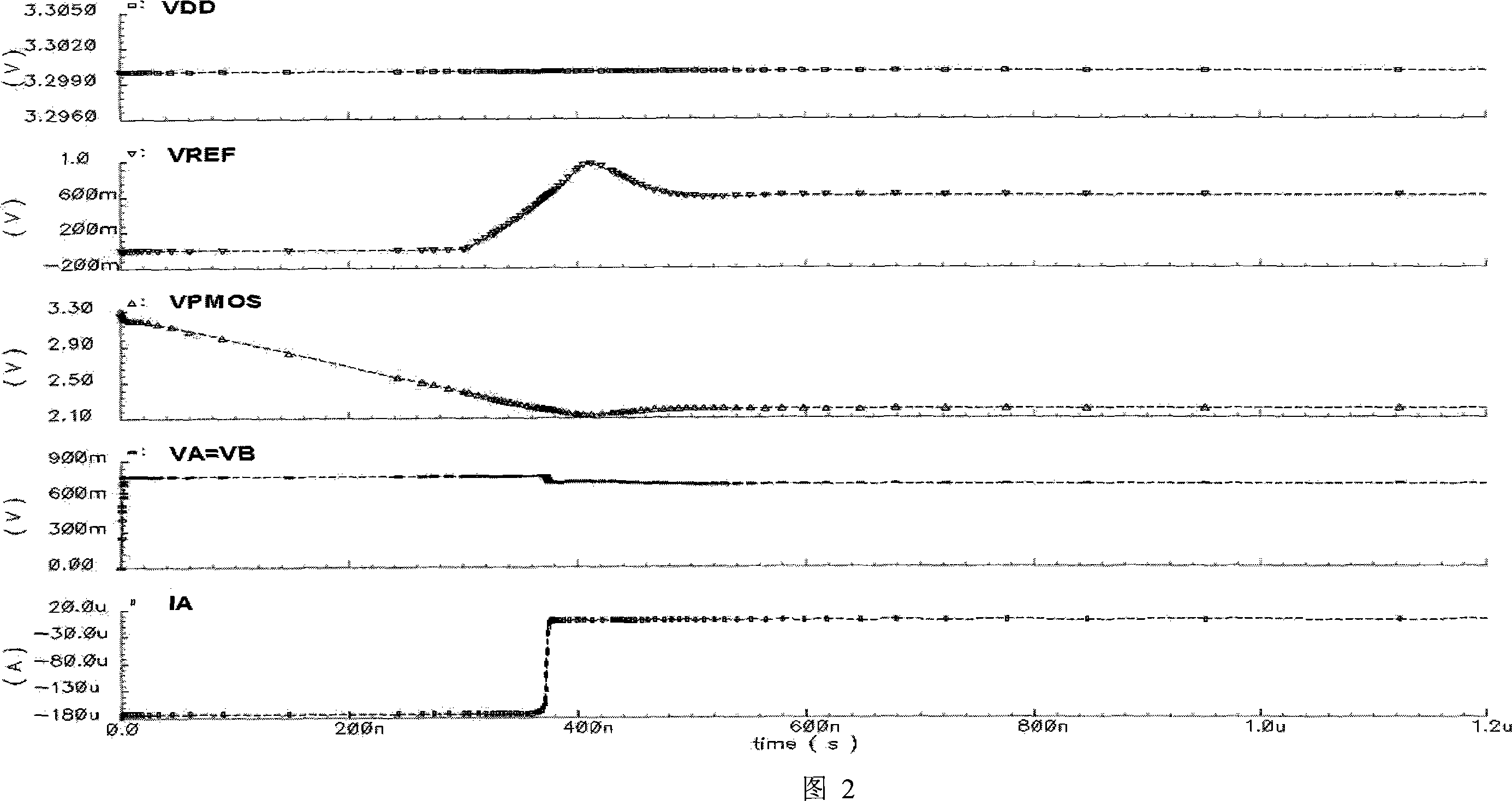

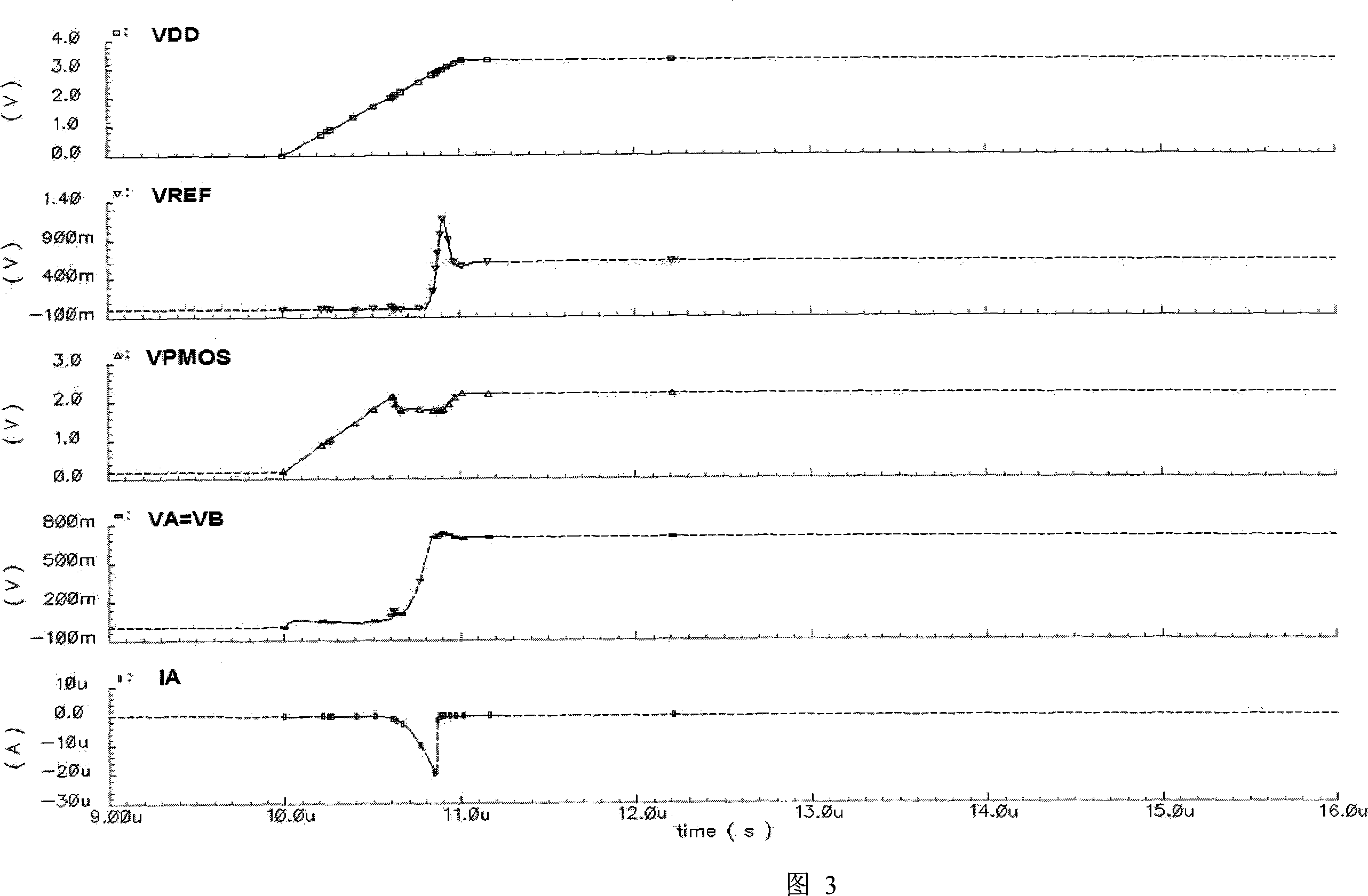

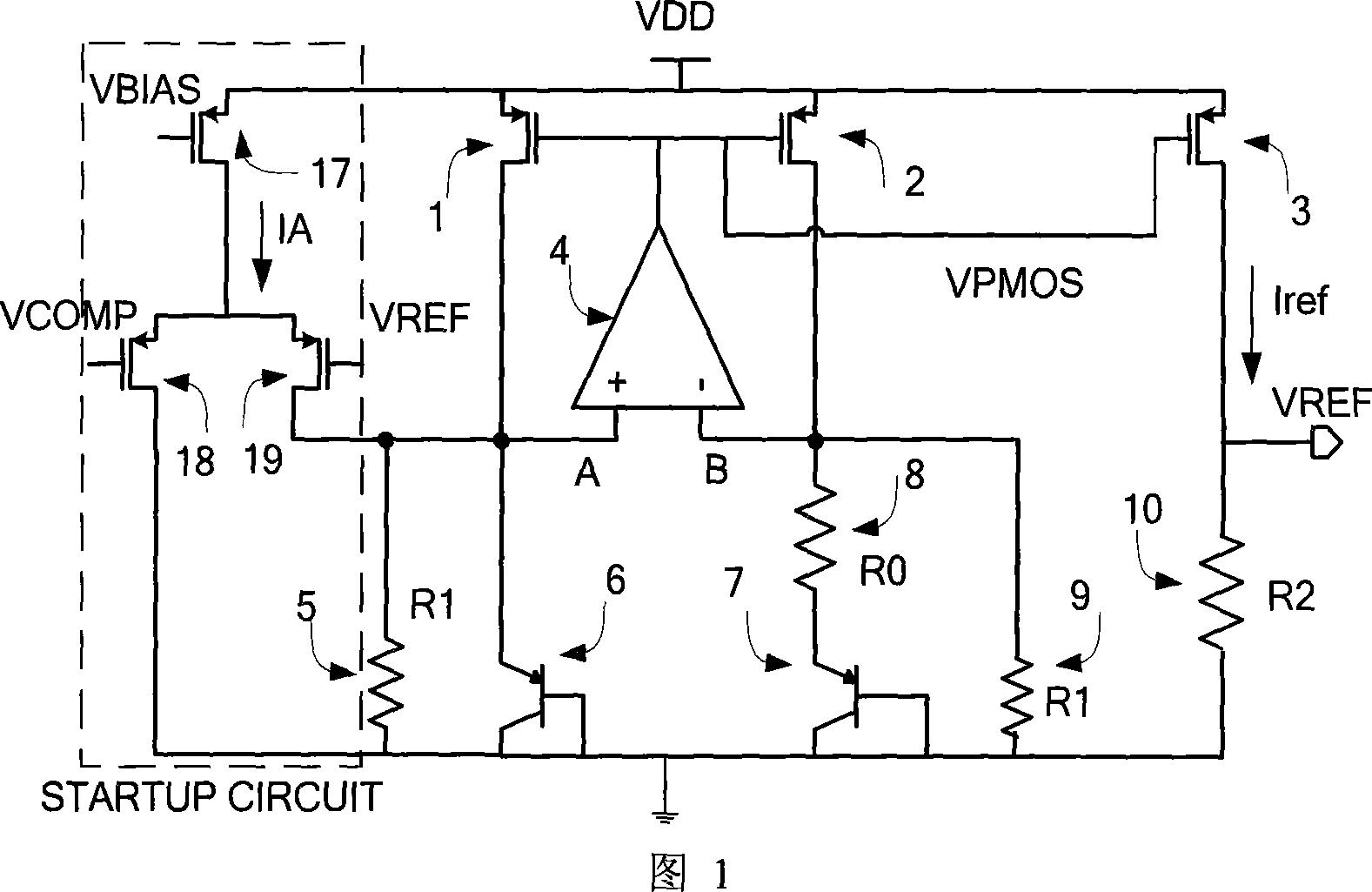

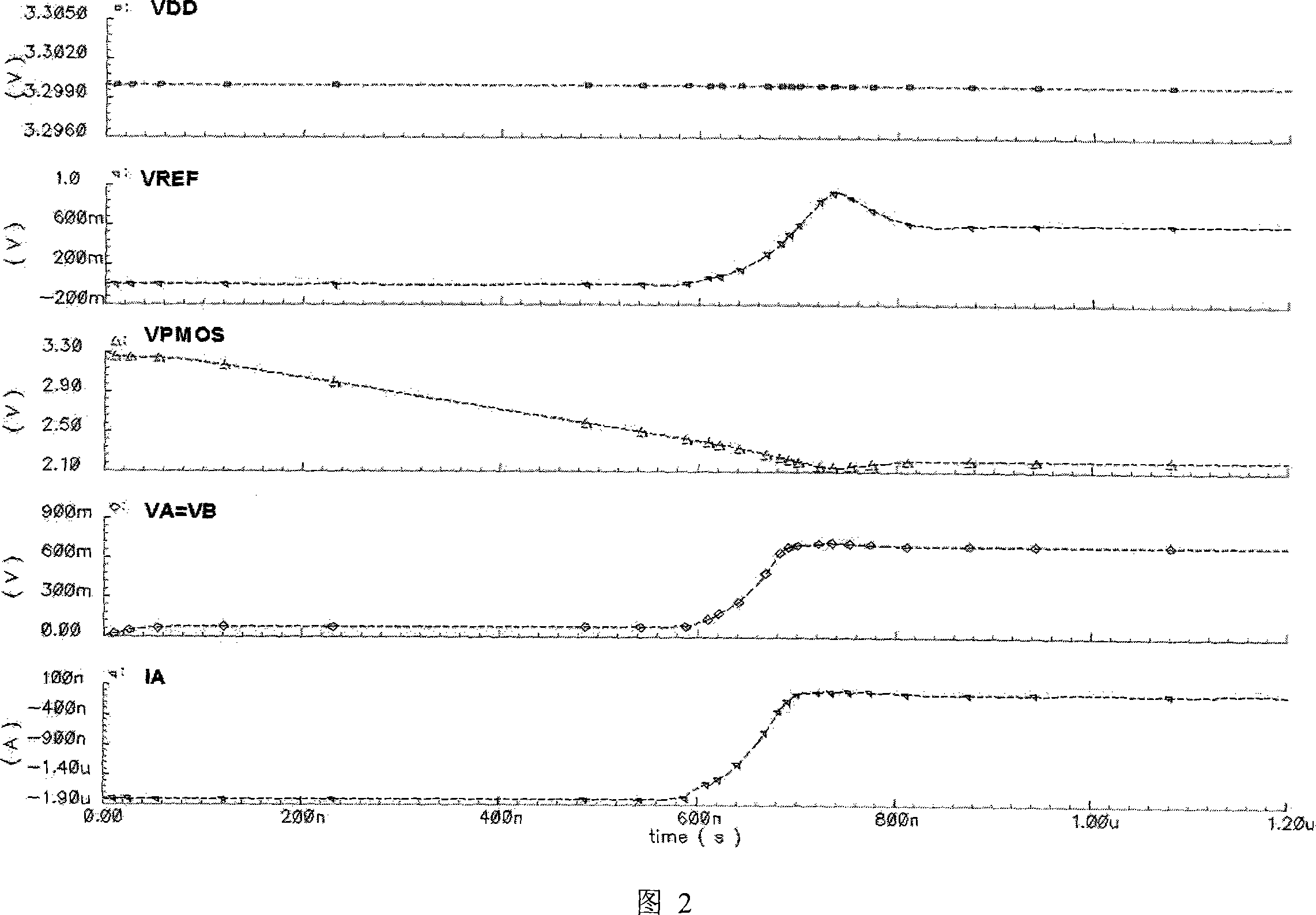

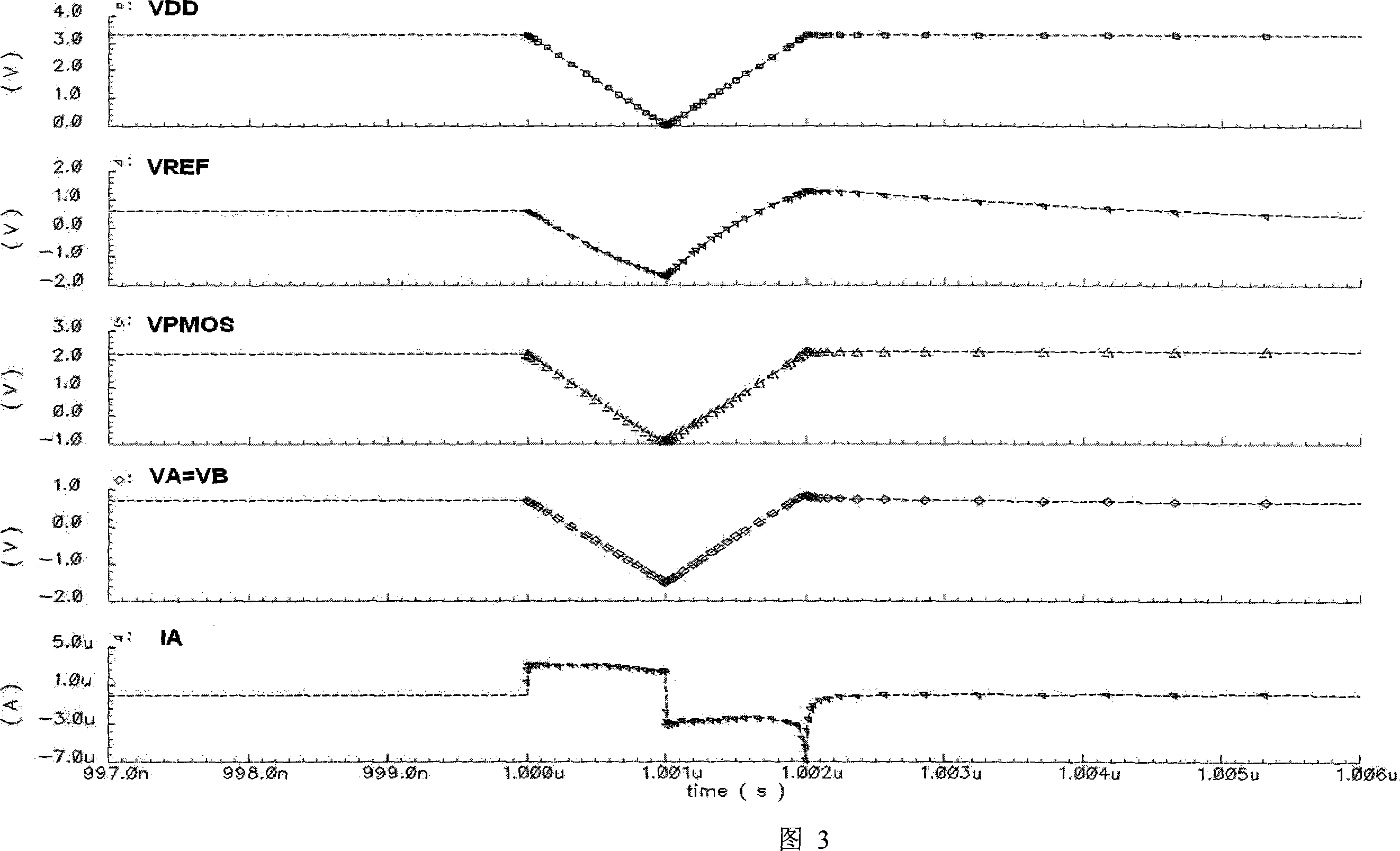

Start circuit for mass production of reference voltage source suitable for Sub1V current mode

InactiveCN101196757AEliminate malfunctionsEasy to implementElectric variable regulationElectrical resistance and conductanceVoltage source

The invention belongs to the technology field of a reference source analog integrated circuit, in particular to a starting circuit being suitable for a reference voltage source capacity with Sbu1V current mode. The circuit is composed of three PMOS pipes, two NMOS pipes and a resistance mutually connected through a circuit. A reference voltage part is composed of three PMOS pipes, an operational amplifier, three triodes and a plurality of resistances mutually connected through a circuit. The starting circuit of the invention can avoid the aftereffect of abnormal working the operational amplifier maladjustment voltage Vos brings to chips and release zero state. The starting circuit has simple structure and easy realization, and is able to be applied in traditional reference voltage source.

Owner:FUDAN UNIV

Start circuit of reference voltage source suitable for Sub1V current mode

InactiveCN101196758AEliminate malfunctionsEasy to implementElectric variable regulationAudio power amplifierCurrent mode

The invention belongs to the technology field of a reference source analog integrated circuit, in particular to a starting circuit being suitable for a reference voltage source wit Sub1V current mode. The circuit comprises three PMOS pipes, a first PMOS pipe is a bias PMOS pipe, at the grid end, bias voltage is provided by VBIAS, the leakage end is connected with source-end of a second PMOS pipe and a third PMOS pipe; the leakage end of the second PMOS pipe is grounding, while the grid end is connected with compare threshold voltage; the grid end of the third PMOS pipe is connected with the output of reference source, while the leakage end is connected with an operational amplifier. The starting circuit of the invention can avoid the aftereffect of abnormal working the operational amplifier maladjustment voltage Vos brings to chips and release zero state. The starting circuit requires three MOS pipes only, has simple structure and easy realization, and is able to be applied in traditional reference voltage source.

