Diamond-based heterogeneously integrated gallium nitride thin film and transistor microelectronic device and preparation method thereof

A microelectronic device, gallium nitride single crystal technology, applied in the direction of semiconductor/solid-state device manufacturing, transistors, semiconductor devices, etc., to achieve the effect of long-term stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] According to a preferred embodiment of the present invention, a method for preparing a diamond-based heterogeneously integrated gallium nitride thin film and transistor microelectronic device is provided, comprising the following steps:

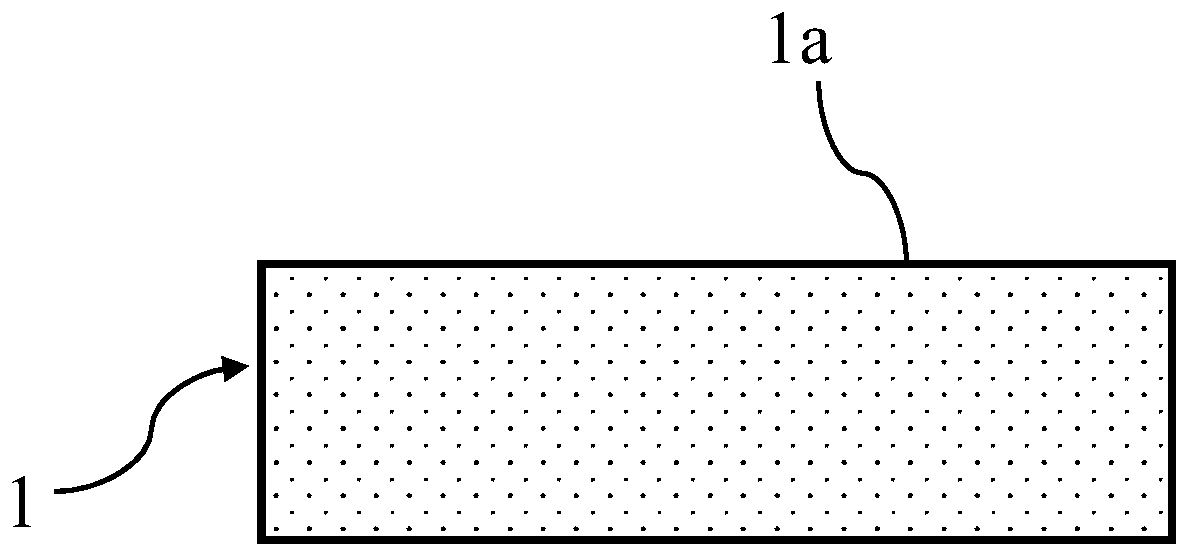

[0033] 1) Provide a gallium nitride single crystal wafer 1 with an injection surface 1a, such as figure 1 shown;

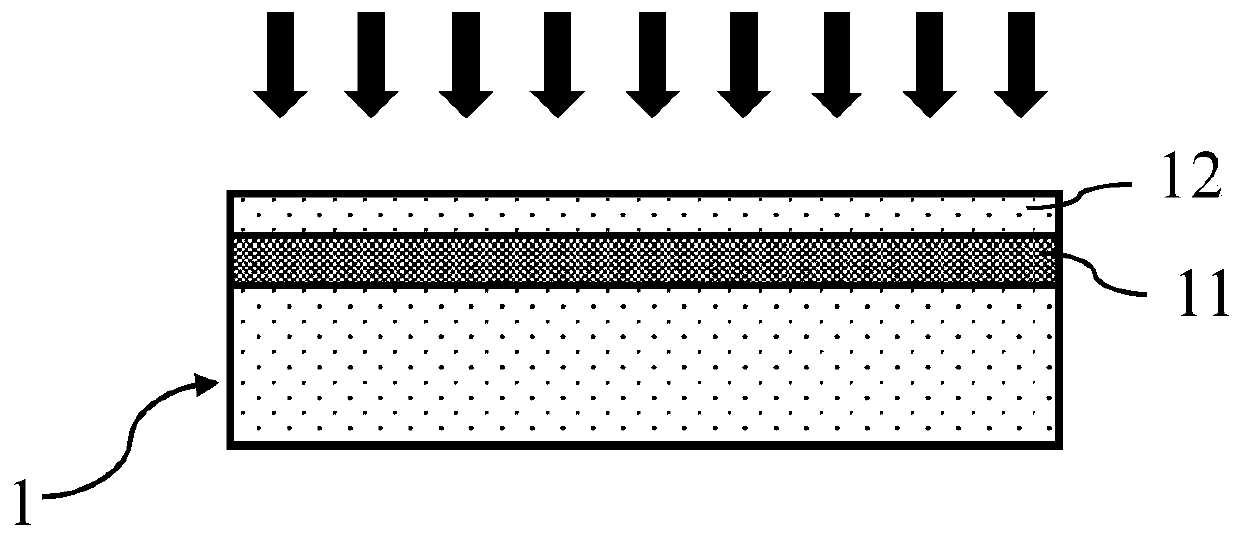

[0034] 2) From the injection surface 1a along figure 2 hydrogen ion implantation is carried out to the gallium nitride single crystal wafer 1 in the arrow direction of single crystal thin film 12, such as figure 2 shown;

