Patents

Literature

134results about How to "Not easy to deform" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

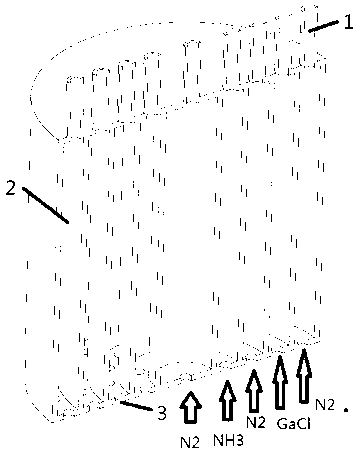

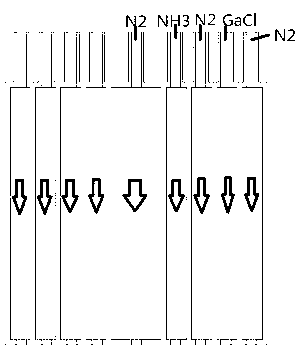

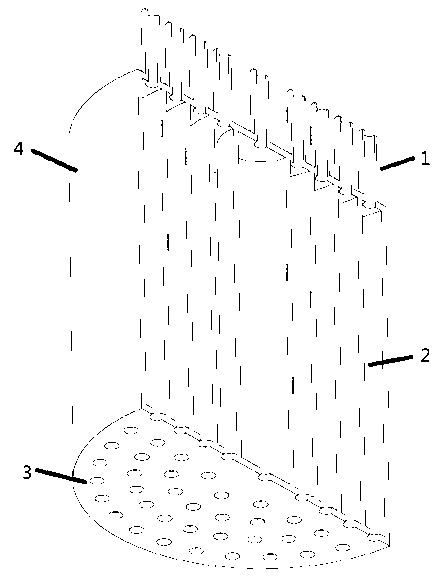

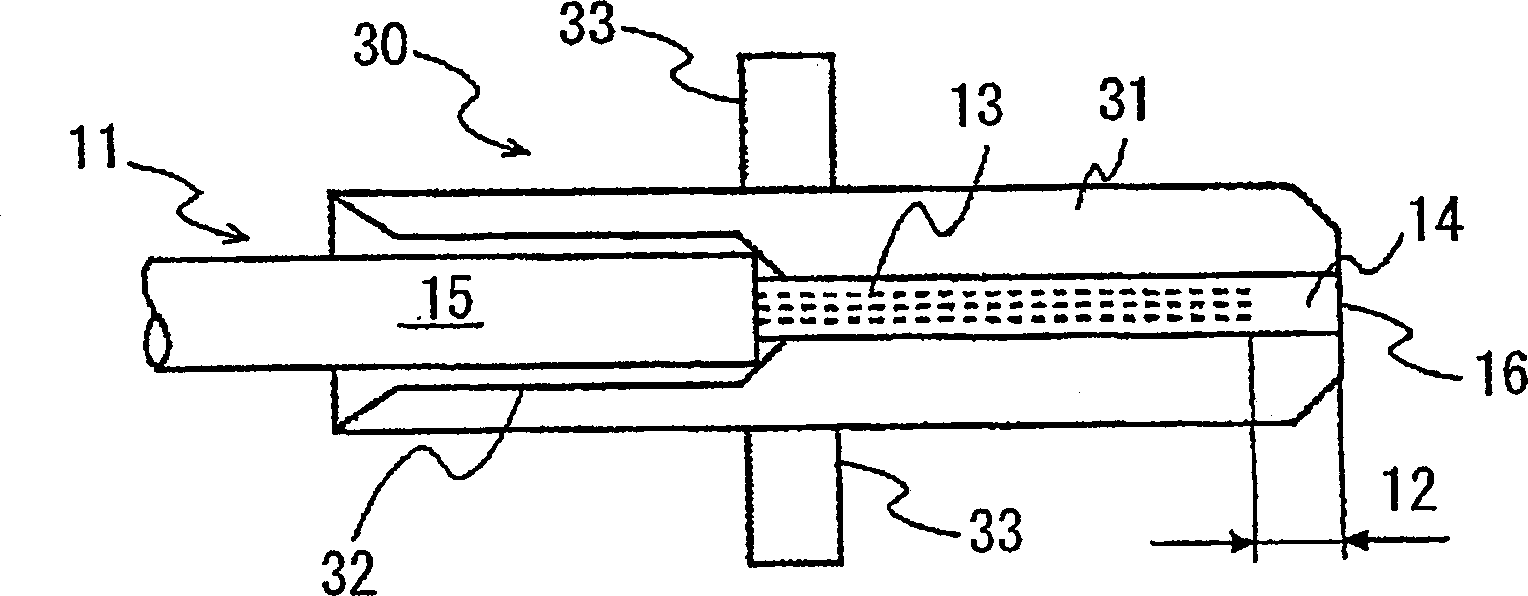

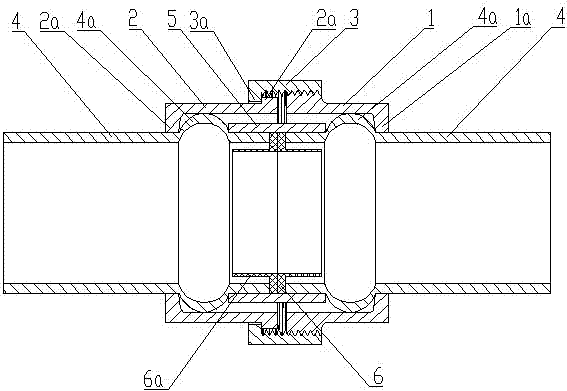

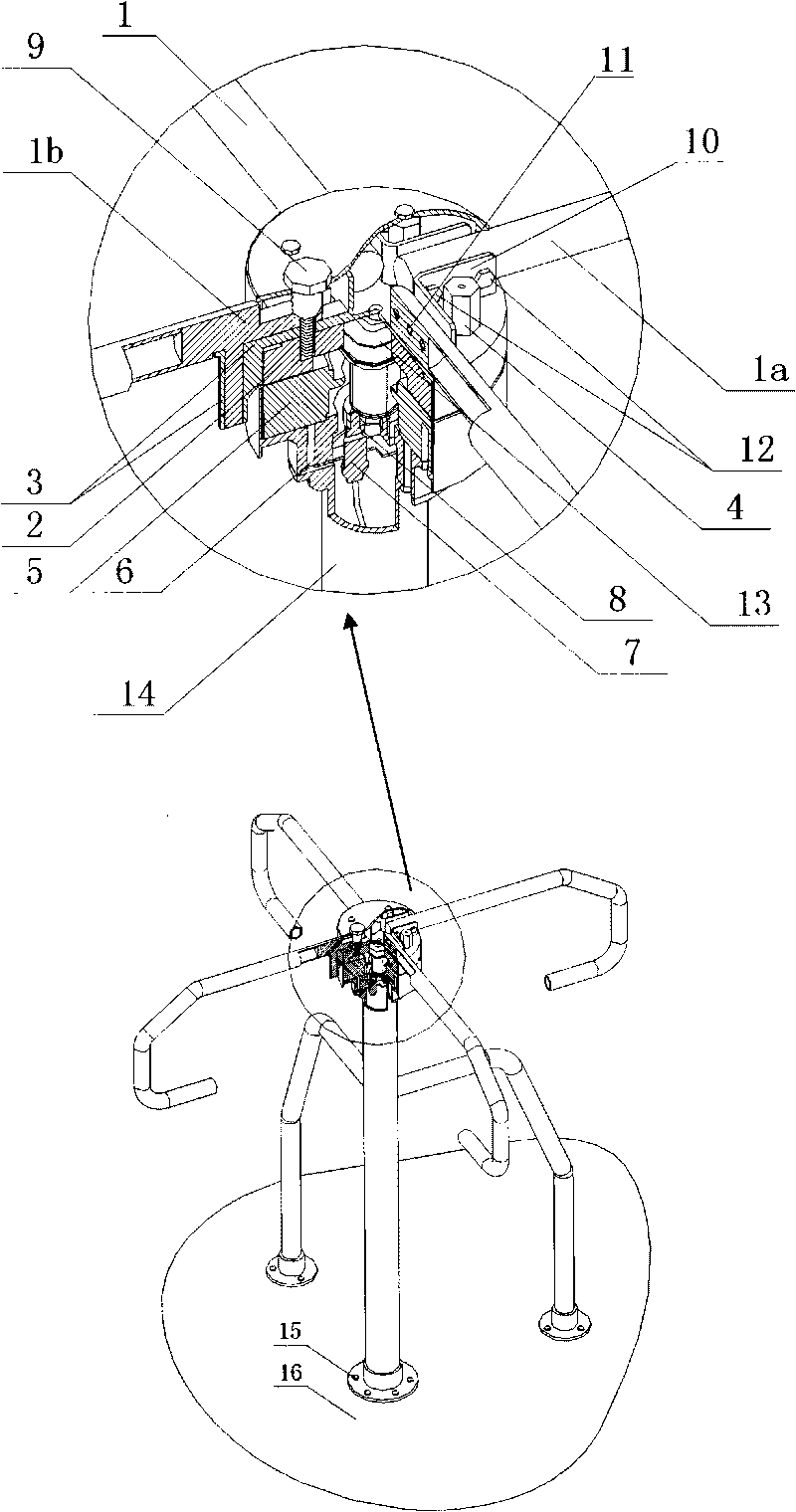

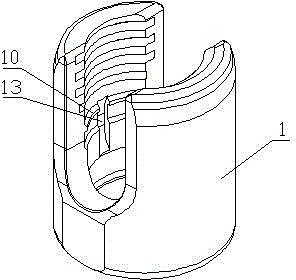

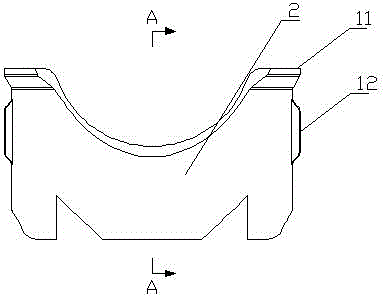

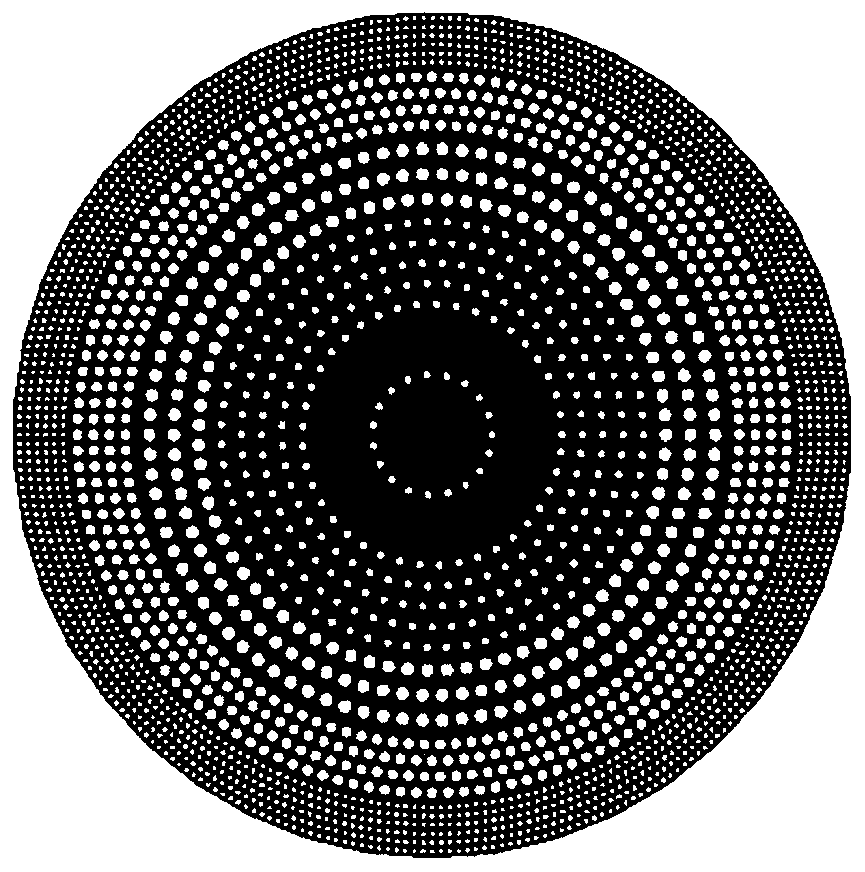

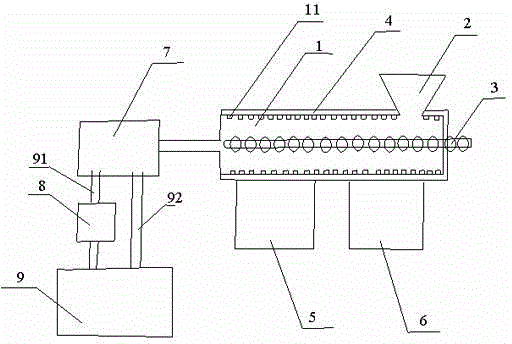

Concentric-ring sprayer structure for material vapor phase epitaxy

InactiveCN103014846ANo effect on growthGrowth impactFrom chemically reactive gasesVapour phase epitaxySprayer

The invention discloses a concentric-ring sprayer structure for material vapor phase epitaxy, which solves the problem that the large-area deposition region provides a uniform flow field of a precursor gas mixture in a large-substrate or multi-substrate crystal growth process. The sprayer structure comprises more than one independent air inlet pipeline, wherein each air inlet pipeline is provided with a controller for monitoring and regulating inlet gas flow speed and flow rate; the bottom of the sprayer is provided with an air outlet baffle; more than one concentric ring is arranged in the sprayer; independent cavities are formed among the concentric rings and are mutually separated; the top end of each concentric ring is connected with one independent air inlet pipeline; and the air outlet baffle at the bottom end of each concentric ring is provided with one or more air outlets. The air sources are mutually separated and independently controlled; and the multi-sprayer integrated use mode obviously improves the quality of the large-area deposited grown crystal, and greatly enhances the production efficiency.

