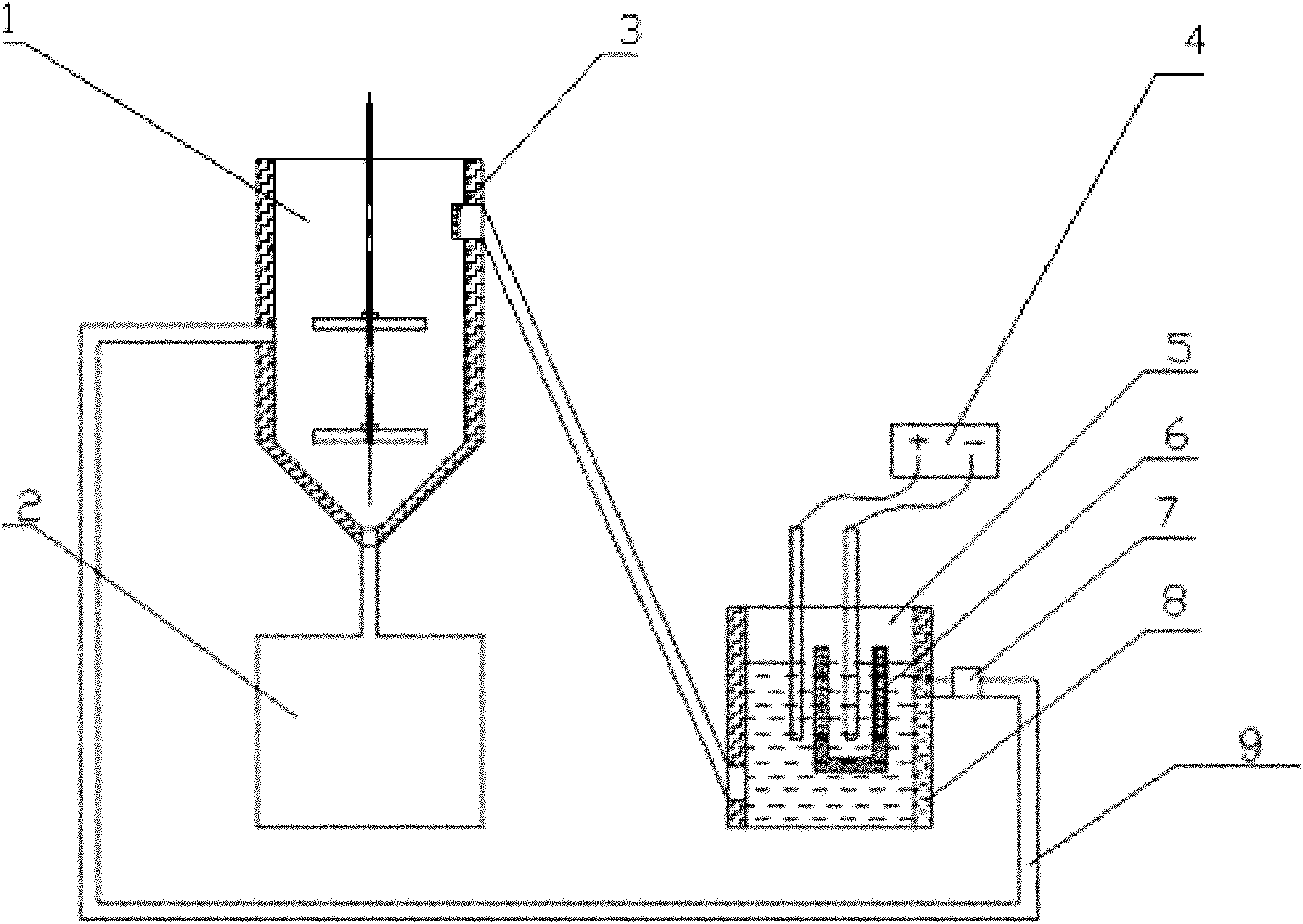

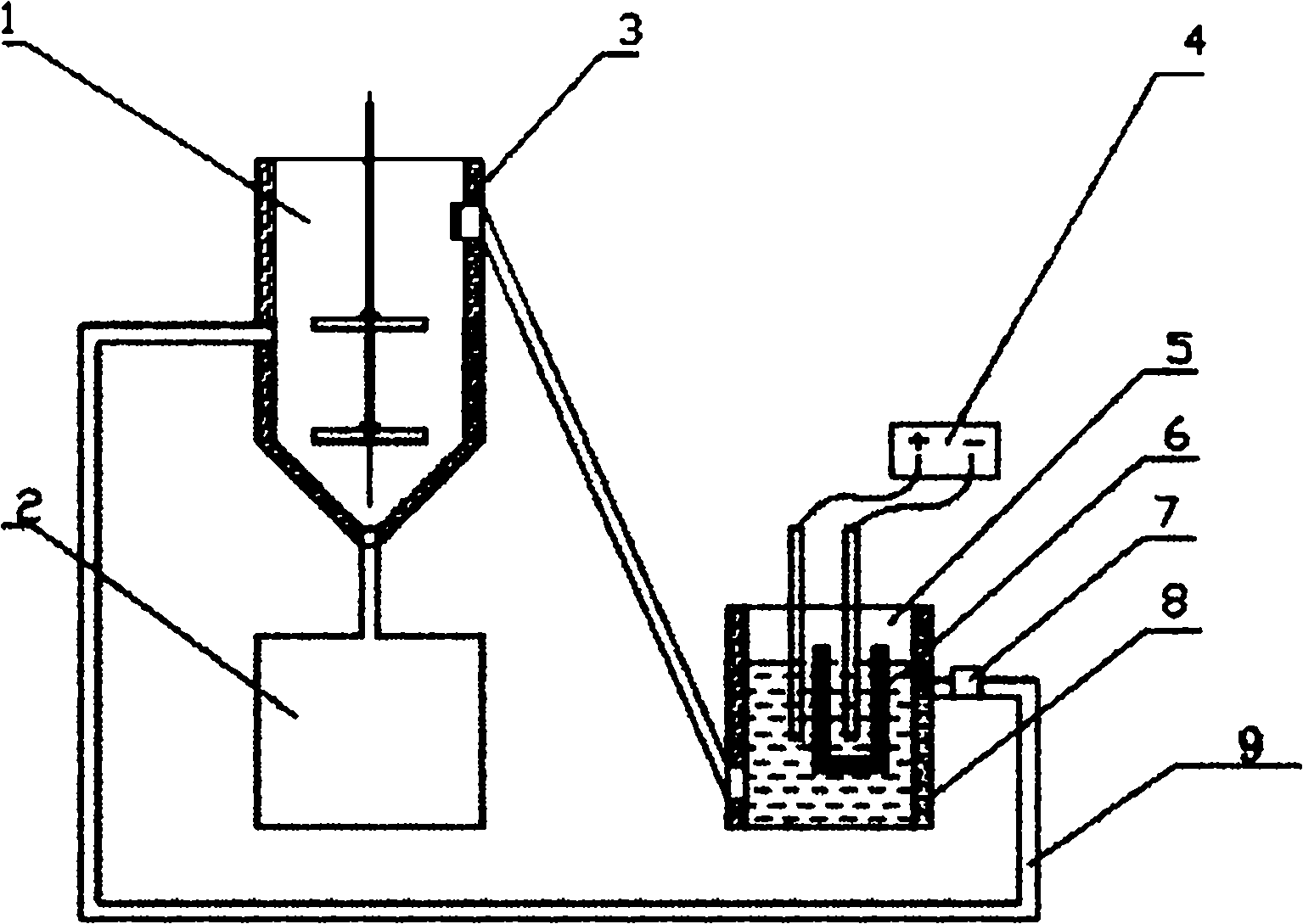

Method and device for recovering metallic lead from lead plaster of waste lead-acid storage battery

A technology for waste lead-acid batteries and lead-acid batteries, which is applied in the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of small application range and low added value, and achieves wide application range, continuous operation and low equipment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Mix 10kg of waste lead-acid battery lead paste with 10kg of waste sulfuric acid in lead-acid batteries and then roast it at a temperature of 150°C for 4 hours; put the roasting sand into a stirring tank; add tap water 0.1m 3 To, stir the roasted sand; add calcium acetate concentration to 100g / L, acetic acid concentration to 75 g / L, nitric acid concentration to 50 g / L, turn on the pump of the solution circulation system to circulate the immersion solution in the electrolytic tank and stirring tank, and leaching Calcined sand, leaching temperature is 50°C, leaching time is 1h; add bone glue to a concentration of 0.1g / L, β-naphthol concentration is 0.05g / L, electrolyze lead at 50°C, cathode current density is 1A / dm 2 ; Electrolysis 5h. The cathode recycles lead, the anode recycles lead dioxide, and the current efficiency is 97.1%. The residue is filtered by a filter press to obtain lead-free slag, and the filtrate is recovered and recycled.

Embodiment 2

[0029] Mix 10kg of waste lead-acid battery lead paste with 10kg of waste sulfuric acid in lead-acid batteries and then roast it at a temperature of 280°C for 1 hour; put the roasting sand into a stirring tank; add tap water 0.1m 3 To, stir the roasted sand; add calcium acetate