Patents

Literature

76results about How to "No quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel-free white copper alloy containing rare earth additional elements and method for manufacturing plates made of same

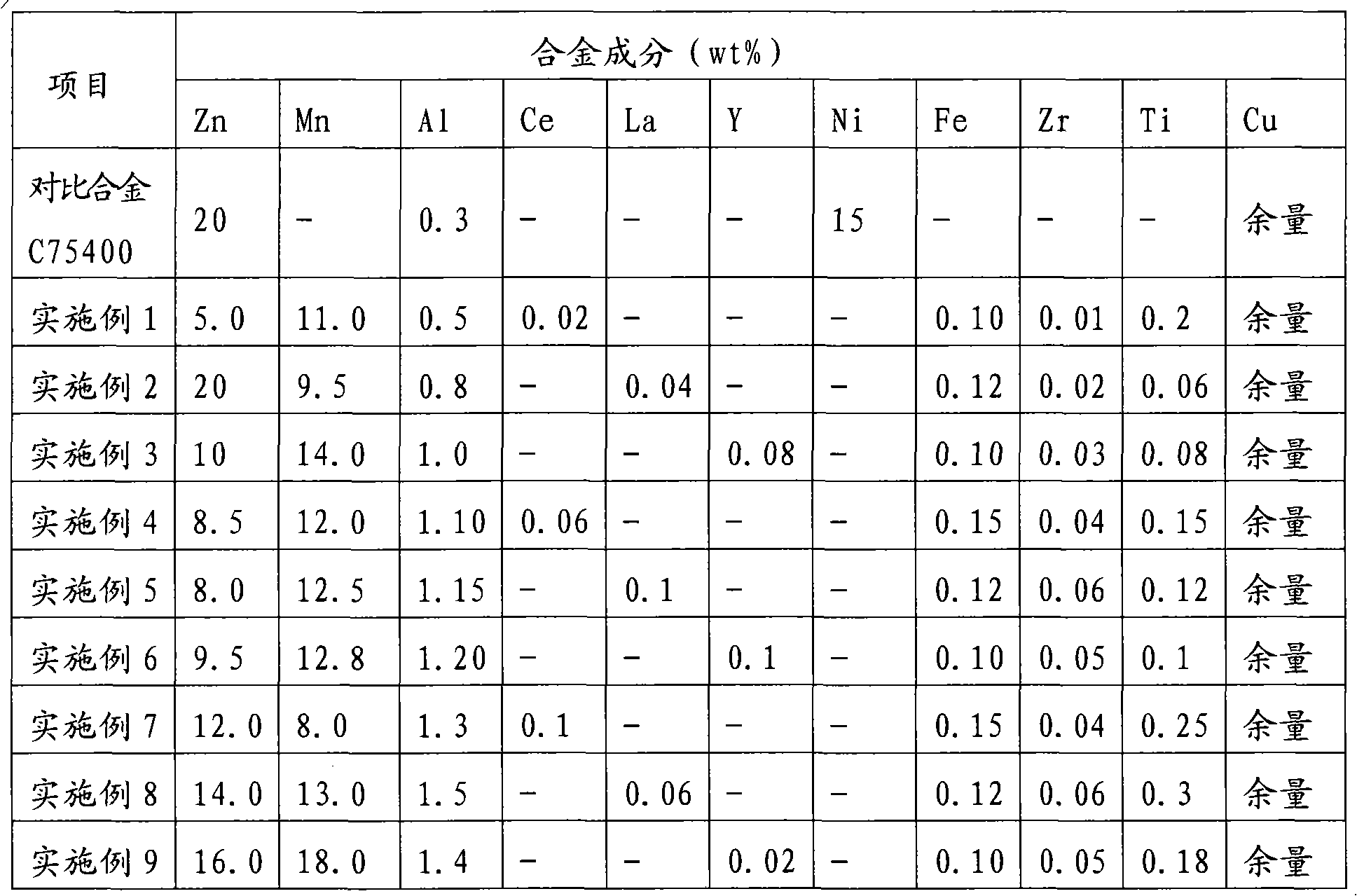

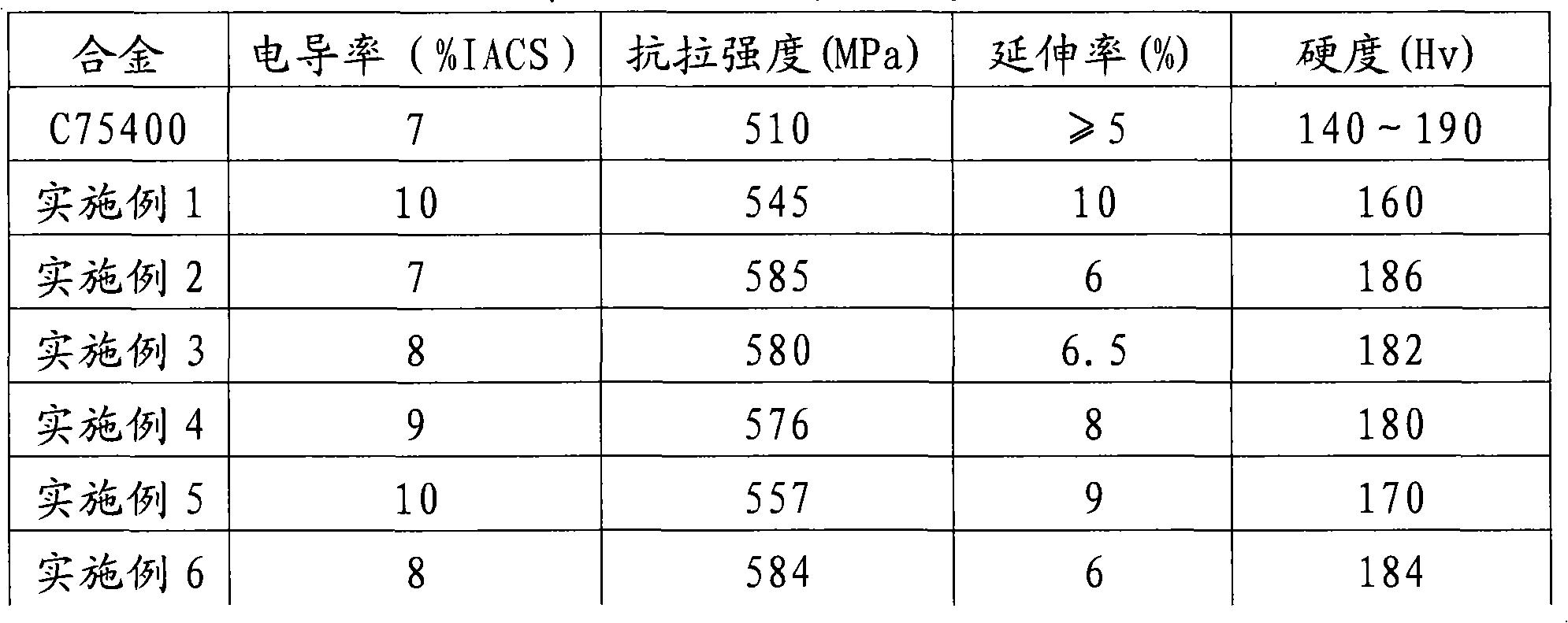

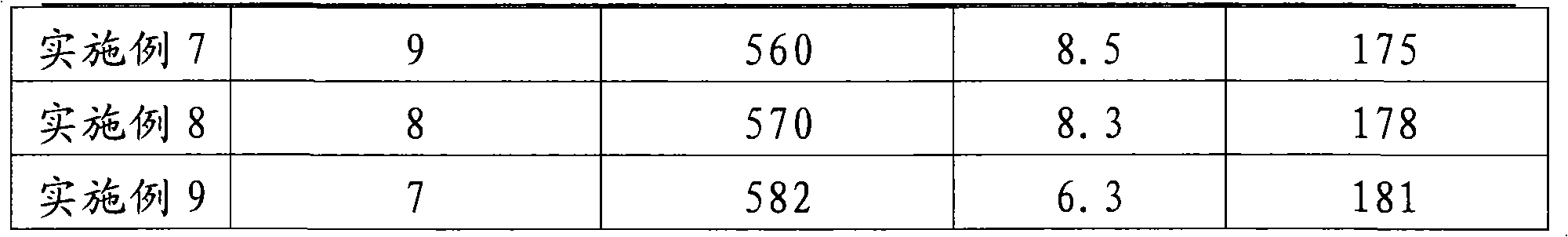

The invention discloses nickel-free white copper alloy containing rare earth additional elements and a method for processing plates made of the same. The nickel-free white copper alloy comprises the following components in percentage by weight: 0.02 to 0.1 percent of rare earth elements, 5 to 20 percent of zinc, 8 to 18 percent of manganese, 0.5 to 2.0 percent aluminum, 0 to 0.5 percent of iron, 0 to 0.5 percent of titanium, 0 to 0.1 percent of zirconium and the balance of copper. An alloy processing method comprises the following major technological processes of: alloy smelting and casting, hot rolling, thermal annealing, cold rolling and the like. The method is characterized in that: copper, zinc, manganese and aluminum are taken as main alloy elements; rare earth elements such as lanthanum, cerium and iridium as well as trace elements such as iron, zirconium and titanium are added in an alloy smelting process; and a human-friendly and environmental-friendly nickel-free white copper alloy plate is manufactured by the technological methods of high-temperature alloying, degassing, impurity removing, casting, cast ingot hot rolling, thermal annealing, cold rolling, finished product annealing and the like.

Owner:JIANGXI UNIV OF SCI & TECH

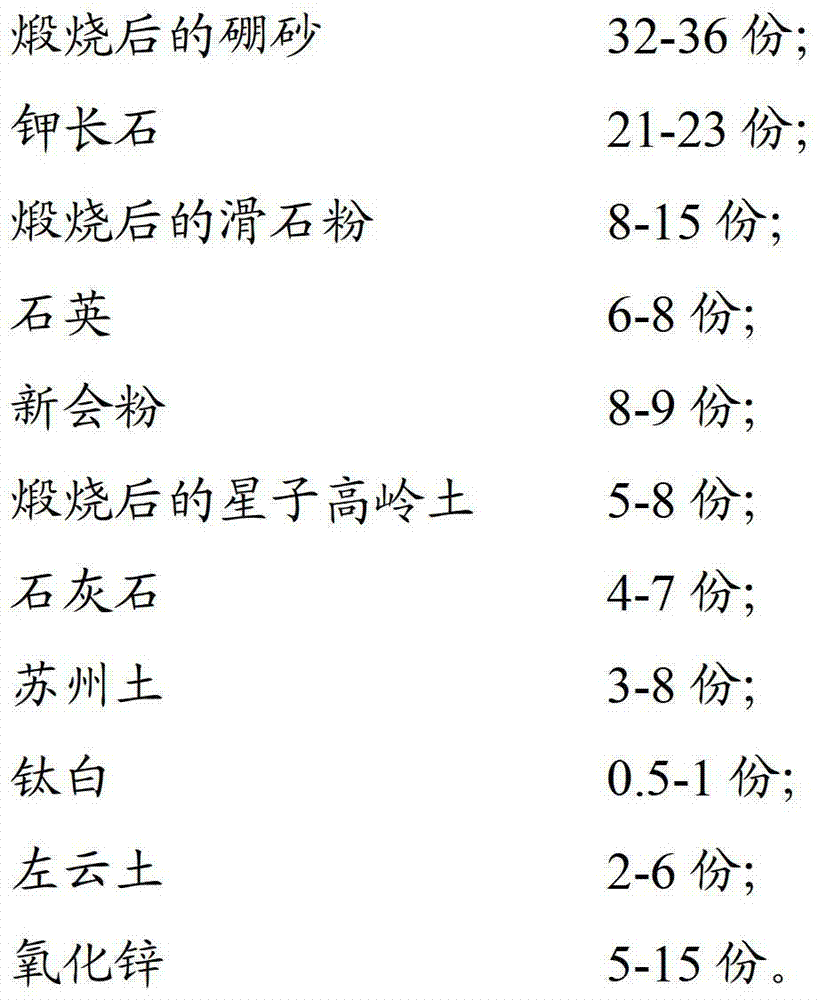

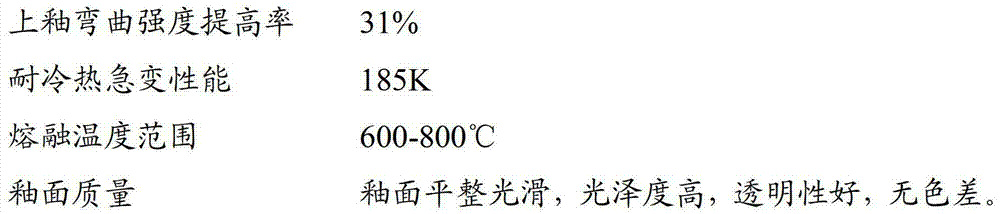

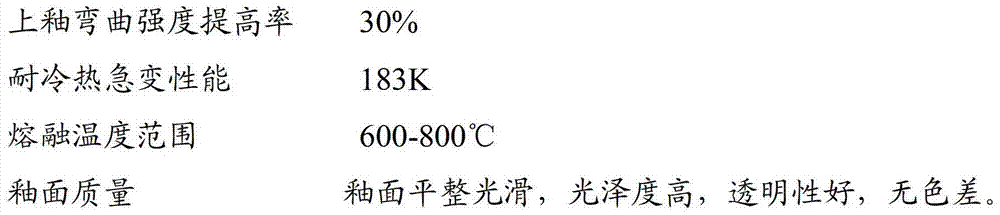

Formula and preparation method of ultralow temperature glaze

The invention discloses a formula of ultralow temperature glaze. The formula comprises 32-36 parts of calcined borax, 21-23 parts of potash feldspar, 8-15 parts of calcined talcum powder, 6-8 parts of quartz, 8-9 parts of Xinhui powder, 5-8 parts of calcined Xingzi kaoline, 4-7 parts of limestone, 3-8 parts of Suzhou soil, 0.5-1 part of titanium dioxide, 2-6 parts of Zuoyun soil and 5-15 parts of zinc oxide. The invention simultaneously discloses a preparation method of the ultralow temperature glaze. The preparation method comprises the following steps of material preparation, material mixing, wet grinding, glazing, drying and calcining. The ultralow temperature glaze prepared by the formula and the preparation method is used for retouching various porcelain blanks and porcelain bodies; a favorable intermediate layer can be formed after glazing; the ultralow temperature glaze can be favorably combined with the porcelain bodies and has excellent mechanical property, and the bending strength of porcelain is more than 30 percent; meanwhile, the porcelain glaze surface is smooth, is of a pale grey and transparent color and luster, has no defect on the surface and meets the market requirements.

Owner:JIANGSU SOUTH PORCELAIN INSULATOR CO LTD

Novel composite aluminium alloy plates and prepn. method

This invention discloses a method for manufacturing a new type of aluminum alloy composite sheets, and solves the problems of low mechanical properties and low yield existing with present aluminum alloy composite sheets. The sheets are composed of three parallel sheets. The top and the bottom sheets are composed of Si 9.4-10 wt.%, Fe 0.4 wt.%, Cu 0.2 wt.%, Mn 0.1 wt.%, Mg 1.2-1.8 wt.%, Zn 0.2 wt.% and Al as balance. The middle sheet is composed of Si 0.4 wt.%, Fe 0.4-0.6 wt.%, Cu 0.07-0.15 wt.%, Mn 1.1-1.3 wt.%, Ti 0.02-0.03 wt.% and Al as balance. The thickness ratio of the three sheets from top to bottom is 1:2.5~13:1. The sheets are manufactured by: smelting the three alloy ingots, casting into sheets, heating and rolling the top and the bottom sheets, chemically washing and welding, hot-rolling, cold-rolling and annealing the intermediate products to obtain the final products. The aluminum alloy composite sheets have good mechanical properties, and the yield of the final products is increased by more than 15%.

Owner:NORTHEAST LIGHT ALLOY CO LTD

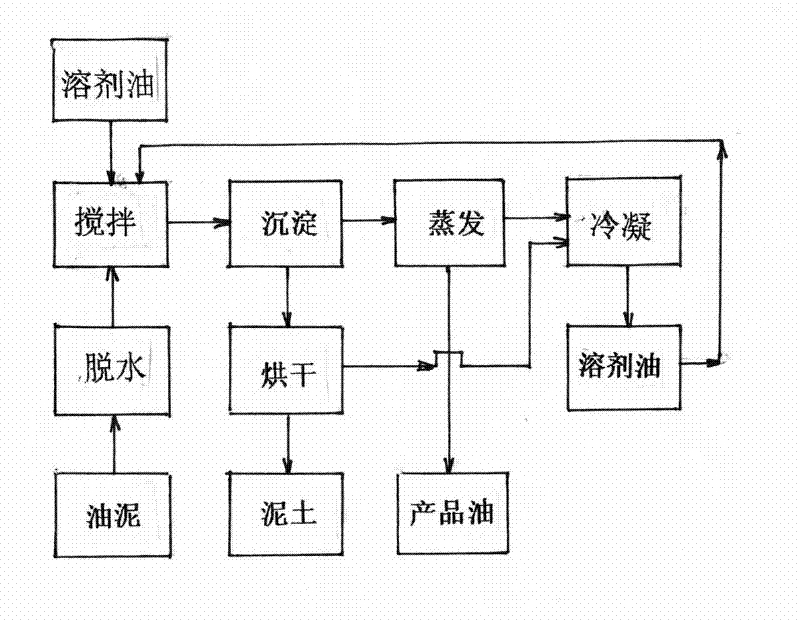

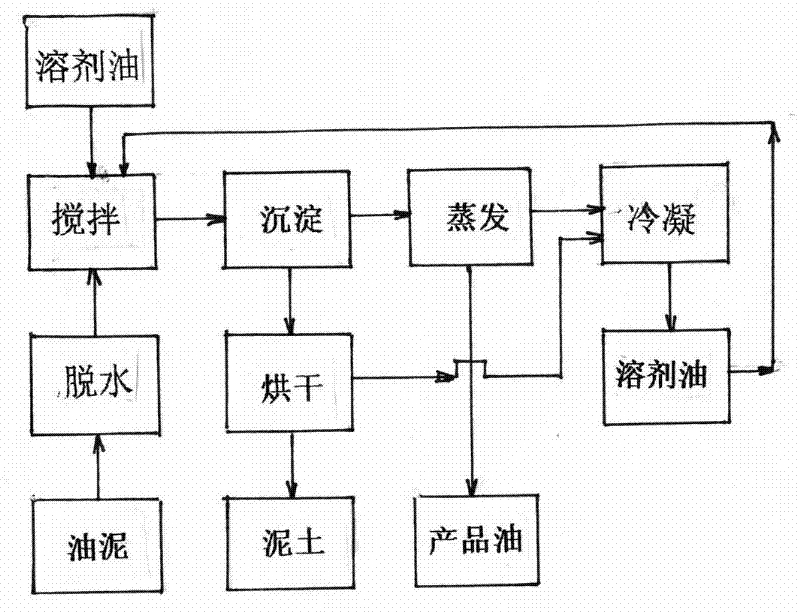

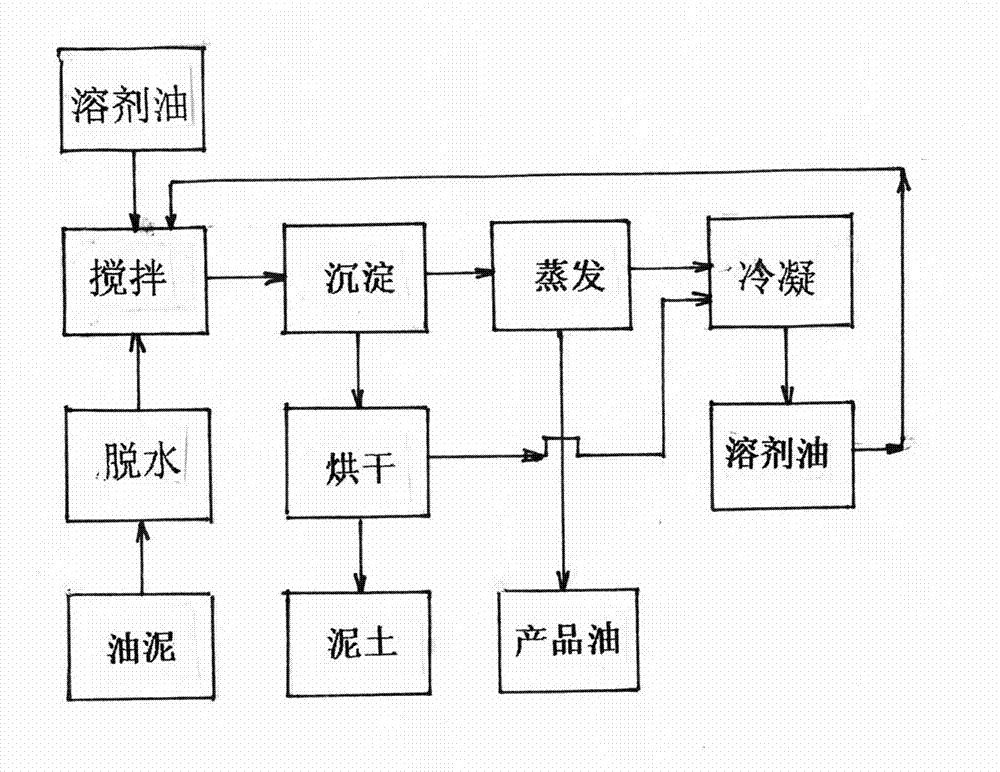

New technology for oil sludge processing

InactiveCN102381821AHigh recovery rateImprove qualityFatty oils/acids recovery from wasteSludge treatment by de-watering/drying/thickeningOil processingFiltration