Owner:SINO NITRIDE SEMICON +1

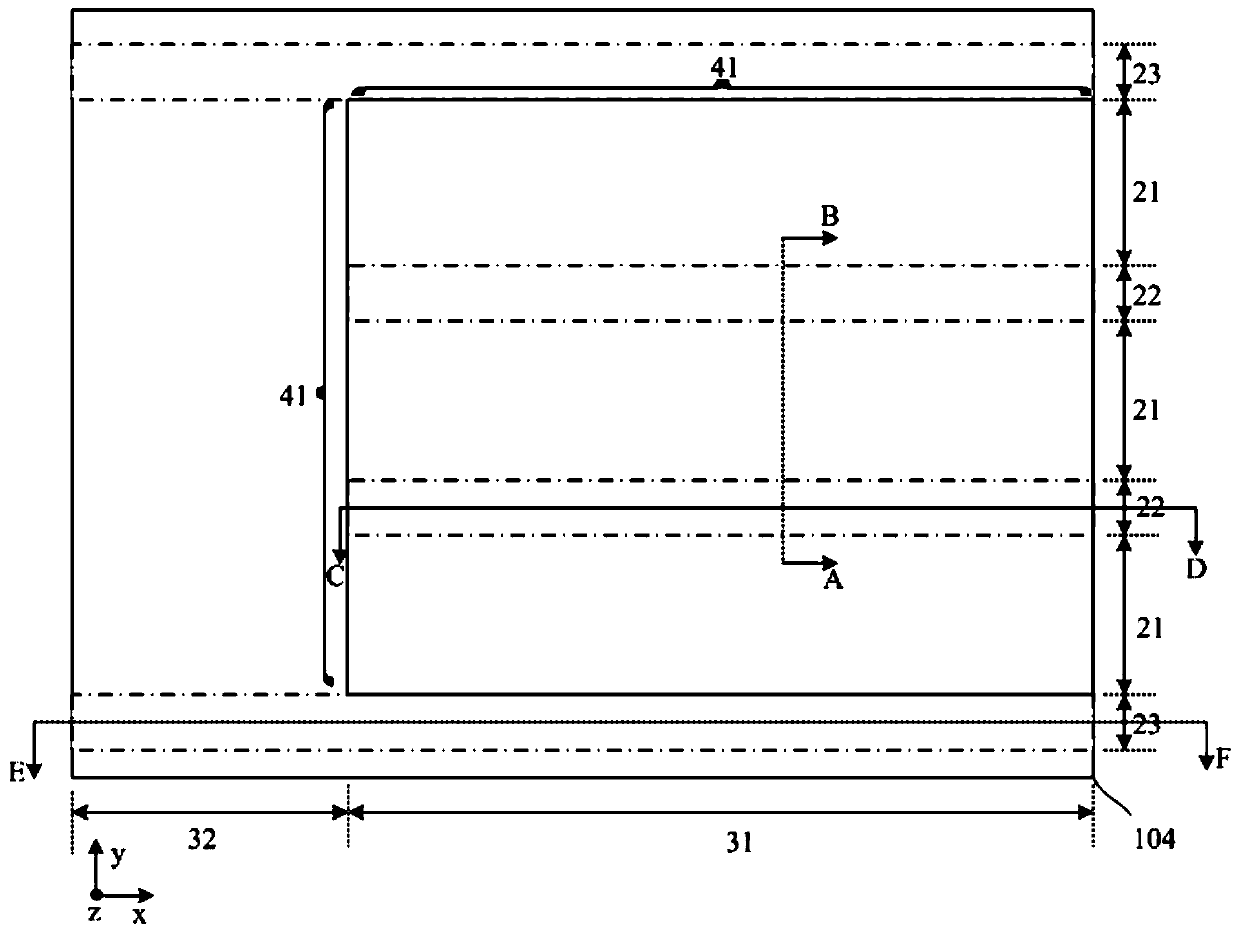

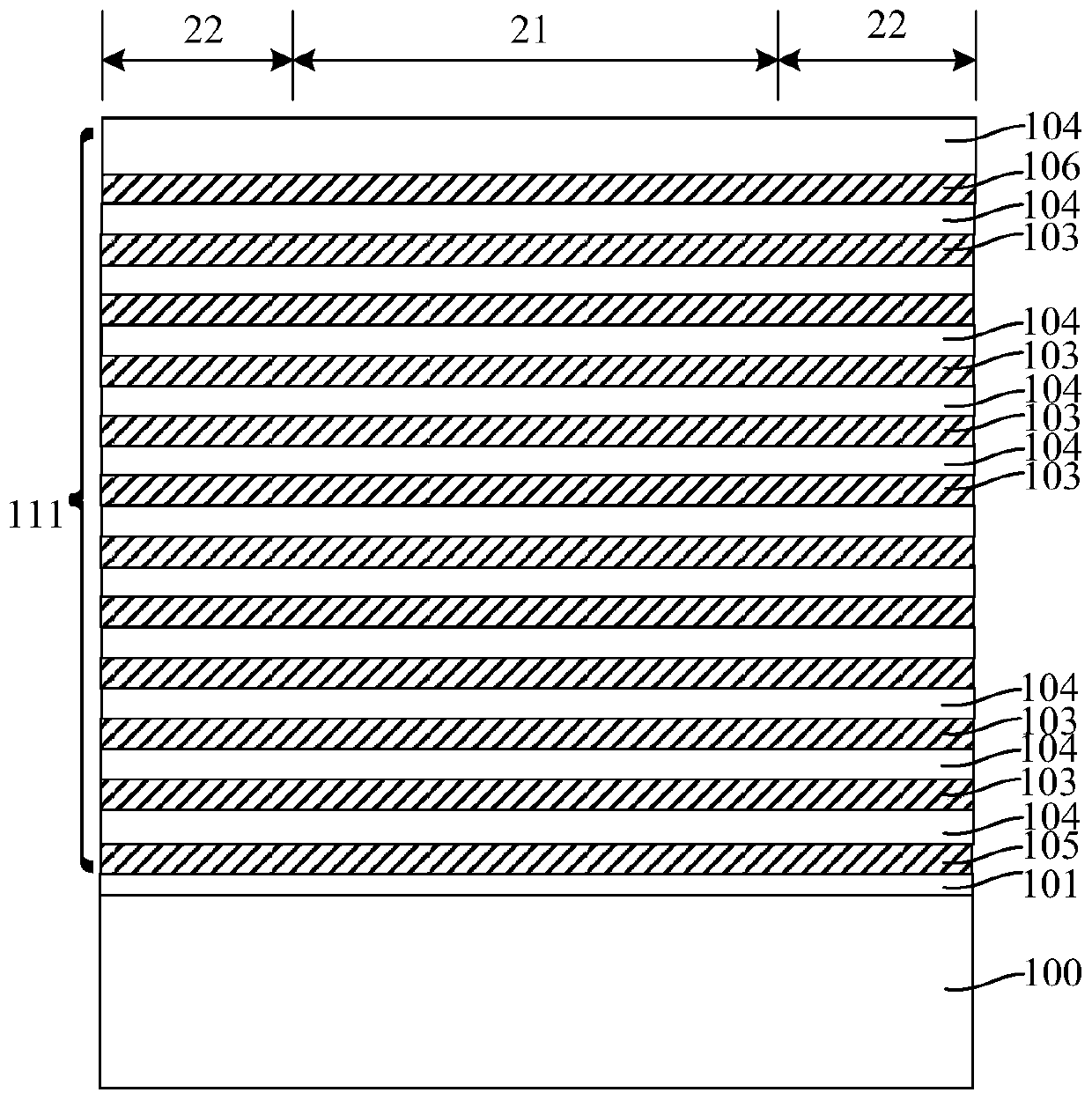

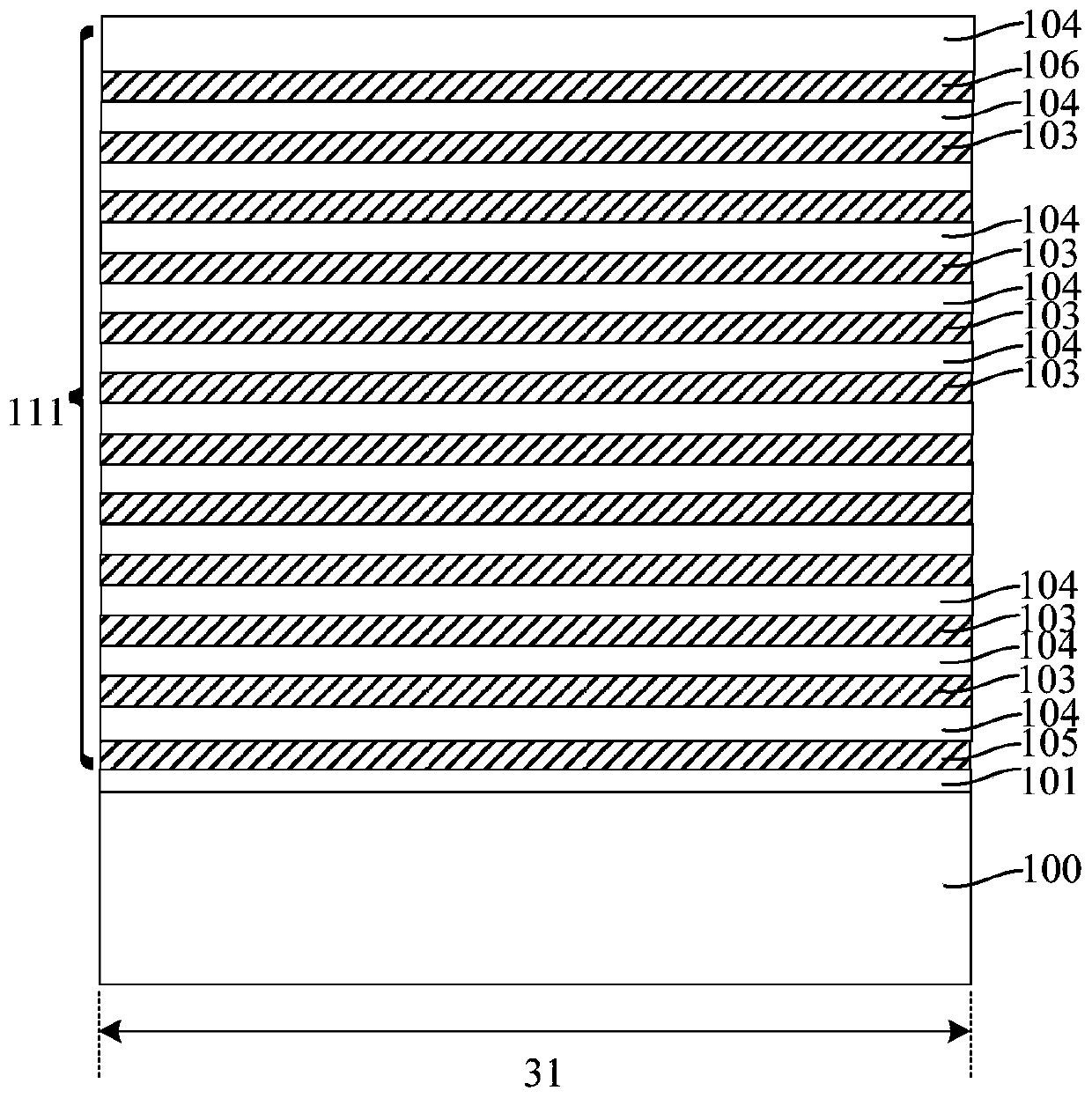

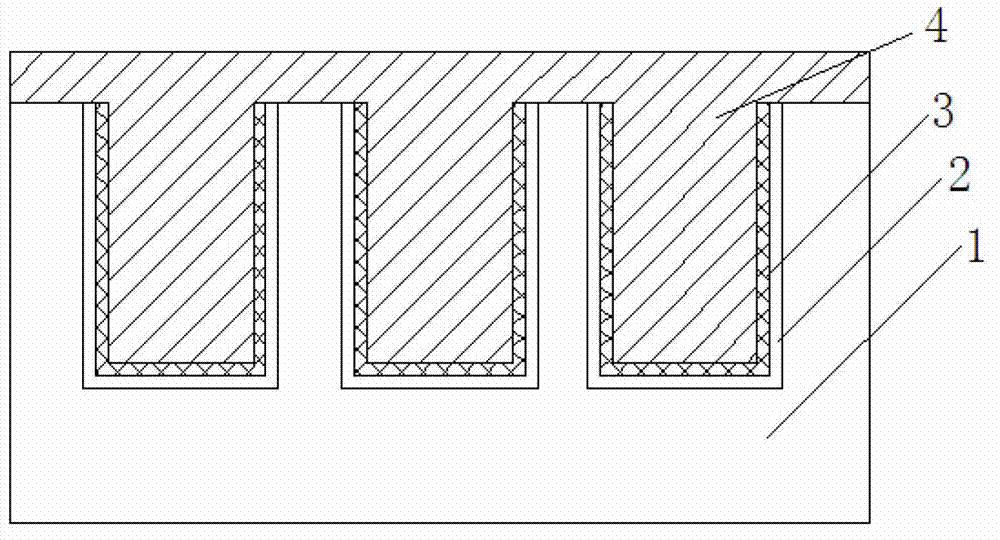

3D NAND storage device and formation method thereof

ActiveCN110176461AImprove support strengthNot easy to deformSolid-state devicesSemiconductor devicesGrid partitionComputer science

The invention discloses a 3D NAND storage device and a formation method thereof. In the formation method of the 3D NAND storage device, a selective grid sacrificial layer in a first grid partition groove area is disconnected through a first grid partition groove and a plurality of grid partition groove partition areas in the first grid partition groove area, a selective grid sacrificial layer in athrough hole area is disconnected through a selective grid partition area in the through hole area, although the selective grid sacrificial layer on the top of the first grid partition groove area isdisconnected through the first grid partition groove and the grid partition groove partition areas, the sacrificial layer at the bottom of the grid partition groove partition area still remains, namely the sacrificial layers and partition layers in each storage block when the first grid partition groove is formed are still connected together, a stacking structure can be of extremely high supporting strength when the first grid partition groove is formed, and the side wall of the first grid partition groove is unlikely to deform or incline, so that the stability of the feature size of the formed first grid partition groove is guaranteed.

Owner:YANGTZE MEMORY TECH CO LTD

Preparation method of TEM (transverse electric and magnetic field) sample

ActiveCN103196718ANot easy to bendNot easy to deformPreparing sample for investigationDiffusionCopper

The invention relates to the field of the manufacture of a semiconductor, and in particular relates to a preparation method of a TEM (transverse electric and magnetic field) sample. The preparation method comprises the following steps of: S1, depositing a first coating layer on the upper surface of a substrate; S2, cutting the first coating layer to the lower surface of the substrate; S3, preparing a second coating layer to cover the surface of a first cross section; S4, cutting the remaining first coating layer on a first sample structure to the lower surface of the remained substrate; S5, cutting the second coating layer to the lower surface of the remained substrate to form a TEM sample structure with a second cross section; and S6, continuously analyzing the target cross section of the TEM sample. According to the preparation method, a protection layer depositing method is improved, and the protection layer depositing time is increased, so that the thickness of the TEM sample can meet an optimal analysis thickness (40-60nm), a diffusion impervious layer and a copper interface can be clearly analyzed in the process of analysis, and the analysis quality of the TEM sample can be improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

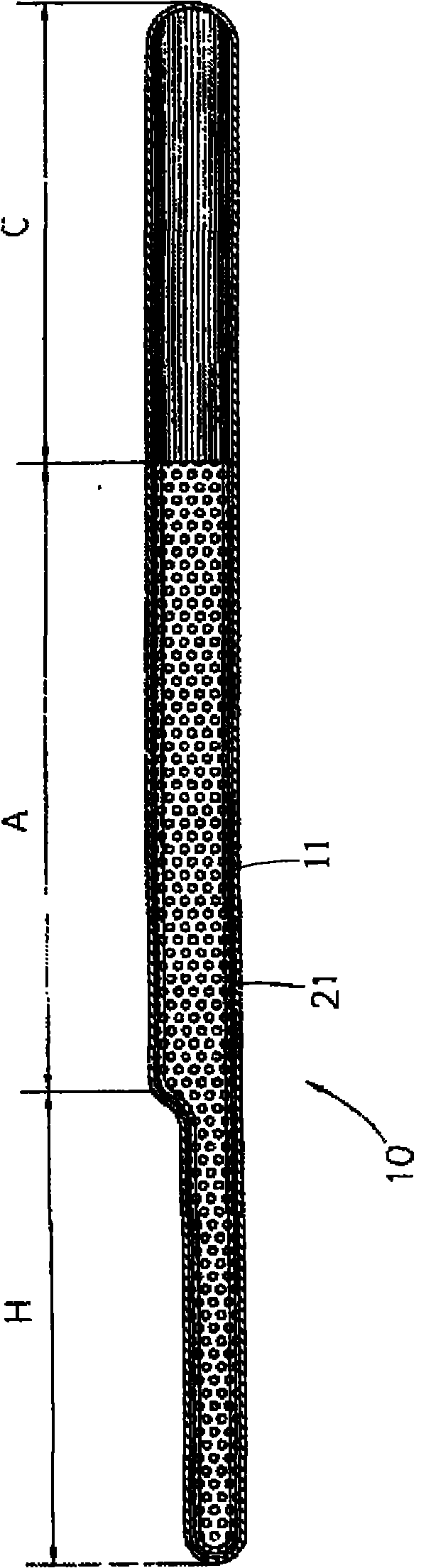

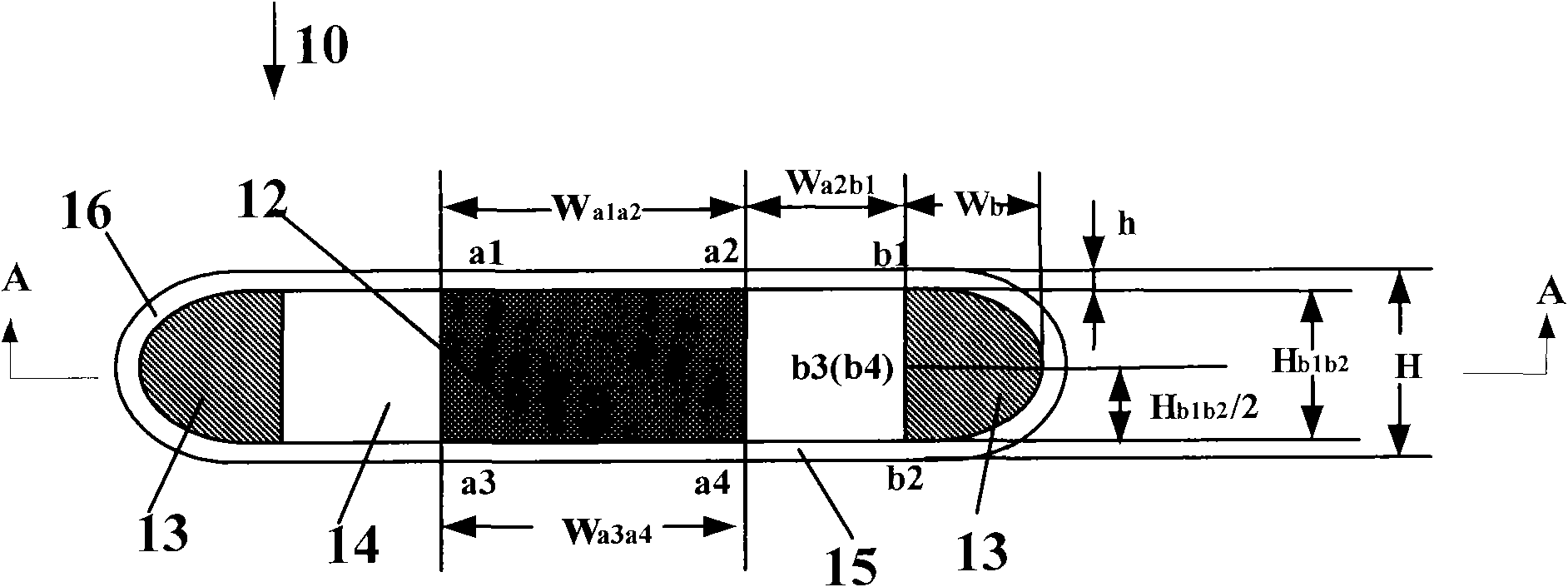

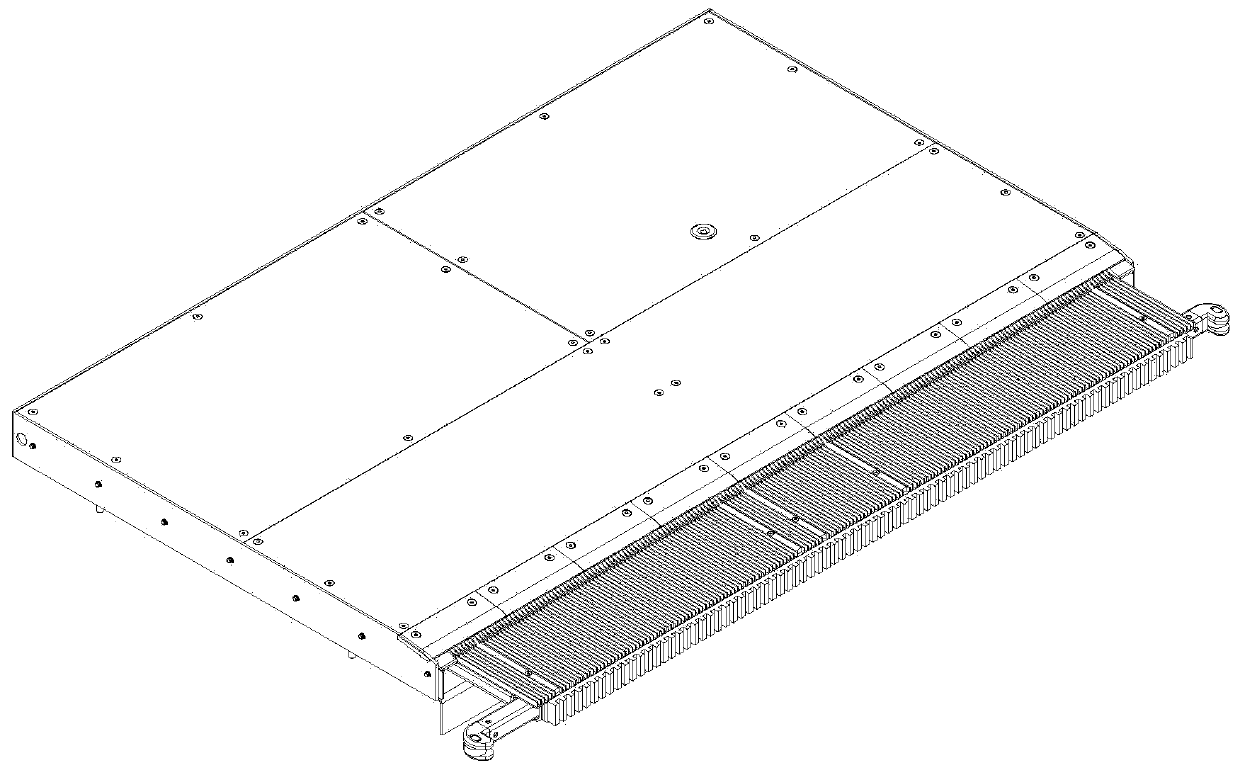

Flat heat radiating pipe and manufacturing method thereof

InactiveCN102147201ADecreased maximum heat transferNot easy to deformIndirect heat exchangersEvaporationEngineering

The invention discloses a flat heat radiating pipe which comprises a pipe cavity with two closed ends and a pipe wall enclosing the pipe cavity along the axial direction, wherein the pipe wall comprises arc walls positioned at two sides and a flat wall for connecting the arc walls, the pipe cavity and the pipe wall are sequentially defined as an evaporation section, a heat insulation section and a condensation section along the axial direction; the pipe cavity is internally provided with a main capillary structure and an auxiliary capillary structure, wherein the main capillary structure is in contact with the flat wall of the evaporation section or in contact with the flat walls of the evaporation section and the heat insulation section; the auxiliary capillary structure is in contact with the arc wall positioned at least one side, the pipe cavity between the main capillary structure and the auxiliary capillary structure is filled with a working medium; and a main gas channel of a heat radiating pipe has enough space so that capillary force of the flat heat radiating pipe is improved and conveying capacity of the working medium is increased, and thus heat transfer efficiency of the flat heat radiating pipe is increased. The invention also provides a manufacturing method of the flat heat radiating pipe.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

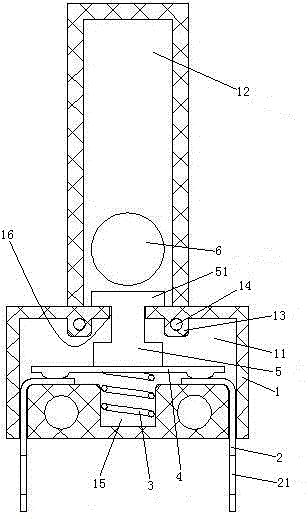

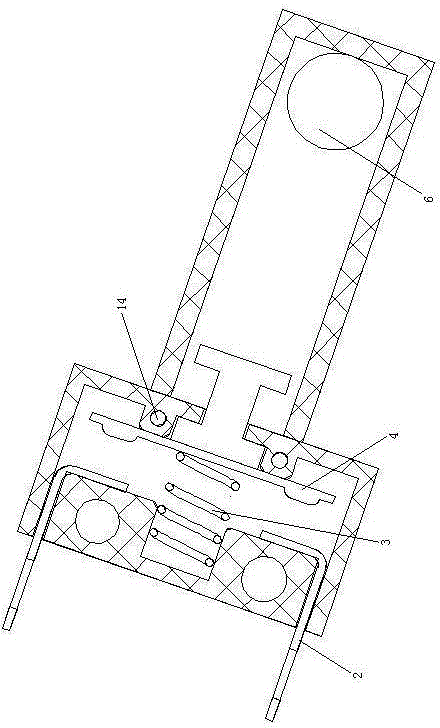

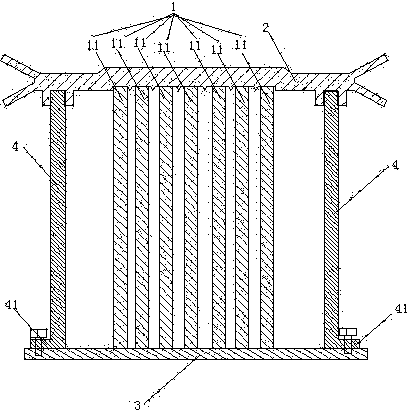

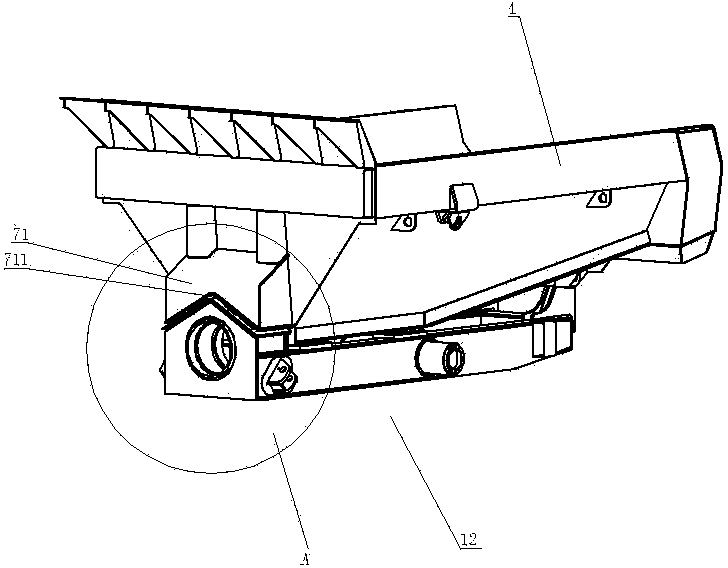

Safety pedal for rail transportation platform

ActiveCN104554282AEven by forceNot easy to deformRailway componentsRailway stationCar doorFixed frame

The invention discloses a safety pedal for a rail transportation platform, which comprises a fixed frame base, a sliding frame and a pedal part. The pedal part is fixedly arranged at the front end of the sliding frame; the sliding frame is connected with roller-type sliding block sets on the fixed frame base in an insertion manner by sliding rails so as to implement telescopic motion. By the telescopic safety pedal, the problem of the potential safety hazard brought to passengers by a gap between the platform and a train door of a train can be effectively solved and obstruction cannot be caused for the train in the running process. Moreover, by coaxial three points (more points also can be provided), the safety pedal is synchronously controlled to extend and retract and the sliding frame of the safety pedal can be subjected to multipoint stressing in the telescoping process so as to enable different positions of the sliding frame to be uniformly stressed in the transverse direction, thereby enabling the safety pedal to be difficult to deform in the long-term running process of the train, prolonging the service life of the safety pedal and ensuring the stability and safety of the safety pedal in the operation process.

