High-gloss transparent glaze formula for daily-use ceramics, as well as preparation method and using method of high-gloss transparent glaze formula

A high-gloss, transparent glaze technology, applied in the field of ceramic manufacturing, to achieve the effect of beautiful appearance and high gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

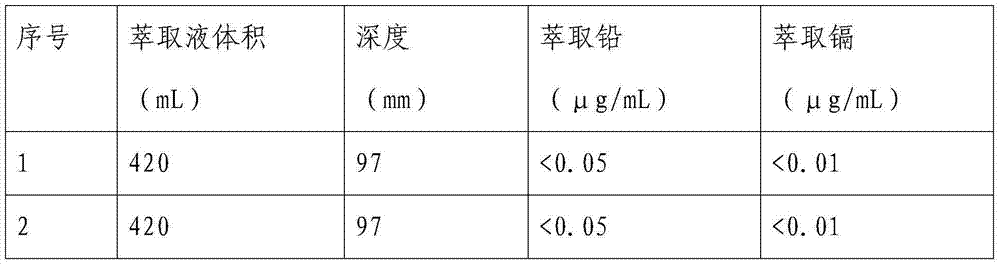

Examples

specific Embodiment 1

[0026] Specific embodiment 1: The glaze formula is as follows in parts by weight: feldspar 31, Shuangfei powder 6, limestone 6, talc 6, dolomite 4, kaolin 8, silicon oxide 22, zinc oxide 7, barium carbonate 3, water 7.

specific Embodiment 2

[0027] Specific embodiment 2: The glaze formula is as follows in parts by weight: feldspar 31, shuangfeishi 12, talc 6, dolomite 5, kaolin 8, silicon oxide 18, zinc oxide 7, barium carbonate 2, water 11.

specific Embodiment 3

[0028] Specific embodiment three: The glaze formula is as follows in parts by weight: feldspar powder 28, Shuangfei powder 8, limestone 2, talc 9, dolomite 4, kaolin 6, silicon oxide 23, zinc oxide 6, barium carbonate 5, water 9.

[0029] The fineness of the high-gloss transparent glaze described in the above specific examples 1 to 3 is less than 1%, and its manufacturing process includes the following steps:

[0030] Step 1: Accurately weigh the raw materials according to the glaze formula;

[0031] Step 2, mixing the raw materials and then wet ball milling to obtain a glaze slurry, wherein the material: ball: water = 1:2:1.5;

[0032] In step 3, the glaze slurry is passed through a 320-mesh sieve and aged for use to obtain a transparent glaze.

[0033] The high-gloss transparent glaze formulation for daily-use ceramics provided by the present invention uses feldspar powder, double-fly powder, limestone, talc, dolomite, kaolin, silicon oxide, zinc oxide, barium carbonate, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com