Three-dimensional metal label pressing and attaching technique method

A technology of metal labels and process methods, applied in labels, labeling machines, packaging and other directions, can solve the problems of manual operation positioning accuracy cannot be guaranteed, manual operation efficiency is low, product quality fluctuations and other problems, and achieve great use value and economic benefits. , The structure design is novel and exquisite, and the effect of pressing and pasting is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

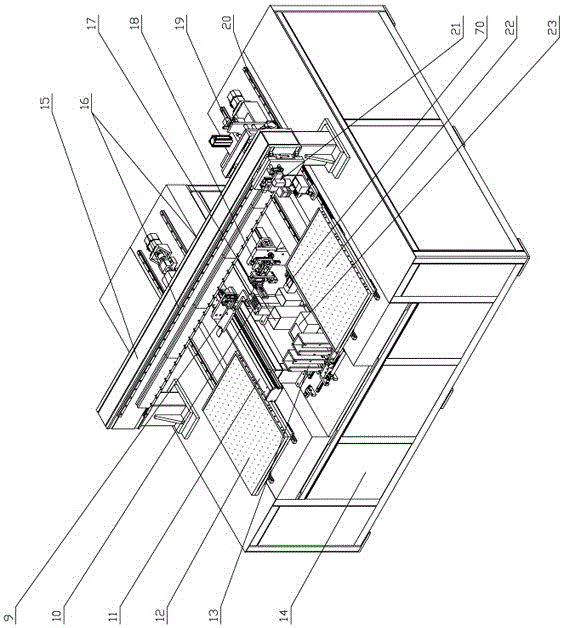

[0048] see Figure 2-Figure 12 , the present invention is a kind of three-dimensional metal label pressing process method, and this pressing process method comprises the following steps:

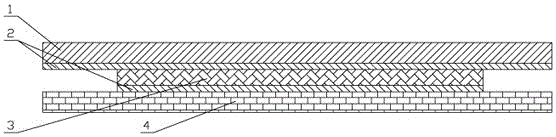

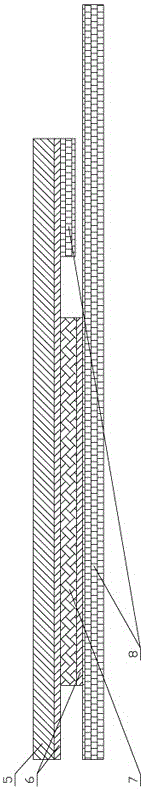

[0049] Step 1: prepare a three-dimensional metal label, which consists of five layers, from top to bottom are the top transparent film 5, the adhesive layer 6, the three-dimensional metal label layer 7, the adhesive layer and the bottom transparent release paper Layer 8, the length of one end of the bottom transparent release paper layer 8 is greater than the length of the top transparent film 5, so that the transparent release paper layer at the bottom is conveniently torn off, and at the same time, it is pasted on the end of the adhesive layer of the top transparent film There is a section of transparent release paper to prevent the extra part of the bottom transparent release paper from sticking together with the upper adhesive layer to affect the tearing of the bottom transparent release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com