The invention which belongs to the dangerous waste processing field relates to oil sludge processing and provides a new technology for the oil sludge processing. The technology is mainly characterized in that: after the oil sludge is processed with steps of dehydration, extraction, deposition, evaporation, extraction, pumping filtration, drying and the like, the content of oil in soil is 1% and accords with discharge standards, the total loss of solvent oil is about 1%, the recovery rate of product oil is more than 99%, and no waste gases and no wastewater are discharged. The technology whichhas the advantages of scientific method, mature process, simple equipment and large investment-output benefit and allows great technical problems, environmental protection problems and production safety problems which are difficult to solve for a long time in the dangerous waste processing field to be well solved deserves to be popularized and applied to broad petroleum enterprises, petroleum byproduct enterprises, and plant oil processing and oil product storage and transportation enterprises.

Owner:李廷安

Diamond-based heterogeneously integrated gallium nitride thin film and transistor microelectronic device and preparation method thereof

InactiveCN111540684ANo qualityNo densityTransistorSemiconductor/solid-state device manufacturingWaferingPhysical chemistry

The invention provides a diamond-based heterogeneously integrated gallium nitride thin film and transistor microelectronic device and a preparation method thereof. The preparation method comprises thefollowing steps: S1, providing a gallium nitride single crystal wafer with an injection surface; S2, carrying out hydrogen ion implantation on the gallium nitride single crystal wafer from the injection surface so that implanted ions reach a preset depth, an injection defect layer is formed, and a gallium nitride single crystal thin film is formed above the injection defect layer; S3, bonding thegallium nitride single crystal thin film with a diamond support substrate; S4, performing annealing treatment to peel along the injection defect layer, and forming a damaged layer on the injection defect layer; S5, performing surface treatment to remove the damaged layer; and S6, performing homogeneous epitaxial growth on the surface of the gallium nitride single crystal thin film to prepare a transistor. The diamond-based gallium nitride transistor prepared according to the invention is greatly improved in performance, has the characteristics of high electron mobility and strong heat dissipation capability, can stably work for a long time in a high-frequency and high-power state, and has very remarkable superiority compared with the prior art.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

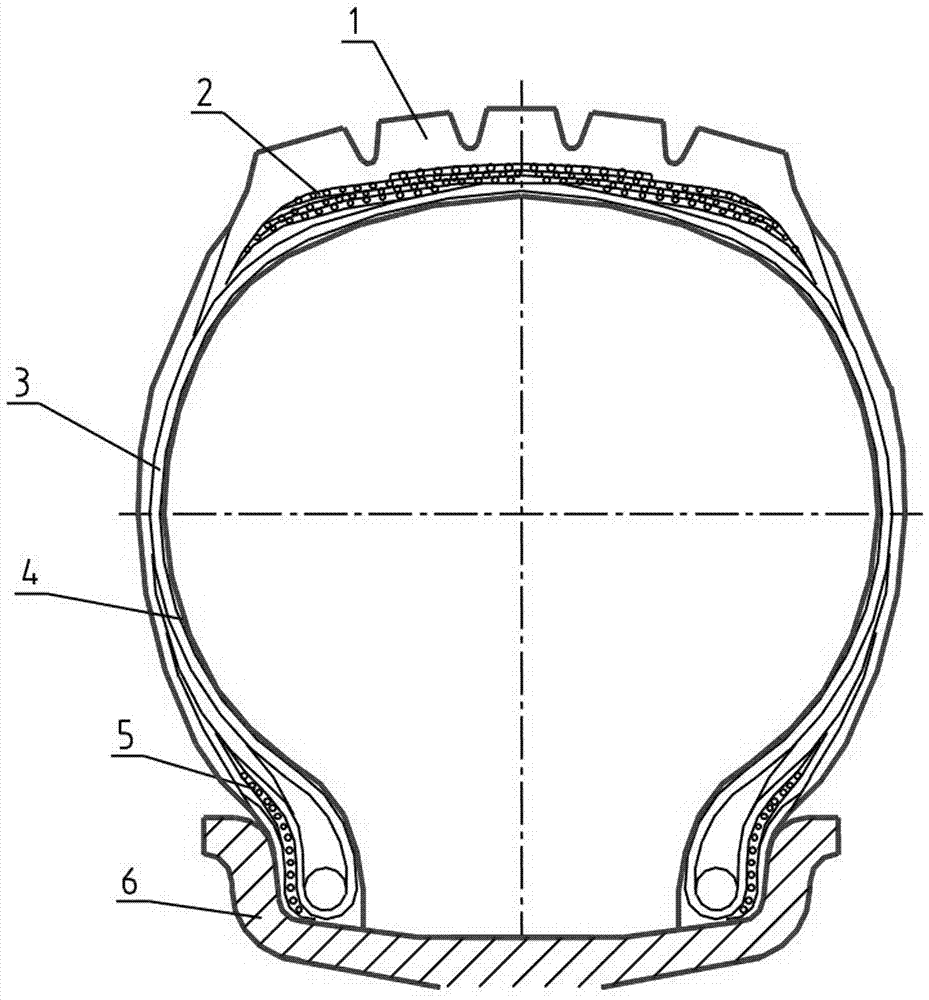

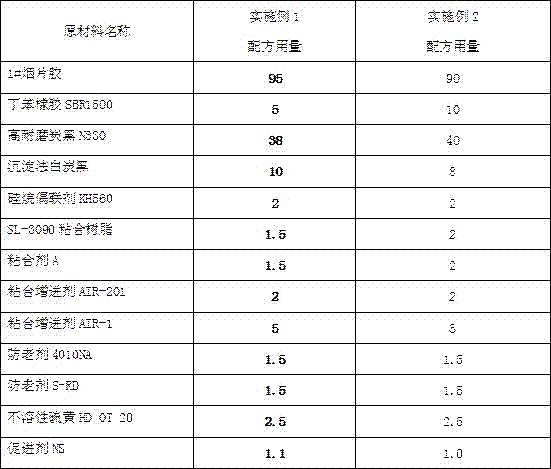

Tread rubber materials for making meridian aircraft tire belt layer cord threads with aramid fiber threads

Disclosed are tread rubber materials for making meridian aircraft tire belt layer cord threads with aramid fiber threads. The rubber materials are prepared according to a certain ratio with 1# smoke sheet rubber as main rubber materials and butadiene styrene rubber, resorcinol bonding resin, formaldehyde bonding resin, a bonding promoter AIR-201 special for the aramid fiber threads, a bonding promoter AIR-1, highly-abrasion-resistant carbon black, precipitated silica, a novel silane coupling agent, insoluble sulfur and a sulfenamide accelerator as main auxiliary materials. The rubber materials have the performance advantages that the bonding strength of the rubber materials and the aramid fiber threads is high, and the bonding retention rate after thermal ageing is high and have the performance characteristics of being high in tensile strength and tearing strength, low in compression fatigue heat generation and high in definite elongation stress. The rubber materials are used as aircraft meridian tire belt layer tread rubber, thus under the high-load and high-speed severe usage conditions, the quality problems of rubber thread loosening or delaminating of layers do not occur to the belt layer position of the aircraft tire, the rubber threads are bonded firmly, and the tire is safe to use.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

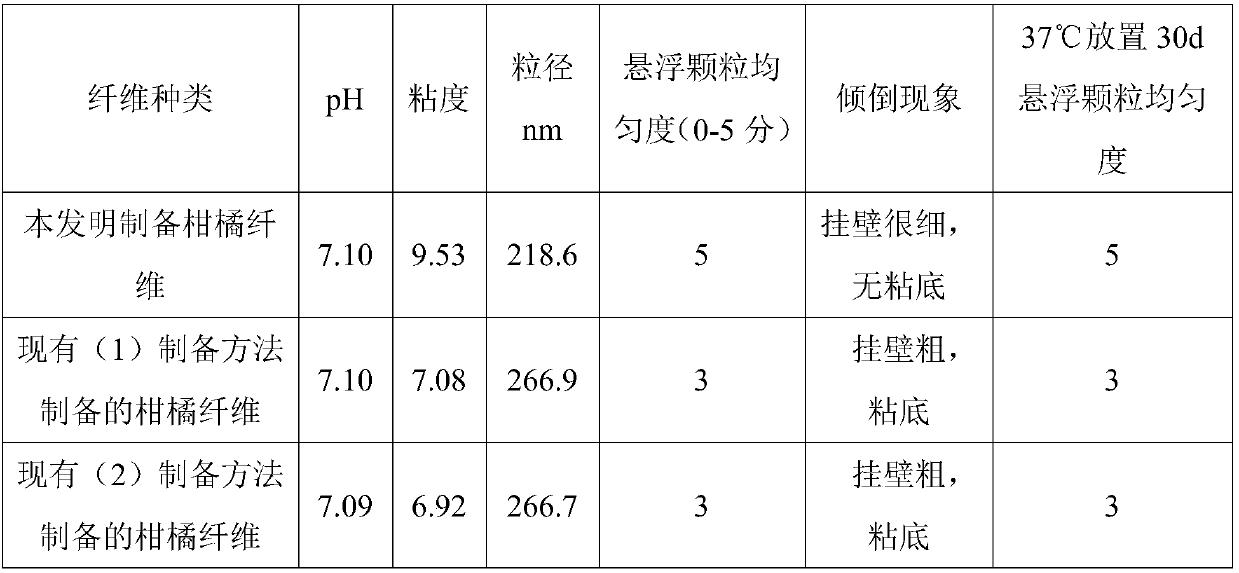

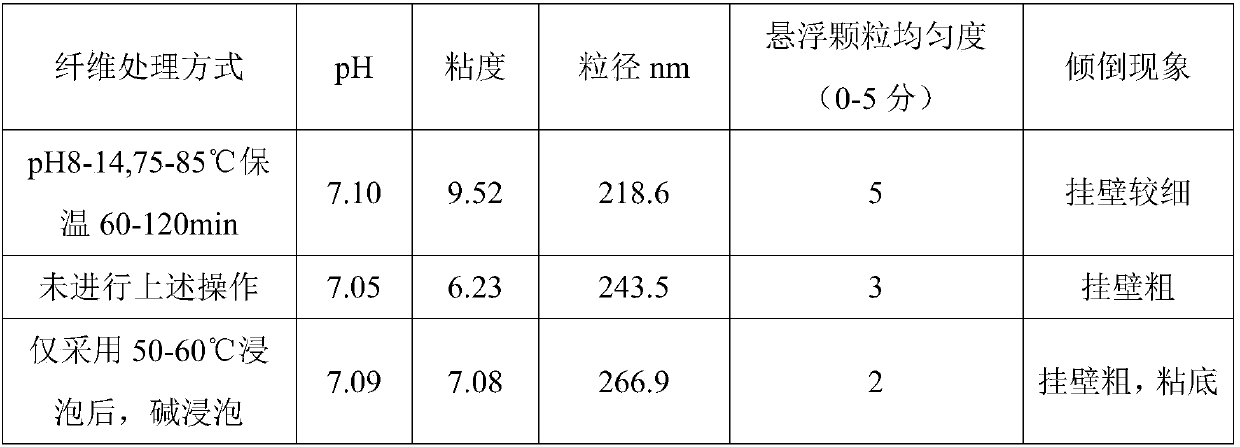

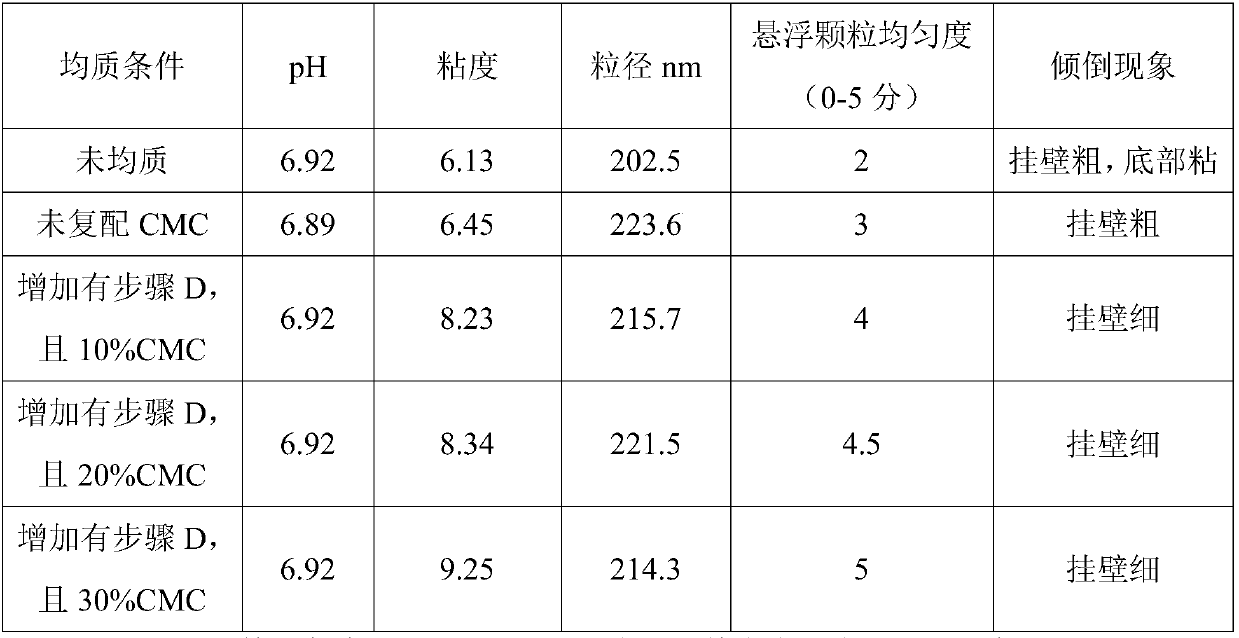

Suspension stabilizer, suspended particle peanut milk beverage and preparation method of suspension stabilizer and suspended particle peanut milk beverage

ActiveCN108013148AEvenly suspendedNo sinkingFood ingredientsMilk substitutesSuspended particlesCarboxymethyl cellulose

The invention relates to a suspension stabilizer, a suspended particle peanut milk beverage and a preparation method of the suspension stabilizer and the suspended particle peanut milk beverage, belonging to the technical field of foods. The suspension stabilizer contains a stabilizer A and a stabilizer B in a mass ratio of (1.5-3) to (1-2), wherein the stabilizer A contains the following components in percentage by mass: 5%-25% of citrus fibers, 10%-60% of microcrystalline cellulose, 10%-30% of sodium carboxymethyl cellulose, 40%-70% of glycerin fatty acid ester and 0-10% of xanthan gum. Theinvention further discloses the preparation method of the suspension stabilizer and the suspended particle peanut milk beverage. By utilizing fruit-vegetable fiber suspension stabilizer, after solid particles are added into the peanut milk beverage, particles are uniformly suspended in material liquid and are uniformly suspended but not precipitate in a UHT sterilization pipeline.

