Method for measuring fatigue test maximum stress of single-journal vane

A technology of maximum stress and fatigue test, applied in the testing of machine/structural components, measuring force, measuring device, etc., can solve the problems of difficult clamping, difficult to determine the position and data of the maximum stress point, and difficult to test, and achieve social and military effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 A method for measuring the maximum stress of a single-journal blade fatigue test blade body

[0023] The equipment used is: electromagnetic vibrating table and special positioning device;

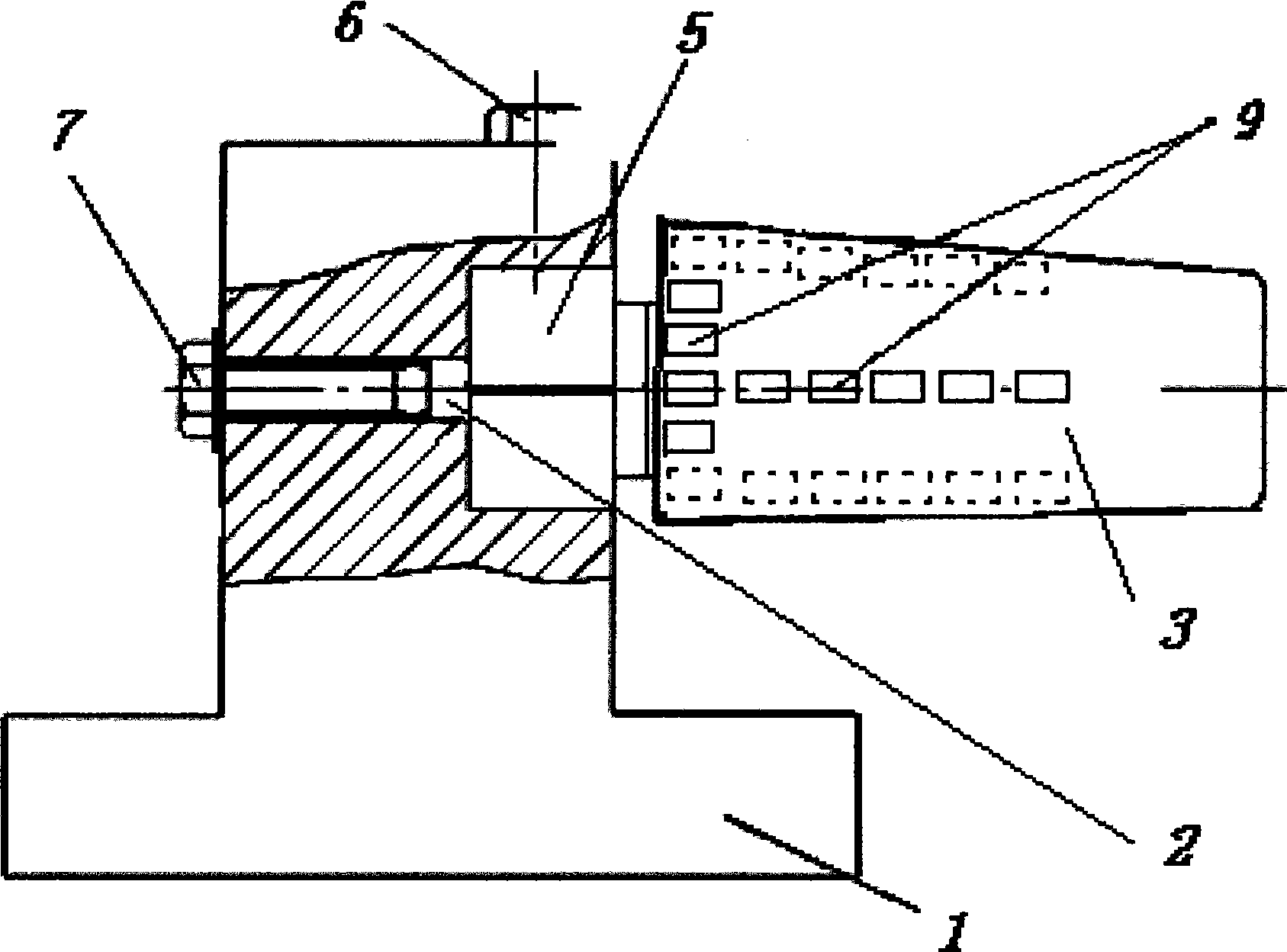

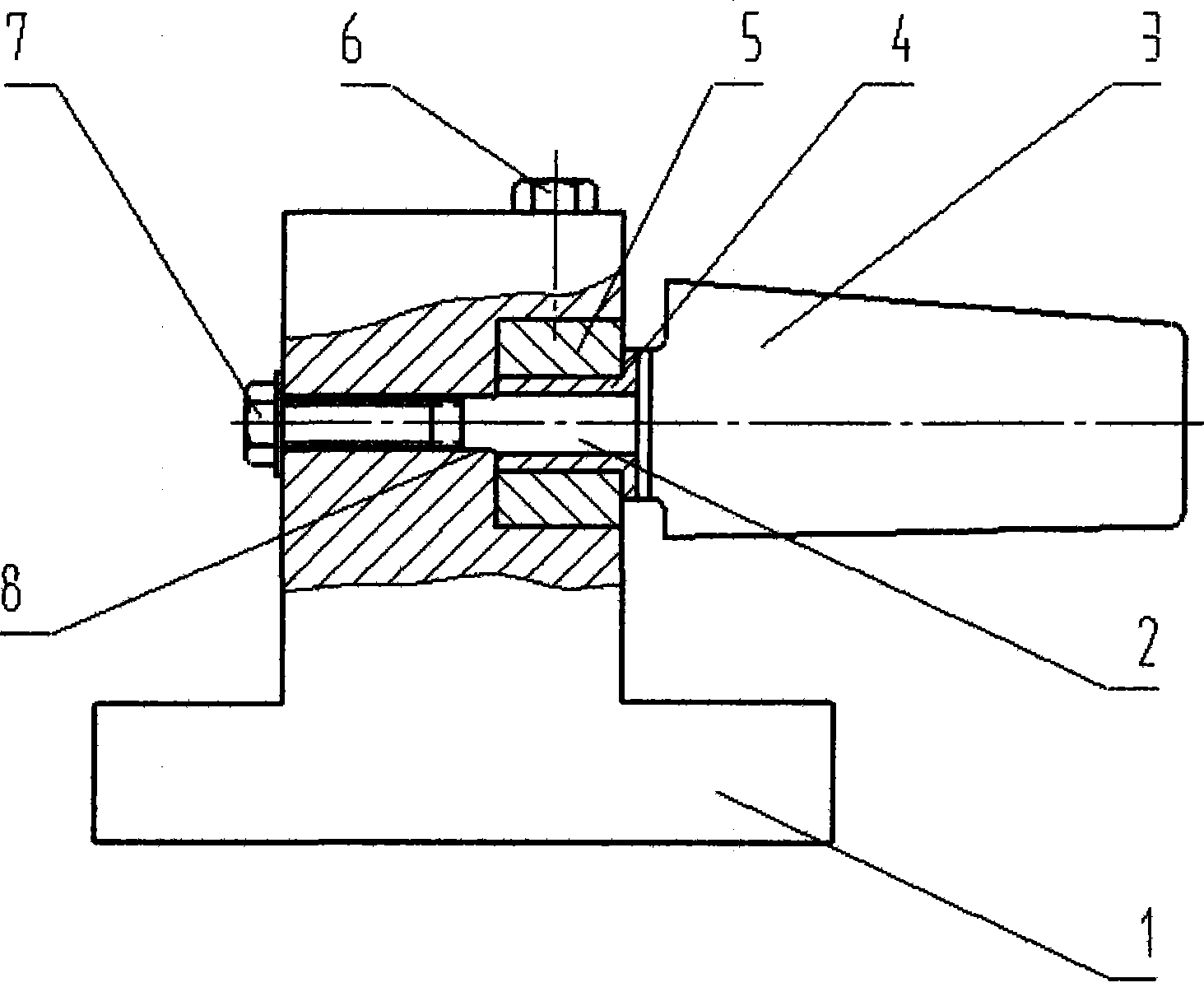

[0024] The specific structure of the special positioning device includes the following parts: clamp body 1, spring collet 4, pressure block 5, clamping screw 6, tension screw 7, angular positioning groove 8; wherein: the clamp for installing the detected blade Specifically 1 is fixed on the electromagnetic vibrating table, the pressure block 5 and the spring sleeve 4 are installed in the hole on the clamp body 1 for fixing the shaft diameter of the blade, and the tension screws 7 are respectively fixed on the clamp body 1 and the tail of the blade to be tested. The tightening screw 6 presses the pressure block 5 in a direction substantially perpendicular to the axial direction of the journal of the blade to be tested.