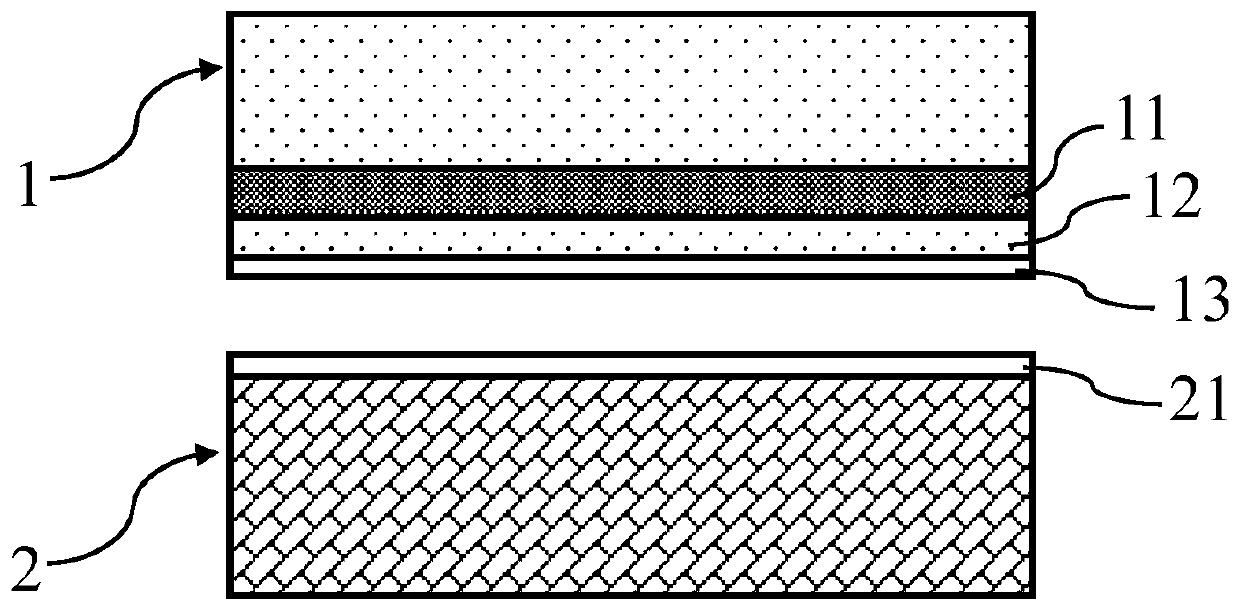

[0035] 3) growing a first dielectric layer 13 on the gallium nitride single crystal wafer 1, growing a layer of second dielectric layer 21 on the diamond support substrate 2, and using plasma to activate the surfaces of the first dielectric layer 13 and the second dielectric layer 21, Such as image 3 shown;

[0036] 4) bonding the first dielectric layer 13 with the second dielectric layer 21, su...

Embodiment 1

[0041] Provide millimeter-scale gallium nitride single crystal wafers. Perform hydrogen ion implantation from the implanted surface, the implantation energy is 75keV, and the implantation dose is 3.5×10 17 ions / cm 2 , an implanted defect layer is formed at a distance of about 500 nm from the implanted surface. A 5nm-thick nano-silicon dielectric layer is grown on a gallium nitride single crystal wafer and a 500μm-thick diamond support substrate and activated by argon plasma, and the nano-silicon dielectric layer is bonded in a vacuum environment, and the bonding temperature is is 20°C. Annealing treatment under vacuum, the annealing temperature is 550°C, and the annealing time is 2h. Chemical mechanical polishing removes the damaged layer. Next, the homoepitaxial growth is carried out on the surface of the GaN single crystal thin film by using the HEMT process to prepare the transistor.

[0042] combine Figure 7 The HEMT process steps are described in detail as follows,...

Embodiment 2

[0048] GaN monocrystalline wafers are provided at the wafer level. Perform hydrogen ion implantation from the implanted surface, the implantation energy is 35keV, and the implantation dose is 2.5×10 17 ions / cm 2 , an implanted defect layer is formed at a distance of about 300 nm from the implanted surface. The injection surface and the surface of the 200 μm thick diamond support substrate were directly bonded under a nitrogen atmosphere after being activated by nitrogen plasma, and the bonding temperature was 20°C. Annealing treatment under nitrogen atmosphere, the annealing temperature is 300°C, and the annealing time is 24h. The damaged layer was removed by ion beam etching, the energy was 2keV, the ambient temperature was 300°C, the incident angle of the ion beam was 60°, and the process time was 5min.

[0049] The HEMT process is the same as above, and a diamond-based heterogeneously integrated gallium nitride thin film and transistor microelectronic device is obtained....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com