Owner:HEBEI BROS ILONG FOOD TECH LLC

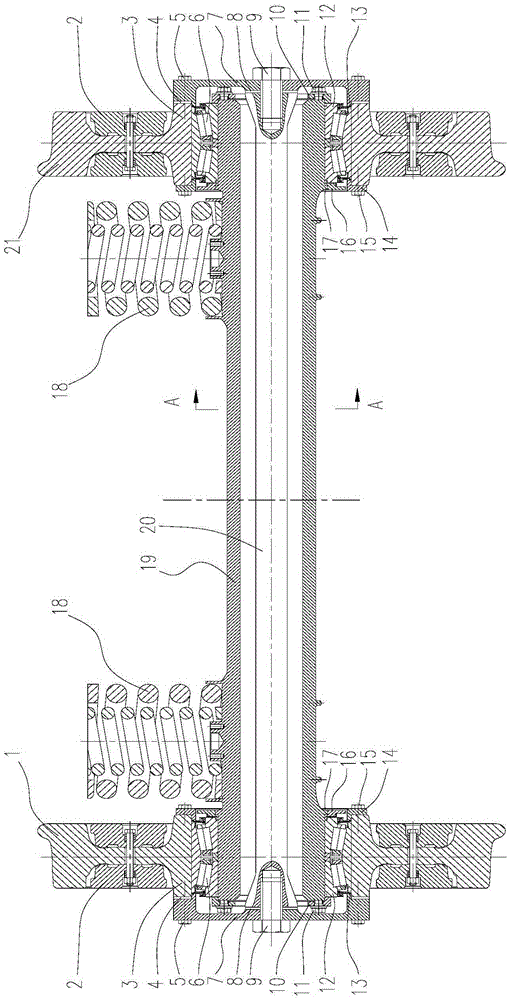

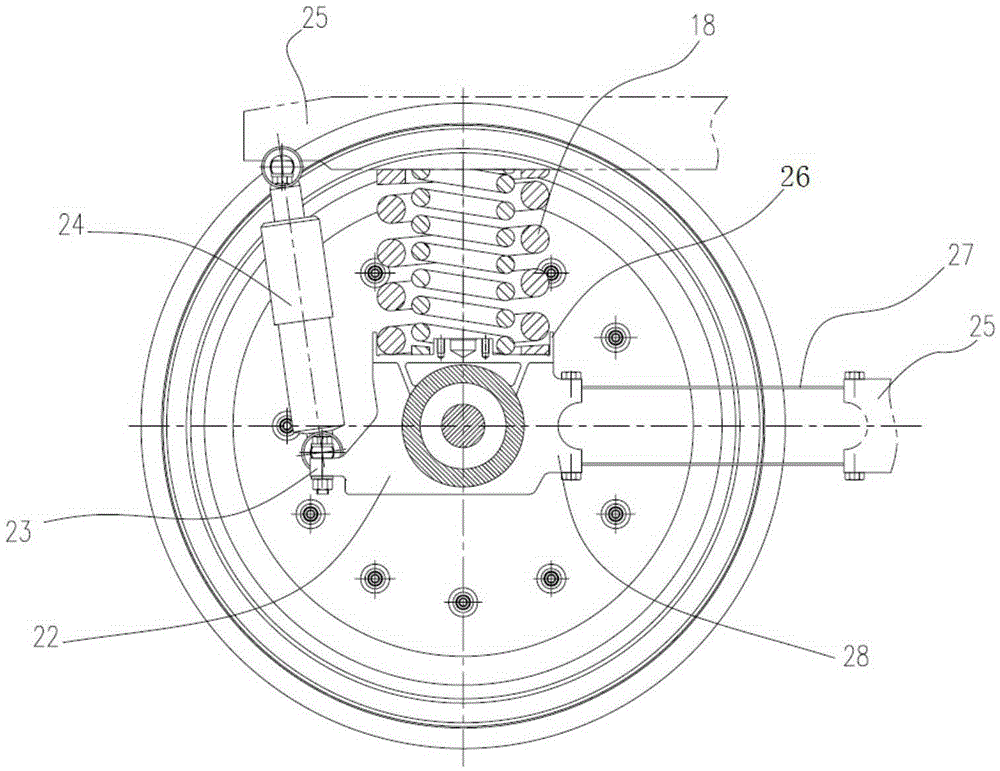

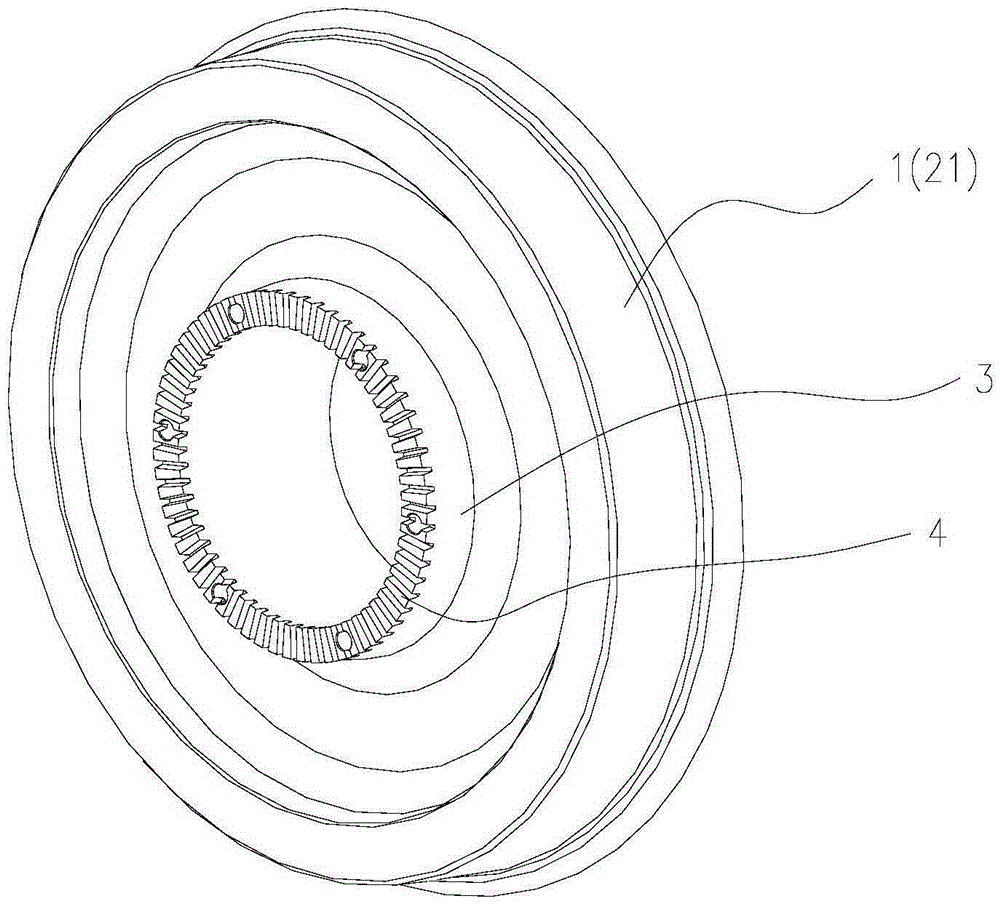

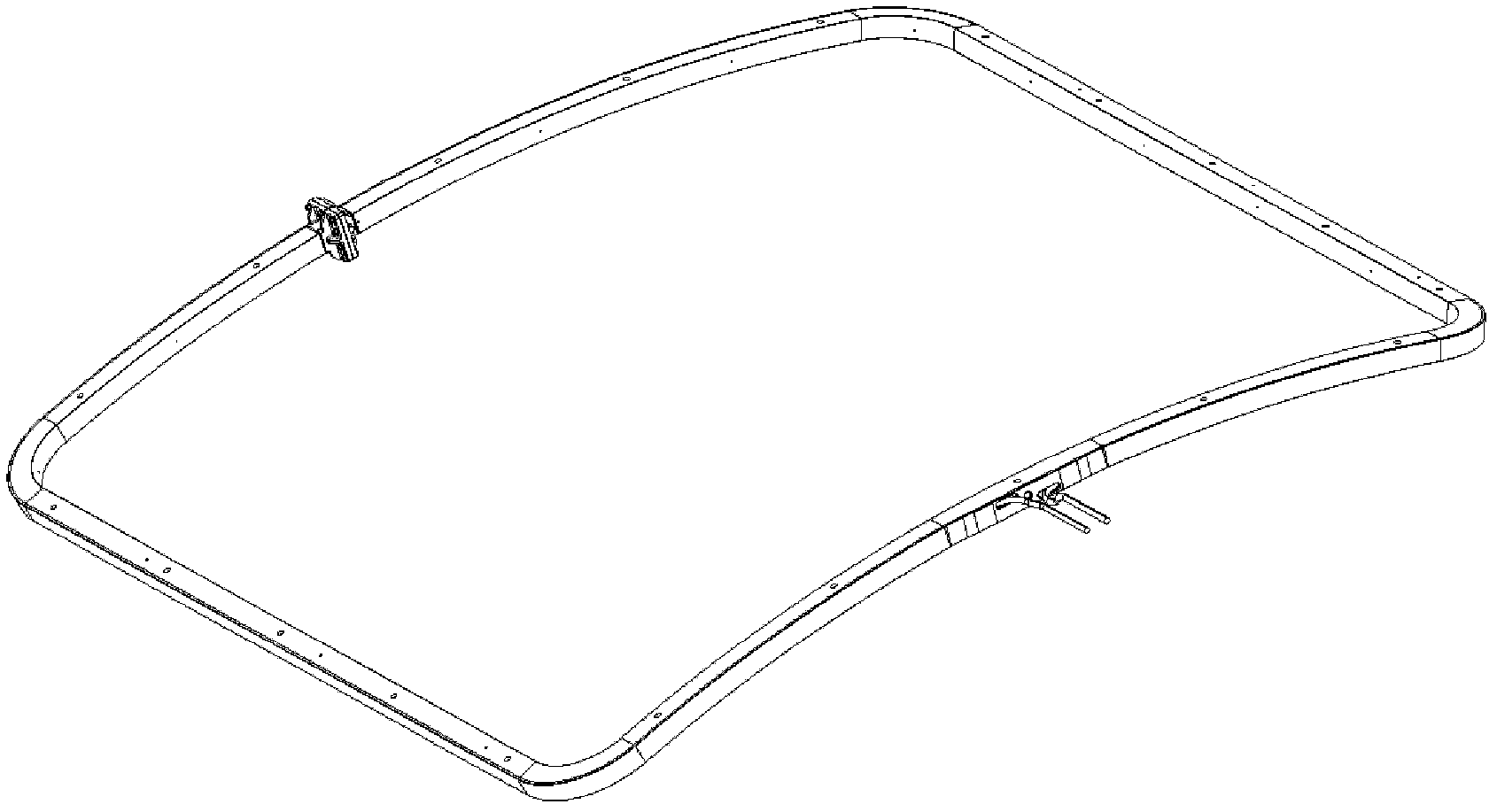

Hollow axle bridge structure and light wheel pair

ActiveCN105416332ASelf-guidedWith synchronous drive brakeAxle unitsBogiesAutomotive engineeringHigh speed train

The invention discloses a light wheel pair. The wheel pair comprises an axle bridge. The axle bridge is arranged in a hub hole of a first wheel and a hub hole of a second wheel through corresponding bearings. The axle bridge is of a hollow tubular structure. A torsion rod is arranged in the axle bridge in a sleeved manner. Transmission discs are arranged at the outer ends of wheel hubs. The inner end faces of the transmission discs and the end of the torsion rod are fixedly connected, and synchronous rotation of the left wheel and the right wheel is achieved. According to the wheel pair, axle stress is reduced, and the weight is reduced by about 20%-30% compared with a traditional wheel pair. Therefore, the speed of a high speed train can be possibly promoted to be further increased, and line loss reducing and energy saving and emission reducing can be facilitated.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

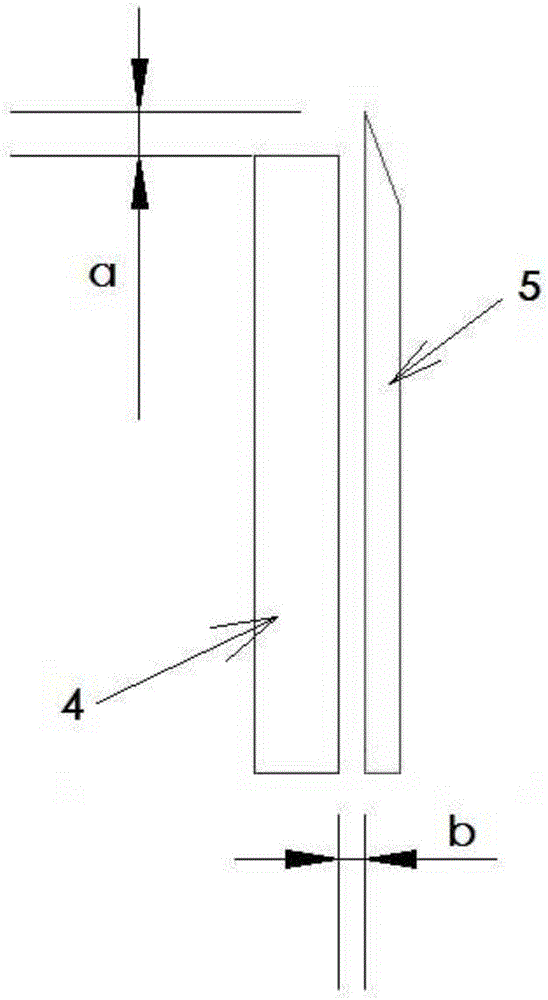

Method for narrow-gap laser welding with filler wires for superconducting coil box

InactiveCN103252578ATo achieve weldingTo meet the welding requirementsLaser beam welding apparatusNuclear fusionSuperconducting Coils

The invention discloses a method for narrow-gap laser welding with filler wires for a superconducting coil box. The method is used for a superconducting coil box of a nuclear fusion reactor, and narrow-gap laser welding with filler wires is performed for a large superconducting coil shell by the aid of laser, so that the whole coil box is sealed. The method includes the steps: firstly, arranging a narrow-gap V-shaped groove on a part to be welded and cleaning weld joints and surfaces by the aid of acetone; secondly, fixedly placing the part to be welded on a bearing fixture and a profiling fixture and continuously welding truncated edges by tack welding and laser through a laser machining head driven by a robot; and finally, performing laser welding with multilayer hot filler wires for groove weld joints to integrally seal the coil box. Layers are welded in a symmetrical and alternant welding sequence. The method solves the sealing problem of a superconducting coil in a first international thermonuclear experimental reactor plan of China, and an effective method for welding an ultra-large structure is provided.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

