Diaphragm wall seam waterproof method and diaphragm wall construction method based on same

An underground continuous wall and waterproof board technology, applied in water conservancy projects, infrastructure projects, artificial islands, etc., can solve the problems of hard damage of the formed wall, difficult construction, water leakage and sand production, etc., to ensure construction quality and economic benefits. Significant, simple process effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

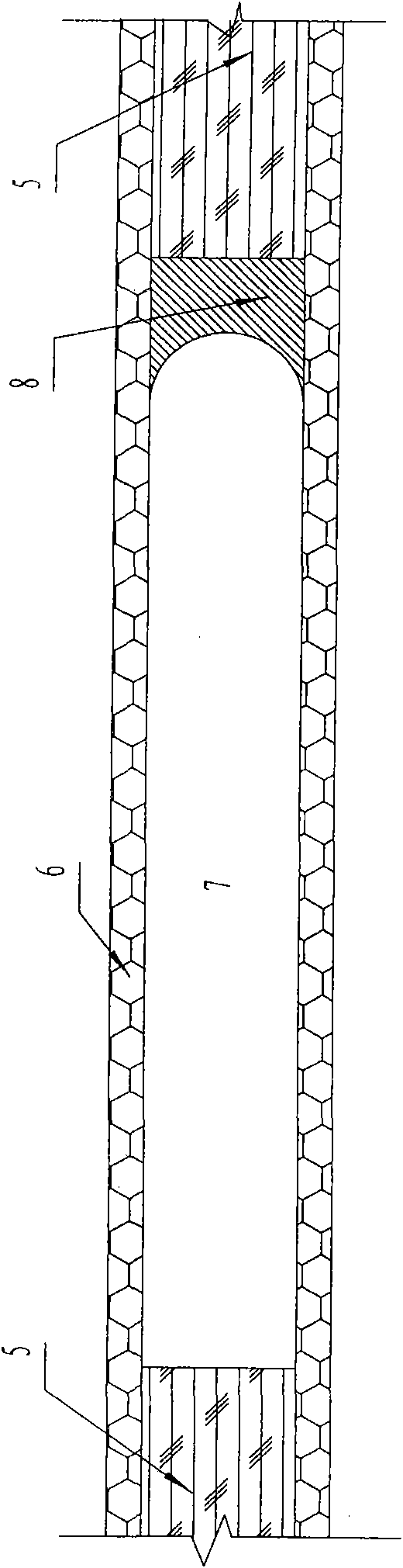

[0026] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0027] The method of waterproofing the construction joints of the underground diaphragm wall, the steps are as follows:

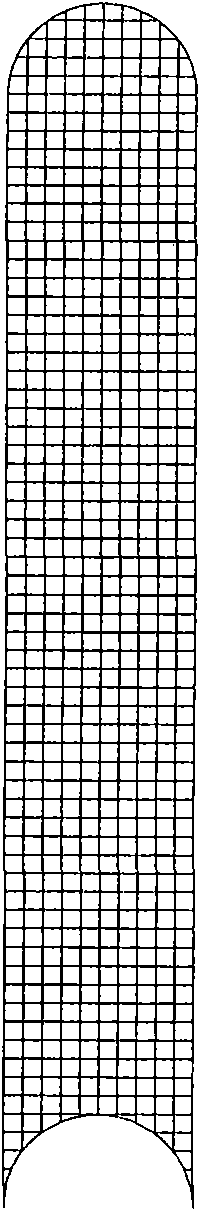

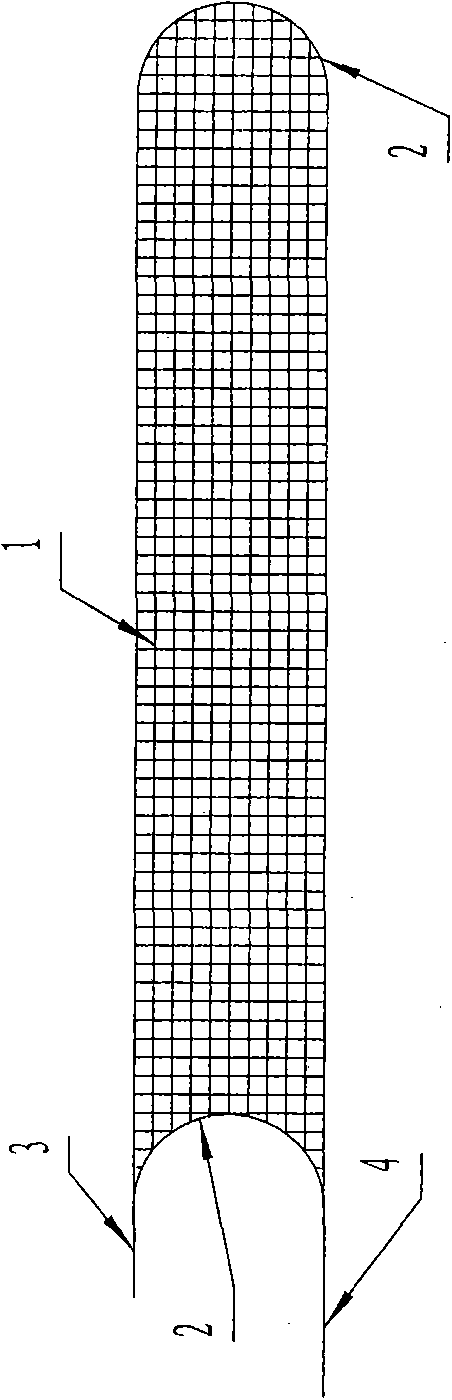

[0028] 1), binding the reinforcement cage 1, the two ends of the reinforcement cage 1 have a concave arc surface at one end, and a convex arc surface at the other end, and the radius of the concave arc surface and the convex arc surface is consistent with the radius of the joint pipe 9, such as figure 1 shown;

[0029] 2) Weld the same-shaped iron cover 2 on the concave arc surface and the convex arc surface to prevent the direct contact between the joint pipe and the pouring concrete, and the pick-up time of the joint pipe is not limited. The inner side and the outer side of the reinforcement cage 1 at one end of the concave arc surface are welded with waterproof boards, and the length of the outer side waterproof board 4 beyo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com