Hand held golf ball cleaner

a golf ball cleaner and golf ball technology, which is applied in the field of hand-held golf ball cleaners, can solve the problems of unfavorable cleaning effect, unportability, and complex parts of the prior art cleaning device, and achieve the effects of eliminating operational errors and malfunctions, being cost-effective to manufacture, and being convenient to us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

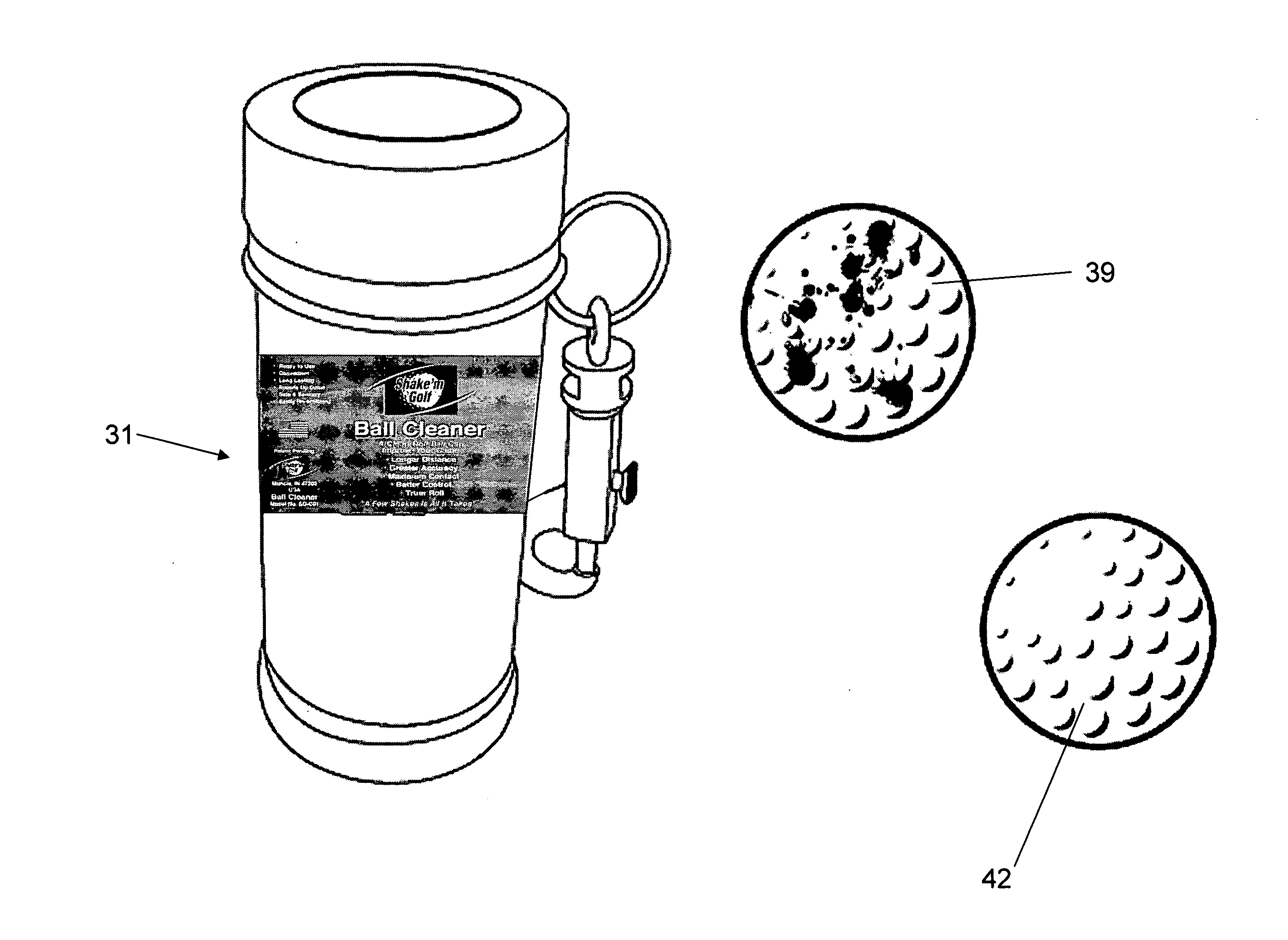

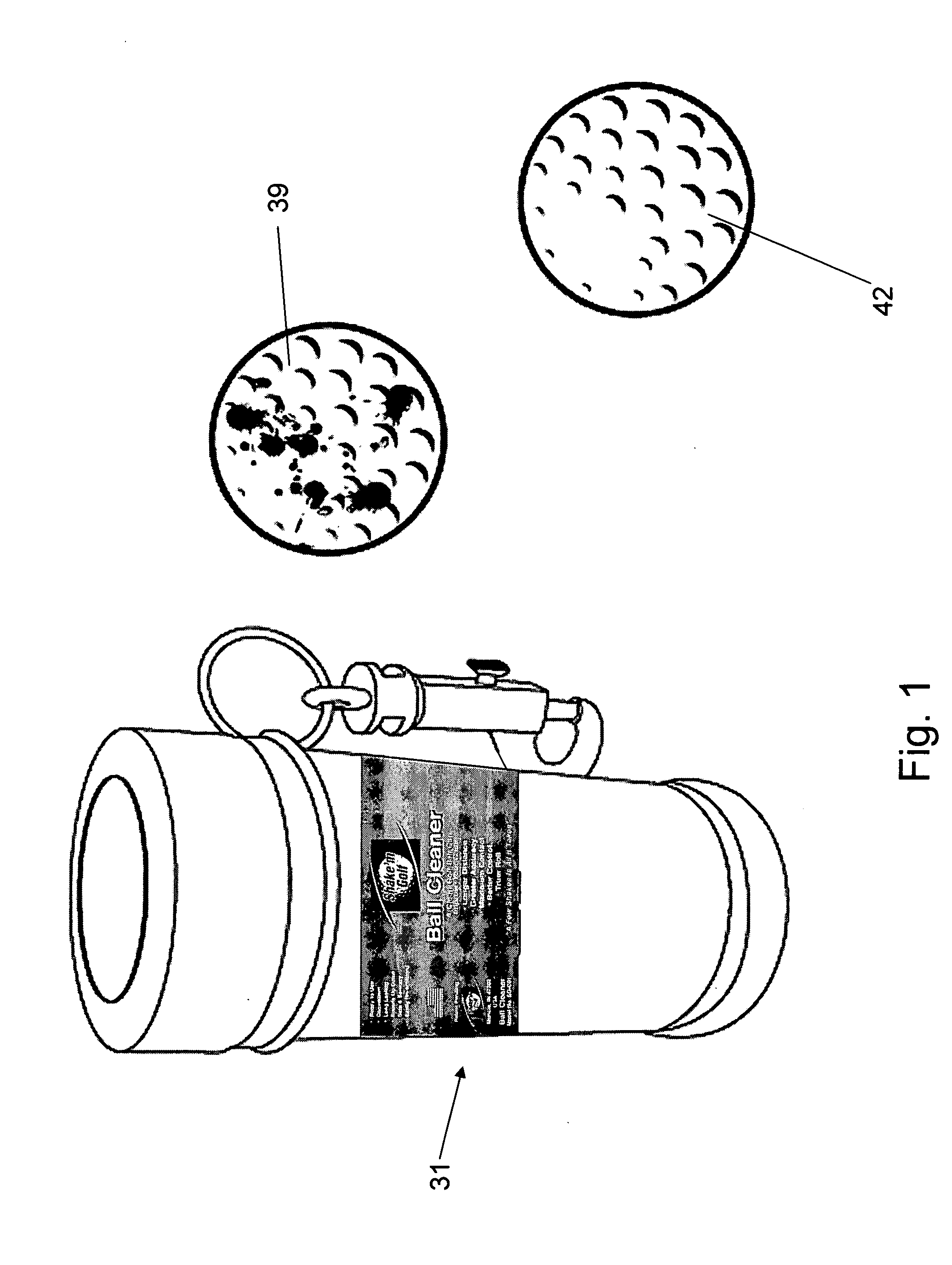