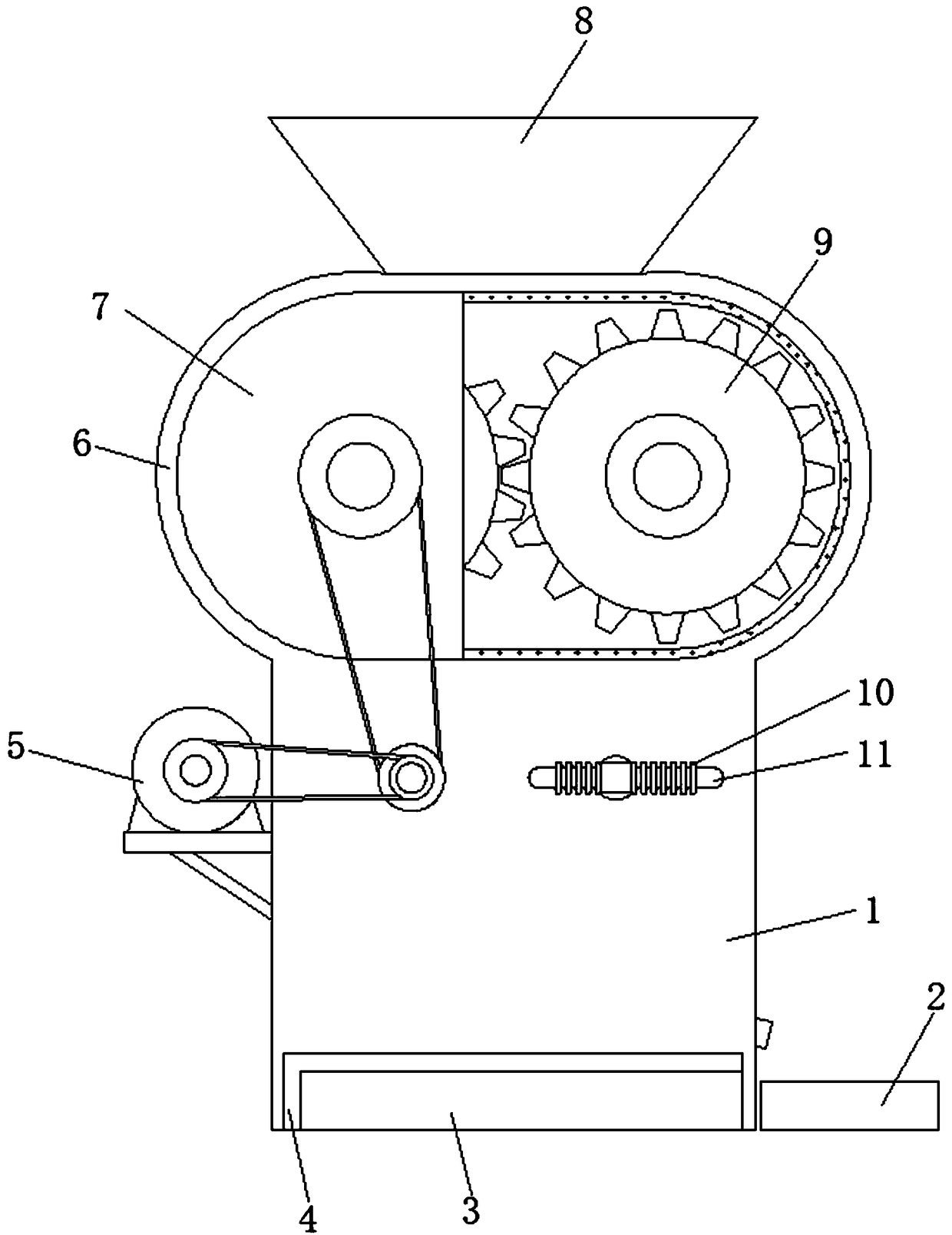

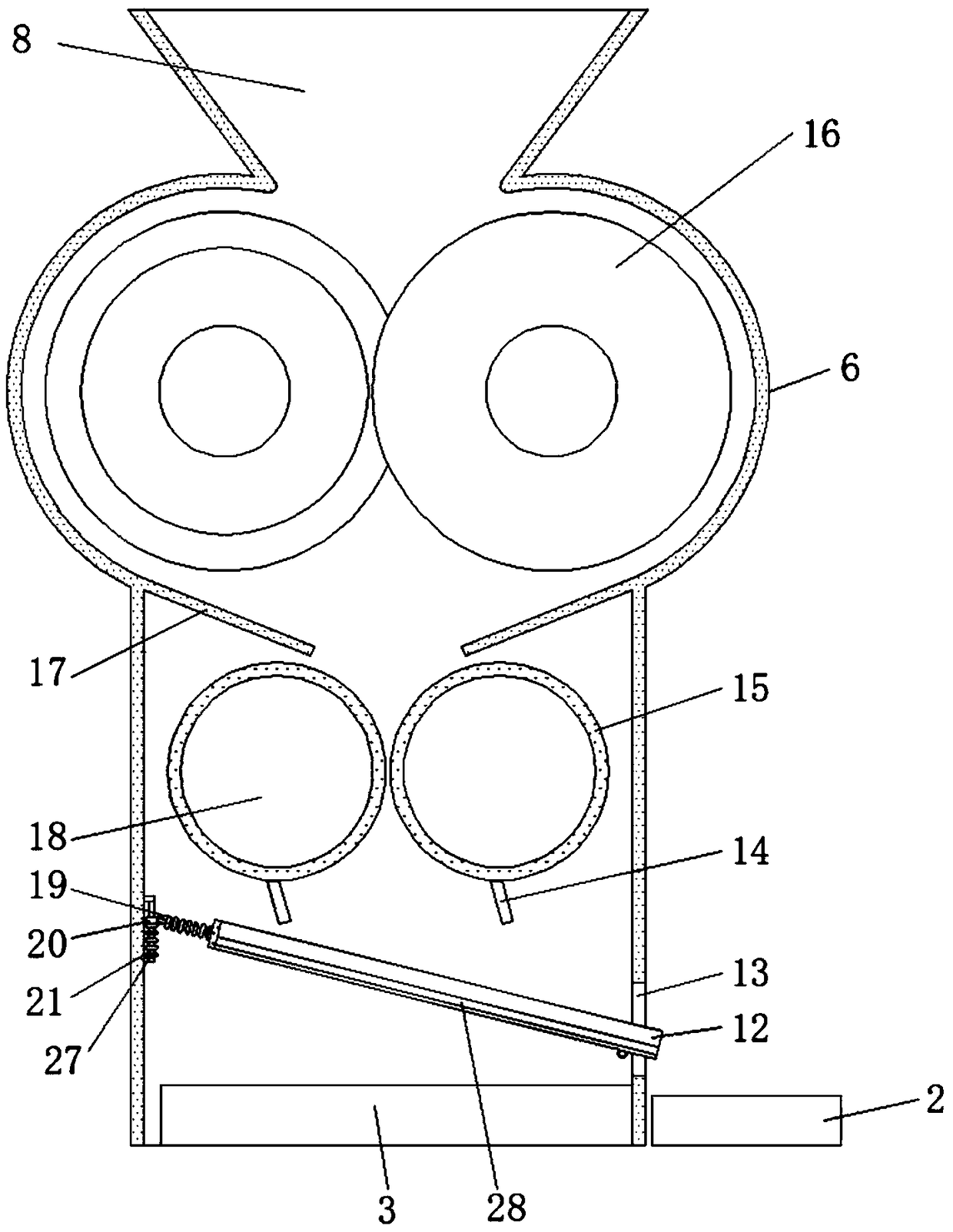

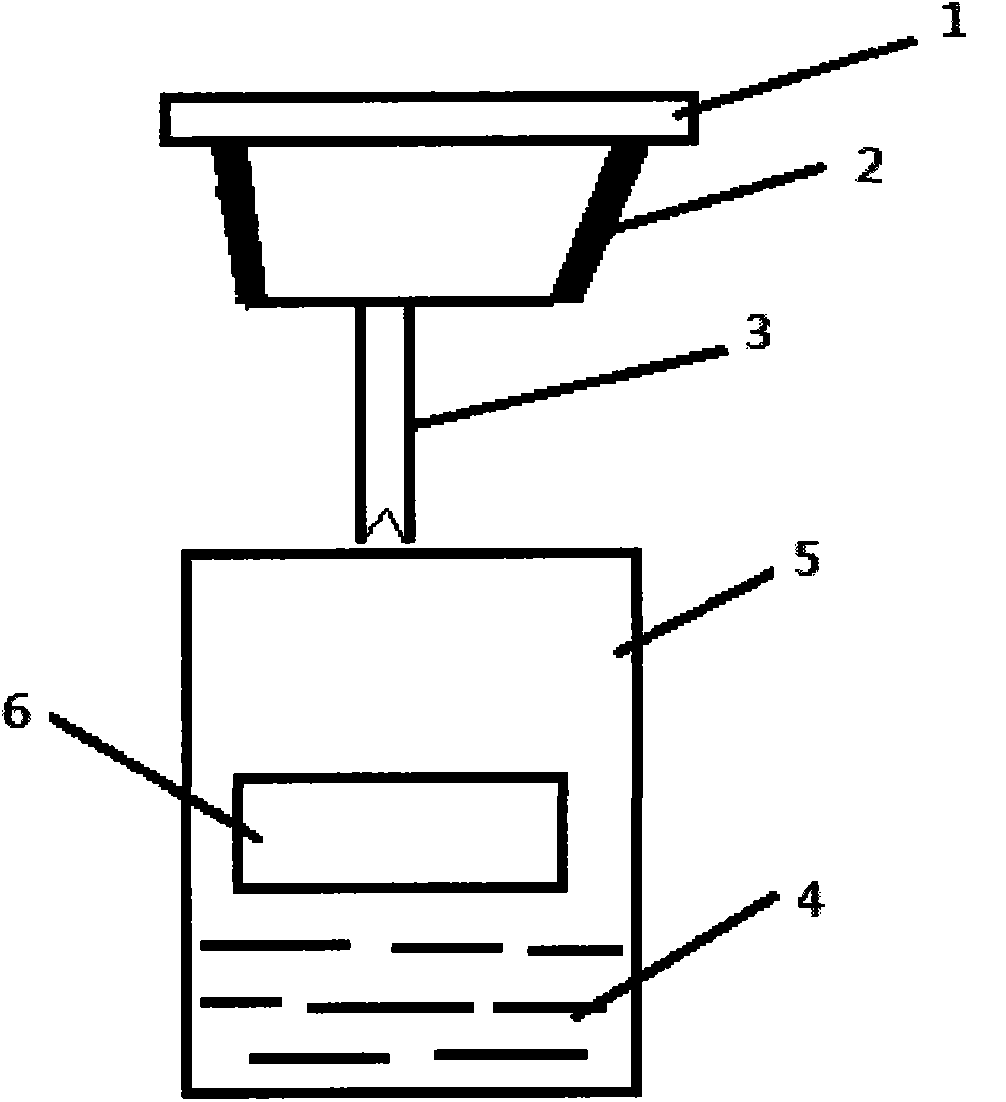

Crushing device used for casting sand recovery in casting process

InactiveCN109014029AGuaranteed sizeNot broken too fineMould handling/dressing devicesDrive motorEngineering

The invention discloses a crushing device used for casting sand recovery in the casting process. The crushing device used for casting sand recovery in the casting process comprises a device body. A crushing box is integrally formed at the top end of the device body. A hopper is arranged at the top end of the crushing box. A driving motor is mounted on the left side face of the device body througha support. A raw material collection box is arranged at the bottom of an inner cavity of the device body. A notch communicating with the inner cavity of the device body is formed in the bottom of thefront side of the device body. A through groove communicating with the inner cavity of the device body is formed in the bottom of the right side face of the device body. According to the crushing device used for casting sand recovery in the casting process, blocky casting sand adhering together is sheared through two crushing rollers which rotate oppositely, so that the large blocky casting sand adhering together is loosened and dispersed; then the dispersed casting sand is ground through two extruding rollers so as to be separated; only the casting sand adhering together is dispersed and separated through the crushing method, the casting sand is not crushed, so that the original size of the casting sand is kept, and the problem that the quality of the casting sand is affected due to the fact that the casting sand is excessively crushed is solved.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