Owner:FUDAN UNIV

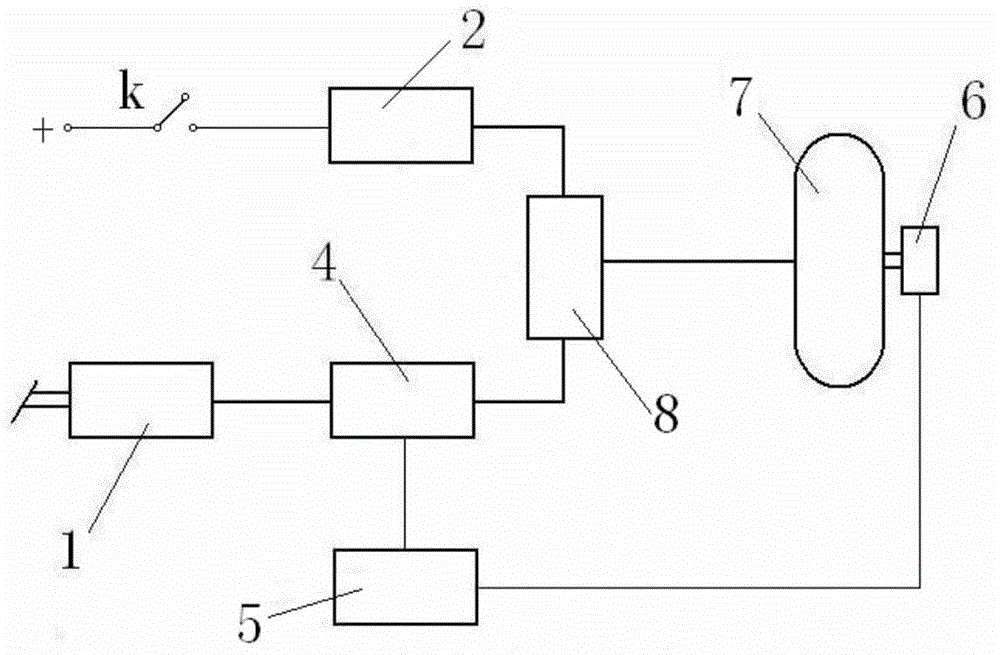

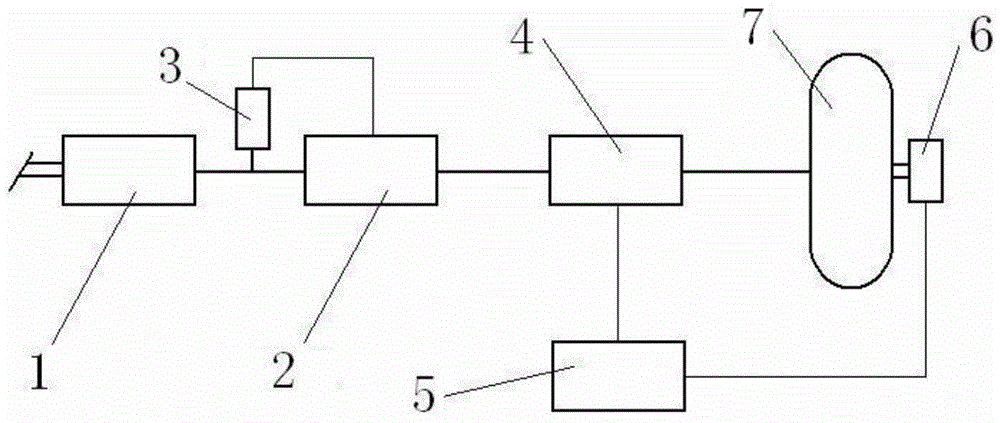

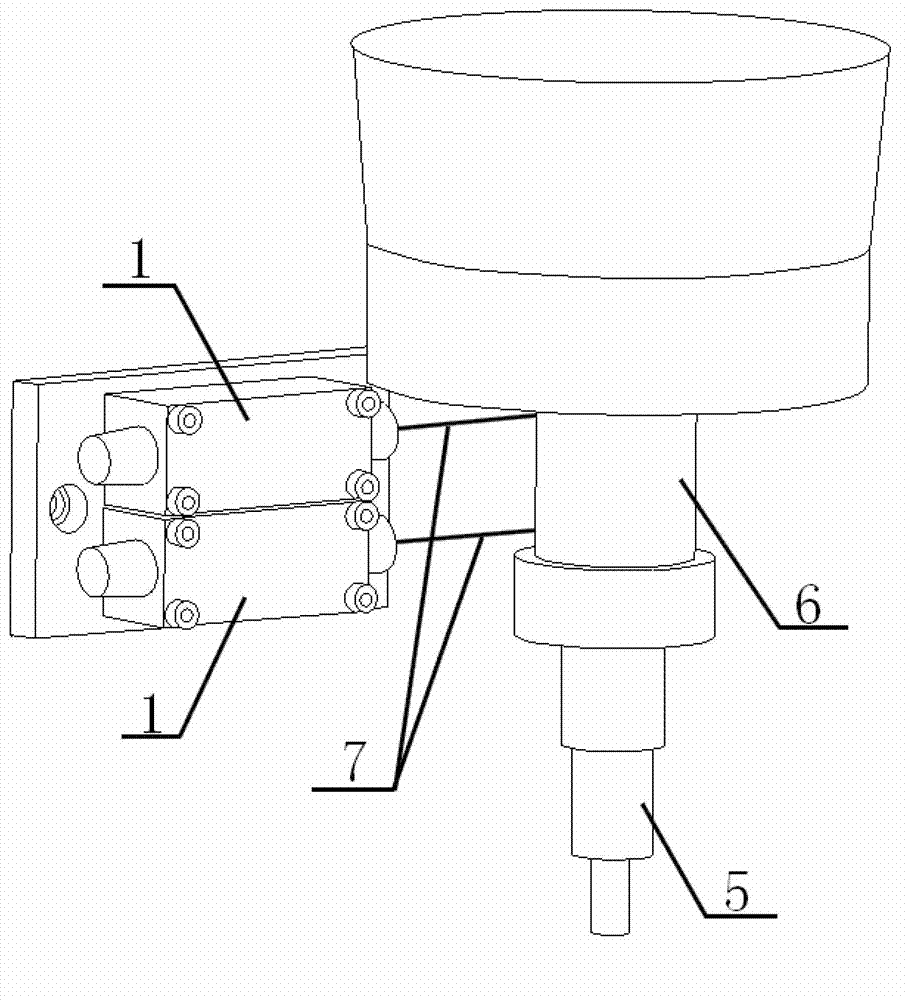

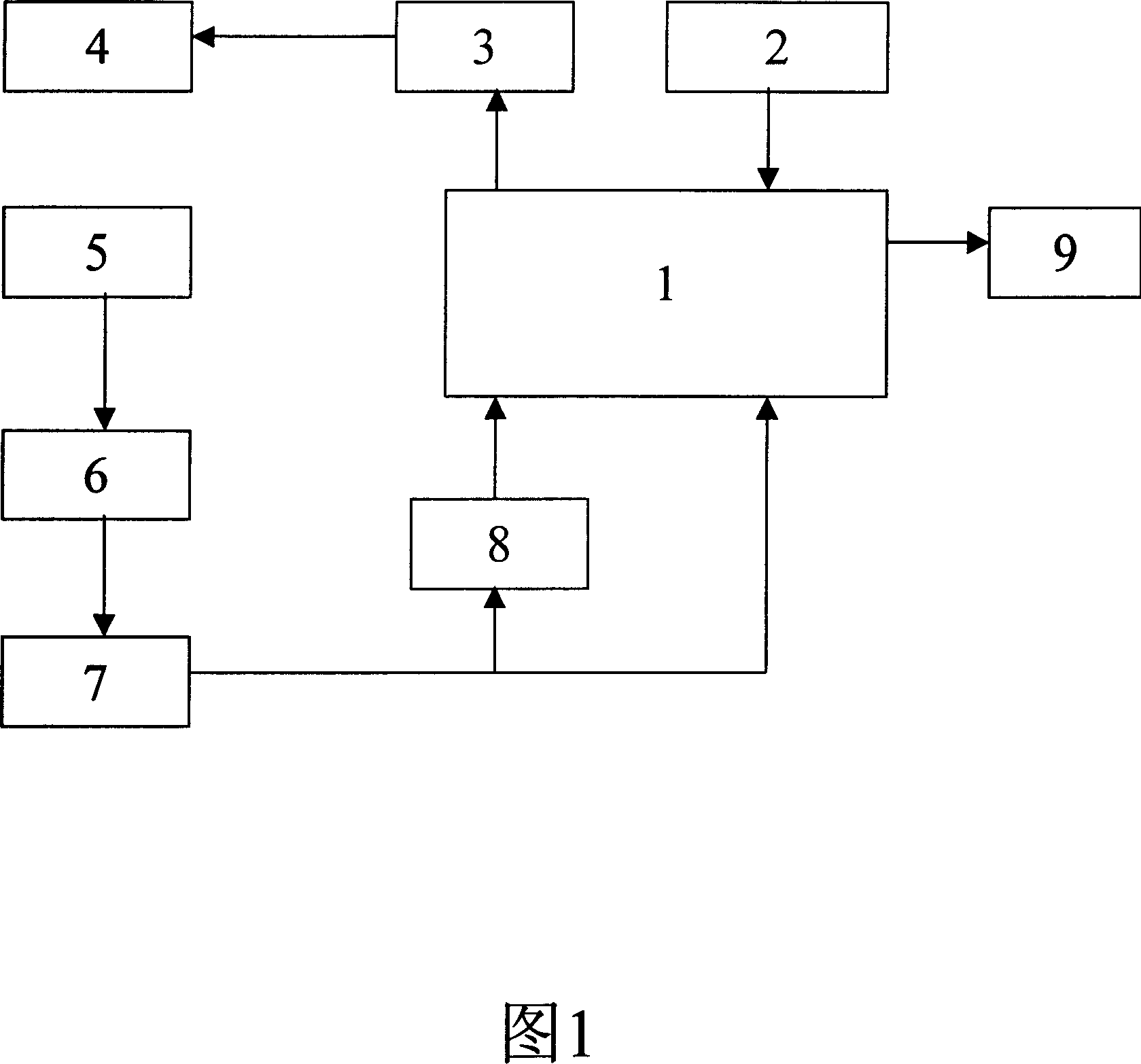

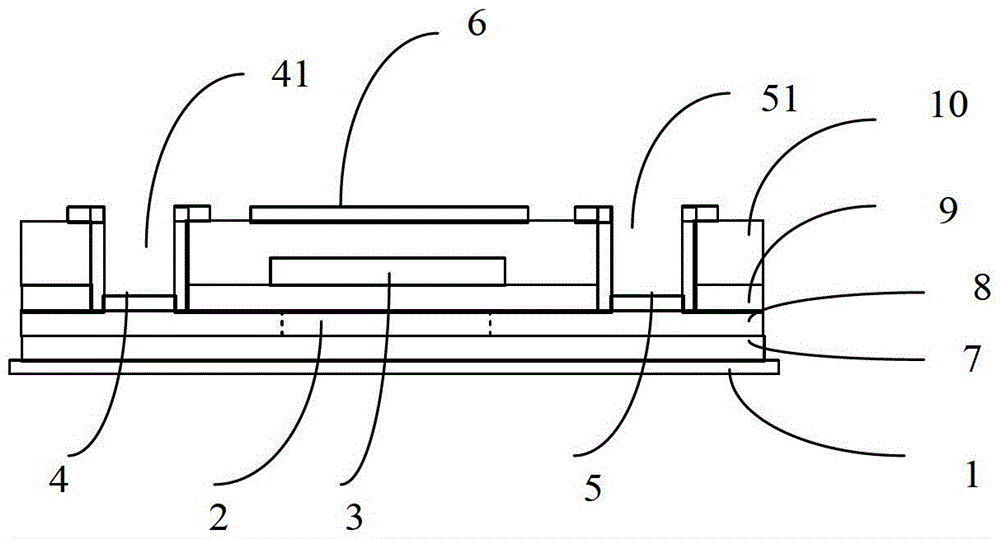

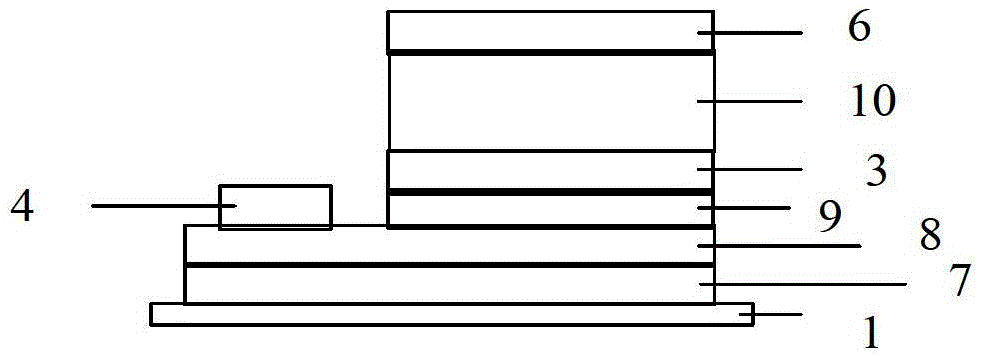

Manipulator control system and control method

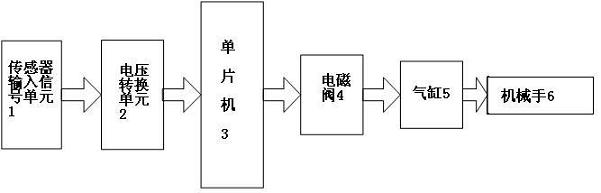

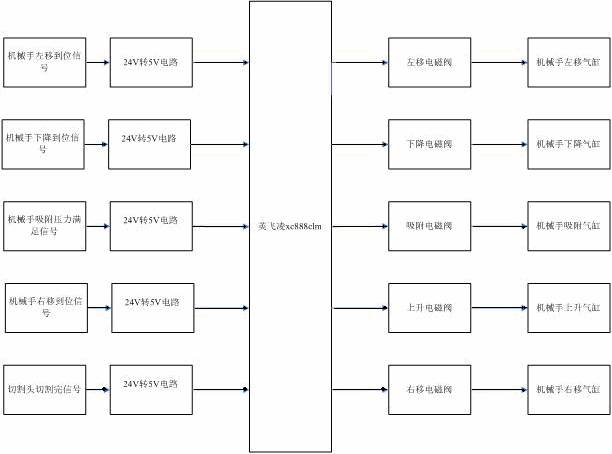

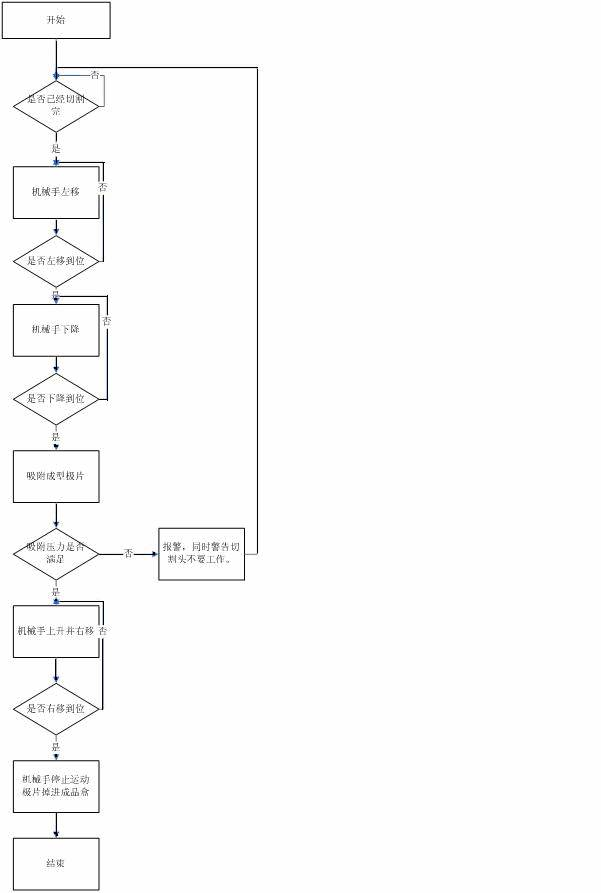

ActiveCN102189553AEliminate malfunctionsImprove securityProgramme-controlled manipulatorLaser beam welding apparatusRobotic controlManipulator

The invention discloses a manipulator control system and a manipulator control method. The control system comprises a sensor signal input unit (1), a voltage conversion unit (2), a singlechip (3), an electromagnetic valve (4), a cylinder (5) and a manipulator (6), wherein the singlechip (1) is used for controlling the electromagnetic valve (4) according to an input signal; the electromagnetic valve (4) is used for controlling the cylinder (5) to act; and the cylinder (5) is used for driving the manipulator (6) to act. Due to adoption of the system, the action of the manipulator can be accurately controlled, the false operation of a cutting head is eliminated, safety protection can be improved, and potential safety hazards can be eliminated.

