Composite carbon fluoride cathode material for lithium primary battery, preparation method and application thereof

A composite fluorocarbon and positive electrode material technology, applied in battery electrodes, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of low material tap density, low volume specific energy, etc., and achieve easy scale-up production, simple preparation method, The effect of increasing the discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Select activated carbon (purity ≥ 99.5%, D 50 ≤ 50µm) 200g into the reaction furnace, heated up to 350°C, passed into F 2 Volume fraction 2% F 2 / N 2The mixed gas was reacted for 12 hours to obtain fluorinated activated carbon, the F / C of which was tested was 0.76, and the tap density was 0.82g / ml.

[0046] Select 200g of carbon fiber (200 mesh) and put it into the reaction furnace, raise the temperature to 100°C, and pass it into F 2 F with a volume fraction of 100% 2 After 24 hours of reaction, fluorinated carbon fiber was obtained, and its F / C was 0.92, and its tap density was 0.94g / ml.

[0047] Put the obtained fluorinated activated carbon and fluorinated carbon fiber into a ball mill jar at a mass ratio of 1:10, and ball mill for 12 hours to obtain a composite fluorinated carbon material, and then mix the mixed fluorinated carbon material with fluorine nitrogen at a concentration of 1% fluorine gas Mixed gas, secondary fluorination treatment at 500°C for 5 hou...

Embodiment 2

[0049] Select activated carbon (purity ≥ 99.5%, D 50 ≤ 50µm) 200g into the reaction furnace, heated up to 250°C, 2 Volume fraction 10% F 2 / N 2 The mixed gas was reacted for 6 hours to obtain fluorinated activated carbon; after testing, its F / C was 0.74 and its tap density was 0.81g / ml.

[0050] Select 200g of carbon fiber (200 mesh) and put it into the reaction furnace, raise the temperature to 400°C, and pass it into F 2 Volume fraction 10% F 2 / N 2 The mixed gas was reacted for 16 hours to obtain fluorinated carbon fibers, the F / C of which was tested was 0.95, and the tap density was 0.96g / ml.

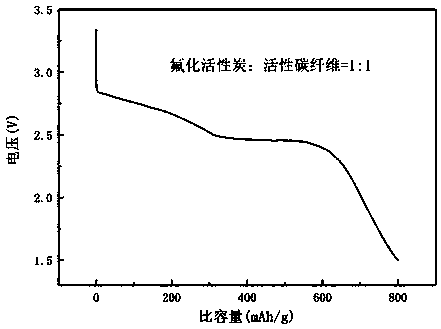

[0051] The obtained fluorinated activated carbon and fluorinated carbon fiber are put into a ball mill jar according to the mass ratio of 1:1, and ball milled for 6 hours to obtain a composite fluorinated carbon material, and then the mixed fluorinated carbon material is mixed with fluorine nitrogen at a concentration of 5% fluorine gas. Mixed gas, secondary fluoridation treat...

Embodiment 3

[0053] Select activated carbon (purity ≥ 99.5%, D 50 ≤ 50µm) 200g into the reaction furnace, heated up to 100°C, 2 F with a volume fraction of 100% 2 After 2 hours of reaction, fluorinated activated carbon was obtained; the F / C was 0.80 and the tap density was 0.85g / ml after testing.

[0054] Select 200g of carbon fiber (200 mesh) and put it into the reaction furnace, raise the temperature to 600°C, and pass it into F 2 Volume fraction 2% F 2 / N 2 The mixed gas was reacted for 4 hours to obtain fluorinated carbon fibers, the F / C of which was tested was 0.96, and the tap density was 0.98g / ml.

[0055] The obtained fluorinated activated carbon and fluorinated carbon fiber are put into a ball mill jar according to the mass ratio of 1:0.1, and ball milled for 0.5h to obtain a mixed fluorinated carbon material. The secondary fluorination treatment was carried out for 1 hour under the condition of ℃, and the secondary fluorination mixed carbon fluoride positive electrode materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com