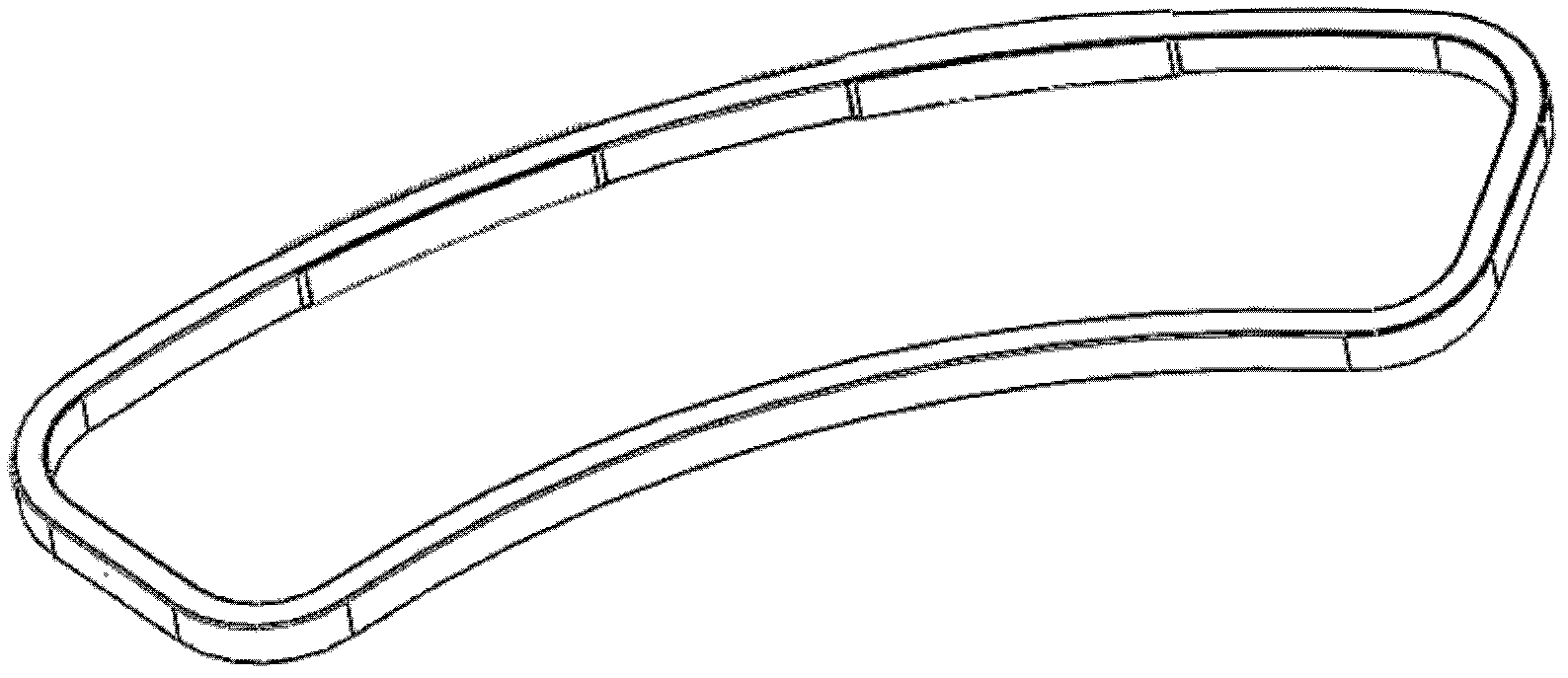

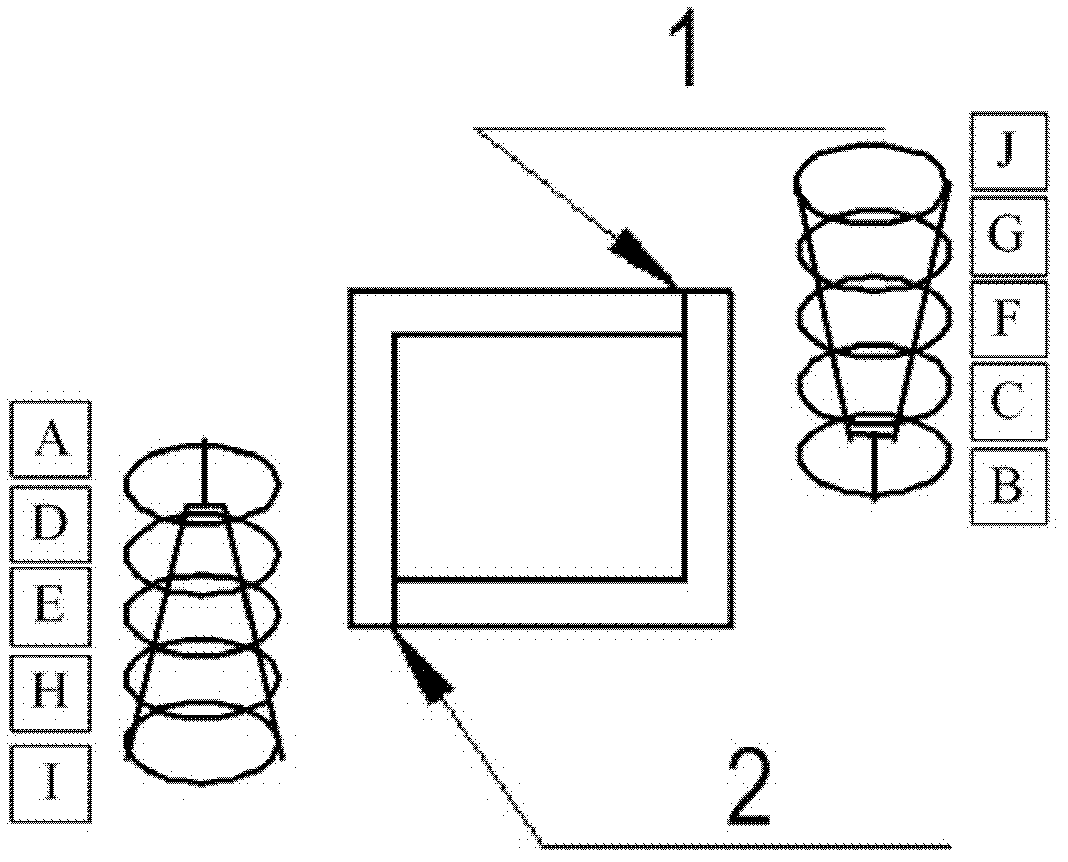

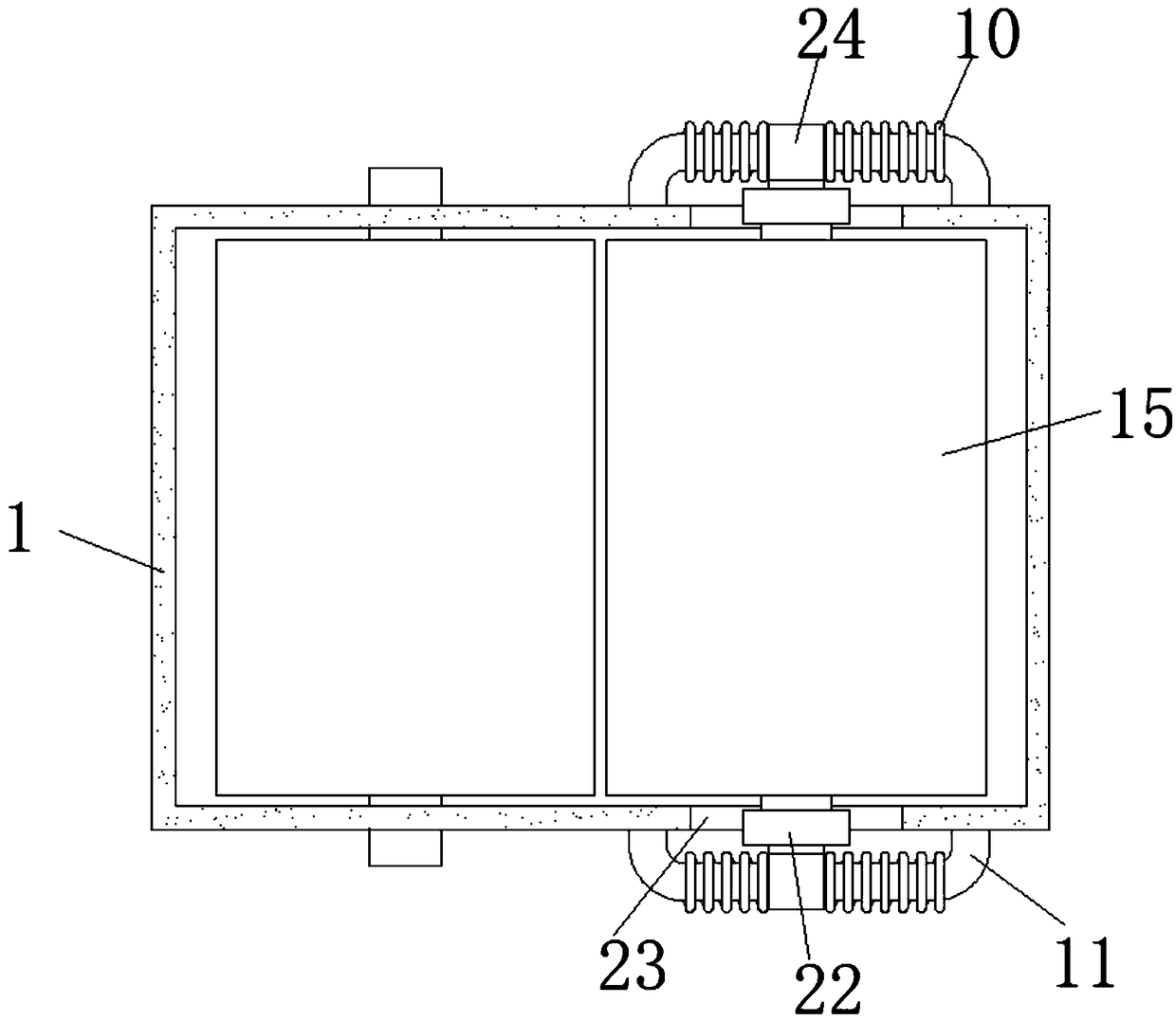

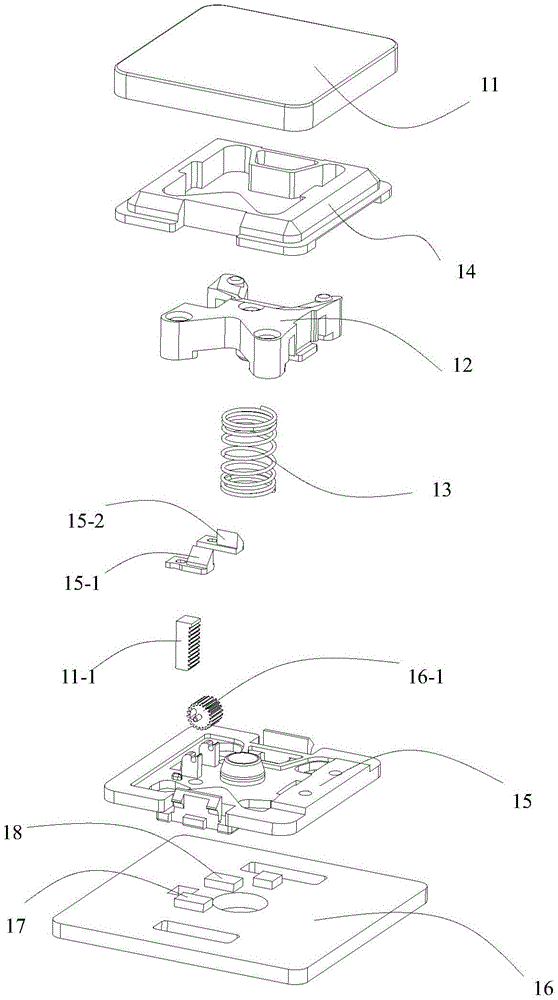

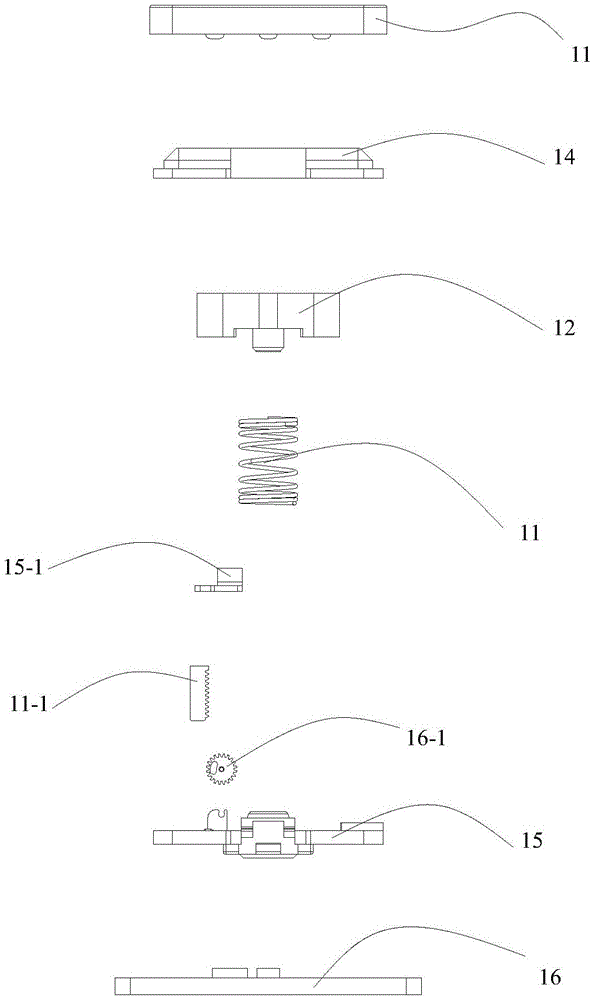

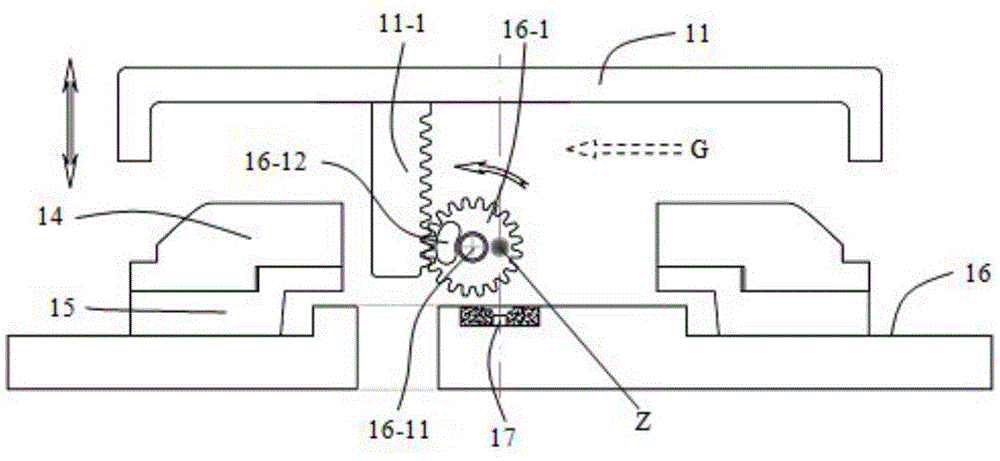

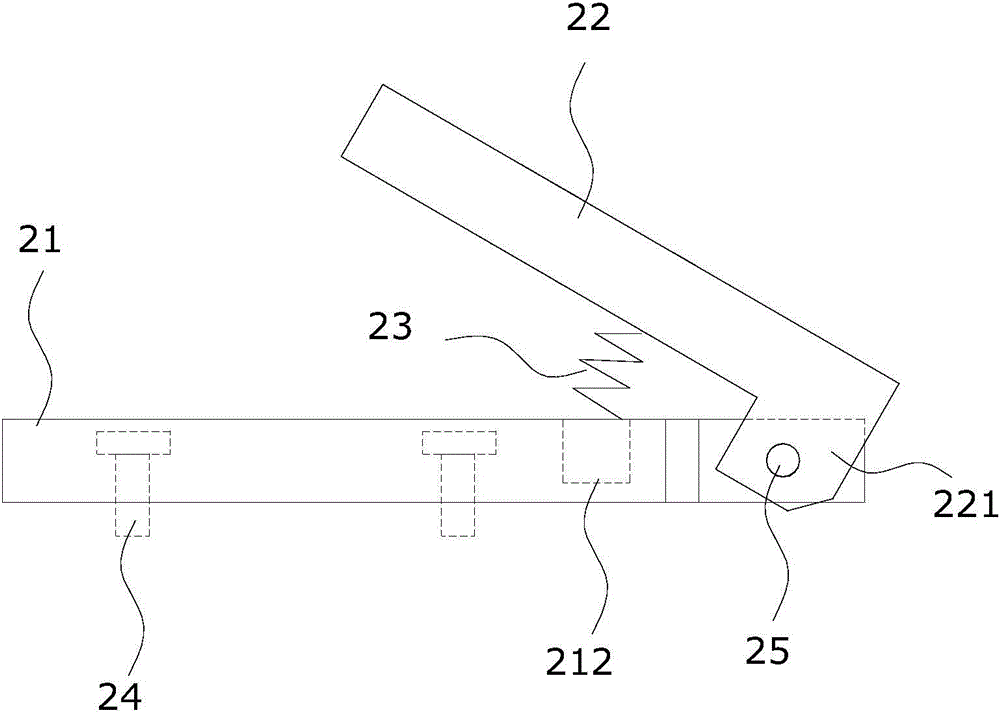

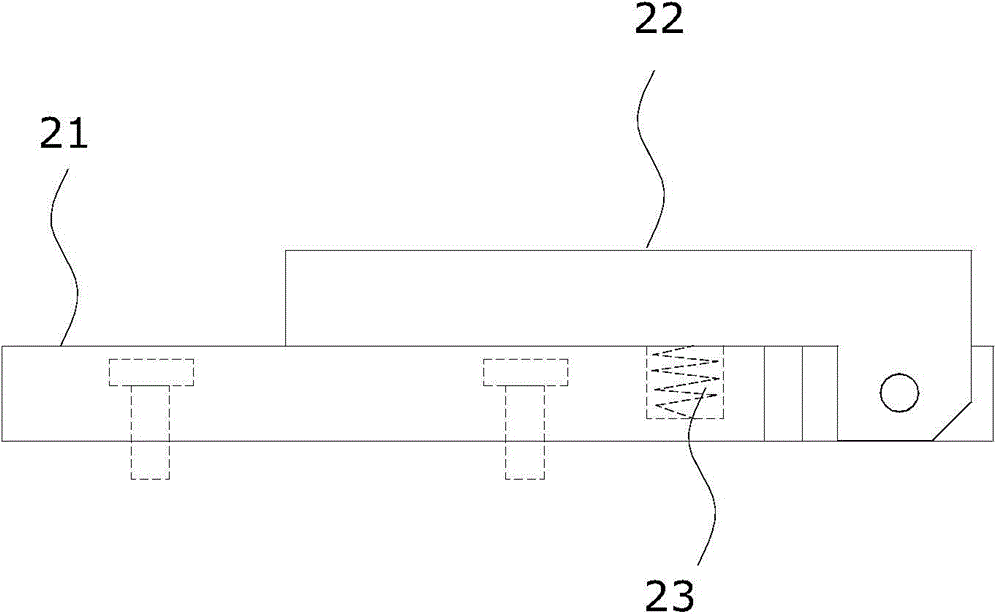

Ultrathin optical reflective input equipment switch module possessing tooth-shaped structure

ActiveCN105118714ASimple structureLow costElectric switchesEmergency protective devicesOptical reflectionEngineering

The present invention discloses an ultrathin optical reflective input equipment switch module possessing a tooth-shaped structure. The ultrathin optical reflective input equipment switch module possessing the tooth-shaped structure comprises a keycap, a key shaft, a spring, an upper fixing shell, a lower fixing shell and a PCB, and an ultrathin reflective photoelectric keyboard switch module also comprises a light emitting device and a light receiving device. A light path channel is formed between the light emitting device and the light receiving device and comprises a light path switch, and the light path switch comprises a rack located below the keycap and a gear or a cam located on the PCB. By pressing the keycap, the rack located therebelow moves up and down to drive the gear or the cam to do the radial rotary movement, thereby conducting or disconnecting the light path channel. The ultrathin optical reflective input equipment switch module possessing the tooth-shaped structure has the characteristics of being simple in structure, low in cost and low in switch module height, being convenient to assemble, etc., and the height of the ultrathin optical reflective input equipment switch module is only 1 / 3-1 / 4 of the height of a conventional mechanical shaft keyboard.

Owner:MIKOLTA OPTICAL TECH CO

Loquat enzyme nutrient solution and preparation method thereof

InactiveCN105193989AHas anti-caries effectGuaranteed sugarOrganic active ingredientsUnknown materialsYeastSide effect

The invention discloses a loquat enzyme nutrient solution and a preparation method thereof and relates to the technical field of biological fermentation solutions. The loquat enzyme nutrient solution comprises raw materials including loquats, dried loquat leaves, honey, oligosaccharide, dried yeast and water. The preparation method comprises steps as follows: the loquats are subjected to pulp making firstly, the dried loquat leaves are boiled with water, are cooled and then are uniformly mixed with the honey, the oligosaccharide and the dried yeast, water is added, and the mixture is uniformly mixed and placed in a container for sealing fermentation; finally, acquired fermentation broth is processed and extracted with an supercritical fluid extraction and separation technology, and the loquat enzyme nutrient solution is obtained. According to the loquat enzyme nutrient solution and the preparation method thereof, the safe loquat enzyme nutrient solution which is free of side effects and can be taken as a beverage for drinking is prepared with lower cost and the simple method and has remarkable cough relieving and sputum reducing effects.

Owner:LIUZHOU JINCHEN TECH

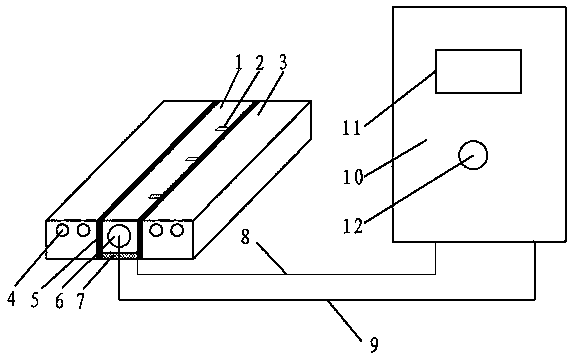

Back auxiliary heating device for titanium and titanium alloy friction stir welding

ActiveCN108890118AImprove plasticityEliminate weld root defectsNon-electric welding apparatusFriction weldingThick plate

The invention relates to a back auxiliary heating device for titanium and titanium alloy friction stir welding. The back auxiliary heating device comprises a support plate and a control system and ischaracterized in that the support plate is spliced by a welding back base plate and a fixing back base plate, the welding back base plate is located under a welding area, the fixing back base plate islocated under a non-welding area, the surface of the welding back base plate is provided with a plurality of thermocouples distributed along the length direction of the welding back base plate at intervals, a heating component distributed along the length direction of the welding back base plate is arranged inside the welding back base plate, the thermocouples and the heating component are connected with the control system, the thermocouples detect the surface temperature of the welding back base plate and transmits the detection data to the control system, and the control system adjusts theheating component according to the detection data to allow the surface temperature of the welding back base plate to be kept at the set temperature. The back auxiliary heating device has the advantages that heating temperature is effectively controlled, the root defects of thick-plate titanium alloy welding are eliminated, stirring head abrasion during welding is reduced, and the quality and efficiency of titanium alloy friction stir welding are increased.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

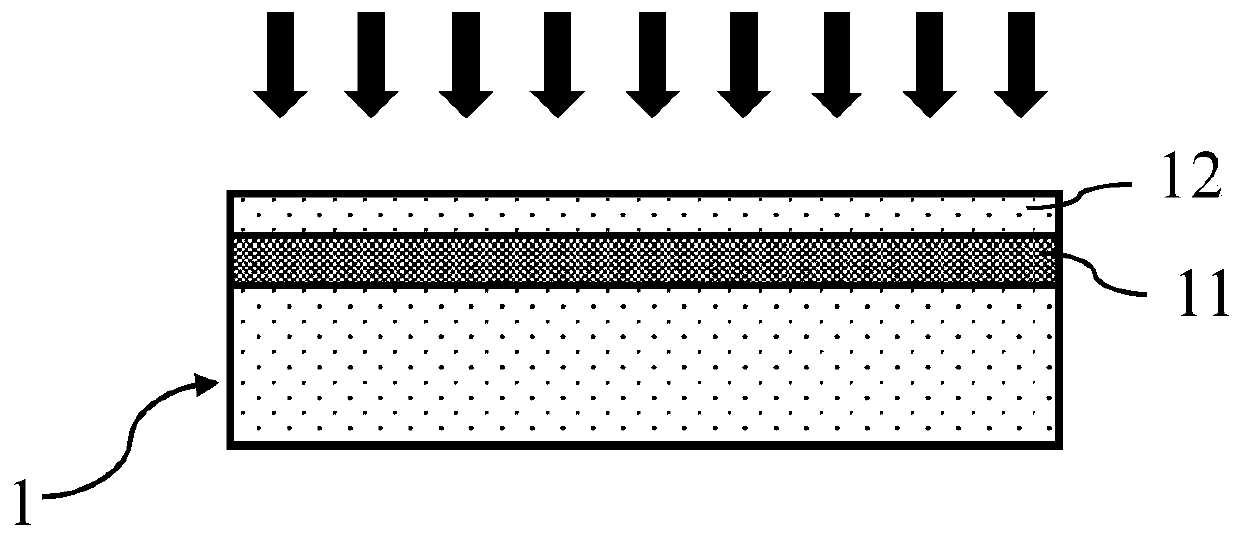

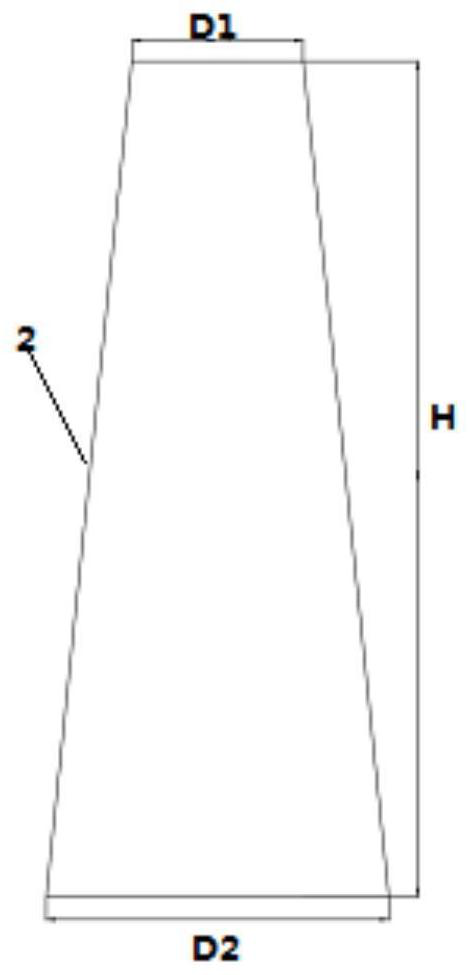

High-temperature-resistant carbon fiber composite material cylinder bearing layer and preparation process thereof

The invention provides a high-temperature-resistant carbon fiber composite material cylinder bearing layer and a preparation process thereof, relates to the technical field of composite materials, and is mainly used in the field of spaceflight as an external bearing layer of missiles and spaceflight launchers. According to the high-temperature-resistant carbon fiber composite material cylinder bearing layer, bismaleimide resin with a glass transition temperature of 260 DEG C is used as a matrix material and T800 carbon fiber is used as a reinforcement material to prepare unidirectional prepreg as a raw material, and an autoclave molding process is adopted to prepare the high-temperature-resistant conical carbon fiber composite material cylinder bearing layer; according to the preparation process, a male mold is adopted as a mold to prepare a pressure equalizing plate, and then the bearing layer is prepared in the manner that the male mold is matched with the pressure equalizing plate; according to the bearing layer, the unidirectional prepreg is laid between a male mold forming surface and the pressure equalizing plate in a belt-laying-like manner, and the laying manner is an orthogonal symmetric laying manner, so that the directivity of fibers and the surface quality of the cylinder bearing layer are ensured; and the high-temperature-resistant carbon fiber composite material cylinder bearing layer prepared by the method meets the use requirements, and the product quality is high.

Owner:NANJING JULONG SCI&TECH CO LTD +2

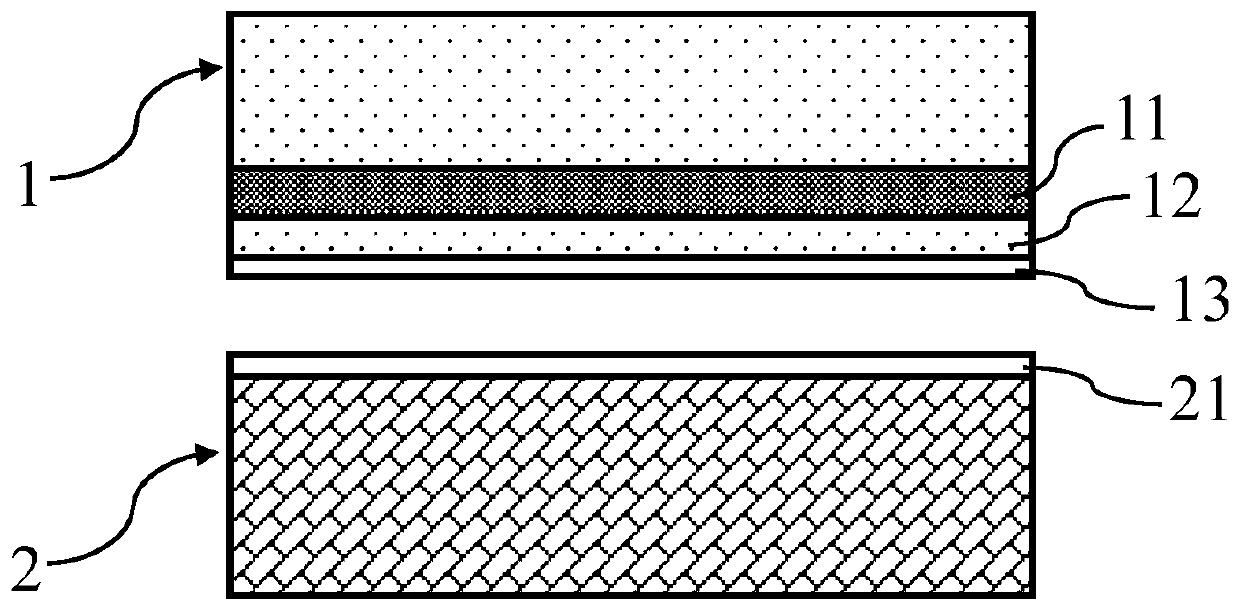

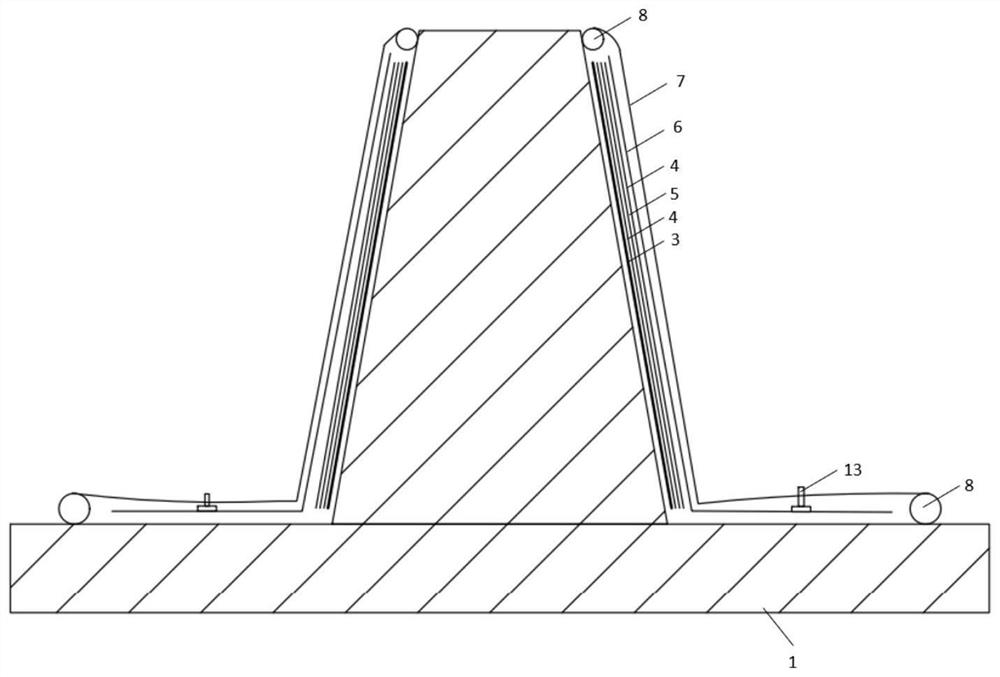

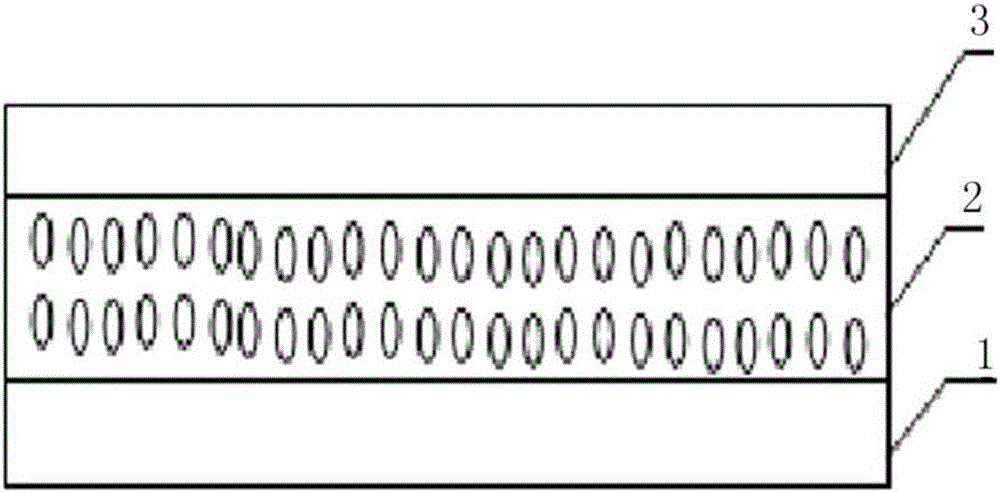

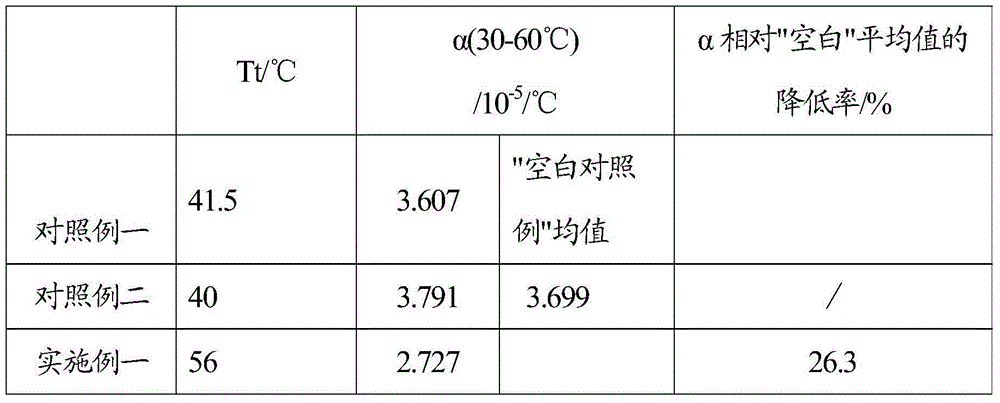

Silicate-modified PVC foamed composite decorative sheet and manufacturing method thereof