Owner:CHERY AUTOMOBILE CO LTD

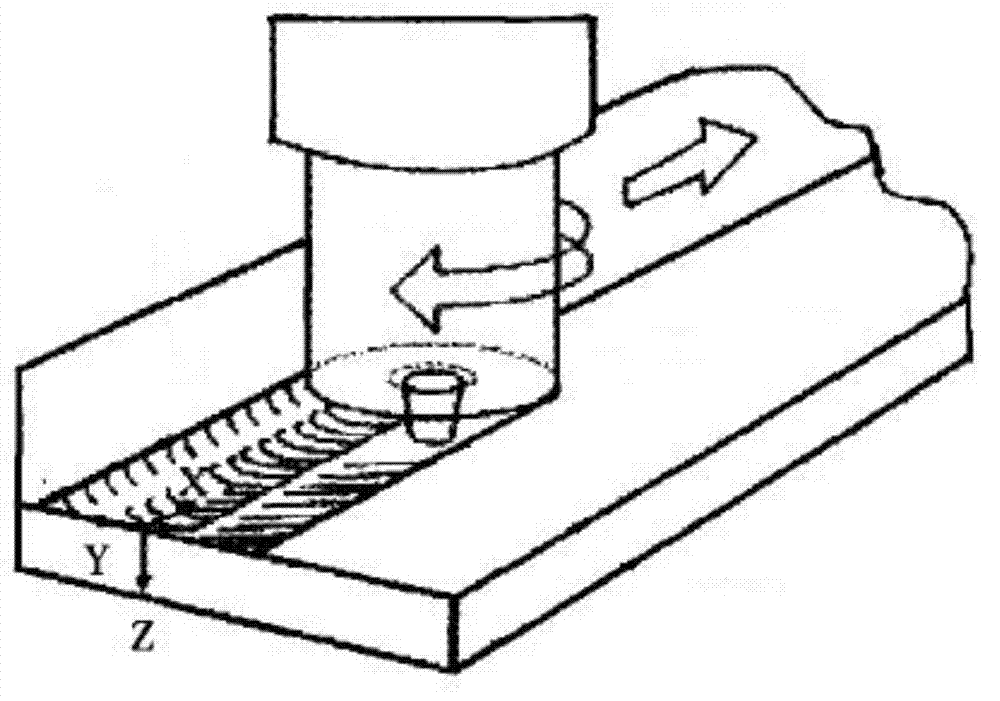

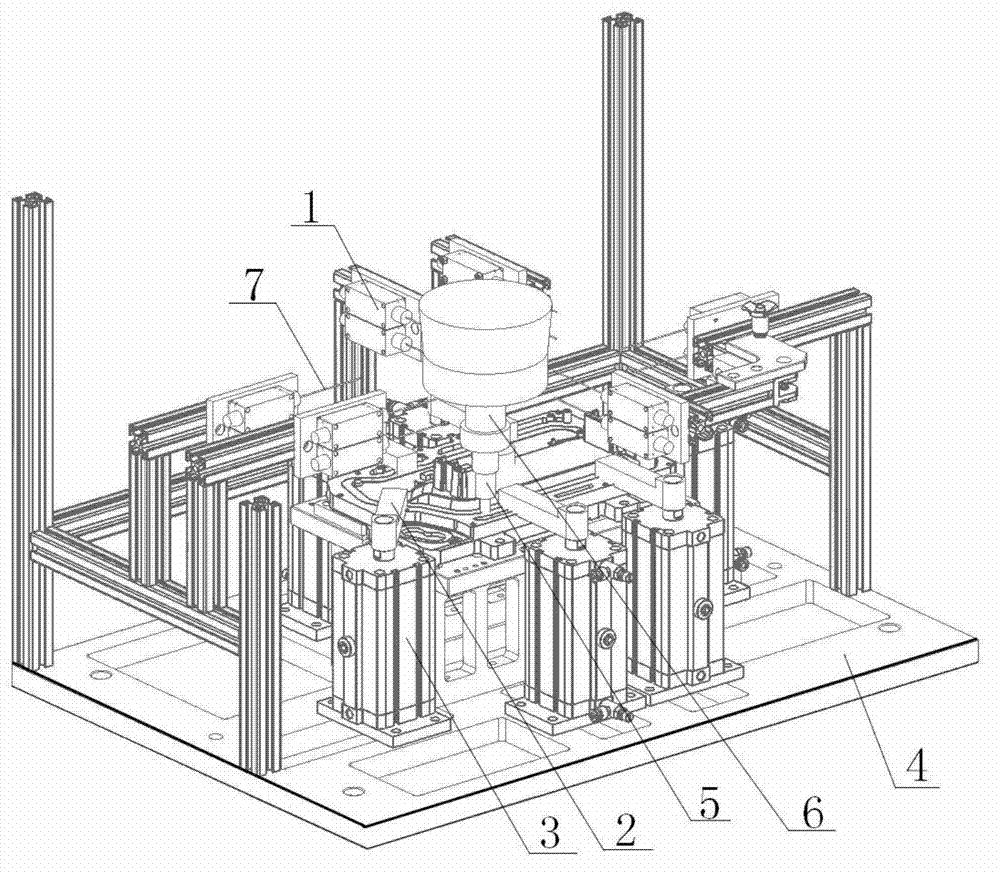

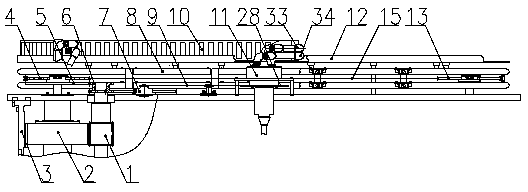

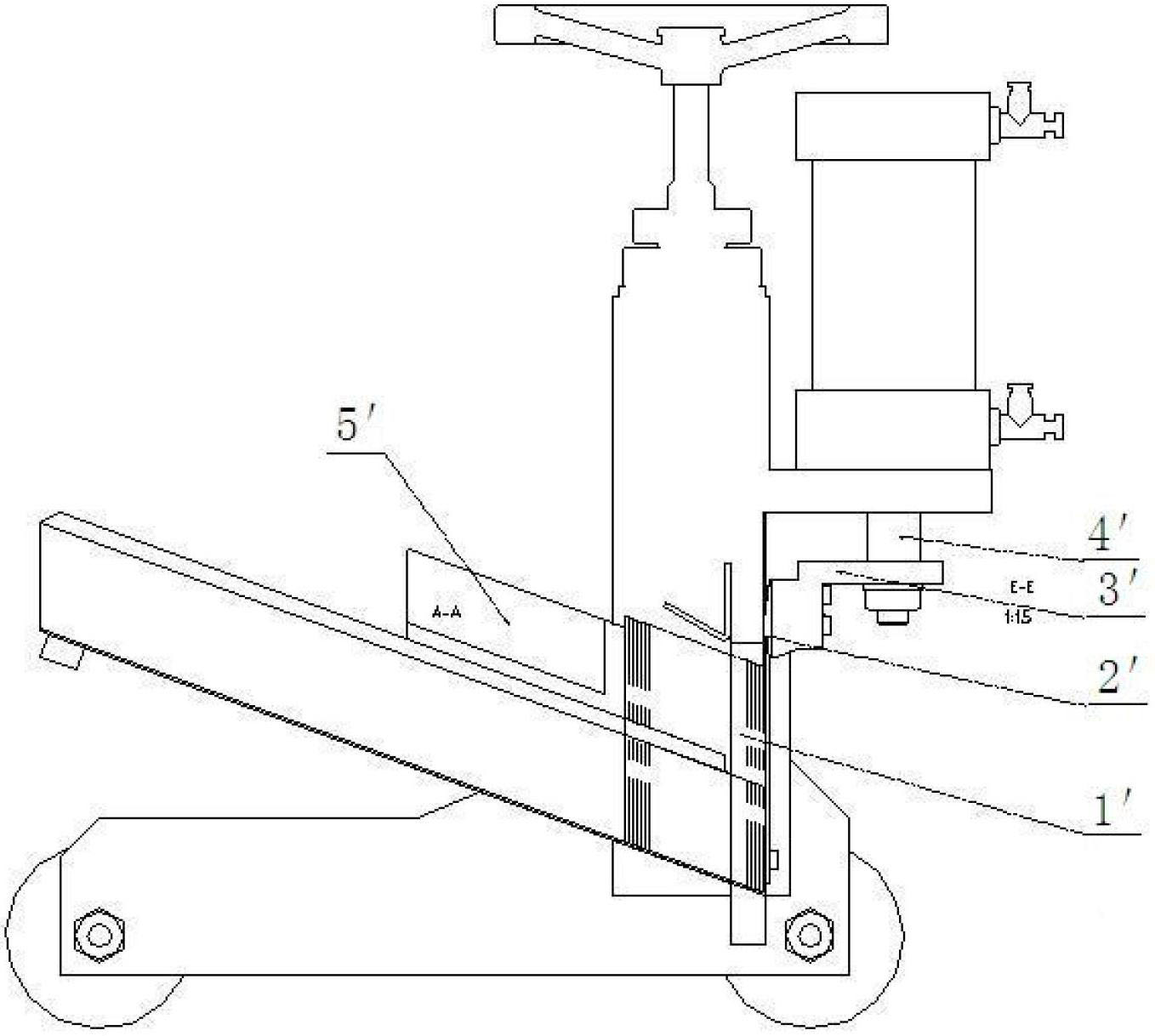

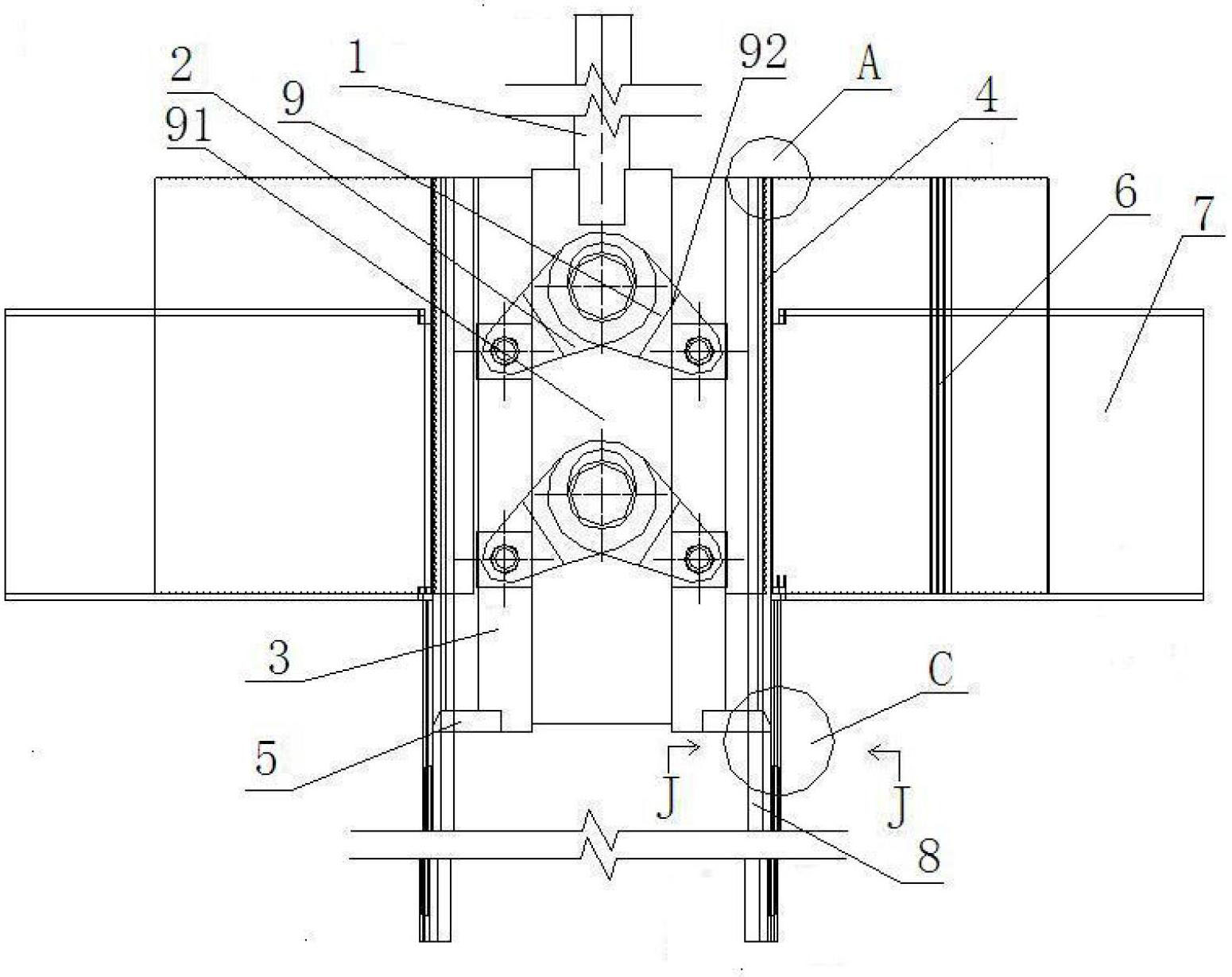

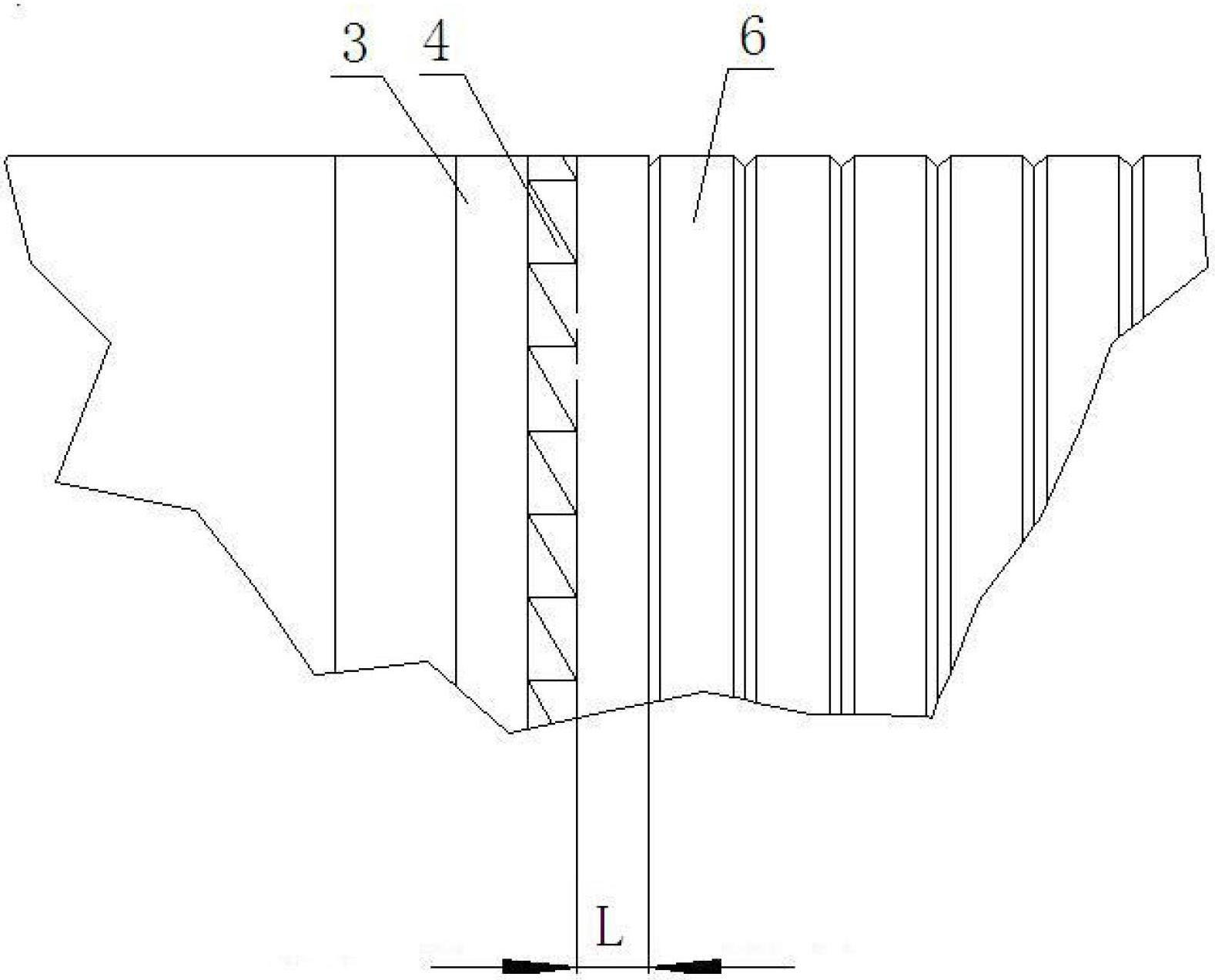

Friction stir welding fixture in mechanical trigger control mode and method for controlling friction stir welding fixture

ActiveCN103042303AEliminate malfunctionsGuaranteed uptimeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringControl mode

The invention discloses a friction stir welding fixture in a mechanical trigger control mode and a method for controlling the friction stir welding fixture. The friction stir welding fixture comprises a fixture base, a control unit, a trigger element, limit switches and a plurality of pressure plates; each pressure plate is connected with a pressure plate cylinder, each pressure plate cylinder corresponds to at least one limit switch and is controlled by the corresponding limit switches, and the limit switches and the pressure plate cylinders are connected with the control unit; and the trigger element and the limit switches are matched with one another and are mounted on a friction stir welding head. The pressure plate cylinders are controlled by the mechanical trigger type limit switches and the trigger element, possibility of malfunction of