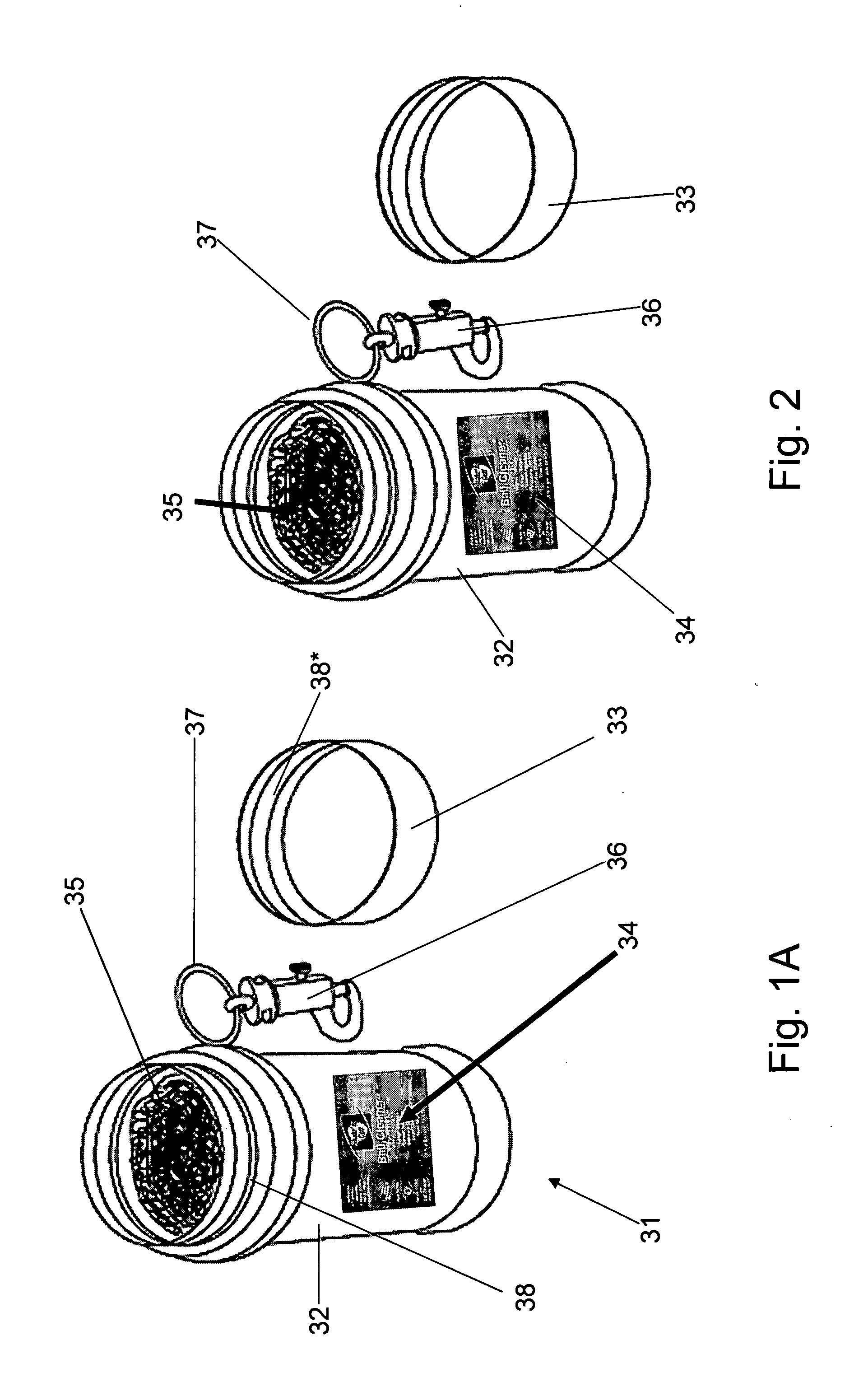

[0068] The present invention is HAND HELD GOLF BALL CLEANER device 31. The main components of this invention are comprised of a container, a lid to the said container, internal abrasive means such as a pad or brush, and an exterior label. The preferred embodiment and alternative embodiments are shown in the accompanying drawings and pictures.

[0069] The materials comprising the device are standard and available from many sources. The materials are primarily the same as utilized in the food industry and the cleaning industry. One skilled in the art can appreciate that a plethora of variations of the fastening system between the container and lid exists. Any one may be used to permit the scope and spirit of this invention as described below and as depicted in the accompanying drawings.

[0070] The entire device is assembled for packaging by taking the container 32, inserting the abrasive material 35, fastening the lid 33 to the container and placing the label 34 on the exterior of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com