Owner:SHANGHAI JIACHENG RAILWAY TRANSPORTATION SAFETY SYST

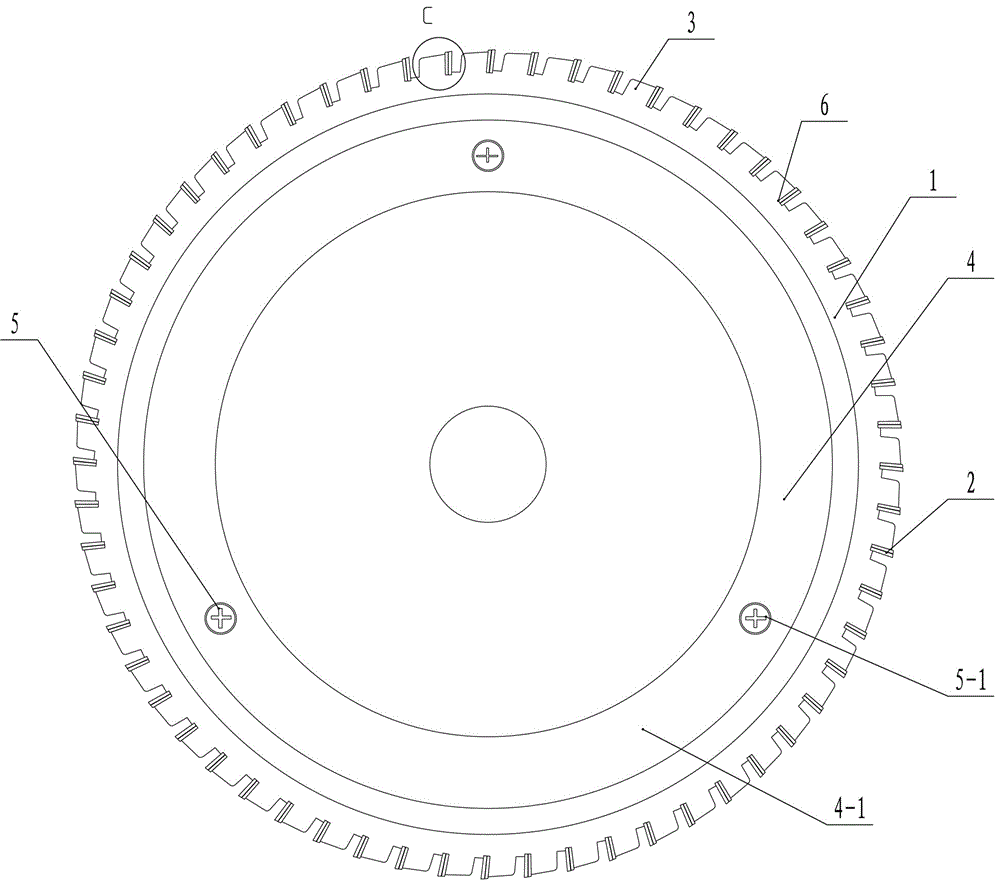

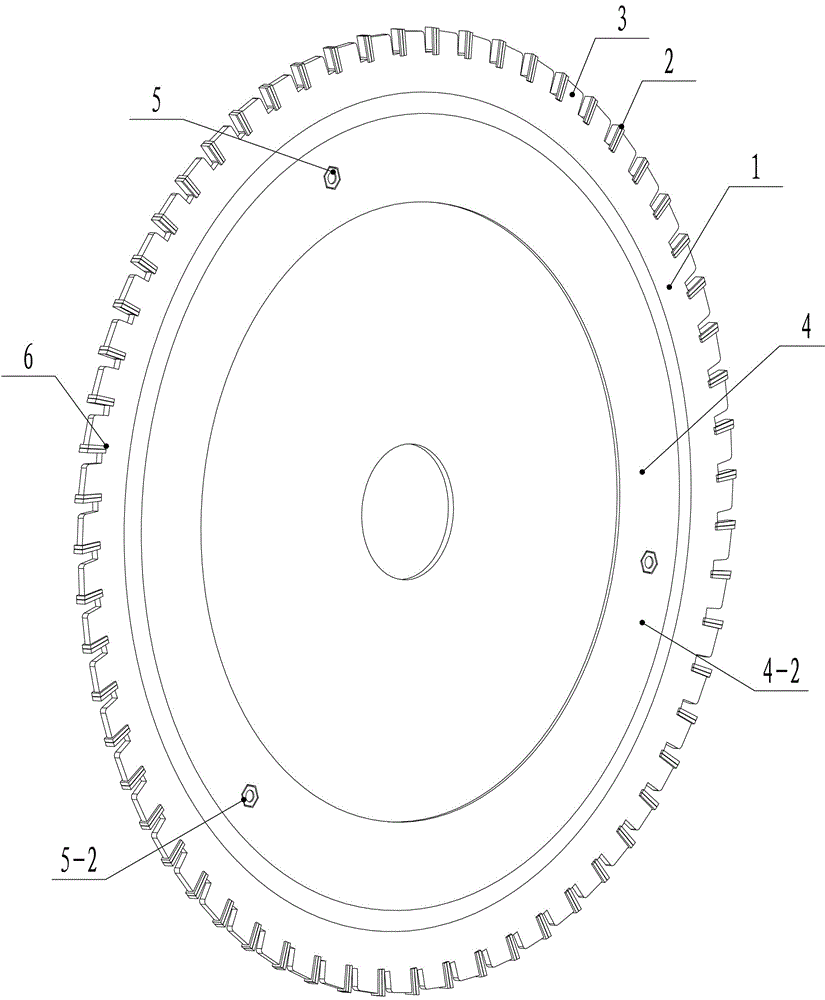

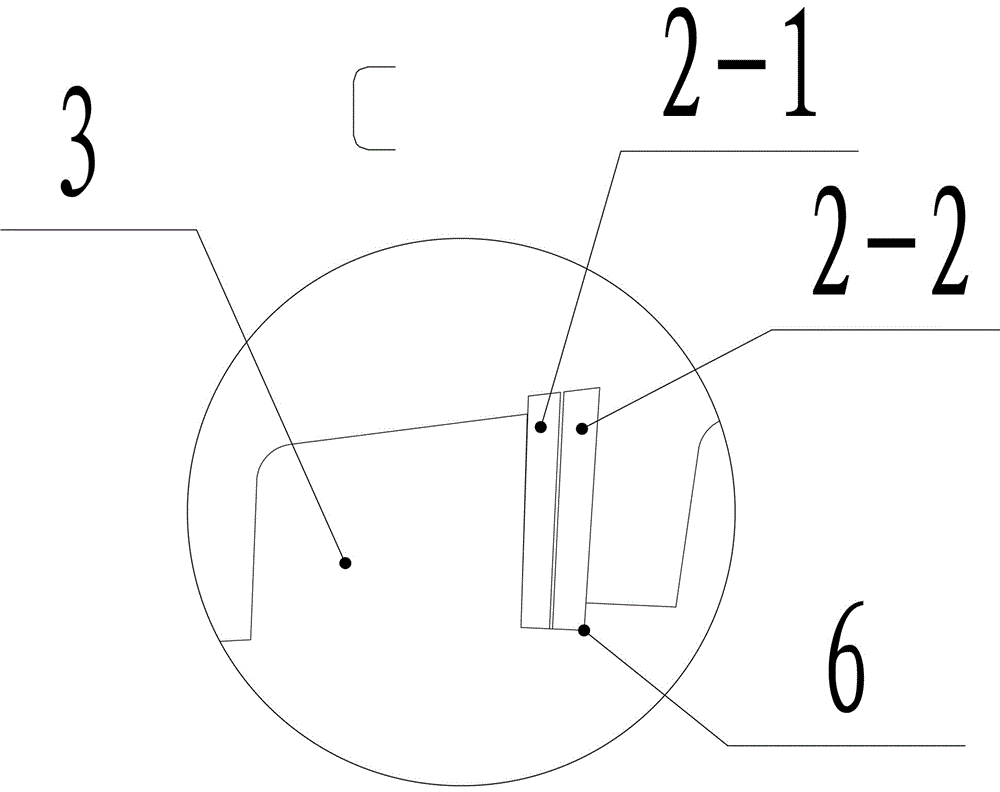

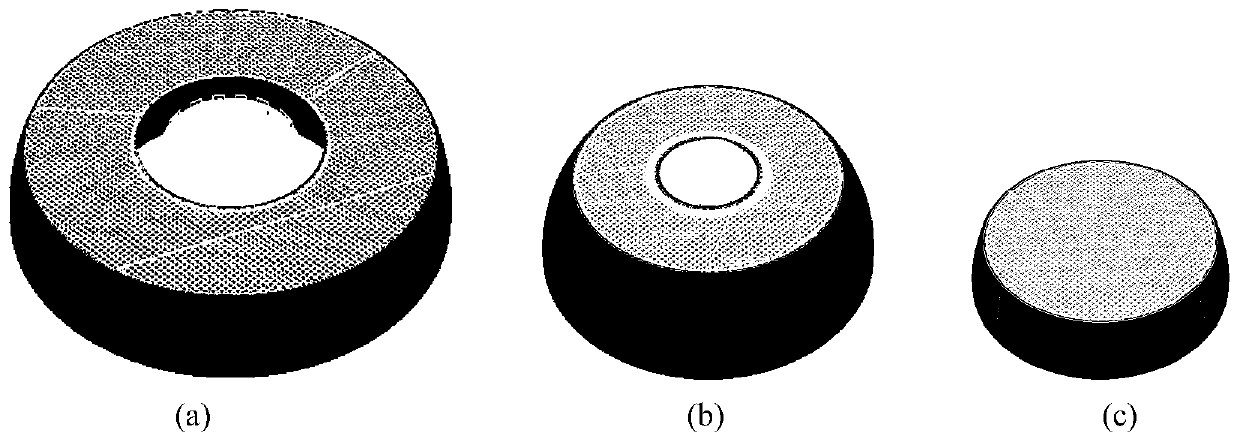

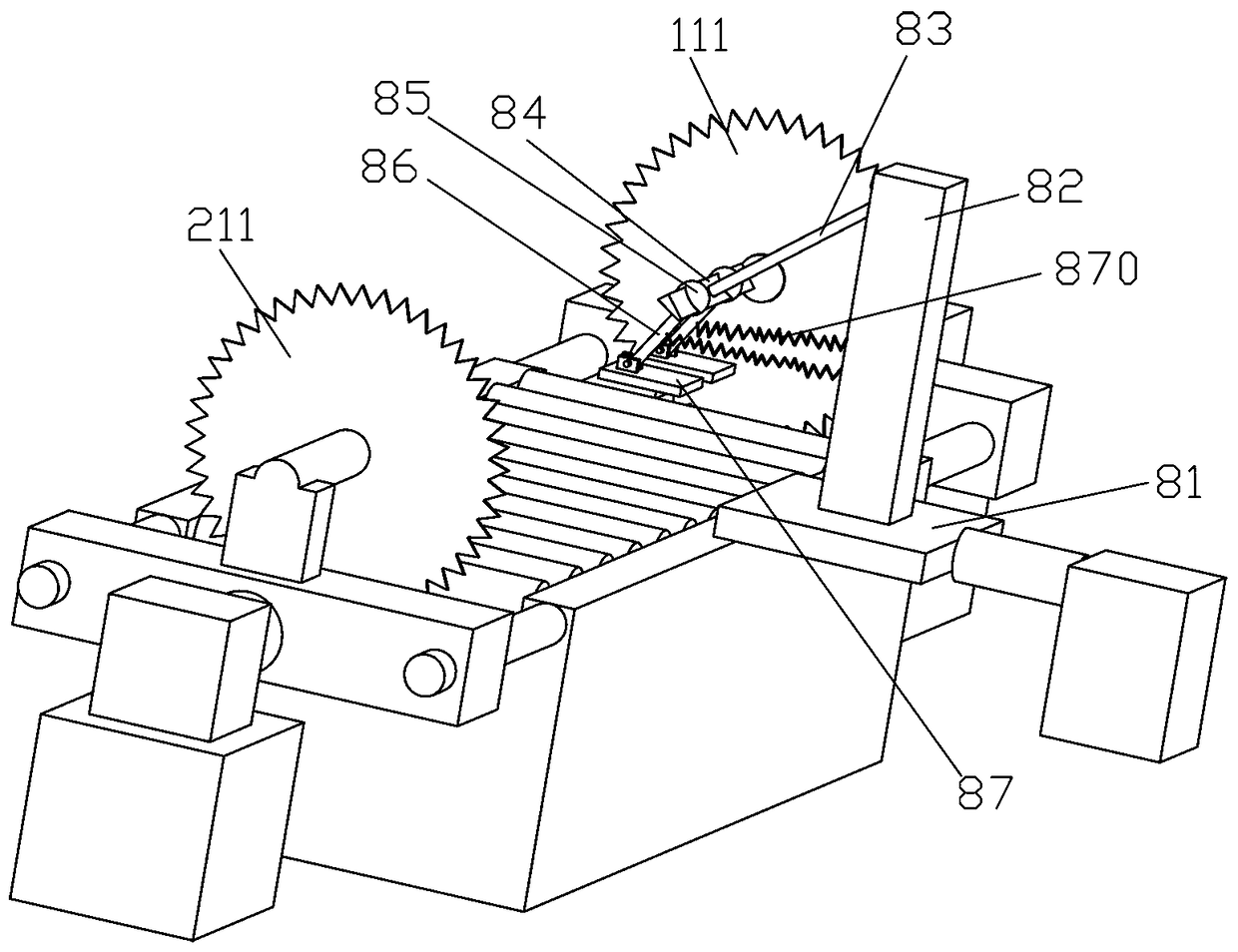

Saw web used for both cutting and grinding

ActiveCN106424940ARepair smoothImprove verticalityEdge grinding machinesMetal sawing toolsEngineeringGrinding wheel

The invention relates to a saw web used for both cutting and grinding. The saw web comprises a saw web body, double-layer cutter heads, tooth backs and a grinding wheel. Grooves are formed in the positions, on the same sides of the tooth backs, of the saw web body. The double-layer cutter heads are welded in the grooves. The grinding wheel comprises an upper grinding wheel body and a lower grinding wheel body. The upper grinding wheel body and the lower grinding wheel body are annular and arranged on the both sides of the saw web body correspondingly. The saw web body, the upper grinding wheel body and the lower grinding wheel body are provided with bolt through holes in fit with one another. The upper grinding wheel body and the lower grinding wheel body are fixed to the saw web body through bolts. By adoption of the saw web used for both cutting and grinding, a cut surface can be cut and ground at the same time, the efficiency is greatly improved, the flatness of the ground surface is improved, and the perpendicularity of the ground surface and a profile is improved; and meanwhile, by designing the embedded cutter heads, the impact resistance of saw web cutter teeth of the saw web to to-be-cut materials during cutting is greatly improved, and the cutter heads are not prone to falling off.

Owner:HEBEI JIMEIDA TOOLS CO LTD

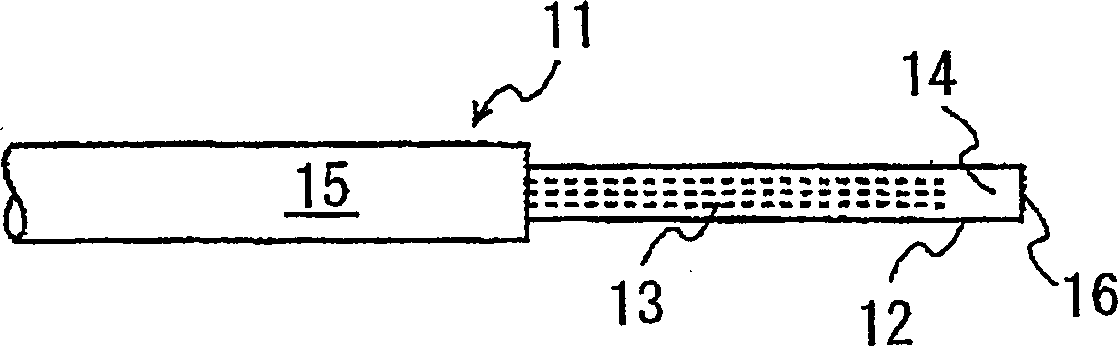

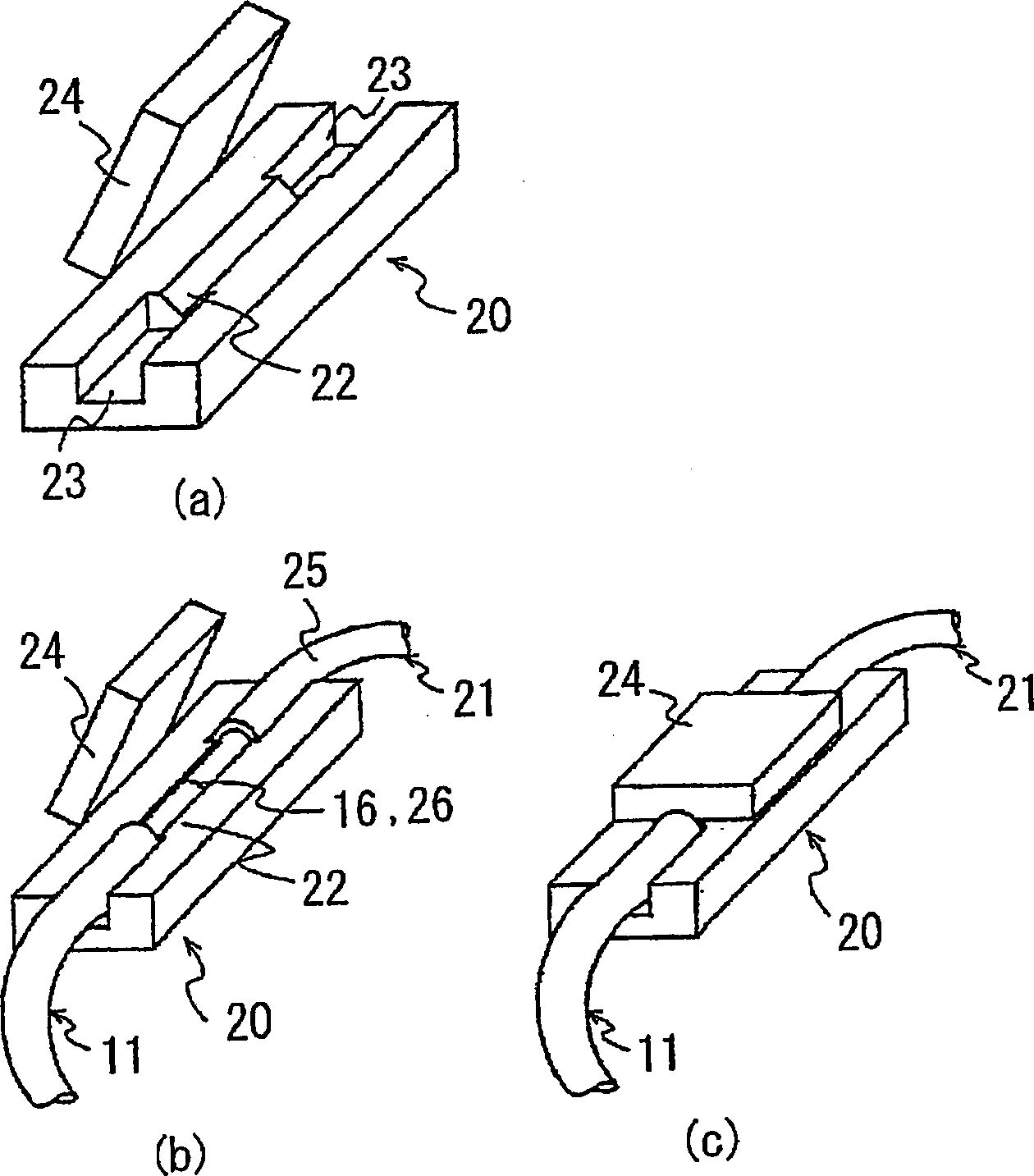

Optical fiber, optical fiber connecting method, and optical connector

InactiveCN1774655AReduce lossesHigh strengthCoupling light guidesOptical waveguide light guideFiberEngineering

An optical fiber in which the hollows near the connecting end of the optical fiber having a plurality of hollows around the core are filled with a light-transmitting substance such as resin or glass having a lower refractive index than quartz-based materials. The connecting portion of the optical fiber connects an optical fiber having a plurality of hollow holes in the cladding around the core to another optical fiber through a refractive index lower than that of the core at the lowest temperature in actual use. A matching agent is used to align and connect the optical fiber with the other optical fiber.