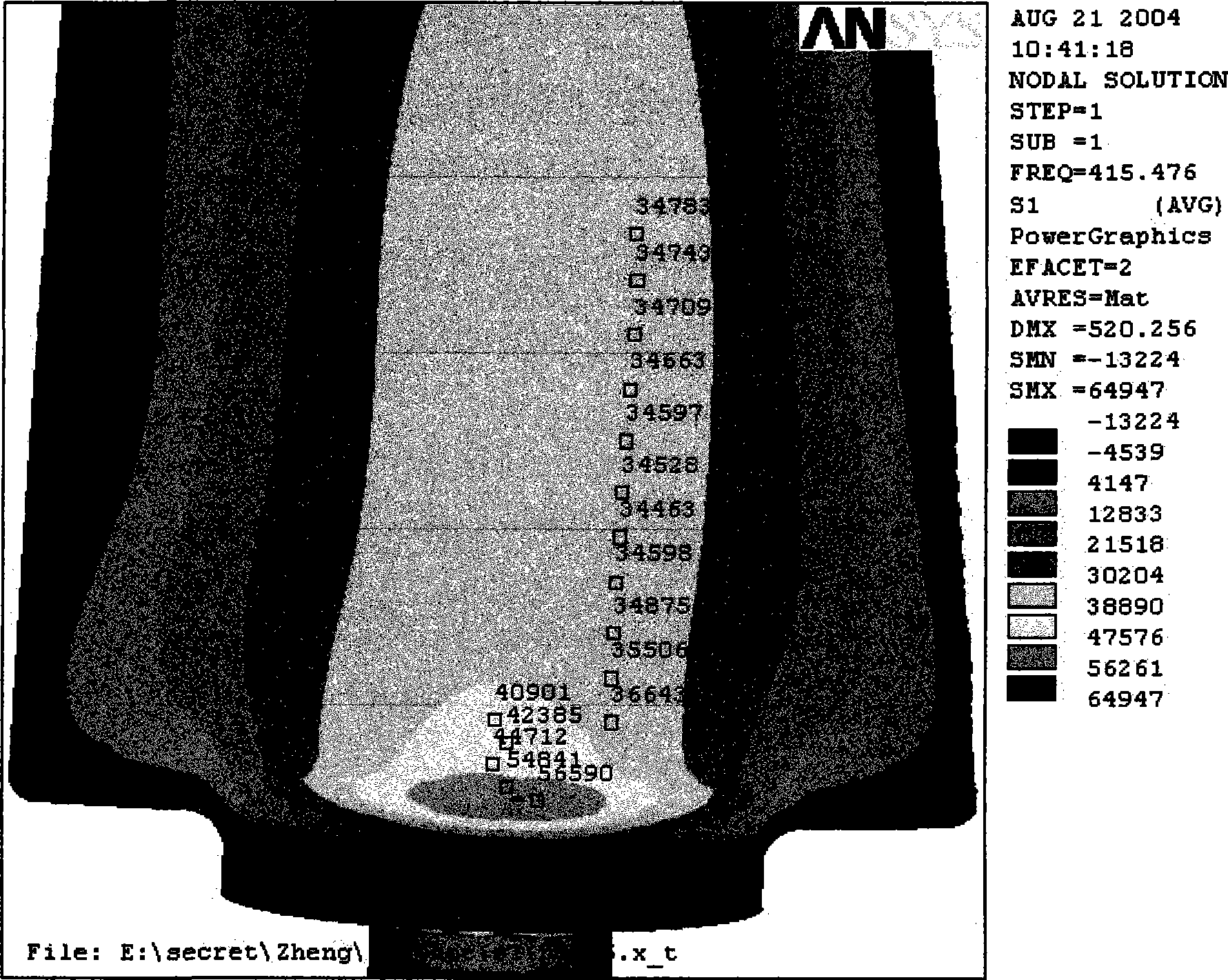

[0025] In the process of measuring the stress distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com