Infrared cold/hot metal detector

A hot metal and detector technology, applied in the field of infrared cold/hot metal detectors, can solve problems such as low measurement accuracy, poor anti-interference ability, and prone to misoperation, and achieve high measurement accuracy, fast response speed, and eliminate The effect of misuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

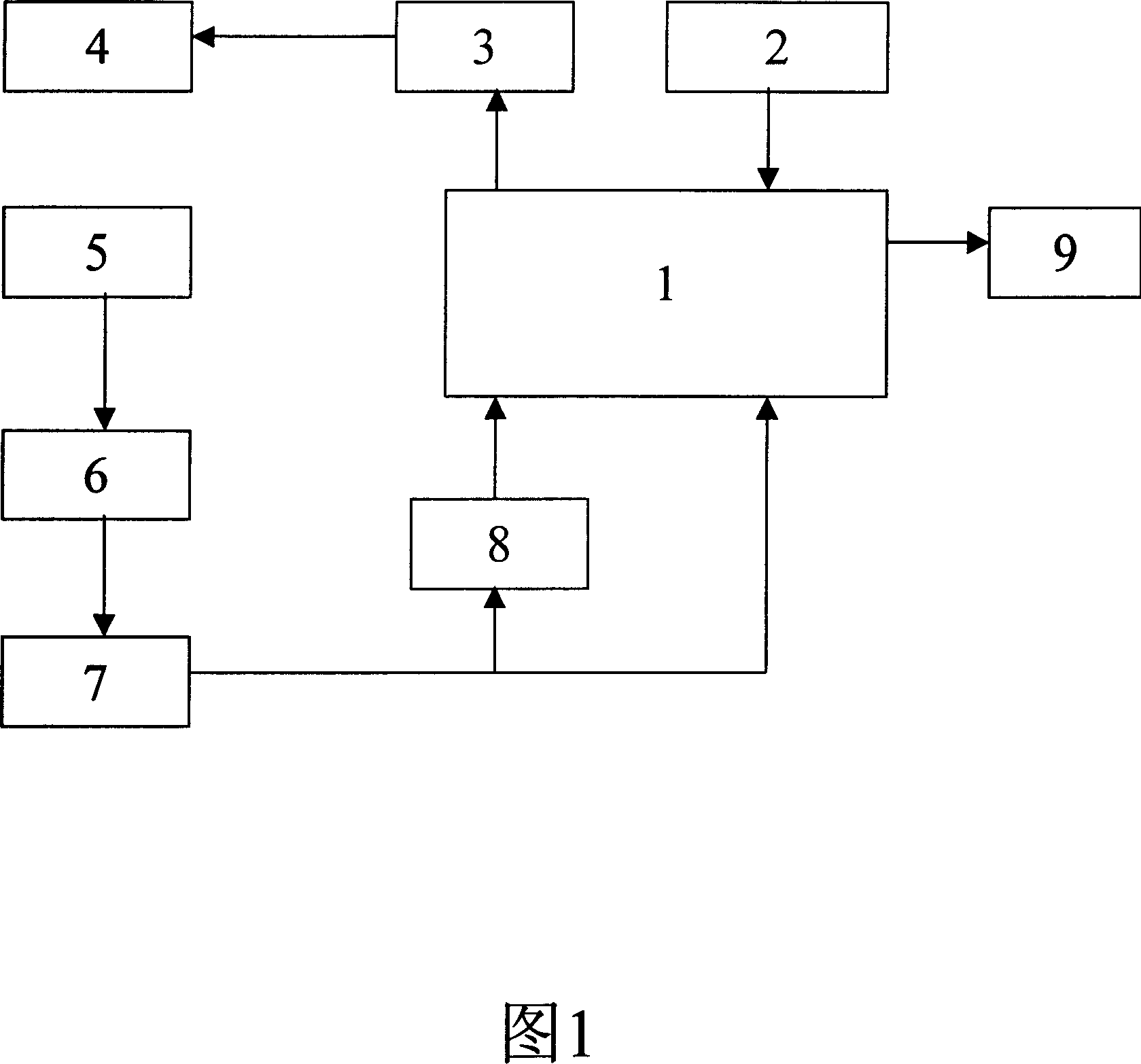

Image

Examples

Embodiment 1

[0020] An infrared laser detection device adopts PIC16F71 microcontroller, LM567 modem, operational amplifier adopts LM6084, semiconductor laser module adopts Sigma laser module, photosensitive receiver adopts PIN-07FSLR, output module adopts LED display output, transistor output and relay switch output .

[0021] The power supply voltage of the device is 24VDC±20%, the visible infrared laser wavelength is 650nm, the laser power is 1nw, the laser spot size is 0.1mm, and the spot deviation is 0.5mrad. position. When there is no object or the object is not in place (that is, in the standby state), the Sigma laser module continuously emits modulated laser light and is reflected back by the mirror. The photosensitive receiving tube PIN-07FSLR receives the modulated signal, filters and amplifies it, and then passes The modem LM567 demodulates and outputs a low level to the microcontroller PIC16F71. At this time, the microcontroller judges that there is no object or the object is n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com