Owner:HITACHI CABLE +1

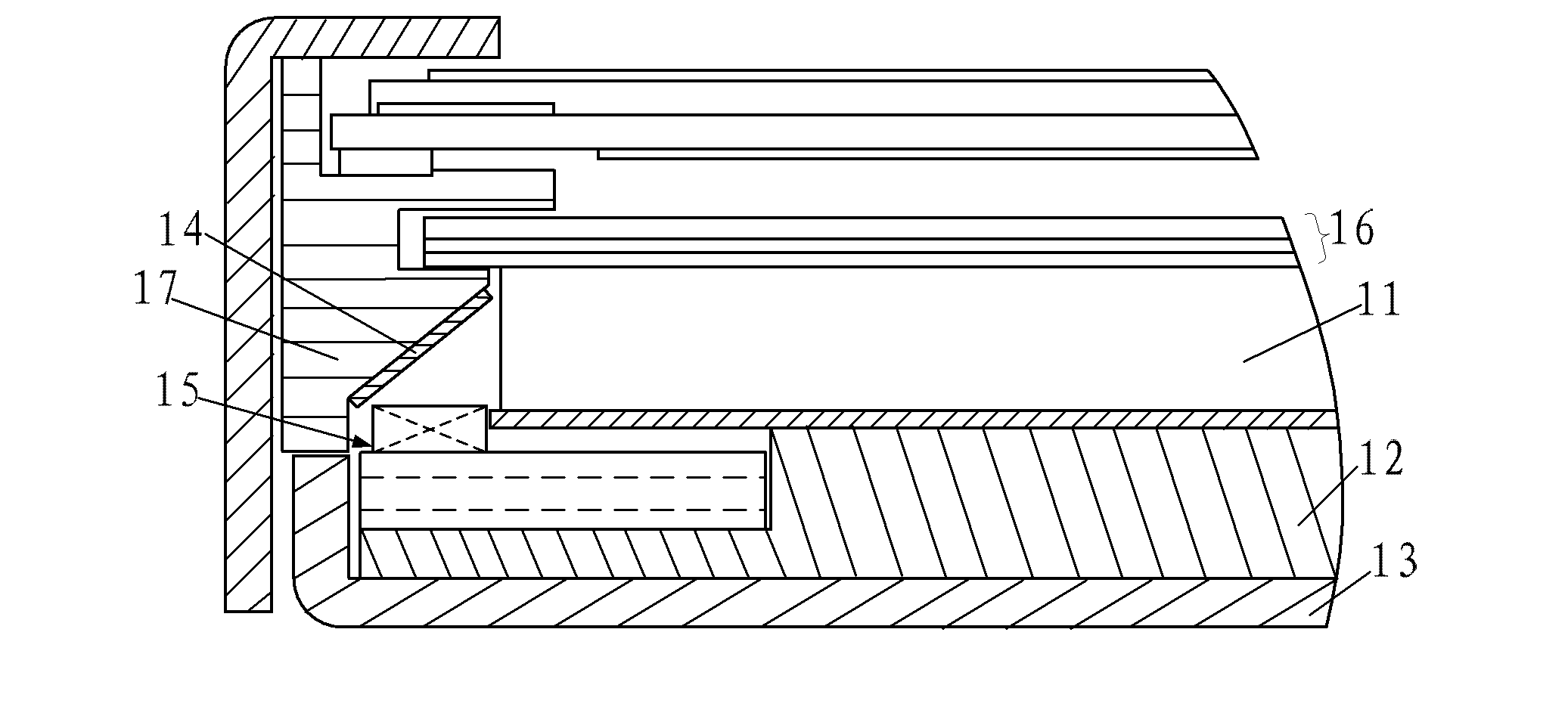

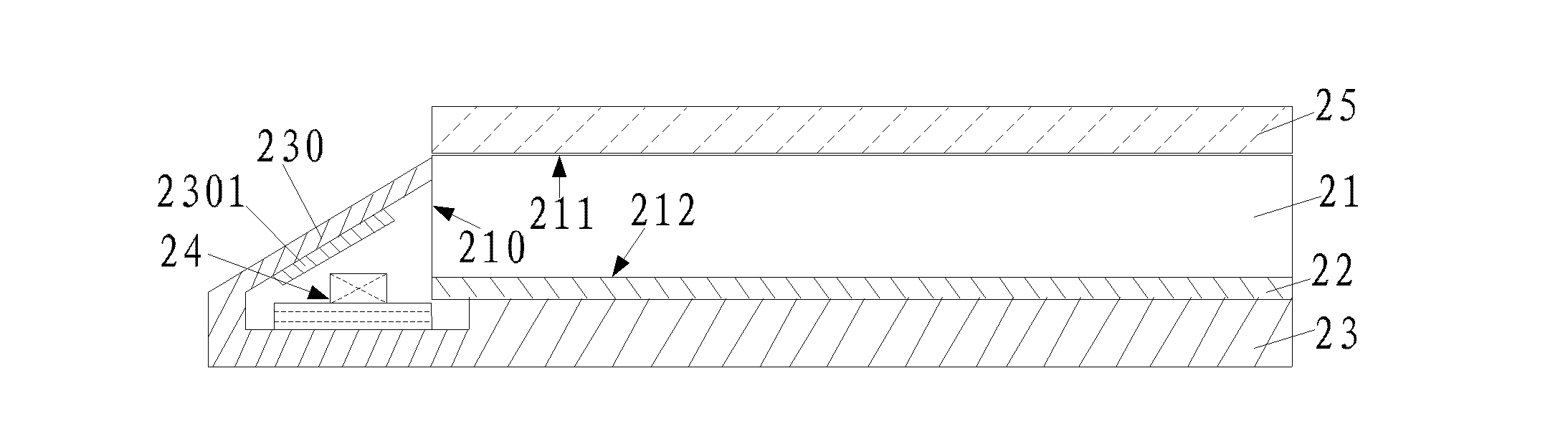

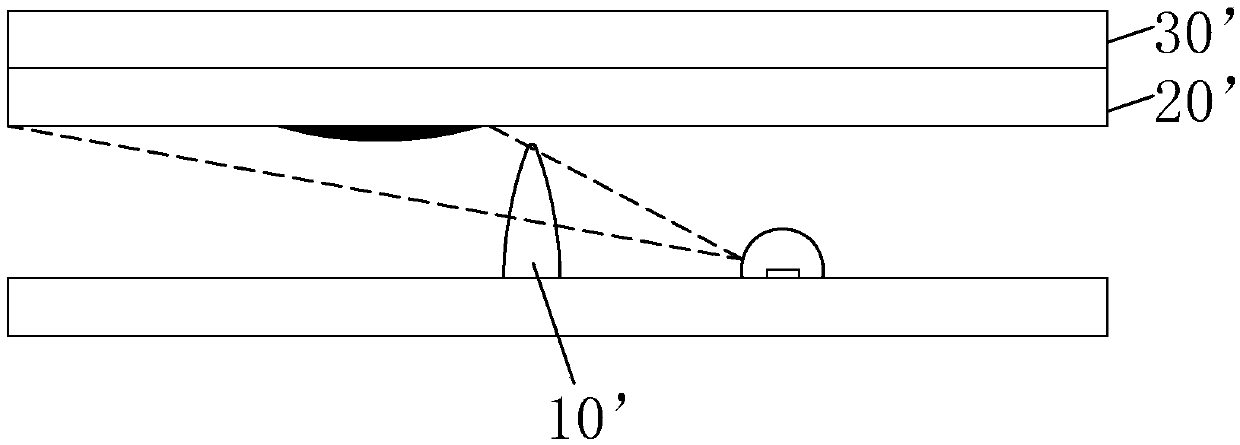

Backlight module and liquid crystal display device

InactiveCN102661543AReduce in quantityImprove stabilityPoint-like light sourceLighting heating/cooling arrangementsLiquid-crystal displayLight guide

The invention discloses a backlight module and a liquid crystal display device. The backlight module comprises a light guide plate, a light source assembly, a back frame and a reflector body. The light guide plate comprises a light inlet face, a light outlet face connected with the light inlet face and a bottom face opposite to the light outlet face. Light sent by the light source assembly is reflected by the reflector body to enter from the light inlet face of the light guide plate to the light guide plate. The back frame is arranged on one side of the bottom face of the light guide plate. The reflector body is formed by extending from one end of the back frame close to the light inlet face along the direction close to the light inlet face. By means of the mode, the backlight module and the liquid crystal display device can save materials, strengthen stability of optical components, and improve optical coupling efficiency between the light source assembly and the light guide plate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Fall automatic power-off switch with spring reset

ActiveCN104934259ANot easy to deformReduce contact resistanceElectric switchesElectrical resistance and conductanceEngineering

The present invention relates to a switch. A fall automatic power-off switch with spring reset comprises an insulating shell and two wiring pins fixed to the shell. The shell is internally provided with an assembly chamber. The inner ends of the two wiring pins are in the assembly chamber which is internally equipped with a weight. The assembly chamber is internally provided with a weight guide cavity which extends along an up and down direction. The weight is in the weight guide cavity. The assembly cavity is also internally provided with a power-off spring which presses the conductive pieces on the inner ends of the two wiring pins under the effect of the weight and allows the conductive pieces to be separated from the wiring pins at the same time. The invention provides the fall automatic power-off switch with spring reset, the resistance of the conductive pieces which are connected to a pair of wiring pins can be maintained to be constant, and the problem of the heat generation phenomenon caused by the increase of the resistance of the conductive pieces which are connected to a pair of wiring pins after multiple times of opening and closing of an existing fall automatic power-off switch with spring reset is solved.

Owner:BULL GRP CO LTD

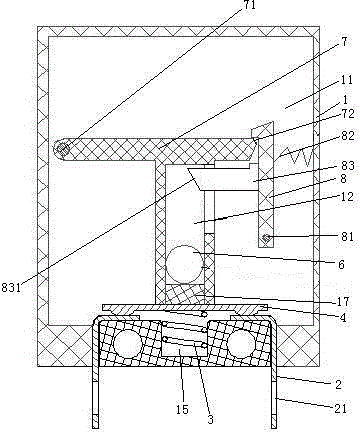

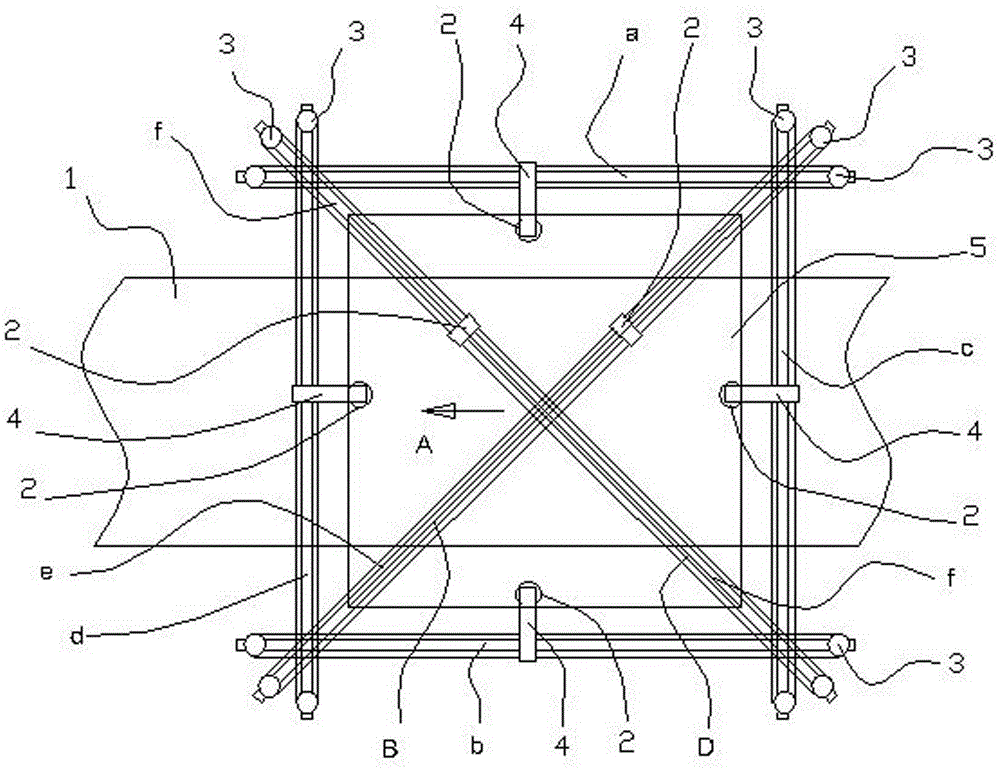

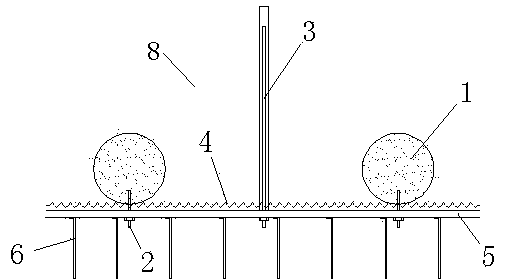

Tile flatness detecting method and device

The invention discloses a tile flatness detecting method and device. The device is characterized by comprising an upper linear guide rail and a lower linear guide rail which are horizontally arranged on the two sides of a tile conveying device, a vertical straight line guide rail perpendicular to the tile conveying direction, an inclined straight line guide rail corresponding to the tile diagonal direction, and laser displacement sensors which are arranged on the straight line guide rails in a sliding mode respectively, the detection direction of the laser displacement sensors faces downwards, and the laser displacement sensors on the straight line guide rails are driven by an electric power mechanism to move. Compared with the prior art, the tile flatness detecting method and device have the advantages that calibration is not needed and tile deformation detection omission is not prone to occurrence.

Owner:GUANGDONG SINID TECH

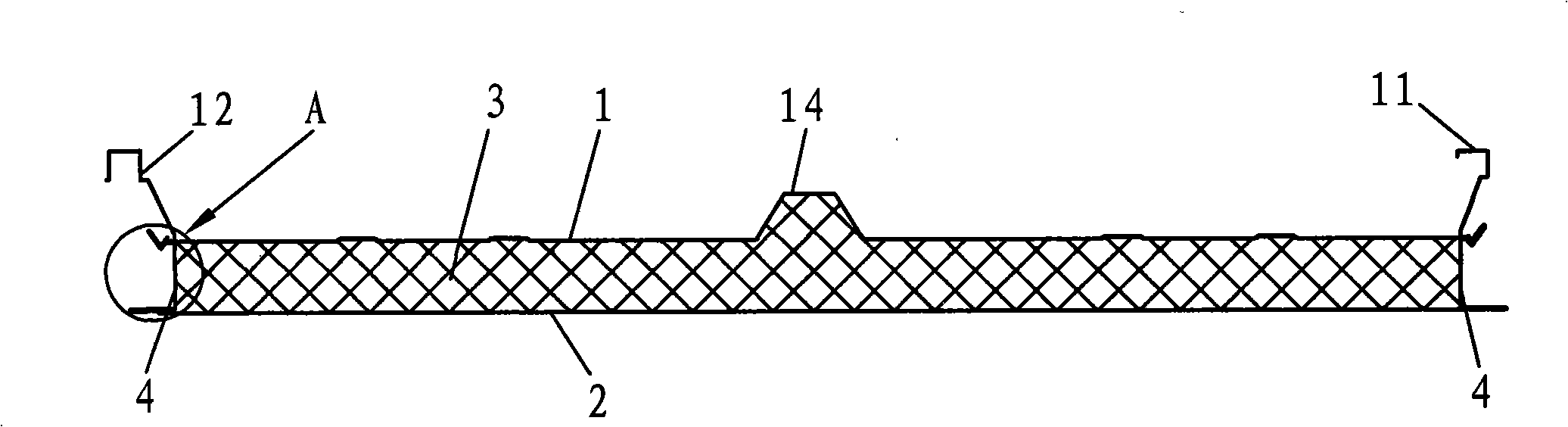

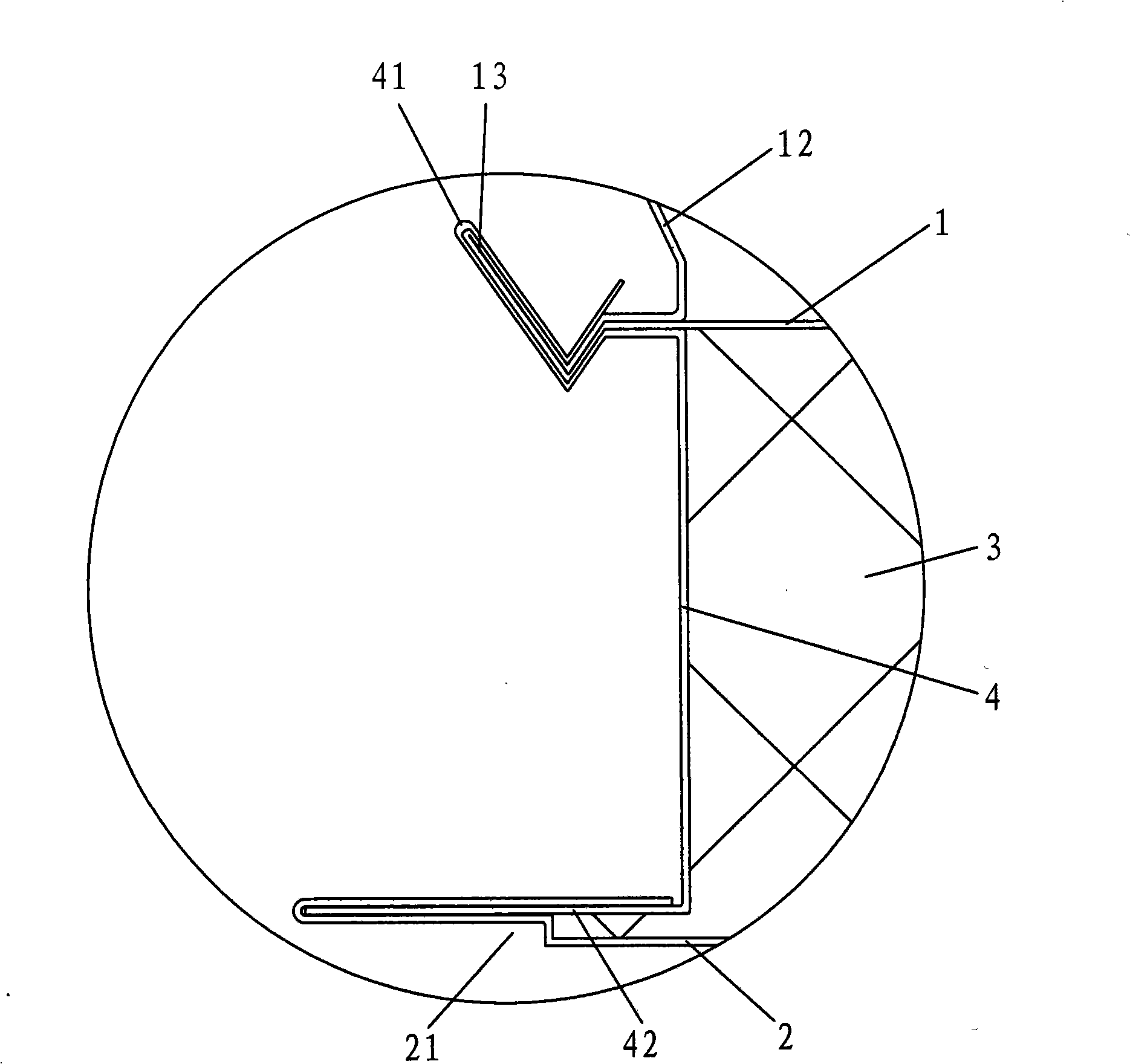

Production method for edge sealing type hidden buckle rock wool laminboard

InactiveCN101403248ANot easy to degummingNot easy to deformRoof covering using slabs/sheetsWater leakageEngineering

The invention relates to the technical field of construction materials, in particular to a manufacture method of an edge-sealed type hidden-fastening rock wool laminboard, which comprises the steps as follows: A. two side edges of a panel are subjected to moulding by pressing and folding respectively so as to form a tile hidden fastner and a tile fastening edge; B. the upper end and the lower end of an edge-sealed side board are subjected to moulding by pressing and folding respectively so as to form an upper connecting edge and a lower connecting edge; C. the panel and the edge-sealed side board are subjected to fastening-mouding by pressing and folding and connected together; D. the rock wool core materials are arranged between the panel and a bottom board; and E. the bottom board and the edge-sealed side board are tightly fixed and connected, wherein, the panel, the bottom board and the edge-sealed side board are combined together to form a sealed border, the clearances of the panel and the two sides of the bottom board are sealed by the edge-sealed side board, and therefore water can not permeate from the edge-sealed side board between the panel and the bottom board easily and can not leak into the rock wool materials, thus preventing water leakage effectively and prolonging the service life; moreover, the rock wool laminboard manufactured by using the method has stable structure of the sealed boarder, and therefore the phenomena such as degumming, deforming, dispersing and the like do not occur on the panel and the bottom board easily.

Owner:DONGGUAN HONGFA STEEL STRUCTURE MATERIAL

Process flow for automatically producing fiber optic connector

The invention discloses a process flow for automatically producing a fiber optic connector, comprising the steps of: a part assembling process of assembling the parts into a connector joint, and injecting glue into the connector joint to keep the glue from solidifying; an automatic curing process of heating a connector for solidification on a curing device and performing constant-temperature cooling; an automatic grinding process of using a manipulator to automatically grind the front end surface of a fiber connector joint by means of 8-shaped grinding; a test process of using a virtualizationtest to individually test three indexes by segment, namely, geometric size, insertion loss and return loss, and setting insertion loss and return loss to automatic discrimination; and an automatic packaging process of using an assembly line of automatic winding, bundling, certificate sticking, and bagging. The process flow provided by the invention greatly saves the labor cost by adopting an automated production mode instead of the post requiring lots of the front-end personnel, and also improves the stability, reliability, excellent rate and production efficiency of the product.