the pressure plate cylinders is eliminated, the pressure plates are driven by the pressure plate cylinders to be automatically opened before the welding head moves to the pressure plates during movement, and are reset to press workpieces after the welding head passes the pressure plates, the integral fixture is automatically controlled and is reliable in running, and the cost is lowered.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

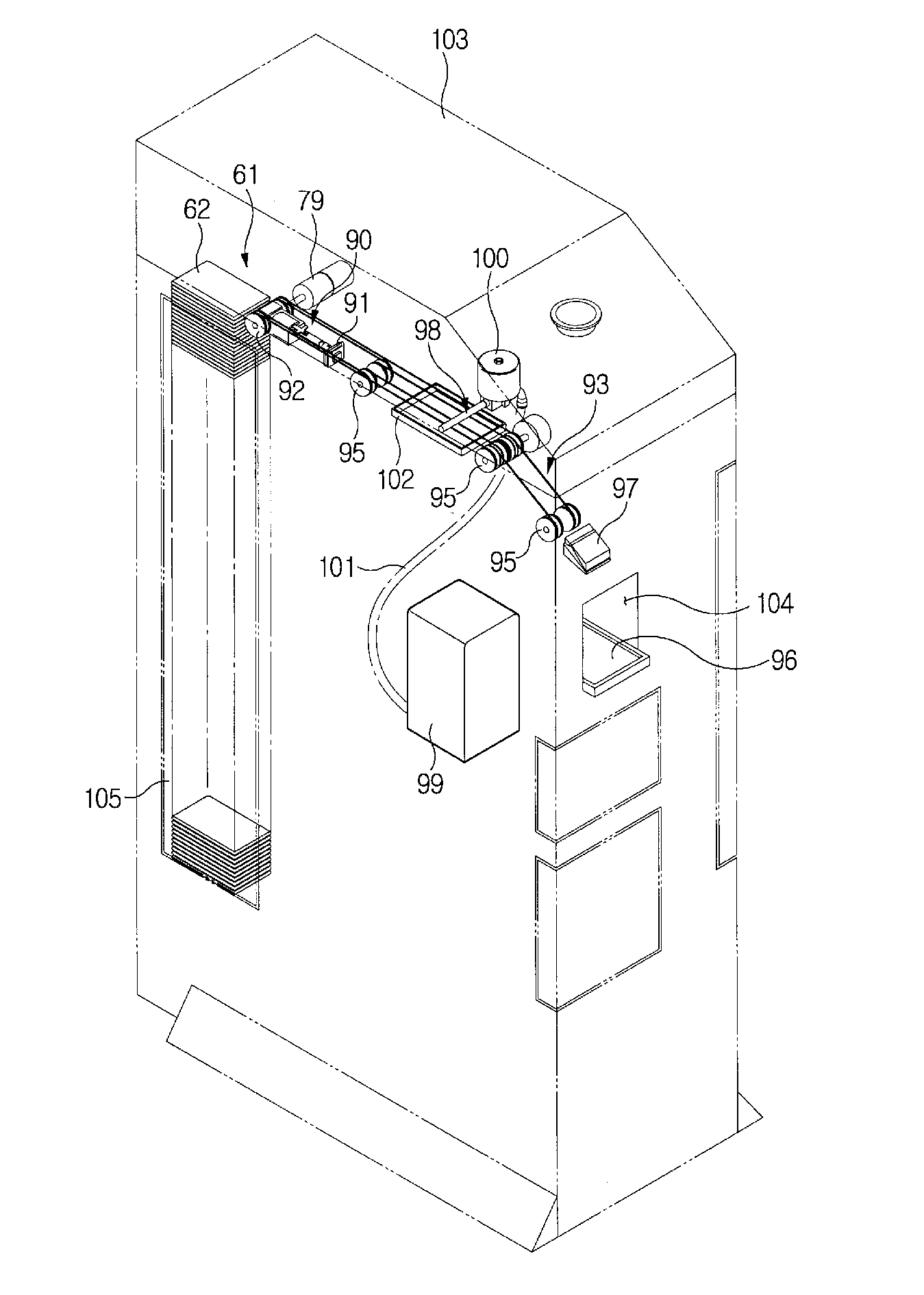

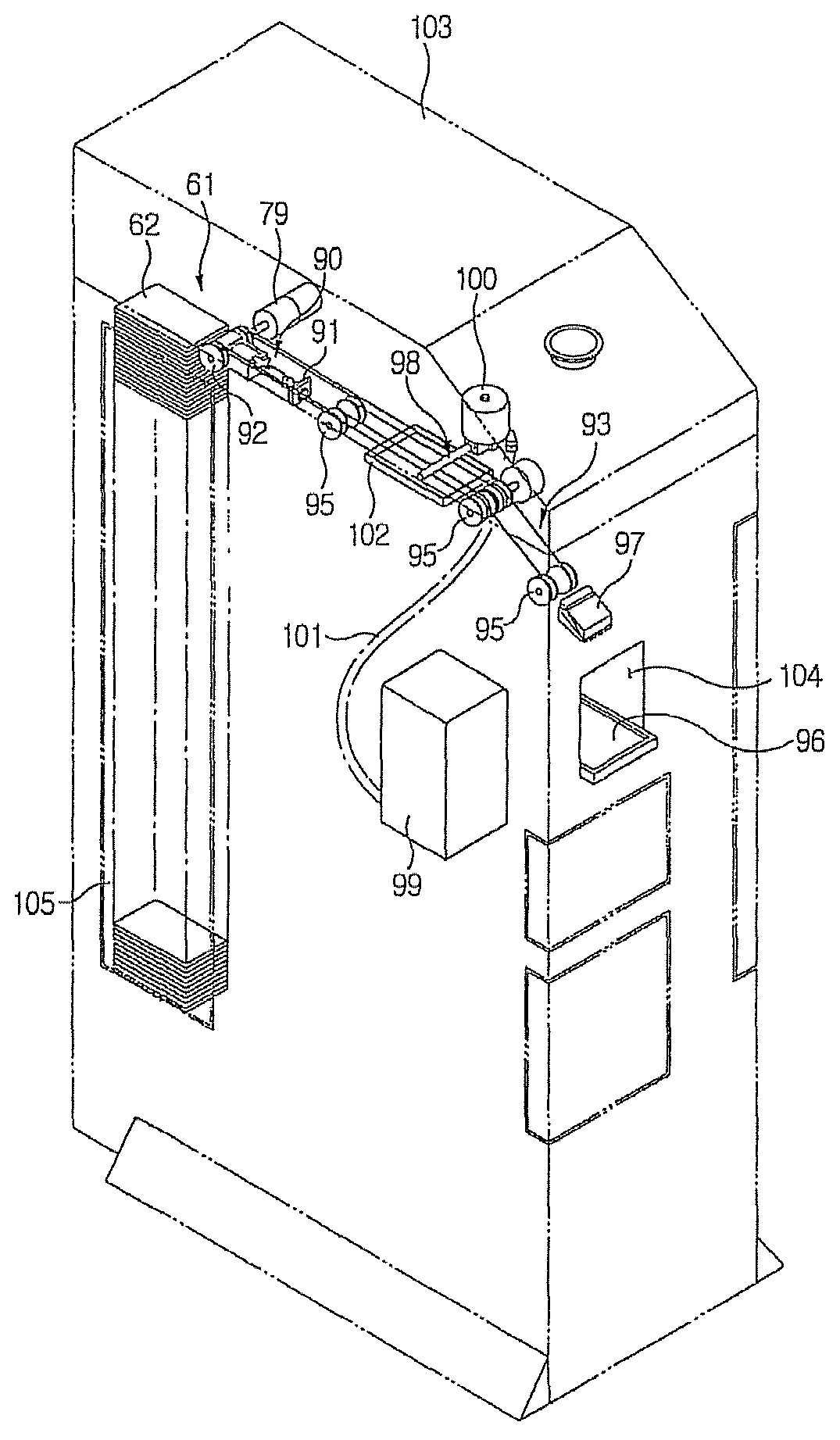

Apparatus for discharging tissue

InactiveUS7677410B2Easy to replaceEasy to checkCoin-freed apparatus detailsDomestic applicationsBiomedical engineering

An apparatus for discharging tissue that is folded several times and stacked is provided. The apparatus includes a cartridge that holds stacked tissue and has a through hole at one end, and a holding member that is disposed adjacent to the through hole of the cartridge and pivots on an axis to grasp and remove tissues one at a time from the top of the stack through an arm. The inventive apparatus allows a user to easily replace tissue and check the amount of tissue used and the amount left to use through visual means. The apparatus virtually eliminates the problem of tissue dispensing failure, and has increased precision and reliability and reduced dispensing time over conventional apparatuses.

