Manipulator control system and control method

A control system and manipulator technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of restarting work, disconnection, potential safety hazards, and malfunction of the cutting head, etc., to improve safety protection, eliminate potential safety hazards, and eliminate errors. effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

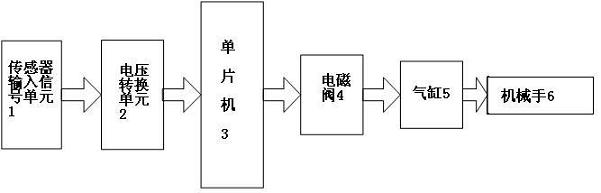

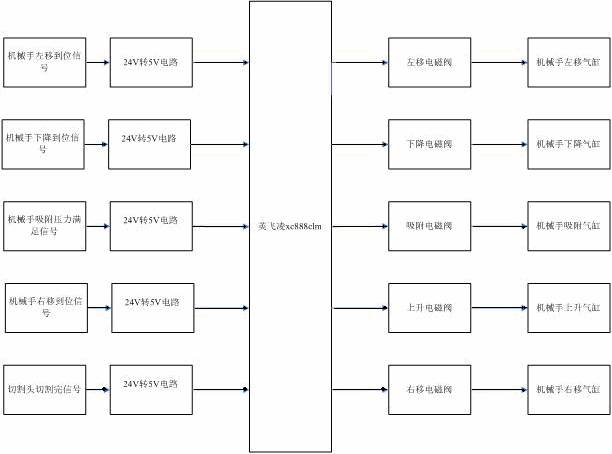

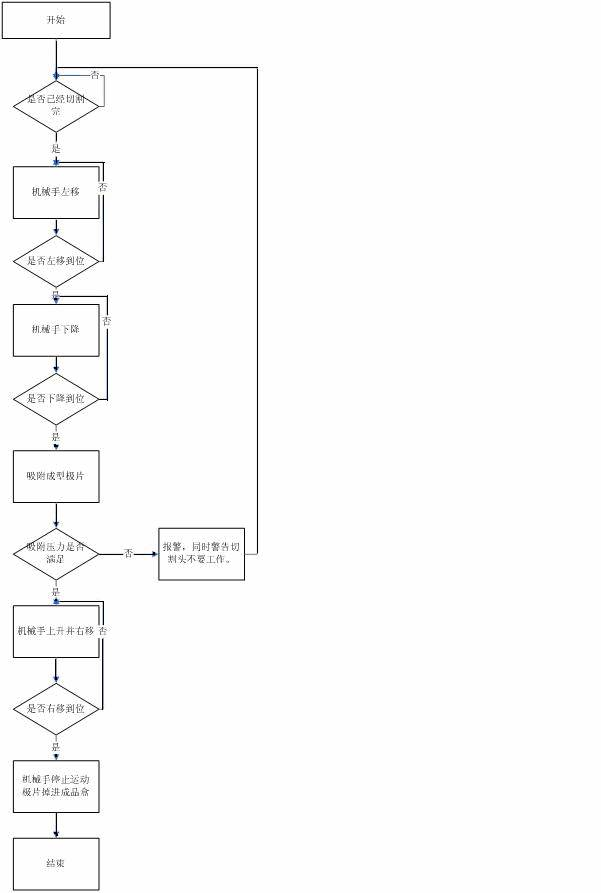

[0020] see Figure 1-Figure 2 As shown, the manipulator control system includes a sensor signal input unit 1, a voltage conversion unit 2, a single-chip microcomputer 3 that processes the converted input signal, a solenoid valve 4 controlled by the single-chip microcomputer, a cylinder 5 controlled by the solenoid valve, and an actuator manipulator 6. Wherein, the signal input by the sensor signal input unit 1 includes the signal of moving to the left, the signal of moving to the right, the signal of falling to the position, the signal of adsorption pressure satisfaction, and the signal of cutting head cutting; The valve 4 includes a left-shift solenoid valve, a descending solenoid valve, an adsorption solenoid valve, an ascending solenoid valve and a right-shift solenoid valve, through which the manipulator cylinder is controlled respectively. The system also includes a single-chip microcomputer power detection unit, a reset unit and a programming unit.

[0021] The working ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com