Lubricating oil regeneration device of waste internal-combustion engine

A regenerative device and internal combustion engine technology, applied in the direction of lubricating composition, molecular distillation, etc., can solve the problems of wasting resources, affecting cooling and lubrication effects, increasing enterprise costs, etc., and achieve the effects of reasonable structural design, large purification benefits and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

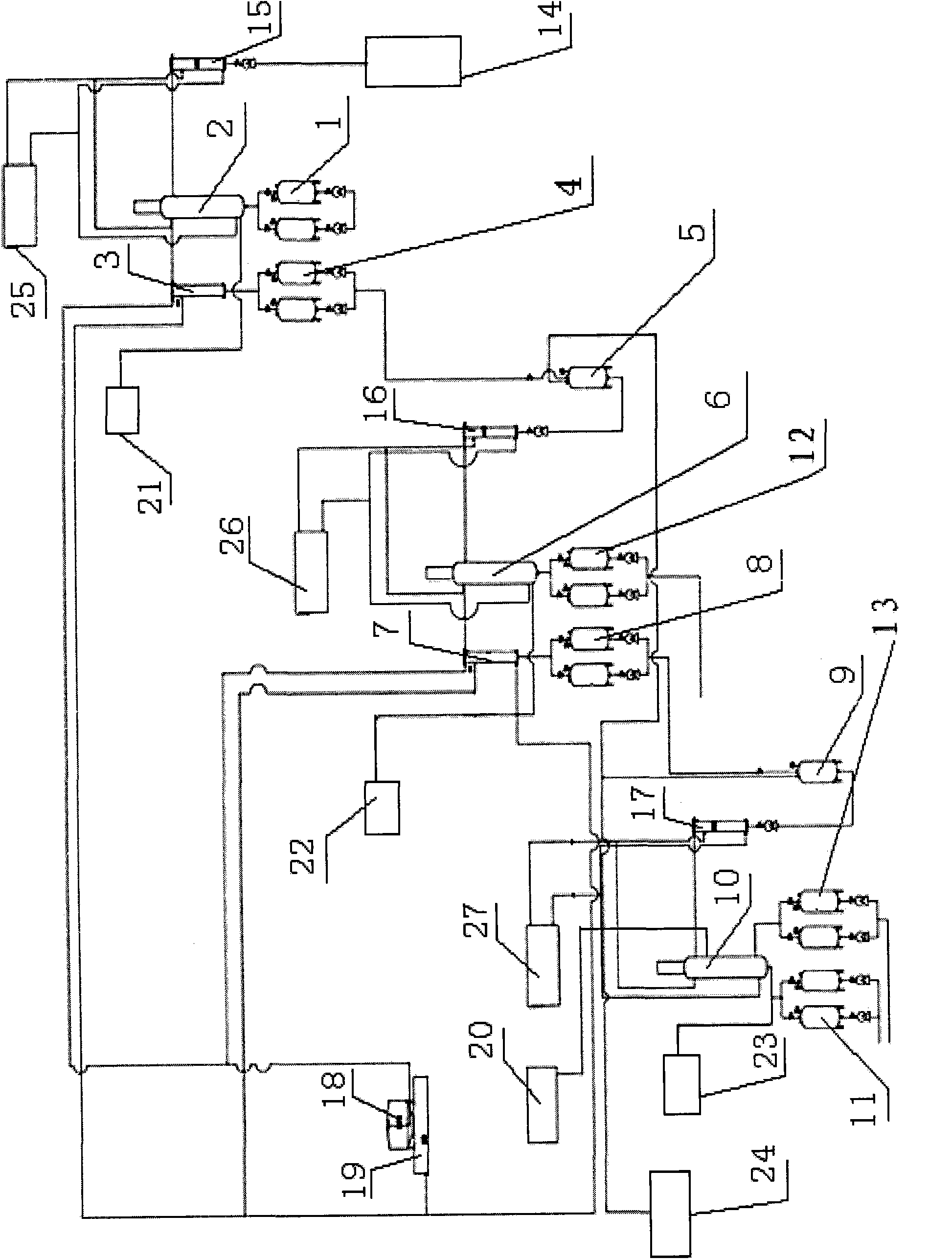

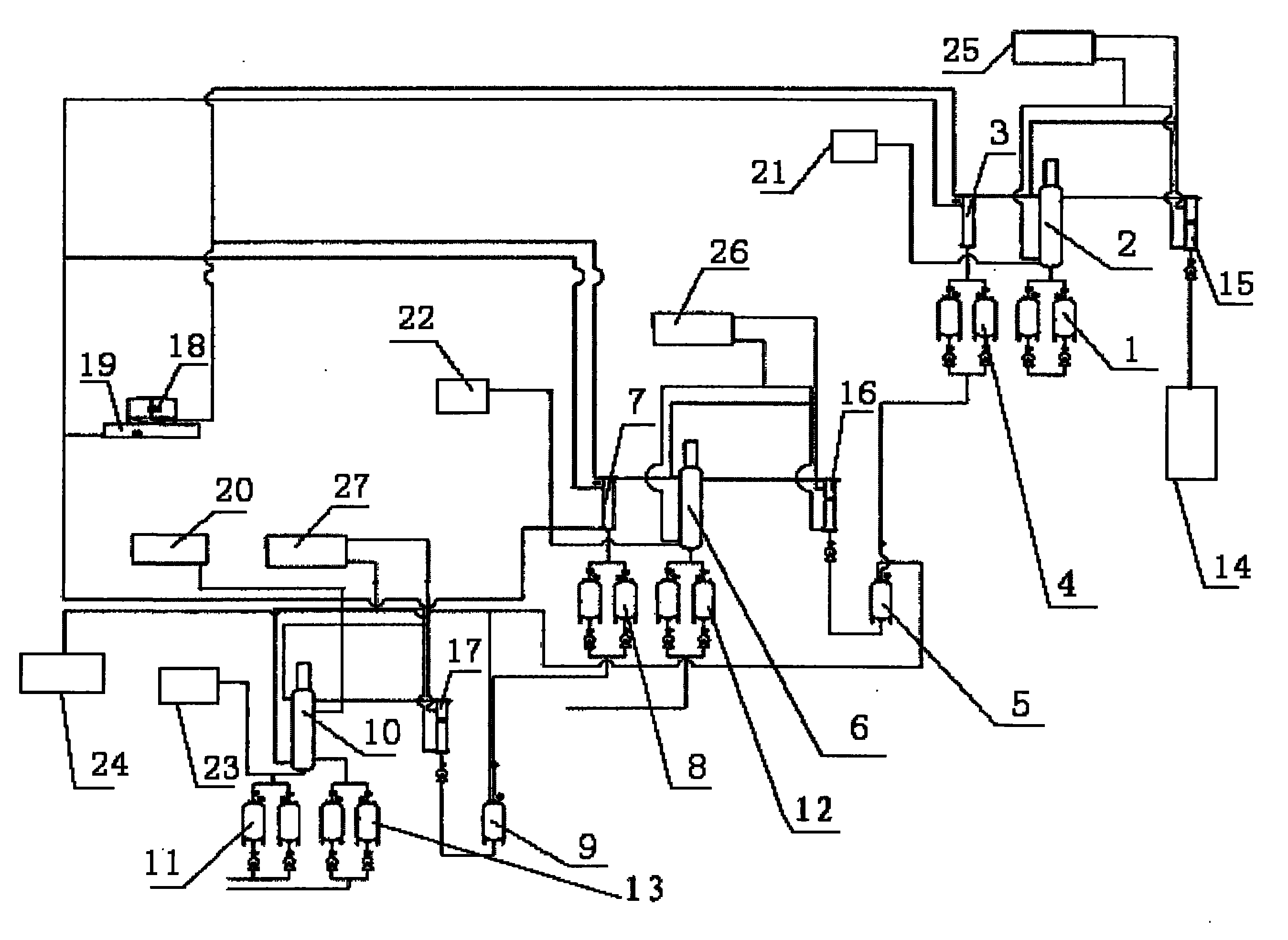

[0017] The waste internal combustion engine lubricating oil regeneration device of this example includes a raw material pretreatment tank 14 for separating free water in waste oil from oil products and removing free water. The primary heat exchanger 15, the primary heat exchanger 15 is connected with the primary distiller 2 for removing the emulsified water in the oil product, and the primary distiller 2 is connected with the primary cooler 3 for cooling the oil product And the primary waste oil tank 1 for collecting emulsified water, the primary cooler 3 is connected with the primary product oil tank 4, the primary product oil tank 4 is connected with the primary intermediate oil tank 5, and the primary intermediate oil tank 5 is connected with the The secondary heat exchanger 16 for reheating the oil product in it, the secondary heat exchanger 16 is connected with the secondary distiller 6 for removing the light component gasoline and diesel oil in the oil product, the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com