Method for extracting ultra-low-ash-content pure coal from coal slime

A technology for ultra-low ash pure coal and coal slime, applied in chemical instruments and methods, wet separation, selective deposition, etc., can solve the problems of increasing coal transportation cost, difficulty in dehydration, long process flow, etc., and achieve significant economical benefits. Benefit and environmental protection value, large economic benefit and environmental protection value, the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Using a coal slime with an ash content of 48% in Yunnan as raw material, the steps for extracting ultra-low ash pure coal are as follows:

[0030]① Use a vertical stirring mill to make pulp by ball milling, and classify with a cyclone to obtain qualified pulp with a fineness of -200 mesh accounting for more than 90% and a pulp concentration of 25%;

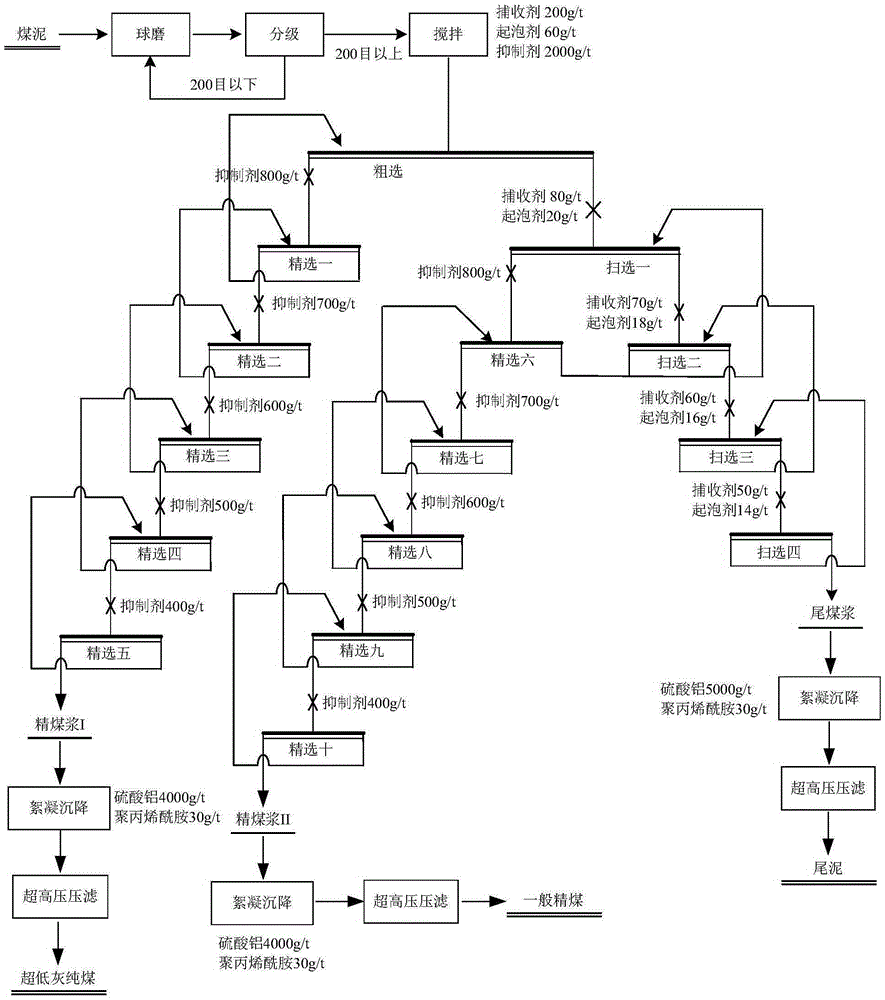

[0031] ②Introduce the obtained pulp into the mixing tank, add collector n-dodecane, foaming agent 2# oil and inhibitor CMC+water glass. First, after a rough separation, the rough separation concentrate and rough separation tailings are obtained, and the obtained rough separation concentrate is subjected to 5 times of separation to obtain clean coal slurry I; after the rough separation tailings are swept once, the sweep Concentrate ore and scavenging tailings, the scavenging concentrate obtained is then 5 times beneficiated to obtain clean coal slurry II; scavenging tailings are scavenged 3 times to obtain tailings slurry. ...