Owner:ELIX CO LTD

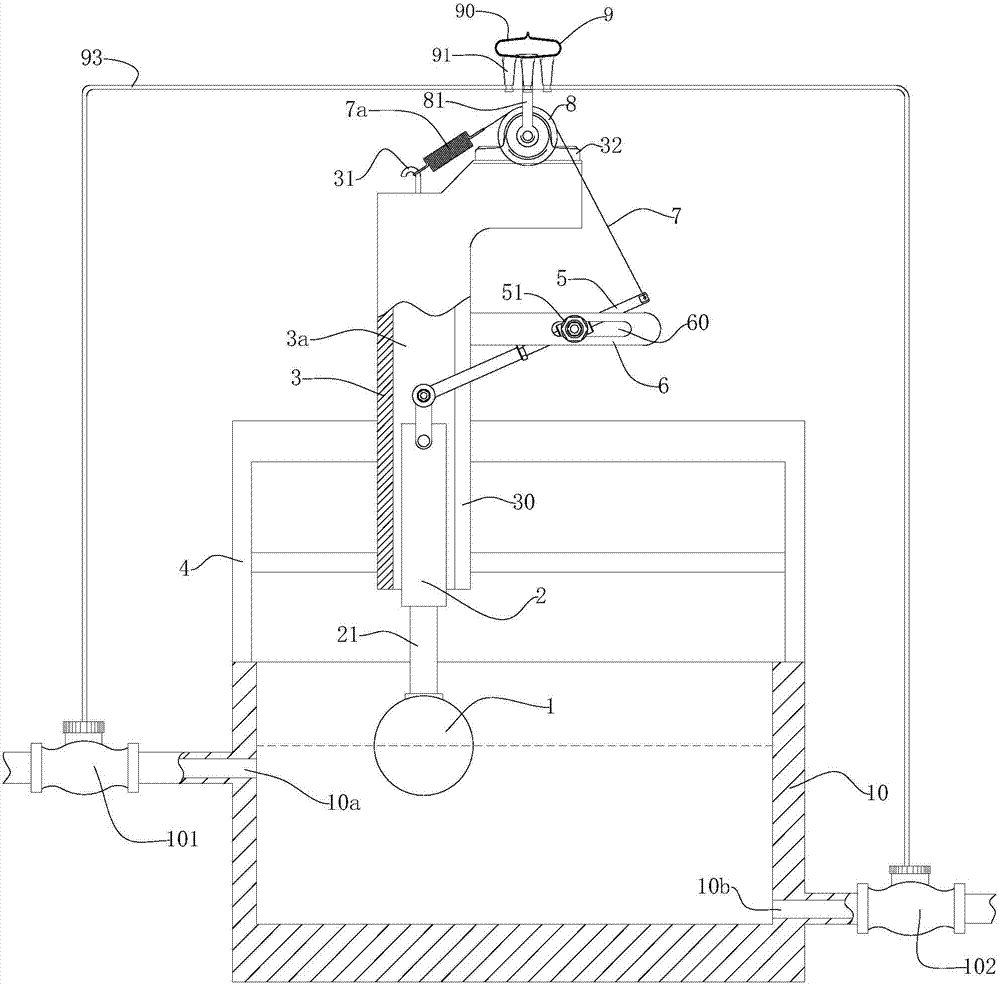

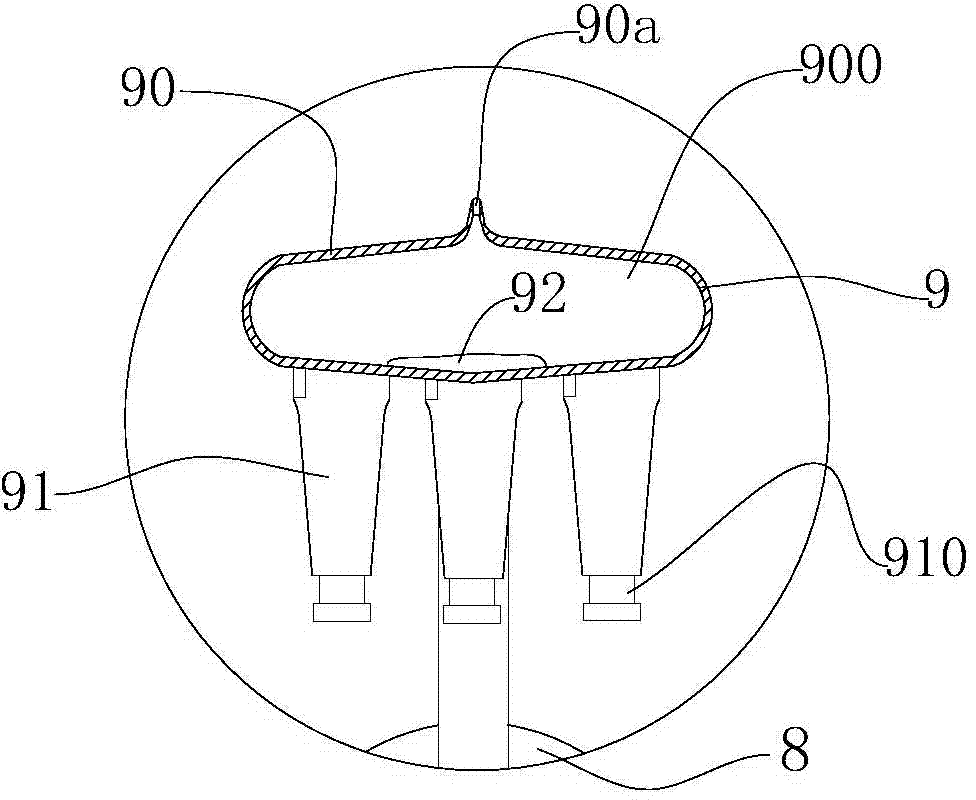

Liquid level control system

ActiveCN103885466AReduce manufacturing costImprove reliabilityLevel controlMarine engineeringControl system

The invention relates to a liquid level control system which comprises a first control valve connected to a water inlet pipeline of a water pool with the liquid level to be tested, a second control valve connected to a water outlet pipeline of the water pool with the liquid level to be tested and a liquid level changing sensing mechanism. The liquid level changing sensing mechanism comprises a base body, a floating ball component, a rocker bar mechanism and a mercury switch. The floating ball component is arranged on the base body. The floating ball component is connected with the mercury switch through the rocker bar mechanism. The mercury switch inclines and can be communicated with a middle electrode and an electrode on one side. The liquid level control system has the advantages of being novel in structure, low in manufacturing cost, adjustable in accuracy, great in flexibility and stability and good in control effect.

Owner:广钢气体(广州)有限公司

Infrared cold/hot metal detector

InactiveCN1987519AImprove anti-interference abilityQuick responseElectromagnetic wave reradiationMicrocontrollerAudio power amplifier

The infrared cold / hot metal detector includes microcontroller (MC), power supply module, modulation drive, semiconductor laser module (SLM), light sensitive receiver (LSR), filter, operational amplifier (OA), modem, and output module. The input end of the modulation drive is connected to the output end of MC. The output end of the modulation drive is connected to the input end of SLM. LSR is setup on laser emission optical path of SLM. The output end of LSR is connected to the input end of the filter. The output end of the filter is connected to the input end of OA. The output signal of OA is divided into two routes to output to MC: one is through modem outputted to MC; and the other is outputted to MC directly. The input end of the output module is connected to the other output end of MC. advantages are: high interference killing feature, quick response speed, and high measuring accuracy, and eliminating misoperation thoroughly.

