Method for narrow-gap laser welding with filler wires for superconducting coil box

A welding method and technology of superconducting coils, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to meet the welding success rate, large heat-affected zone, and high cost of electron beam welding, and achieve extensive epitaxy. and extensible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

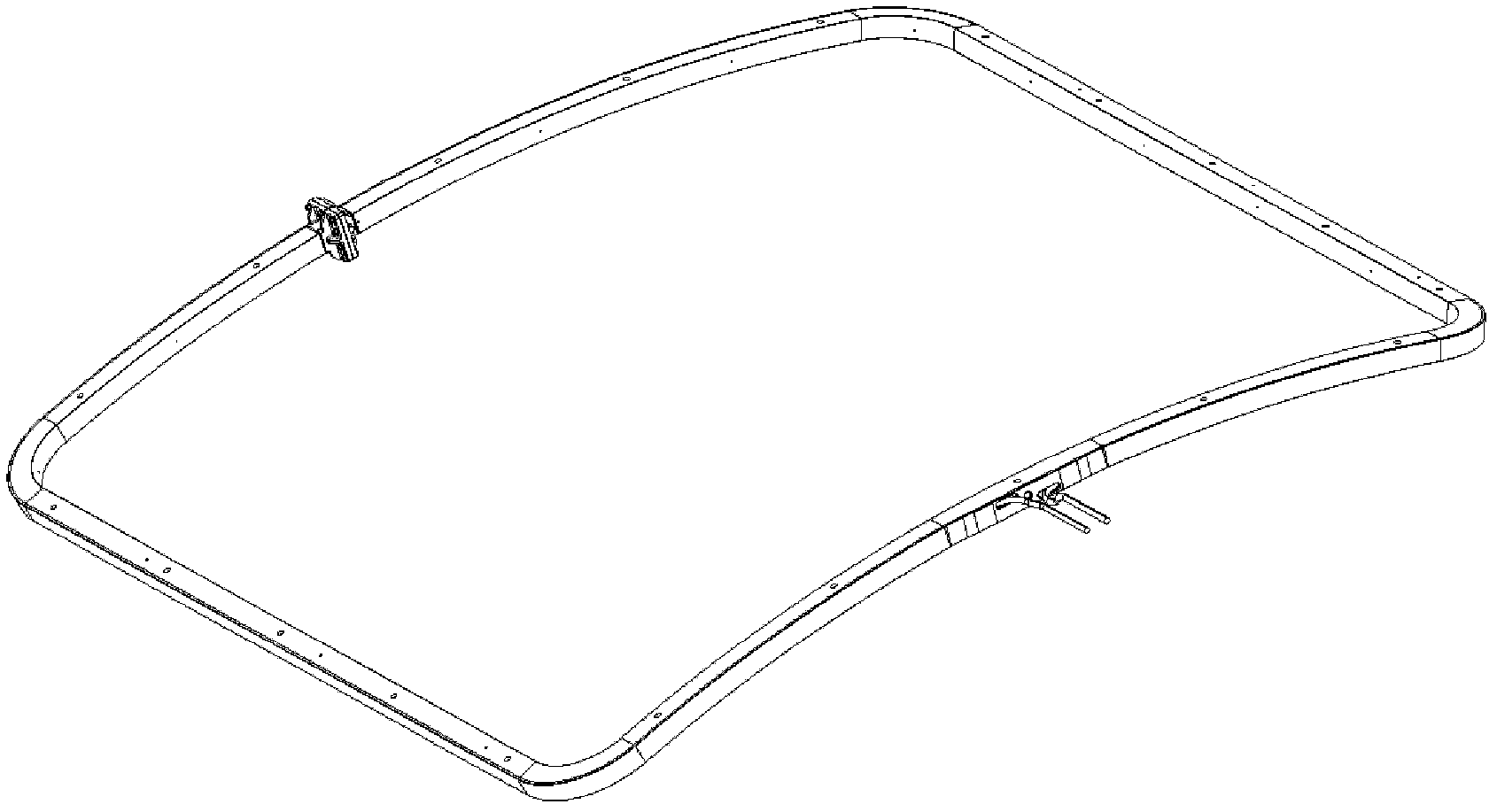

[0032] This embodiment is the implementation step of welding the coil box of the SCC structure. The structure of the coil box is as figure 1 As shown, the specific welding steps are:

[0033] (1) Process the welding seam of the superconducting coil box into a V-shaped groove and clean it with acetone to remove the oil and impurities on the surface.