Owner:SICHUAN TIANYI COMHEART TELECOM

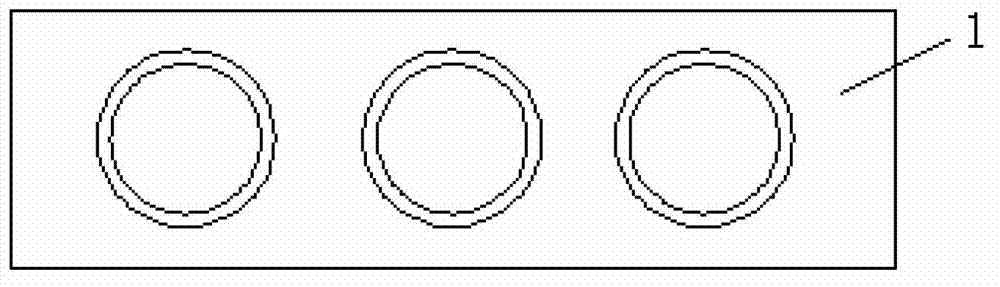

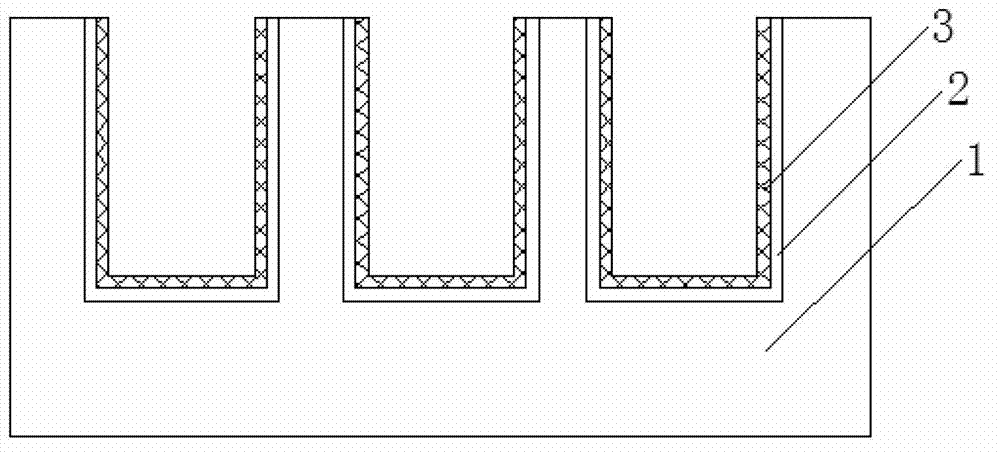

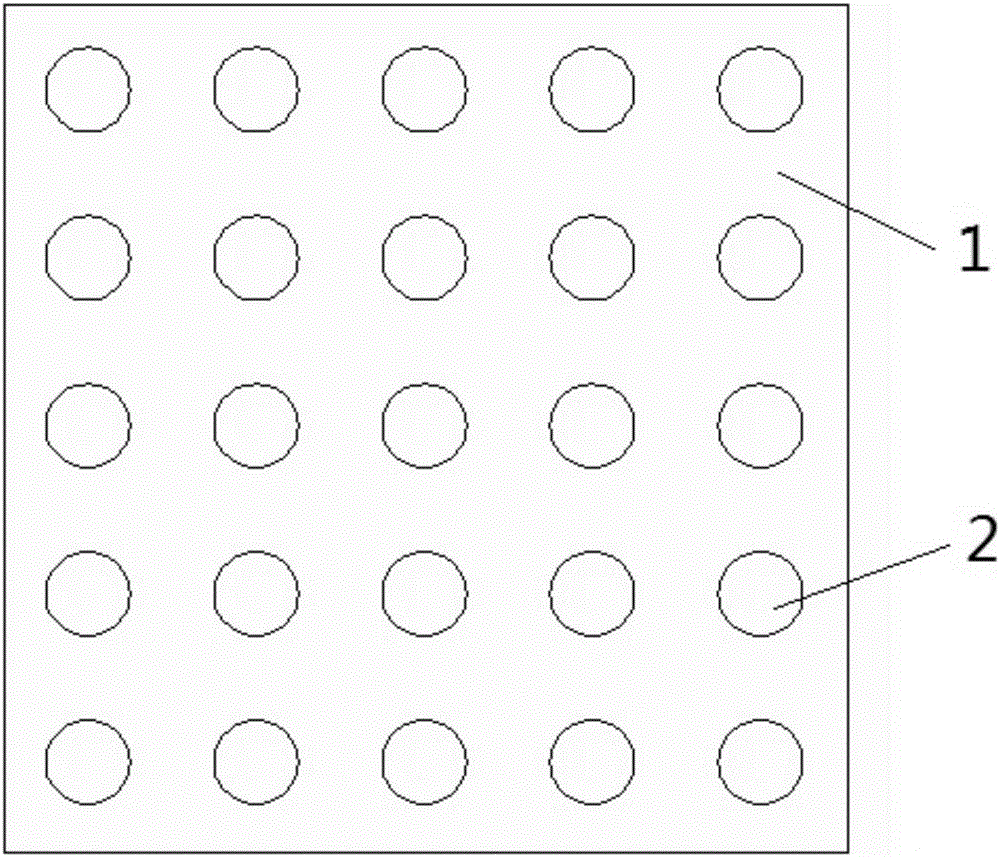

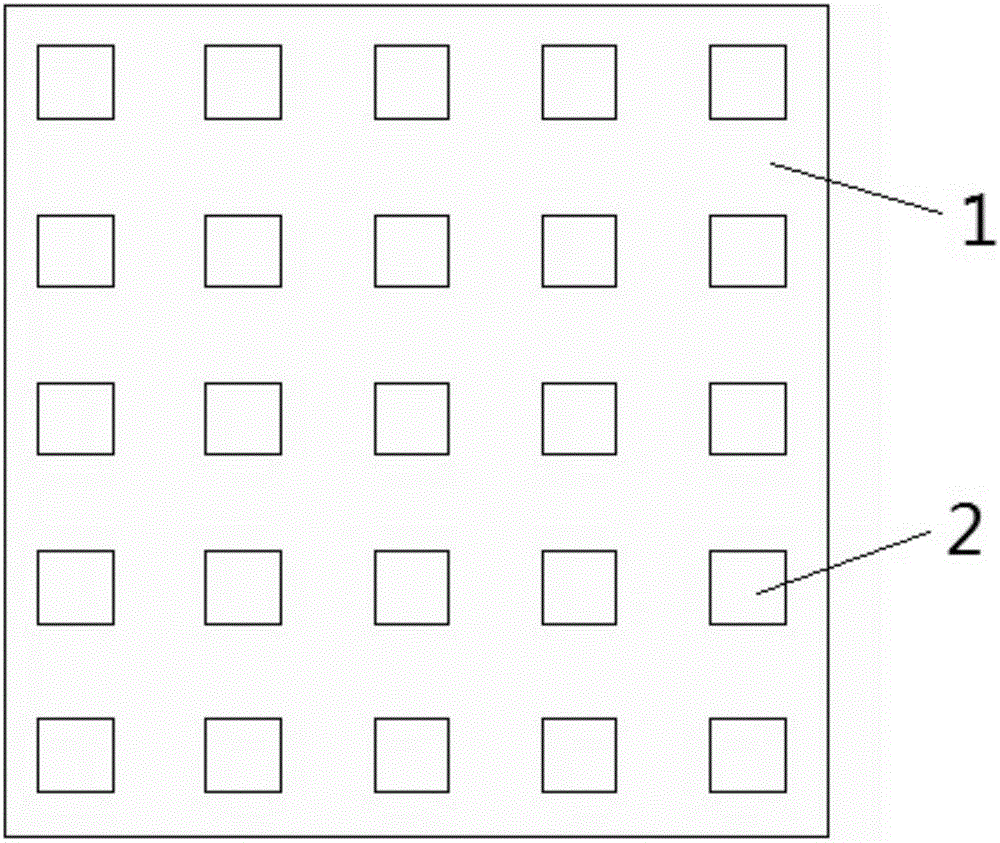

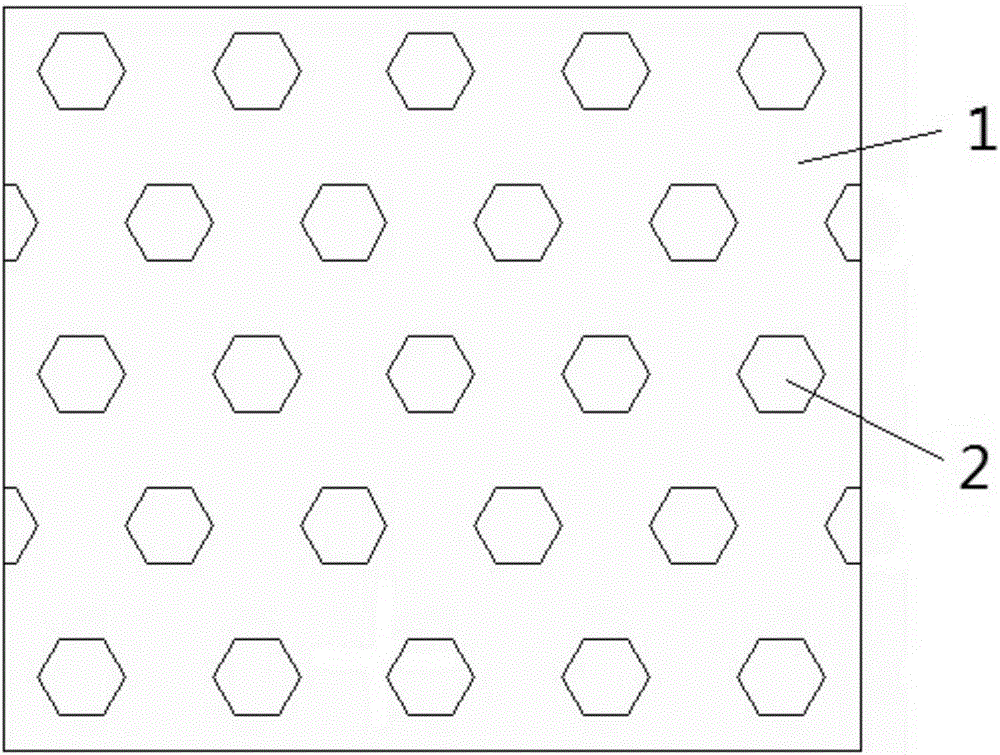

Film-substrate micro-through-hole-array biochip and preparation method thereof

InactiveCN106119095ANot easy to deformAvoid background light interferenceApparatus sterilizationMicrobiological testing/measurementChemistryMicroscope

The invention discloses a film-substrate micro-through-hole-array biochip and a preparation method thereof. The film-substrate micro-through-hole-array biochip is mainly based on the property that cancer cells usually greater than normal cells and employs a series of through holes with diameters greater than the diameters of normal cells and less than the diameters of cancer cells for separation of cancer cells from normal cells by using a filtering and screening method. The film-substrate micro-through-hole-array biochip provided by the invention is a transparent film with uniform thickness, and micro-through-hole arrays are distributed on the film; and biochip is prepared by using a photoetching method. According to the invention, a transparent-film through-hole structure is employed for separation of cancer cells, which facilitates combination of conventional mature pathological analysis means and observation excited by an inverted fluorescence microscope after dyeing and prevents interference by backlight; moreover, the film is a high polymer material which is widely available and low in cost; the shapes and distribution of micro through holes are diversified; so the biochip has a higher degree of freedom in performance optimization and industrial application and promotion of the biochip are benefited.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI

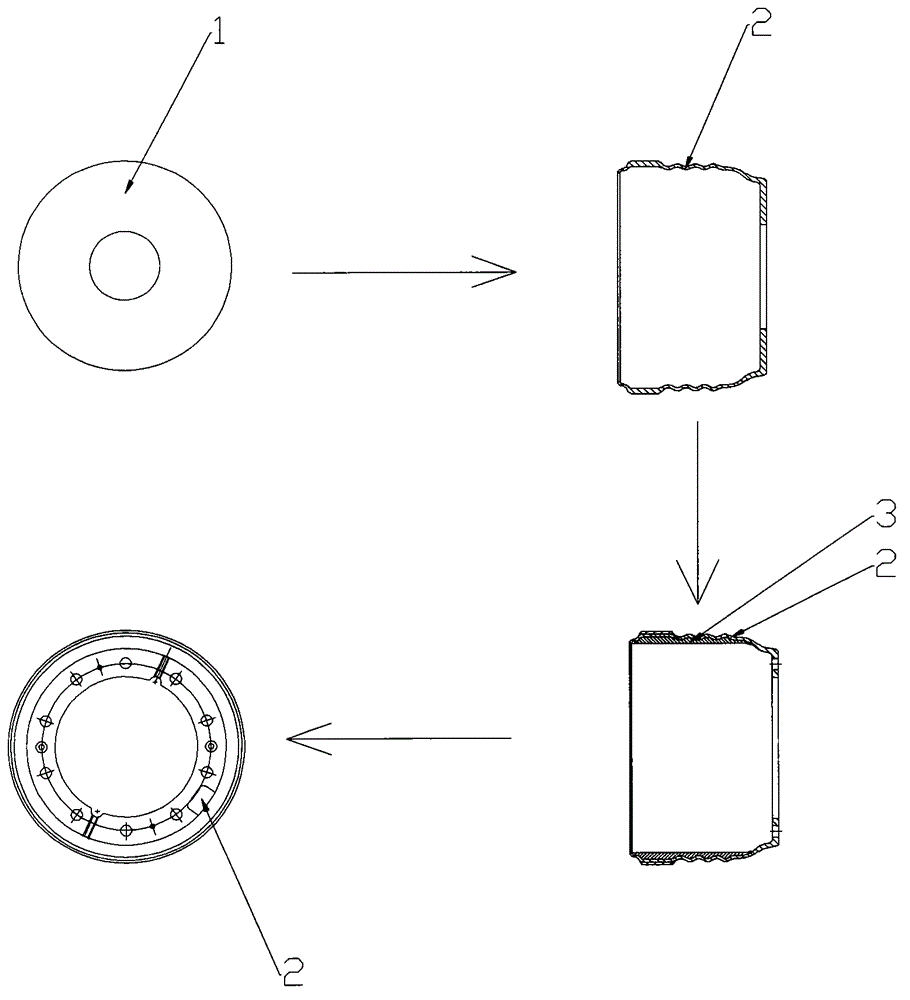

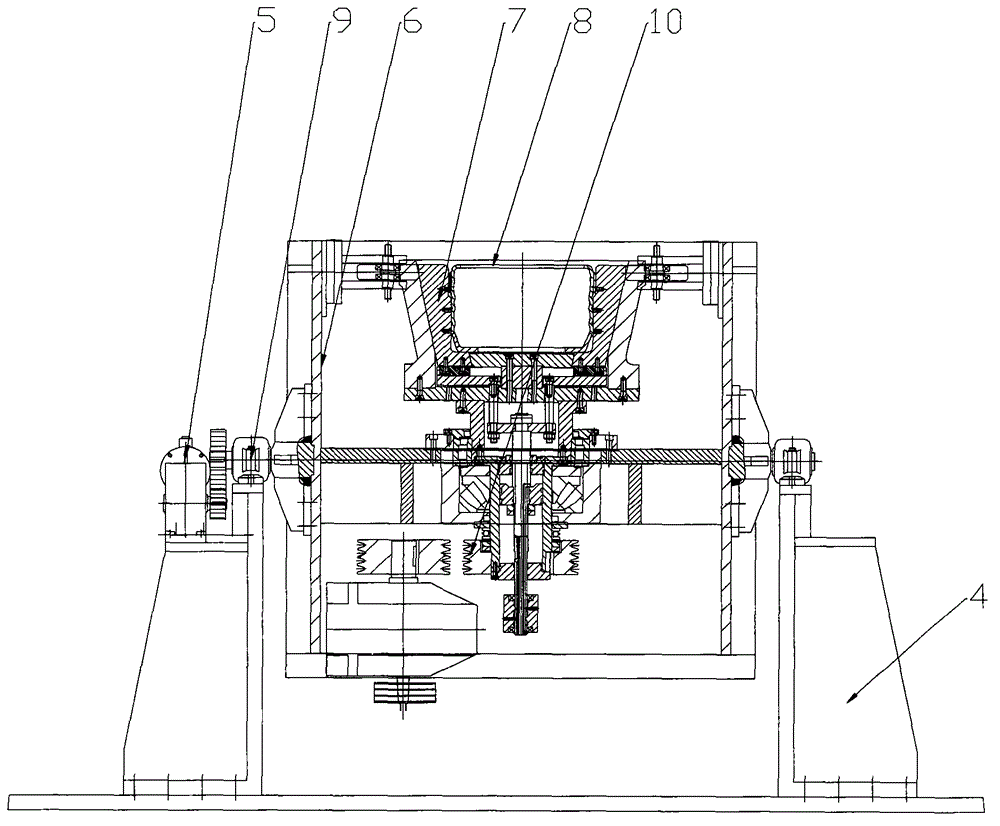

Centrifuge and process for manufacturing anti-cracking type composite brake drum by adopting centrifuge

The invention provides a centrifuge and relates to the field of manufacturing of an automobile part. The centrifuge comprises a support, a centrifugal casting chamber and an overturning mechanism, wherein the overturning mechanism comprises an overturning frame, a speed changer and a transmission mechanism; the overturning frame is arranged on the support; a motor is used for driving the overturning frame to overturn relative to the support by the transmission mechanism and the speed changer; a locking reshaping block, a centrifugal casting mechanism and a rotation mechanism are arranged in the centrifugal casting chamber; the rotation mechanism comprises a transmission mechanism and a speed changer; a main motor is used for driving the locking reshaping block and the centrifugal casting mechanism to rotate relative to the centrifugal casting chamber by the transmission mechanism and the speed changer. The invention further provides a process for manufacturing an anti-cracking type composite brake drum by the centrifuge. The process adopts a special centrifugal casting manner and the manufactured brake drum has high bearing capability, good anti-cracking performance and long service life.

Owner:SHANDONG TAIYANG AUTO PART

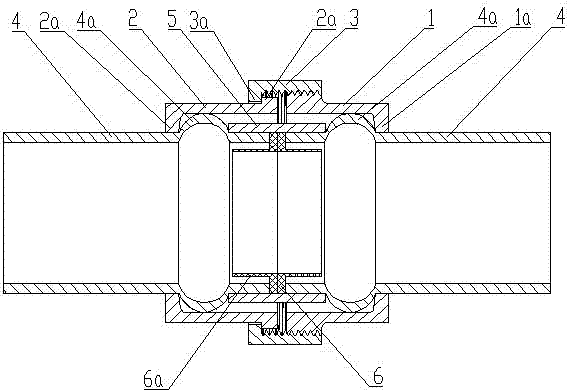

Inner expansion connecting structure for screw sleeve type steel and plastic composite pipe

ActiveCN102313086APull-out resistance can be improvedPull out is not easy to produceJoints with sealing surfacesButt jointEngineering

The invention discloses an inner expansion connecting structure for a screw sleeve type steel and plastic composite pipe, which comprises a threaded sleeve and a clamp sleeve in coaxial parallel arrangement, wherein a screw sleeve for regulating the distance between the threaded sleeve and the clamp sleeve is sheathed outside the threaded sleeve and the clamp sleeve, the end part of the threaded sleeve far away from the clamp sleeve and the end part of the clamp sleeve far away from the threaded sleeve are respectively provided with inwards projected annular shoulders in the radial direction,two pipelines requiring the butt joint respectively extend into the structure from the annular shoulder parts of the threaded sleeve and the clamp sleeve, annular expansion bulges are respectively and outwards expanded on the extending sections of the two pipelines requiring the butt joint in the radial direction, the two expansion bulges are respectively and tightly butted on the two annular shoulders, an lining sleeve sheathed outside the two pipelines requiring the butt joint is rightly butted and arranged between the two expansion bulges, both sides of the expansion bulges are respectively butted by the end parts of the annular shoulders and the lining sleeve, the expansion bulges can not easily generate and recover the deformation to disconnect the pipeline even when the pipeline receives excessive disconnecting force, and the anti-disconnecting capability of the connecting structure is effectively improved, simultaneously, the expansion bulges can not easily generate the deformation, the position of a pipe opening is relatively fixed, and the sealing is more reliable.

Owner:重庆顾地塑胶电器有限公司 +1

Novel bus duct

InactiveCN104184091AImprove securityEasy to useTotally enclosed bus-bar installationsPulp and paper industry

The invention provides a novel bus duct. The top of a bus bar is provided with a cover plate, the bottom of the bus bar is provided with a bottom plate, the two sides of the bus bar are provided with lateral plates, the two ends of a cover plate body are respectively provided with a dustproof mechanism, the two ends of the bottom of the cover plate body are respectively provided with a lateral plate positioning mechanism, the center of the top of the cover plate body is provided with a reinforced protrusion portion, the center of the bottom of the cover plate body is provided with a bus positioning groove, a plurality of positioning edges are arranged in the bus positioning groove, the tops of the lateral plates are embedded into lateral plate positioning grooves, the lateral plates and the cover plate can be fixed through the lateral plate positioning grooves, the bottoms of the lateral plates are provided with flangings outwards, and the flangings are fixed to the top of the bottom plate through bolts. The bus bar comprises a plurality of buses, the buses are installed in the bus duct through the bus positioning groove in the cover plate, and the buses can be positioned in a spaced mode through the positioning edges. The novel bus duct is good in dustproof effect, convenient to install, simple in operation, high in deformation resistant capacity and high in safety coefficient; heat dissipation can be conducted conveniently.