Owner:上海派恩科技有限公司

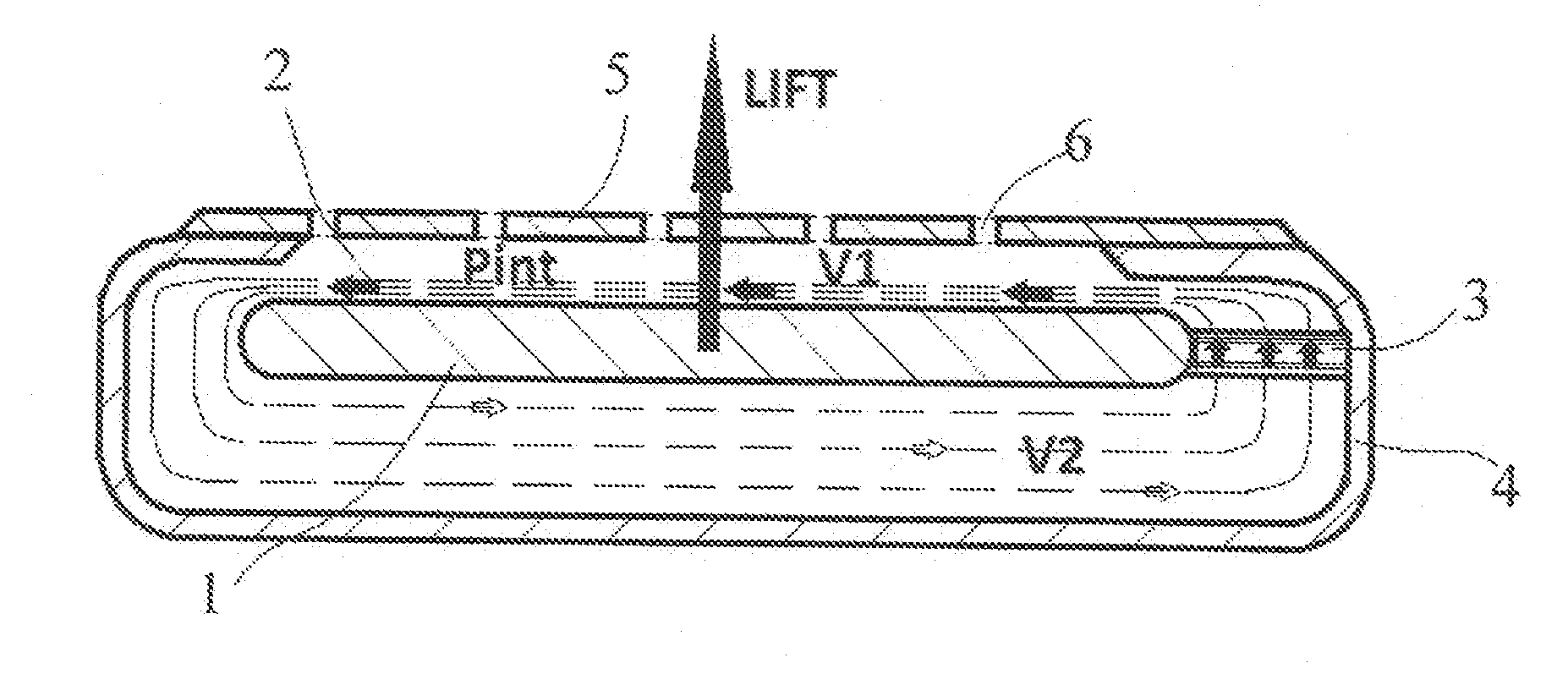

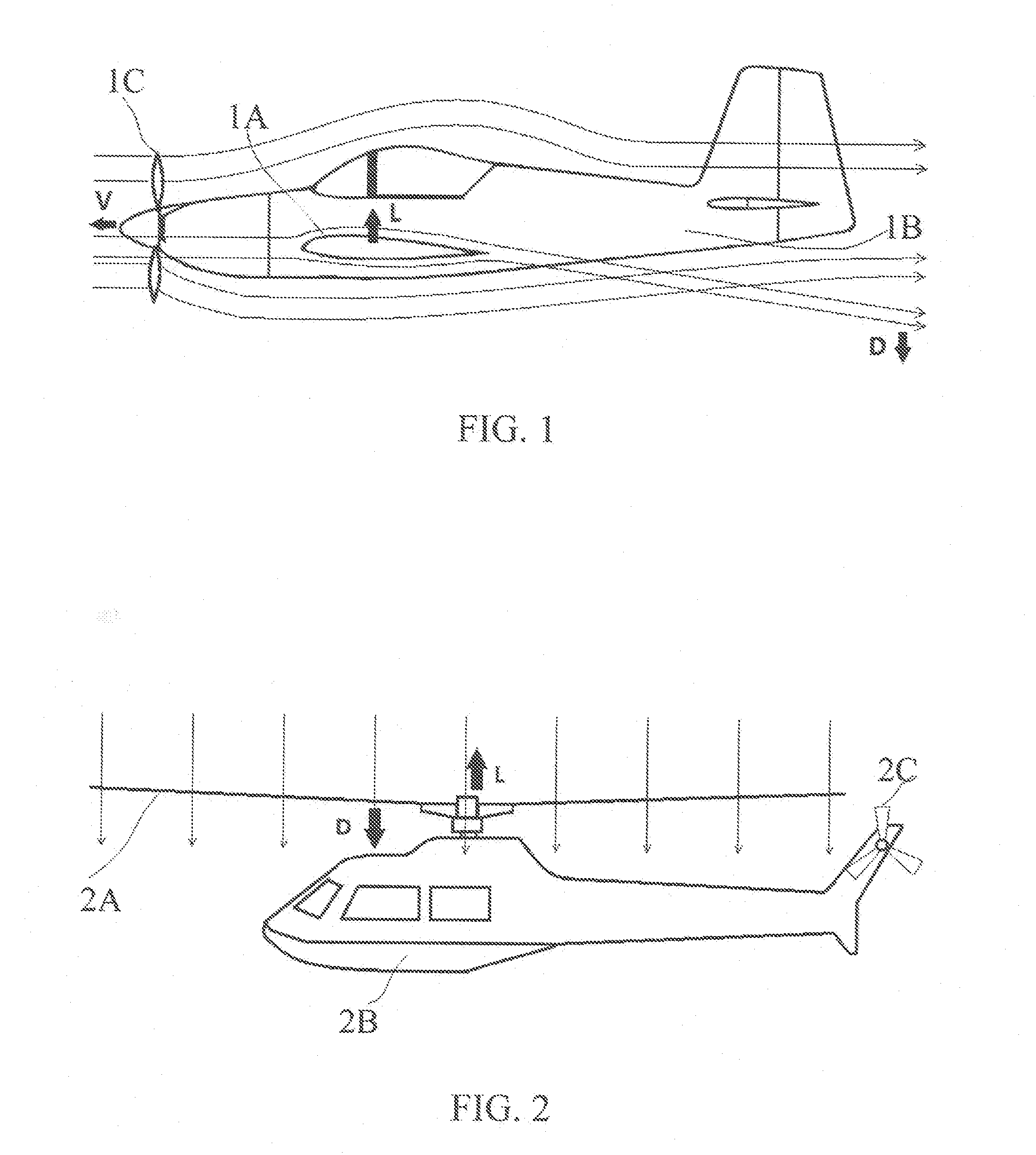

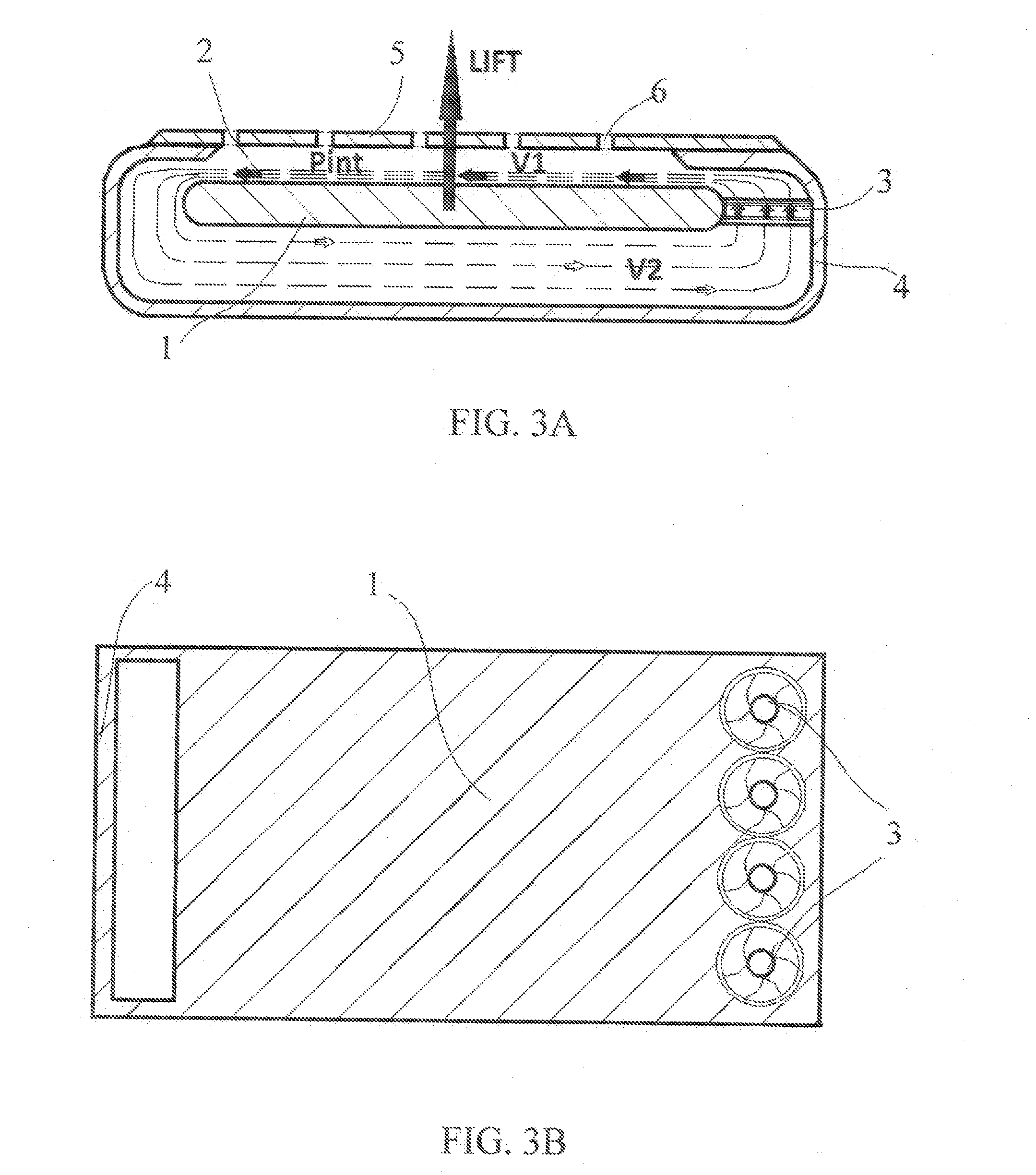

Semi-open Fluid Jet VTOL Aircraft

InactiveUS20160009376A1Eliminate malfunctionsProvide stabilityWingsVertical landing/take-off aircraftsSemi openPropeller

The herein invention is presenting a lift generating method based on a semi-open fluid jet flowing in a closed circuit around a lifting airfoil. A VTOL aircraft with maximized pay load room and car-like shape is the preferred embodiment of the invention. The herein aircraft uses no wings, exposed propellers, hot gas jets or other high injury risk means for propulsion and life, and it can be driven by ordinary skilled people. Furthermore the aircraft has a small footprint and can land, take off and even cruise on water in one of the preferred embodiments.

Owner:BUCHERU BOGDAN TUDOR

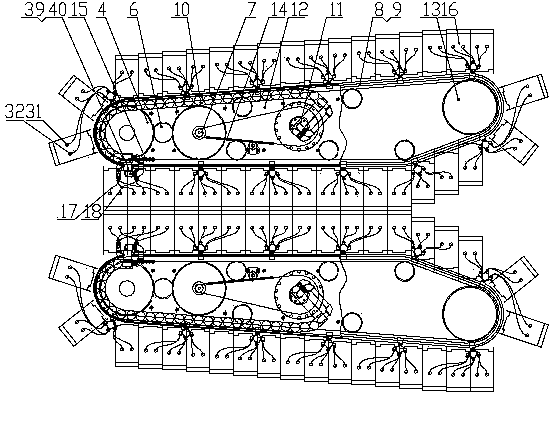

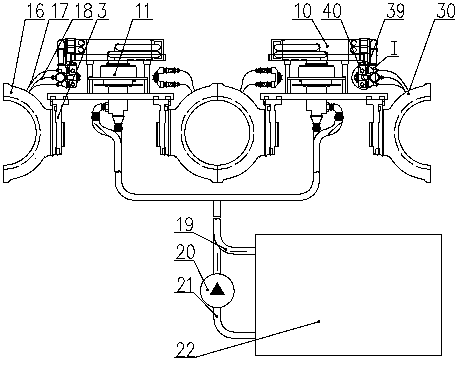

Plastic pipe mould cooling device capable of carrying out continuous circulating operation

The invention discloses a plastic pipe mould cooling device capable of carrying out continuous circulating operation. The plastic pipe mould cooling device capable of carrying out continuous circulating operation comprises at least two plastic pipe moulds, wherein each plastic pipe mould comprises at least two mould bodies which carry out circulating operation along annular rails, the mould bodies on the plastic pipe moulds are correspondingly arranged in a one-to-one mode, a cooling water cavity is arranged inside each mould body, and each cooling water cavity is communicated with a cooling water movement pipeline. Due to the fact that water inlets and water outlets of the plastic pipe moulds are connected with cooling water circulating pipelines in a one-to-one mode through water feeding pipelines and water discharging pipelines, a cooling water circulating channel is a totally-closed pipeline, leakage cannot easily happen, and the fault rate is low; due to the fact that operation of the cooling water feeding pipelines, the cooling water discharging pipelines and operation of rotation pipeline converters are in continuous same-direction movement, movement impact is low, and the service life is long; due to the fact that a drive system is in gear drive and chain wheel and chain drive, the drive ratio is constant, the same power source is used by the drive system and is used for drive of the plastic pipe moulds, and elimination of malfunctions is ensured. The plastic pipe mould cooling device capable of carrying out continuous circulating operation has the advantages of being high in cooling efficiency, stable and reliable in operation, and capable of carrying out high-speed and high-efficiency operation.

Owner:青州市塑霸机械有限公司

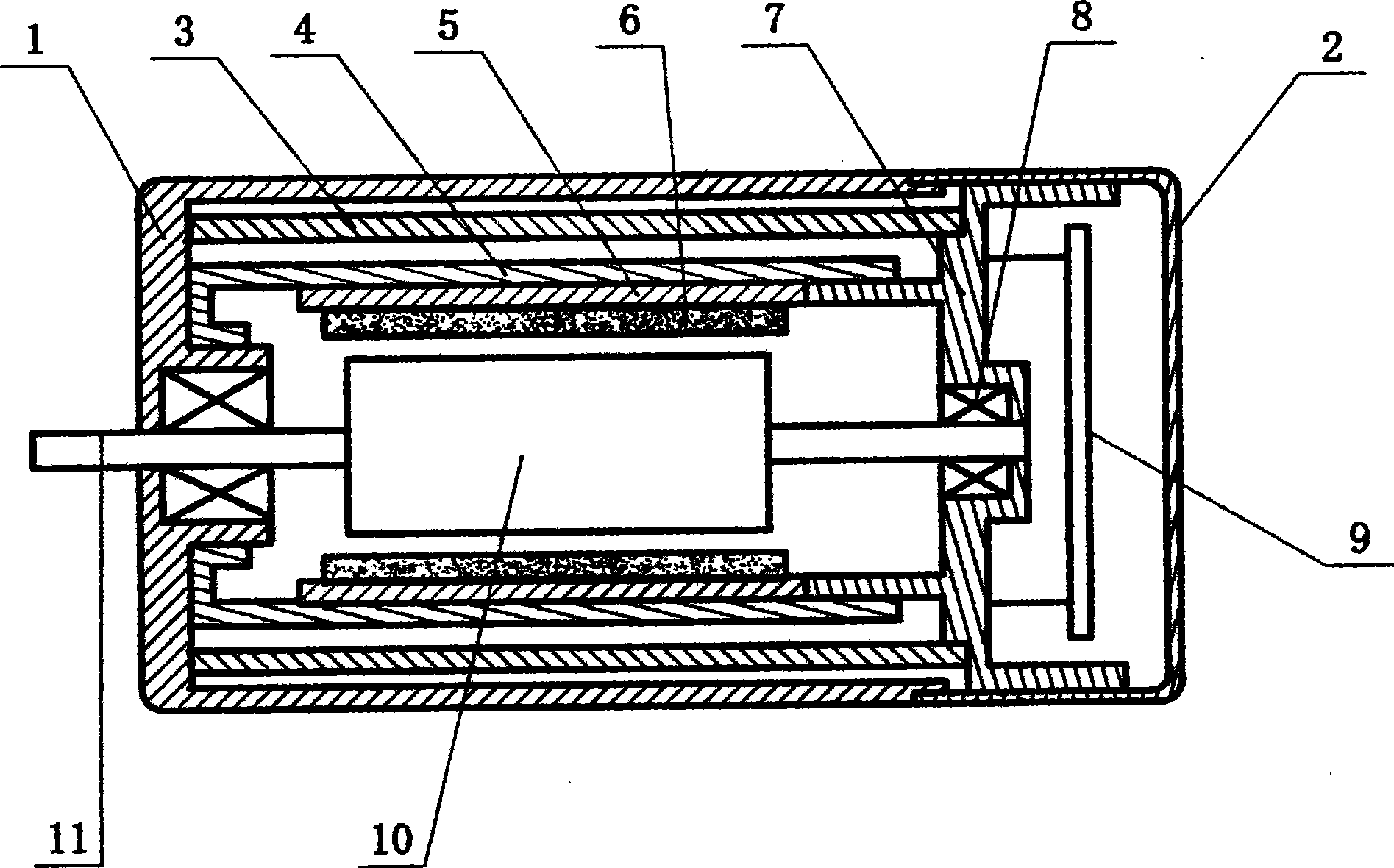

Electromagnetic interference resistant control servo motor

InactiveCN101453141AImprove dry electromagnetic interference capabilityEliminate malfunctionsMagnetic/electric field screeningSupports/enclosures/casingsServo actuatorElectromagnetic interference control

The invention relates to the field of motor manufacturing, in particular to an anti-electromagnetic interference control servo-actuator. The servo-actuator is characterized in that on the basis of the prior control servo motor structure, the outside of a servo-actuator shell (4) is coated with one or a plurality of outer shielding covers (3); the whole machine core is arranged inside a large shell consisting of a front cover (1) and a rear shielding cover (2); the front cover (1) is made of metal and forms a shielding layer with the rear shielding cover (2); and a stator is formed by assembling a shielding magnetic shoe sleeve (5) and a magnetic shoe (6). The anti-electromagnetic interference control servo motor strengthens shielding on the whole and further improves the capacity for controlling anti-electromagnetic interference of the servo-actuator, thereby putting an end to failure phenomenon of a currency counting machine or a currency detector and further improving the currency counting precision of the currency counting machine.

Owner:管洪安

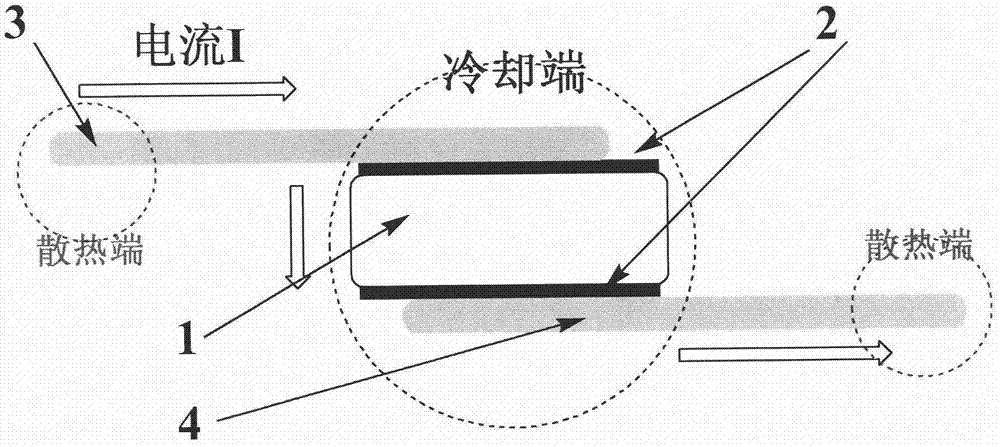

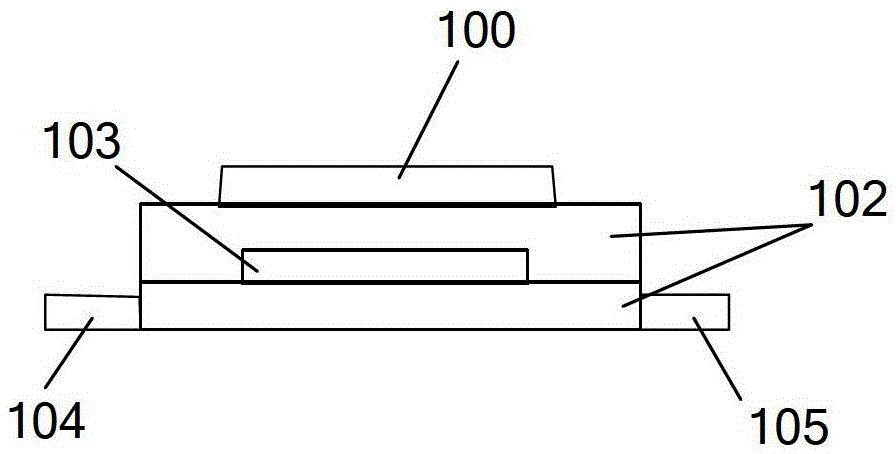

PTC (Positive Temperature Coefficient) over-current protection component capable of eliminating accumulated heat influence

ActiveCN107275017AEliminate malfunctionsResistor terminals/electrodesCurrent responsive resistorsTemperature coefficientPositive temperature

The invention discloses a PTC (Positive Temperature Coefficient) over-current protection component capable of eliminating accumulated heat influence. The PTC over-current protection component comprises a polymer-based PTC core layer, contact electrodes compounded on two sides of the core layer, and two conductive pins, wherein at least one of the two conductive pins is a thermoelectric semiconductor material; surface mount of the thermoelectric semiconductor pin has directionality; the thermoelectric semiconductor pin is mounted on one side on which current flows out; an N-type semiconductor is mounted on one side on which current flows in; one end, which is far away from the PTC chip, of the pin is radiated when the component works; and one end of the pin mounted on the chip electrode absorbs heat so as to achieve an effect of eliminating the PTC accumulated heat. Compared with the traditional PTC over-current protection component, the PTC over-current protection component disclosed by the invention has the advantages that the PTC chip is locally cooled in a low-current state by the two thermoelectric semiconductors, false operations caused by time accumulation joule heat are eliminated, and the component only performs over-current protection on transient joule heat generated by a high-current state.