[0034] (2) Fix the superconducting coil box to the load-bearing and profiling fixture, and use the fixture to tighten.

[0035] (3) The laser welding head and wire feed nozzle are connected with the robot arm to control the coordinated action of the robot and the laser.

[0036] (4) Start the welding device, set the laser output power, the distance between the processing head and the wire feeding nozzle and the surface of the workpiece, the shielding gas flow, the distance between the gas nozzle and the molten pool, the welding speed, the wire feeding speed, etc. to start welding.

[0037] (5) For the welding sequence of the SCC coil box, t...

Embodiment 2

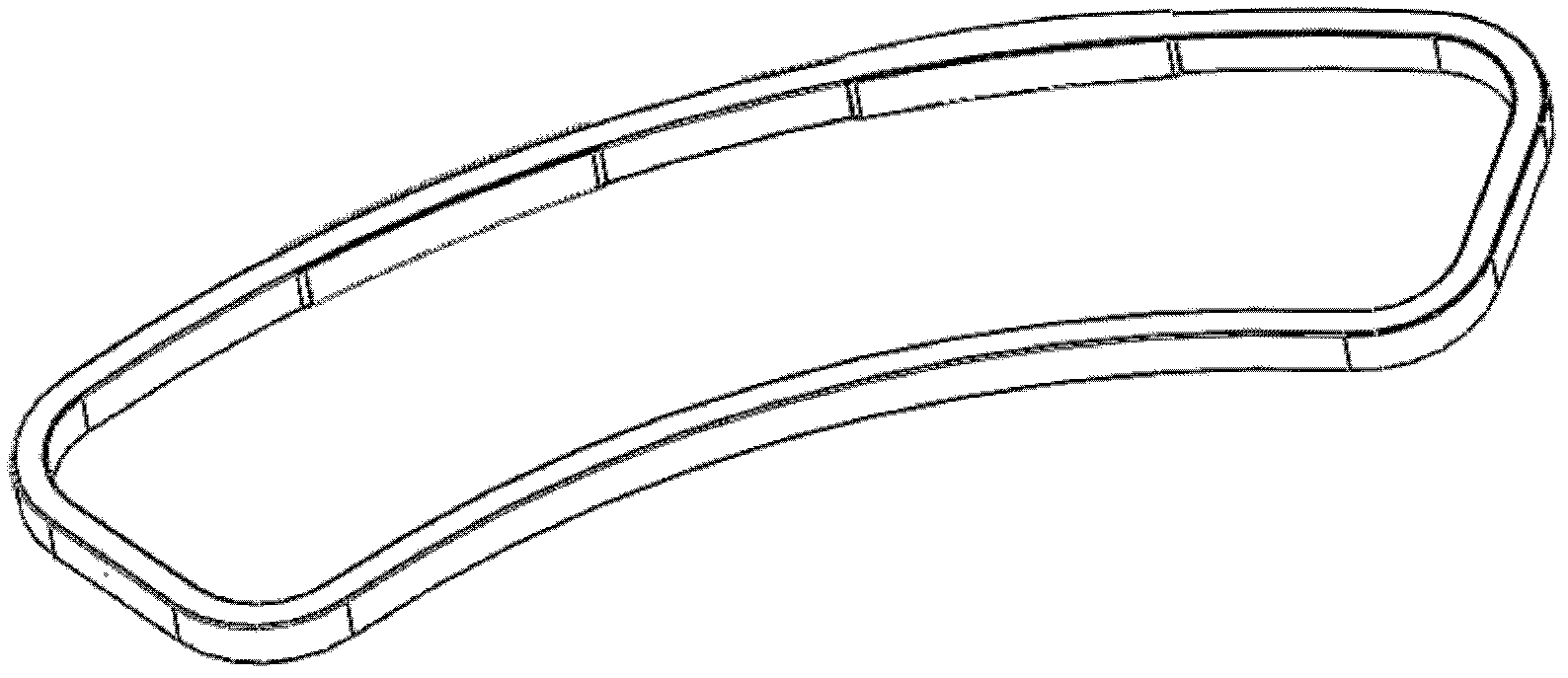

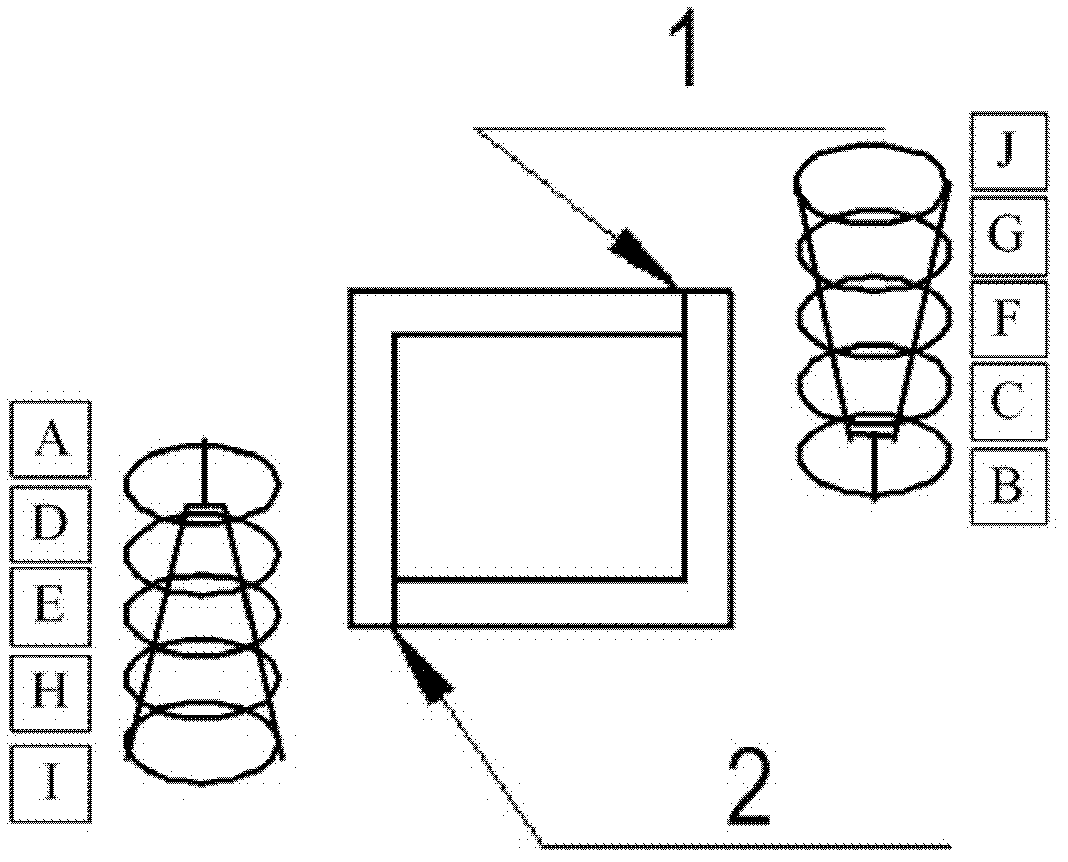

[0046] This embodiment is the implementation step of welding the coil box of the B / TCC structure. The structure of the coil box is as figure 2 As shown, the welding steps are roughly the same as those of Example 1, except that the B / TCC coil box is divided into a`, b` large arc segments, c`, d` straight line segments, e`, f, g`, h`small arc, such as Figure 4 As shown, the weld bead is divided into outer weld bead 3 and inner test weld bead 4, which are also symmetrical and alternately welded for each section and inner and outer weld beads. However, the coil box does not need to be turned over and the welding process is simplified. Therefore, in order to reduce heat Accumulation of input, using such as Figure 4 Welding sequence: Fill the first layer (A` layer) to the outer weld bead 3, then fill the first layer (B` layer) to the inner test bead 4, and then fill the second layer (C` layer) to the outer weld bead, Then fill in the D` layer, E` layer, F` layer in turn... and so o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com