Embodiment 2

[0034] Using a coal slime with an ash content of 40% in Yunnan as raw material, the steps to extract ultra-low ash pure from it are as follows

[0035] ① Use a vertical stirring mill to make pulp by ball milling, and classify with a cyclone to obtain qualified pulp with a fineness of -200 mesh accounting for more than 90% and a pulp concentration of 15%;

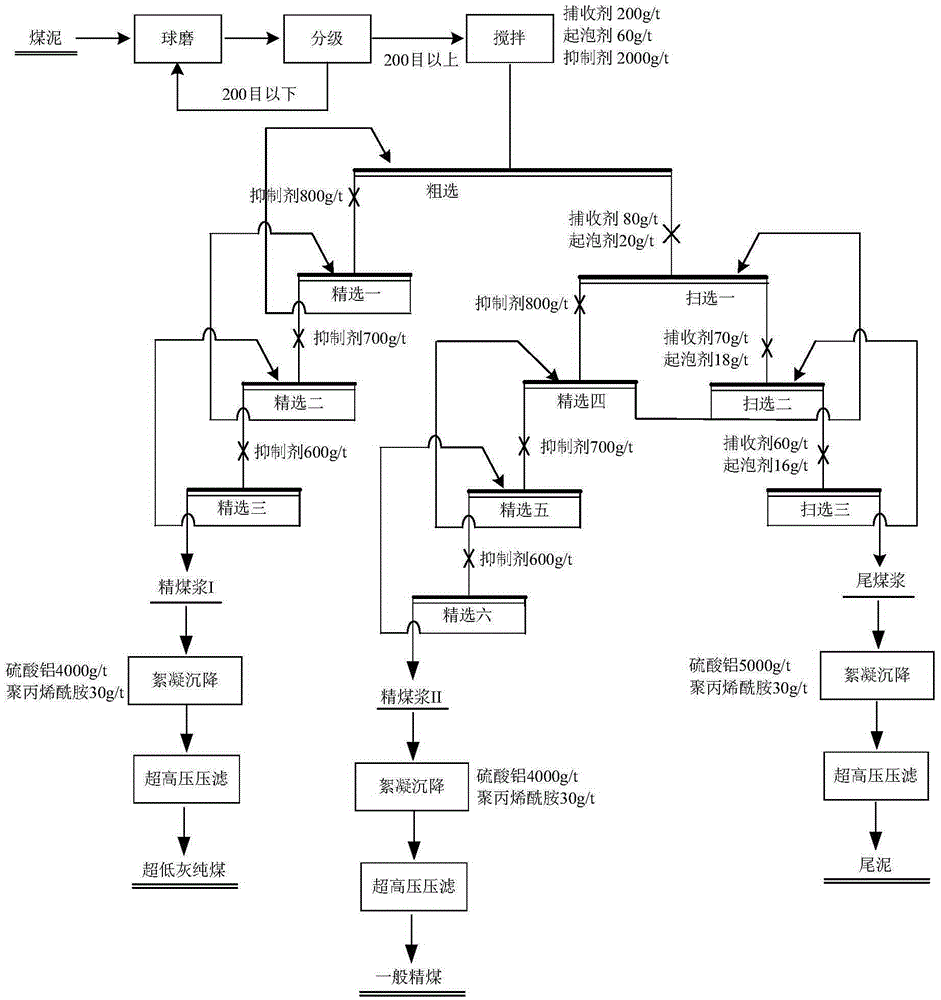

[0036] ②Introduce the obtained pulp into the mixing tank, add collector n-dodecane, foaming agent 2# oil and inhibitor CMC+water glass. First, after a rough separation, the rough separation concentrate and rough separation tailings are obtained, and the obtained rough separation concentrate is subjected to three times of separation to obtain clean coal slurry I; Concentrated ore and scavenging tailings, the obtained scavenging concentrate is subjected to three times of beneficiation to obtain clean coal slurry II; the scavenging tailings are then scavenged twice to obtain tailings slurry. Pharmaceutical systems and processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com