Owner:上海萃励电子科技有限公司

Novel ice cream rod inserting work station

InactiveCN102640835AAvoid coordination difficultiesLower requirementFrozen sweetsEngineeringIce cream

The invention relates to a novel ice cream rod inserting work station, used for inserting a rod into ice cream. The novel ice cream rod inserting work station comprises a rack, a reciprocating linear driving mechanism and an inserting plate, wherein a power output end of the reciprocating linear driving mechanism is connected with one side of the inserting plate by virtue of a planar mechanism which can move in the horizontal direction and the vertical direction at the same time, the other side of the inserting plate is provided with a rod wiping rack, the inserting plate is provided with an inserting tongue at one end departing from an output end of the reciprocating linear driving mechanism and at the same side with the rod wiping rack, the side of the rack, which is adjacent to the rod wiping rack, is provided with a rod slot used for holding rods, the rod slot is provided with a first rod compactor, and the rods are compacted on the rod wiping rack by virtue of the first rod compactor; and the rack near a discharge hole of the rod slot is provided with a second rod compactor used for clamping the rods output from the rod slot. The novel ice cream rod inserting work station disclosed by the invention has the characteristics of low cost, high efficiency and high reliability.

Owner:江苏百胜机械制造有限公司

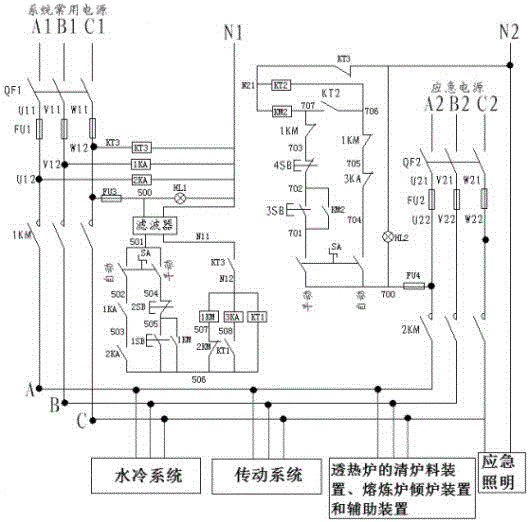

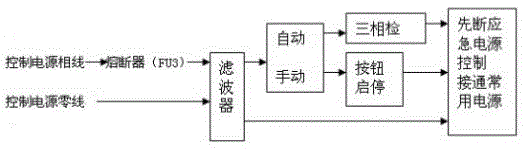

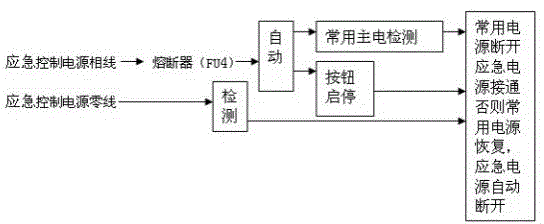

Switching control device of special emergency power supply of medium-frequency induction furnace complete equipment

InactiveCN104426231AEasy selectionSimple control systemEmergency power supply arrangementsControl systemHarmonic

The invention relates to the specific protection field of accidental power failure in the operation process of the medium-frequency induction furnace complete equipment, and particularly relates to a switching control device of a special emergency power supply of medium-frequency induction furnace complete equipment. The switching control device comprises a water-cooling system, a transmission system, a furnace charge clearing device of a heating furnace, a furnace inclining device of a smelting furnace and an auxiliary device, an emergency illuminator, a frequently-used power supply and an emergency power supply, and further comprises a switching control device body. The switching control device is simple in control system, convenient to select models of apparatuses, low in price, simple and easy to implement; the normal elements are adopted, so that the switching reliability of the device further can be increased; the filter element is additionally arranged, so that the wrong operation due to interferences of harmonic waves produced by a medium-frequency furnace further can be excluded.

Owner:XIAN SIKUN ELECTRONICS SCI & TECH

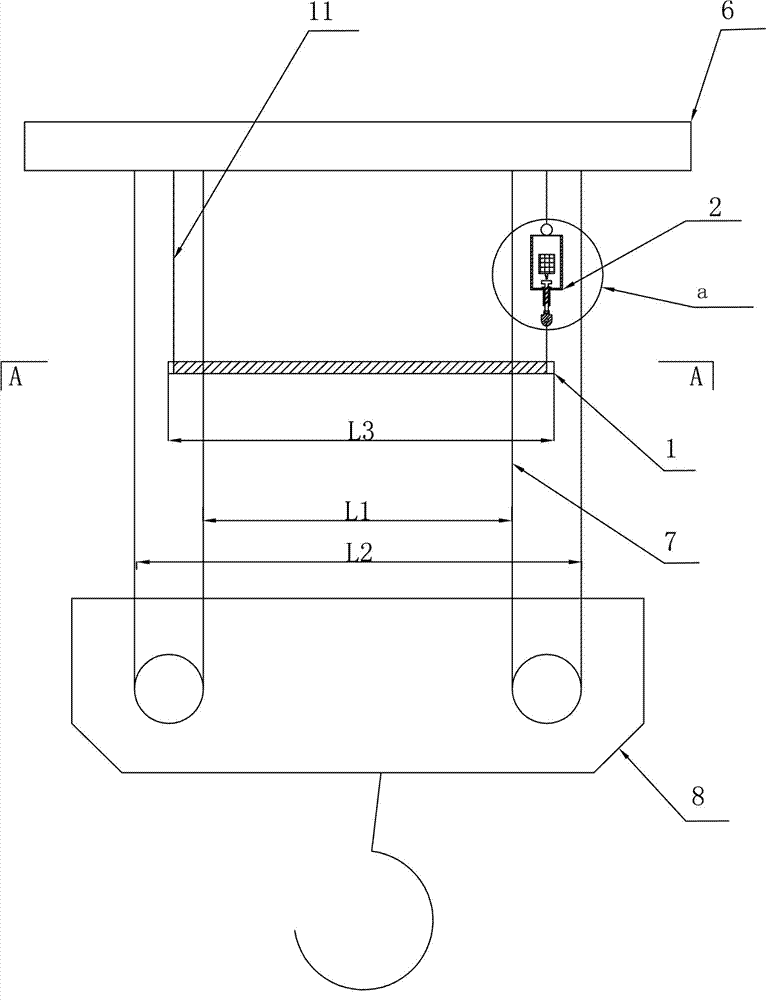

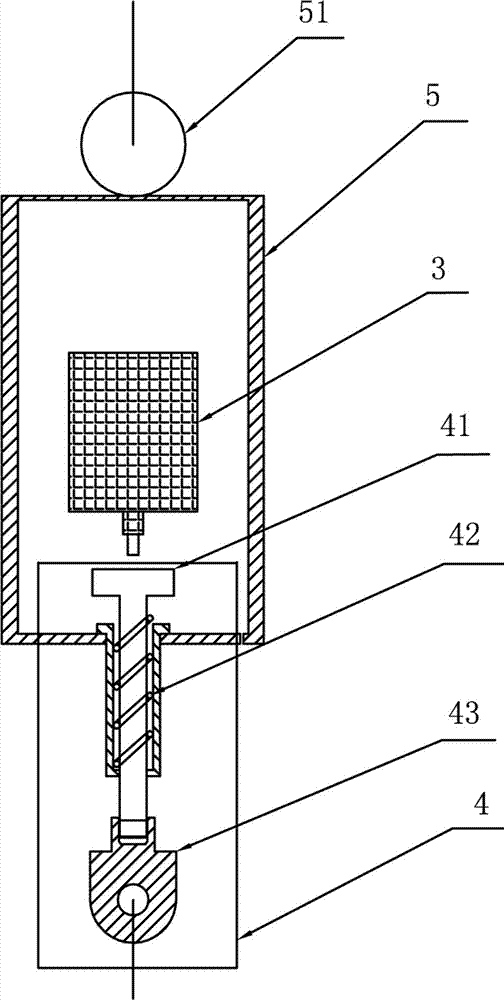

Spring type safety limiting caution device for lifting rope of gantry crane

ActiveCN102897670AEliminate malfunctionsSolve the problem of rust damageSafety gearGantry craneWater seepage

The invention discloses a spring type safety limiting caution device for a lifting rope of a gantry crane. The spring type safety limiting caution device comprises a safety limiting frame and a limiting detector, wherein two sides of the safety limiting frame are suspended on a lower chord of an arm head of a lifting arm through a steel wire rope; and the limiting detector is mounted in the middle of the steel wire rope on one side of the safety limiting frame. Compared with design technology of a frequently-used lever type heavy punch limiting device, the phenomenon of false operation of a switch caused by high-altitude shaking of a heavy punch due to insufficient self weight is eliminated, problem of corrosion damage of the limiting switch caused by easy water seepage and accumulation of the original lever type heavy punch limiting hinge point is solved, the normal and continuous production of the crane is ensured, and safety performance is more reliable. The spring type safety limiting caution device is simple in structure, convenient to mount and dismount, and stable in performance.

Owner:CHINA GEZHOUBA GROUP CO LTD

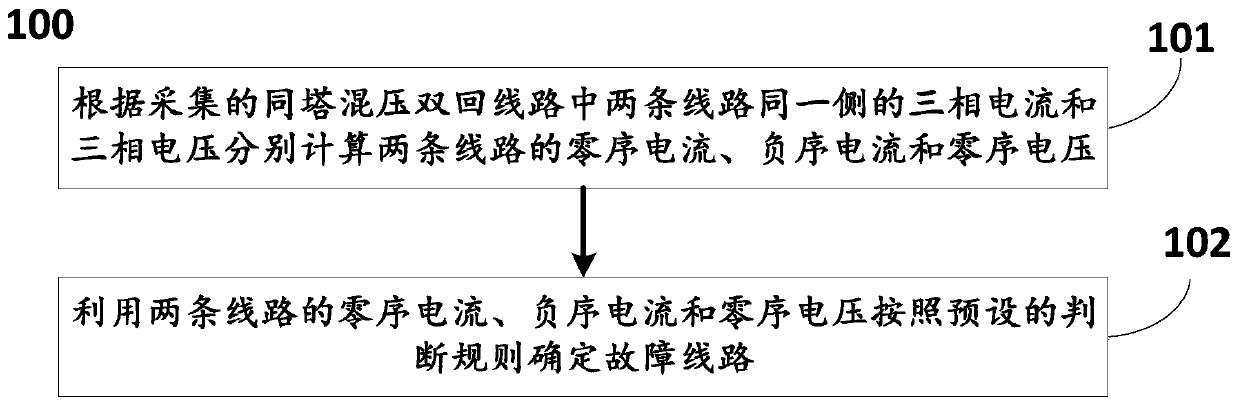

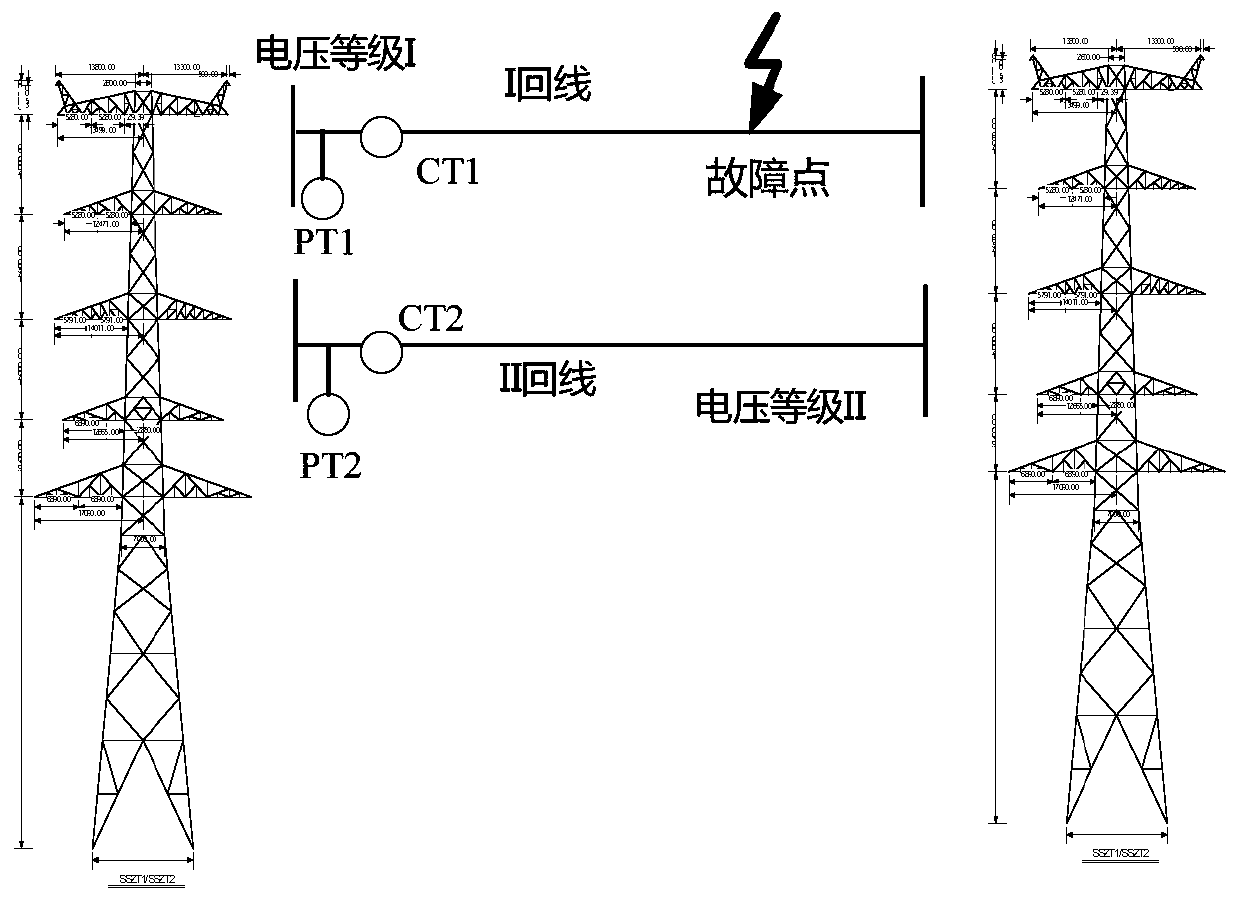

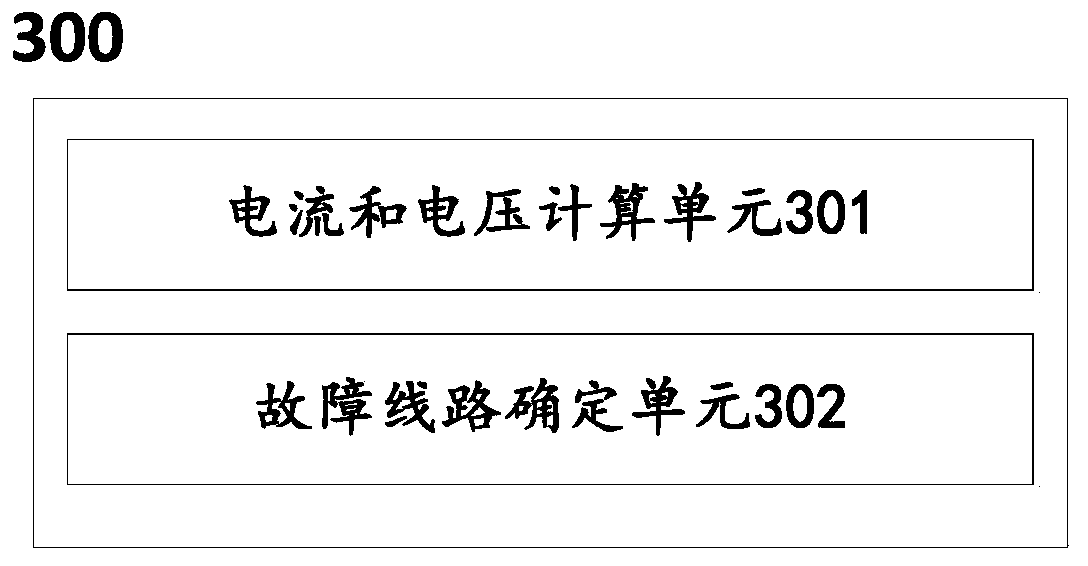

Method and system for determining faulty line based on station domain information