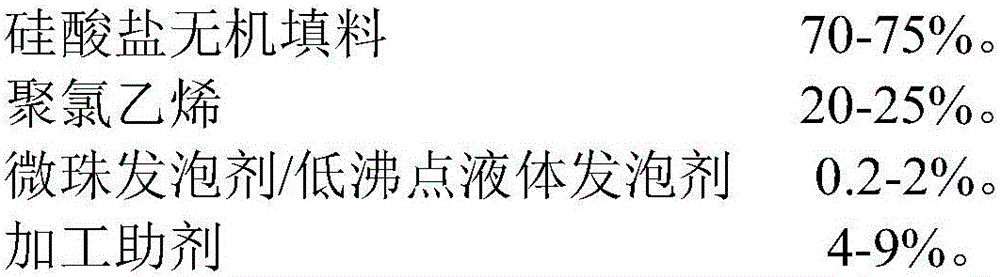

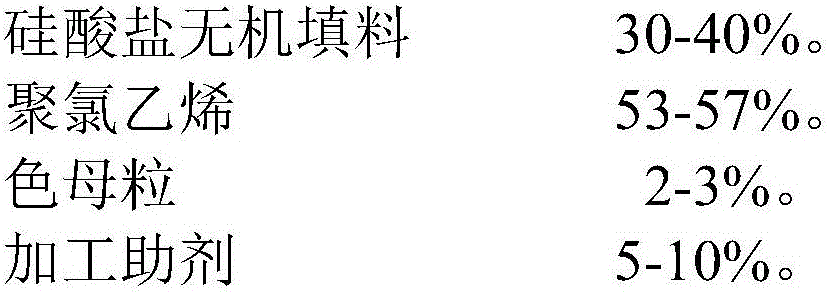

The invention discloses a silicate-modified PVC foamed composite decorative sheet and a manufacturing method thereof. The manufacturing method is mainly used for manufacturing a decorative sheet used in occasions such as a family, an office, a shopping mall and a meeting, and belongs to the technical field of composite materials. The silicate-modified PVC foamed composite decorative sheet mainly comprises three layers, namely a decorative layer, a foaming layer and a supporting layer, wherein the supporting layer is mainly prepared from silicate inorganic filler, polyvinyl chloride and a processing aid; the foaming layer is mainly prepared from silicate inorganic filler, polyvinyl chloride, a foaming agent and a processing aid; the decorative layer is mainly prepared from silicate inorganic filler, polyvinyl chloride, a color masterbatch and a processing aid. The decorative sheet has the advantages of being free of toxicity and odor as well as formaldehyde, being capable of preventing water, dampness, worm damage, light mass and high surface decoration property, being nailable, sawable and planeable, being capable of reducing the consumption of wood and macromolecular polymers, and being relatively high in strength and relatively long in service life.

Owner:SICHUAN MIANNING XICHENG TALC MINING

Navel orange enzyme nutrient solution and preparation method thereof

InactiveCN105192830APromote circulationImprove immunityYeast food ingredientsNatural extract food ingredientsAcute hyperglycaemiaSide effect

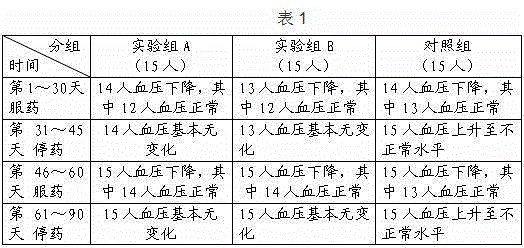

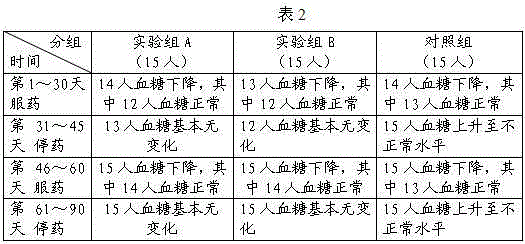

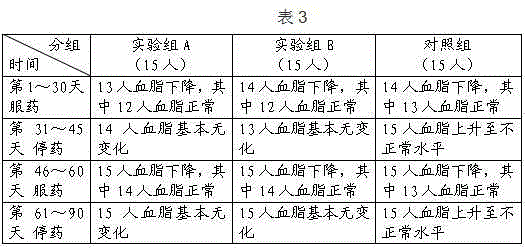

The invention discloses a navel orange enzyme nutrient solution and a preparation method thereof and relates to the technical field of biological fermentation solutions. The navel orange enzyme nutrient solution comprises raw materials including navel oranges, dried liquorice, honey, oligosaccharide, dried yeast and water. The preparation method comprises steps as follows: the navel oranges are subjected to pulp making firstly, the dried liquorice is boiled with water, is cooled and then is uniformly mixed with the honey, the oligosaccharide and the dried yeast, water is added, and the mixture is uniformly mixed and placed in a container for sealing fermentation; finally, acquired fermentation broth is processed and extracted with an supercritical fluid extraction and separation technology, and the navel orange enzyme nutrient solution is obtained. According to the navel orange enzyme nutrient solution and the preparation method thereof, the safe navel orange enzyme nutrient solution which is free of side effects and can be taken as a beverage for drinking is prepared with lower cost and the simple method, can replace western medicine, effectively assists a body in automatic regulation of blood pressure and can be used for reducing cholesterol, and hypertension, hyperglycemia and hyperlipemia can be relieved and repaired when the human body is properly supplemented with the orange enzyme.

Owner:LIUZHOU JINCHEN TECH

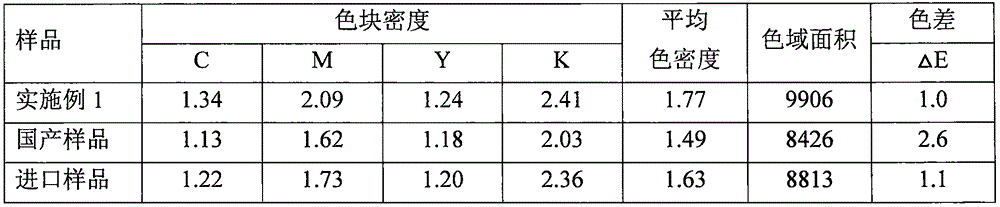

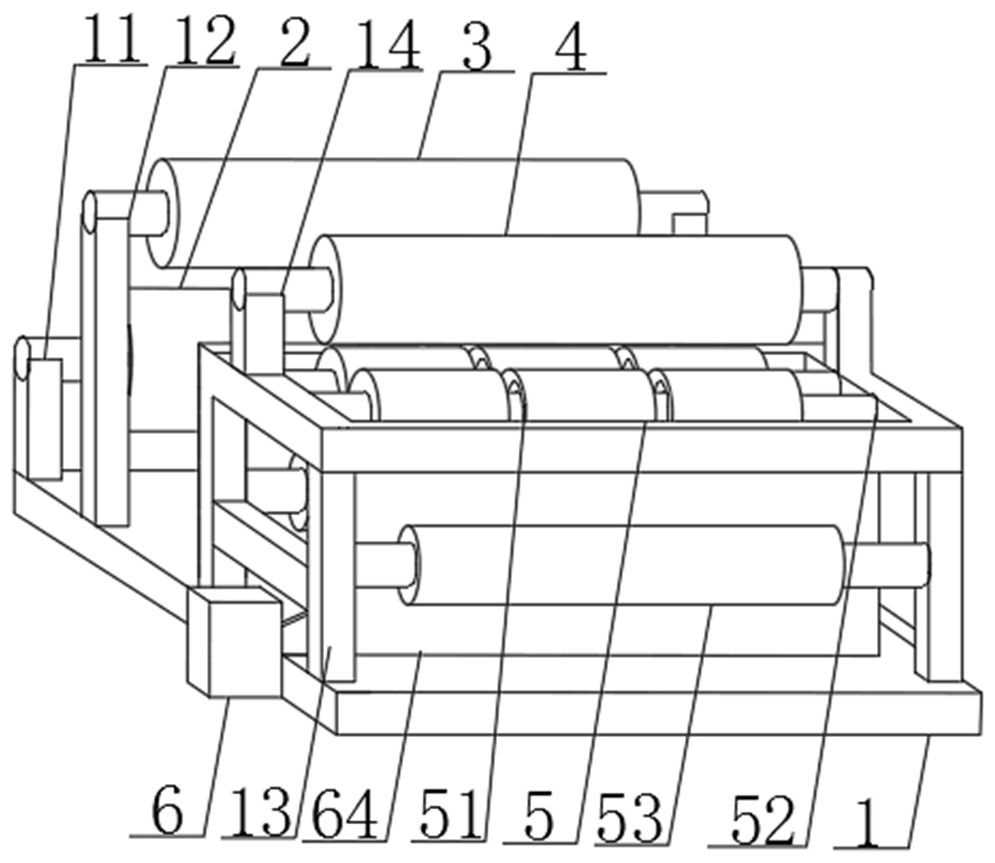

Method for producing ink-jet printing substrate in curtain type coating manner

ActiveCN105730038AGuaranteed uptimeEvenly distributedDuplicating/marking methodsPore distributionEngineering

The invention discloses a method for producing an ink-jet printing substrate in a curtain type coating manner, and particularly relates to a manufacturing method for the coating-layer-provided substrate used when a multicolor ink-jet printing machine is adopted for conducting color pattern printing. The method is characterized in that a continuously-rolled machined sheet is adopted as a coating substrate, coating of an ink-jet printing coating layer is carried out on the front face of the coating substrate in the curtain type coating manner, and an optimized coating formula can meet the requirement that curtain type coating normally runs under the lower car speed condition; the produced coating layer of the ink-jet printing substrate and the pore distribution of the coating layer are even and consistent; during printing, the ink absorption speed is high, the color is even and consistent, and the problems of printing dots, printing patterns and the like are solved; and the quality of products in different batches is stable, and obvious chromatic aberration can be avoided. According to the manufacturing method, high-end coating equipment is adopted, an advanced coating process is used in a combined manner to conduct production, stable production control can be achieved, and therefore the stable product quality is obtained. The problem that at present, high-end products cannot be produced in China is solved.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

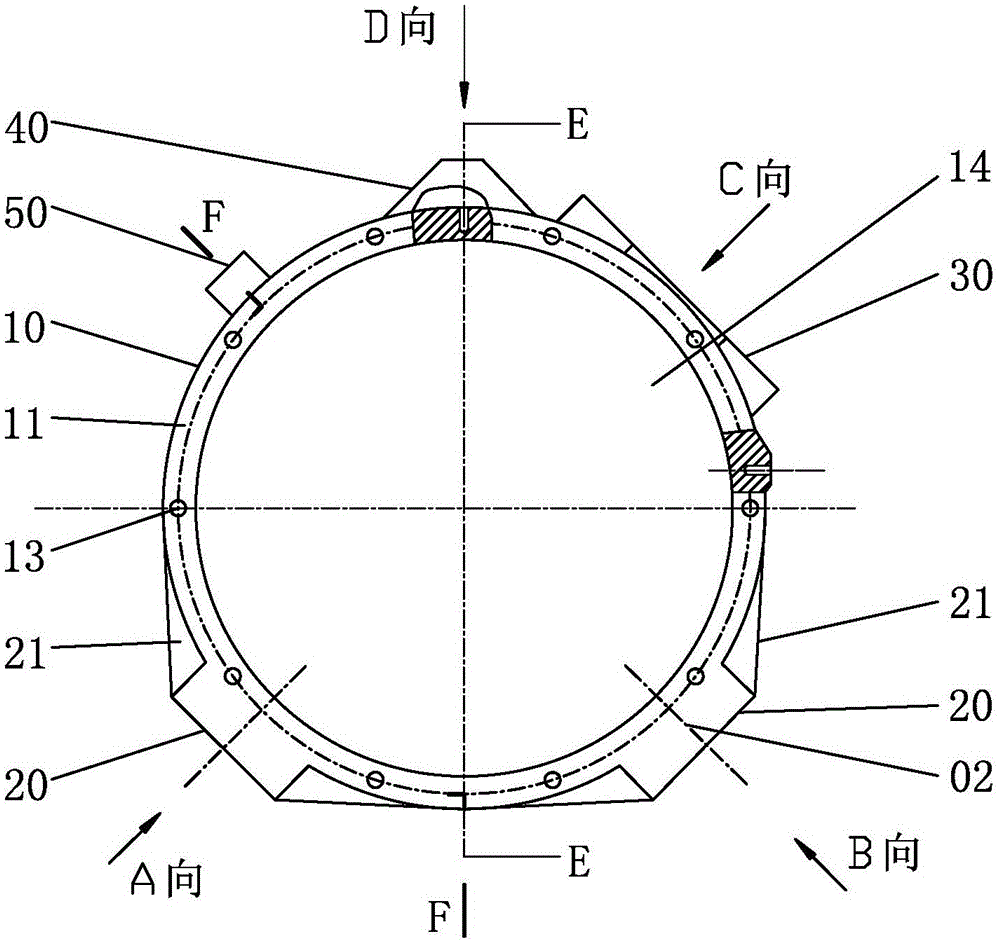

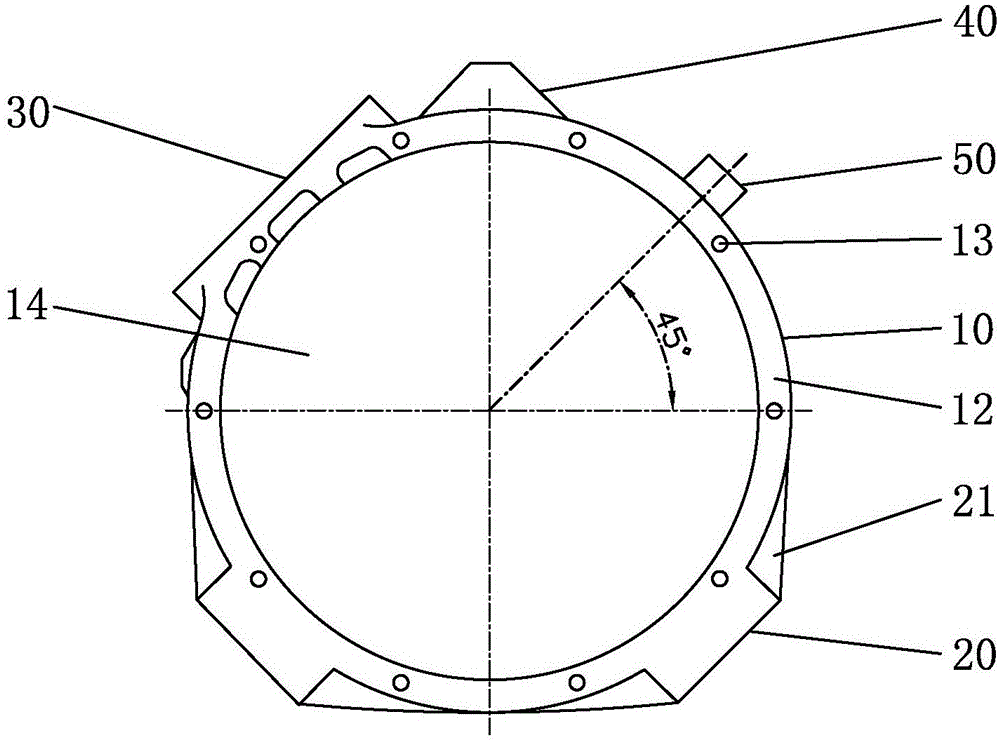

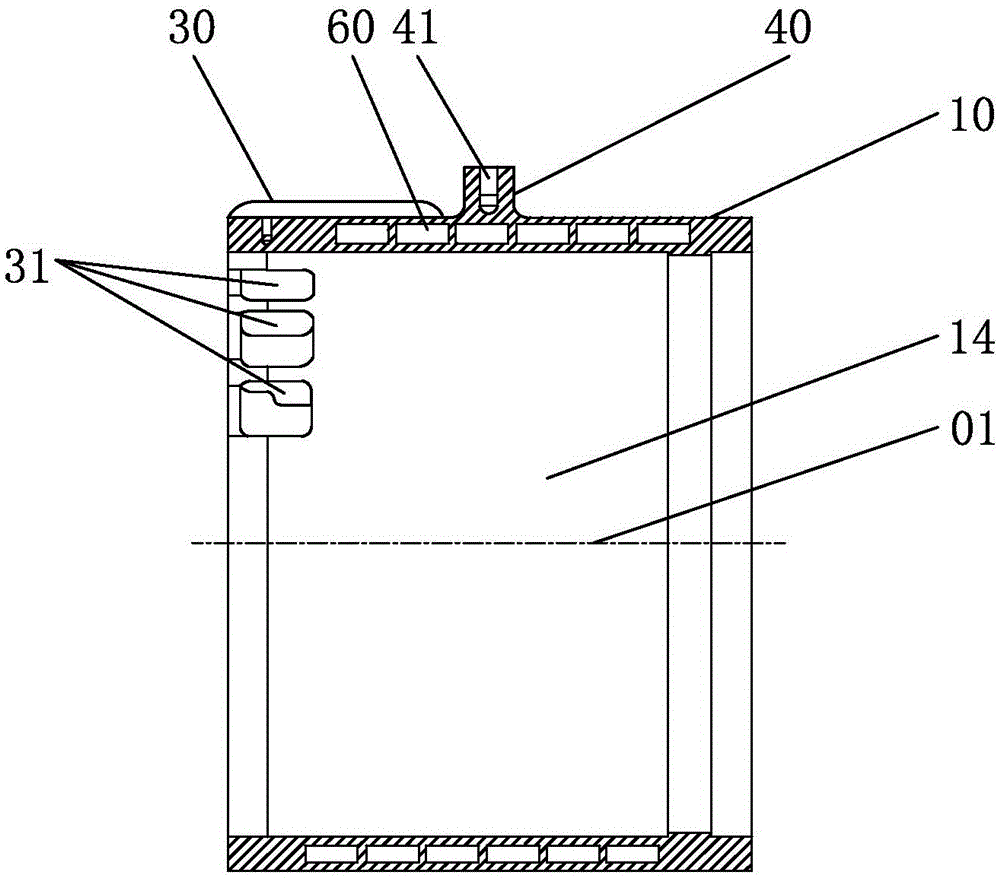

Integrated type permanent magnet synchronous motor shell

ActiveCN105071617AOutstanding and Beneficial Technical EffectsNo thermal conductivitySynchronous machine detailsSupports/enclosures/casingsFailure ratePermanent magnet synchronous motor

The invention belongs to the motor shell technical field and relates to an integrated type permanent magnet synchronous motor shell. A spiral heat dissipation water channel is formed in the side wall of a cylinder with a cylindrical central hole, wherein the spiral heat dissipation water channel and the cylinder are molded integrally; the outer wall of the cylinder is provided with a junction box, a hanging lug and at least three circumferentially-arranged protruding bars of which the axes are arranged along a vertical direction, wherein the junction box, the hanging lug, the protruding bars and the cylinder are molded integrally; a water inlet and a water outlet at the upper end and the lower end of the spiral heat dissipation water channel pass through the side wall of the cylinder and are located at the upper part and the lower part of the protruding bar at the left side of the junction box; the upper sides and the lower sides of the other two protruding bars are respectively provided with an installation seat; more than two threaded blind holes are formed in each installation seat; each installation seat is provided with more than two transverse reinforcing ribs; threaded blind holes are circumferentially formed at two end surface of the cylinder at intervals; wire through holes which pass through the side wall of the cylinder are formed in the side wall of the cylinder and are located inside the junction box; and the junction box and the three protruding bars are separated out from each other by 90 degrees. The integrated type permanent magnet synchronous motor shell has the advantages of excellent heat conduction and heat dissipation performance, structural simplicity, practicability, low failure rate and low production cost, and can be suitable for high-power permanent magnet synchronous motors.