Owner:JIANGSU HENLEY ELECTRIC

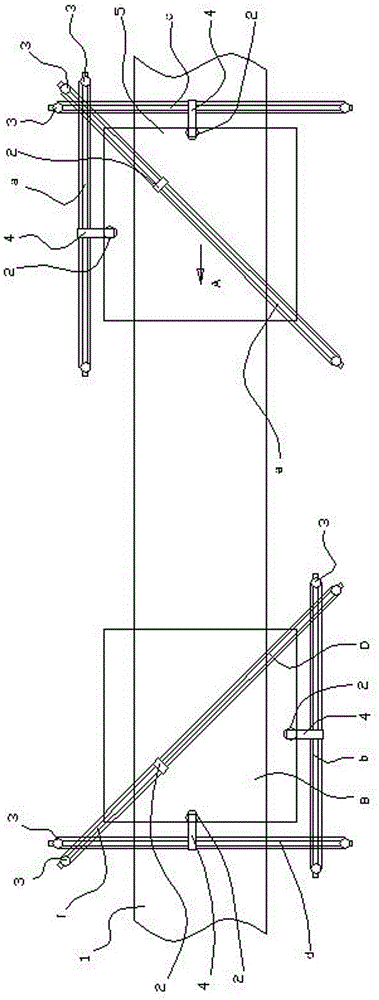

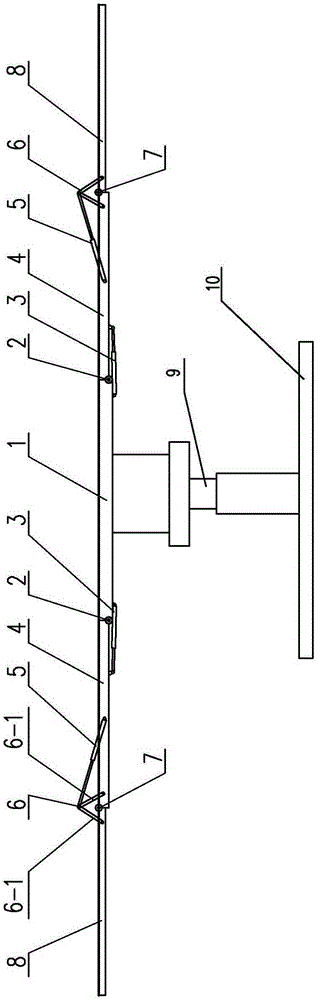

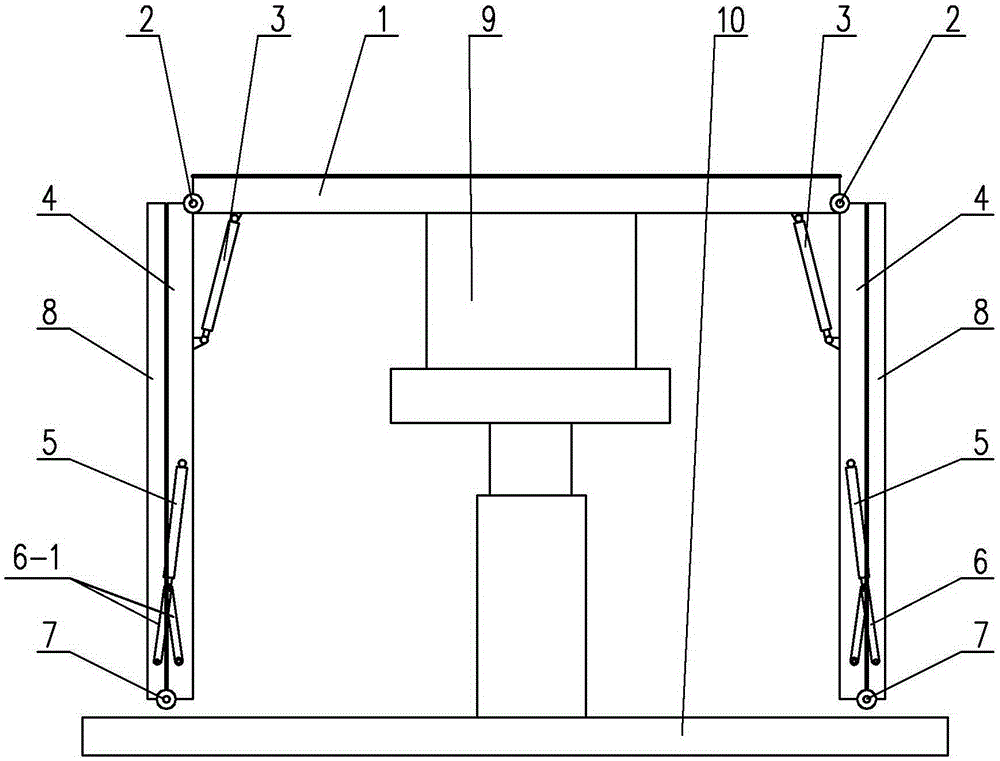

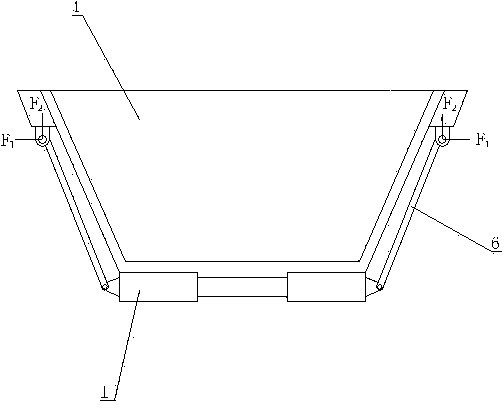

Double-folding type solar battery panel bearing device

InactiveCN105227117AHigh precisionNot easy to deformPV power plantsPhotovoltaic energy generationVehicle frameSmall arms

Owner:HEILONGJIANG XINGAN NEW ENERGY

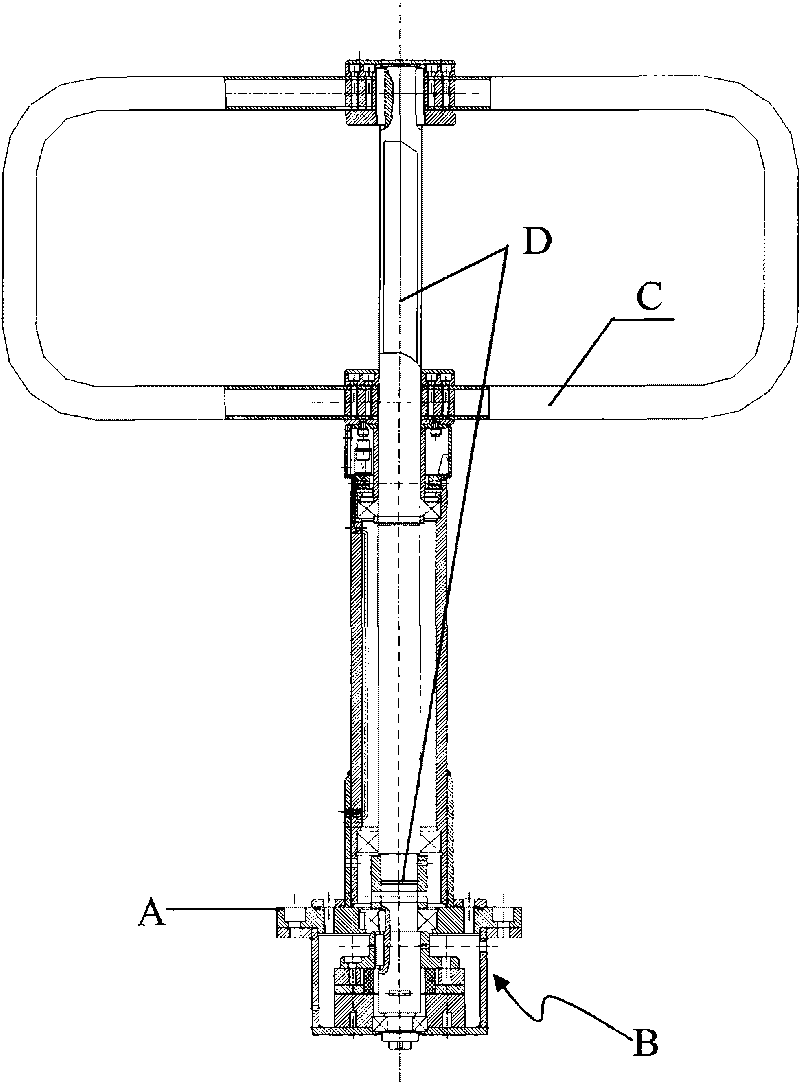

Cross door access machine

InactiveCN101748958AReduce torqueNot easy to deformRevolving doorsTurnstilesAgricultural engineeringEmergency situations

The invention discloses a cross door access machine, comprising a door leaf, a main shaft, a brake, a sensor kit and a bracket; the brake is installed at the lower end of the central part of the door leaf; the sensor kit is installed below the brake; and the bracket supports the cross door access machine by means of the combination with the ground through screw nails. The cross door access machine has the following advantages that: the brake is installed at the upper part of the door access machine with short main shaft and small torque, and the main shaft is not easy to deform and damage, thereby simultaneously preventing damage of water and dust, prolonging the service life of the machine and facilitating maintenance; the machine has simple structure, convenient installation and low cost, and an emergency device provides better guarantee for use convenience.

Owner:天津渤海化学股份有限公司

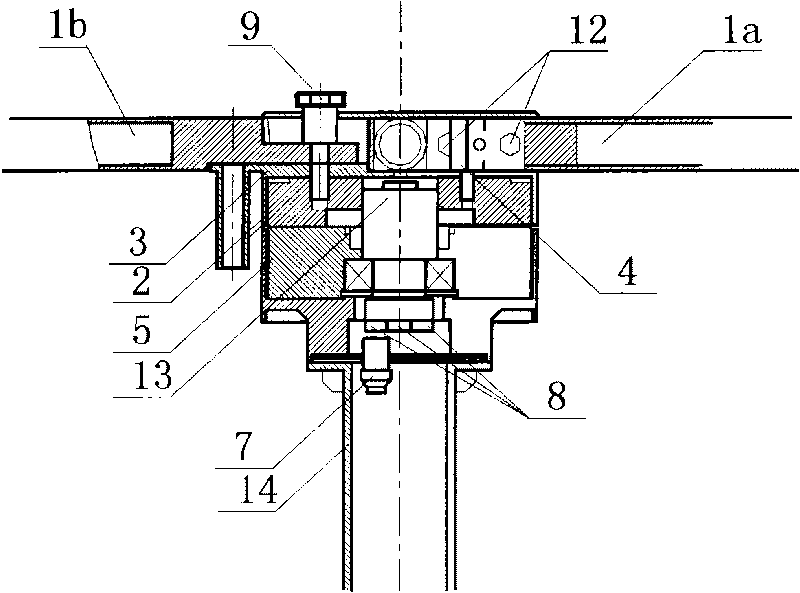

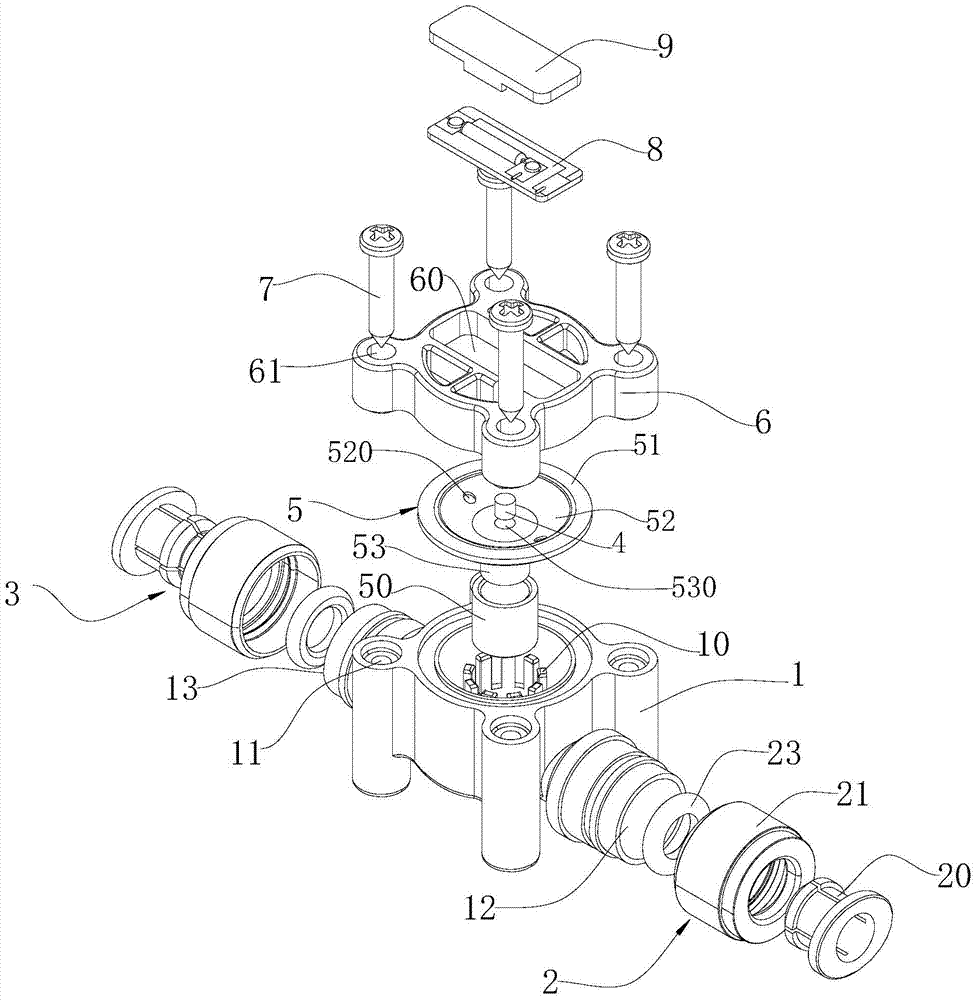

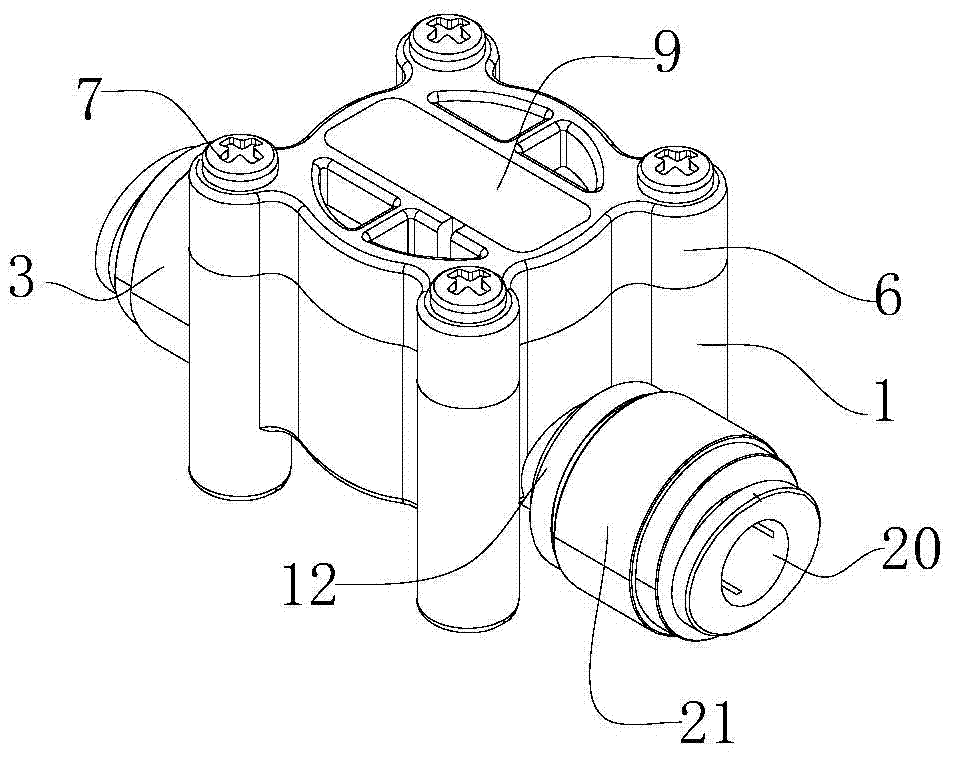

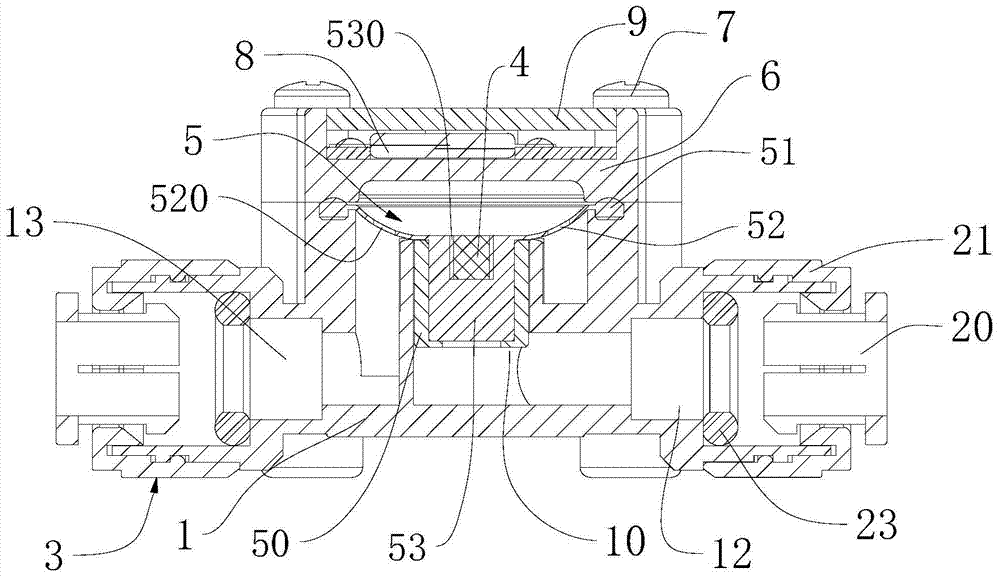

Water flow inductive switch

ActiveCN103700540AOvercoming the defect of offset errorNot easy to deformMagnetic/electric field switchesWater flowEngineering

The invention relates to an inductive switch for inducing a water flow pressure signal in a flowing water pipeline. The water flow inductive switch comprises a casing with a water inlet and a water outlet, an elastic resetting membrane element, a magnetic block and a magnetic induction circuit board, wherein a mounting cavity is formed in the inner side of the casing; the water inlet of the casing is communicated with the water outlet through the mounting cavity; the elastic resetting membrane element and the magnetic block are positioned on the inner side of the casing; a pushing and pressing column part which is elastically plugged in the mounting cavity is arranged at the lower part of the elastic resetting membrane element, and an annular deformation membrane is arranged at the upper part of the elastic resetting membrane element, and surrounds and is fixedly connected to the outer peripheral wall of the top of the pushing and pressing column part; the top of the annular deformation membrane is propped against the inner wall of one side of the casing; the magnetic induction circuit board is positioned on the outer side of the casing, and corresponds to the annular deformation membrane; the magnetic block is embedded into the top end part of the pushing and pressing column part; an induction gap changing along with the deformation state of the annular deformation membrane is reserved between the magnetic block and the magnetic induction circuit board. The water flow inductive switch is novel in structure, and has the advantages of high pressure signal induction sensitivity and stability, good using effects, long service life and the like.