ActiveCN111025080AImproved Action CriterionEliminate malfunctionsDirection of current indicationVoltage polarity indicationPhase currentsControl theory

The invention discloses a method and a system for determining a fault line based on station domain information. The method comprises the following steps: respectively calculating zero-sequence current, negative-sequence current and zero-sequence voltage of two lines according to acquired three-phase current and three-phase voltage on the same side of the two lines in a same-tower mixed-voltage double-circuit line; and determining a fault line by utilizing the zero-sequence current, the negative-sequence current and the zero-sequence voltage of the two lines according to a preset judgment rule.According to the method, the fault line of the same-tower mixed-voltage double-circuit power transmission line is accurately identified by utilizing the station domain information, the action criterion of a non-fault line direction element is improved, and the fault line can be correctly cut off; the zero-sequence direction element misoperation caused by zero-sequence mutual inductance can be eliminated, the protection reliability is improved, and the accident range is limited to be expanded.

Owner:CHINA ELECTRIC POWER RES INST +1

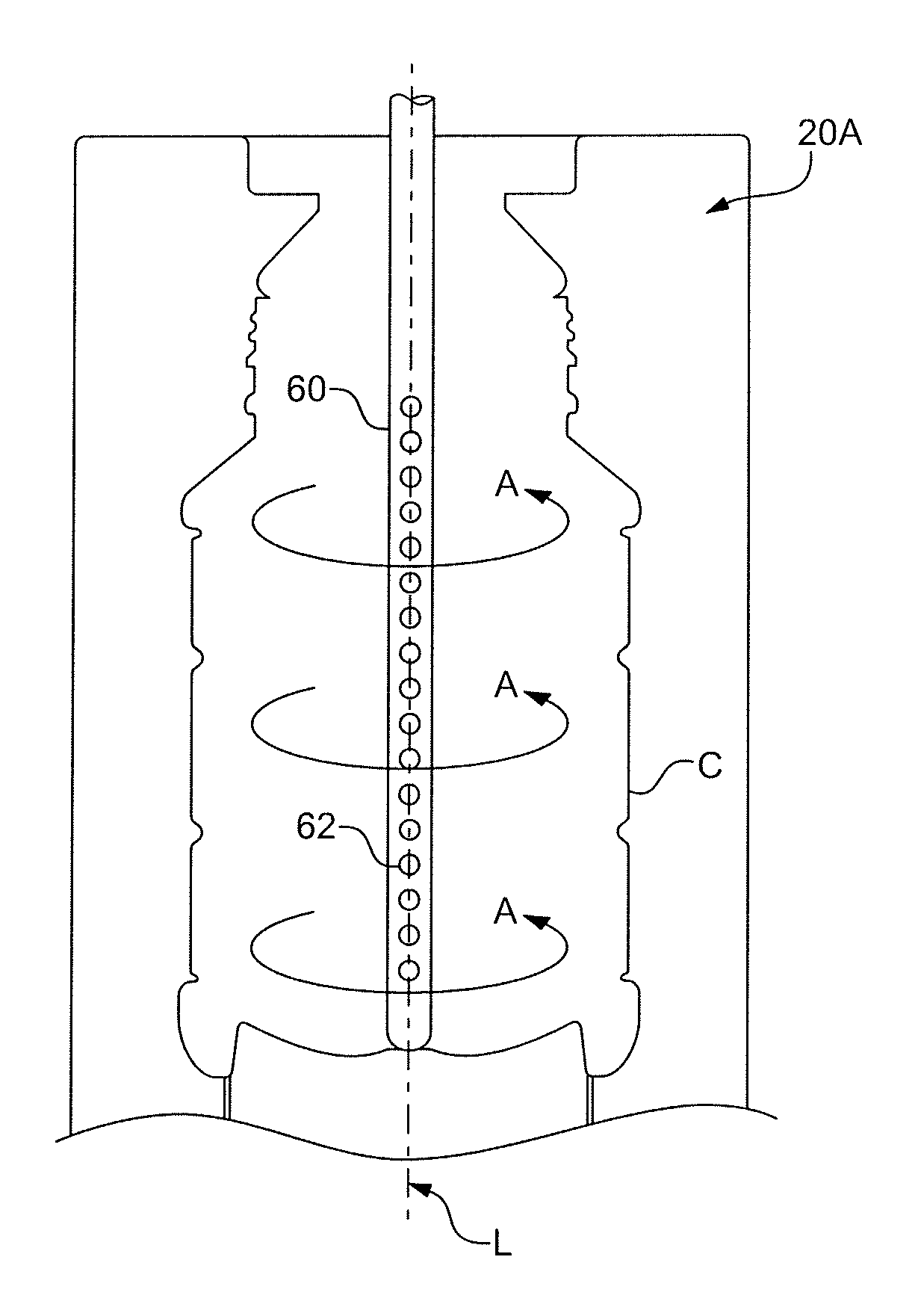

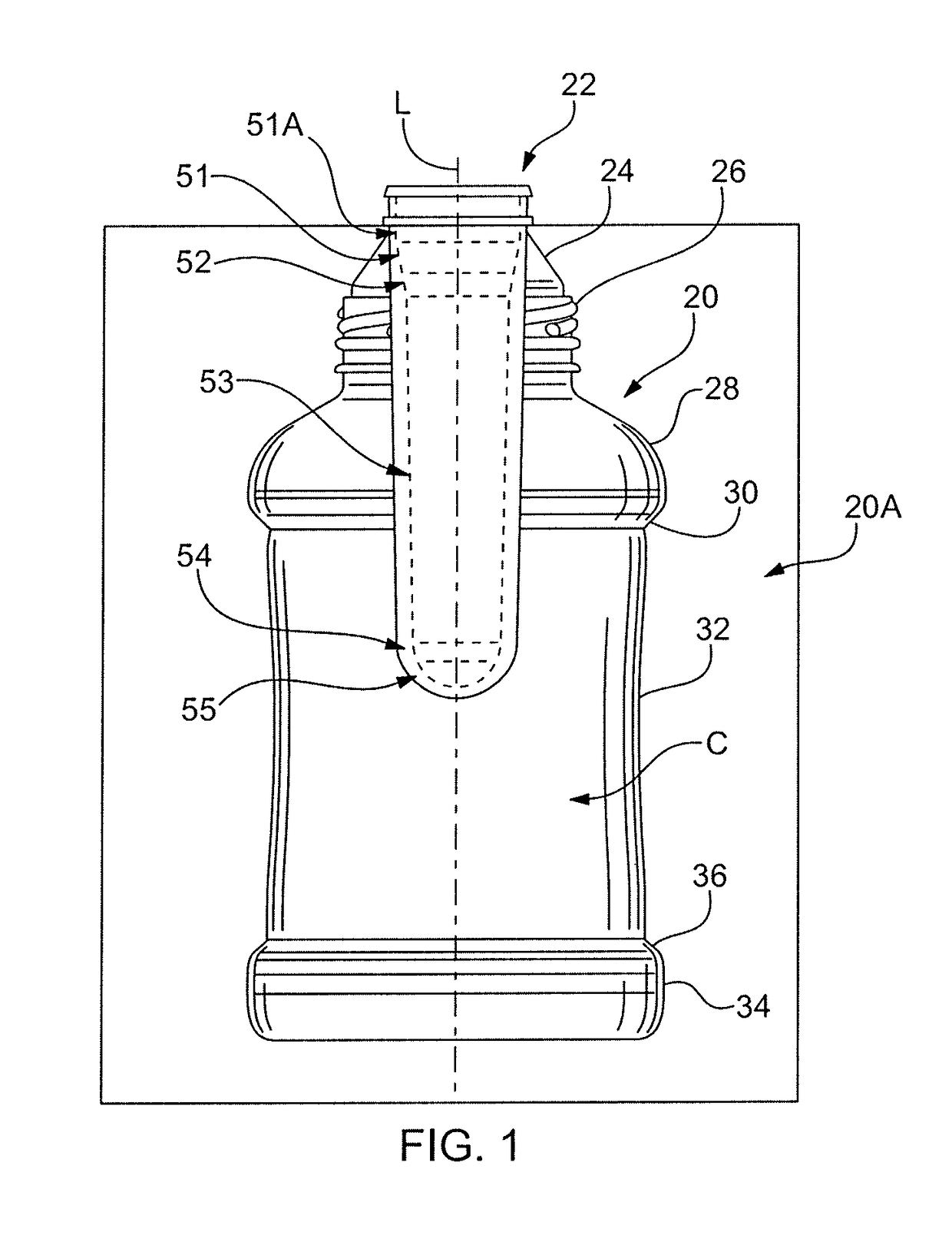

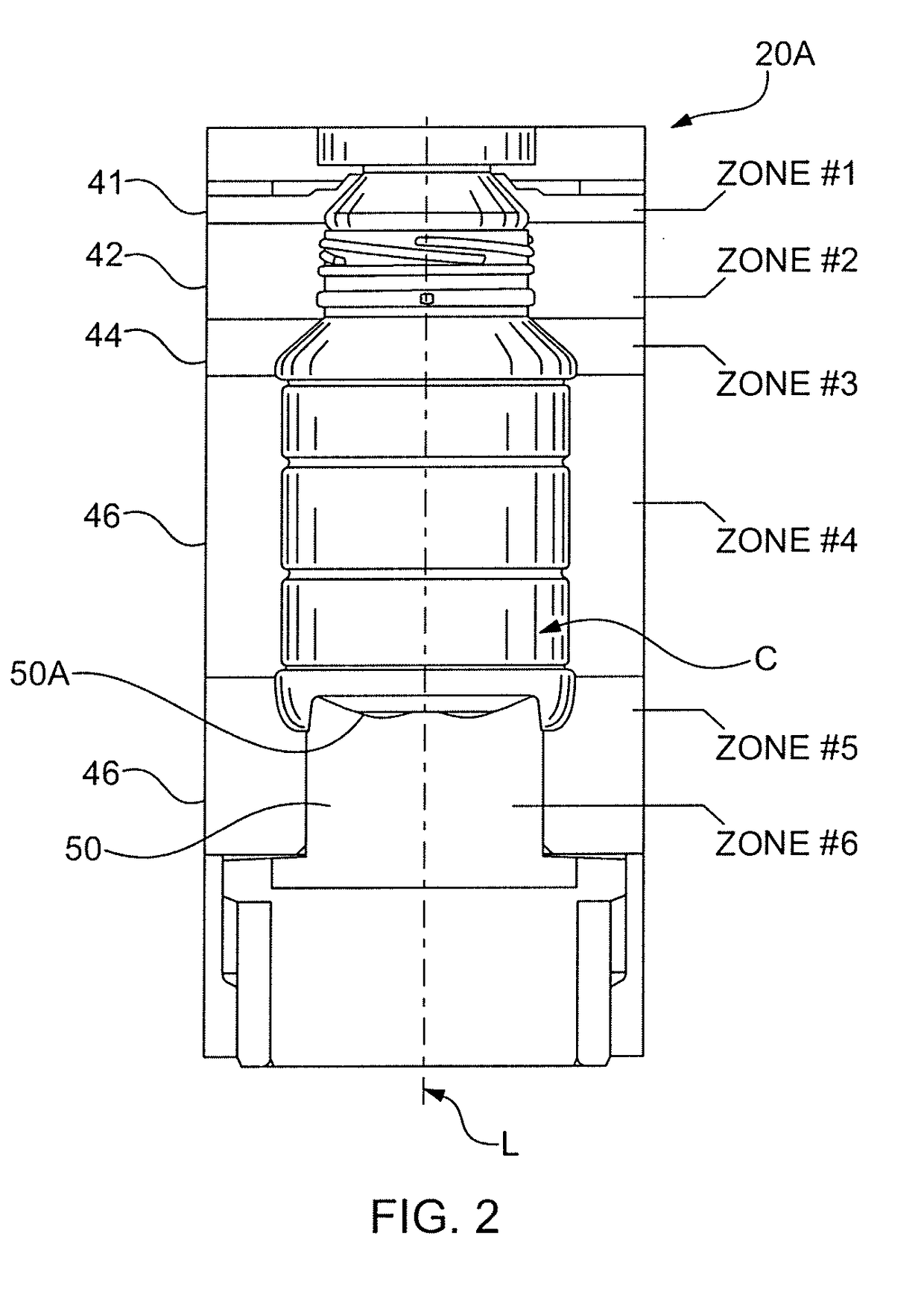

In-line blow mold cleaning device and method of use

A mold cleaner for in-line cleaning of a mold cavity of a blow mold of a blow molding machine. The cleaner has a mount attaching the cleaner to the collet of the machine, enabling the feed belt of the machine to transport the collet and the cleaner to and from the blow mold to be cleaned. An air-powered motor engages the mount, has a motor shaft, and receives air from the blow seal of the machine, which activates the motor and rotates the motor shaft. A bearing carrier surrounds the motor and engages the mount. A cleaning unit is carried by the bearing carrier and rotated by the motor shaft, and contacts the mold cavity to clean the mold cavity. A related method is also provided of using the mold cleaner to perform in-line cleaning of a mold cavity of a blow mold of a blow molding machine.

Owner:GRAHAM PACKAGING CO LP

Floating gate transistor and its manufacturing method, application method, and display driving circuit

ActiveCN103199116BEliminate malfunctionsTransistorStatic indicating devicesDisplay deviceThreshold voltage

The present invention relates to a floating gate transistor, a manufacturing method thereof, an application method, and a display driving circuit, wherein the floating gate transistor includes a substrate, a floating gate, a source electrode, a drain electrode and a control gate arranged on the substrate, and further includes: the substrate A first layer of insulating film and a polysilicon film are sequentially provided on the top, a channel region is formed in the middle of the polysilicon film, and the position of the channel region corresponds to the position of the floating gate. The beneficial effects of the present invention are: adopting the floating gate transistor of the present invention can adjust the TFT threshold voltage, eliminating the possibility that the entire circuit will not work due to the inaccurate TFT threshold voltage during the production process of the backplane.

Owner:BOE TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com