Owner:浙江双菱新能源科技有限公司

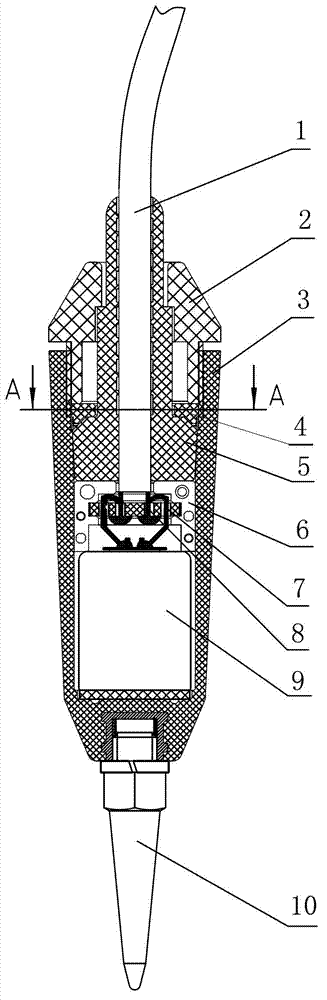

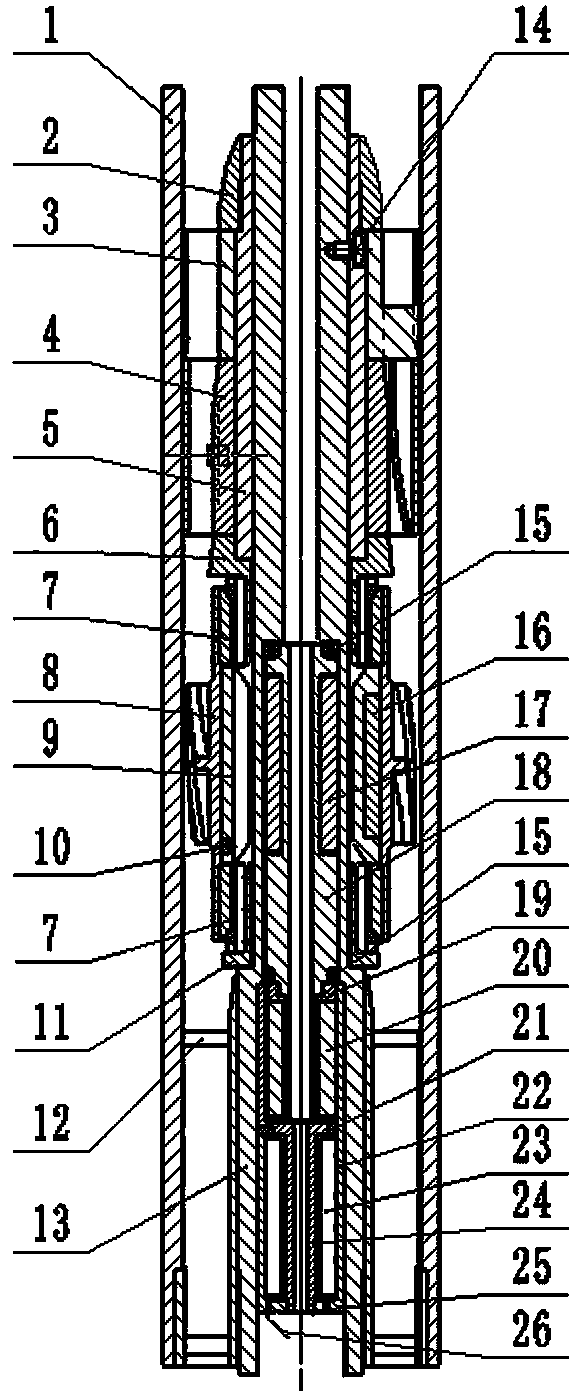

Marsh geophone

The invention relates to a marsh geophone which solves the technical problems that a connecting wire core of the existing marsh geophone is difficult to weld; the production efficiency is low during batch production; quality defects of cold solder joint, welding slags of welding spots and the like occur frequently; the maintenance is difficult; the stretching resistance between an outgoing cable and a geophone core is weak; and the welding spot is easy to snap and short out because of the twisting force. The marsh geophone is provided with an outer protecting shell, a geophone core, a supporting shock insulator, a sealing guide sleeve, a compression plug, a pressure pad, an outgoing cable and a tail core, wherein the supporting shock insulator, which is a tensile supporting shock insulator, is provided with a tensile notch and a tensile connecting circuit board; and the pressure pad is a torsion-proof pressure pad. The marsh geophone can be widely used for marsh and shoal geophones.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

Peripheral sealing process of foamed instrument panel

The invention discloses a peripheral sealing process of a foamed instrument panel and a processing technology of automotive interior parts, mainly solving the problems of leakage and lack of materials, and the like of an existing peripheral sealing process of the foamed instrument panel. The peripheral sealing process comprises the following steps: sealing the front edge of the instrument panel bya soft seal, and placing an inflatable sealing strip in a U-shaped groove of a foaming mold; inserting both ends of the inflatable sealing strip into an inflatable core port; heating the foaming mold, paving the surface in a fixing mold to enable the surface to be adsorbed on the fixing mold, placing an instrument panel skeleton on the surface, closing a moving mold and the fixing mold, pressingcopper blocks on the left and right sides of the instrument panel against the surface by a cylinder, and pushing the inner side against the instrument panel skeleton by the moving mold to achieve thesealing effect. The main and co-driver positions are pressed against a sealing rib by the interaction of the moving mold and the fixing mold of the foaming mold to achieve the sealing effect. The sealing strip can be pressed against the front end of the instrument panel after being fully filled to achieve the sealing effect. The peripheral sealing process has the advantage of avoiding the problemof leakage and lack of materials of the foamed product.

Owner:JINXING AUTOMOTIVE INTERIOR DECORATION

Die-cutting machining die structure

The invention provides a die-cutting machining die structure. A narrow-edge double-faced adhesive tape is attached to the lower bottom surface of a product; the product is attached to a die-cutting machining die; a stop strip is arranged along the side, which is required to be cut, of a frame of the die-cutting machining die; the stop strip and the inside position of the narrow-edge double-faced adhesive tape are positioned in the same horizontal line; the distance between the stop strip and the inside of the narrow-edge double-faced adhesive tape is 0.03 to 0.05 mm; the height of the stop strip is 0.03 to 0.05 mm lower than that of a cutting edge of the die. Due to the adoption of the technical scheme, the current common die structure of the die-cutting machining die structure provided by the invention is redesigned on the basis of not changing a material, and the same linear stop strip is added to the position which is 0.03 to 0.05 mm away from the narrow-edge double-faced adhesive tape, so that the product quality problems of glue overflowing and transformation after the narrow-edge double-faced adhesive tape is die-cut and stamped are avoided.

Owner:TIANJIN RIJIN TECH

Removable vehicle paster and preparation method and application thereof

InactiveCN107603508AEasy to removeEasy to integrateNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedBenzoyl peroxide

The invention belongs to the technical field of materials and especially relates to a removable vehicle paster and a preparation method and application thereof. The vehicle paster successively contains a water-based ink-jet ink-drawing layer, a primer layer, a PVC layer, a removable pressure sensitive adhesive layer and release paper. The water-based ink-jet ink-drawing layer is obtained by mixingand stirring 17-20% of water-based ink-drawing resin, 0.5-1% of a wetting agent and 79-82.5% of water. The primer layer is obtained by mixing and stirring 10-20% of water-based resin, 0.5-1% of a wetting agent and 89.5-79% of water. The removable pressure sensitive adhesive layer is composed of 20-30% of butyl acrylate, 1.5-3% of acrylic acid, 15-23% of methyl methacrylate, 0.5-2% of benzoyl peroxide, 18-30% of toluene, 27-40% of ethyl acetate, 1-5% of a curing agent, 1-5% of latex powder and 2-6% of nano-attapulgite. The vehicle paster can 100% remove residual gum, has good curved surface adhesion, and has no bubble, crease or edge warping phenomena.

Owner:ZHEJIANG FULAI NEW MATERIAL CO LTD

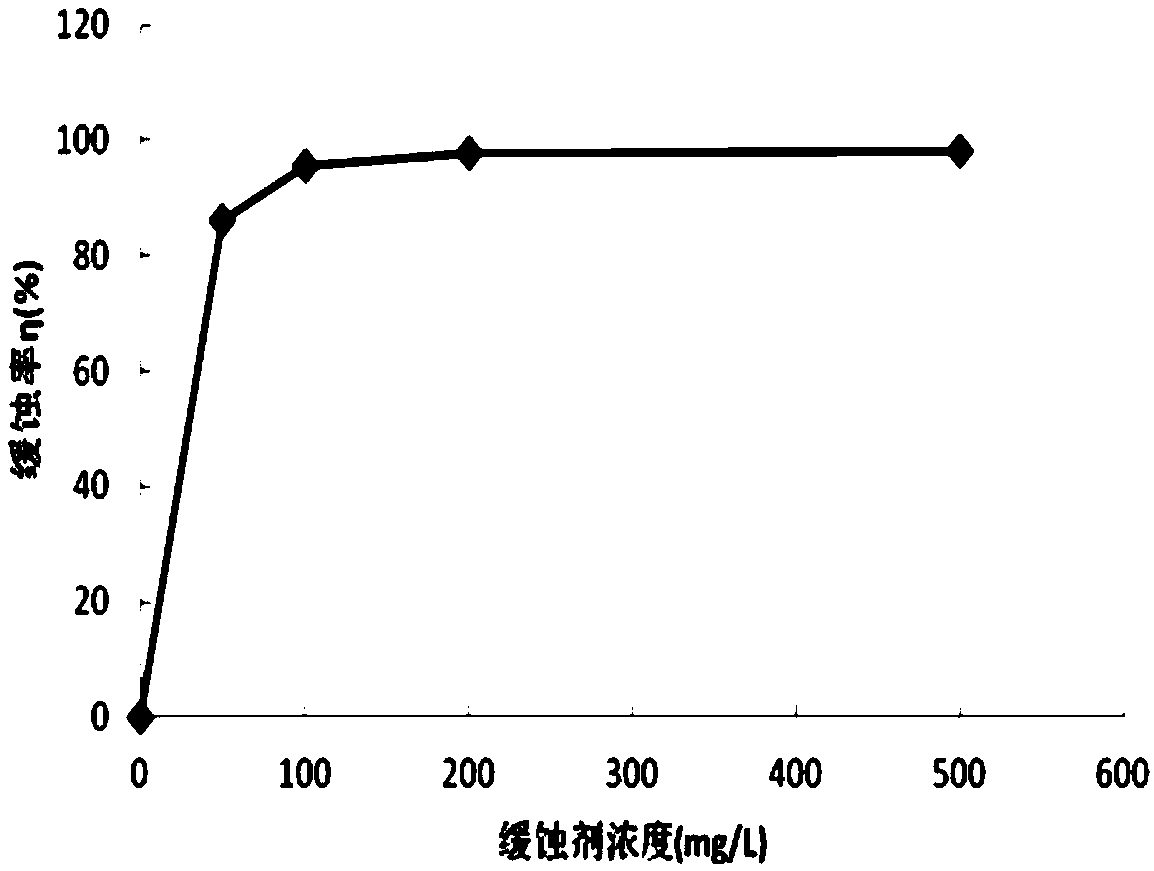

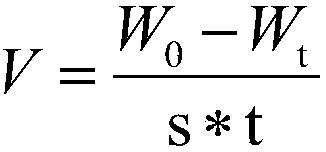

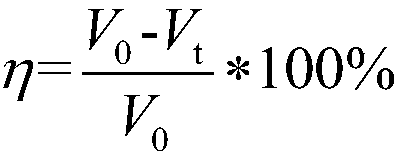

Cold-rolling acid-pickling corrosion inhibitor and preparation method thereof

The invention discloses a cold-rolling acid-pickling corrosion inhibitor. The cold-rolling acid-pickling corrosion inhibitor is prepared by sequentially performing condensation reaction and constant-temperature stirring reaction on vitamin B3 and organic amine in a molar ratio of (1.5 to 1) to (1 to 1.5), performing distillation and removing a solvent, wherein the carbon number of the organic amine is 8 to 16. According to the cold-rolling acid-pickling corrosion inhibitor disclosed by the invention, reaction between the vitamin B3 and the organic amine is carried out so as to synthesize a novel corrosion inhibitor for the first time, and the organic amine is applied to the processes including cold rolling and acid pickling and the like, so that the advantages of less consumption, high corrosion inhibition efficiency and the like are achieved, the surface quality of steel plates subjected to acid pickling can be effectively promoted, quality defects such as no black spots and darkeningare avoided, and a brand new means is provided for a high-efficient clear process; moreover, the preparation method disclosed by the invention is simple, the cost is low, and the cold-rolling acid-pickling corrosion inhibitor has important popularization and application value.

