Silver nanowire positive electrode for zinc-silver battery and preparation method thereof

A silver nanowire, zinc-silver battery technology, applied in battery electrodes, silver storage batteries, alkaline storage battery electrodes, etc., can solve the problem of high resistance of micron-sized silver powder positive electrode, small contact surface between granular silver powder and current collector, poor structural integrity, etc. To achieve the effect of improving specific energy and rapid discharge performance, improving specific energy and rapid discharge performance, and reducing polarization current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a positive electrode of silver nanowires for a zinc-silver battery of the present invention comprises the following steps: laying pretreated silver nanowires on the upper and lower sides of the current collector, and obtaining silver nanowires after compression molding and vacuum sintering positive electrode.

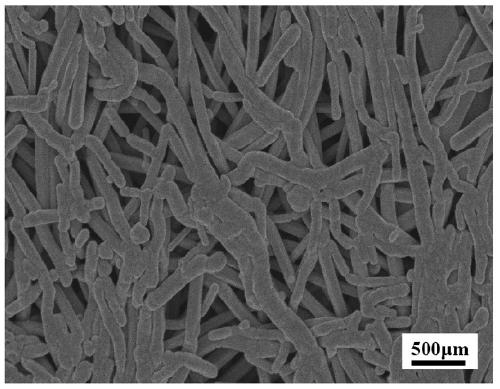

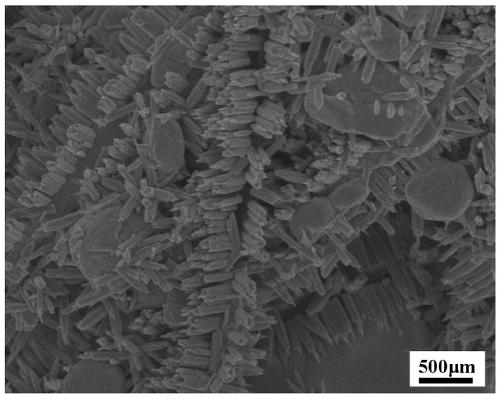

[0039] The invention adopts the silver nanowire to prepare the silver nanowire positive electrode, and the extremely small diameter of the silver nanowire is beneficial to improving the specific energy of the battery. When charging, the silver nanowires with extremely small diameters are converted into silver oxide, and their thickness is much smaller than that generated by micron-sized silver powder, so the O -2 The hindrance of ion and electron migration is limited, the oxidation reaction of the silver nanowire core is sufficient, and the conversion rate of silver oxide is improved. Vacuum sintering realizes the welding between silver nan...

Embodiment 1

[0041] A method for preparing a silver nanowire positive electrode for a zinc-silver battery in this embodiment comprises the following steps:

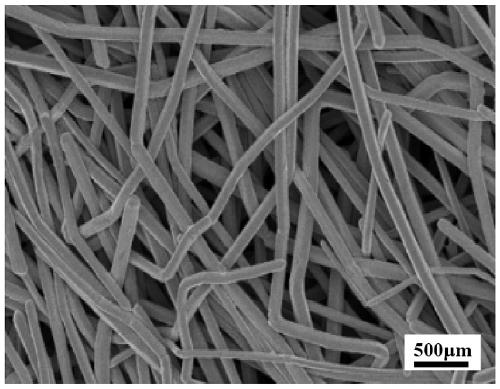

[0042] 1. Pretreatment of silver nanowires: Prepare silver nanowires by conventional alcohol-thermal method, separate and purify the obtained silver nanowires, dilute the reaction solution containing silver nanowires by 2 times with ethanol, press filter under 1Mpa pressure, After the solid-liquid separation is complete, take out the precipitate, disperse the precipitate in ethanol, press filter under 1Mpa pressure, after solid-liquid separation, take out the precipitate, then repeat the dispersion-press filter for 3 times until the ethylene glycol (EG) and The total content of impurities such as polyvinylpyrrolidone (PVP) is ≤0.5%, and the separated and purified silver nanowires are obtained. The prepared silver nanowires are as follows: figure 1 As shown, the diameter is 100 nm and the length is 25 μm.

[0043] 2. Compression molding...

Embodiment 2

[0049] A method for preparing a silver nanowire positive electrode for a zinc-silver battery in this embodiment comprises the following steps:

[0050] 1. Pretreatment of silver nanowires: Prepare silver nanowires by conventional alcohol-thermal method, separate and purify the obtained silver nanowires, dilute the reaction solution containing silver nanowires by 4 times with alcohol, and centrifuge at 1500rad / min 5min, pour out the supernatant, take out the precipitate, disperse the sediment in alcohol, centrifuge at a speed of 1500rad / min for 5min, take out the precipitate after solid-liquid separation, and then repeat the dispersion-centrifugation of the precipitate 4 times until ethylene glycol ( EG) and polyvinylpyrrolidone (PVP) and other impurities with a total content of ≤0.5%) to obtain separated and purified silver nanowires, the prepared silver nanowires have a diameter of 100nm and a length of 25μm.

[0051] 2. Compression molding: Then weigh 0.5g of pretreated silv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com