PTC (Positive Temperature Coefficient) over-current protection component capable of eliminating accumulated heat influence

A technology of overcurrent protection components and heat, which is applied in the direction of electrical components, current response resistors, resistor components, etc., can solve problems such as packaging heat dissipation misoperation, line operation influence, etc., and achieve the effect of eliminating misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

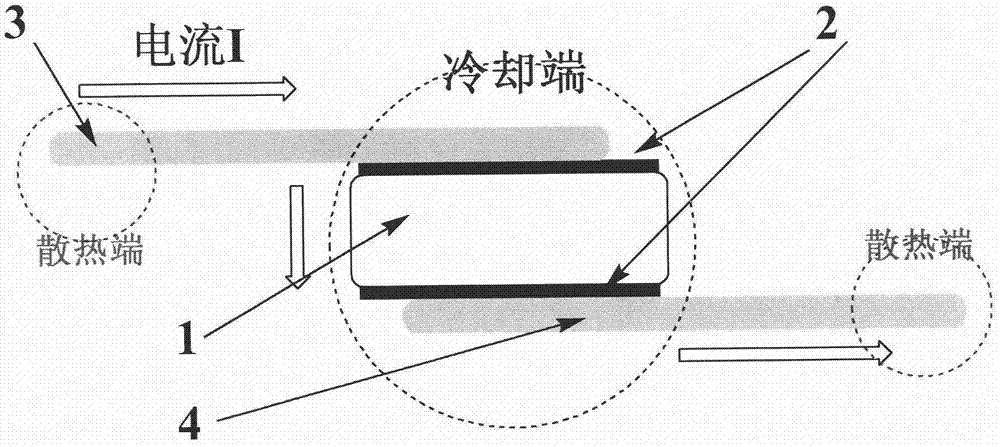

[0012] PTC overcurrent protection element that can eliminate the influence of accumulated heat, the structure is as figure 1 Shown: The PTC chip is a blended composite material of high-density polyethylene (HDPE) and Ni powder, the two sides of the PTC chip are covered with nickel-plated copper foil contact electrodes, and the N-type thermoelectric semiconductor Bi 2 Te 2.7 Se 0.3 and metal Ni electrodes are respectively welded on the nickel-plated copper foil on both sides. When working, the current flows from the N-type Bi 2 Te 2.7 Se 0.3 The pin flows in and flows out from the metal Ni pin, which plays a role in cooling the PTC chip.

Embodiment 2

[0014] PTC overcurrent protection element that can eliminate the influence of accumulated heat, the structure is as figure 1 Shown: The PTC chip is a blended composite material of high-density polyethylene (HDPE) and Ni powder. The two sides of the PTC chip are attached with metal Cu foil contact electrodes, metal Cu electrodes and P-type thermoelectric semiconductor Bi. 0.5 Sb 1.5 Te 3 The lead-out electrodes are respectively welded on the metal Cu electrodes on both sides. When working, the current flows from the metal Cu pin, from the P-type Bi 0.5 Sb 1.5 Te 3 The pins flow out to cool the PTC chip.

Embodiment 3

[0016] PTC overcurrent protection element that can eliminate the influence of accumulated heat, the structure is as figure 1 Shown: The PTC chip is a blended composite material of high-density polyethylene (HDPE) and Ni powder, the two sides of the PTC chip are attached with metal Ni foil contact electrodes, and the N-type thermoelectric semiconductor Bi 2 Te 2.7 Se 0.3 and P-type thermoelectric semiconductor Bi 0.5 Sb 1.5 Te 3 The lead-out electrodes are respectively welded on the metal Ni electrodes on both sides. When working, the current flows from the N-type Bi 2 Te 2.7 Se 0.3 pin inflow, from P-type Bi 0.5 Sb 1.5 Te 3 The pins flow out to cool the PTC chip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com