Owner:佟勇华

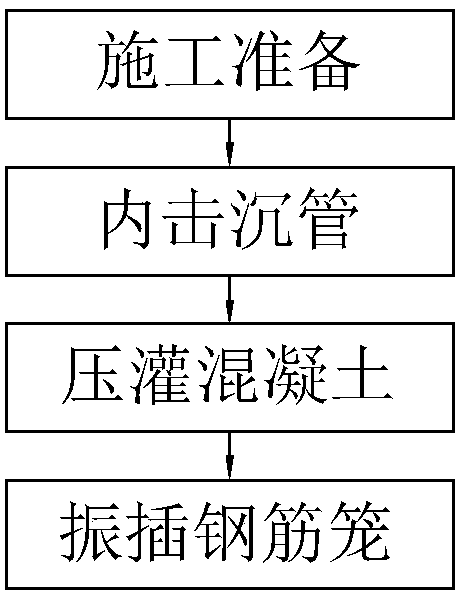

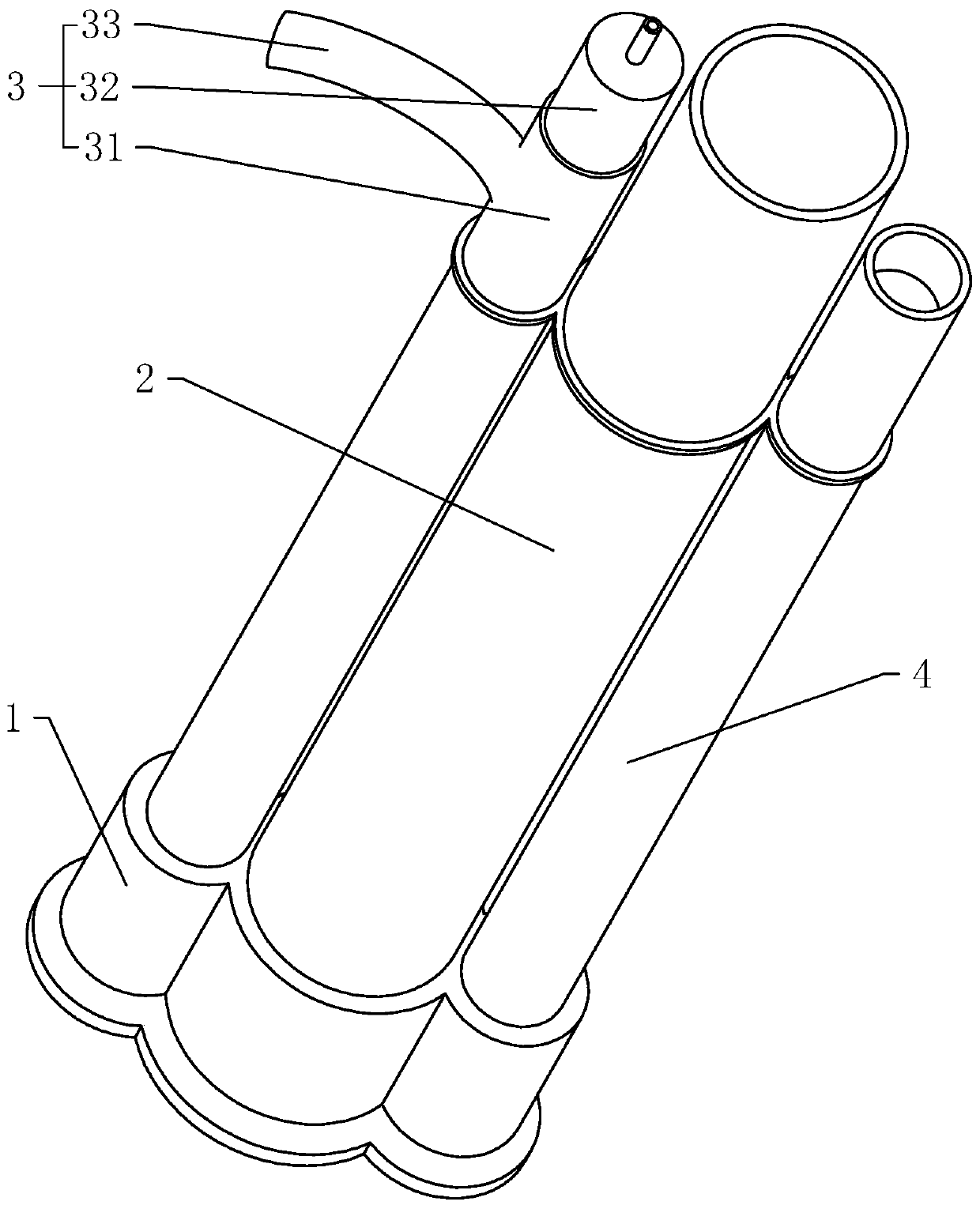

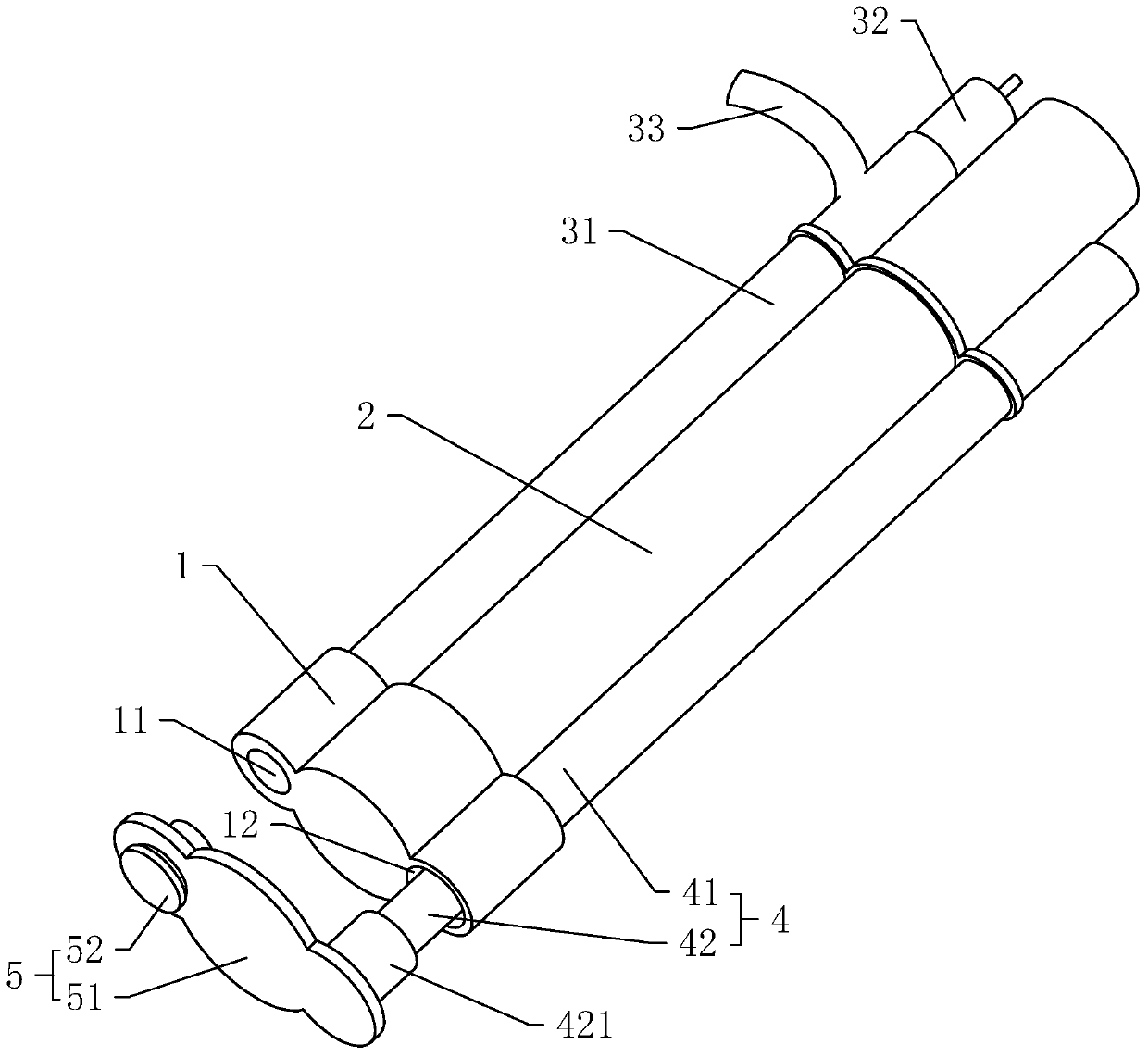

Pipe sinking pressure fillingconstruction method of cast-in-place pile

InactiveCN110258571ANot easy to bend and deformImprove molding qualityBulkheads/pilesRebarPoor quality

The invention discloses a pipe sinking pressure fillingconstruction method of a cast-in-place pile, and relates to building technology.The pipe sinking pressure fillingconstruction method of the cast-in-place pile is used for solving the problem of poor quality of ordinary pressure-filled piles andcomprises the following steps that construction is prepared, a pile machine and a pile pipe are assembled in a pile position, and the pile pipe is kept vertical; asinking pipe is stricken inwardly, aninwardly stricken hammer directly acts on a bottom plate, so that the pile pipe sinks into a soil layer to form a pile hole; concrete is subjected to pressure filling, the concrete is poured under the bottom plate, and the pile pipe is pulled upwards to be separated from the pile hole; areinforcement cage is inserted in a vibration mode, the reinforcement cage is inserted into the pile hole to complete pile foundation construction; the hammering method directly applying the force to the bottom plate causes the pile pipe to be pulled during the process of penetrating the soil layer, so that the pile pipe is not prone to producing bending deformation under the action of the hammering force, and the pile hole forming quality is higher, meanwhile the pile pulling method of pushing the pile pipe to float by the poured concrete can always press the inner wall of the pile hole, so that the pile hole is also not prone to producing shrinkage during the floating of the pile pipe, and thus the pile foundation is better in pile quality.

Owner:深圳建中路桥工程有限公司

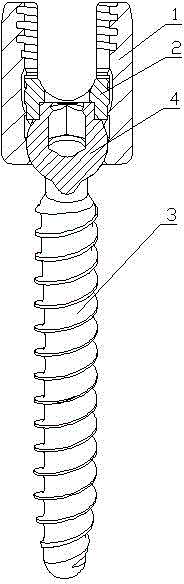

Single-plane pedicle screw

ActiveCN104939902ANot easy to deformImprove stabilityInternal osteosythesisDiagnosticsEngineeringPedicle screw

The invention discloses a single-plane pedicle screw and relates to the technical field of orthopedics department medical apparatus. The single-plane pedicle screw comprises a screw base, a positioning compression ring and a ball-head screw and is characterized in that lateral platforms are disposed on the left side and the right side of the upper portion of the ball head of the ball-head screw, the upper side of each lateral platform is arc-shaped and protrude upwards, the ball head, between the two lateral platforms, of the ball-head screw is provided with a central boss, the upper side of the central boss is arc-shaped and protrude upwards, the arc circle center of the central boss and the connecting line of the arc circle centers of the two lateral platforms are on the same straight line, two arc-shaped concave faces matched with the two lateral platforms are disposed on the lower portion of the positioning compression ring and on the left side and the right side of a rod placing groove, and an arc-shaped groove matched with the central boss is disposed in the positioning compression ring in the middle of the two arc-shaped concave faces. The single-plane pedicle screw has the advantages that the single-plane pedicle screw is even in stress and high in overall strength, the screw is less prone to deformation during use, a screw-rod system is good in overall stability and safe and reliable, and the like.

Owner:SHANDONG WEIGAO ORTHOPEDIC DEVICE COMPANY +1

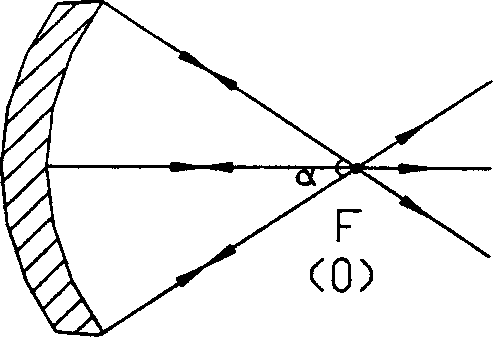

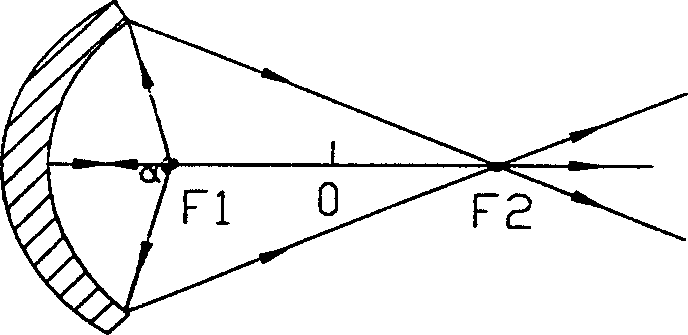

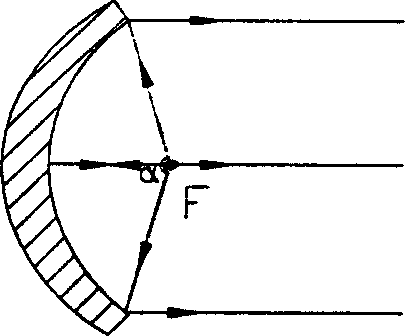

Curved reflector

This invention discloses a curved reflecting mirror, which is used to reflect the light from light source in the projection system. The inner surface of the said curved reflecting mirror serves as reflecting surface. The said curved surface comprises non-sphere mirror and sphere mirror, which are in same axis and their inner surfaces, are designed relatively and their focal point overlaps. And the said sphere mirror bottom is opened with a hole as light-out channel. The light source is located on the overlapping focal point. The said invention can increase light effect and prolong service life, and reduce cost and increase reflecting light uniformity.

Owner:罗筱泠

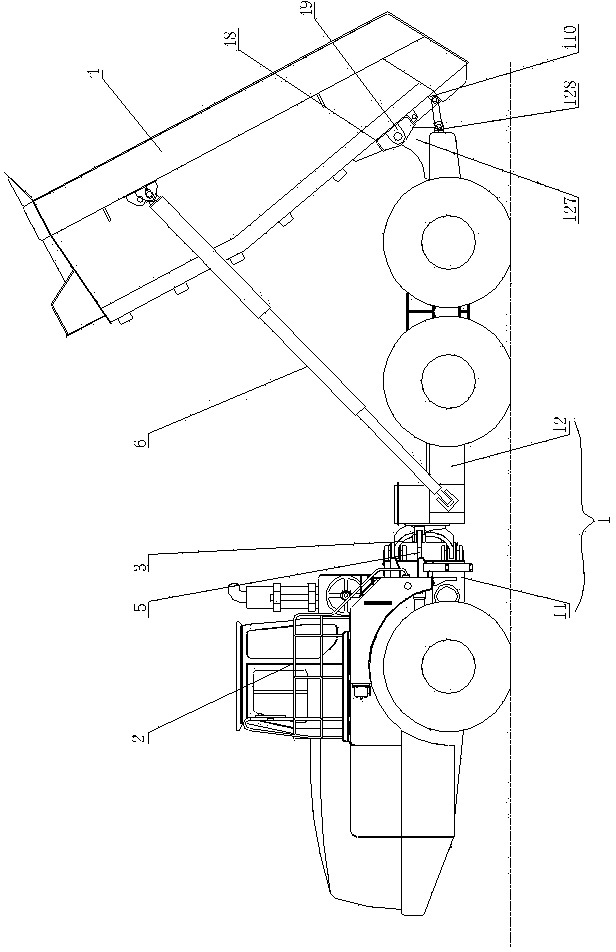

Hinged dumper container assembly, and loading and unloading methods thereof

ActiveCN104071063AHigh strengthImprove carrying capacityUnderstructuresVehicle with tipping movementVehicle frameEngineering

The invention discloses a hinged dumper container assembly, and loading and unloading methods thereof. The container assembly comprises a rear frame and a container, wherein the rear frame comprises a rear frame longitudinal beam assembly, a frame anti-torsion tube, a rear frame lifting seat, a lower hinge seat, a lower bolt seat and a hinge body bearing; the container comprises a bottom plate, a rear tilted plate, a left side plate, a right side plate and a front plate, a left longitudinal beam and a right longitudinal beam are arranged on the left side plate and the right side plate respectively, a left lifting support seat and a right lifting support seat bulging out of the left longitudinal beam and the right longitudinal beam are arranged on the left longitudinal beam and the right longitudinal beam respectively, and an upper hinge seat and an upper bolt seat are arranged at the bottom of the container. The loading method is as follows: returning the container, and loading materials in the container; the unloading method is as follows: turning the container by a lifting oil cylinder, and when the container is turned to a certain position, connecting the upper bolt seat with the lower bolt seat by a bolt; during the turnover process of the container, the materials are detached from the container. The container assembly, and the loading and unloading methods thereof disclosed by the invention are capable of improving the anti-torsion capacity of the frame, improving the bearing capacity and strength of the lifting support seat realizing location for the container, and improving the safety performance of loading and unloading.

Owner:GUANGZHOU ELECTRICAL LOCOMOTIVE

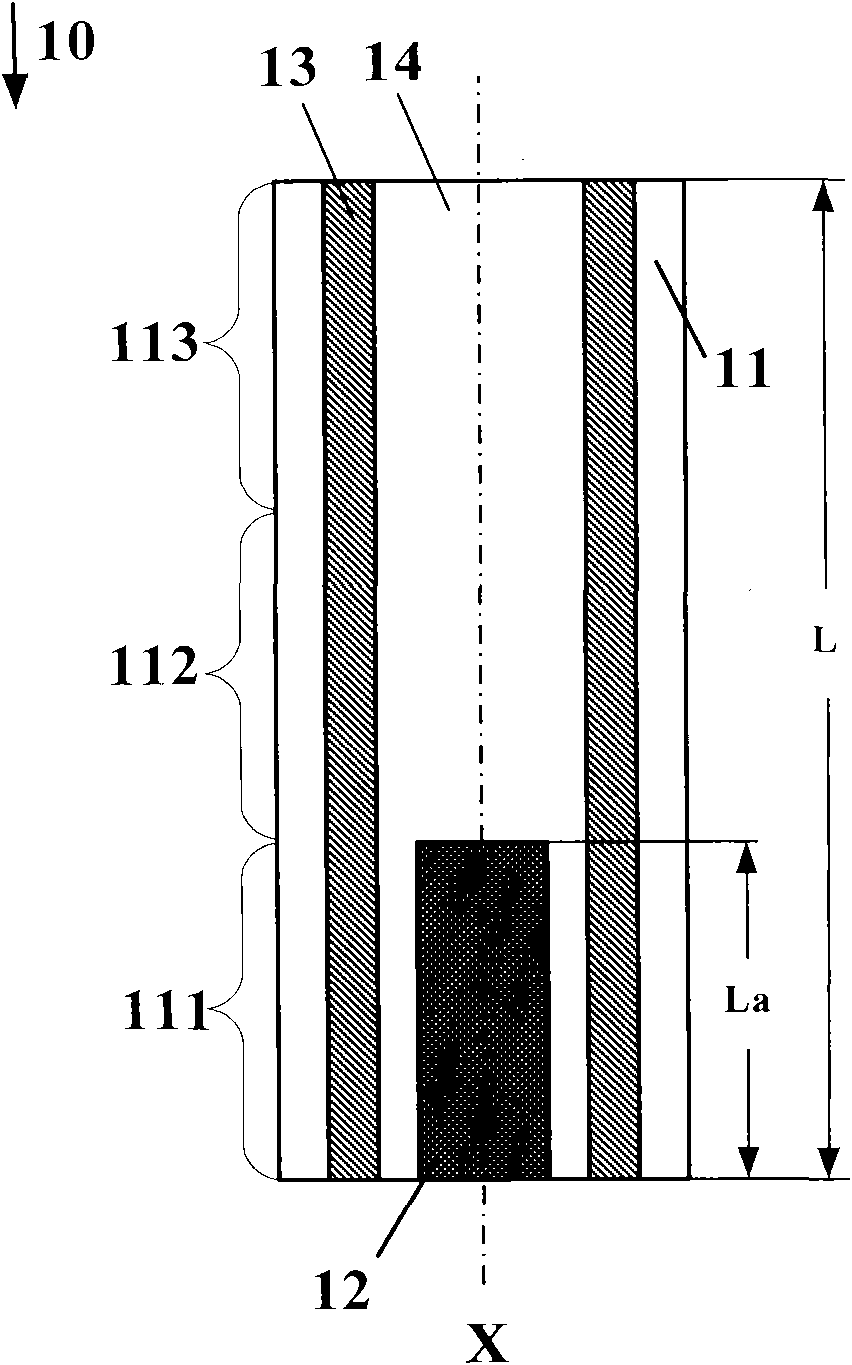

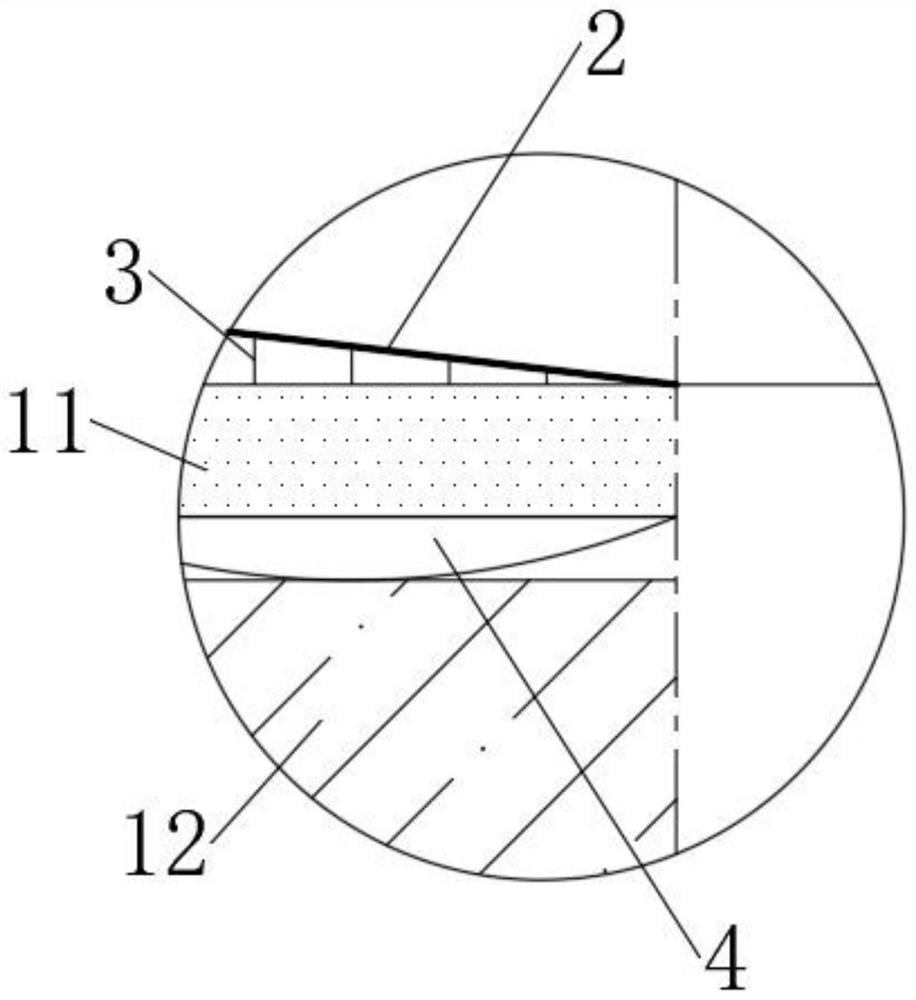

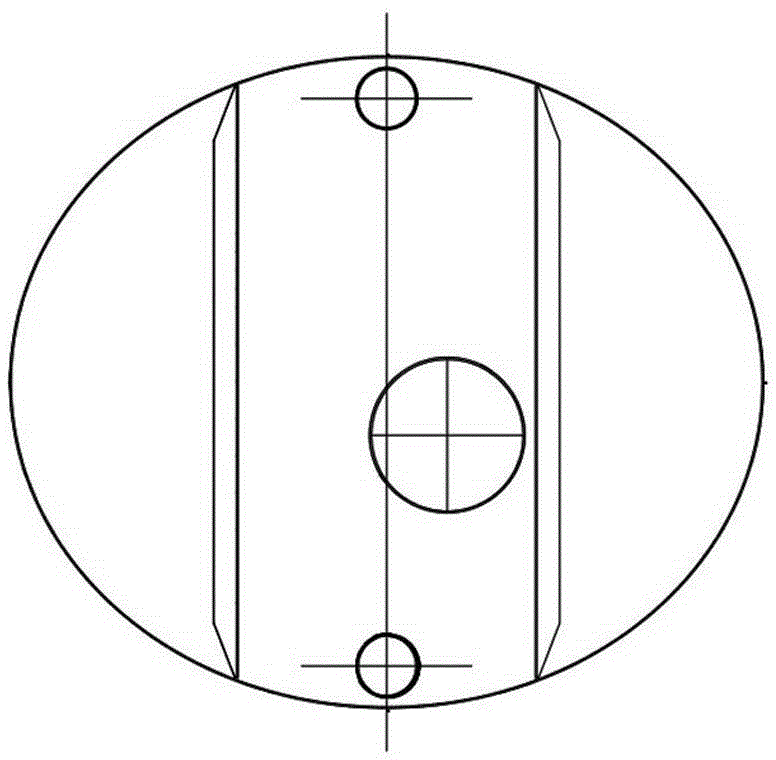

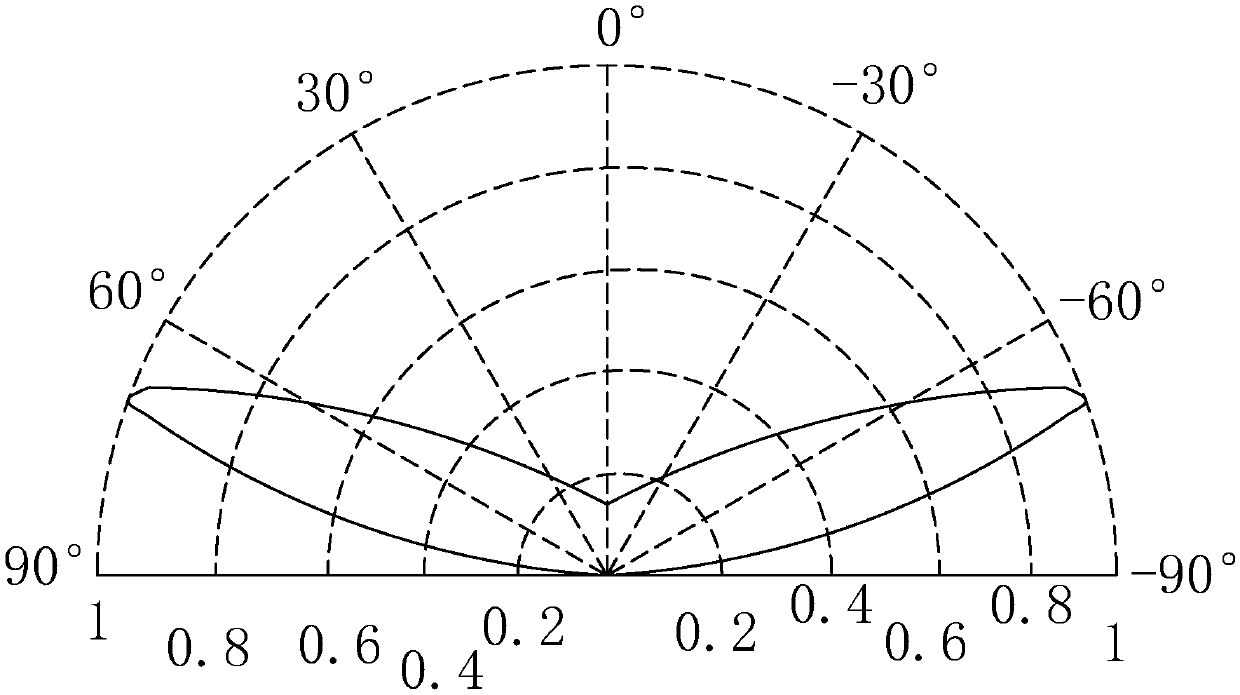

Low-cost Luneberg lens antenna designed based on 3D printer

InactiveCN110336135ASimplify the design processSimplify the optimization processAntenna supports/mountingsRadiating elements structural formsAntenna designRadar

The invention provides a low-cost Luneberg lens antenna designed based on a 3D printer, which mainly solves the problems of complicated structure and inconvenient processing in the prior art. The antenna comprises a hemispherical lens (1), a circular metal reflecting plate (2), a plastic bracket (3) and a Vivaldi feed source (4). The hemispherical lens is fixed on the upper surface of the circularmetal reflecting plate, and the spherical center coincides with the circular center of the reflecting plate. The Vivaldi feed source is fixed at the focal length position of the hemispherical lens. The hemispherical lens is a meshed filling structure composed of a spherical core (11) and two layers of hemispherical shells (12, 13), wherein a first layer of hemispherical shell is nested outside the spherical core, a second layer of hemispherical shell is nested outside the first layer of hemispherical shell, and the spherical core and the two layers of hemispherical shells have different equivalent dielectric constants and correspond to filling media with different filling rates. The antenna of the invention has the advantages of simple structure, low cost, high gain, convenient processingand manufacturing and good scanning beam consistency in the whole frequency band, and can be used in satellite communication, automobile anti-collision radar and microwave remote sensing.