Owner:武汉钢铁有限公司

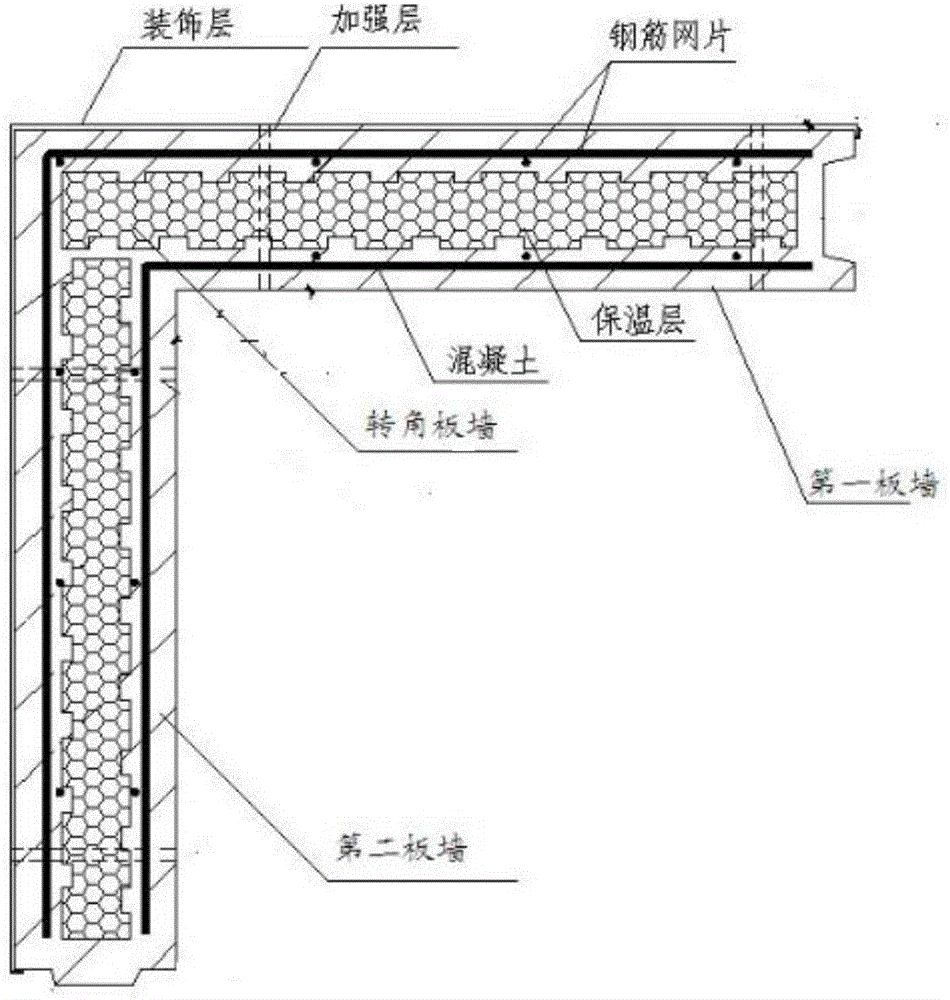

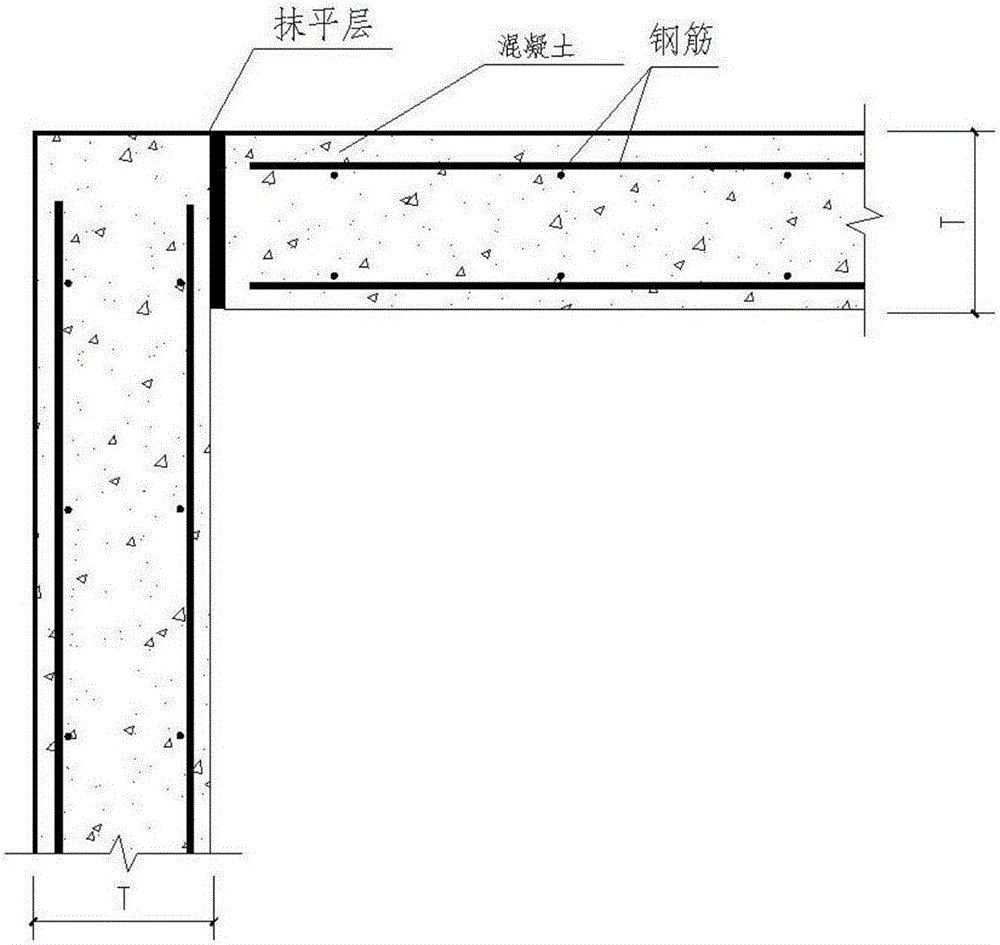

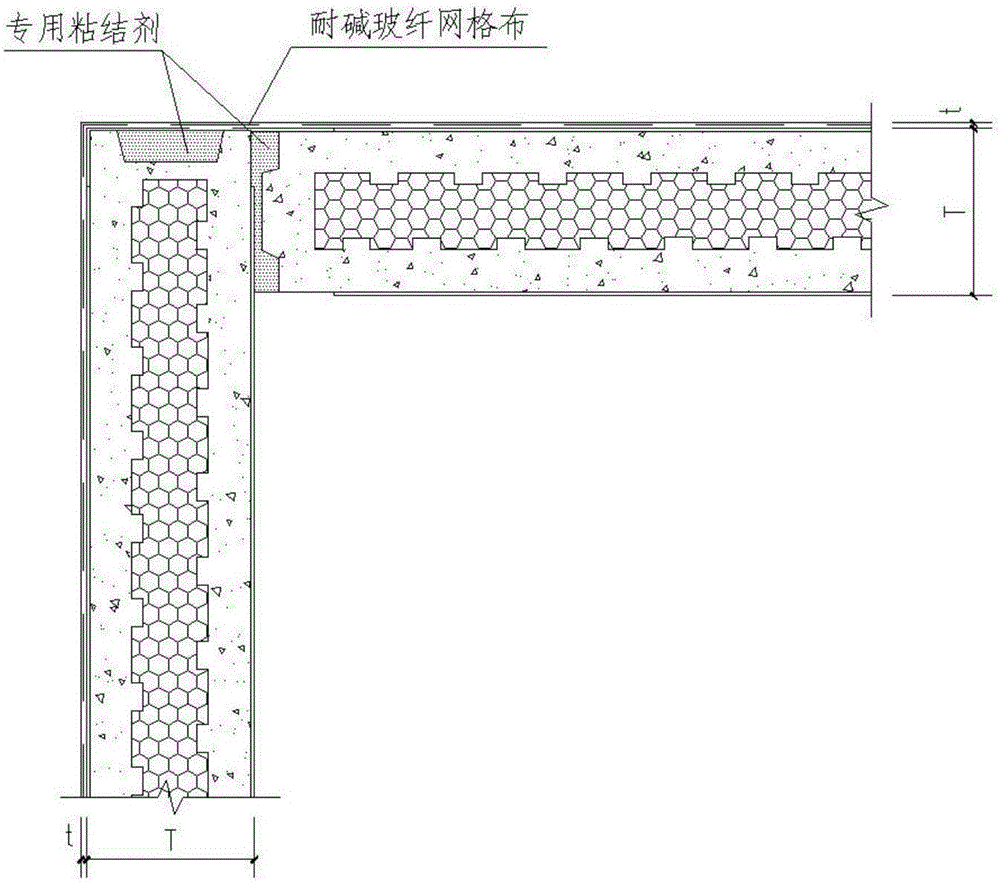

Integrally decorated abnormity prefabricated core sandwich concrete panel

The invention provides an integrally decorated abnormity prefabricated core sandwich concrete panel comprising a right angle wall, a linear wall and a joint portion; the right angle wall comprises a first board wall, a second board wall and a corner board wall forming an integral moulding structure, wherein one ends of the first and second board walls are connected with the corner board wall, and the other ends are connected with the linear wall through the joint portion. In the prior art, joint mounting is needed in corners when the panels are installed, the wall surface secondary decoration construction operation is complex, and the surface layer has shedding, water leakage and cracking quality problems; the integrally integration sandwich panel can be directly used, is easy to mount, reliable in quality, and durable.

Owner:李予新

Loading device for PCB hot pressing

The invention discloses a loading device for PCB hot pressing. The device comprises a base used for loading a PCB and a plurality of elastic stopping clamps, the elastic stopping clamps are arranged on the surface of the base and are capable of forming an arraying region of the PCB; each elastic elastic stopping clamp comprises an elastic portion and a fixing portion connected to the base, one end of the fixing portion is rotationally connected to the elastic portion, and an elastic recovery member is arranged between the fixing portion and the elastic portion. The PIN needle is omitted, the operations of copper foil, PCB pre-arraying boards, pressing board paper and other relative materials can be omitted, the work intensity during the hot pressing procedure can be reduced, unqualified rate is decreased, and the producing efficiency can be improved accordingly.

Owner:KALEX MULTI LAYER CIRCUIT BOARD (ZHONGSHAN) CO LTD

Underground magnetic coupling turbine power cantilever type alternating current generator

ActiveCN103701259ANo qualityNo performanceMagnetic circuit rotating partsDynamo-electric gearsCouplingStator coil

The invention discloses an underground magnetic coupling turbine power cantilever type alternating current generator, which comprises flow pipes, pressing caps, flow guide rings, fluid directors, supporting pipes, upper bearings, magnetomotive turbine assemblies, lower bearings, straight-wing fluid directors, a generator shell, a positioning screw, supporting bearings, a generator rotor and a generator stator, wherein the generator rotor is a cantilever type alternating current generator rotor and consists of coupling magnetic steel, a coupling magnetic steel bracket, a rotor magnetic steel bracket and rotor magnetic steel; the generator stator is a cantilever type alternating current generator stator and consists of a magnetic separation frame, a stator outer shell body, a stator coil, a stator inner shell body and a locating pin. The generator has the advantages of high power generation efficiency, low manufacture and use cost and long service life, and large-power generation can be realized.

Owner:东营市创元石油机械制造有限公司

High-quality battery aluminum foil slitting device

PendingCN113263531AImprove cutting efficiencyNo warpingMetal working apparatusElectrical batteryEngineering

The invention belongs to the technical field of aluminum foil production, and particularly relates to a high-quality battery aluminum foil slitting device, which comprises a base; a material distributing roller is installed at one end of the top of the base; aluminum foil is wound on the outer wall of the material distributing roller; a first material guiding roller is installed at the top of the base, and a slitting mechanism is installed at the other end of the top of the base; a second material guiding roller is installed above the slitting mechanism through a fourth supporting column; and a negative pressure collecting box is installed on the side face of the base. The aluminum foil is slit into the specified width through the slitting mechanism, the slitting efficiency is high, the quality problems of edge warping, rough warping and the like are solved, aluminum powder falling in the slitting process is collected through the arranged negative pressure collecting box, and the phenomenon that pressing pits are formed after the aluminum powder falls on the material surface and is rolled is avoided, and meanwhile the phenomenon that too light aluminum powder forms aluminum dust and floats in the air, and the body health of workers is affected is avoided.

Owner:安徽力幕新材料科技有限公司

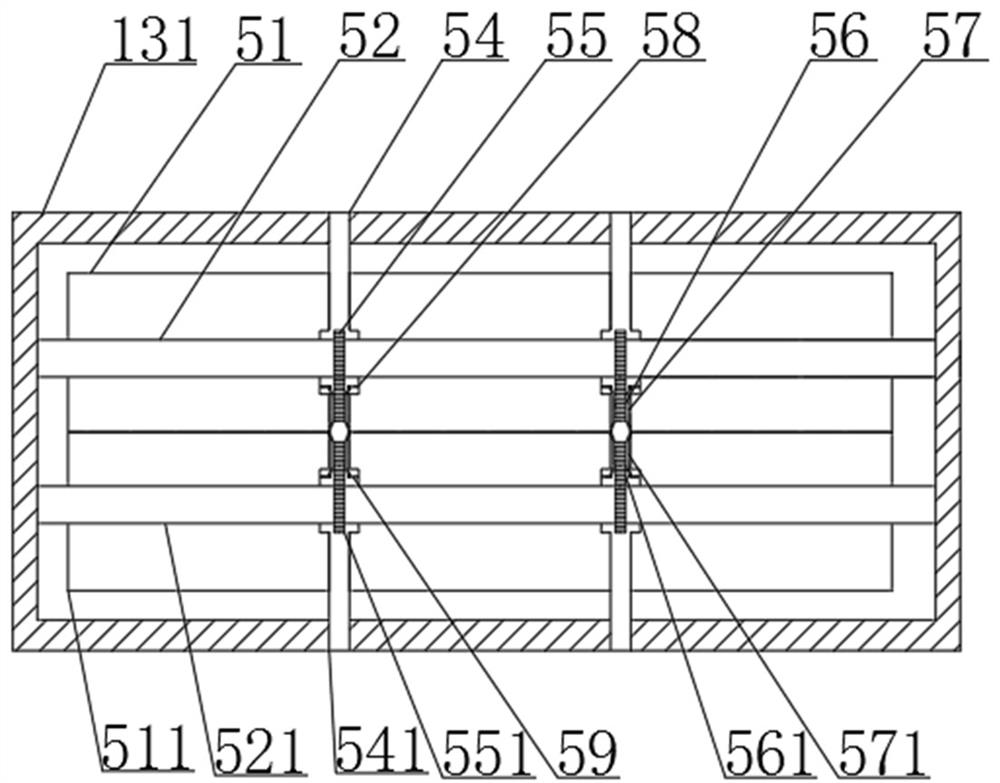

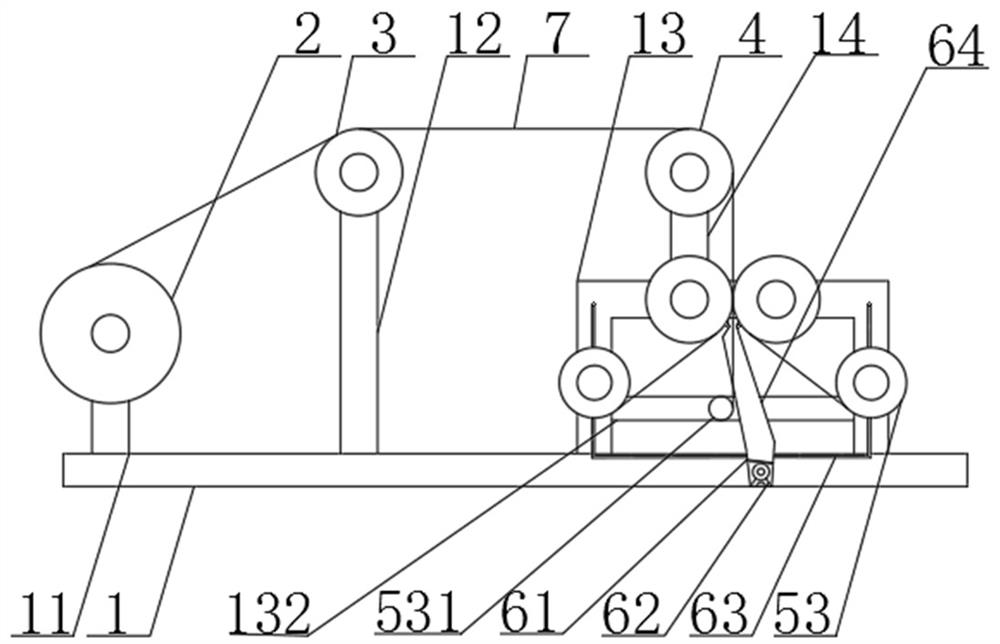

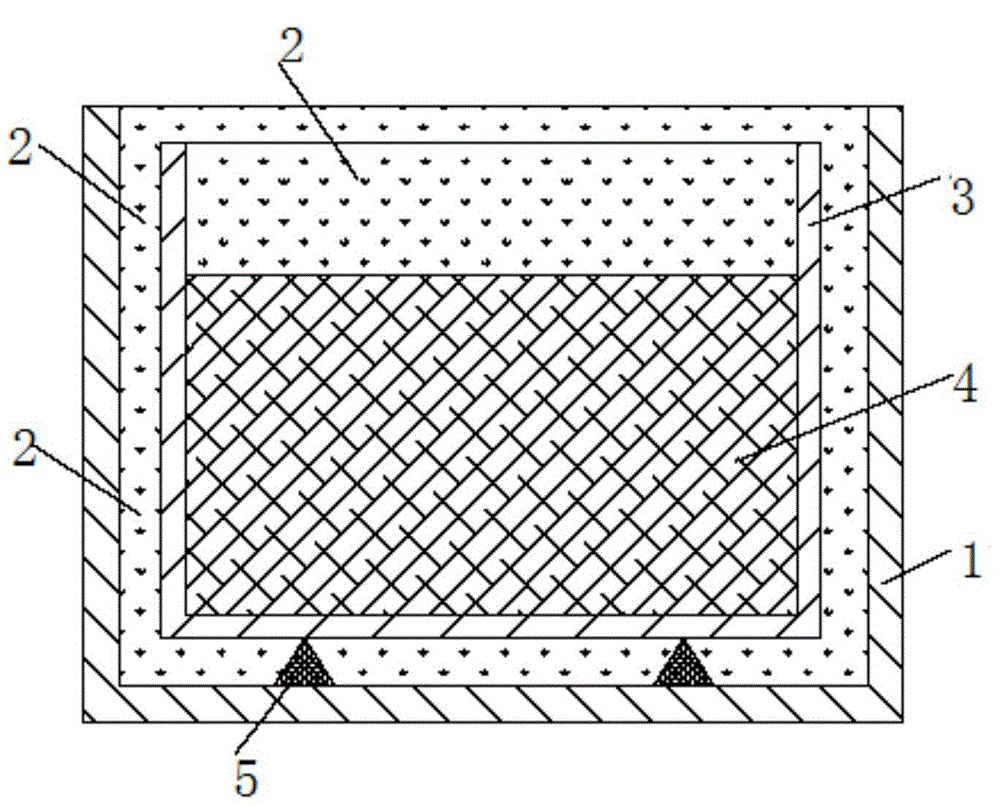

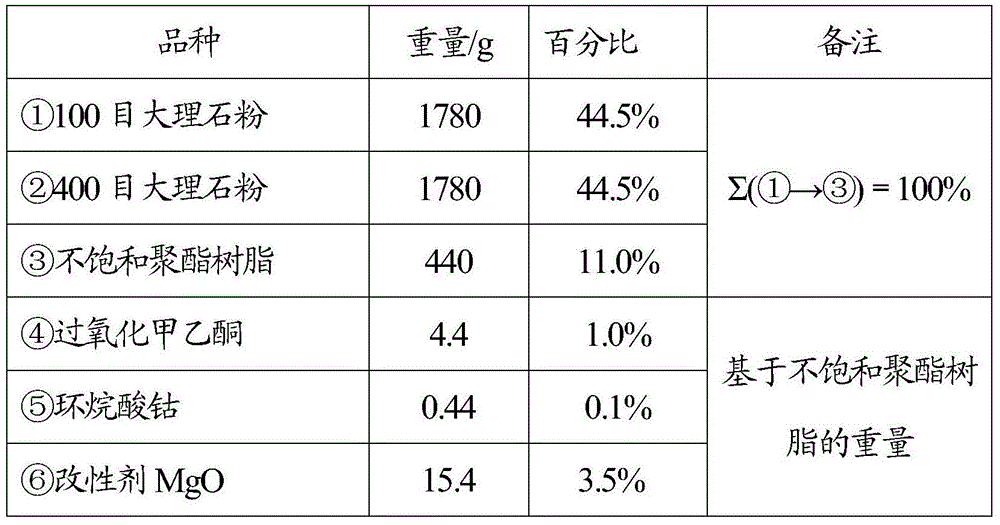

Post treatment process of man-made stone raw materials

InactiveCN105563628AReduce internal cracksNot easy to deformCeramic shaping apparatusLiquid mediumRoom temperature

The invention discloses a post treatment process of man-made stone raw materials. After pressing and before cutting, the man-made stone raw materials are subjected to soaking and curing treatment by liquid media with the temperature higher than the normal temperature; and then, normal-temperature maintenance is performed. The post treatment process has the advantages that the pressed man-made stone raw materials are subjected to maintenance post treatment, so that the traditional normal-temperature maintenance node is changed; the mode of firstly performing soaking, heating and curing treatment by liquid media with the temperature higher than the normal temperature and then performing normal-temperature maintenance is used; by using the post treatment process of soaking, heating and curing, unsaturated polyester resin reaction can be sufficient; and the stable product performance is achieved on the original basis, so that the quality problems of internal cracking, easy product deformation, warping and the like of the man-made stone raw materials are reduced.

Owner:WANFENG COMPOUND STONE TECH

Novel pathological specimen bottle

InactiveCN103950641ANo changeNo pollution in the processPackaging under vacuum/special atmosphereBottle capSample Label

The invention discloses a novel pathological specimen bottle. The novel pathological specimen bottle comprises a bottle cap, a paraffin sealing layer, preset fixing fluid, a biopsy stripping needle and a sample label, wherein the bottle cap and a bottle body are sealed by the paraffin sealing layer; the paraffin sealing layer is fixed on the bottle cap; the preset fixing fluid is positioned in the bottle body; the biopsy stripping needle is fixedly connected with the bottle cap; the sample label is pasted on the bottle body, and is used for labeling samples to avoid errors. The bottle overcomes the defects of the existing pathological specimen inspecting container, and has the characteristics of transparency, sealing, cleanness, and no interfering substances in the bottle, and pathological specimens cannot be changed during the inspecting process. The bottle is suitable for the inspection of the pathological specimens with small volume. The size of the specimen bottle can be changed according to the volume of the pathological specimens, so that the bottle is suitable for all collected pathological specimens. For the bottle, no pollution of the pathological specimens and the quality of the specimens are ensured, the workload and the operation damage due to the self configuration of the specimen bottle by a nurse is reduced, and the design satisfies the clinic requirements and ensures the quality of the pathological specimens.

Owner:张弘炎

New technology for oil sludge processing

InactiveCN102381821BHigh recovery rateImprove qualityFatty oils/acids recovery from wasteSludge treatment by de-watering/drying/thickeningOil processingFiltration

The invention which belongs to the dangerous waste processing field relates to oil sludge processing and provides a new technology for the oil sludge processing. The technology is mainly characterized in that: after the oil sludge is processed with steps of dehydration, extraction, deposition, evaporation, extraction, pumping filtration, drying and the like, the content of oil in soil is 1% and accords with discharge standards, the total loss of solvent oil is about 1%, the recovery rate of product oil is more than 99%, and no waste gases and no wastewater are discharged. The technology whichhas the advantages of scientific method, mature process, simple equipment and large investment-output benefit and allows great technical problems, environmental protection problems and production safety problems which are difficult to solve for a long time in the dangerous waste processing field to be well solved deserves to be popularized and applied to broad petroleum enterprises, petroleum byproduct enterprises, and plant oil processing and oil product storage and transportation enterprises.

Owner:李廷安

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com