concentration to 200g / L, acetic acid concentration to 50 g / L, nitric acid concentration to 75 g / L, turn on the pump of the solution circulation system to circulate the immersion solution in the electrolytic tank and stirring tank, and leaching Calcined sand, leaching temperature is 40°C, leaching time is 2h; add bone glue to a concentration of 0.2g / L, β-naphthol concentration to 0.5g / L, electrolyze lead at 40°C, and a cathode current density of 0.5A / dm 2 ; Electrolysis 5h. The cathode recycles lead, the anode recycles lead dioxide, and the current efficiency is 98.9%. The residue is filtered by a filter press to obtain lead-free slag, and the filtrate is recovered and recycled.

Embodiment 3

[0031] Mix 10kg of waste lead-acid battery lead paste with 10kg of waste sulfuric acid in lead-acid batteries and then roast at a temperature of 200°C for 2 hours; put the roasting sand into a stirring tank; add 0.1m of tap water 3 To, stir the roasted sand; add calcium acetate concentration to 150g / L, acetic acid concentration to 100 g / L, nitric acid concentration to 100 g / L, turn on the pump of the solution circulation system to circulate the immersion solution in the electrolytic tank and stirring tank, and leaching Calcined sand, the leaching temperature is 30°C, the leaching time is 3h; add bone glue to a concentration of 2.5g / L, the concentration of β-naphthol is 0.01g / L, lead electrolysis at 30°C, and the cathode current density is 5A / dm 2 ; Electrolysis 5h. The cathode recycles lead, the anode recycles lead dioxide, and the current efficiency is 98.1%. The residue is filtered by a filter press to obtain lead-free slag, and the filtrate is recovered and recycled.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com