Owner:XIDIAN UNIV

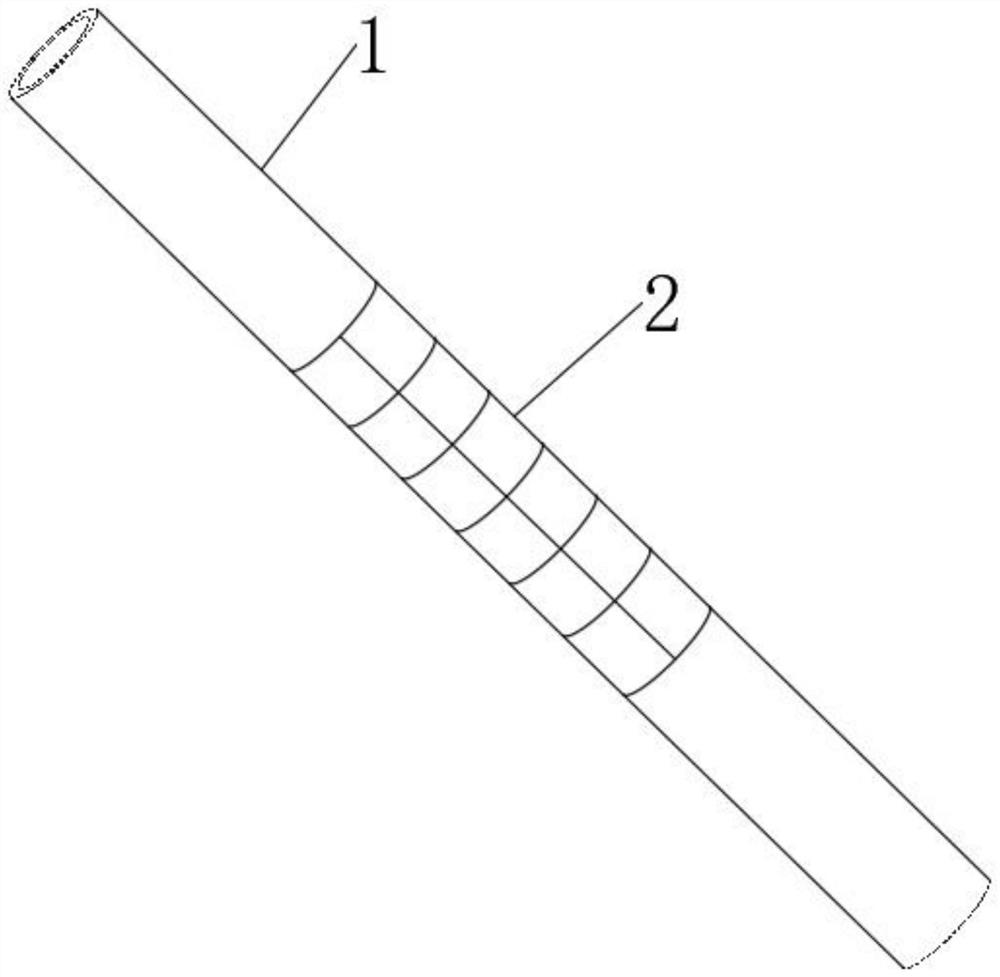

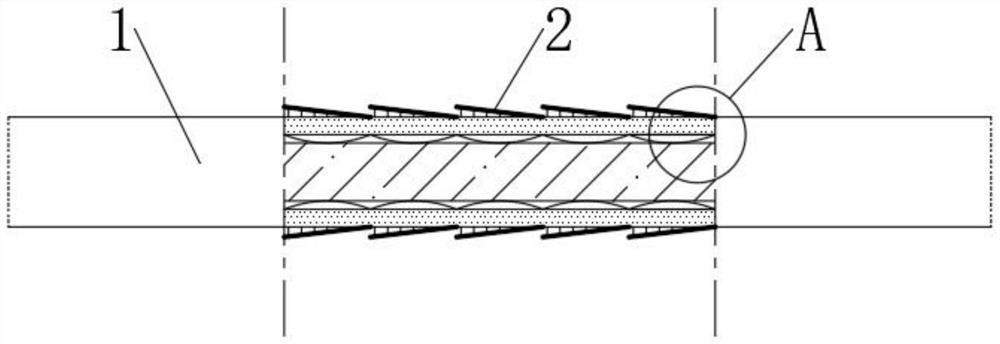

Durable communication cable

PendingCN113871091ADoes not affect bendingDoes not affect stretchingCommunication cablesInsulated cablesAdhesive glueStructural engineering

The invention discloses a durable communication cable, which belongs to the technical field of cables, and can realize coating type mechanical protection on a cable body by covering a specific area on the cable body with mutually lapped protective flakes, and cannot influence bending and stretching of the cable body in a normal range on the other hand, meanwhile, a certain gap is kept between the protective flakes and the cable body to meet heat dissipation, the inner supporting magnetic bundles at the inner ends of the protective flakes can provide an elastic buffering effect, damage caused by the fact that external force directly acts on the cable body is avoided, and even if the cable body cracks due to excessive bending or stretching, a magnetic attraction rubber bag on the inner side of the cable body attracts the corresponding inner support magnetic bundle to promote the inner support magnetic bundle to extend to the cracking part, and meanwhile, the magnetic attraction rubber bag can also be compressed to release glue to glue the cracking part, so that a temporary repairing effect is achieved, early warning is given to technicians, and the durability of the cable body can be greatly improved.

Owner:胡守盛

Butterfly-shaped wave-resistance plate structure of tank semi-trailer

InactiveCN105383829AImprove the anti-wave effectNot easy to deformLarge containersBiochemical engineeringSemi-trailer

The invention discloses a butterfly-shaped wave-resistance plate structure of a tank semi-trailer. The butterfly-shaped wave-resistance plate structure comprises butterfly-shaped wave-resistance plates and butterfly-shaped strengthening rings. The butterfly-shaped strengthening rings are welded to the butterfly-shaped wave-resistance plates, and the butterfly-shaped wave-resistance plates and the butterfly-shaped strengthening rings are welded to the interior of a semi-trailer tank body. According to the butterfly-shaped wave-resistance plate structure of the tank semi-trailer butterfly-shaped wave-resistance plate structure, the wave-resistance effect of the wave-resistance plates is further improved through the tank body of the butterfly-shaped wave-resistance plate structure, meanwhile, double-face welding can be achieved, sealing performance is better, the interior of the tank body is supported by the butterfly-shaped wave-resistance plate structure, and therefore the tank body is not likely to be deformed or pulled to be cracked.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

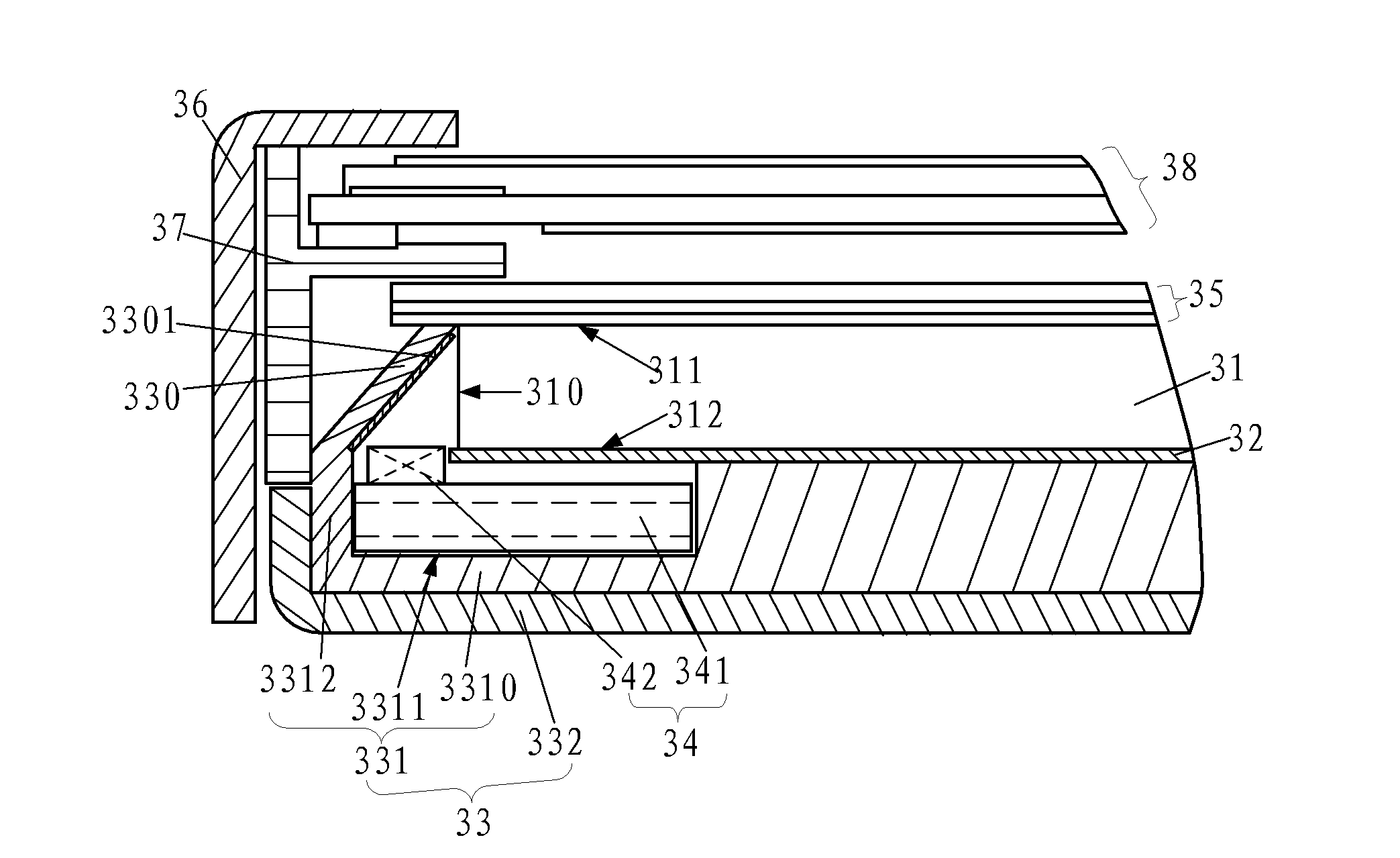

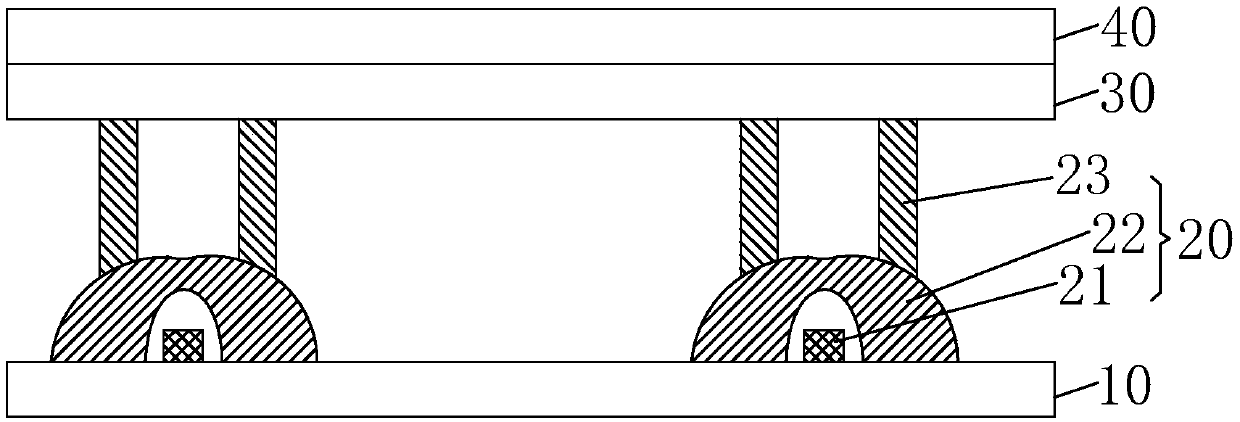

Backlight module and liquid crystal display module

InactiveCN109633980ASmall size and heightNot easy to deformNon-linear opticsLiquid-crystal displayEngineering

The invention provides a backlight module and a liquid crystal display module. The backlight module comprises a back plate, a plurality of light emitting units arranged on the back plate at intervals,and a diffusing plate arranged on the light emitting units. Each light emitting unit comprises a light emitting diode, an LED lens which covers the light emitting diode and at least one support structure arranged on the LED lens, wherein the support structure and the LED lens support the height of a cavity together. The support structure provided by the invention has smaller height and size thana support structure in the prior art, and is not easy to deform. Due to the LED lenses, most of lights emitted by the light emitting diodes are centralizedly emitted out from the sides of the LED lenses. Since the support structures are located above the LED lenses, lights are not blocked, and shadows on the diffusing plate are avoided. The light emitting quality of the backlight module is improved.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD

Injection molding machine

The invention discloses an injection molding machine which comprises an injection molding pipe provided with a feed port, a screw rod positioned in the injection molding pipe, an injection mold and a cooling water tank, wherein a plurality of convex blocks are uniformly arranged on an inner wall of the injection molding pipe; a heat preservation layer is arranged on the outer surface of the injection molding pipe; the injection molding pipe is connected with a strong heating electricity box and a weak heating electricity box; the cooling water tank is communicated with the injection mold mutually through a water inlet pipe and a water outlet pipe; and an air compressor is arranged on the water inlet pipe. The injection molding machine shortens the service time of a material pushing process, and improves the production efficiency of a product; the air compressor can provide high pressure to cooling water, to allow that no melt in the mold deforms easily in a cooling process; and the quality of the product is ensured.

Owner:NANJING BLESSED HYDRAULIC MACHINERY

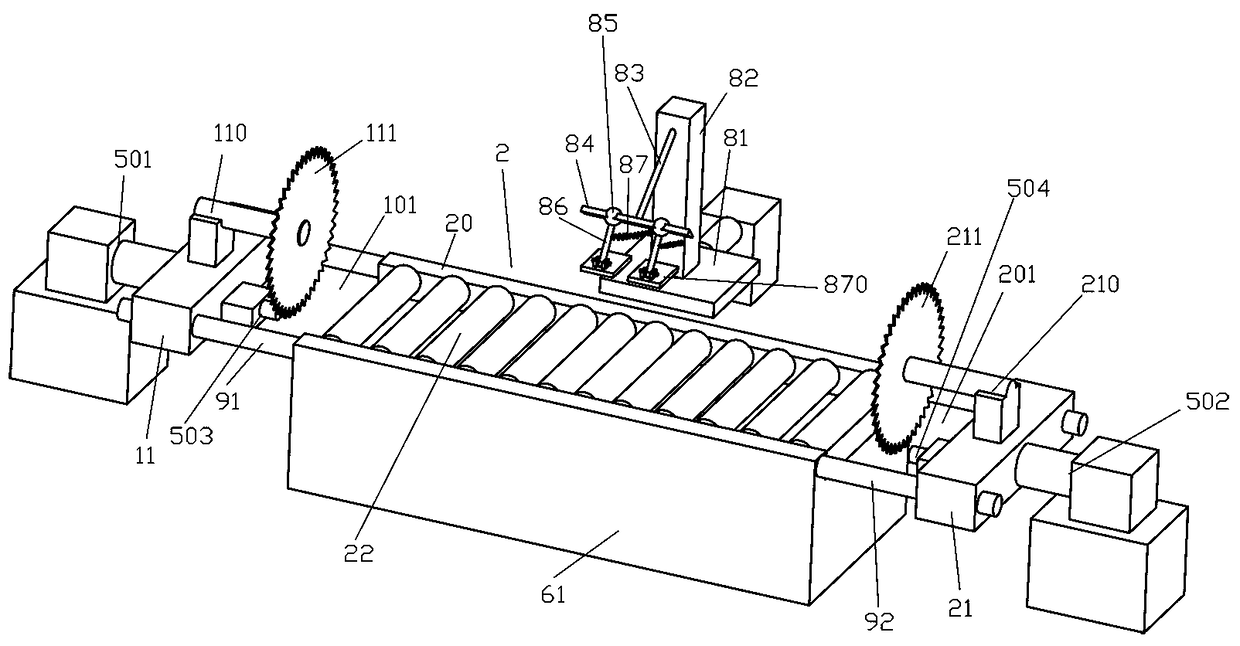

Regular metal section adjustable double-end cutting machine

PendingCN109262061AImprove stabilityEasy to adjustMetal sawing devicesEngineeringMechanical engineering

The invention relates to the technical field of cutting equipment, in particular to a regular metal section adjustable double-end cutting machine. The cutting machine comprises a worktable. The upperportion of the worktable is provided with a rail for placing a metal section, the front end of the rail is fixedly provided with two front guide posts arranged at interval on the left and the right and extending forwards, and the rear end of the rail is fixedly provided with two rear guide posts arranged at interval on the left and the right and extending backwards. The two front guide posts are provided with a front adjustment plate capable of moving back and forth, and the front adjustment plate is provided with a front side sawing disc. The two rear guide posts are provided with a rear adjustment plate capable of moving back and forth, and the rear adjustment plate is provided with a rear side sawing disc. A front side cutting space for cutting the front end of the metal section is defined by the rear side of the front adjustment plate, the two front guide posts and the front end of the rail, and a rear side cutting space for cutting the rear end of the metal section is formed between the two rear guide posts and the rear end of the rail. The cutting machine can cut both ends of the metal section at the same time.

Owner:福清市龙港金属制品有限公司

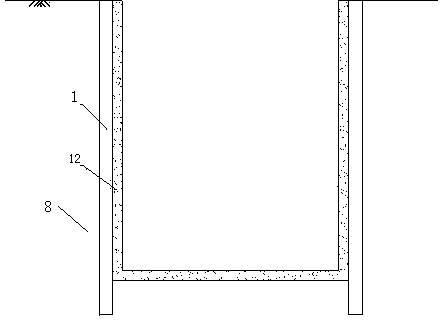

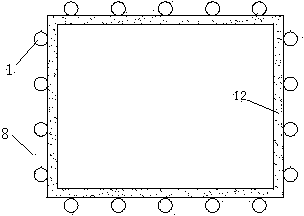

Installation method of underground concrete wall formwork of row pile supporting structure

InactiveCN103485365AGuaranteed StrengthGuaranteed stiffnessArtificial islandsExcavationsShotcreteReinforced concrete

The invention relates to an underground concrete structure construction method, in particular to an installation method of an underground concrete wall formwork of a row pile supporting structure. The method includes the steps: firstly, arranging reinforced concrete supporting piles in surrounding soil of a foundation pit; secondly, excavating the foundation pit; thirdly, arranging embedded steel bar bolts on the supporting piles, and arranging tension anchor bolts in lateral soil between every two piles; fourthly, covering the lateral soil of the foundation pit with a steel wire mesh; fifthly, arranging an annular girder; sixthly, arranging formwork split bolts on the side face of the annular girder; seventhly, spraying a concrete supporting layer to the side face of the foundation pit all sidedly; eighthly, installing a concrete poured formwork on the basis of the formwork split bolts, and fixing the concrete poured formwork. The method is suitable for side wall construction of underground reinforced concrete structures in arrangements in various shapes, strength, rigidity and stability of a concrete poured formwork system constructed by the method are guaranteed, and the formwork is less prone to deformation during concrete pouring.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com